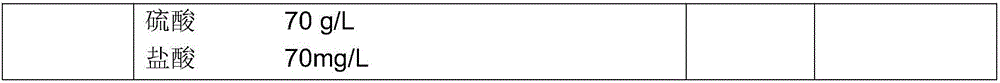

Patents

Literature

65 results about "Galvanic anode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A galvanic anode is the main component of a galvanic cathodic protection (CP) system used to protect buried or submerged metal structures from corrosion. They are made from a metal alloy with a more "active" voltage (more negative reduction potential / more positive electrochemical potential) than the metal of the structure. The difference in potential between the two metals means that the galvanic anode corrodes, so that the anode material is consumed in preference to the structure.

Integrated plating and planarization process and apparatus therefor

A method and apparatus are described for performing both electroplating of a metal layer and planarization of the layer on a substrate. Electroplating and electroetching of metal (such as copper) are performed in a repeated sequence, followed by chemical-mechanical polishing. An electroplating solution, electroetching solution, and a non-abrasive slurry are dispensed on a polishing pad in the respective process steps. The substrate is held against the pad with a variable force in accordance with the process, so that the spacing between substrate and pad may be less during electroplating than during electroetching.

Owner:GLOBALFOUNDRIES INC

Galvanic anode system for corrosion protection of steel and method for production thereof

ActiveUS7851022B2Reliable and long-lasting corrosion protectionLow costMolten spray coatingPretreated surfacesGalvanic anodeCationic polyelectrolytes

The invention relates to a galvanic anode system for the corrosion protection of steel, comprised of a solid electrolyte and a galvanic anode material, preferably zinc and its alloys, glued to the solid electrolyte or embedded in the solid electrolyte. The solid electrolyte is characterised by a high ion conductivity and comprises at least one anionic and / or cationic polyelectrolyte and / or preferably at least one compound that forms complex compounds with the anode material, preferably with zinc. The solid electrolyte is produced by applying a coating agent, preferably as an aqueous dispersion or suspension, to the steel and / or to the mineral substructure, preferably to concrete. The anode material is characterised in that it forms a galvanic element in combination with the solid electrolyte and the steel to be protected, in which the steel forms the cathode. The inventive galvanic anode system is further characterised in that the anode material is applied to the surface of the solid electrolyte as a foil, network or grid, preferably by gluing, and / or is embedded in the solid electrolyte.

Owner:SCHWARZ WOLFGANG

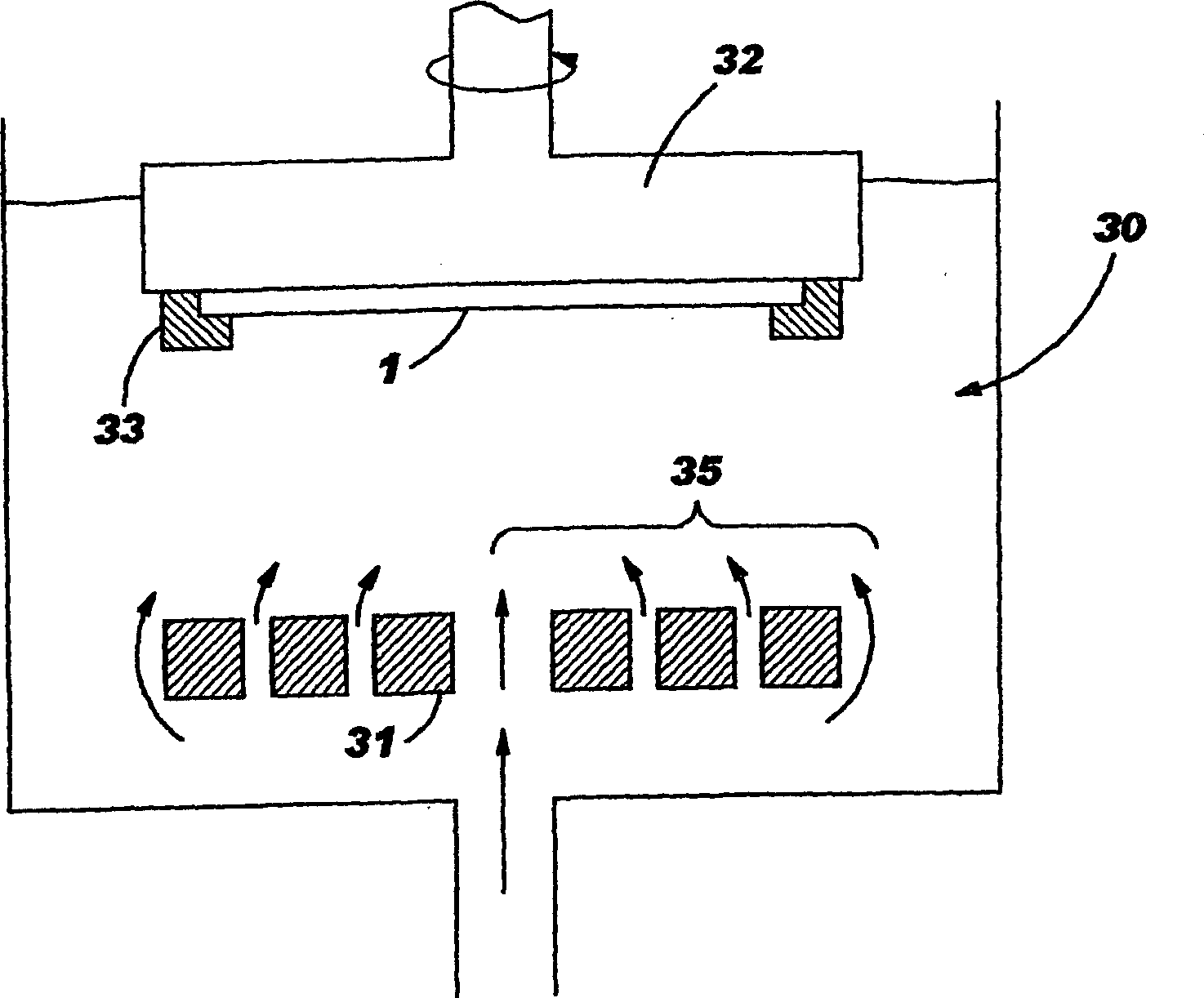

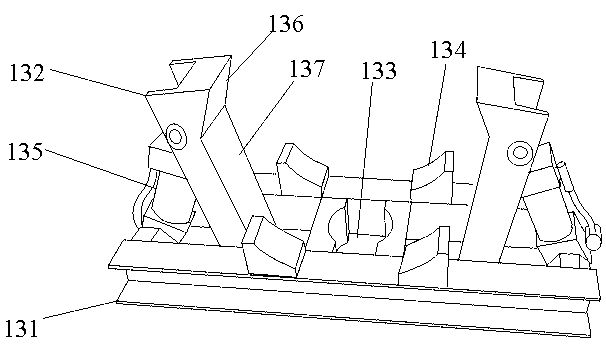

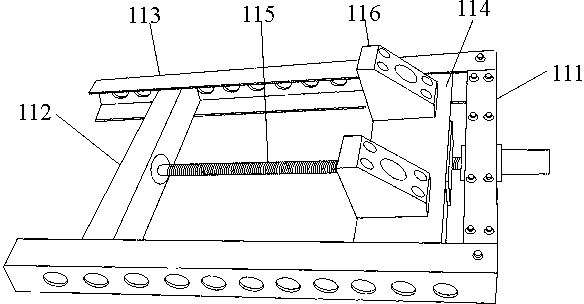

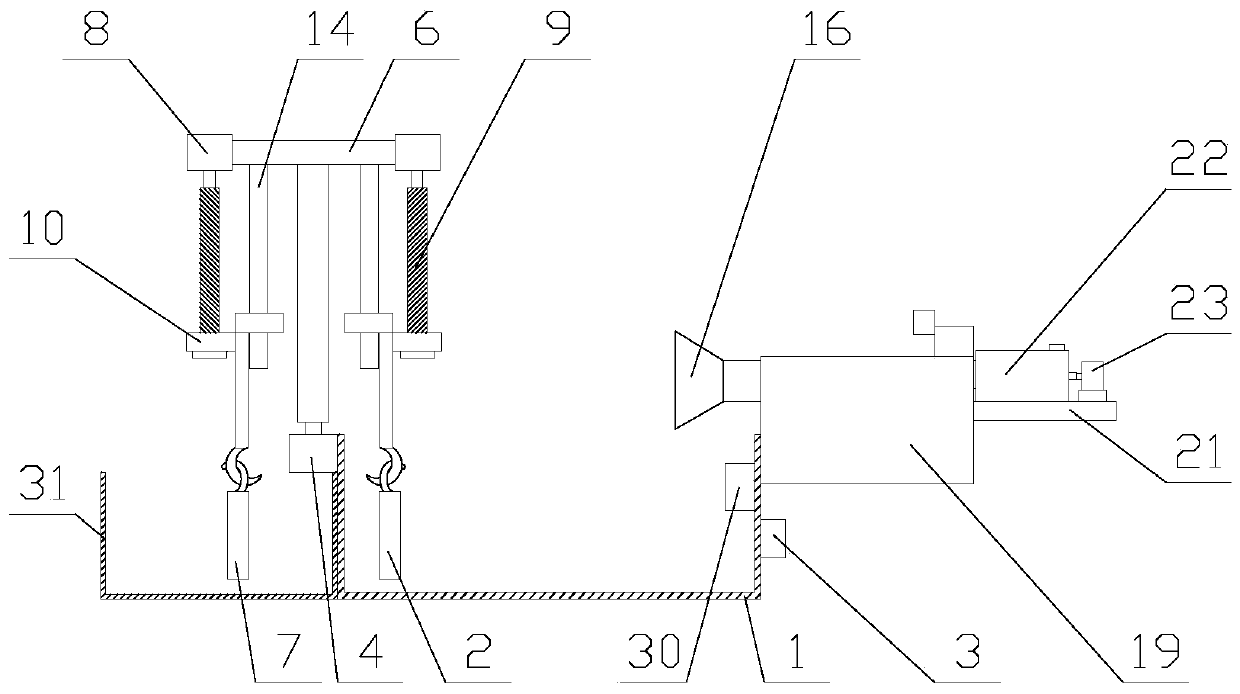

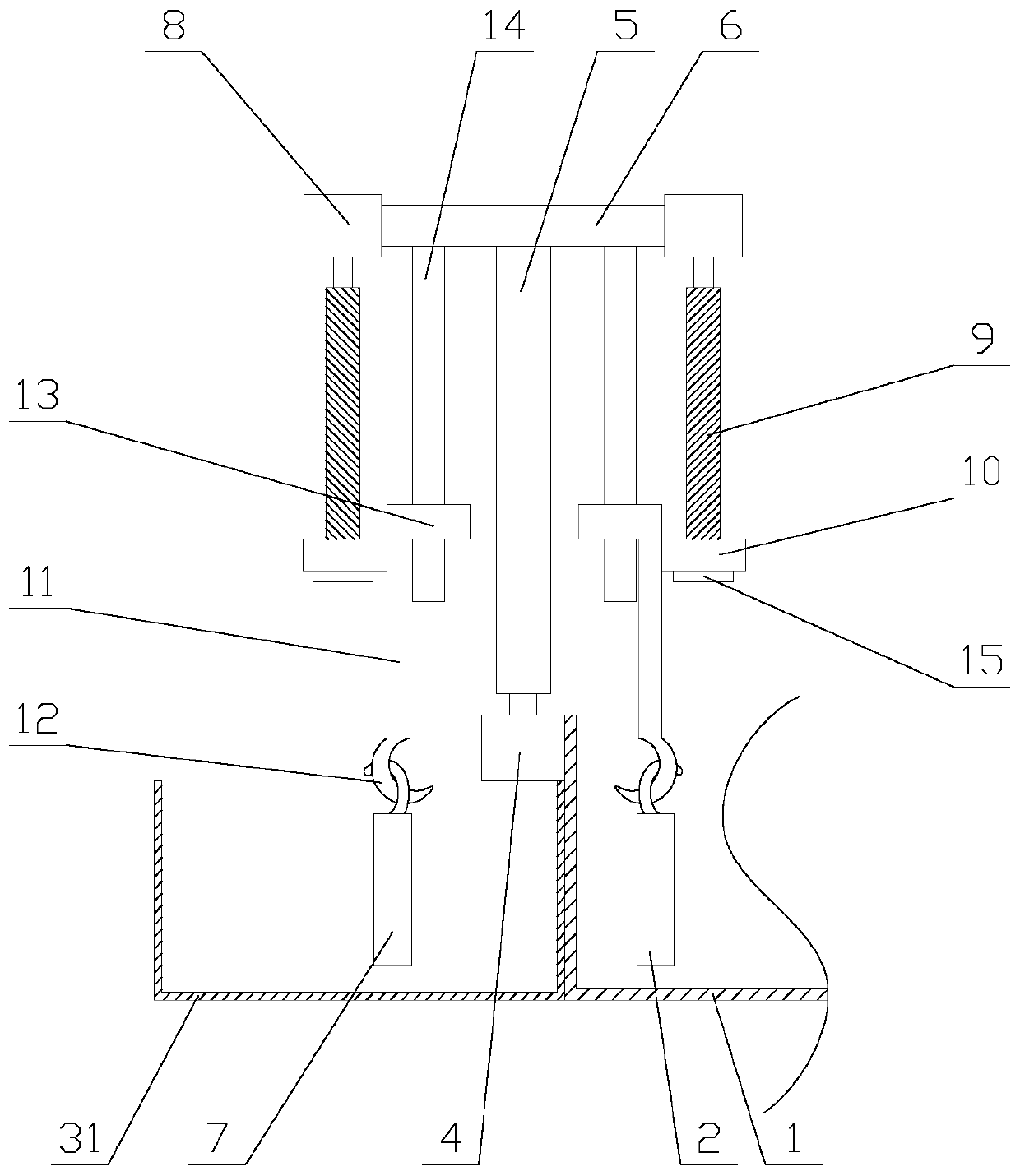

Underwater robot friction welding system and welding method thereof

ActiveCN103302396AQuick installationFor quick replacementNon-electric welding apparatusGalvanic anodeFriction welding

The invention discloses an underwater robot friction welding system and a welding method thereof. The system comprises a bracket, a welding gun and a clamp, wherein the clamp comprises a clamp table and a pair of clamp arms symmetrically arranged on the clamp table; one end of each clamp arm is movably connected with the clamp table and controlled through hydraulic pressure; a para-position through hole is formed in the center of the clamp table; the front end of the welding gun is corresponding to the para-position through hole, and is perpendicularly fixed on the clamp table; a vertical lifting table controlled through hydraulic pressure is arranged on the bracket; and the clamp table is fixedly connected with the vertical lifting table of the bracket. The underwater robot friction welding system, provided by the invention, uses friction welding technology to weld welding bolts on the submarine pipeline walls, enables the mounting and the replacing process of the submarine pipeline galvanic anode to be simple, convenient and fast, is high in welding quality and small in pipeline damage, can realize accurate positioning through ROV (Remote Operated Vehicle), doesn't need underwater operation by the personnel, avoids the risk of the constructer to operate underwater, reduces the construction cost, and improves the construction efficiency.

Owner:D&R SUBSEA

Preparation method of CNT (carbon nano tube) reinforced aluminum composite

The invention provides a simple preparation method of a CNT (carbon nano tube) reinforced aluminum composite. The method comprises the following steps: firstly, CNTs are subjected to acidification pretreatment for 2-4 h; then the CNTs are dispersed in a mixed organic solution formed by ethanol and acetone, aluminium nitrate is added for ultrasonic processing, and a uniformly dispersed CNT electroplating solution is obtained; then, electrophoretic deposition is performed with aluminum foil serving as an electroplating cathode and a stainless steel sheet serving as an electroplating anode, an aluminum foil laminate obtained through electrophoretic deposition is subjected to SPS (spark plasma sintering) and room-temperature rolling, and the CNT reinforced aluminum composite is obtained. The CNT reinforced aluminum composite prepared with the process not only has high tensile strength, but also has improved work hardening rate and uniform deformability while keeping better elongation, is simple to operate and low in cost, and has good generalizability.

Owner:FUZHOU UNIV

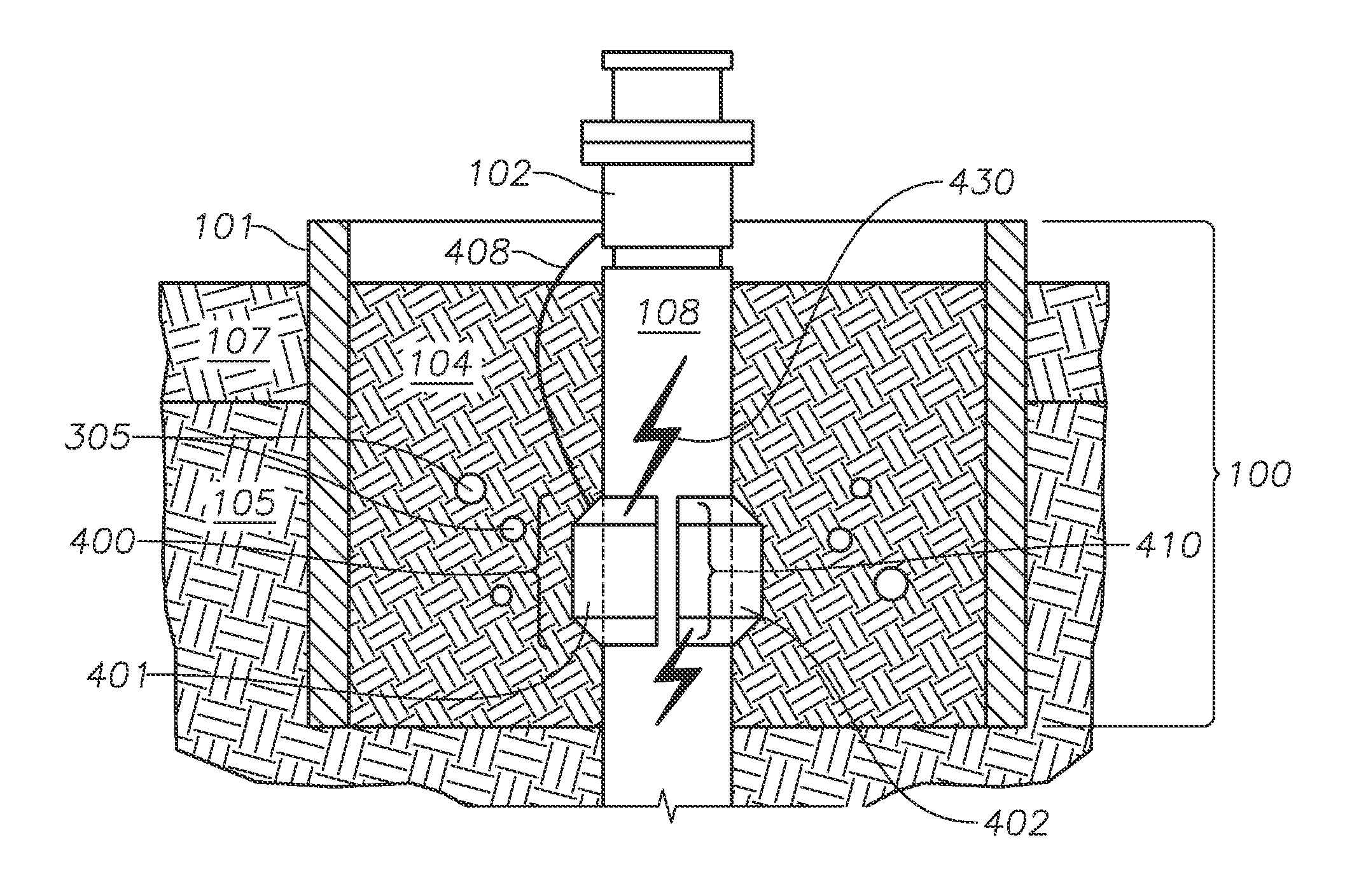

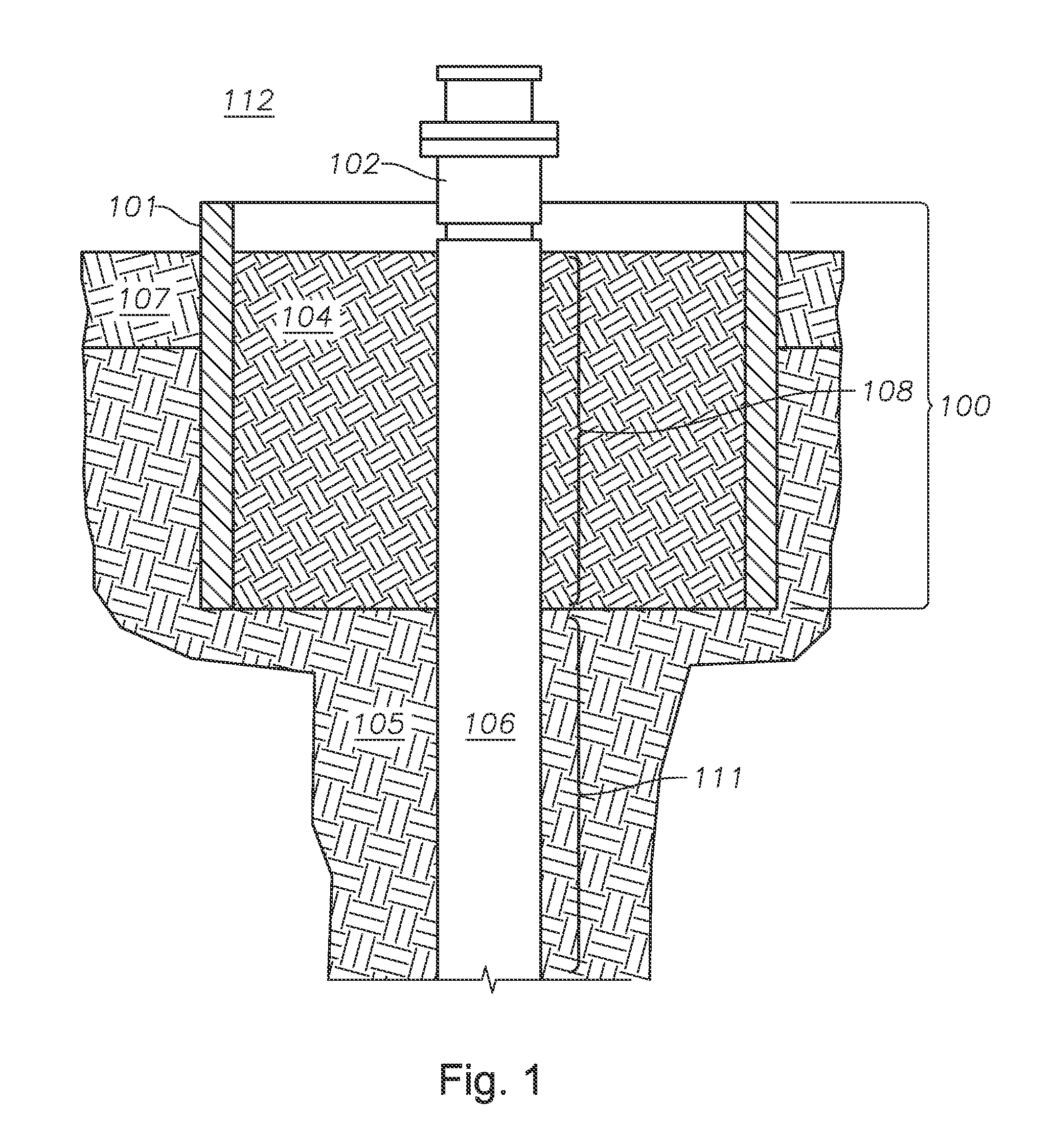

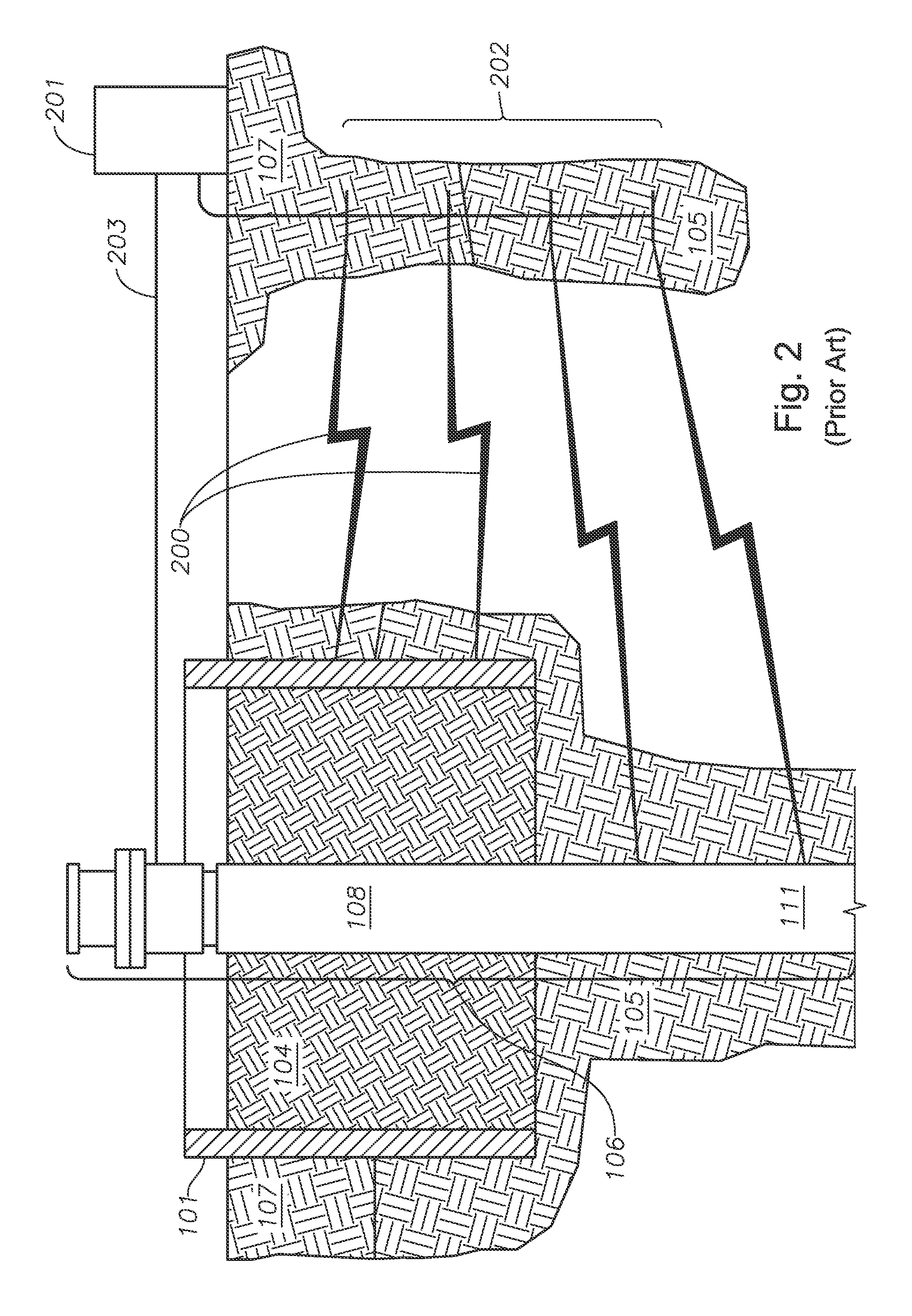

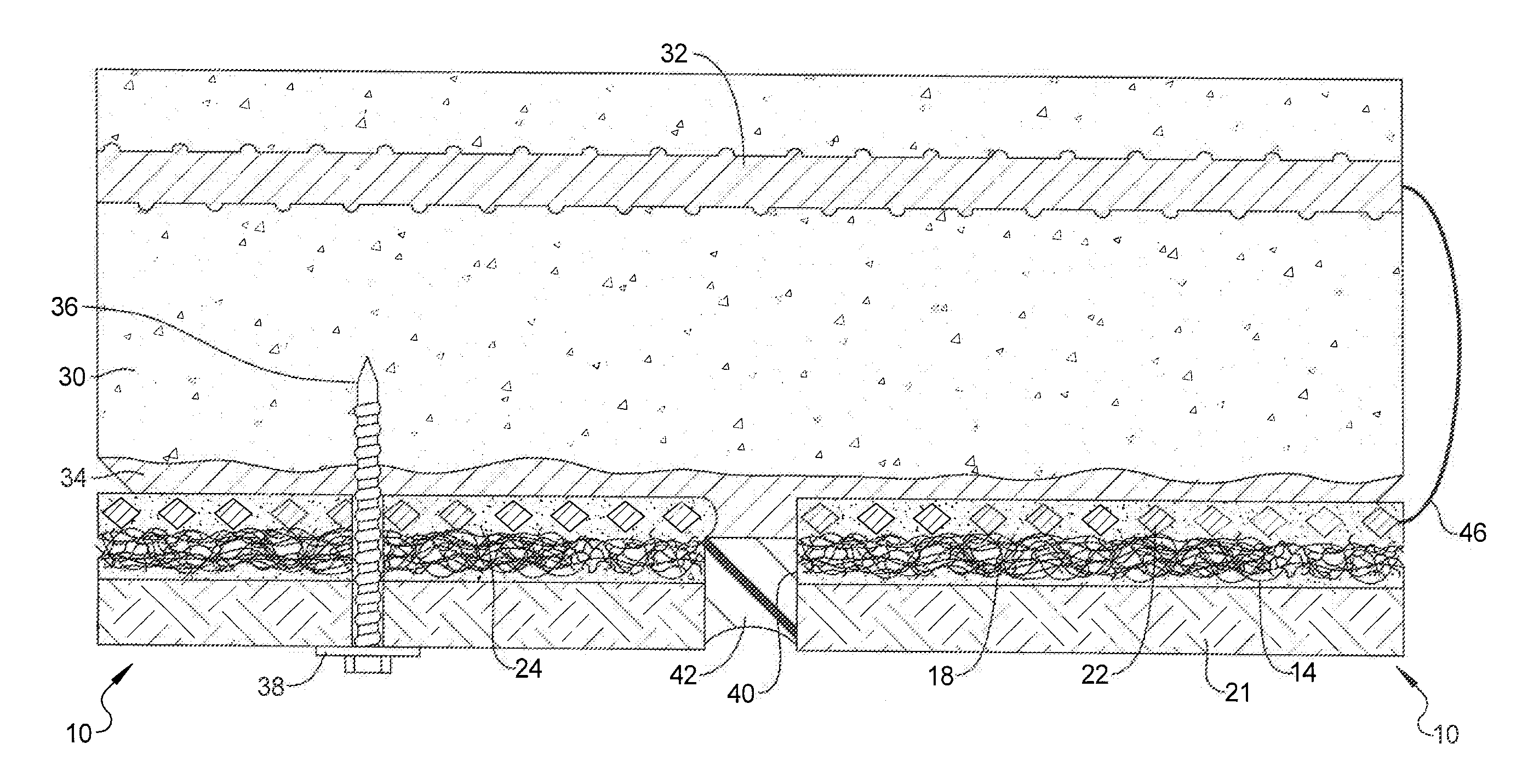

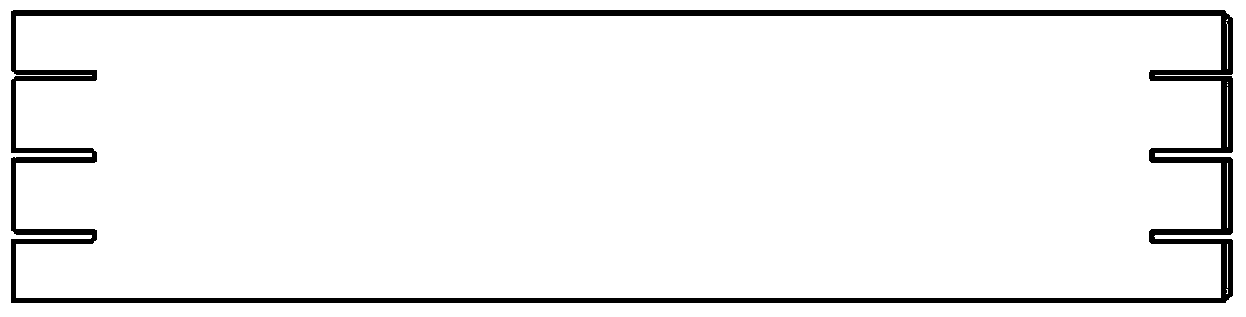

System, Apparatus, and Method for Utilization of Bracelet Galvanic Anodes to Protect Subterranean Well Casing Sections Shielded by Cement at a Cellar Area

ActiveUS20130081955A1Reduced shieldingImprove the effect of cathodic protectionSealing/packingGalvanic anodePower flow

A cathodic protection system is provided for a subterranean well casing having an enclosed upper section of the well casing being substantially shielded by a cellar from an impressed-current cathodic protection circuit passing through earth media. The impressed-current cathodic protection circuit is provided to protect an unenclosed lower section of the well casing. To protect the enclosed upper section of the well casing, a supplemental cathodic protection circuit is provided. The supplemental cathodic protection circuit is a galvanic anode cathodic protection circuit comprising the enclosed upper section of the well casing and one or more bracelet galvanic anodes being circumferentially mounted to the enclosed upper section. The enclosed upper section of the well casing and the one or more bracelet galvanic anodes are substantially surrounded by a cellar backfill, and the galvanic anode cathodic protection circuit is equally effective throughout a broad range of non-homogeneity within the cellar backfill.

Owner:SAUDI ARABIAN OIL CO

Novel high-performance magnesium alloy galvanic anode material

The invention relates to a novel cathode protection used high-performance magnesium alloy galvanic anode material, and belongs to the technical field of new materials. The material provided by the invention is prepared by alloying and smelting an AZ31 magnesium alloy, which is used as a base material, with eight types of alloy elements Ce, Ca, Cd, Y, Sn, Ga, In and Ti added. The prepared novel high-performance magnesium alloy galvanic anode material overcomes the defects such as low current efficiency of a current internationally-used galvanic anode material. Compared with the performance of GB / T17731-2004 magnesium alloy anode series, the material provided by the invention has the characteristics of low open circuit potential, high current efficiency, a low self-corrosion rate and the like.

Owner:张万友 +2

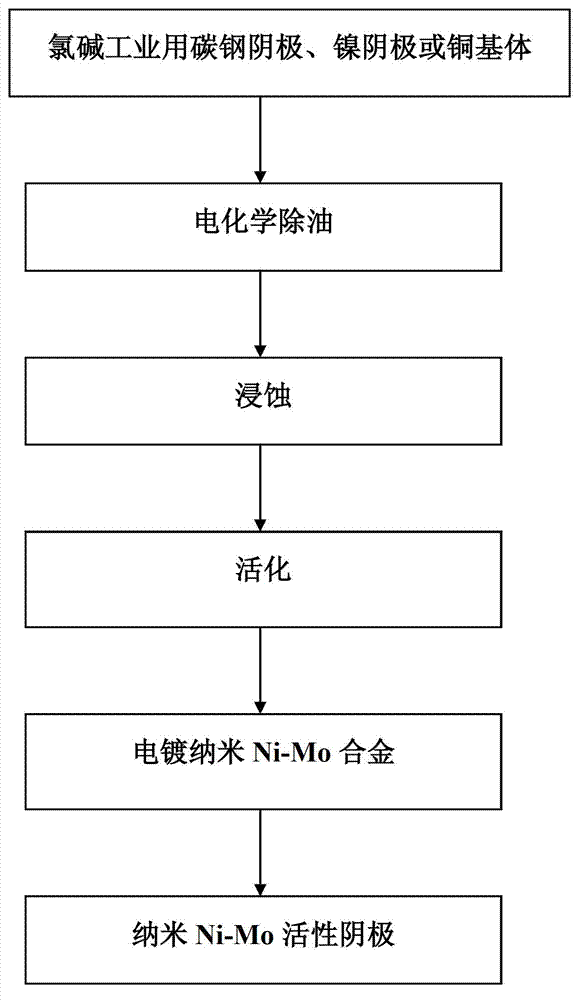

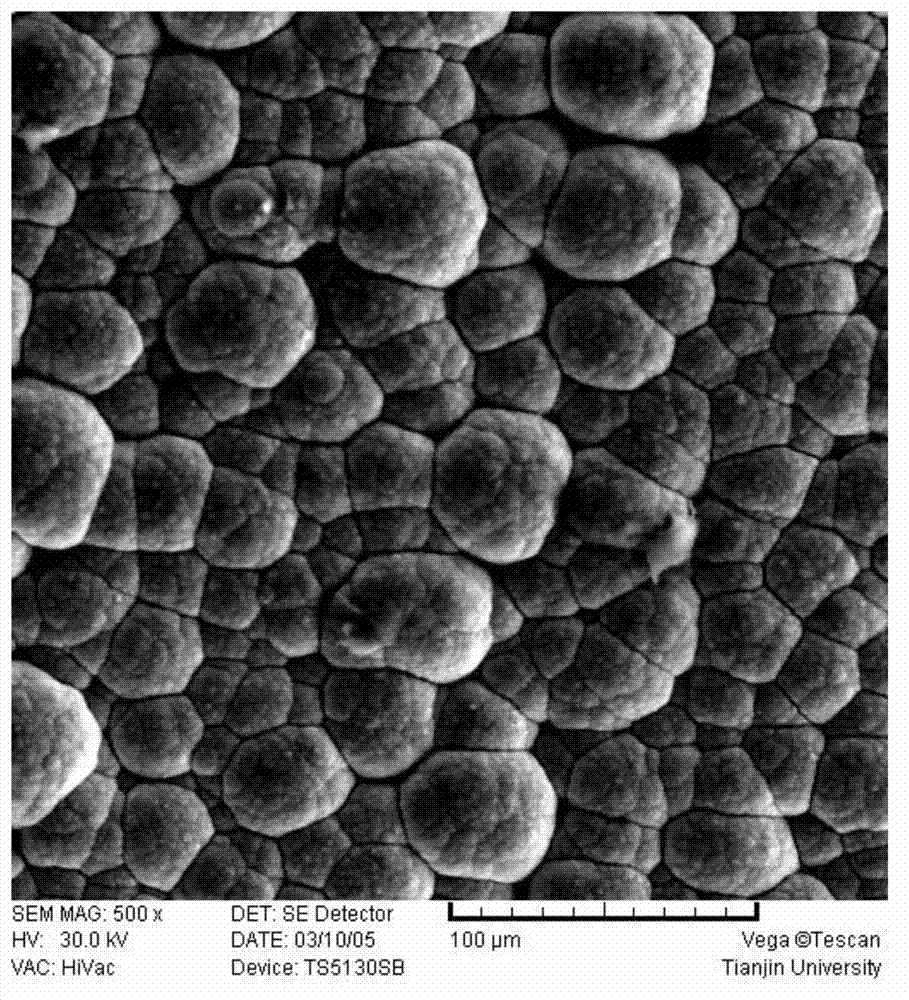

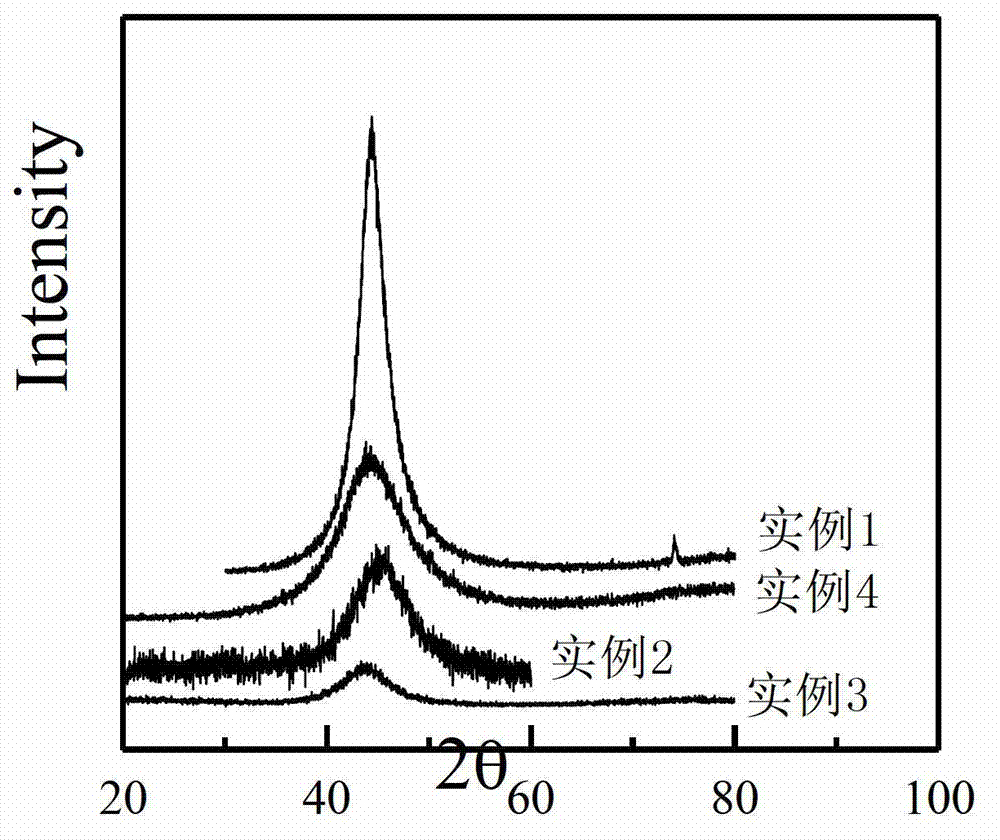

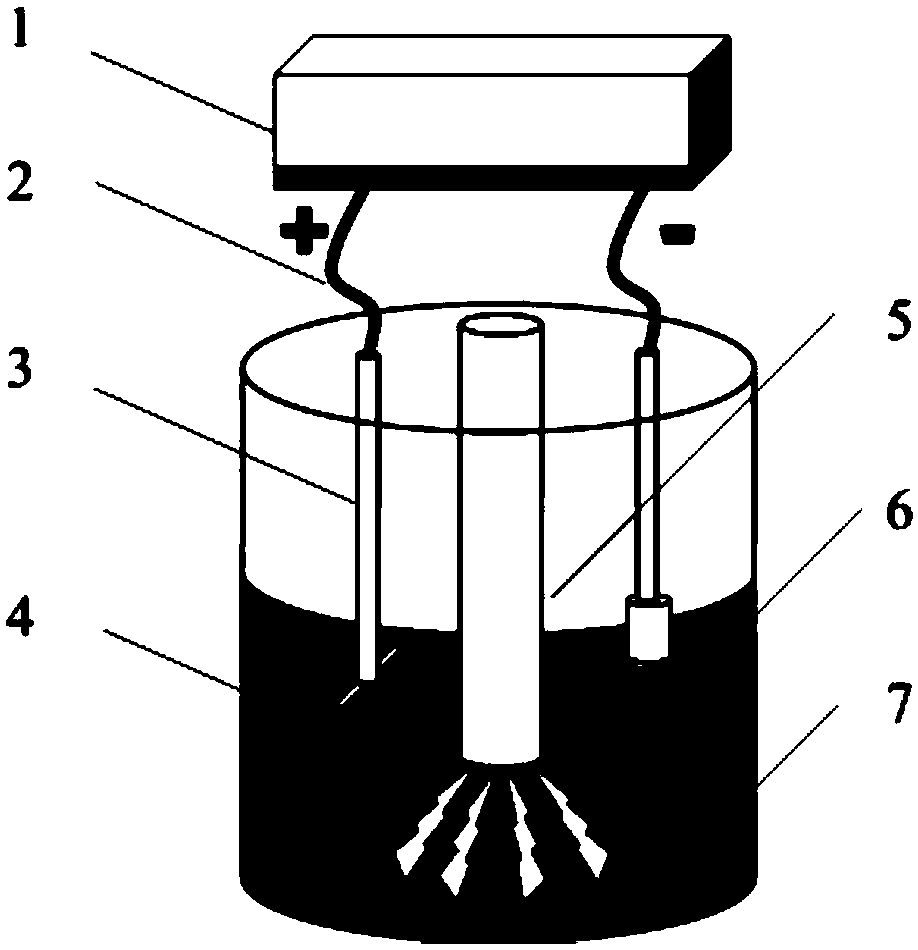

Nickel molybdenum active cathode with nanostructure for chlor-alkali industry and preparation method thereof

The invention relates to a nickel molybdenum active cathode with nanostructure for chlor-alkali industry and a preparation method thereof. The active cathode comprises a conducting base and a nanostructured alloy coating; the coating is made of Ni-Mo alloy, and has average grain size of 2-50nm and thickness of 20-120 mum. The preparation method is as follows: first removing oil and rust on the base; then placing the base into a plating bath; and plating the Ni-Mo alloy, wherein an electroplating anode is ruthenium titanium mesh, and an area ratio of the anode to the cathode is 2:1. The active cathode with nanostructure can be easily obtained by a conventional plating process, so as to facilitate convenient operation and realization of industrialization. An electrolysis experiment in the chlor-alkali industry is simulated; and when the current density is at 4KA.dm<-2>, cathode potential is 250 mV lower than a current industrial nickel cathode. Through repeated power-off, the active cathode does not corrode, and cell voltage fluctuates within 20 mV, so as to gain good electrochemical stability.

Owner:TIANJIN UNIV

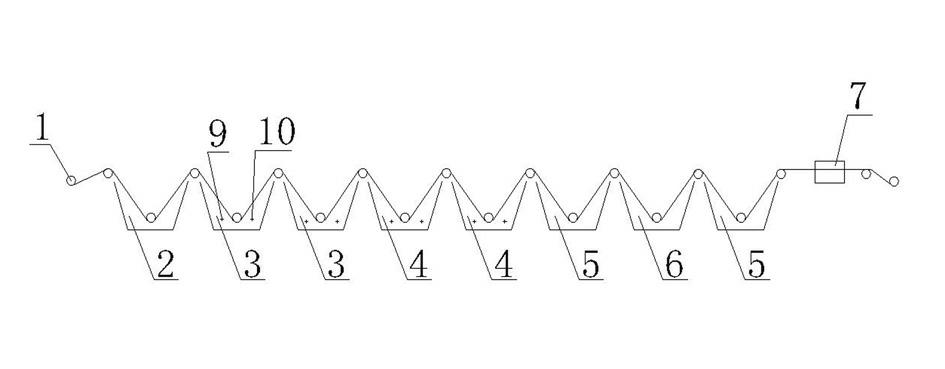

Method for synchronously roughening both surfaces of electrolytic copper foil and equipment thereof

ActiveCN102181899AUniform and fine surface contourHigh elongationElectrolytic coatingsGalvanic anodeRough surface

The invention relates to a method for synchronously roughening both surfaces of an electrolytic copper foil and equipment thereof, which belong to the technical field of electrolytic copper foils. The technical key point is that: corresponding anode plates are arranged on a smooth surface and a rough surface and electrolyte flows through the space between the electrolytic copper foil and the anode plates when the electrolytic copper foil passes through a roughening groove and a solidifying groove so as to perform electroplating copper precipitation treatment on the smooth surface and the rough surface of the electrolytic copper foil synchronously at a time, wherein the electroplating anode plates in the roughening groove and the solidifying groove of the used equipment are distributed in the middle and on the front side of a groove body. Compared with the prior art, the method for synchronously roughening both surfaces of the electrolytic copper foil and the used equipment thereof have the advantages that: the smooth surface and the rough surface of the copper foil can be synchronously electroplated at a time, so that production efficiency is improved, and energy consumption is reduced.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

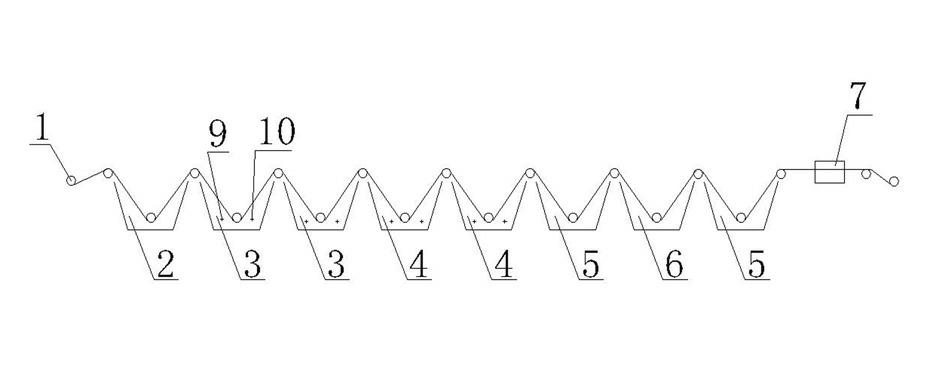

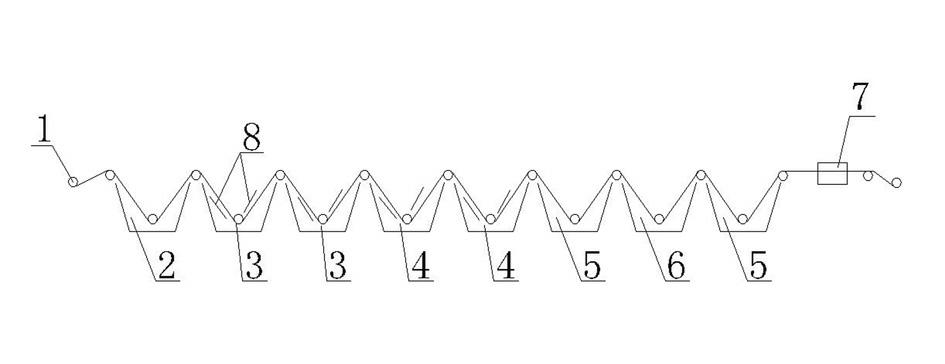

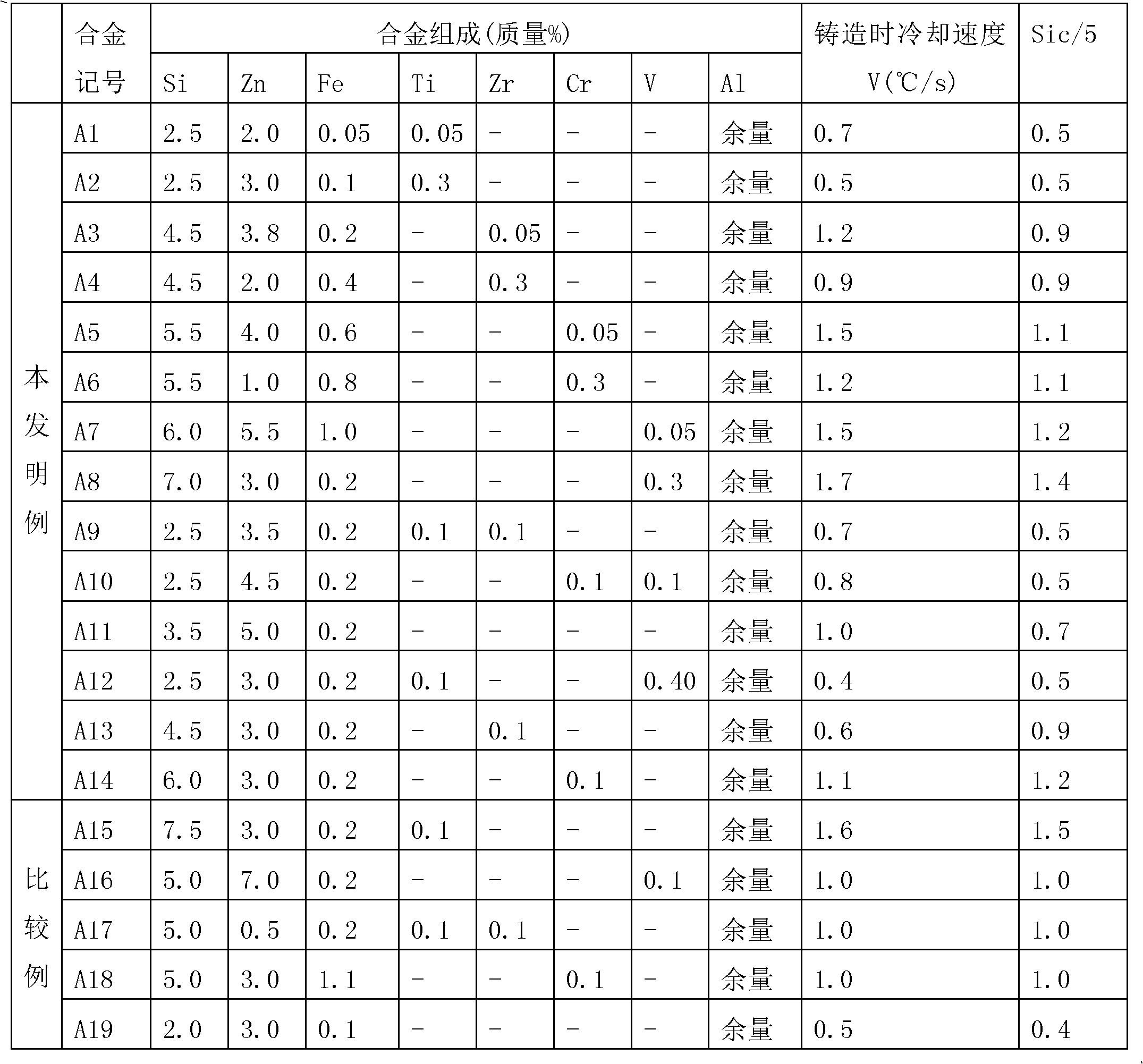

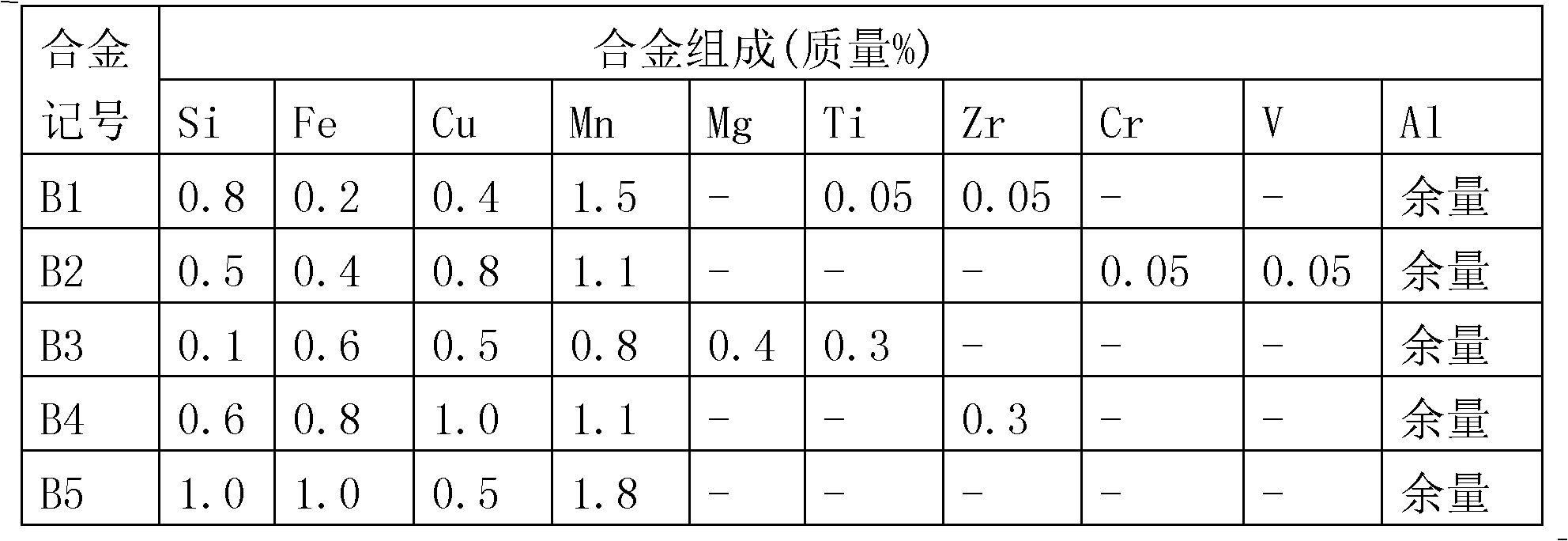

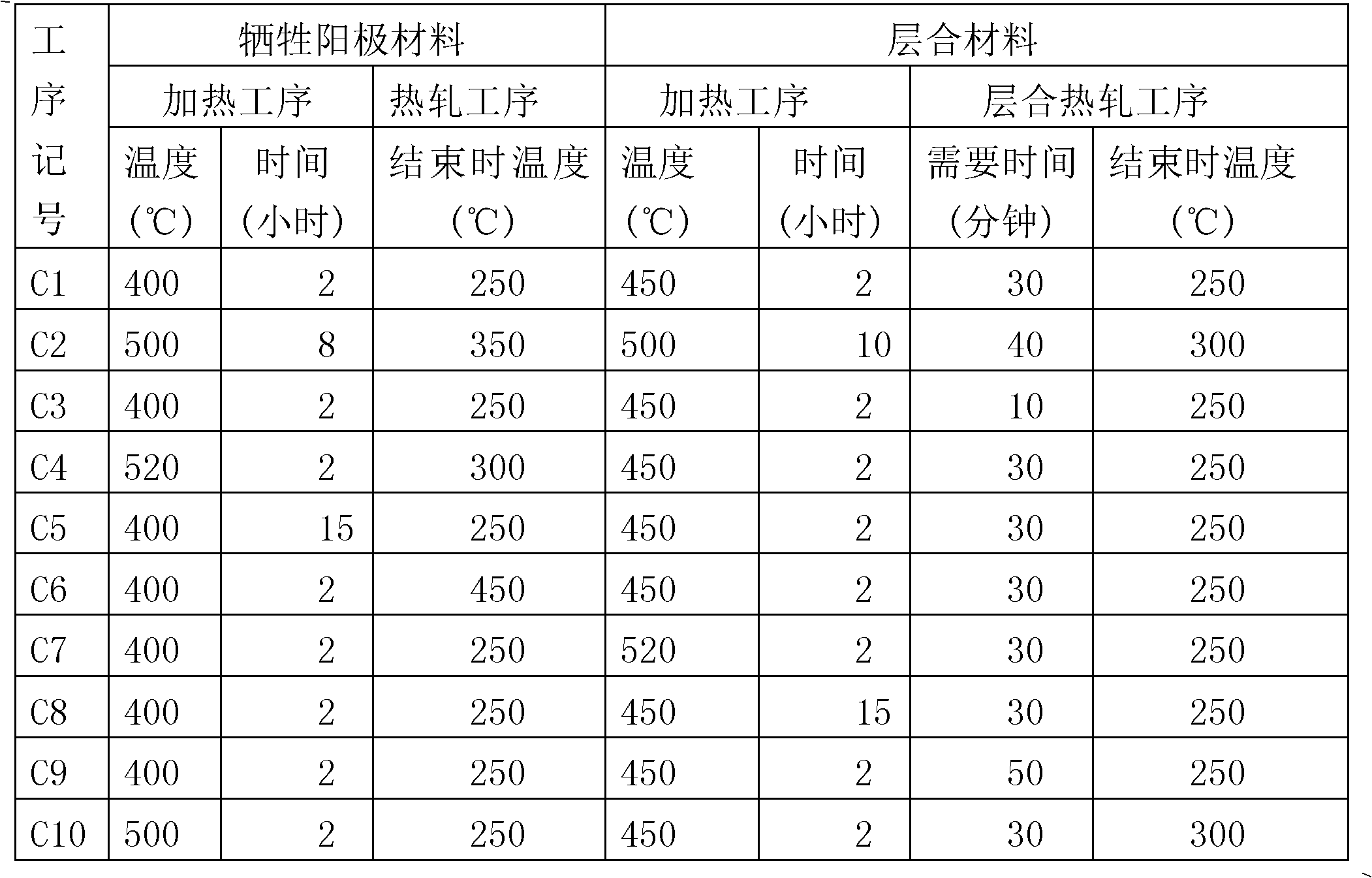

Highly corrosion-resistant aluminum alloy brazing sheet, process for production of the brazing sheet, and highly corrosion-resistant heat exchanger equipped with the brazing sheet

Disclosed are: an aluminum alloy brazing sheet which does not undergo the diffusion of a molten brazing filler material into a core material during brazing and therefore has good brazing properties, and has excellent corrosion resistance against an exhaust gas condensate after brazing; a process for producing the aluminum alloy brazing sheet; and a highly corrosion-resistant heat exchanger utilizing the aluminum alloy brazing sheet. Specifically disclosed is a highly corrosion-resistant aluminum alloy brazing sheet which comprises: an aluminum alloy core material; a galvanic anode material that is cladded on one surface of the core material; and an Al-Si-based alloy brazing filler material that is cladded on the other surface of the core material.; The brazing sheet is characterized in that the galvanic anode material contains 2.5-7.0 mass% of Si, 1.0-5.5 mass% of Zn and 0.05-1.0 mass% of Fe, with the remainder being Al and unavoidable impurities. The brazing sheet is also characterized in that the clad thickness of the galvanic anode material is 25-80 [mu]m.

Owner:FURUKAWA SKY ALUMINUM CORP

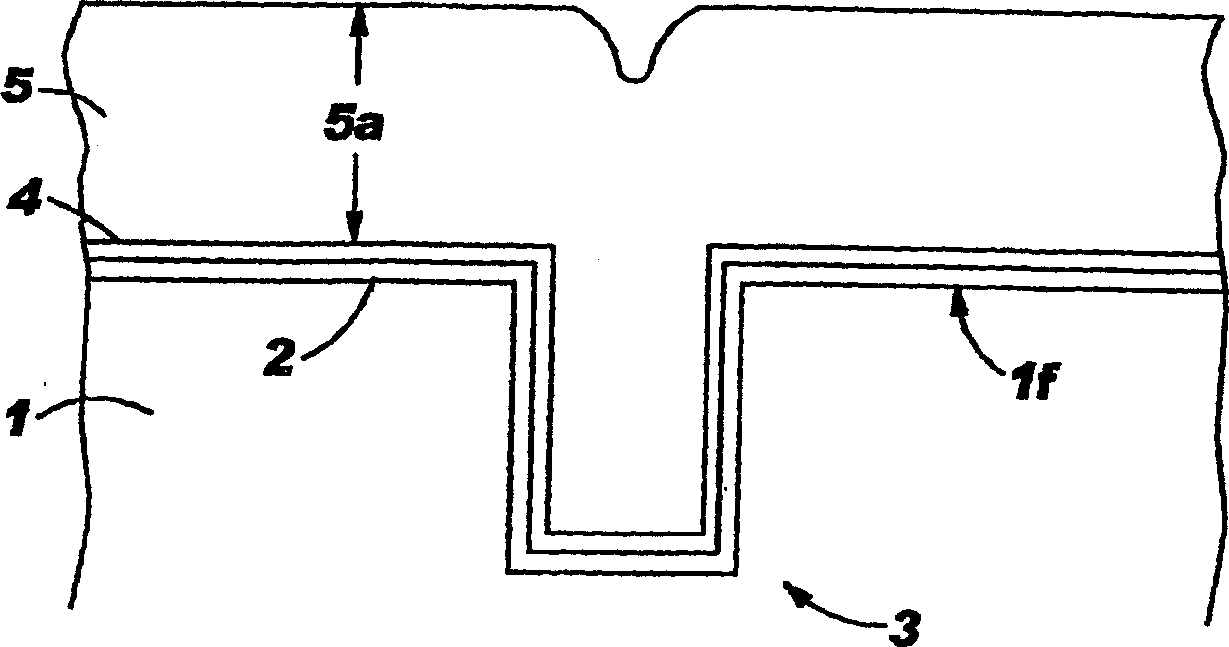

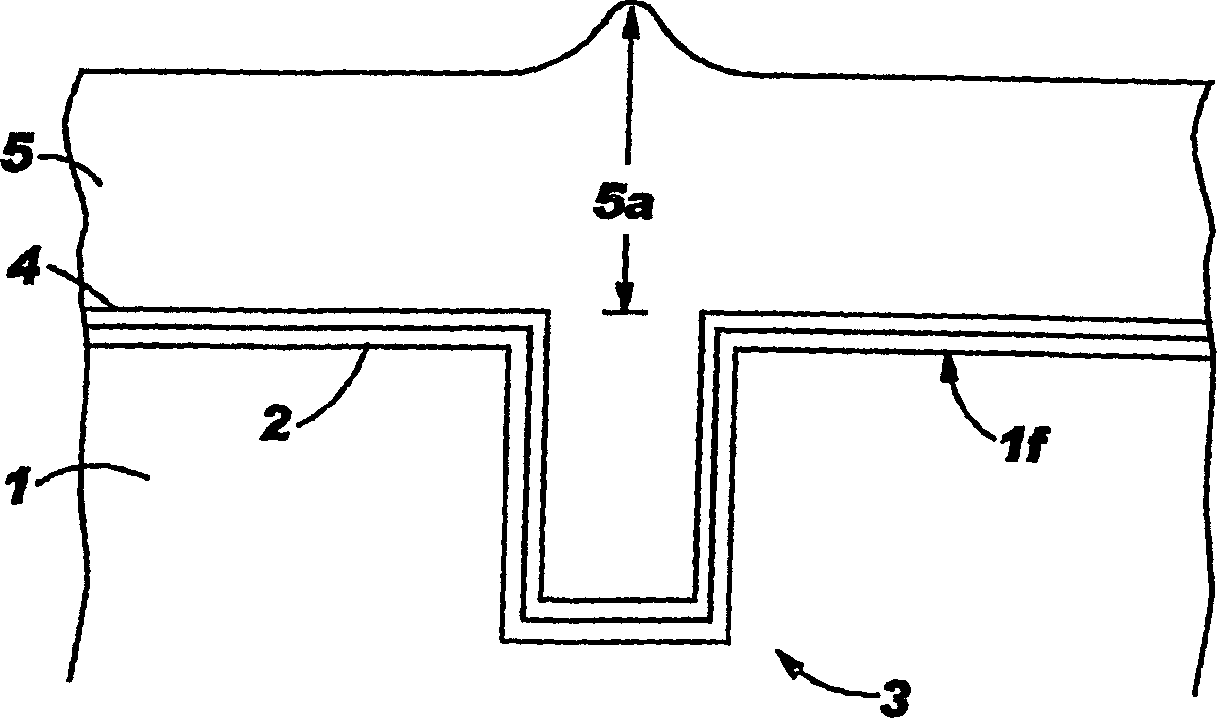

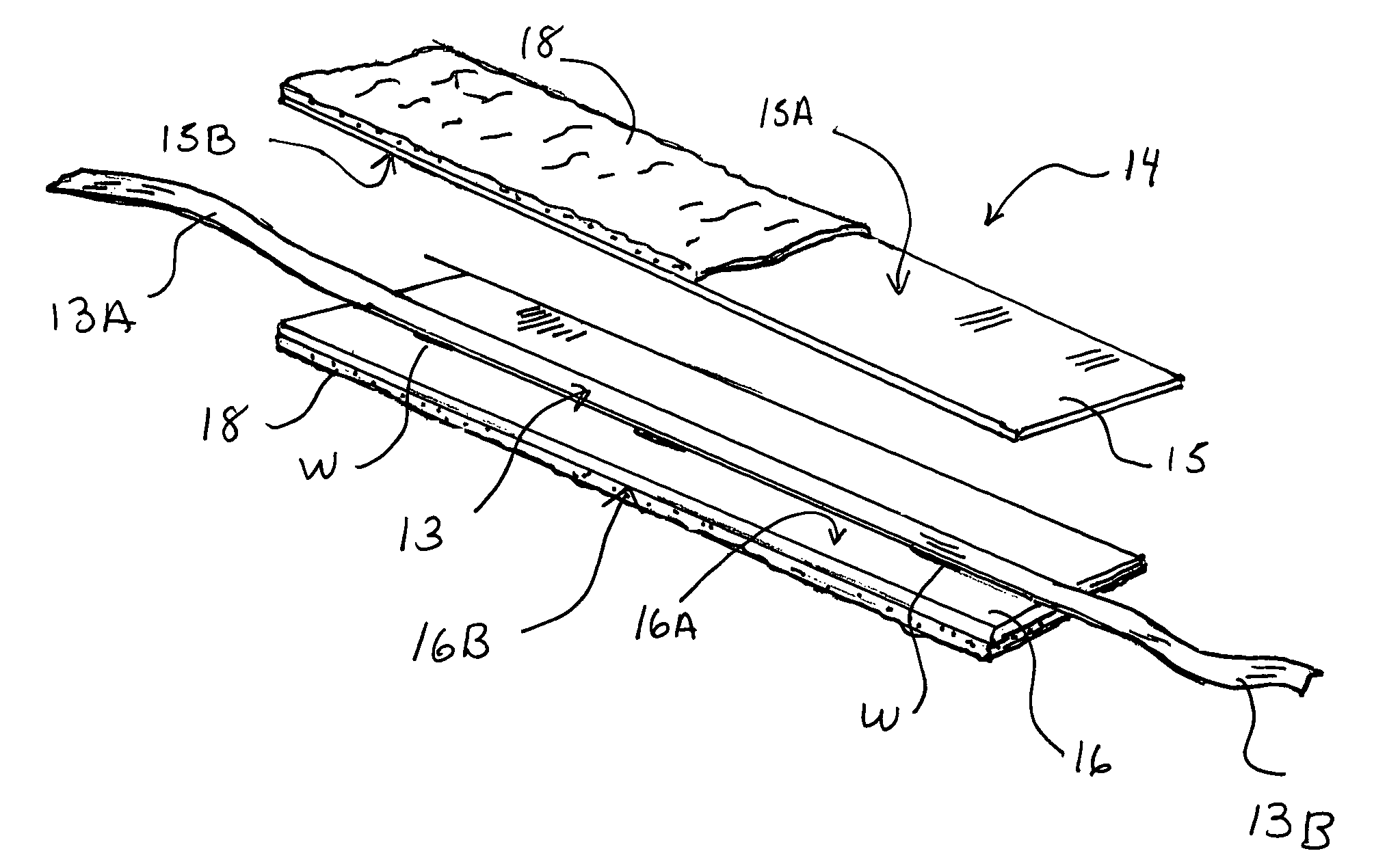

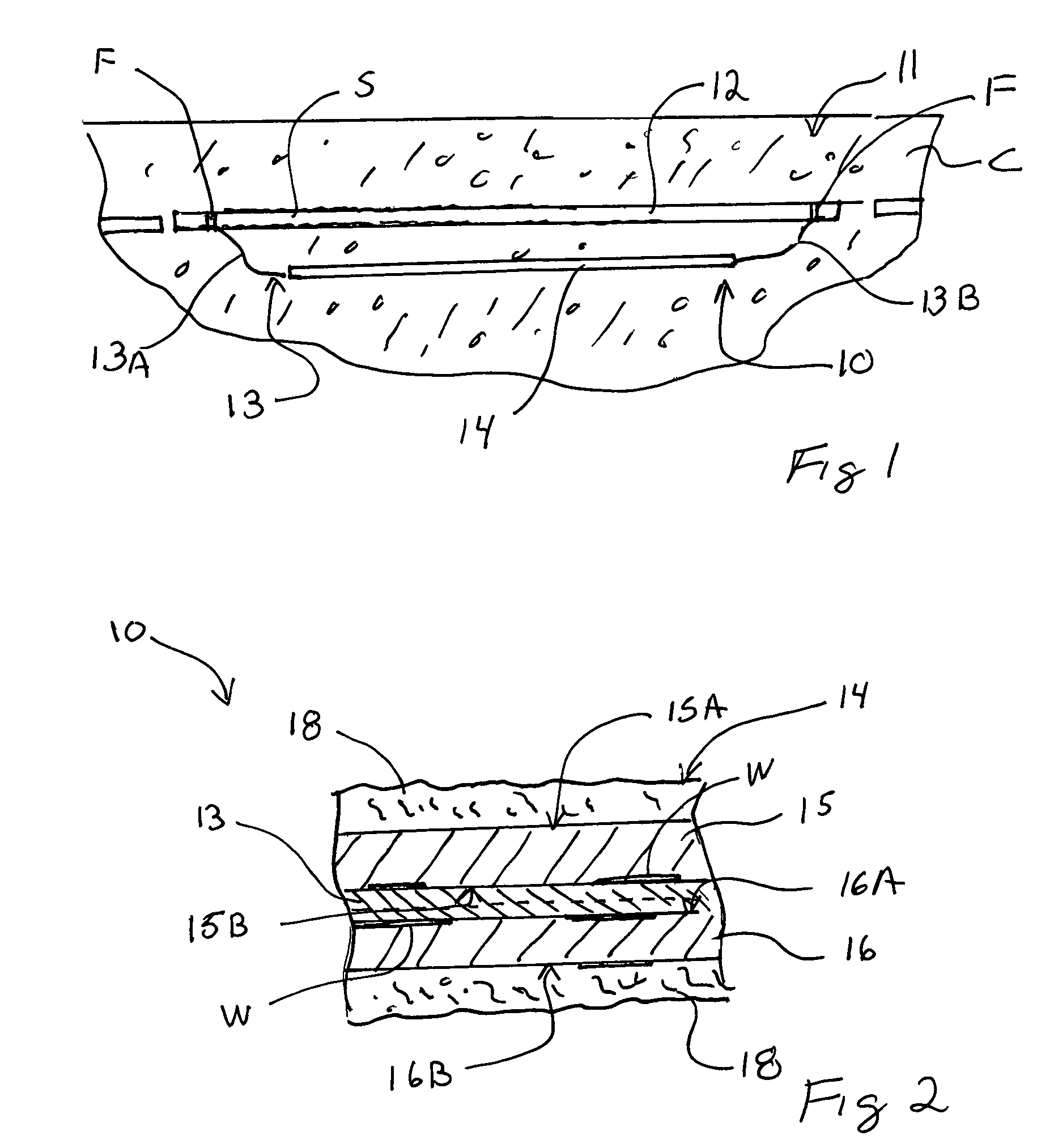

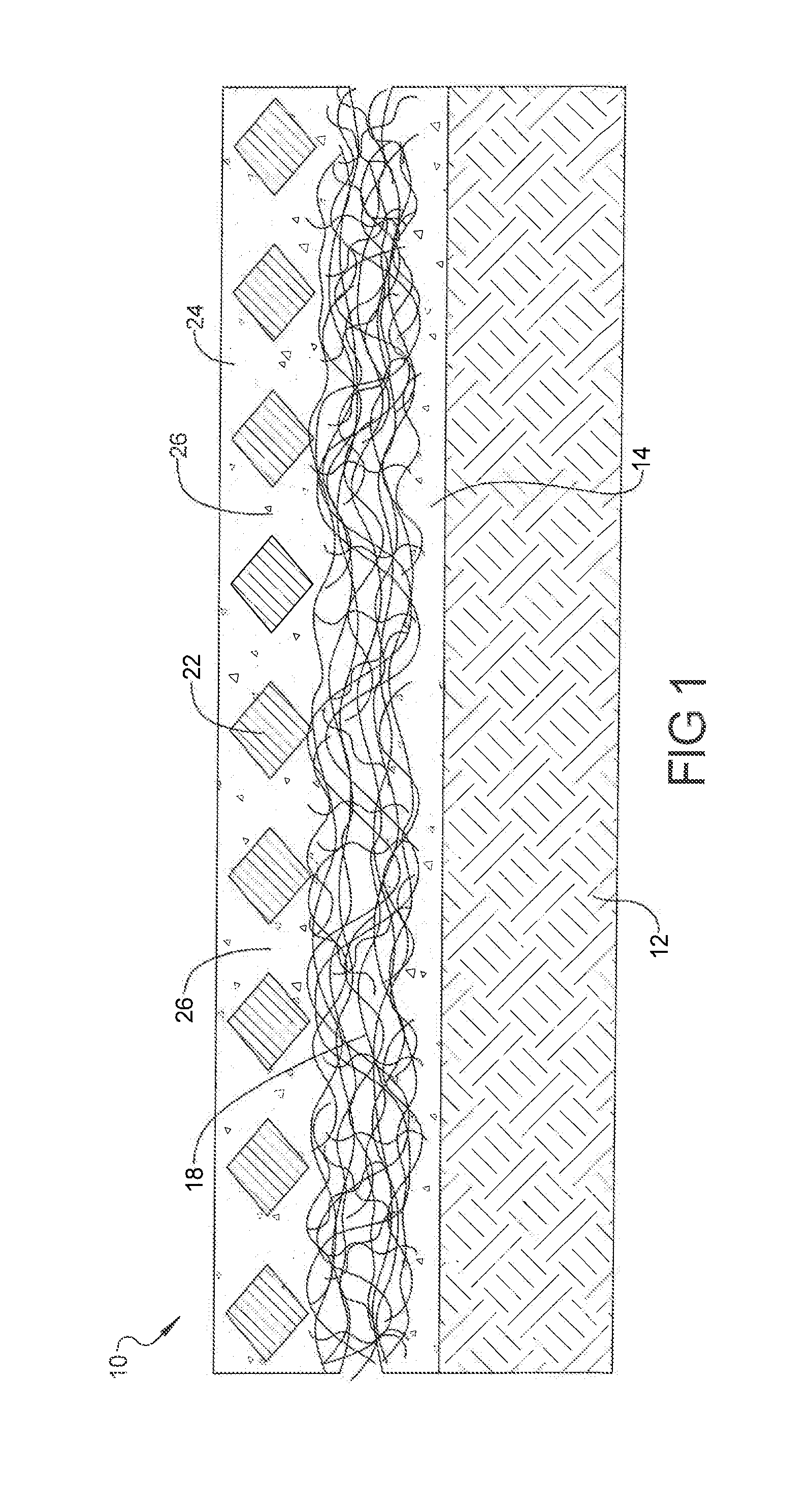

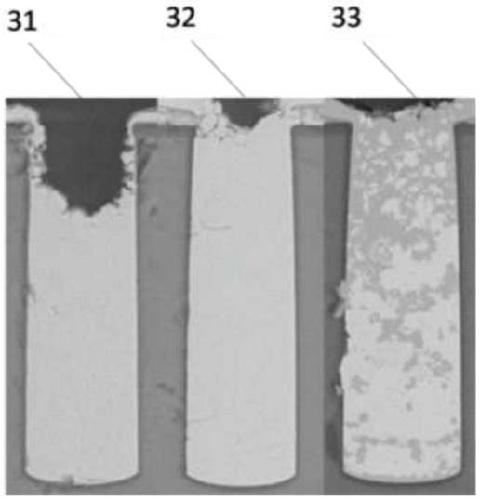

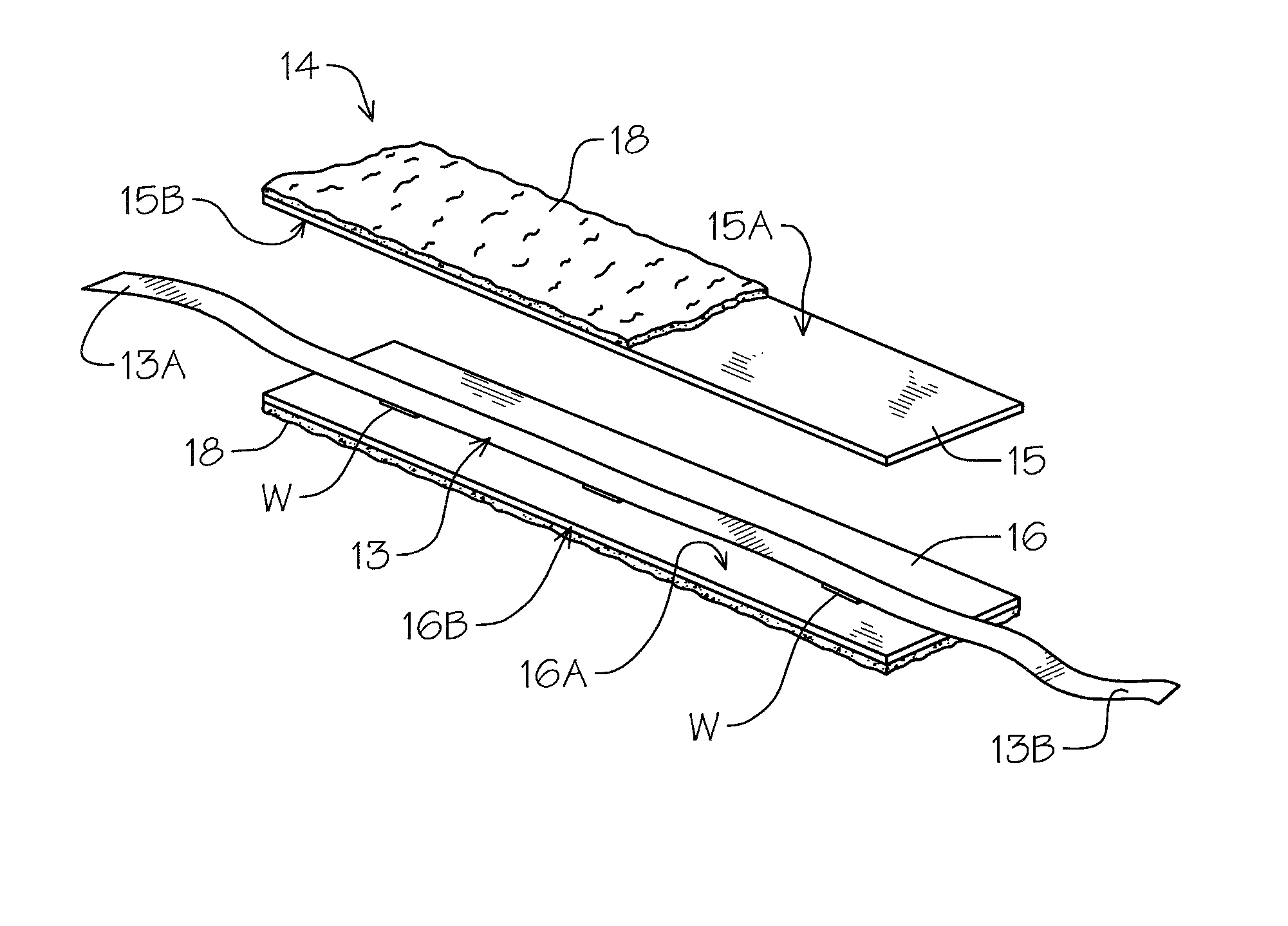

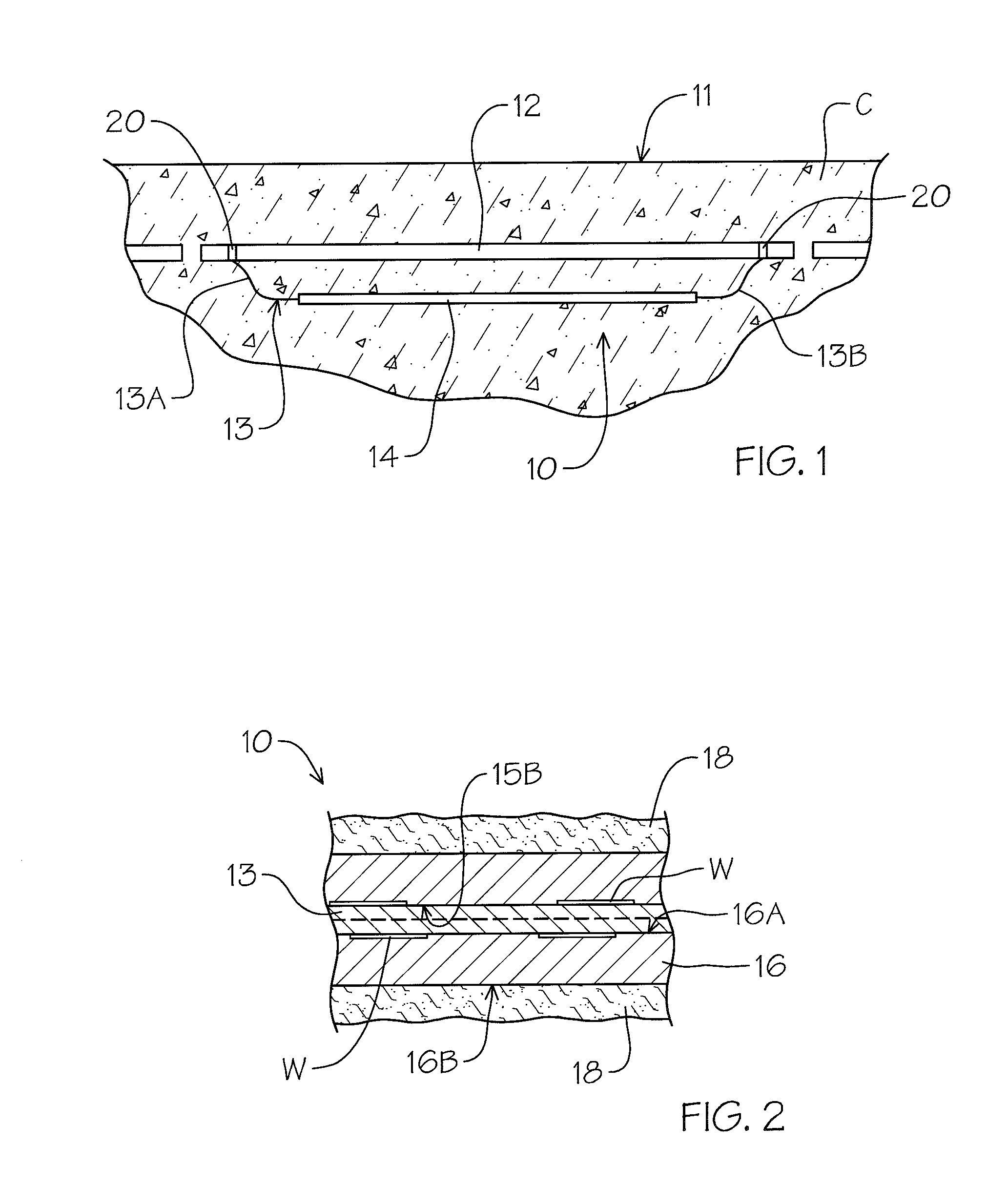

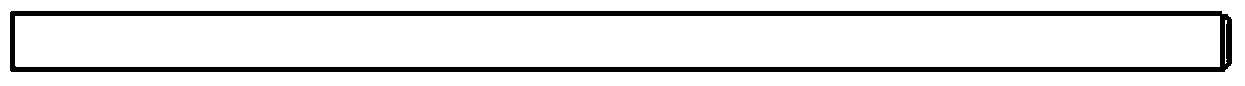

Galvanic anode for reinforced concrete applications

An improved sacrificial galvanic anode assembly for cathodic protection of a steel reinforced concrete structure. A galvanic cathodic protection device uses a multi-layered embedded sacrificial anode such as zinc covered with a flexible layer of paste to provide a continuous electrolyte to keep it active. The formulated paste is inert to cement embedment material and is pre-coated on the anode body prior to encapsulation. An integrated conductive contact band extends from within the coated anode to attachment to a reinforcement bar for establishing electrical conductively therewith in the concrete structure transferring galvanic corrosion to the anode.

Owner:GIORGINI ROBERTO

New method and system for TSV blind hole filling

InactiveCN107675233AFacilitated DiffusionImprove adsorption capacityElectrolytic coatingsSemiconductor devicesGalvanic anodeEngineering

The invention discloses a new method and system for TSV blind hole filling. The new method includes the following steps that firstly, a silicon piece with a TSV blind hole is put into deionized water,vacuum suction pretreatment is conducted, and gas in the TSV blind hole is exhausted; secondly, the silicon piece obtained after pretreatment is integrally connected with an electroplating cathode; thirdly, an additive agent, an inhibiting agent and an accelerating agent are added into an electroplating solution, sufficient mixing is conducted, and a suspension electroplating solution is formed;fourthly, the suspension electroplating solution is added into an electroplating bath, an electroplating anode and an electroplating cathode of an electroplating power source are put into the suspension electroplating solution so that the silicon piece can be subjected to standing in the suspension electroplating solution, and the electroplating solution reaches adsorption balance preliminarily inthe TSV blind hole; fifthly, an inlet and an outlet of a circulation pump communicate with the suspension electroplating solution, the inlet communicates with the position of the electroplating anode, and the outlet communicates with the position of the electroplating cathode; and sixthly, a circulation pump is started, the electroplating power source is started at the same time, electroplating begins, and the flowing speed is provided for the suspension electroplating solution in the electroplating bath through the circulation pump. The filling efficiency can be effectively improved, and thecost is reduced.

Owner:CENT SOUTH UNIV

Preparation method of three-dimensional connecting device

ActiveCN103025060AHigh precisionNot limited by line widthPrinted circuit manufactureGalvanic anodeAlkalinity

The invention provides a preparation method of a three-dimensional connecting device. The preparation method comprises the following steps of: A. metallizing a non-electric conduction base material and forming a non-inert metal layer on the surface of the non-electric conduction base material; B. carrying out laser engraving on the non-inert metal layer on the surface of the non-electric conduction base material, and dividing the non-inert metal layer into a circuit region and a non-circuit region which are completely separated; and C. connecting the circuit region of the surface of the non-electric conduction base material with a power source cathode, connecting an electroplating anode material with a power source anode, then putting the non-electric conduction base material and the electroplating anode material in acidity or alkalinity electroplate liquid for electroplating treatment, forming an electroplating thickening layer on the surface of the non-inert metal layer of the circuit region, corroding and removing the non-inert metal layer of the non-circuit region by the acidity or alkalinity electroplate liquid. The preparation method of the three-dimensional connecting device has no special requirement on the base material and has high machining efficiency; and simultaneously the circuit accuracy is greatly improved.

Owner:BYD CO LTD

Plating method for preventing hydrogen bubbles of copper-tin alloy plating layer

InactiveCN101649475APrevent hydrogen bubblingHydrogen Bubble EliminationGalvanic anodeSquare waveform

The invention provides a plating method for preventing hydrogen bubbles of a copper-tin alloy plating layer. A plating anode material is a high-purity copper plate with purity of 99.9 percent, a cathode material is a 27 SiMn steel plate which is processed by oil-removing treatment, copper-tin alloy plating liquid is industrial low-tin bronze electrolyte, and pH is 8-9. The plating method comprisesplating parameters: the plating adopts a square-wave impulse plating technology, the impulse average current density is 1-5 A / dm<2>, the frequency is 500Hz-2500Hz, the duty ratio is 25-40 percent, aspace between a cathode and an anode is 5-10cm, the area ratio of the cathode to the anode is from 1:1.5 to 1:5, and the electrolyte temperature is from 25 DEG C to 35 DEG C. Compared with the traditional DC plating copper-tin alloy technology, the plating method introduces impulse current and effectively inhibits hydrogen generation in a planting process, and optimal technological parameters of the impulse plating technology are sieved, thereby the hydrogen bubbles of the copper-tin alloy plating layer can be prevented. The plating method for preventing hydrogen bubbles of a copper-tin alloyplating layer has simple technology, low cost, strong applicability, and the like.

Owner:HARBIN ENG UNIV

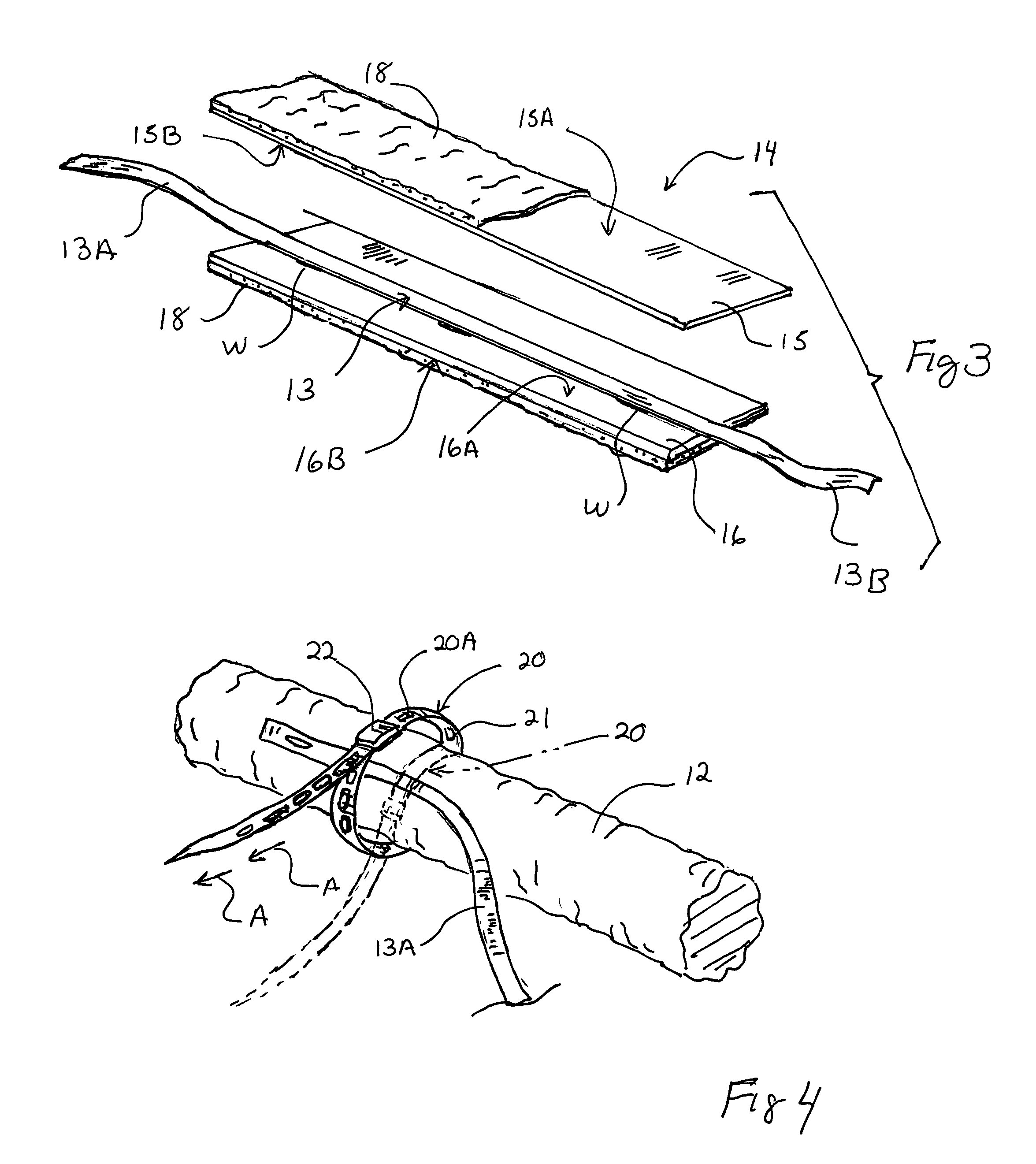

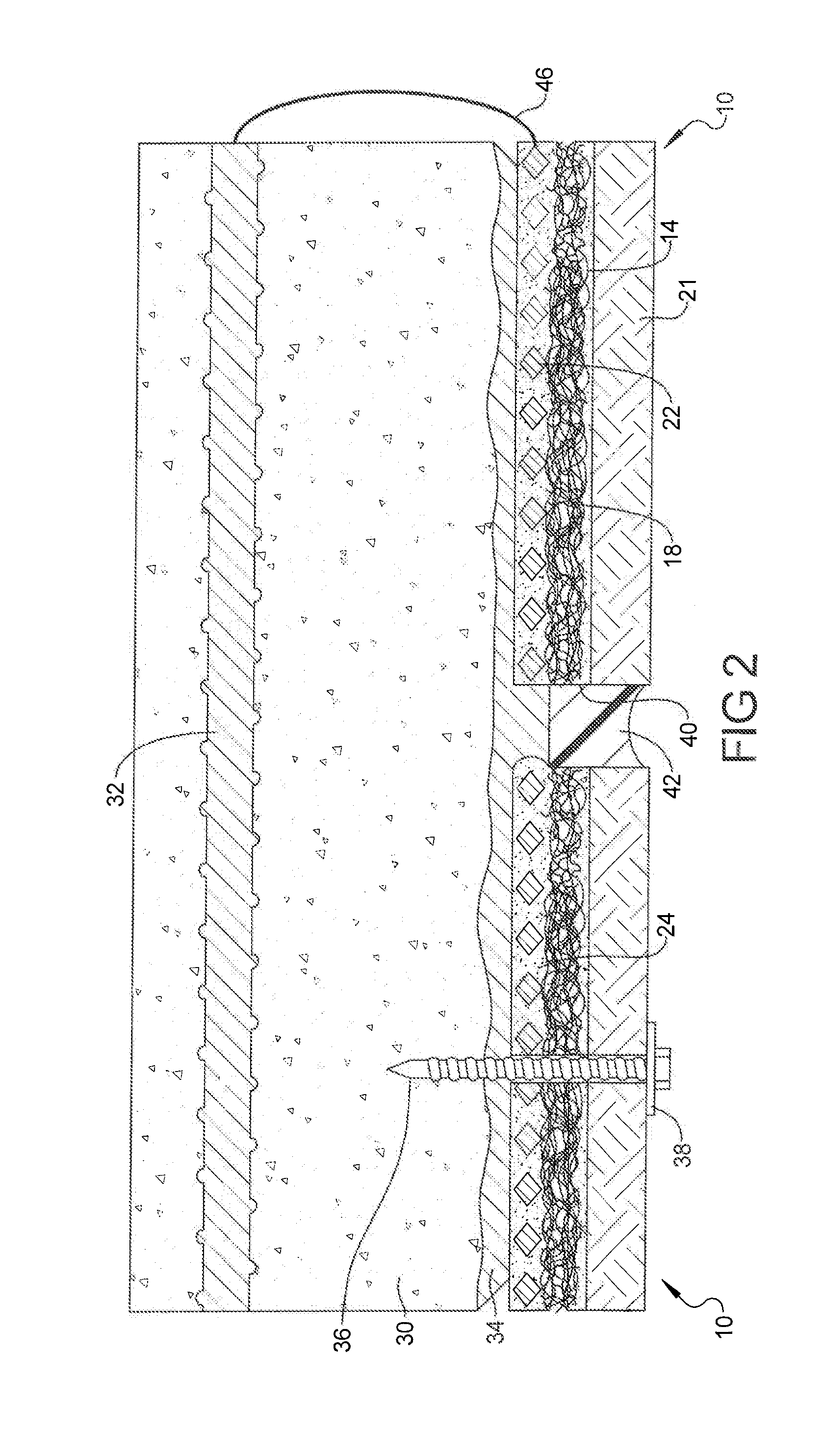

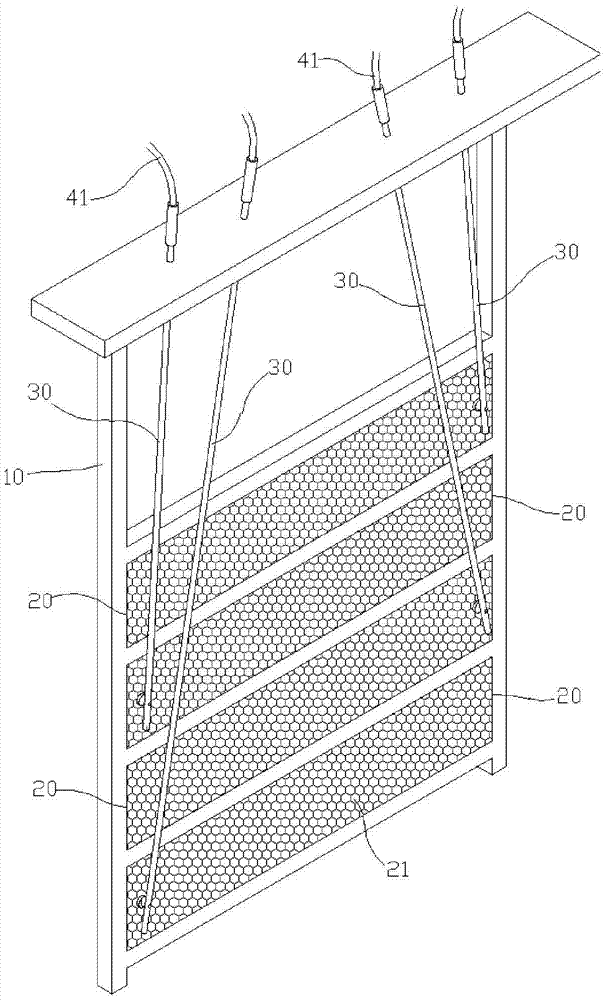

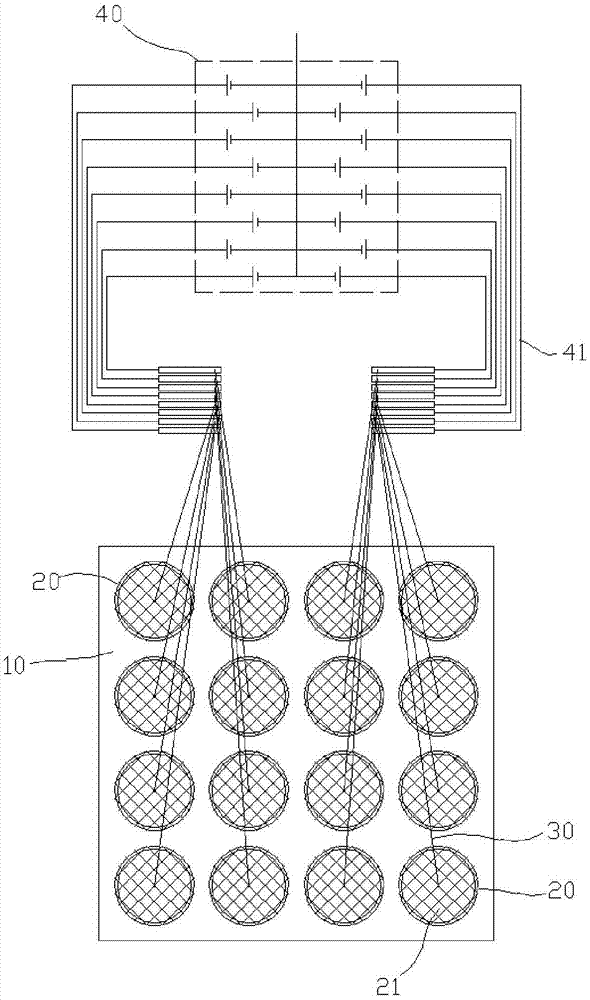

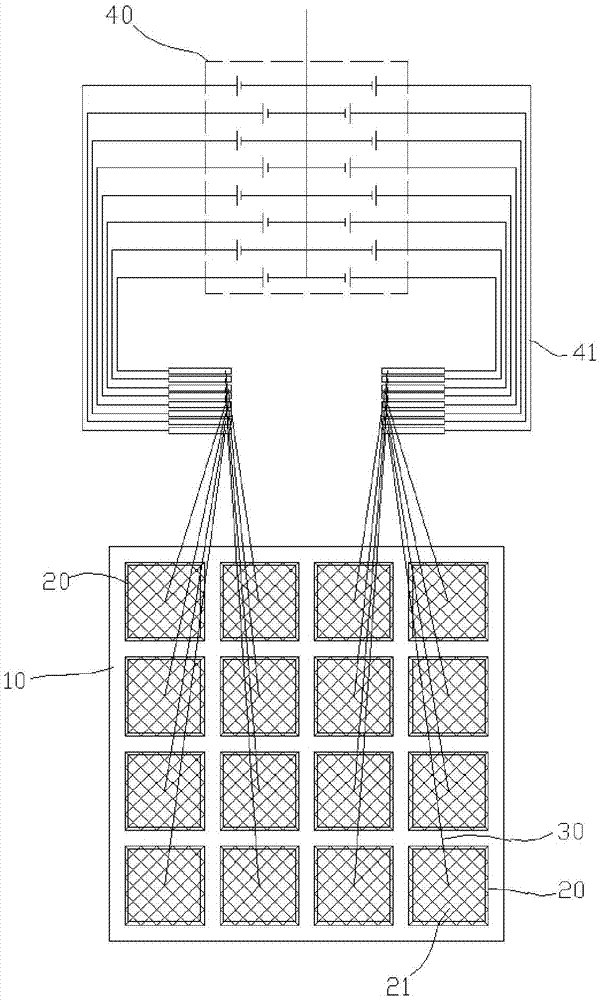

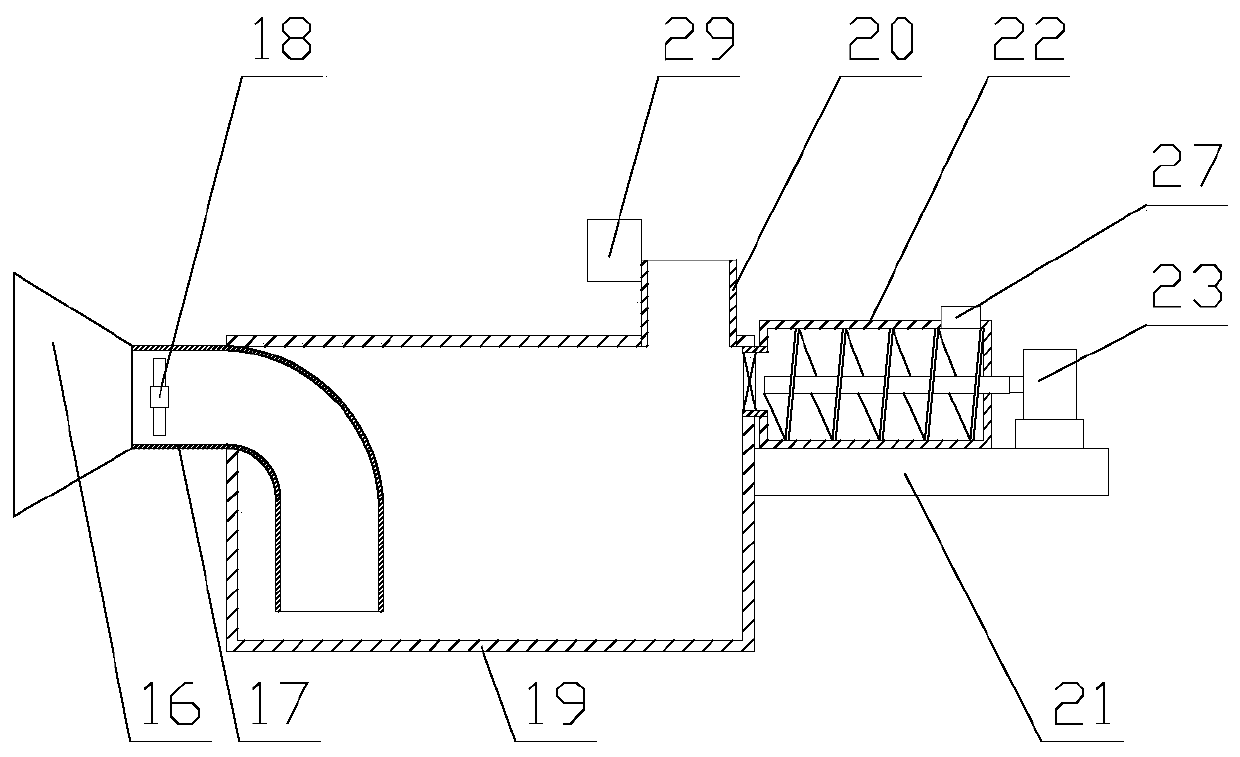

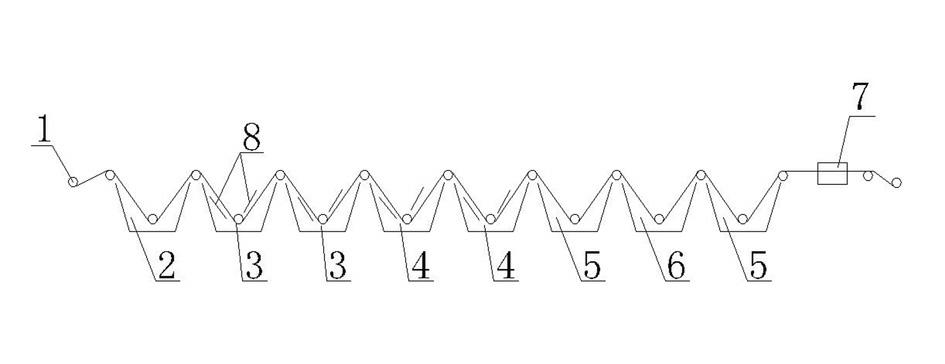

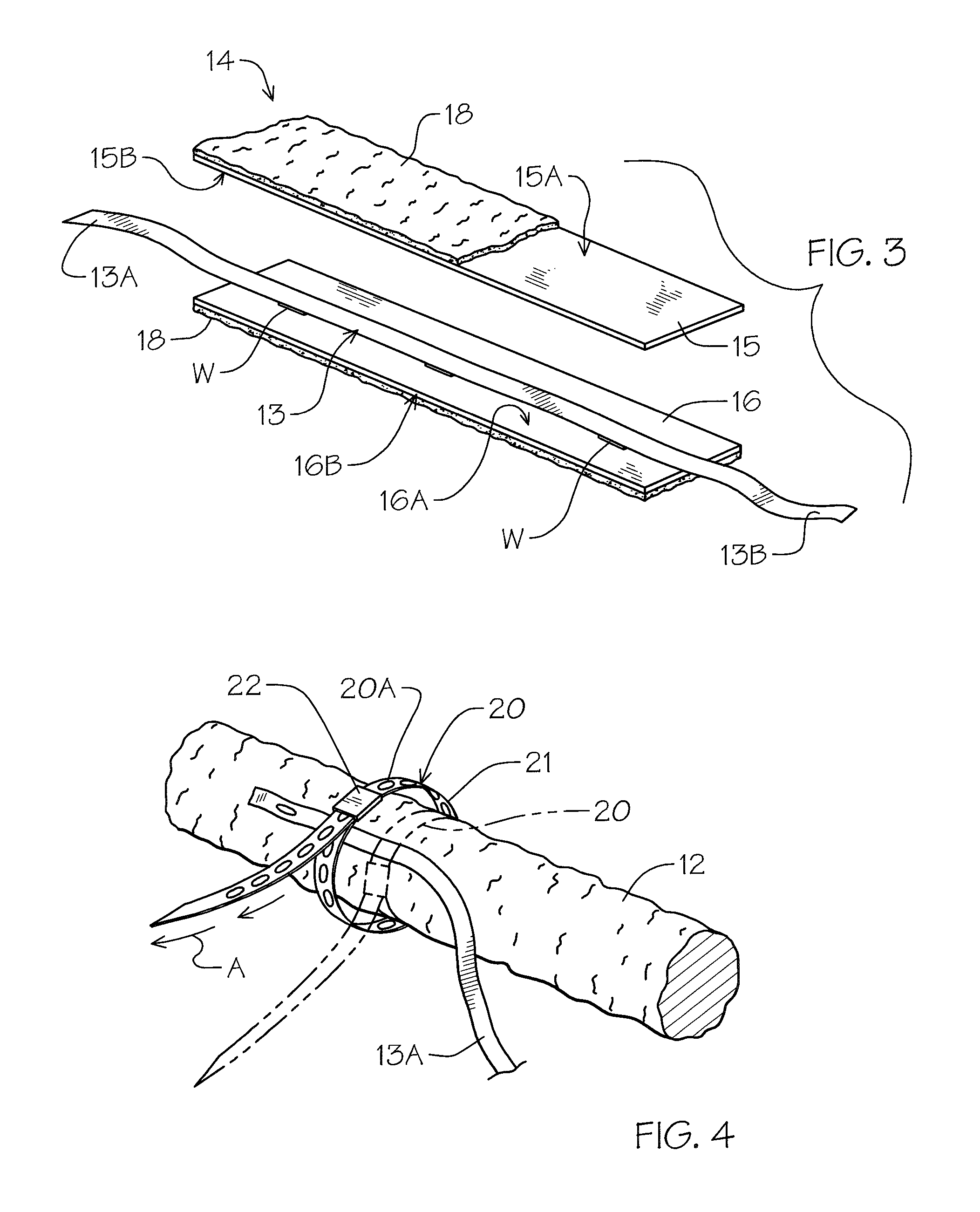

Galvanic Panel with Compliant Construction

A prefabricated sacrificial galvanic anode panel includes a rigid or semi-rigid backing board or similar support surface over which a thin layer of cement, mortar or adhesive is applied for holding a compliant layer of material in place on the support surface. The layer of wet adhesive, cement or mortar is sufficiently thin so that upon drying it does not cause warping of the support surface. The compliant or spongy layer is laminated or sandwiched between a thicker layer of ionically conductive galvanic mortar and the substrate support surface. The compliant or spongy layer prevents the thicker layer of galvanic mortar from wetting the backing board or substrate support surface so as to prevent warpage upon drying of the thicker layer of galvanic mortar and also accommodates the expansion of corrosion products from the galvanic anode material.

Owner:ARTAZN LLC

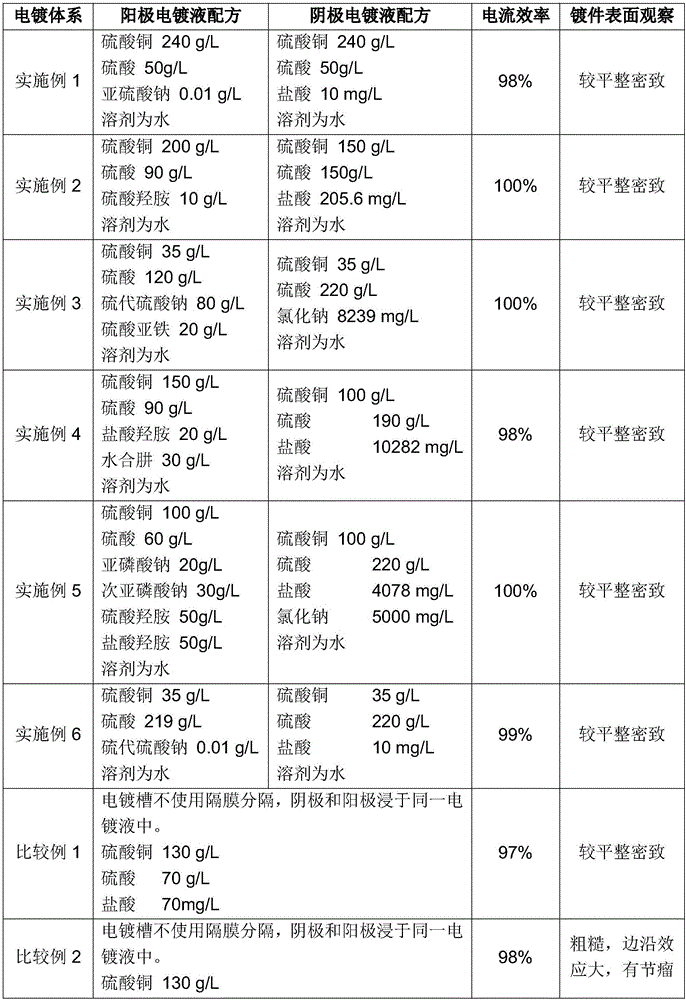

Novel anode electroplating liquid and acidic copper electroplating process using same

The invention discloses a novel anode electroplating liquid which comprises 5-240 g / L of copper sulfate, 50-220 g / L of sulfuric acid and 0.01%-150 g / L of a reducing agent. When the anode electroplating liquid is used for electroplating production, an excellent-quality electroplating product can be obtained without using phosphor copper as an electroplating anode, and toxic phosphorus wastewater is prevented from being generated in the electroplating process. The invention further discloses an acidic copper electroplating process using the novel anode electroplating liquid.

Owner:叶旖婷

Anode used for electroplating of alkaline zinc-nickel alloy

ActiveCN103911650AZinc ion concentration is stableDoes not increase the difficulty of electroplating process managementElectrodesGalvanic anodeZinc

The invention relates to an electroplating anode, and in particular relates to an anode used for electroplating of an alkaline zinc-nickel alloy. The anode comprises a zinc material and a blocking device, wherein the blocking device can be used for increasing or reducing the contact area between the zinc material and an electroplating solution when the anode used for electroplating of the alkaline zinc-nickel alloy is placed in the electroplating solution, and the blocking device is prepared from a material of which the electrode potential is higher than that of zinc. When performing electroplating by adopting the anode used for electroplating of the alkaline zinc-nickel alloy, the relative stability of the zinc ion concentration in the electroplating solution can be ensured, and the management difficulty of the electroplating process can not be improved.

Owner:湖南领湃达志科技股份有限公司

Efficient electroplating device capable of achieving complete plating layer

The invention provides an efficient electroplating device capable of achieving a complete plating layer. The efficient electroplating device capable of achieving the complete plating layer comprises aframe, and is characterized in that an annular track is horizontally arranged at the bottom of the interior of the frame, electrolytes are detachably connected to the bottom of an electroplating anode, and an electroplated workpiece is detachably connected to the bottoms of electroplating cathodes. The efficient electroplating device capable of achieving the complete plating layer is simple in structure and convenient to operate. Air outlet pipes with inclined and downward air nozzles are arranged on the inner wall of an electroplating bath, a rotating motor is matched with the electroplatingbath and drives the electroplating bath to rotate in the annular track, and therefore the difference, caused by the different distances between the surface of the metal workpiece and the electrolytes, of the concentrations of the electrolytes is reduced in the electroplating process, the plating layer can be uniform, and the electroplating effect is improved. Lifting tracks and a lifting plate are arranged, and therefore the movement of the metal workpiece in the electroplating process is achieved, electroplating of the metal workpiece can be complete, the situation that electroplating omission exists on the surface of the metal workpiece is avoided, and the electroplating quality of the metal workpiece is improved.

Owner:TIANJIN KAIXIN METAL PRODN

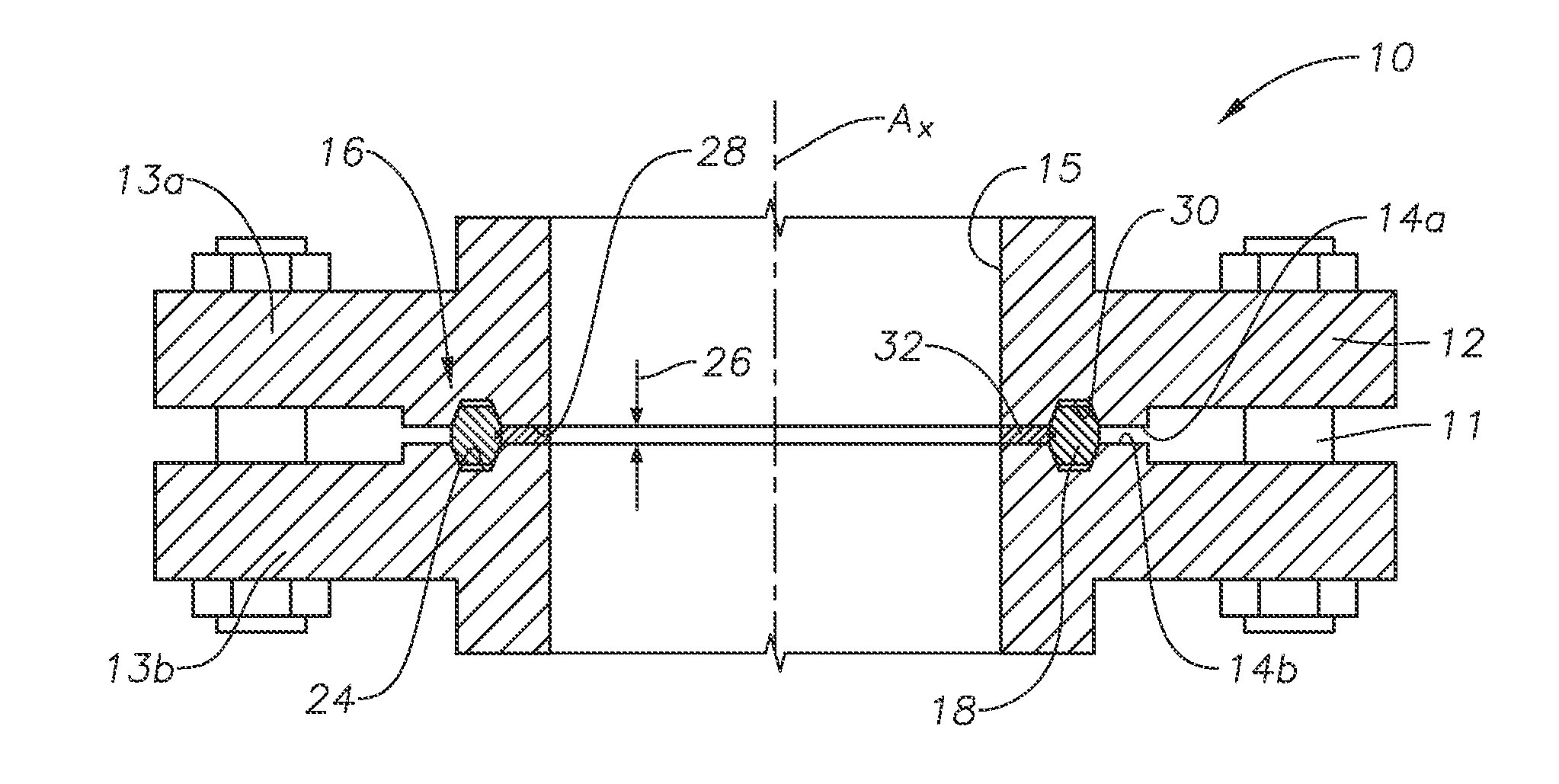

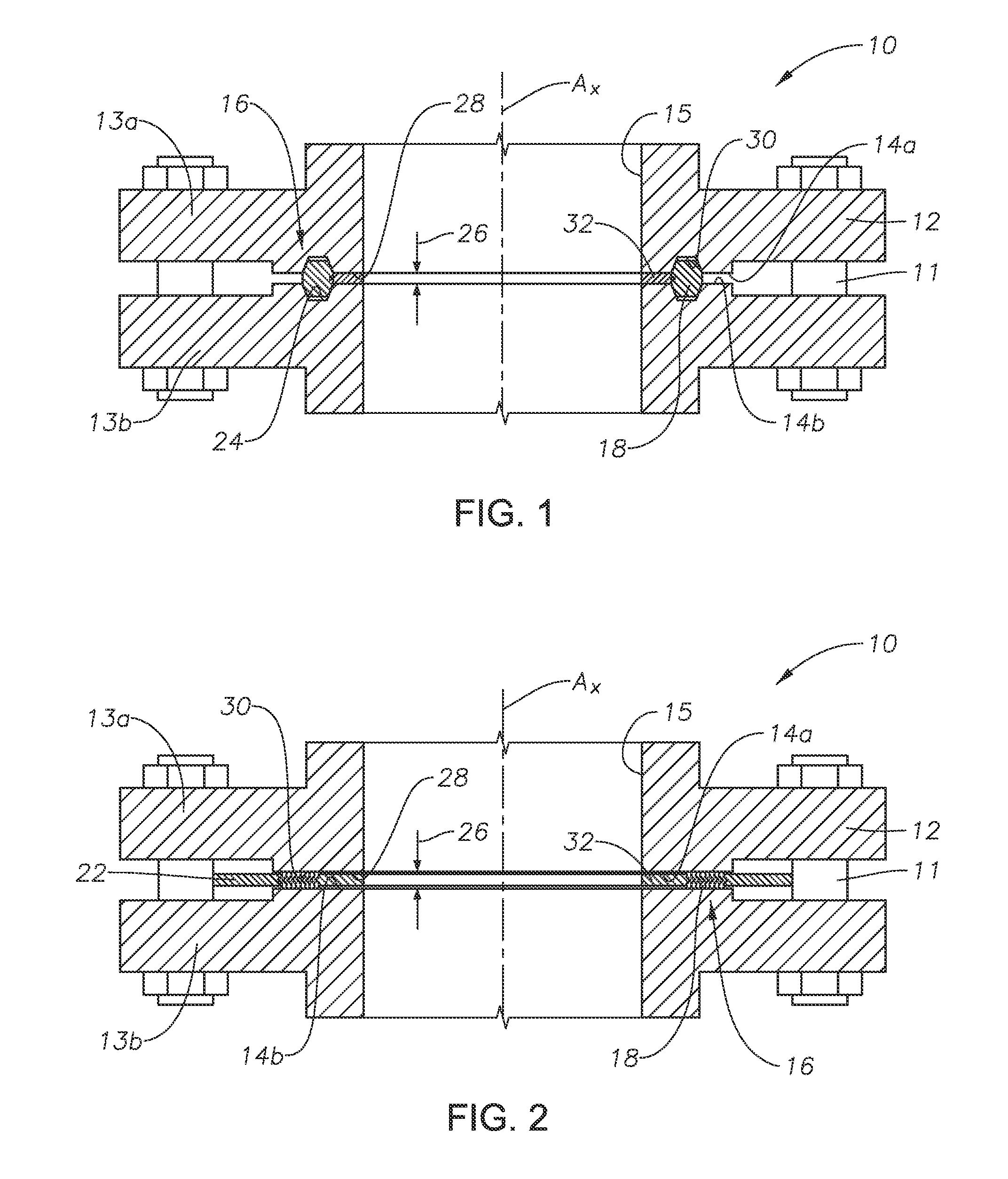

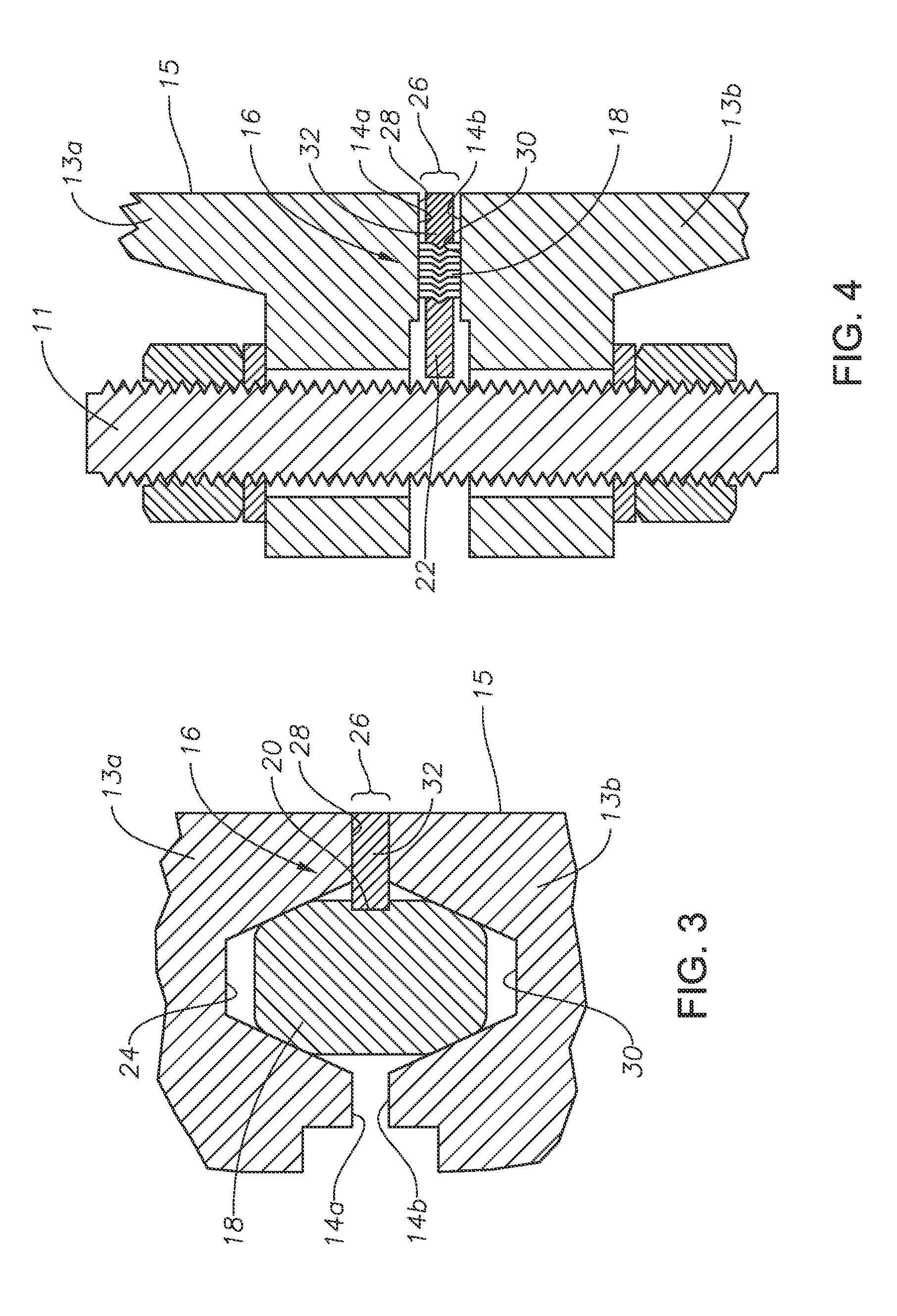

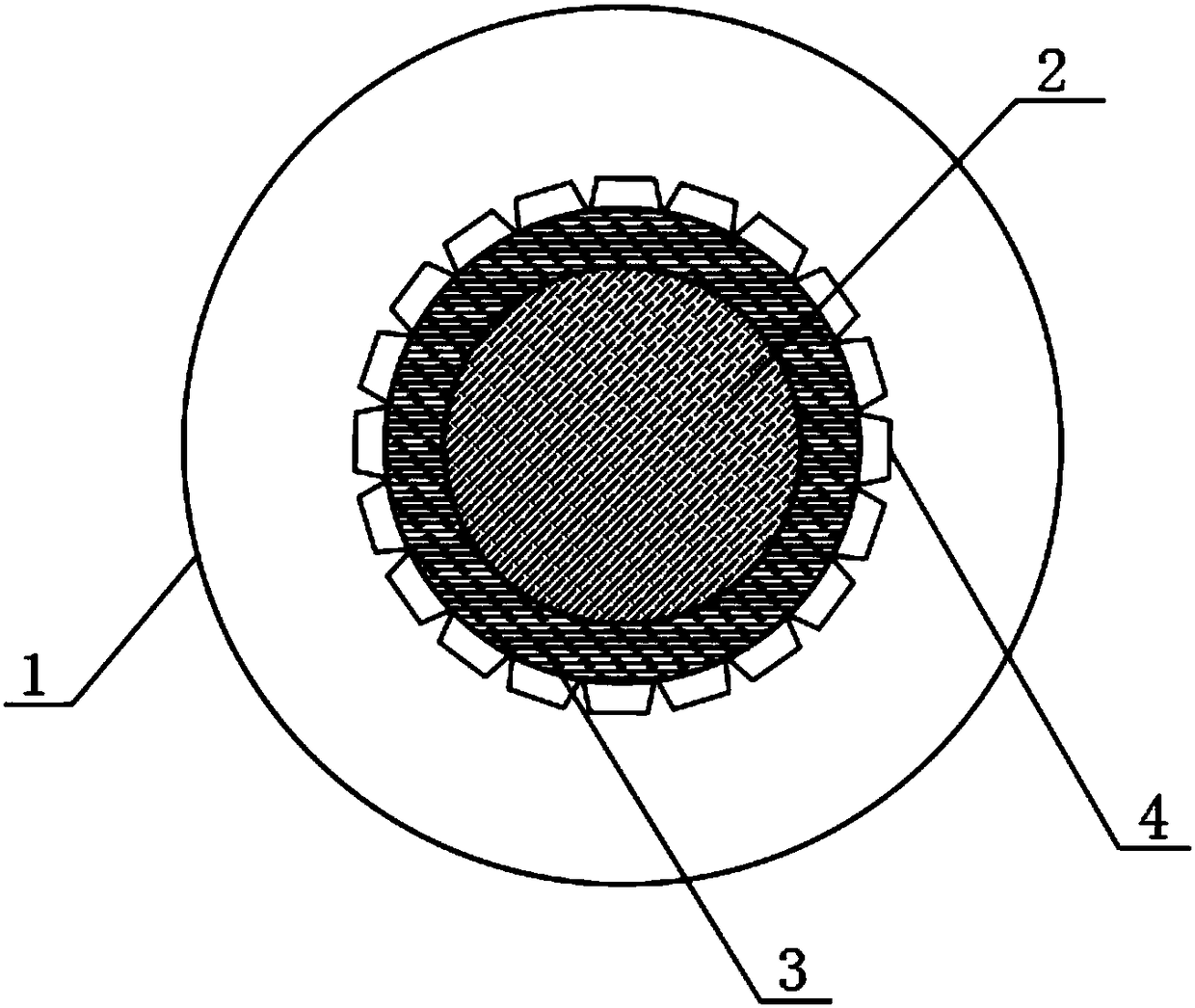

Gasket With Internal Galvanic Anode Ring

A gasket assembly for sealing between mating flange faces of a flanged connection with a central bore includes a seal member. The seal member is ring shaped and has a seal member profile on an inner diameter. A galvanic anode is a ring shaped member with an outer diameter that is in engagement with the seal member profile, and an inner diameter that is at least as large as a diameter of the central bore.

Owner:SAUDI ARABIAN OIL CO

Anode electroplating device

InactiveCN107190307AGuarantee the quality of platingCurrent conducting devicesElectrodesGalvanic anodeEngineering

The electroplating anode device of the present invention is mainly designed with a plurality of anode parts which can be used to control the conduction of the circuit respectively on a frame, so that any or any number of anode parts can be energized in the electroplating tank. Generate different power line distribution states; especially, when the appearance of the product to be electroplated or the hanging configuration type is changed, it only needs to simply switch the current supply circuit to generate the corresponding power line distribution state, so that it can be relatively more It is a positive and reliable means to ensure the quality of product electroplating.

Owner:BOARDTEK ELECTRONICS CORP

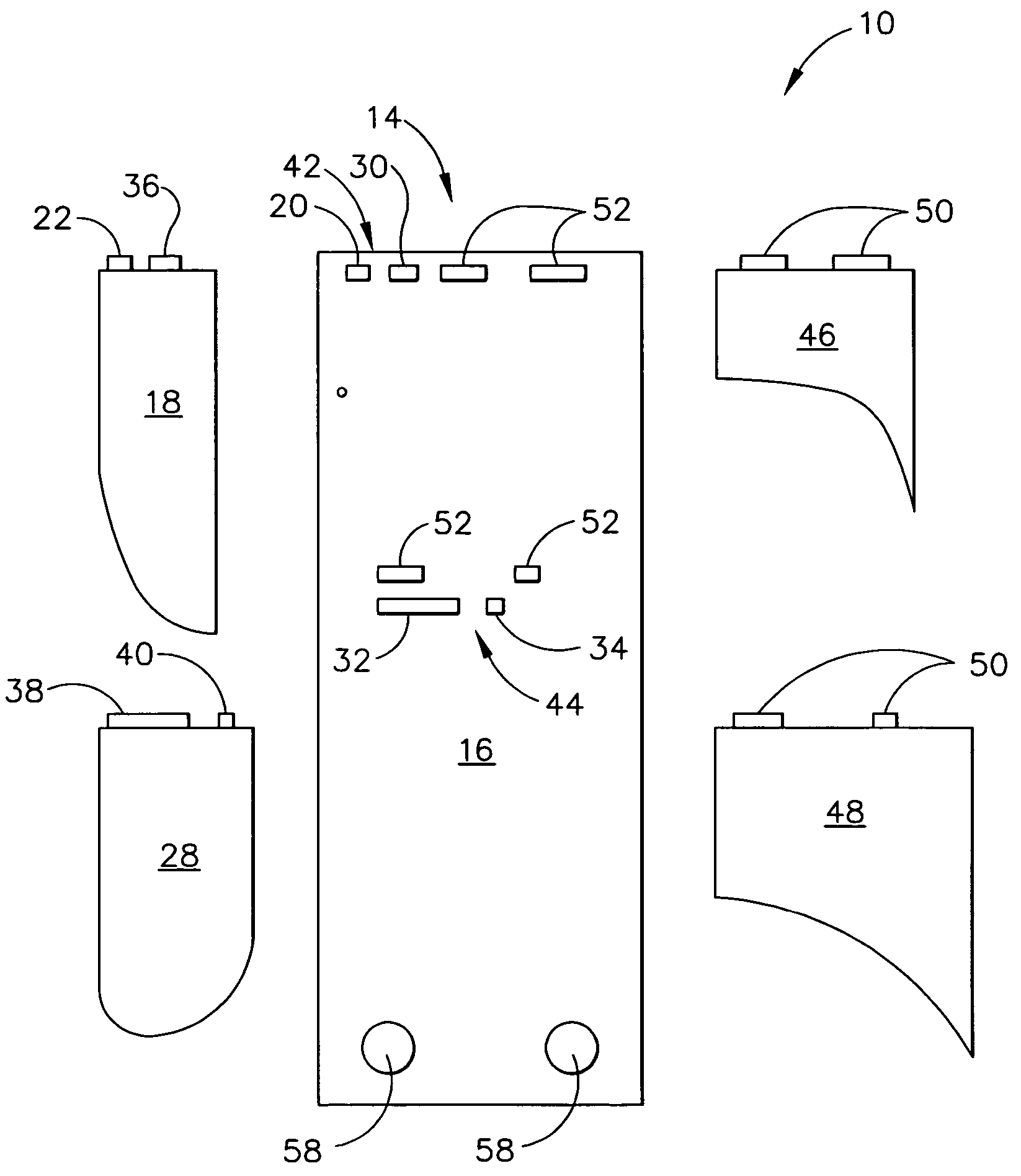

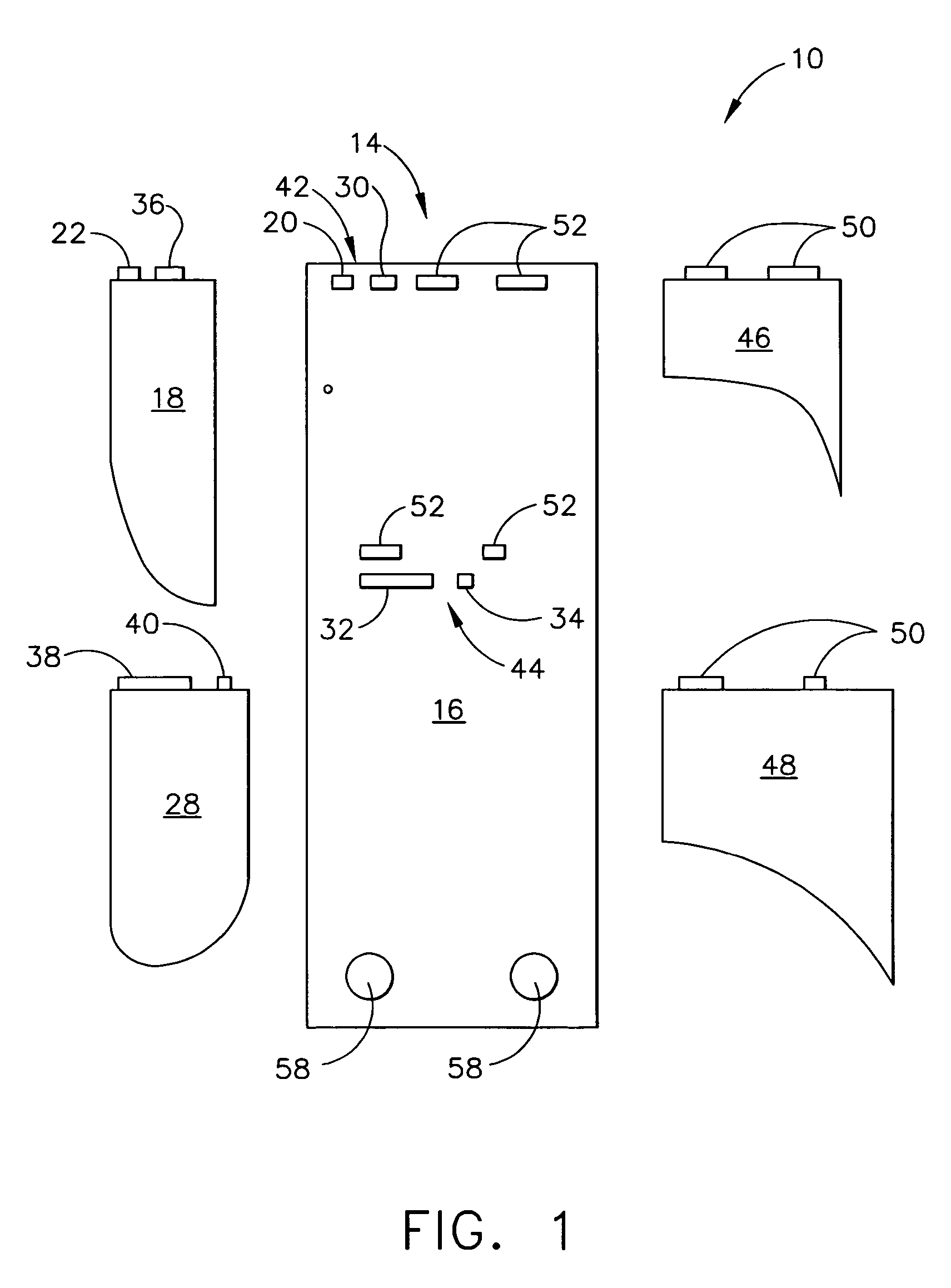

Electroplating apparatus and method for making an electroplating anode assembly

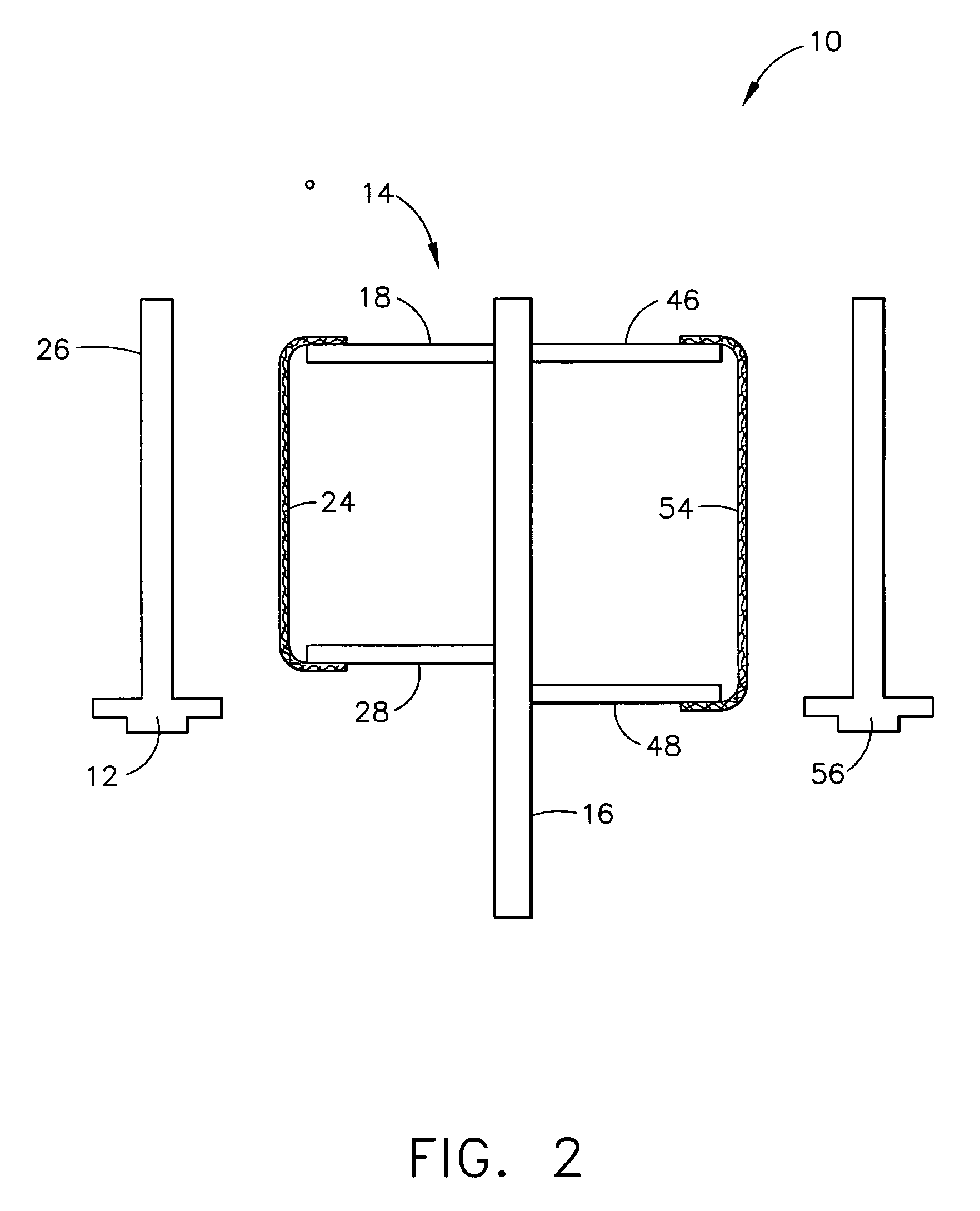

ActiveUS7494576B2Precise positioningShort manufacturing timeMachining electrodesCellsGalvanic anodeElectroplating

Apparatus for electroplating a workpiece includes an unassembled electroplating anode assembly having weldable first and second structural anode members. The first structural anode member includes a positioning slot. The second structural anode member includes a positioning tab disposable in the positioning slot. A method for making an electroplating anode assembly includes obtaining an electroplating-anode-assembly first structural anode member having a positioning slot and obtaining an electroplating-anode-assembly second structural anode member having a positioning tab. The method also includes locating the positioning tab in the positioning slot and welding together the first and second structural anode members.

Owner:GENERAL ELECTRIC CO

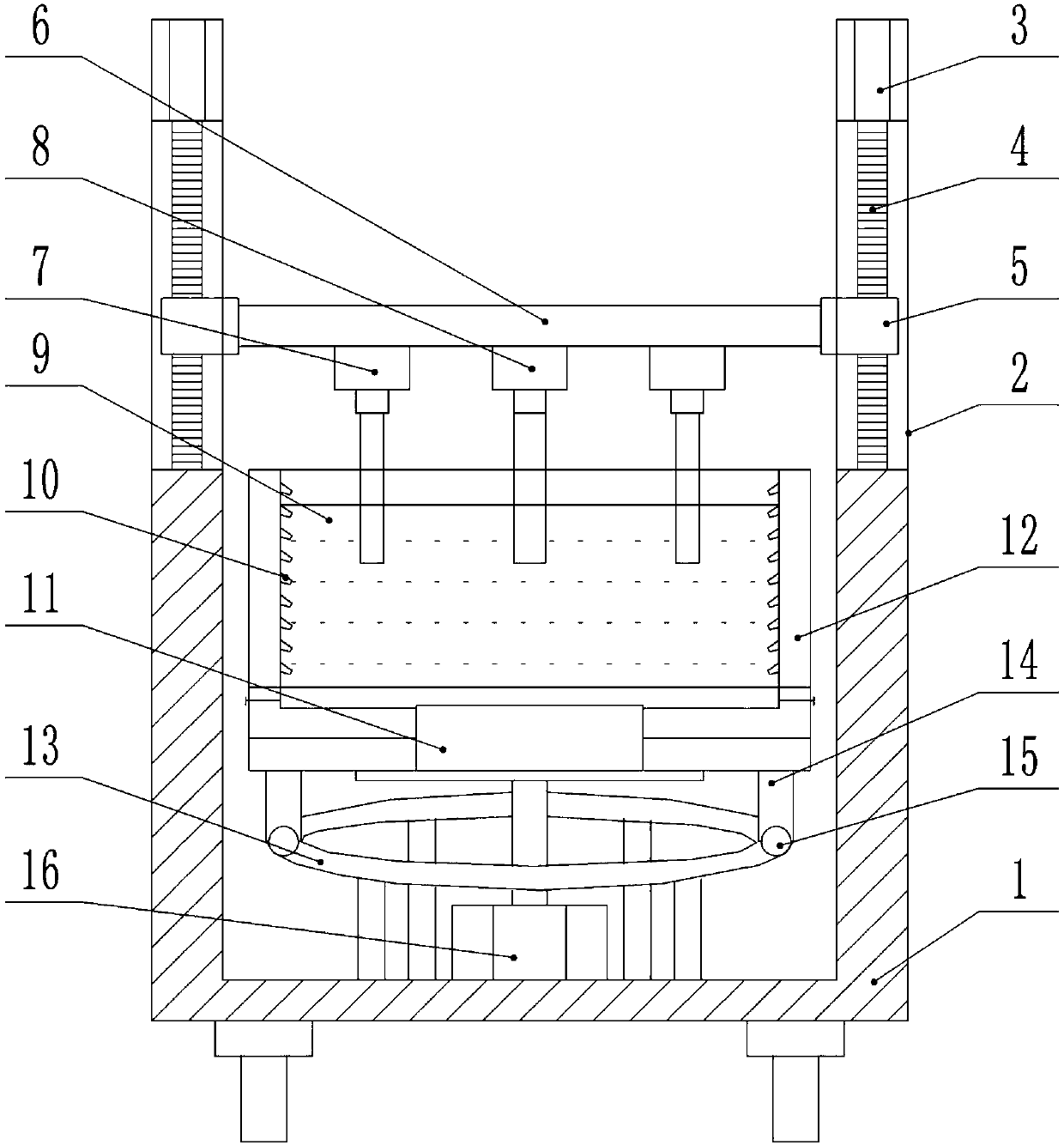

Anode unit for continuous electroplating of belt poor conductor

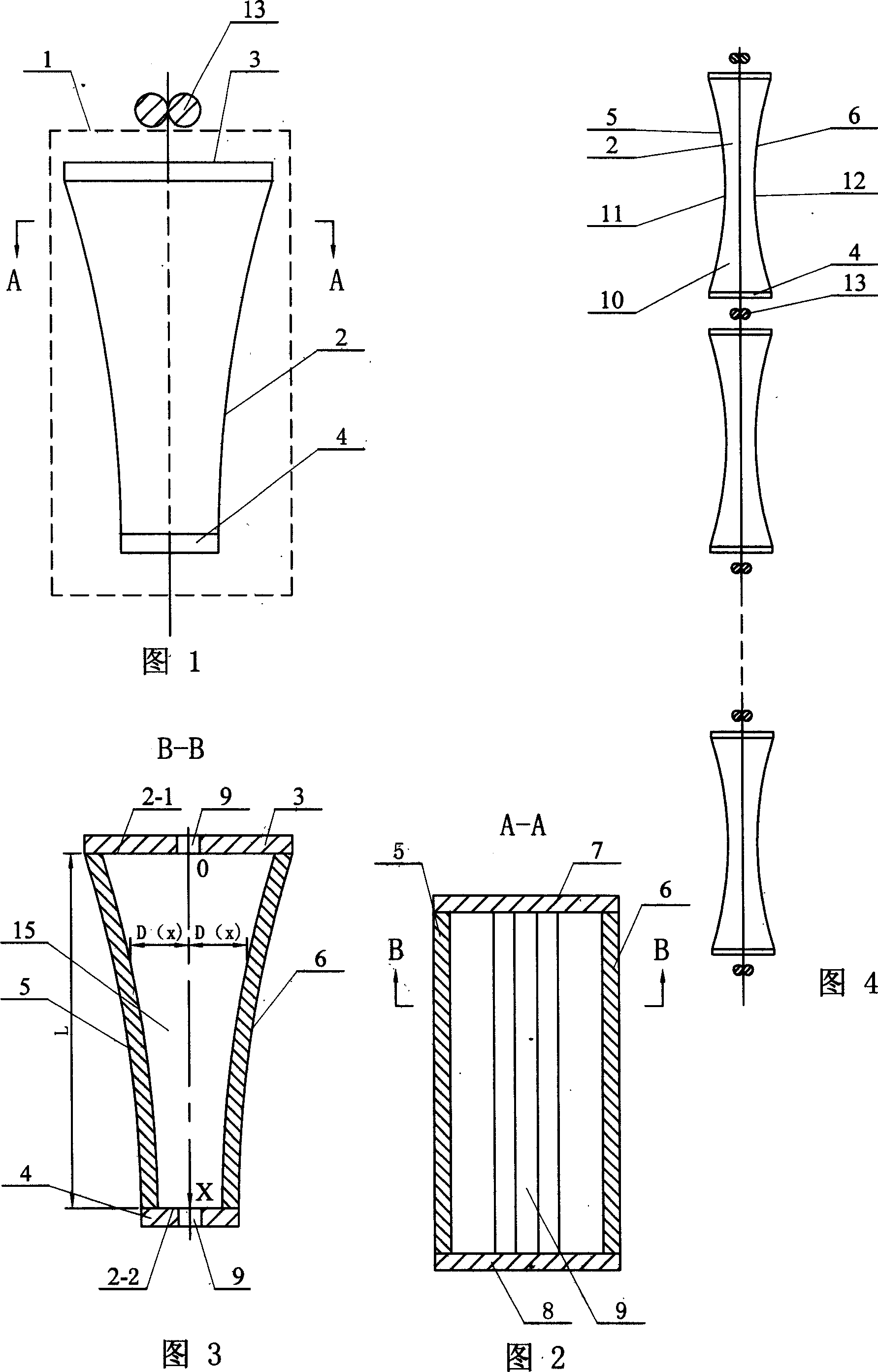

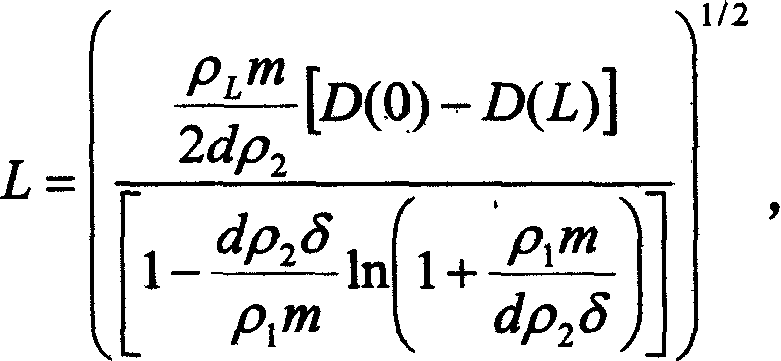

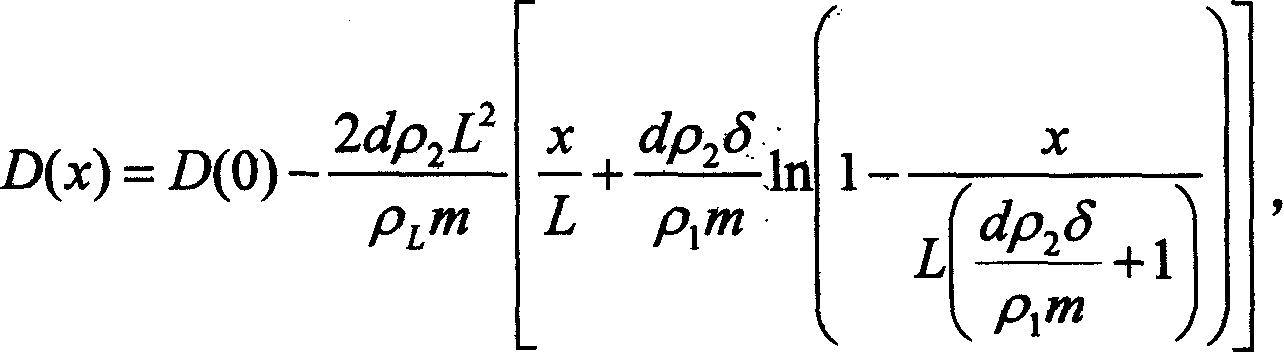

InactiveCN1637173AUniform distribution of current densityOptimal Current Density ControlElectrodesGalvanic anodeProduction line

The anode device for continuous electroplating of belt poor conductor consists of at least one anode unit. The anode unit consists of one through cavity, one upper insulating cover plate and one lower insulating cover plate. The through cavity is formed with the first anode plate, the first insulating baffle, the second anode plate and the second insulating baffle connected successively. The upper insulating cover plate is connected to the upper port of the through cavity, the lower insulating cover plate to the lower port, and both the upper insulating cover plate and the lower insulating cover plate have slot with symmetrical plane coinciding with that of the through cavity. The through cavity has flared longitudinal profile passing through two anode plates. Owing to the special shape of anode to control the current density for electrically depositing metal, the single electroplating bath may have maximum anode length, and the continuous electroplating production line may have least electroplating baths.

Owner:HARBIN INST OF TECH

TSV rapid filling method and device

ActiveCN109628968AFast depositionPromote growthElectrolysis componentsSemiconductor devicesGalvanic anodeTransformer

The invention provides a TSV rapid filling method and device. The TSV rapid filling method comprises the following steps of conducting pretreatment, wherein a silicon slice comprising a TSV blind holeis placed in a metal nanometer particle suspension liquid for 20 hours or above with the opening being upward; taking out the silicon slice and heating the silicon slice at the temperature of 200-500DEG C for 15-60 min; conducting copper electroplating, wherein copper electroplating is conducted on the heated silicon slice until the TSV blind hold is completely filled. The TSV rapid filling device comprises an electroplating anode, an electroplating cathode, an electroplating power source, an electroplating liquid and an ultrasonic amplitude transformer. After pretreatment, metal nanoparticles are deposited in the TSV hole in advance after pretreatment, then the TSV rapid filing device is utilized to conduct copper electroplating, the deposition speed of the copper is accelerated, and therefore the production efficiency is improved.

Owner:CENT SOUTH UNIV

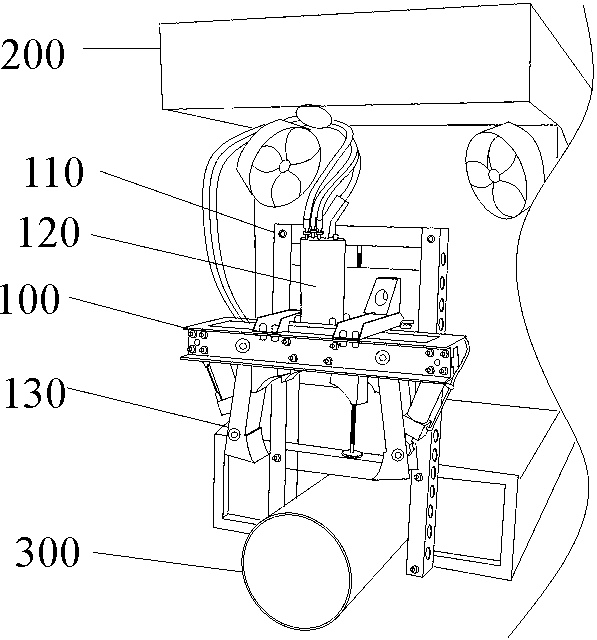

Environment-friendly electroplating production system capable of replacing anode

The invention relates to an environment-friendly electroplating production system capable of replacing an anode. The environment-friendly electroplating production system comprises an electroplating device, wherein the electroplating device comprises a tank body, an electroplating anode, a processor, a replacing mechanism and a purification mechanism; the replacing mechanism comprises a first motor, a driving shaft, a rotating rod, a standby anode and two lifting components; each lifting component comprises a second motor, a screw rod, a moving block, a connecting rod, a suction head, an air inlet pipe, a fan, a purification chamber, an air outlet pipe and a feeding component; and each feeding component comprises a supporting plate, a feeding cylinder, a third motor, a rotating shaft, a feeding pipe and a plurality of spiral blades. According to the environment-friendly electroplating production system capable of replacing the anode, the anode is replaced by the replacing mechanism, sothat the anode passivation is prevented from affecting the electroplating effect; and moreover, harmful gas is absorbed through the purification mechanism, so that the system is more environment-friendly, and improves the safety and practicability.

Owner:嘉兴市兴达铝业股份有限公司

Solid-oxide fuel battery and manufacturing method thereof

InactiveCN101345321AImprove usage characteristicsLow costFinal product manufactureSolid electrolyte fuel cellsOxide ceramicGalvanic anode

The invention relates to a solid oxide fuel battery and a preparation method thereof, belonging to the field of battery power technique. The solid oxide fuel battery comprises a battery core which is formed by the assembly of an oxide ceramic core and a metal connector; dual surfaces of the oxide ceramic core have metal articles; the interior of the oxide ceramic core is composed of an anode, an electrolyte and a cathode. The preparation method of the invention comprises the steps as follows: 1) electro-plating of metal article; anode metal, electrolyte metal and cathode metal are electro-plated on the metal article; 2) welding of metal article; after electro-plated, a layer of metal article is welded; 3) an oxide ceramic battery core naked part is prepared by micro-arc oxidation, and the anode metal, the electrolyte metal and the cathode metal are oxygenated so as to prepare the ceramic battery core naked part; 4) welding and assembling of the battery core; the oxide ceramic battery core naked part is welded with the metal connector so as to prepare the battery core; and 5) assembling of the battery; according to the sequence of anode and cathode, the battery core is sequentially welded and assembled as the solid oxide fuel battery. The solid oxide fuel battery has the advantages of simple process, convenient control, low cost, long service life, high efficiency, large power, small volume, etc.

Owner:姜建国

Electroplating anode phosphorus copper ball and preparation method thereof

The invention discloses an electroplating anode phosphorus copper ball and a preparation method thereof. The electroplating anode phosphorus copper ball comprises a ball body; a hollow groove is formed in the ball body; reinforcing rings are encircled around the outer side of the hollow groove; and projection blocks are encircled around the outer sides of the reinforcing rings. Hydrogen peroxide is added in a reaction kettle, and can oxidize copper powder to improve the phenomenon of looseness, unevenness and no luster of a cathode deposition layer caused by uniform deposition of Cu+ on a loose crystal and to improve the service life and the beauty of the phosphorus copper ball; through continuous stirring of melts, uniform distribution of phosphorus elements is guaranteed, so that the purposes of compact crystallizing particles and compact structure are achieved, and formation of monovalent copper ions is effectively inhibited; and phosphorus is proper in content and uniform in distribution, anode mud is less, and an anode bag is generally cleaned generally more than half a year, so that the electroplating production efficiency is improved, and such auxiliary raw materials as theanode bags are saved.

Owner:江西江南新材料科技股份有限公司

Electroplating anode device and chromium plating method

ActiveCN107620114AChange distributionImprove the uniformity of current density distributionElectrodesGalvanic anodeElectroplating

The invention discloses an electroplating anode device and a chromium plating method. The electroplating anode device comprises multiple anode rods. The multiple anode rods form a cage-shaped structure through supporting of a supporting structure. The cage-shaped structure is used for being arranged on the outer side of a chromium plating area on the outer circle of a workpiece in a sleeving manner. A clearance exists between the anode rods and the outer circle of the workpiece. A cathode gasket is arranged between the cage-shaped structure and the end portion of the outer circle of the workpiece. The anode rods are electrically connected with an anode. The workpiece is electrically connected with a cathode. The anode device is simple in structure, cage-shaped anode and workpiece hanging and electric conduction are integrated, in addition, installation is convenient and fast, practicability is high, and the chromium plating effect is good.

Owner:LANDING GEAR ADVANCED MFG

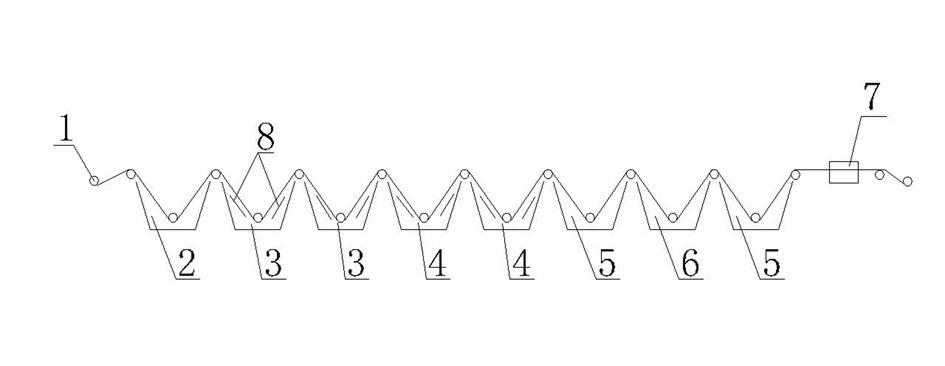

Method for synchronously roughening both surfaces of electrolytic copper foil and equipment thereof

ActiveCN102181899BUniform and fine surface contourHigh elongationElectrolytic coatingsGalvanic anodeRough surface

The invention relates to a method for synchronously roughening and solidifying both surfaces of an electrolytic copper foil and equipment thereof, which belong to the technical field of electrolytic copper foils. The technical key point is that: corresponding anode plates are arranged on a smooth surface and a rough surface and electrolyte flows through the space between the electrolytic copper foil and the anode plates when the electrolytic copper foil passes through a roughening groove and a solidifying groove so as to perform electroplating copper precipitation treatment on the smooth surface and the rough surface of the electrolytic copper foil synchronously at a time, wherein the electroplating anode plates in the roughening groove and the solidifying groove of the used equipment are distributed in the middle and on the front side of a groove body. Compared with the prior art, the method for synchronously roughening and solidifying both surfaces of the electrolytic copper foil and the used equipment thereof have the advantages that: the smooth surface and the rough surface of the copper foil can be synchronously electroplated at a time, so that production efficiency is improved, and energy consumption is reduced.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Galvanic anode for reinforced concrete applications

An improved sacrificial galvanic anode assembly for cathodic protection of a steel reinforced concrete structure. A galvanic cathodic protection device uses an embedded sacrificial anode of metallic foam for increased reactive surface area covered with a flexible penetrating coating to provide a continuous electrolyte to keep it active. The formulated coating paste is inert to cement embedment material and is pre-applied on the anode body prior to encapsulation. An integrated conductive contact band extends from the coated anode to attachment to a reinforcement bar for establishing electrical conductively therewith within the concrete structure transferring galvanic corrosion to the anode.

Owner:GIORGINI ROBERTO

A kind of preparation method of three-dimensional connecting device

ActiveCN103025060BHigh precisionNot limited by line widthPrinted circuit manufactureGalvanic anodeAlkalinity

The invention provides a preparation method of a three-dimensional connecting device. The preparation method comprises the following steps of: A. metallizing a non-electric conduction base material and forming a non-inert metal layer on the surface of the non-electric conduction base material; B. carrying out laser engraving on the non-inert metal layer on the surface of the non-electric conduction base material, and dividing the non-inert metal layer into a circuit region and a non-circuit region which are completely separated; and C. connecting the circuit region of the surface of the non-electric conduction base material with a power source cathode, connecting an electroplating anode material with a power source anode, then putting the non-electric conduction base material and the electroplating anode material in acidity or alkalinity electroplate liquid for electroplating treatment, forming an electroplating thickening layer on the surface of the non-inert metal layer of the circuit region, corroding and removing the non-inert metal layer of the non-circuit region by the acidity or alkalinity electroplate liquid. The preparation method of the three-dimensional connecting device has no special requirement on the base material and has high machining efficiency; and simultaneously the circuit accuracy is greatly improved.

Owner:BYD CO LTD

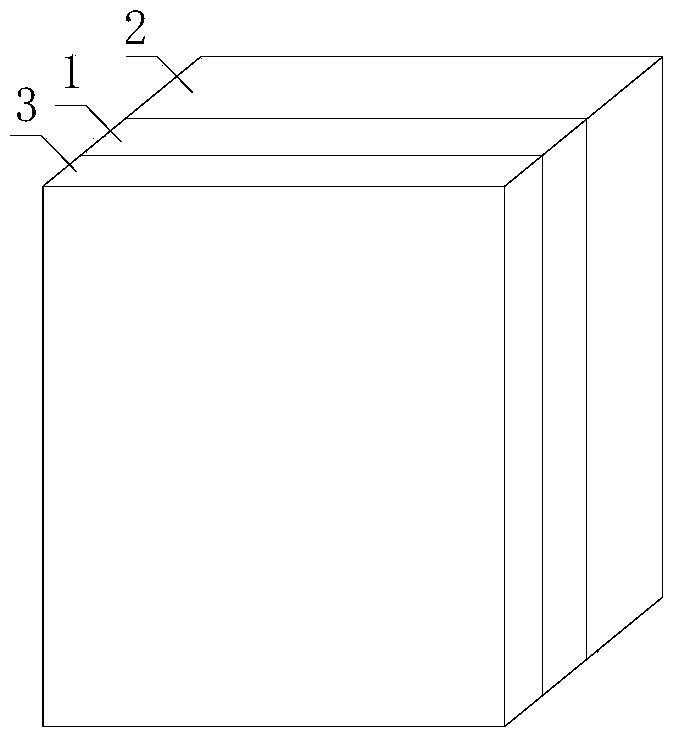

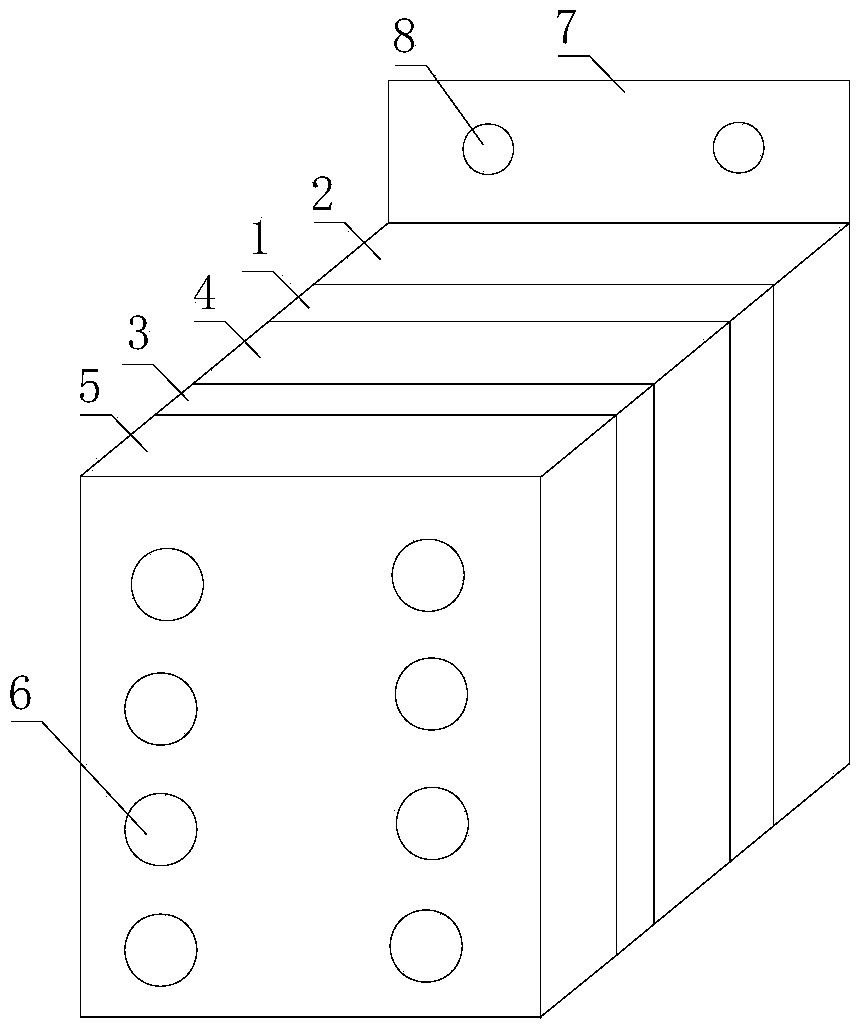

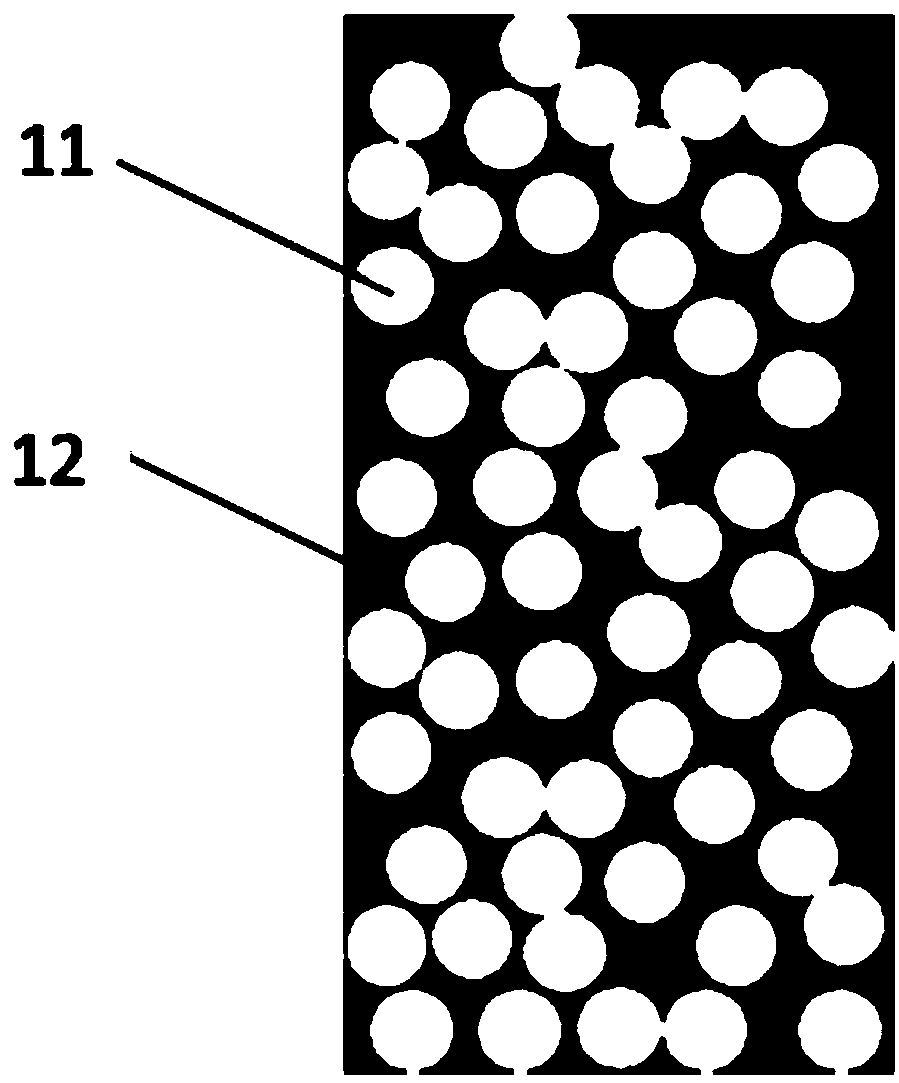

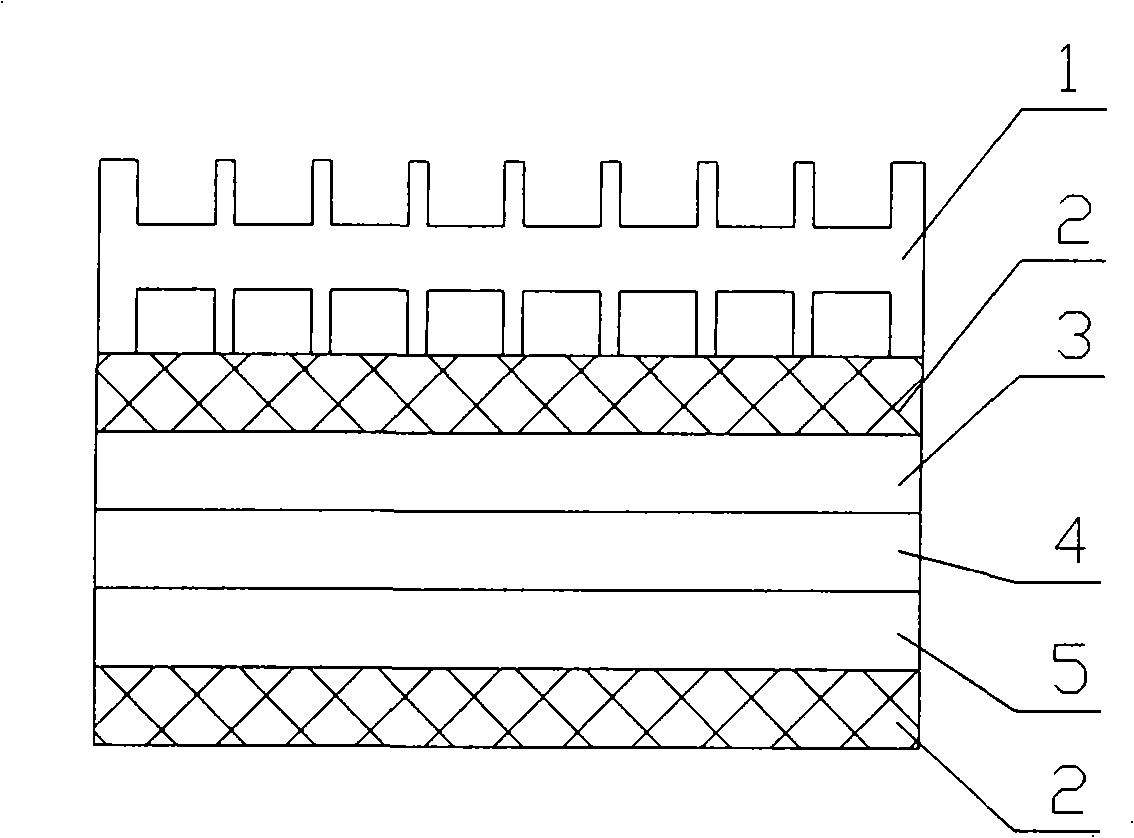

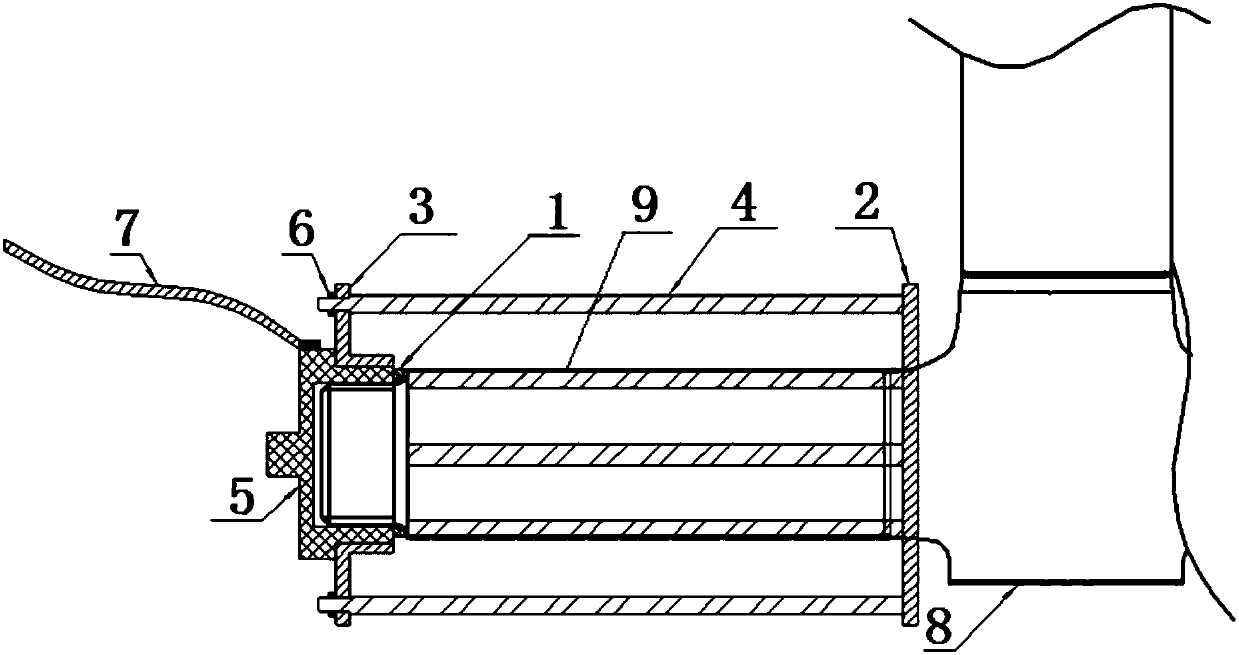

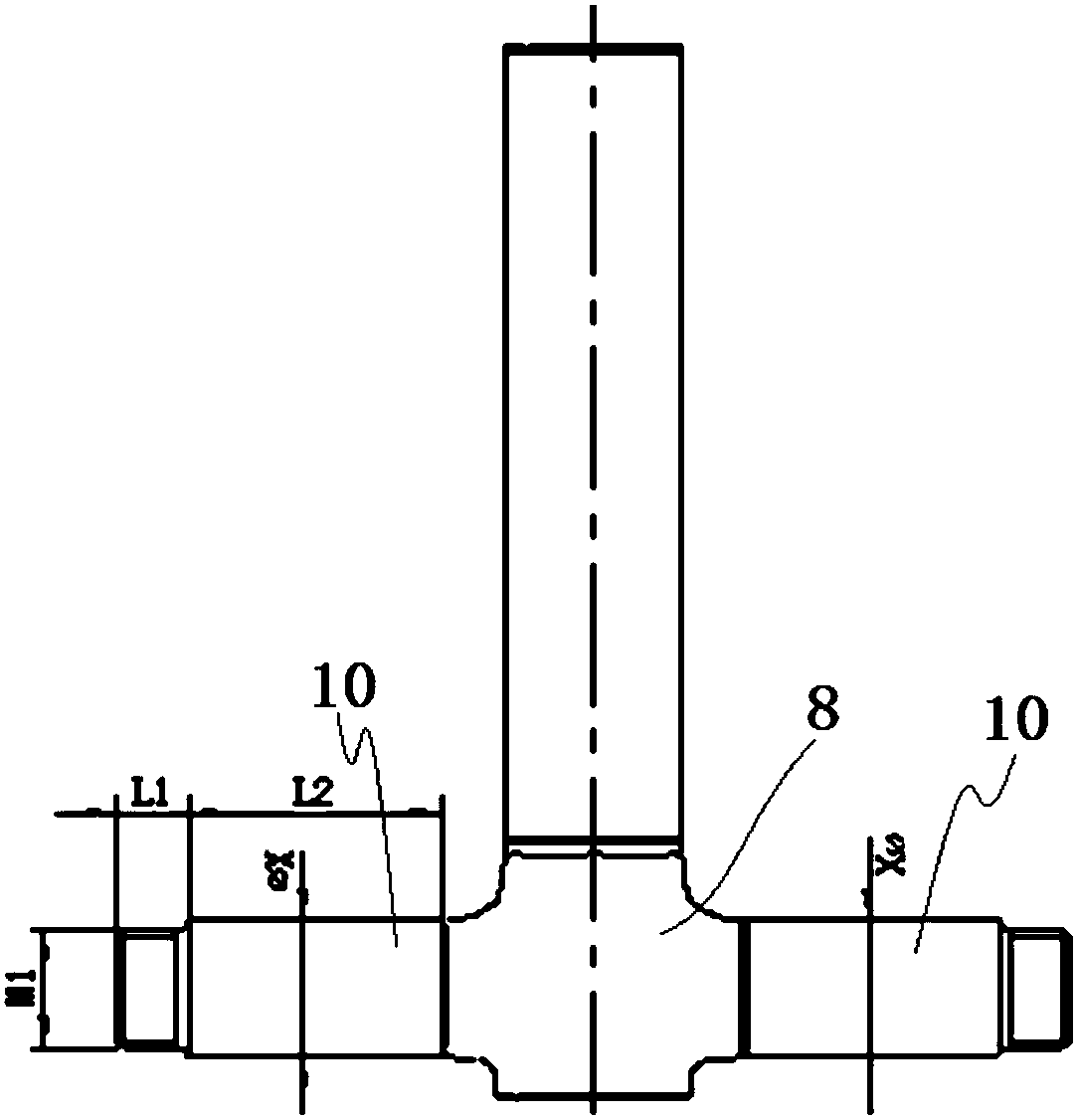

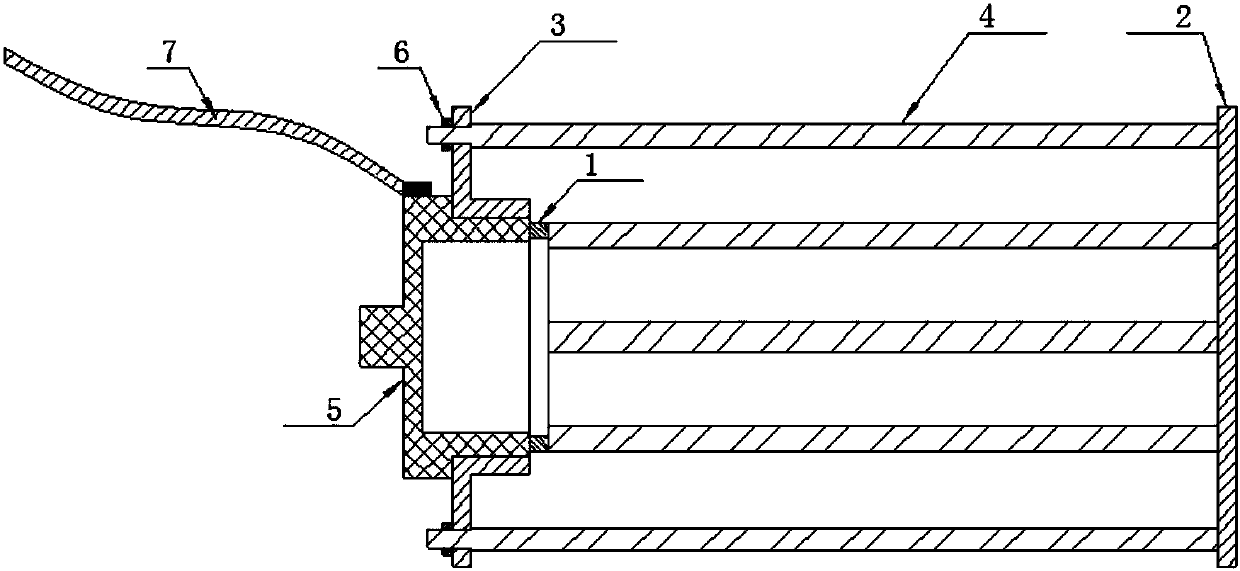

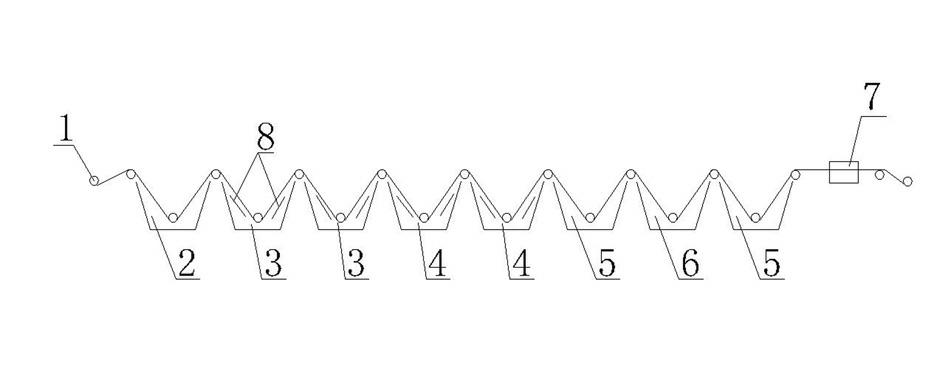

Anti-corrosion magnetic medium box used for vertical ring high-intensity magnetic separator

ActiveCN103464279AReduce pollutionSimple structureHigh gradient magnetic separatorsElectricityGalvanic anode

The invention discloses an anti-corrosion magnetic medium box used for a vertical ring high-intensity magnetic separator. The anti-corrosion magnetic medium box comprises galvanic anodes (1), a magnetic medium box body (2) and an electroplated layer (3). According to the anti-corrosion magnetic medium box used for the vertical ring high-intensity magnetic separator, the magnetic medium box body is used as a framework, the galvanic anodes are embedded or welded to the anti-corrosion magnetic medium box body, the galvanic anodes are electrically communicated with the magnetic medium box body, and the electroplated layer (3) is electroplated on the surface of the magnetic medium box body (2). The anti-corrosion magnetic medium box is simple and clear in structure, reasonable in design and wide in application range. Compared with a medium box in the prior art, the anti-corrosion magnetic medium box has the advantages of being longer in service life, easy to operate and maintain, little in environment pollution and the like and is the ideal anti-corrosion magnetic medium box used for the vertical ring high-intensity magnetic separator at present.

Owner:LONGI MAGNET CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com