Electroplating anode device and chromium plating method

An anode device and anode technology, applied in the direction of the electrode, etc., can solve the problems of increased electroplating operation and safety risks, poor dispersibility of chromium plating solution, uneven thickness of coating deposition, etc., to achieve uniform appearance color, smooth and compact appearance, tooling The design is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

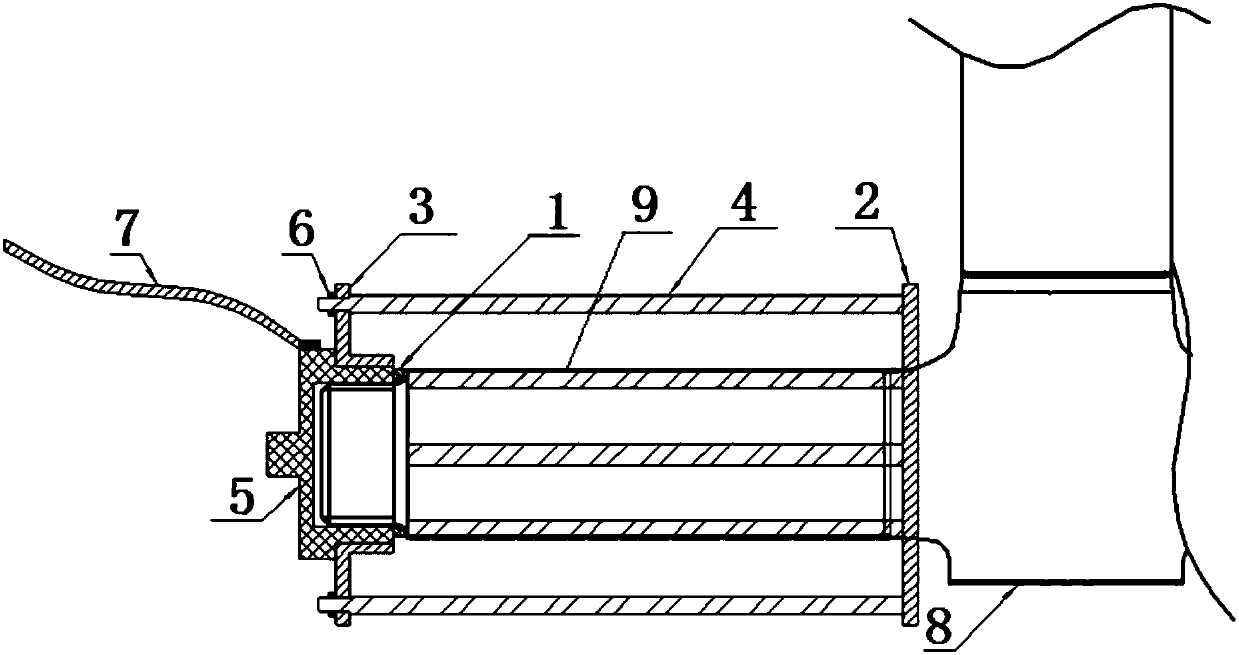

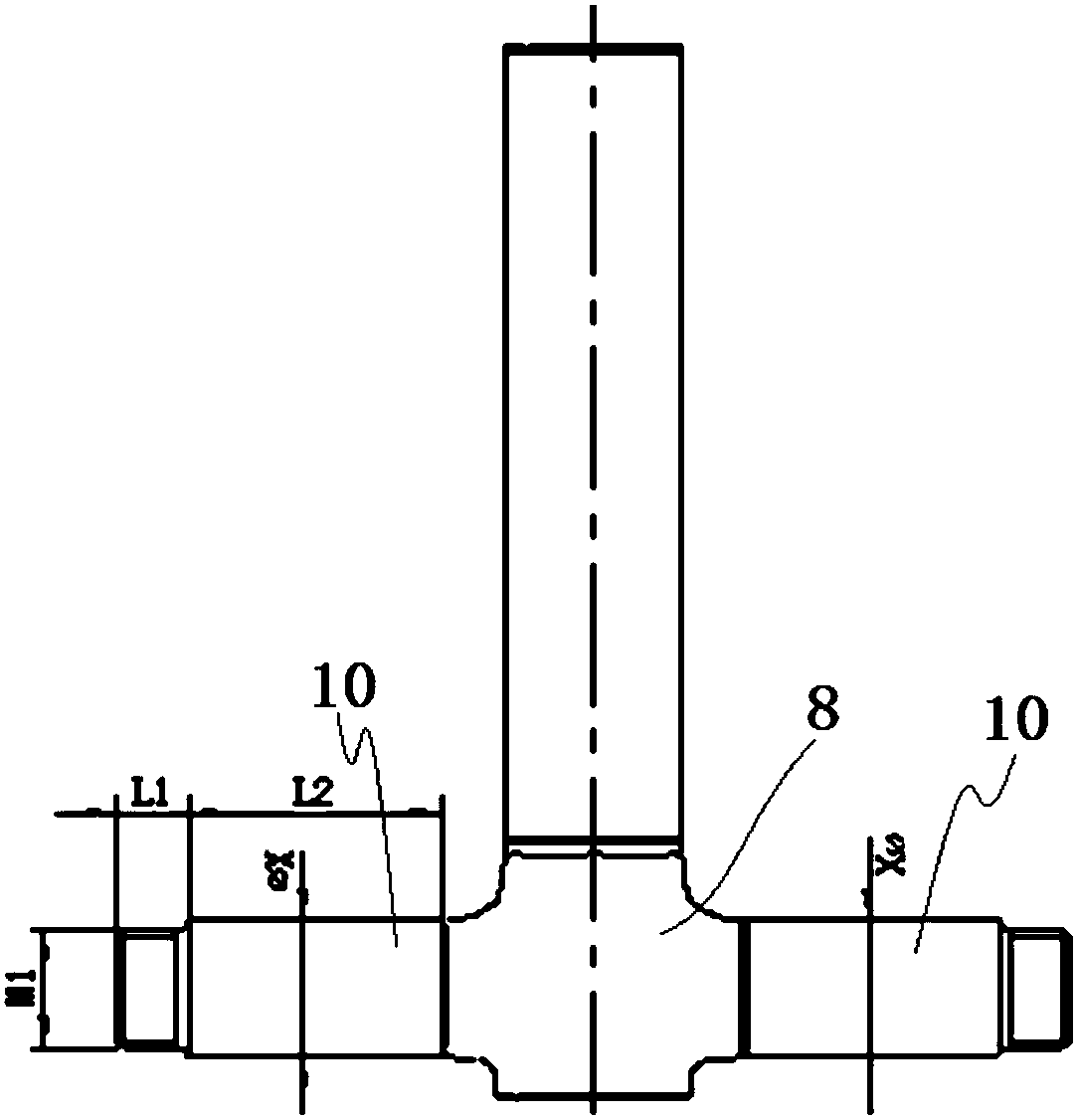

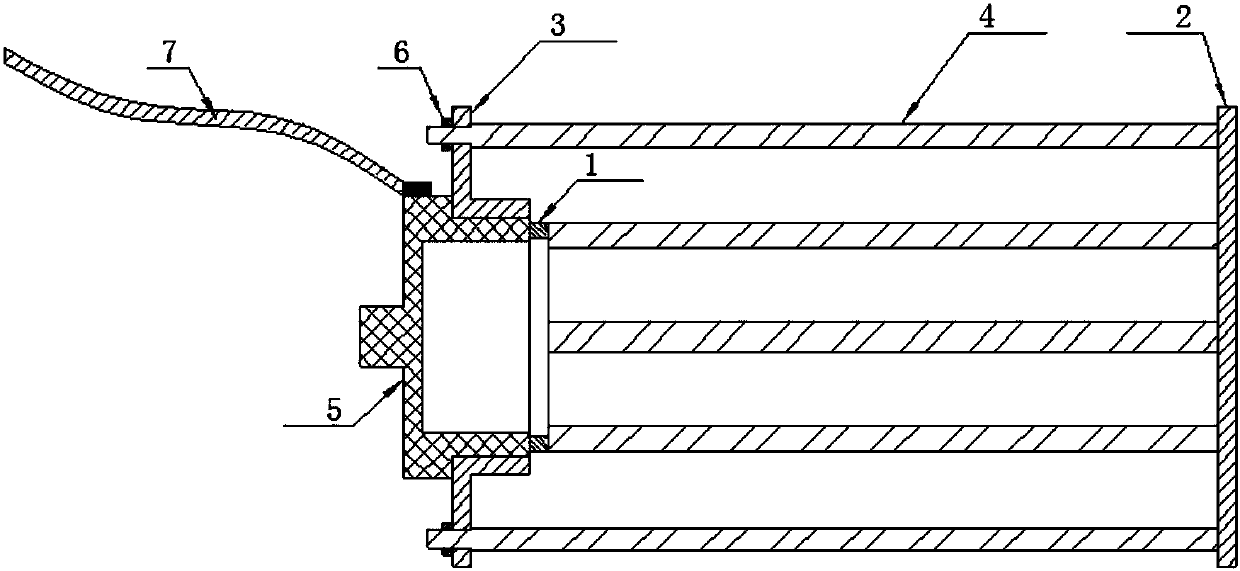

[0039] A kind of cage structure electroplating anode device, such as figure 1 and 3 As shown, the designed device is not affected by the structure and position of the chrome-plated surface. A plurality of anodes evenly distributed on the chrome-plated circumference are designed as a special cage-shaped anode through the combination of the support plate and the anode opening ring, and the anode is fixed by converting the sleeve. In the parts, the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com