Integrated plating and planarization process and apparatus therefor

A planarization, equipment technology, used in the field of semiconductor processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

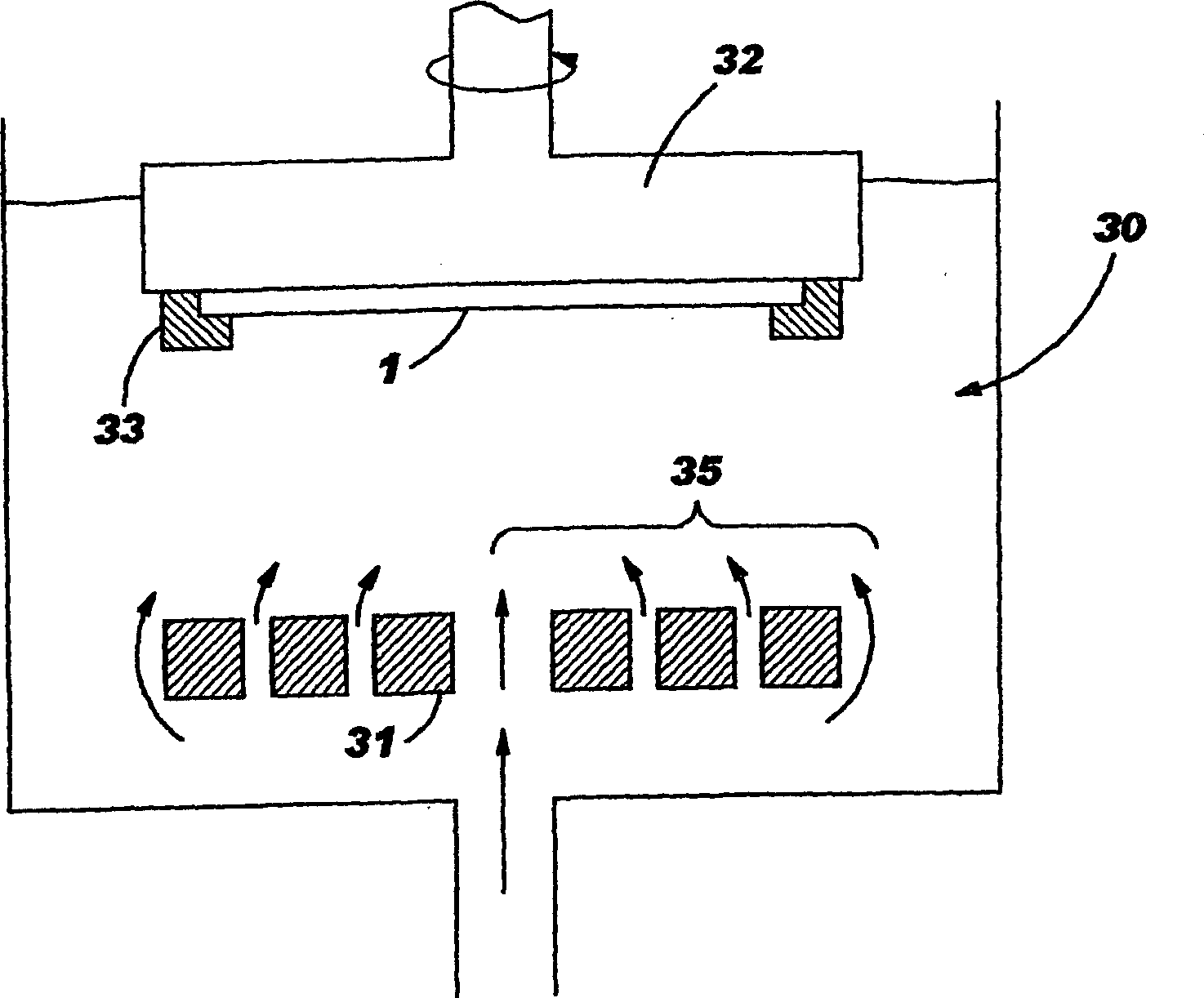

[0026] According to the present invention, an apparatus is provided that allows CMP to be performed after metal deposition (electroplating) and metal removal (electroetching) in optional steps, where each step has discrete process conditions and does not require Remove the wafer from the device. Copper plating and removal will be described to illustrate the invention. It should be understood that the present invention is not limited to the type of material deposited on the wafer.

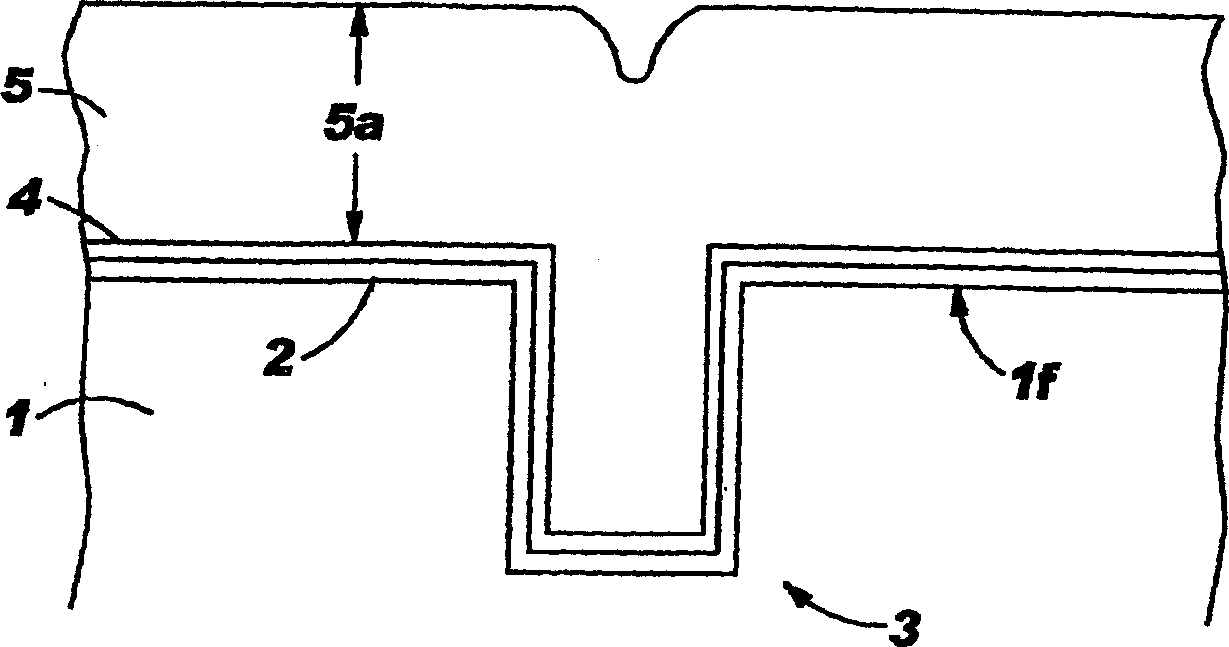

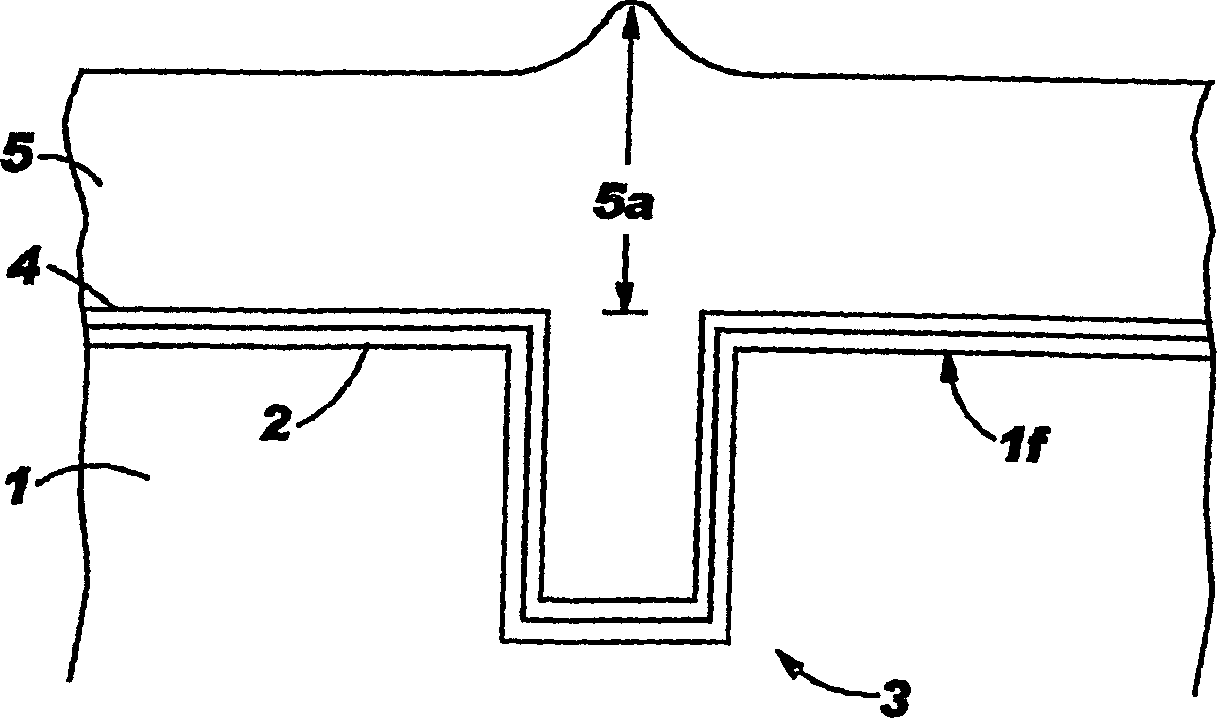

[0027] Embodiments of the present invention may be understood as modifications of CMP equipment. A conventional CMP apparatus is schematically shown in Fig. ID. Wafer 1 is fixed upwards on wafer carrier 12 which rotates relative to table 10 with polishing pad 20 and polishing slurry thereon. The polishing rate is determined in part by the force with which the wafer 1 is pressed against the polishing pad 20 . Thus, the wafer carrier 12 is adjustable to provide a variable force on the polishing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com