Corrosion Protection Method And Corrosion Protection Structure

a corrosion protection and corrosion protection technology, applied in the direction of electrically conductive paints, etc., can solve the problems of galvanic anode consumption problem, difficult to obtain commercial power source, etc., and achieve the effect of preventing contamination, deterioration, and damage of the semiconductor layer, effective corrosion protection treatment, and increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0099]Hereunder is a specific description of the present invention with reference to examples.

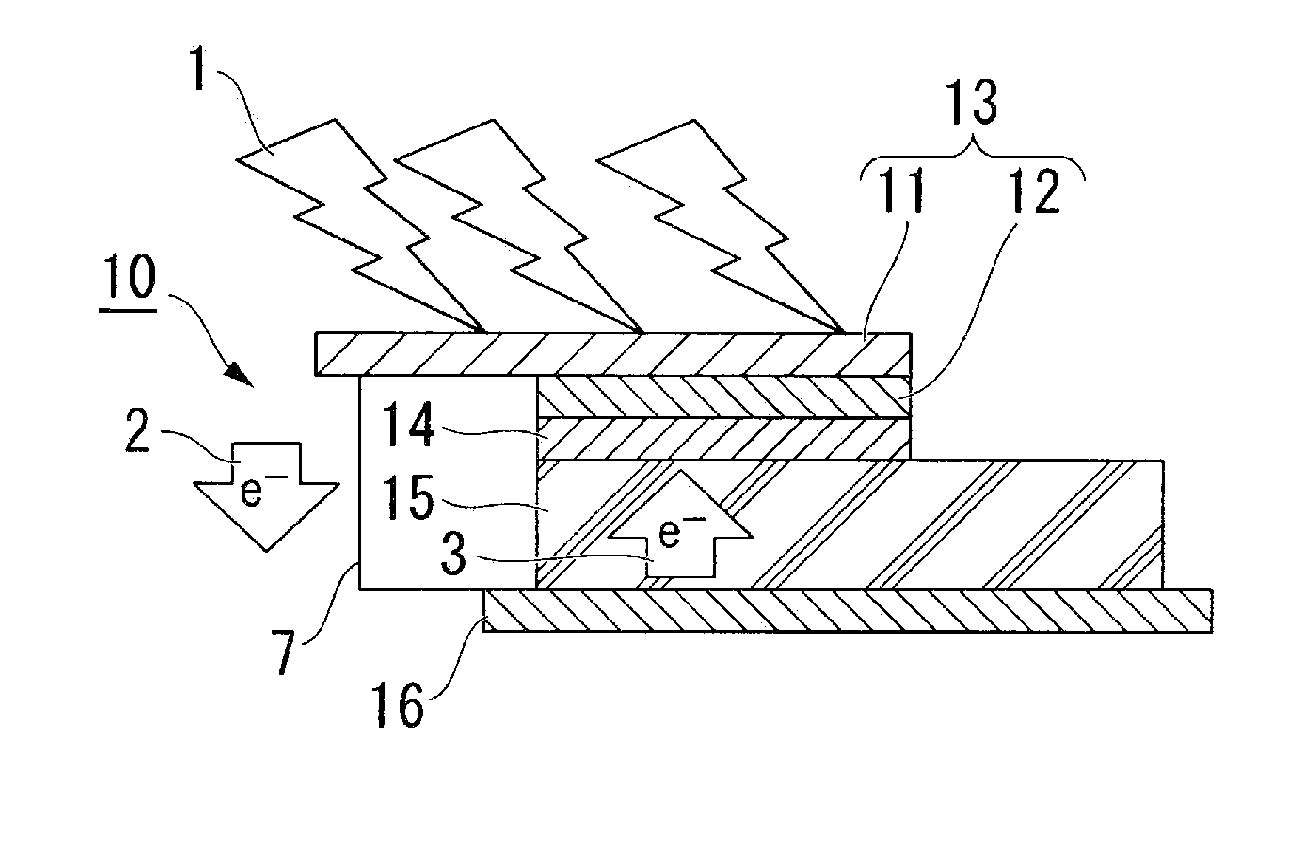

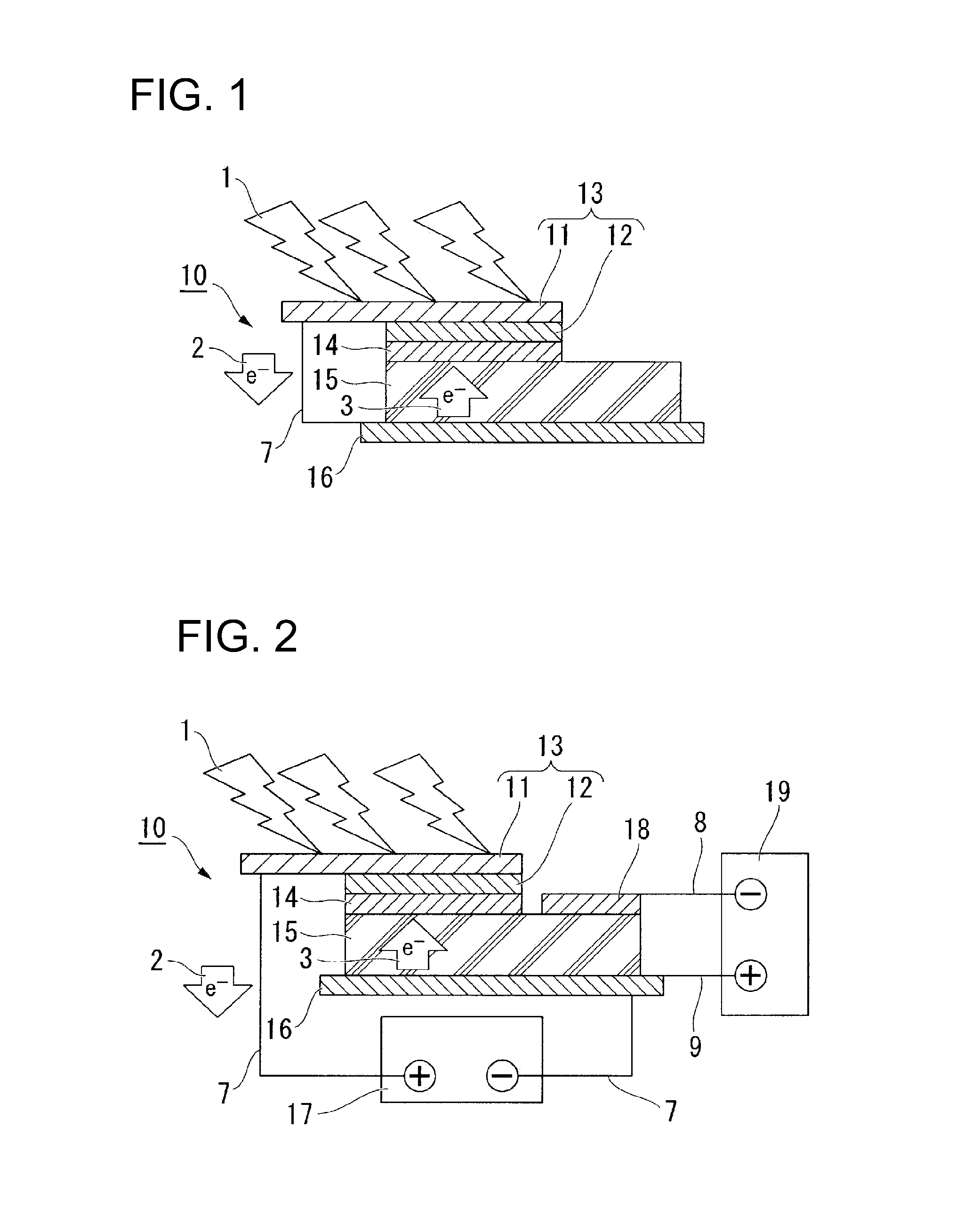

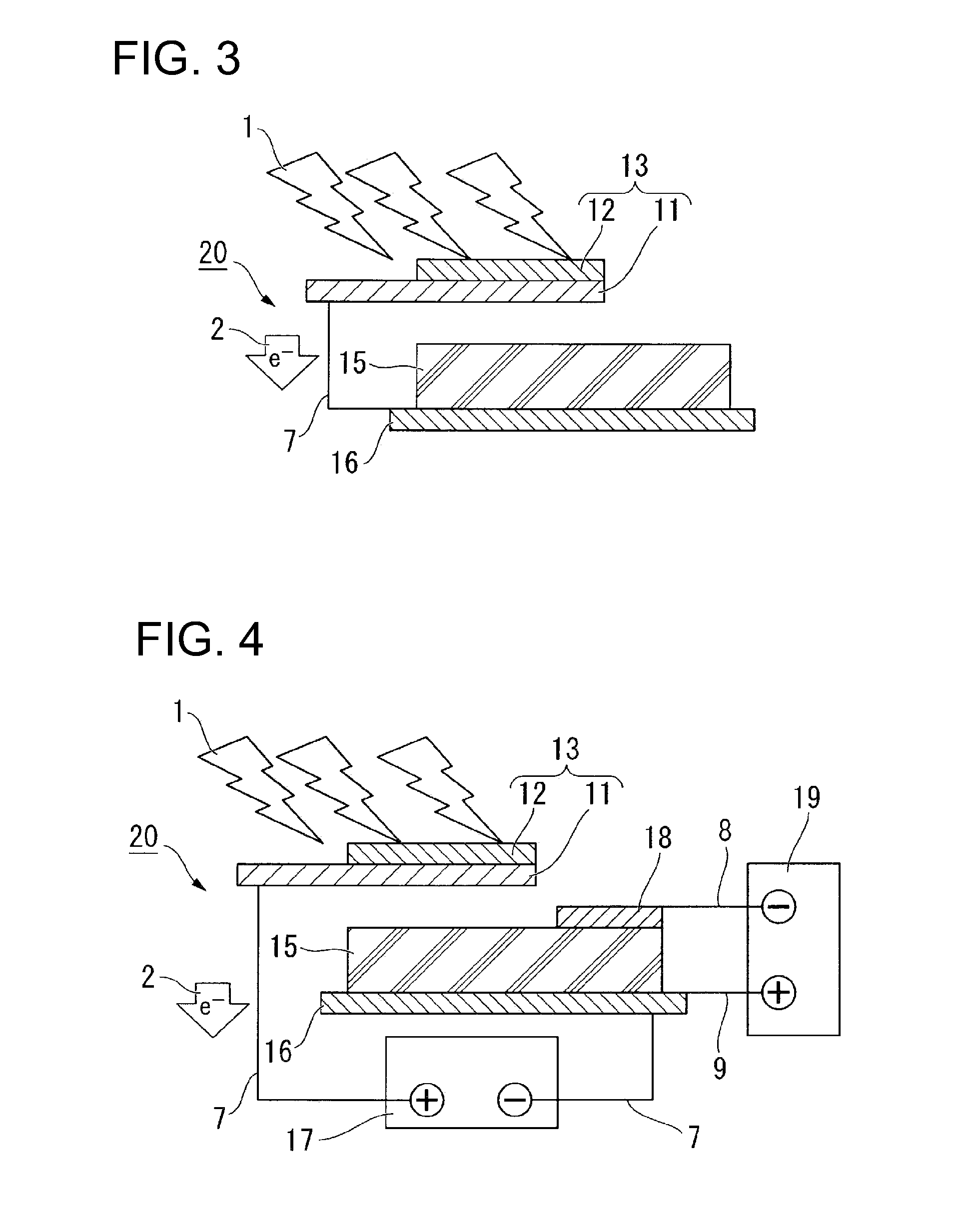

[Corrosion Protection Structure of Example 1]

[0100]ITO was vacuum-deposited on a transparent PEN film with a thickness of 200 μm to prepare a supporting member 11 with a dimension of 50×35 mm with which electrical conductivity of a surface resistance: 10Ω / □ (square) was provided.

[0101]On the ITO-deposited surface of the PEN film, a brookite-type titanium oxide paste (C-paste manufactured by SHOWA DENKO K. K.) as a semiconductor layer 12 was applied and dried in a size of 40×25 mm to provide a titanium oxide layer 12 with a thickness of 10 μm. Thus, an electron supplier 13 was obtained.

[0102]As an object to be protected against corrosion 16, a steel material (SS400 material) with a dimension of 60 mm×70 mm×2 mm was used which had been blasted with alumina. To simulate a steel material 16 in a concrete layer 15, a cement paste was applied on the steel material 16 and a mortar plate with a siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com