Assembled grade crossing

A level crossing, assembled technology, applied in the field of level crossings, can solve the problem of not being able to overcome the problems such as the outside of the rail crossing, such as the mud and mud, and achieve the effect of longer service cycle, improved stability and strong integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

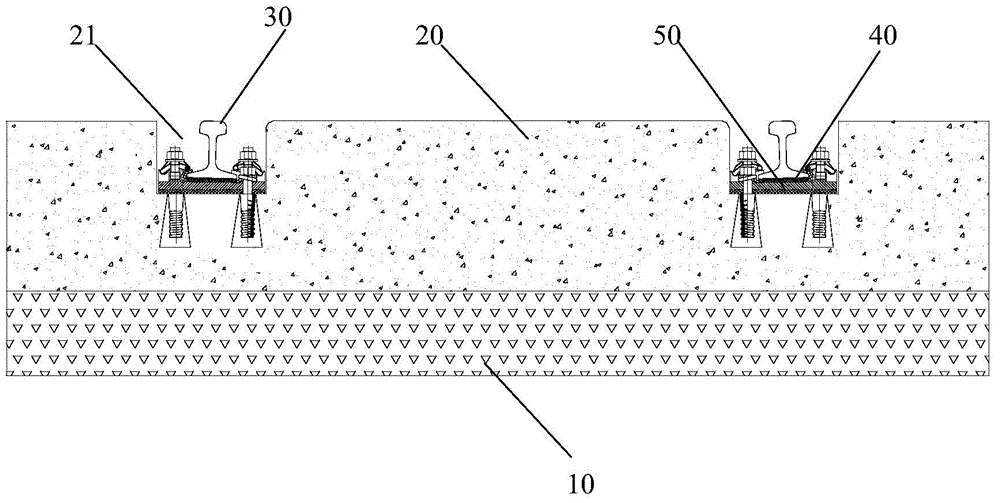

[0021] Next, a prefabricated level crossing as an example of the present invention will be described based on the drawings.

[0022] figure 1 It is a schematic cross-sectional view showing the assembled level crossing of the present invention.

[0023] Such as figure 1 As shown, the assembled level crossing of the present invention has a graded gravel layer 10 , an integral ballast bed 20 and a track 30 .

[0024] The graded gravel layer 10 is laid on the foundation of the crossing. The integral ballast bed 20 is arranged on the graded gravel layer 10 , and two grooves 21 for track installation are formed on the upper surface of the integral ballast bed 20 . The rail 30 is installed in the groove 21 for rail installation.

[0025] When constructing such a level crossing, it is only necessary to hoist the prefabricated block of the integral track bed on the graded gravel layer, then lay the line, fill it with cement mortar, and finally connect the road surface on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com