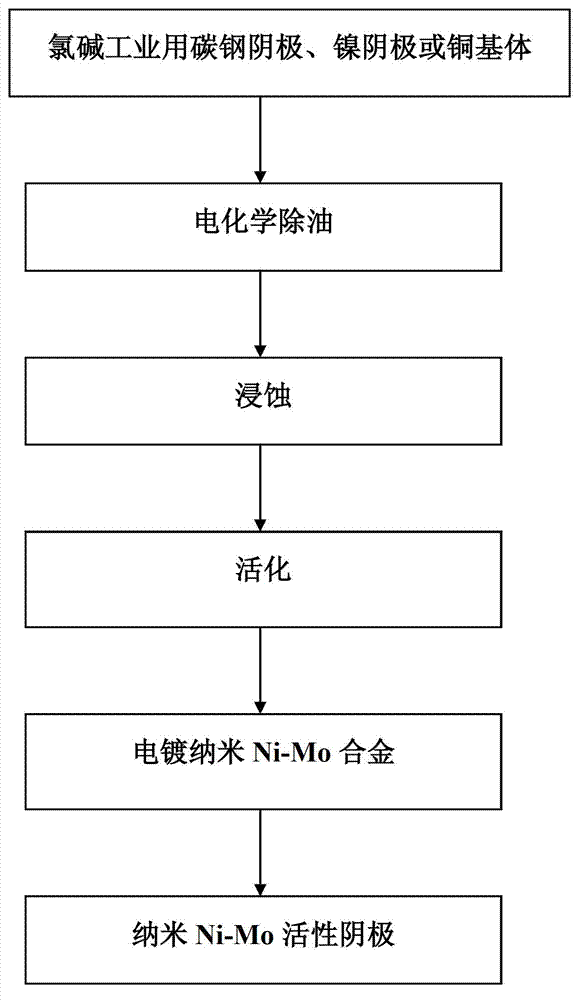

Nickel molybdenum active cathode with nanostructure for chlor-alkali industry and preparation method thereof

A nanostructure and active cathode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of cathode activity decline, loss, cathode working environment and other problems, and achieve the effect of saving time, convenient operation and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] After degreasing, etching, and activation, the copper sheet is used as the substrate, and Ni-Mo alloy is electroplated on its surface. The bath composition is NiSO 4 ·6H 2 O: 30g·L -1 ; (NH 4 ) 6 Mo 7 o 24 ·7H 2 O: 10g·L -1 ;C 6 h 5 Na3 o 7 2H 2 O: 80g·L -1 ;NaCl: 20g·L -1 ; 1-4 butynediol: 0.6g L -1 ; NH 3 ·H 2 O: 25mL·L -1 ;The pH value of the plating solution is 8, the temperature of the plating solution is 45°C, and the cathode current density is 12A / dm 2 , electroplating for 60min. The anode is ruthenium titanium mesh (RuO 2 / TiO 2 ), and the area ratio of anode to cathode is 2:1.

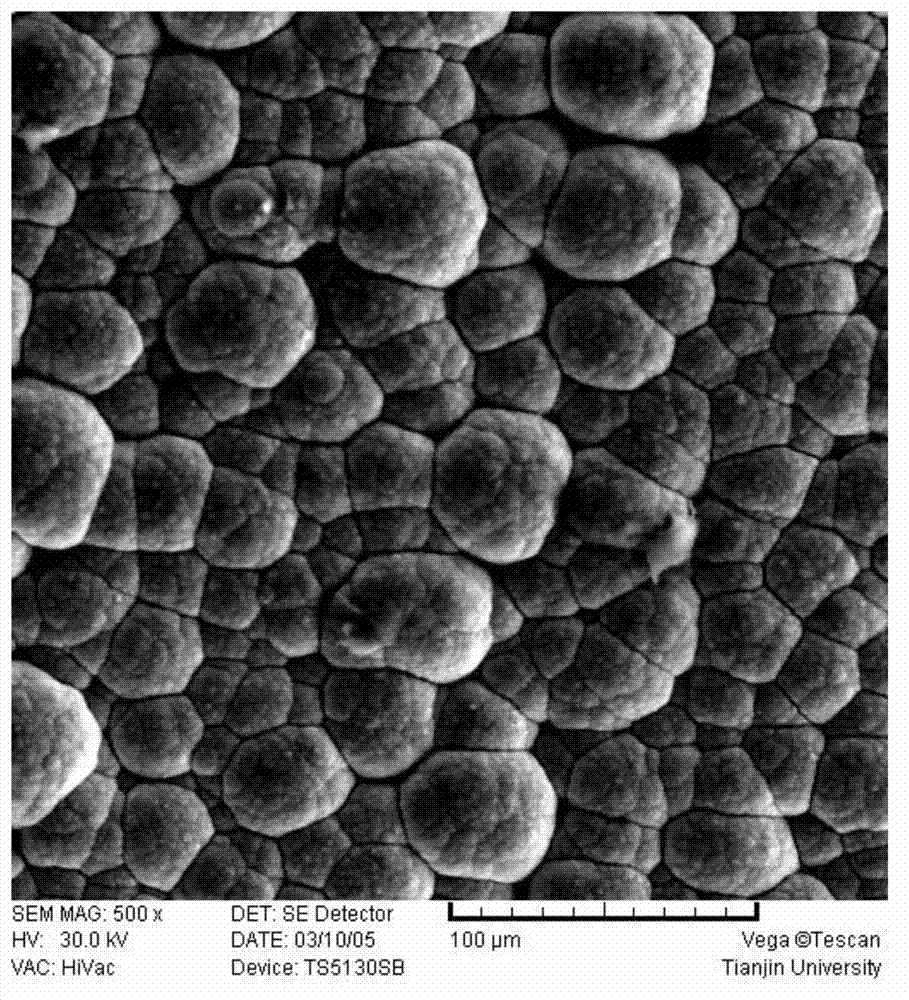

[0040] Use the VEGATS-5130SB scanning electron microscope (SEM) produced by TESCAN to observe the surface morphology of the electrode after electroplating Ni-Mo alloy. The SEM photos are attached figure 2 shown. The surface of the electrode is uneven, and the real surface area of the electrode increases.

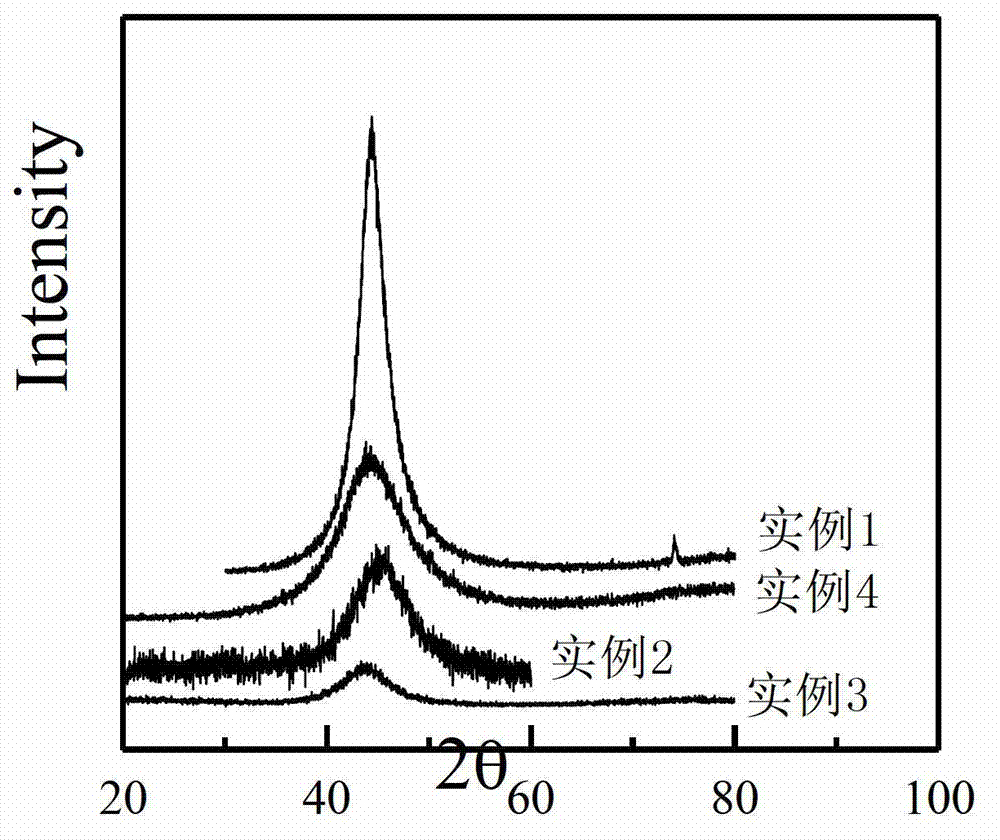

[0041] Use the X’Pert Pro X-ray diffractometer (XRD) p...

Embodiment 2

[0044] With the iron mesh cathode used in the chlor-alkali industry as the substrate, firstly, the substrate is electrochemically removed in the degreasing tank to remove the oil stains adhering to the surface. The composition of the degreasing liquid is: sodium hydroxide (NaOH), 15 g / L (g / L ); sodium carbonate (Na 2 CO 3 ), 25 grams / liter (g / L); sodium phosphate (Na 3 PO 4 12H 2 O), 25 grams per liter (g / L). The temperature is 70°C, the current density is 3 amperes / square decimeter (A / dm 2 ), the anode degreasing time is 5 minutes (min). After degreasing, the substrate is rinsed in hot water at 80°C, and then rinsed with cold water to carefully remove residual lye.

[0045] Then place the substrate in 1:1 hydrochloric acid aqueous solution for derusting, at room temperature, until all the rust and oxide layer on the surface are removed. Remove the substrate and rinse with cold water to carefully remove residual acid.

[0046] The substrate after the pretreatment can e...

Embodiment 3

[0051] With the copper sheet as the substrate, Ni-Mo alloy is electroplated on the surface after degreasing, etching and activation. The bath composition is NiSO 4 ·6H 2 O: 50g·L -1 ; (NH 4 ) 6 Mo 7 o 24 ·7H 2 O: 50g·L -1 ;C 6 h 5 Na 3 o 7 2H 2 O: 100g·L -1 ;NaCl: 30g·L -1 ; 1-4 butynediol: 0.8g L -1 ; NH 3 ·H 2 O: 30mL·L -1 ; The pH value of the plating solution is 10, the temperature of the plating solution is 50°C, and the cathode current density is 10A / dm 2 , electroplating for 120min. The anode is ruthenium titanium mesh (RuO 2 / TiO 2 ), and the area ratio of anode to cathode is 2:1.

[0052] Use the X’Pert Pro X-ray diffractometer (XRD) produced by PANALYTICAL to test the structure of the Ni-Mo alloy. See the attached XRD spectrum image 3 . The average grain size of the Ni-Mo alloy can be calculated from the half maximum width of the diffraction peak to be 2nm.

[0053] The surface of the Ni-Mo alloy coating is smooth without obvious cracks, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com