Patents

Literature

96results about How to "Uniform appearance and color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel hot-stamped product with aluminum or aluminum alloy plating layer and manufacturing method thereof

ActiveCN106466697AUniform appearance and colorUniform shapeHot-dipping/immersion processesVehicle componentsHot stampingPunching

The invention discloses a manufacturing method of a steel hot-stamped product with an aluminum or aluminum alloy plating layer. The manufacturing method comprises the following steps: 1) blanking: a steel plate with the aluminum or aluminum alloy plating layer is machined to a part blank with a needed shape by a blanking or laser cutting method; and the thickness of the steel plate with the plating layer is not more than 2.8 mm; 2) blank heat treatment: the blank is put in a heating furnace for heating and insulation; the temperature of the heating furnace is 900-950 DEG C; the atmosphere in the heating furnace guarantees the oxygen content to be more than 15%; and the total stop time of the blank in the heating furnace is 2.5-10 minutes; 3) blank transmission: the heated blank is quickly conveyed into a mold for punching; the conveying time is 4-12 seconds; and the temperature of the blank before punching is 680-750 DEG C; and 4) blank hot stamping: the heated blank is directly punched in the mold; the mold is cooled in the punching process; and the surface temperature of the mold before punching is lower than 100 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

Leather retanning method

InactiveCN102517409AHigh fullnessImprove firmnessTanning treatmentPre-tanning chemical treatmentIndustrial waste waterElectrical energy consumption

The invention relates to a leather retanning method. The method comprises the following steps of: water washing, rewetting to soften, retanning with chrome, neutralization, dyeing to fill, adding grease, dyeing in set and the like; and finally, drying, finishing and coating to obtain the finished product, i.e. leather. In the invention, the process of retanning with chrome is adjusted and a proper environment-friendly tanning agent is adopted, so the content of chrome in chrome liquid can be reduced, the fullness and the toughness of the leather is effectively improved, dyed color is uniform,the heat and humidity resistant stability of the leather can be improved, the physical performances of the leather are uniform, and the finished leather is soft and bend-resistant and is high in tensile strength; the amount of used water in the processing process is small, and the generated industrial waste water is little, so environment protection is facilitated; and the process period is relatively short, so the electric energy consumption is low, the cost is low, and the method has a better economic benefit.

Owner:郑州科信化工有限公司

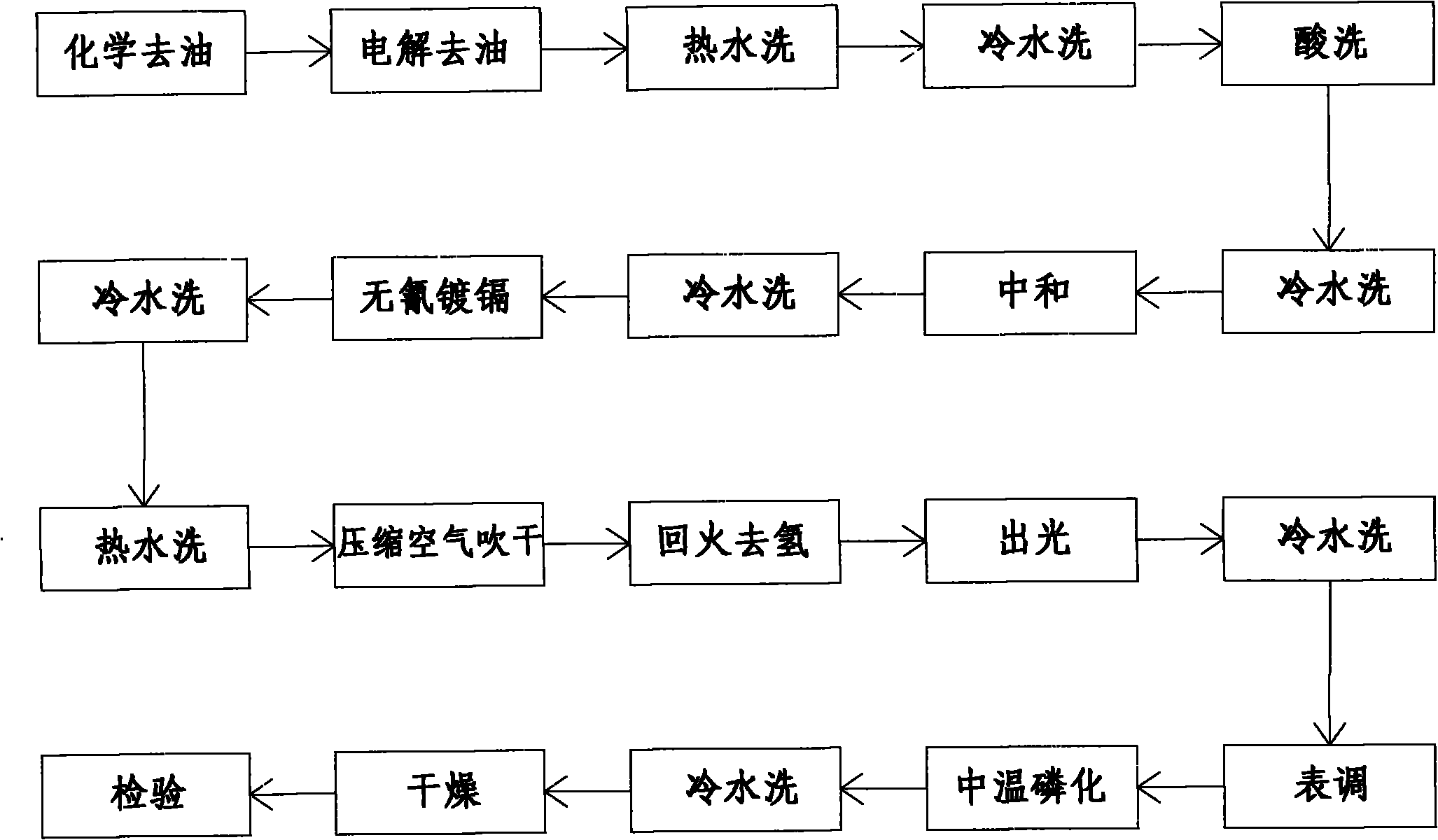

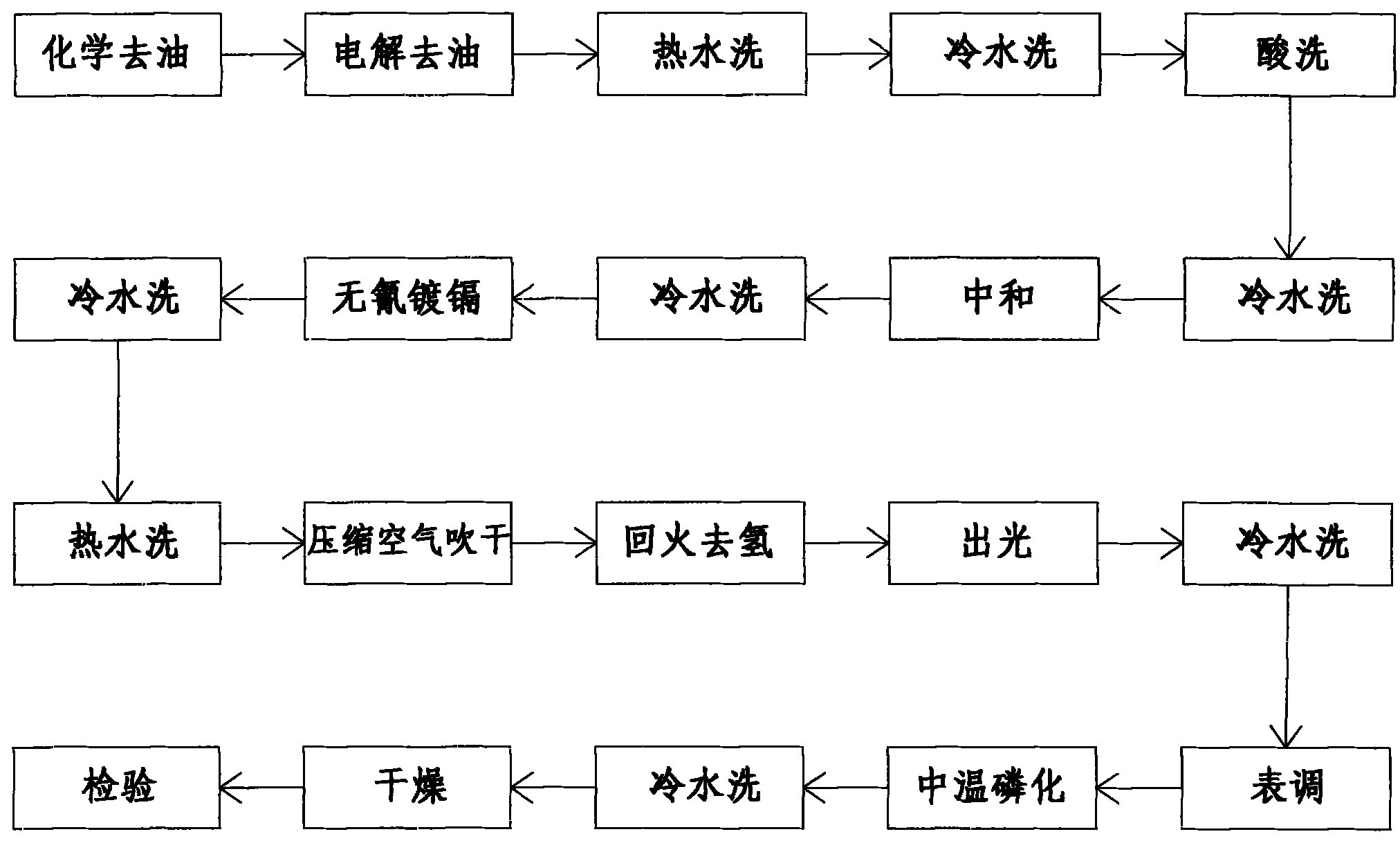

Process for plating cadmium on shaped steel part with deep/blind hole

InactiveCN101942681AWide current density rangeStrong dispersion abilitySuperimposed coating processNitrilotriacetic acidCadmium sulfate

The invention discloses a process for plating cadmium on a shaped steel part with a deep / blind hole, which comprises the following steps of: chemical oil removal, electrolytic oil removal, hot water washing, cold water washing, acid washing, cold water washing, neutralizing, cold water washing, cyanogen-less cadmium plating, cold water washing, hot water washing, compressed air drying, tempering dehydrogenizing, bright dipping, cold water washing, surface conditioning, middle-temperature phosphating, cold water washing, drying and detection, wherein the formula of each liter of electroplating liquid comprises: 40 to 50g of cadmium sulfate, 180 to 220g of ammonium chloride, 50 to 70g of nitrilotriacetic acid, 25 to 30g of ethylene diamine tetraacetic acid, a main additive, a brightener and a refiner, and the pH value is 6.2 to 6.7. The process effectively improves the quality and stability of special products, guarantees the use performance of the products and prolongs the service life of the products; and the production process is clean and environmentally-friendly, can effectively protect the environment and the physical and metal health of operators and meets the requirements of pollution-free production.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

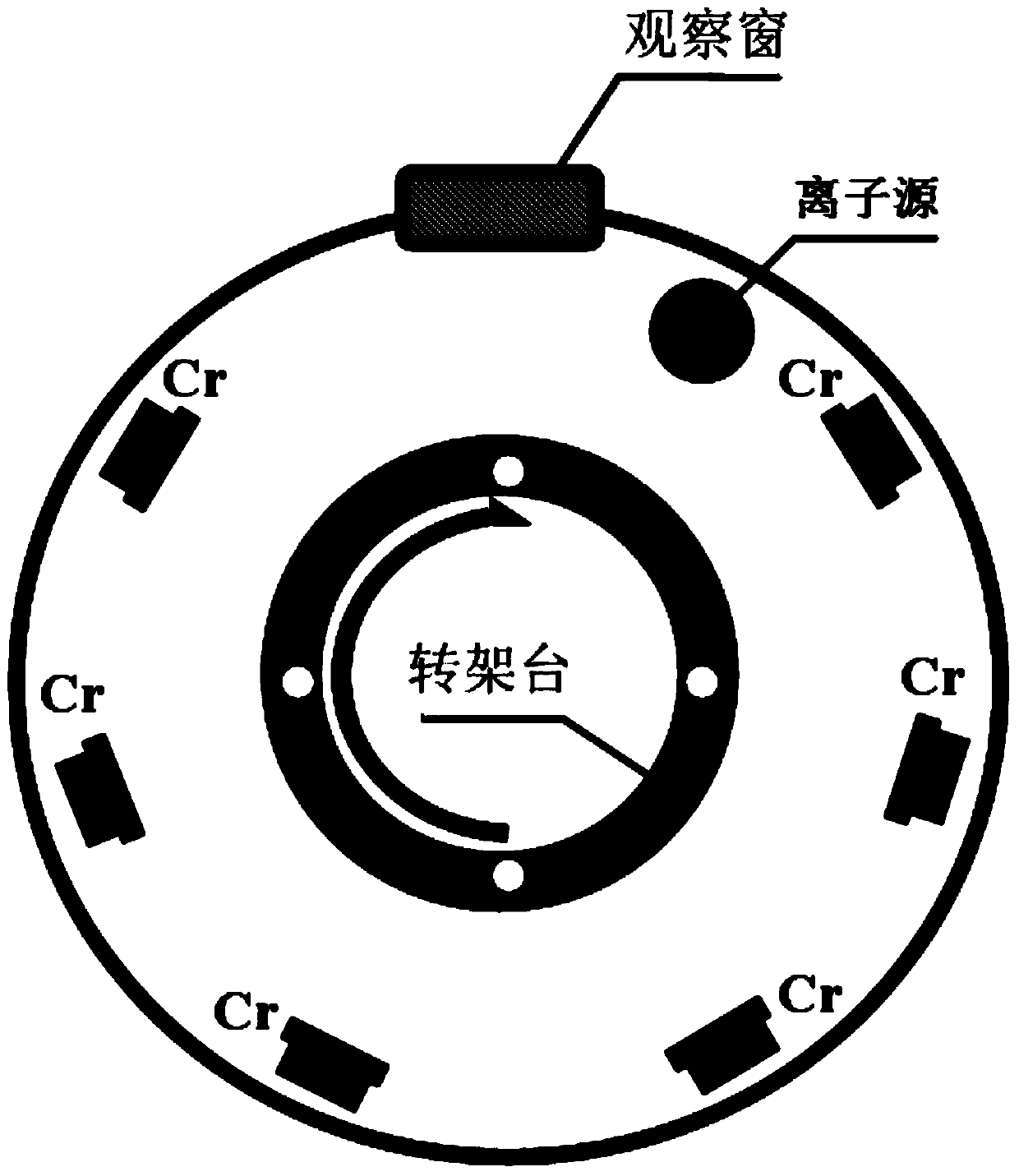

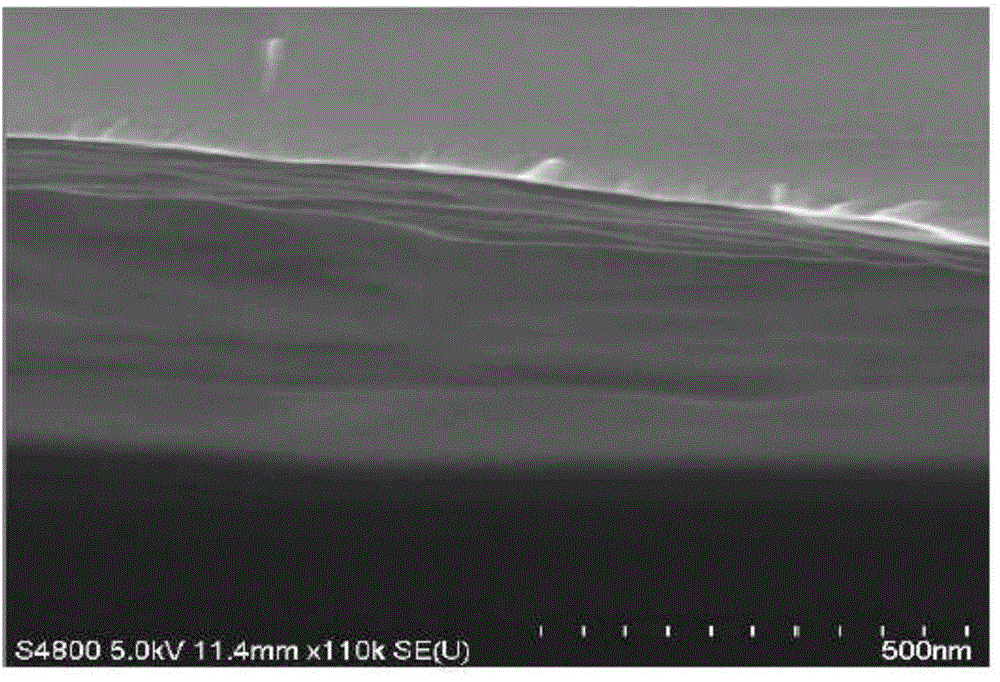

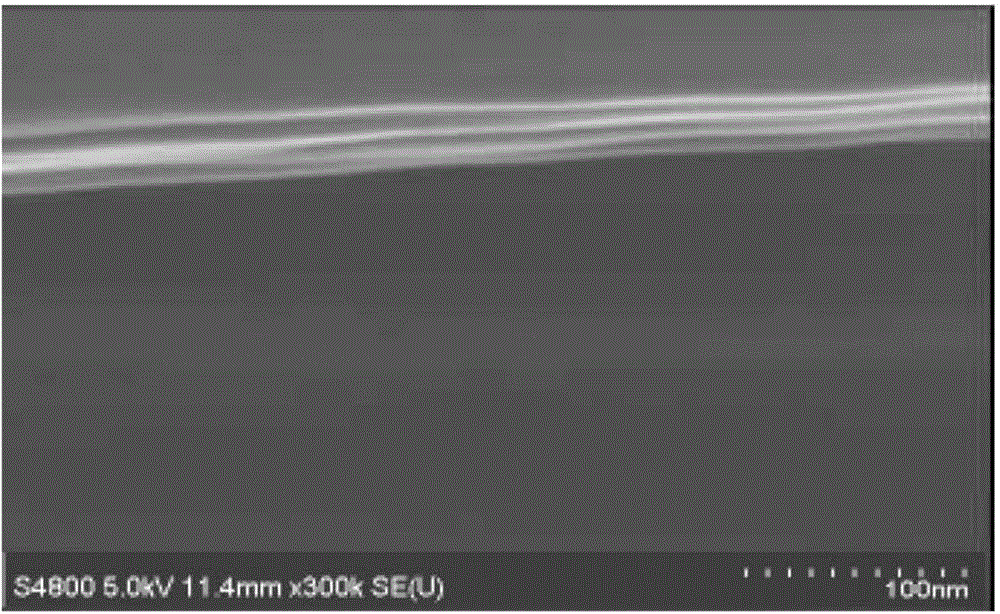

Preparation method of decorating protective coating for CrNx-based component gradient transition

ActiveCN103741108AUniform appearance and colorImprove bindingVacuum evaporation coatingSputtering coatingIonizationTriple layer

The invention discloses a preparation method of a decorating protective coating for CrNx-based component gradient transition. The method comprises the following steps: adopting three pairs of plane Cr targets as sources of a corresponding Cr element; uniformly installing the three pairs of plane Cr targets on the inner wall of ion source-enhanced magnetron sputtering ion plating equipment; controlling the sputtering rate of three pairs of plane Cr targets by adjusting the current of a medium-frequency pulse power supply; adopting an anode layer gas ion source to improve the ionization rate of the gas and the energy of reaction particles; adopting high-purity Ar as a target sputtering gas; adopting high-purity N2 as a reaction gas; ionizing and combining with Cr particles sputtered from the target after passing through an anode layer gas ion source; depositing and forming a Cr base layer / a CrNx-based gradient transition layer / a CrN outer layer in a triple-layer structure on the surface of the sample. The coating is smooth and compact in surface, the microhardness is Hv800, the film-substrate adhesion achieves 80N, the dry friction coefficient of the CrNx-based coating is 0.35 when the friction pair is Al2O3 balls, and the corrosion resistance of a neutral salt spray test exceeds 672 hours.

Owner:晨光真空技术(东莞)有限公司

Humidity chromogenic indicator and chromatropic silica gel prepared therwith and its preparing method

InactiveCN1470869AAvoid harmReduce manufacturing costAnalysis using chemical indicatorsSilicon compoundsInorganic saltsOrganic solvent

The indicator comprises organic solvent with 10-40wtúÑ inorganic salt and 0.1wtúÑ-5wtúÑ chromaticity indicator without cobalt. Thus, factor of polluting environment and harming health to people is removed thoroughly. The invented product is excellent product of environment protection with low cost. Allochroic silica gel made from the invented indicator can be used in multiple regenerations.

Owner:李永兆

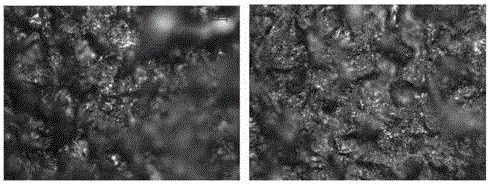

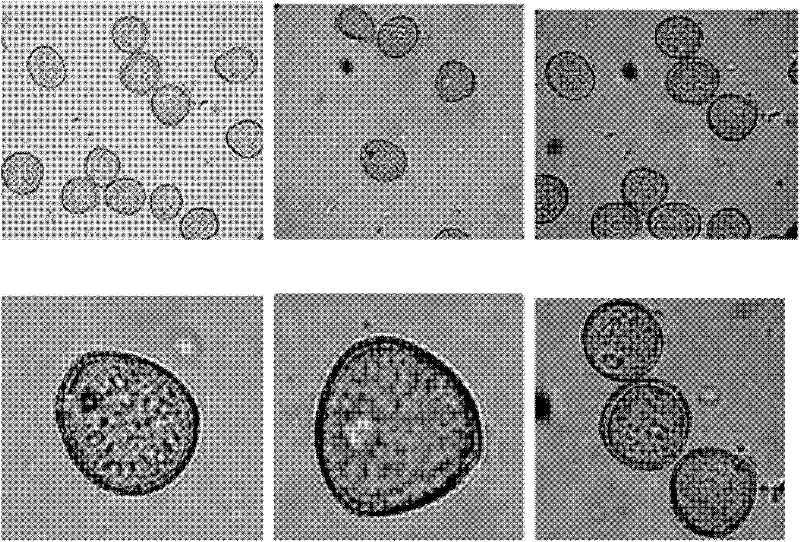

Cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing

ActiveCN103394484AImprove photoelectric conversion efficiencyReduced compound centerAfter-treatment detailsFinal product manufactureSurface structureOxidizing agent

The invention discloses a cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing. A polycrystalline silicon wafer is cleaned through an acid solution containing an oxidizing agent or a base solution containing the oxidizing agent after acid texturing. According to the cleaning technology, the surface structure of the silicon wafer is optimized, residual composition on the surface of the silicon wafer is removed, texturing liquid remaining on the surface of the silicon wafer after the silicon wafer is textured can be cleaned, porous silicon can be removed as well, so that the recombination centers on the surface of the silicon wafer are greatly reduced, the short-circuit current and start voltage are improved, and the effect that the photoelectric conversion efficiency of a solar cell is improved is achieved. After the cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing is adopted, the porous silicon generated after acid texturing can be removed, pointed structures on the textured face are reduced, the color and the luster of the appearance of the silicon wafer are even, the difference between different crystalline grains is small, and the polycrystallization degree is not enhanced. In addition, the cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing is simple, easy to operate, compatible with an existing technology and good in repeatability.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

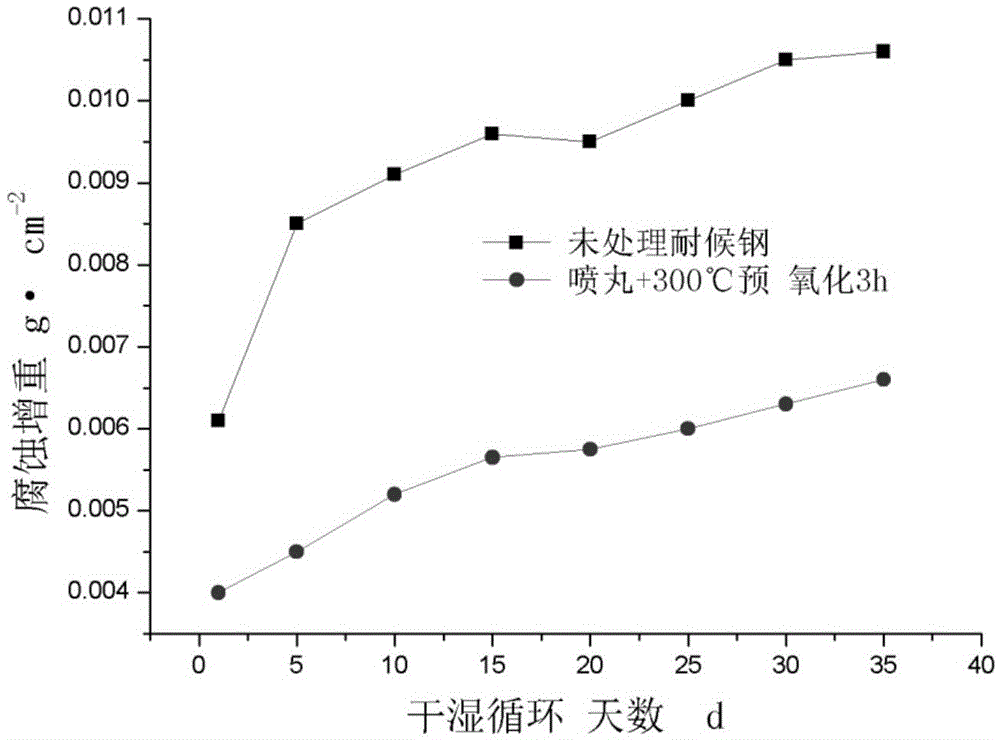

Surface treatment method for weathering resistant steel

ActiveCN105568208AThe process steps are simpleUniform appearance and colorSolid state diffusion coatingPeeningRust

The invention discloses a surface treatment method for weathering resistant steel. The method comprises the following steps that firstly, the weathering resistant steel is subjected to surface shot blasting treatment, and the surface roughness of the weathering resistant steel is between Ra 2.50 microns and Ra 3.50 microns; and secondly, the weathering resistant steel subjected to shot blasting treatment is subjected to high-temperature oxidation for 1 h-4 h at the temperature of between 250 DEG C and 350 DEG C, and then a dense rufous oxidation layer can be obtained. The appearance and color of the oxidation layer are similar to those of the weathering resistant steel used for a long time, and forming of a stable rust layer can be promoted. The method is simple in procedure, cost is low, environment friendliness is achieved, and it is avoided that a common surface stabilization coating applying method is utilized for rapidly stabilizing the weathering resistant steel, and consequently the environment is polluted.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

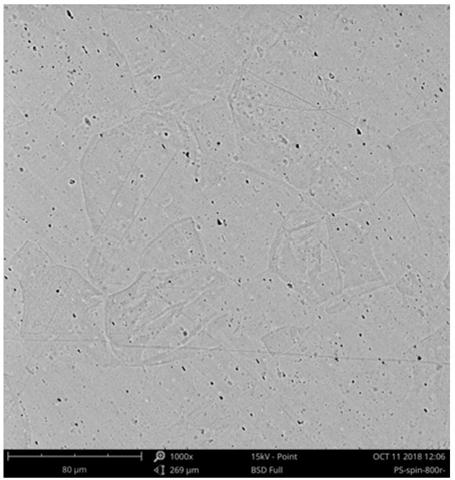

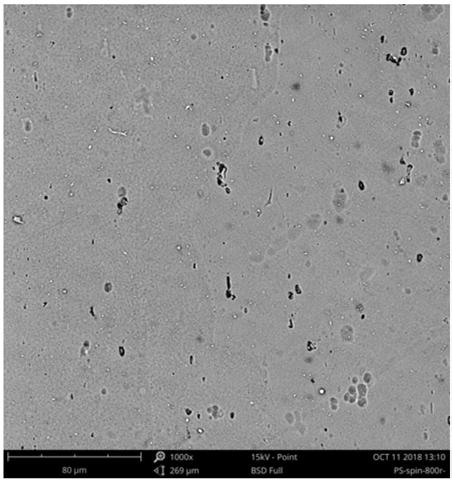

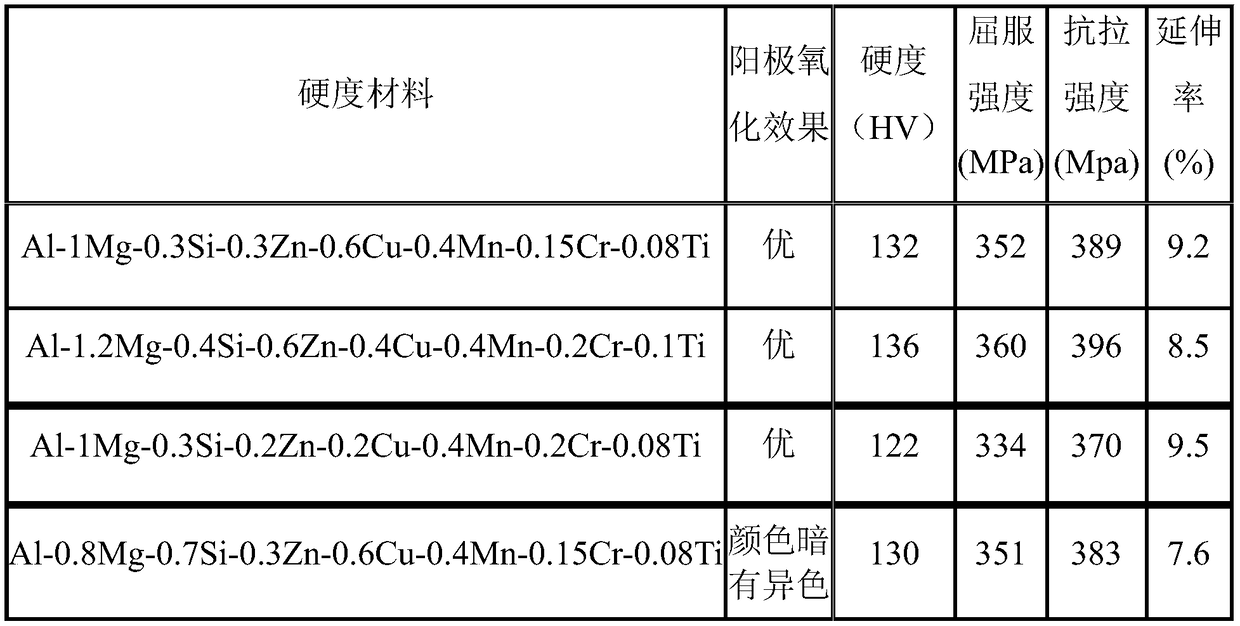

Anode oxidizable high-strength 6xxx series aluminum alloy and preparation method thereof

The invention relates to an anode oxidizable high-strength 6xxx series aluminum alloy and a preparation method thereof. The aluminum alloy comprises the following components of 0.7-1.5wt% of Mg, 0.2-0.5wt% of Si, 0.2-0.8wt% of Zn, 0.3-0.7wt% of Cu, 0.2-0.6wt% of Mn, 0.1-0.3wt% of Cr, 0.03-0.12% of Ti, less than or equal to 0. 13wt% of other impurity elements, and the balance Al. The specific preparation method comprises the following steps that pure Al ingots, pure Mg ingots, pure Zn ingots, AlSi intermediate alloy, AlCu intermediate alloy, AlZr intermediate alloy and AlMn intermediate alloy are taken as raw materials, and are put into a smelting furnace in proportion, a melt is subjected to stirring, refining, purifying, degassing and slagging off and standing treatment, then casting is conducted into cast ingots, then extruding is conducted into an aluminum alloy profile according to the extrusion ratio of 15-30:1, and then quenching, T6 heat treatment and anodic oxidation treatmentare conducted. Compared with the prior art, the anode oxidizable high-strength 6xxx series aluminum alloy and the preparation method thereof have the advantages that the Vickers hardness of the 6xxx series alloy extruded profile prepared by the method is greater than 130 HV, the yield strength is larger than 350 Mpa, the elongation rate is larger than 8%, and the surface is uniform in color, and free of the defects such as spots and lines after being subjected to anode oxidation.

Owner:上海铱钡新材料科技有限公司

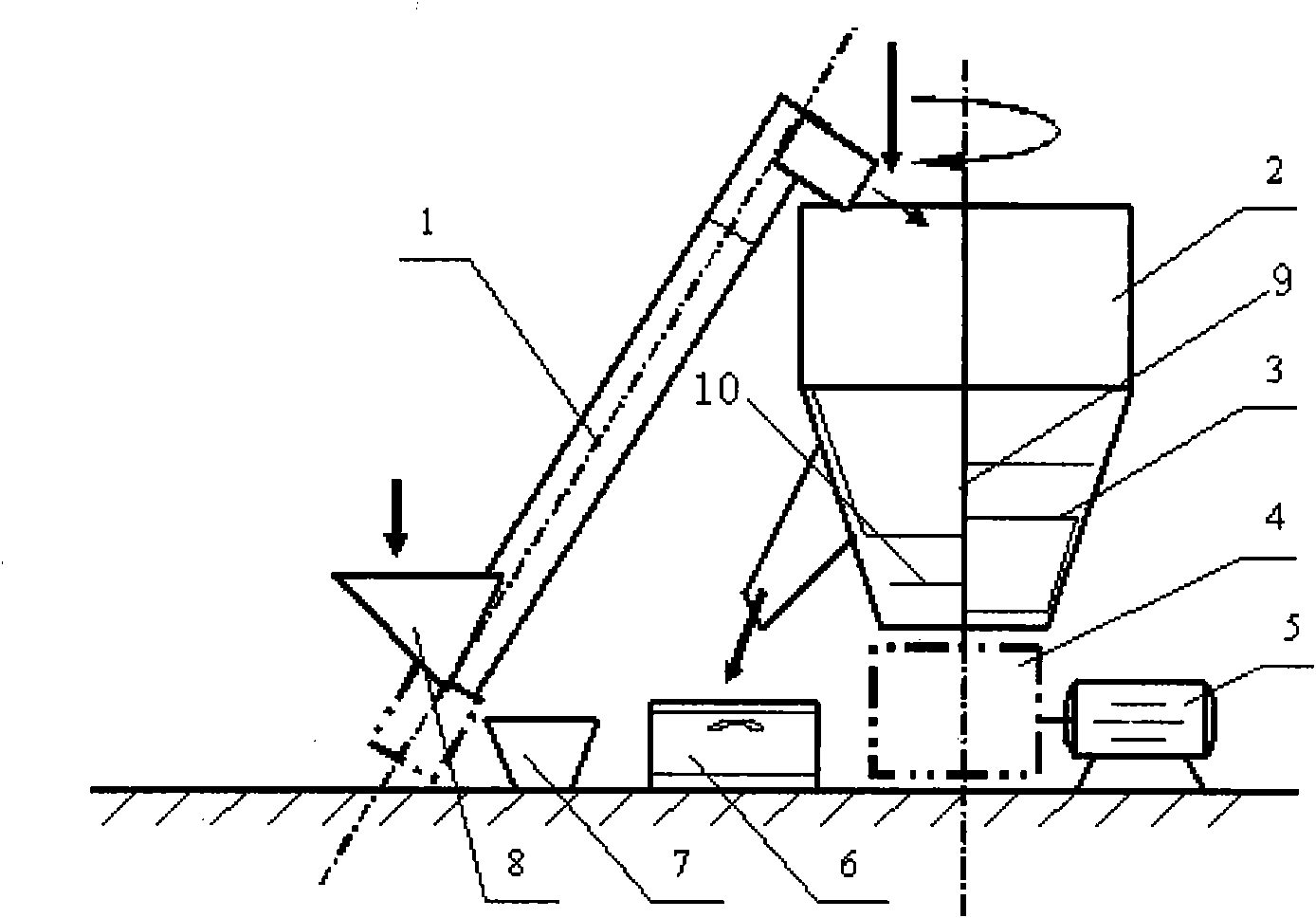

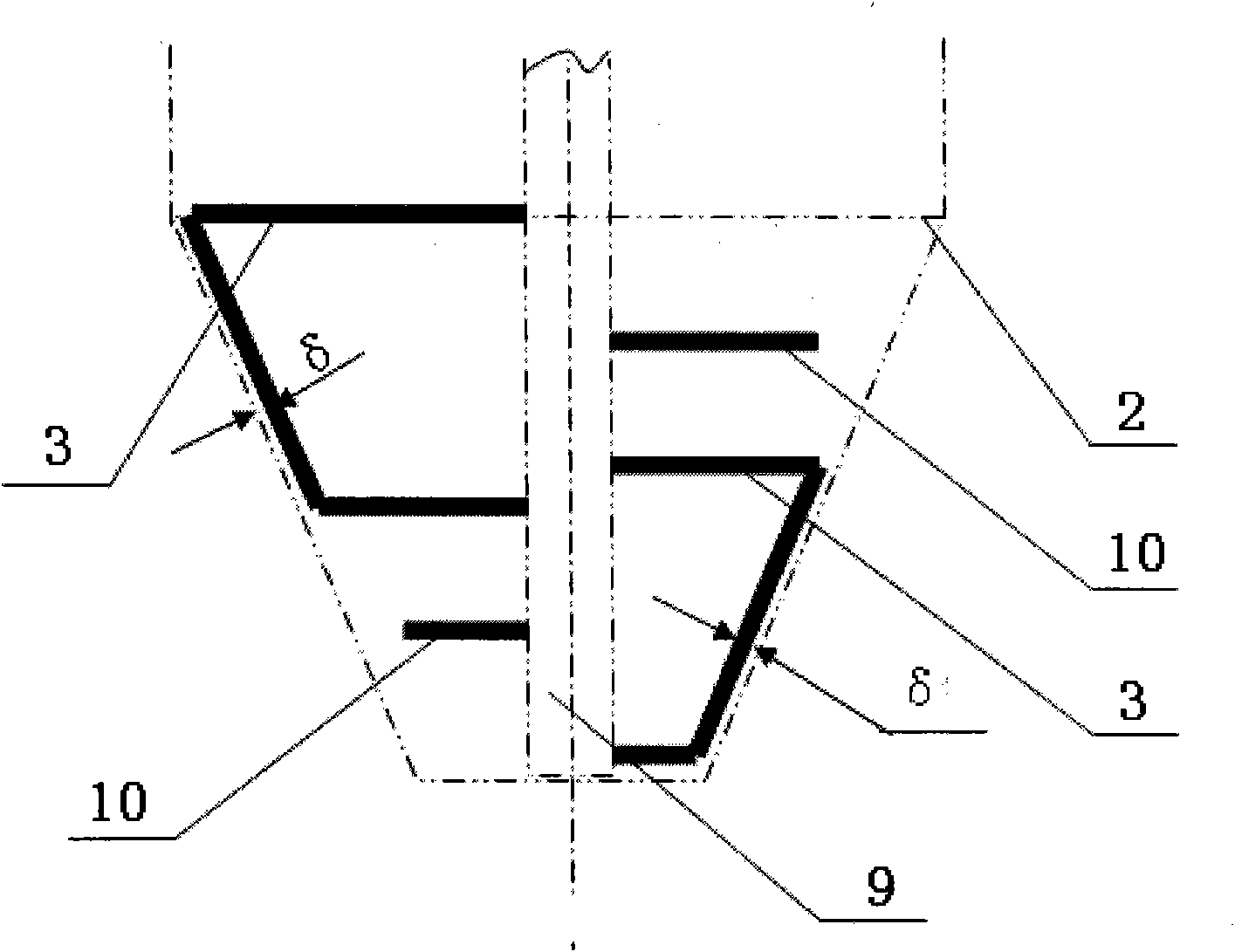

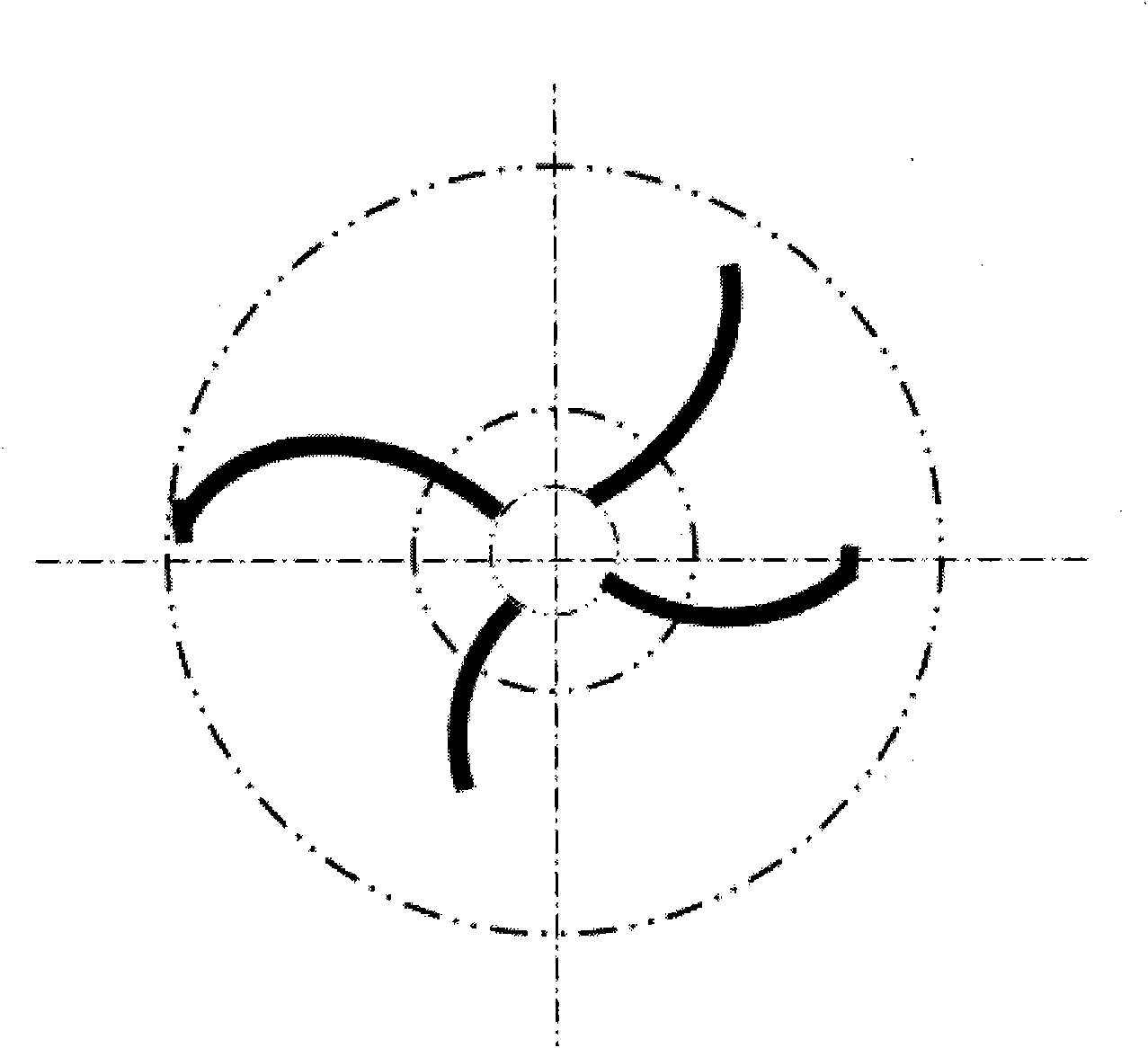

High-quality composting pretreatment method and device for urban kitchen waste

InactiveCN102101796AUniform appearance and colorAvoid breedingClimate change adaptationOrganic fertilisersPretreatment methodMixed materials

The invention relates to a high-quality composting pretreatment method and a high-quality composting pretreatment device for urban kitchen waste. The kitchen waste is pressed by a pressofiner; the pressed kitchen waste, a moisture regulation auxiliary material and a biological regulation auxiliary material are put into an agitation tank of a stirrer; and the mixed materials are crushed, rolled and stirred uniformly to form a composting pretreatment substance. By the invention, the kitchen waste can be pretreated efficiently in real time, and the high-quality composting of the kitchen waste is facilitated.

Owner:姜虎

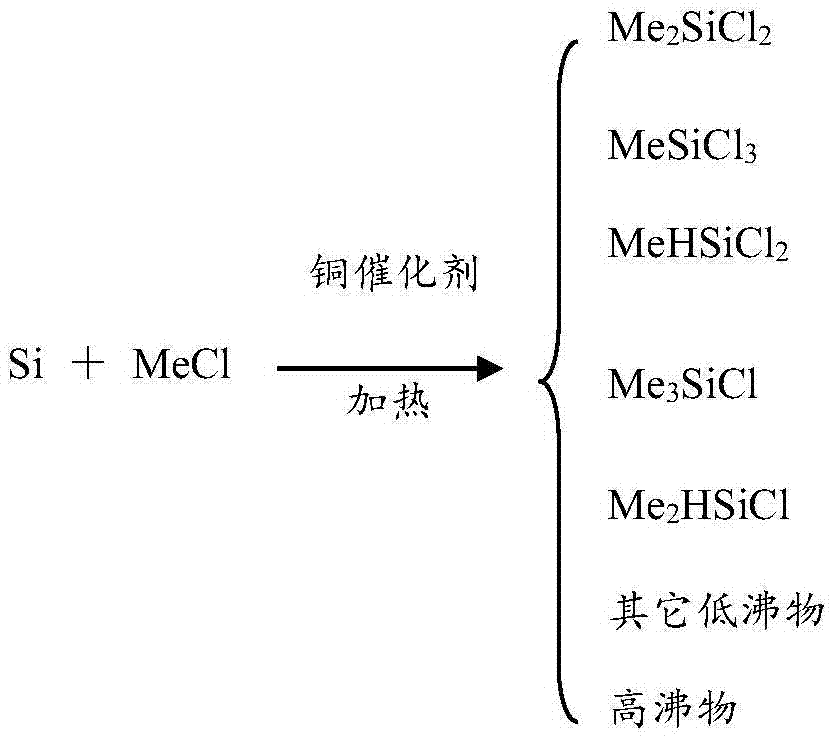

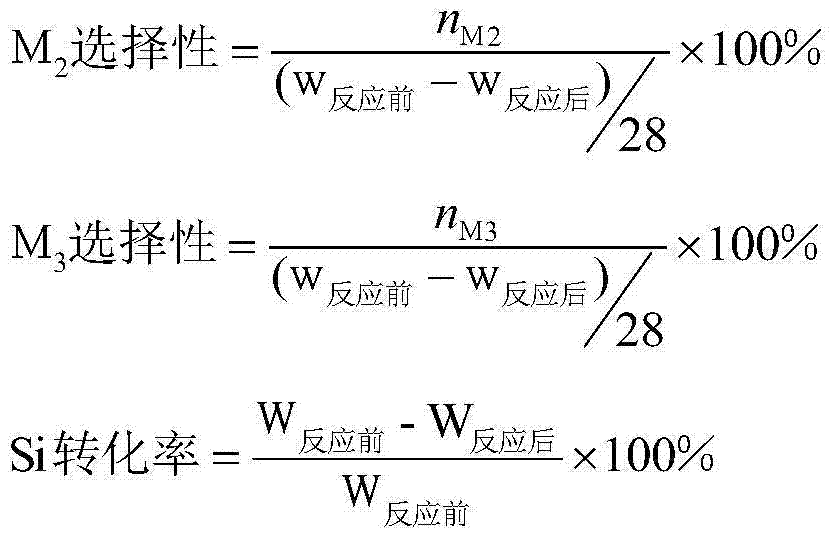

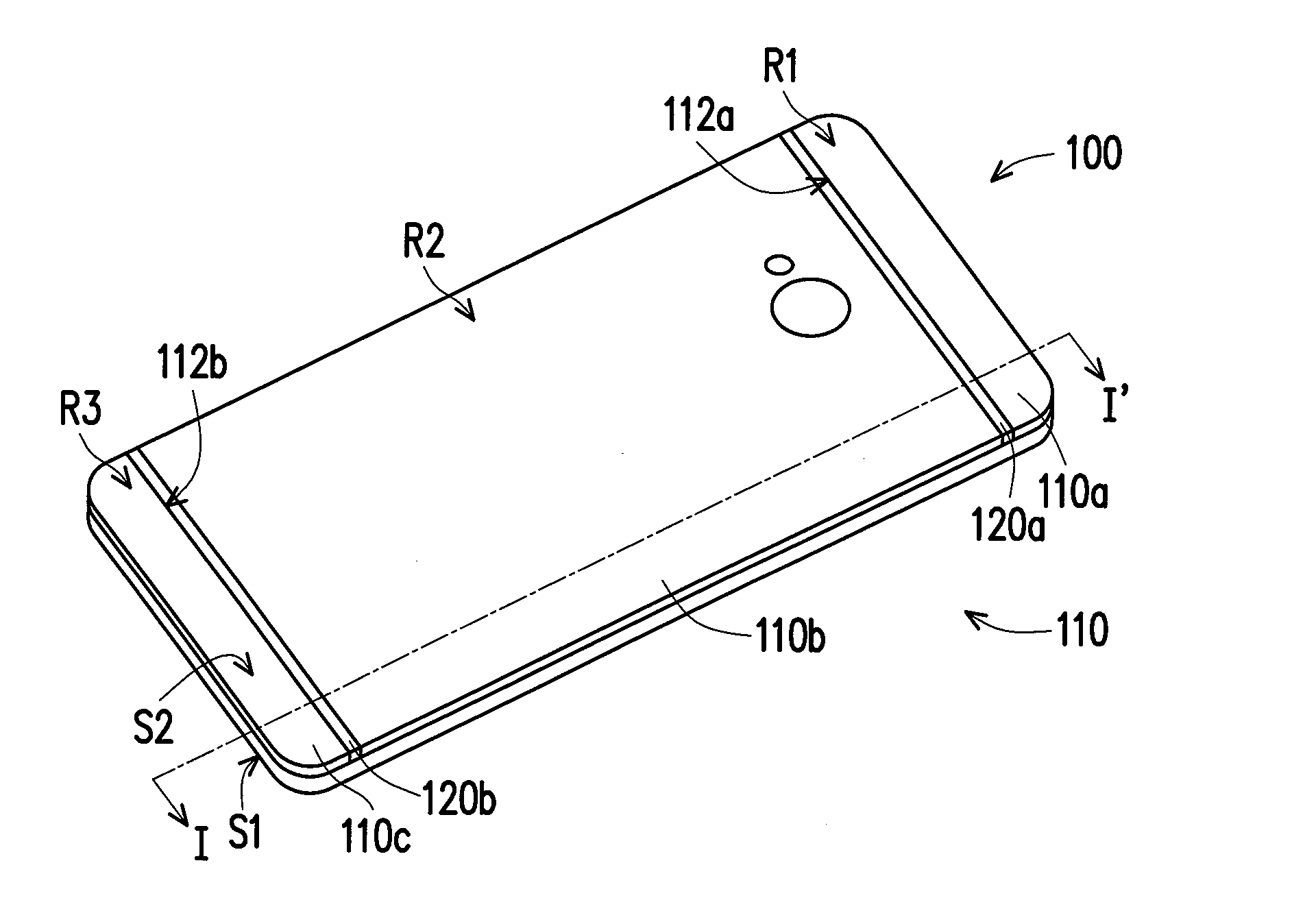

Preparation method of ZnO assistant-containing copper catalyst for synthesis of methylchlorosilane

ActiveCN103831110AUniform appearance and colorEvenly distributedGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsChemistryPartial oxidation

The invention discloses a preparation method of a ZnO assistant-containing copper catalyst for synthesis of methylchlorosilane. The preparation method comprises the following steps of in wet-method preparation of zinc oxide, adding copper powder into the preparation system, carrying out stirring mixing, carrying out filtration and drying to obtain a uniform mixture of basic zinc carbonate and the copper powder, carrying out calcination at a temperature of 400-600 DEG C for 1-5h to obtain a uniform mixture of zinc oxide and Cu-Cu2O-CuO powder, carrying out ball milling, carrying out filtration and carrying out drying to obtain the ZnO assistant-containing copper catalyst. The preparation method realizes preparation of the ZnO assistant-containing copper catalyst by combination of copper powder partial oxidation and wet-method preparation of zinc oxide, and has simple processes, a high equipment utilization rate and a low production cost. Uniform mixing of raw materials are realized easily by a wet method, and after sintering, sintered particles comprising uniformly mixed Cu-Cu2O-CuO powder and zinc oxide are obtained. The preparation method is conducive to further ball milling and uniform dispersion of a ZnO assistant. The ZnO assistant-containing copper catalyst has high catalyst activity and high selectivity.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Zinc ingot mold coating and preparation method

ActiveCN105537508AUniform appearance and colorEliminate chromatic aberration defectsFoundry mouldsFoundry coresSodium BentonitePhosphate

The invention discloses a zinc ingot mold coating, and belongs to the technical field of non-ferrous metal casting. The zinc ingot mold coating is used for coating the surface of an inner cavity of the ingot mold during casting of zinc and zinc alloy. The zinc ingot mold coating is composed of 20%-30% of graphite powder, 7%-10% of zinc oxide, 10%-15% of sodium-based bentonite, 5%-7% of aluminum dihydrogen phosphate, 5%-8% of sodium carboxymethyl cellulose, 8%-10% of quartz powder and the balance water. The preparation method for the zinc ingot mold coating comprises the steps that, the graphite powder, the zinc oxide, the sodium-based bentonite, the sodium carboxymethyl cellulose and the quartz powder are put into the water with the temperature being not lower than 60 DEG C at first; and finally the aluminum dihydrogen phosphate is added. When the zinc ingot mold coating is used, the prepared coating is sprayed on the surface of the inner cavity of the ingot mold with the temperature being 60 DEG C-80 DEG C. According to the zinc ingot mold coating, using is convenient, on-line using can be achieved, the appearance color of a zinc ingot or a zinc alloy ingot is uniform after the coating is adopted, and the appearance quality defects of black spots, dark spots and the like are completely overcome.

Owner:KUNMING UNIV OF SCI & TECH

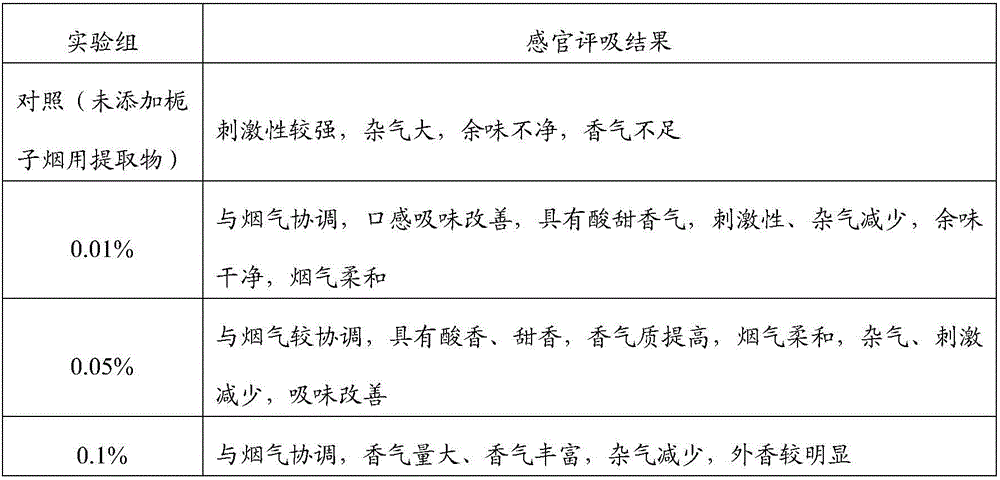

Preparation method and application for fructus gardeniae extract for tobacco

ActiveCN106136303AImprove qualityGood lookingTobacco treatmentTobacco devicesAlcoholLactarius alnicola

The invention discloses a preparation method for a fructus gardeniae extract for tobacco. The preparation method is characterized by comprising the following steps: (1) crushing fructus gardeniae fruits, adding the crushed fructus gardeniae fruits into an extracting tank, adding water, and adding lactobacilli and complex enzyme for fermenting to obtain fructus gardeniae fruit fermentation liquid, wherein the fructus gardeniae fruit and the water are in the mass ratio of 1 : (20 to 40); (2) performing alcohol precipitation and purification on the fructus gardeniae fruit fermentation liquid to obtain secondary fructus gardeniae concentrated liquid; (3) performing molecular distillation refining, namely, performing vacuum concentrating on the secondary fructus gardeniae concentrated liquid to obtain tertiary fructus gardeniae concentrated liquid, adding propylene glycol, performing further separation and purification on the tertiary fructus gardeniae concentrated liquid in molecule distillation equipment, collecting a light component, performing molecular distillation purifying on a heavy component again, and combining two light components to obtain the fructus gardeniae extract for the tobacco. According to the preparation method, the fructus gardeniae extract for the tobacco is prepared by adopting compound fermenting, solvent low-temperature extracting and molecular distillation refining, and is applied to reconstituted tobacco, so that the appearance colour and lustre of the reconstituted tobacco are more natural and uniform, and are close to those of high-quality tobacco; the pH value of smoke is reduced; aroma is enriched; stimulation and miscellaneous gas are reduced; the smoking taste is improved.

Owner:HUBEI CHINA TOBACCO IND

Process for packing products of diaminium phosphate and cooling process

InactiveCN1793062AReduce consumptionImprove appearance qualityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateFluidized bed

The invention discloses a packaging and cooling method for diammonium phosphate product that controlling the discharge temperature of diammonium phosphate at 70-100 degree centigrade, after drying, directly sending the material into the packaging machine to take packaging process, cooling the material to 55 degree centigrade in fluidized bed cooling machine. The invention could save the power consumption, decrease producing cost, and it has good appearance.

Owner:GUIZHOU KAILIN GRP CO LTD

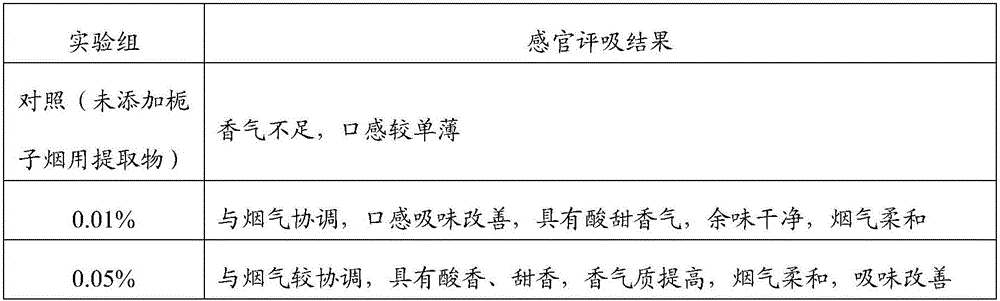

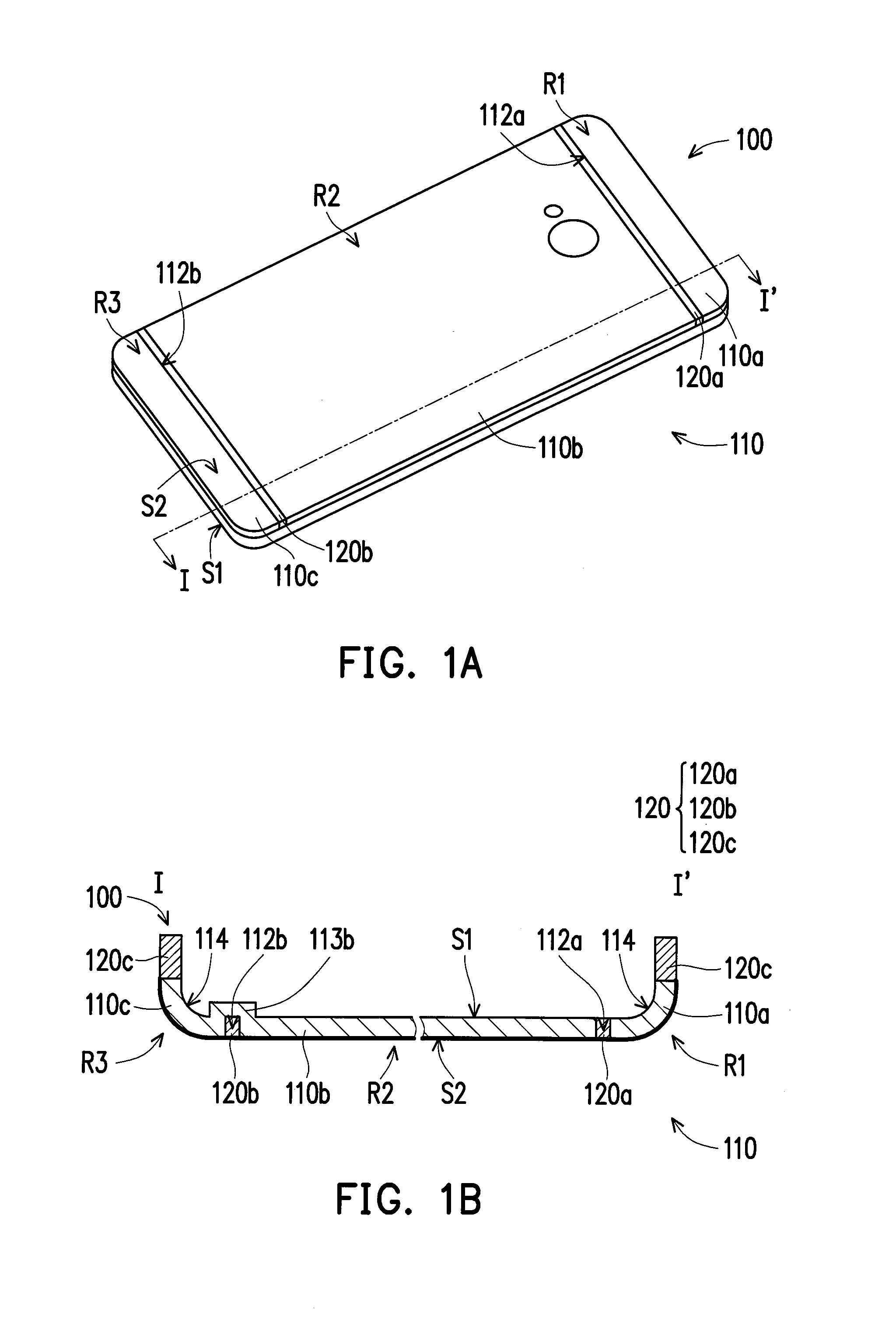

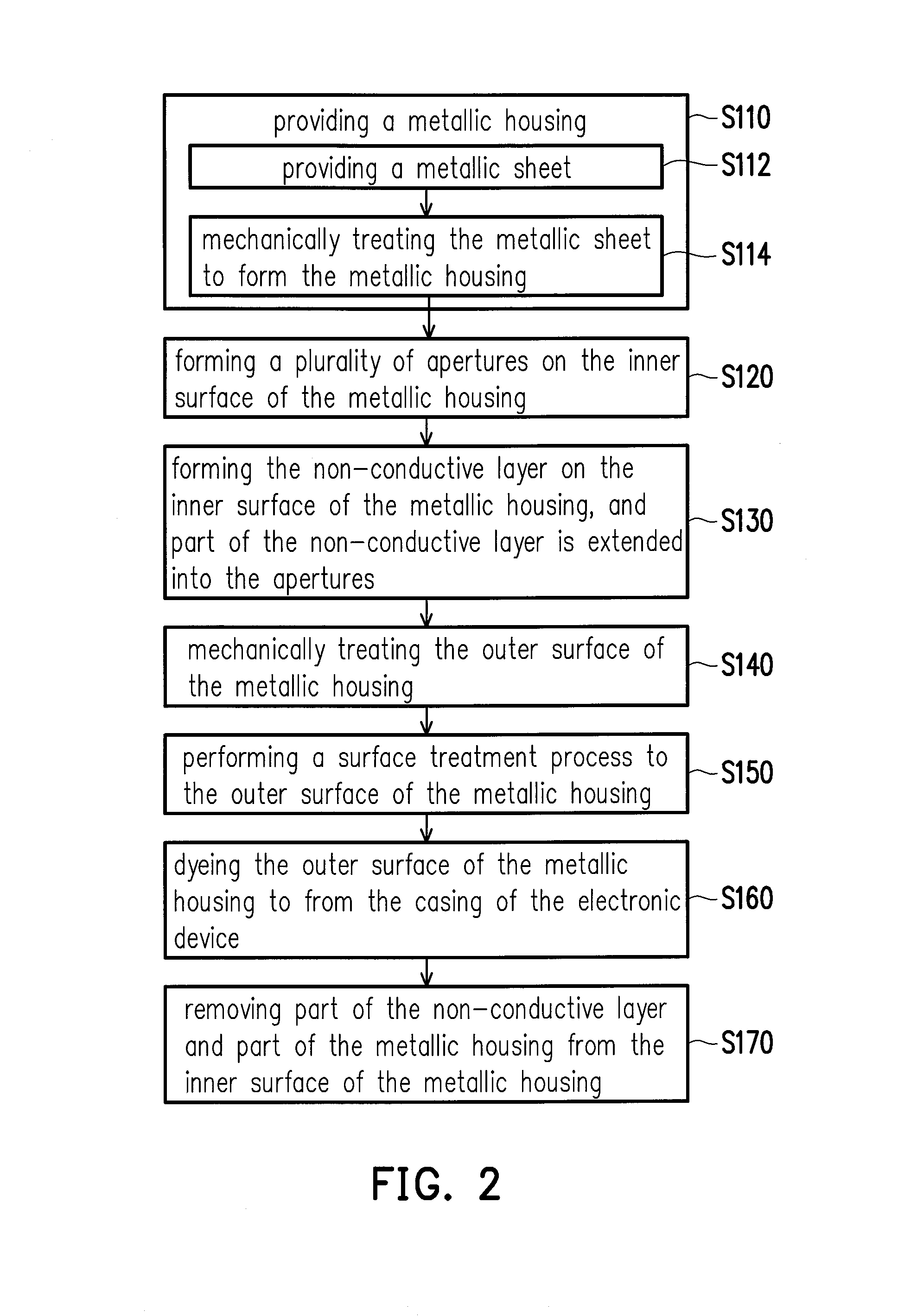

Casing of electronic device

ActiveUS20160120052A1High mechanical strengthUniform appearance and colorAnodisationClosed casingsElectrical and Electronics engineering

Owner:HTC CORP

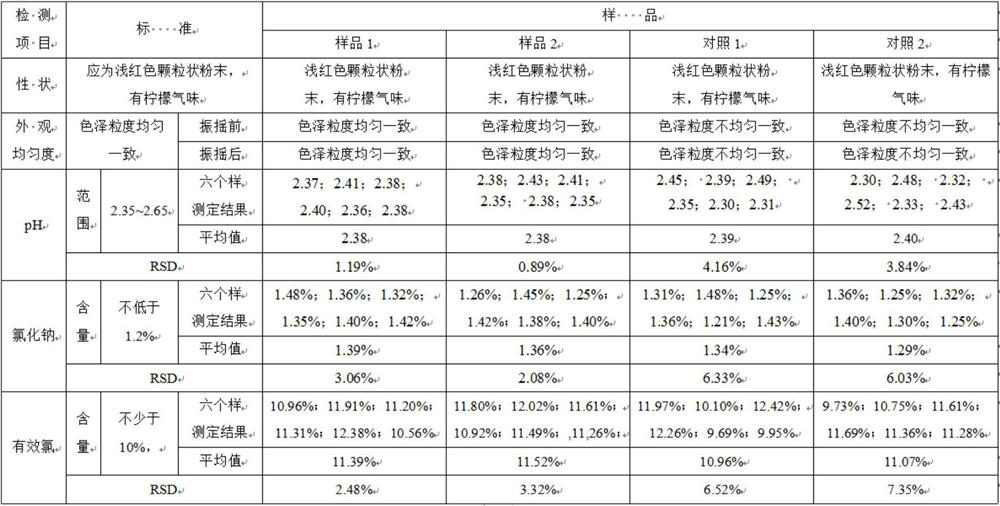

Potassium hydrogen persulfate composite powder with uniform and stable quality and preparation process thereof

ActiveCN111903674AReduce pollutionSimple processBiocideFungicidesSODIUM METAPHOSPHATESodium phosphates

The invention relates to the field of pharmaceutical chemicals, in particular to potassium hydrogen persulfate compound powder with uniform and stable quality and a preparation process thereof. The potassium hydrogen persulfate compound powder comprises the following components: a potassium hydrogen persulfate compound, sulfamic acid, sodium hexametaphosphate, sodium dodecyl sulfate, sodium chloride, an anti-caking agent and trisodium citrate, and also comprises essences and pigments. The potassium hydrogen persulfate compound powder disclosed by the invention is superior to potassium hydrogenpersulfate compound powder on the market, the process is simple, and the cost is hardly increased; the compound powder is uniform in appearance, color and content; a user can conveniently monitor theeffective disinfection concentration in real time in clinical use, products are not layered in the transportation process, and the product quality is more stable. According to the process, closed integrated equipment can be adopted for production in actual production, so that pollution to people and the environment is greatly reduced, and the process is the direction of safe and environment-friendly production in the future.

Owner:马保臣

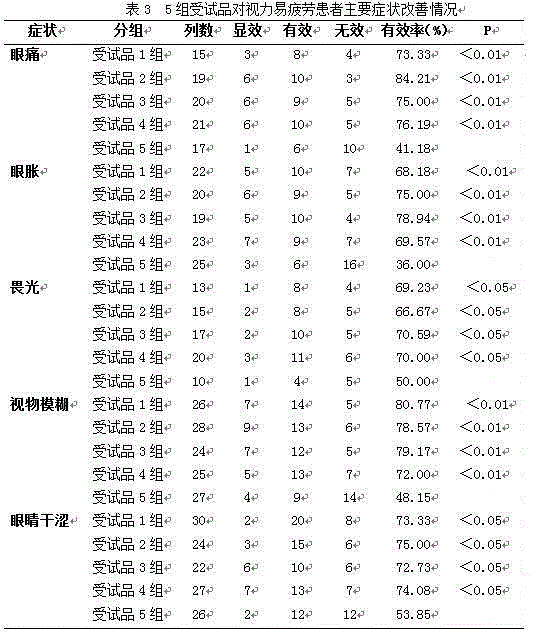

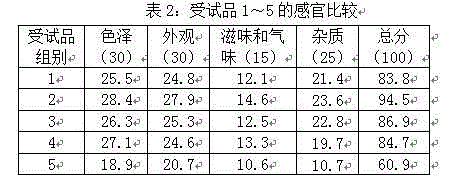

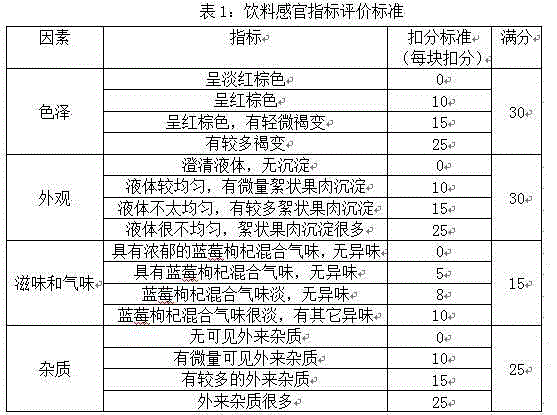

Blueberry and Chinese wolfberry fruit beverage having effect of improving eyesight

The invention relates to a beverage having the effects of improving eyesight and alleviating asthenopia. The beverage is prepared from blueberries and Chinese wolfberry fruits. The beverage disclosed by the invention has the health-care effects of improving eyesight and alleviating asthenopia, can be used for preventing asthenopia syndromes of healthy crowds, and can also be used for auxiliary treatment of asthenopia crowds.

Owner:JIANGXI JIANGZHONG DIETOTHERAPY TECH CO LTD

Okra seed dietary fiber gluten-free biscuits high in slowly-digestible starch content and high in resistant starch content and making method of okra seed dietary fiber gluten-free biscuits

ActiveCN109463417AMature manufacturing technologyHas an anti-digestive effectDough treatmentModified nutritive productsDigestible starchBlood sugar

The invention relates to okra seed dietary fiber gluten-free biscuits high in slowly-digestible starch content and high in resistant starch content. The okra seed dietary fiber gluten-free biscuits consist of the raw materials in parts by weight of based on 100 parts of rice flour and okra seed powder by total weight, 94-98 parts of the rice flour, 2-6 parts of the okra seed powder, 20-30 parts ofbutter, 30-80 parts of eggs, 0.5-2 parts of baked powder, 0.5-1 part of salt and 6-20 parts of water. The rice flour and the okra seed powder are used, so that the okra seed dietary fiber gluten-freebiscuits high in slowly-digestible starch content and high in resistant starch content are made. The preparation technology of products is mature, and the okra seed dietary fiber gluten-free biscuitscan maintain blood sugar stable and satiety, reduce the hungry feeling, and besides, have positive role on the effect of regulating intestinal flora. According to the okra seed dietary fiber gluten-free biscuits, in the range of the required additive amount of the okra seed powder, the products are uniform in appearance color, light golden, and crisp, fragrant and sweet in mouth feel.

Owner:河北玉桥食品有限公司

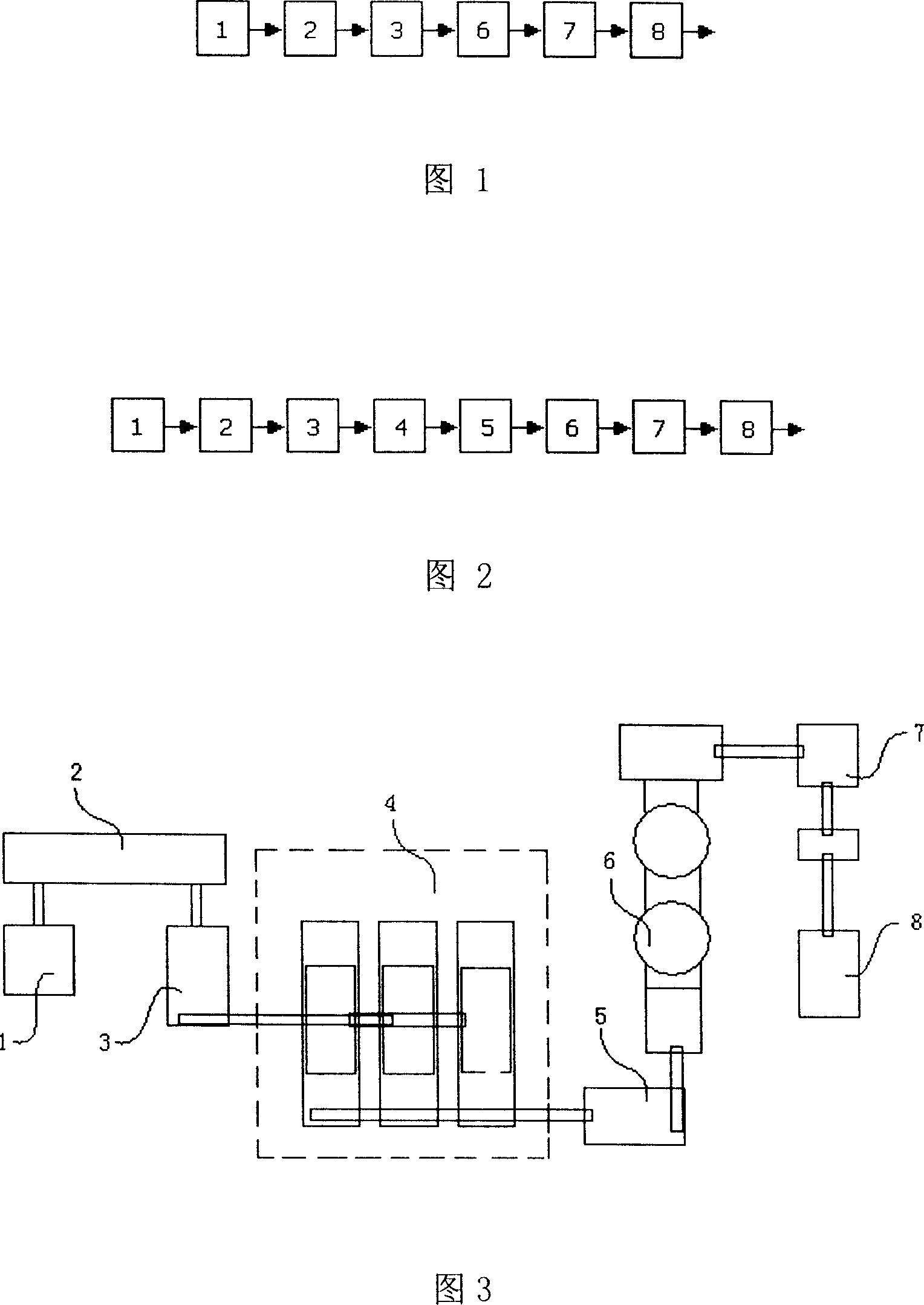

Processing method of tobacco stem and the device thereof

InactiveCN101095556AImprove the quality of sensory inhalationHigh fillingTobacco preparationTobacco treatmentPulp and paper industry

The invention relates to a method for treating tobacco stem, and device used for tobacco stem processing. The stem is stored for 1-6 hours after feeding process, and then is fed into drying and expanding process. The invention can improve tobacco stem quality and reduce cost.

Owner:CHINA TOBACCO HUNAN INDAL CORP

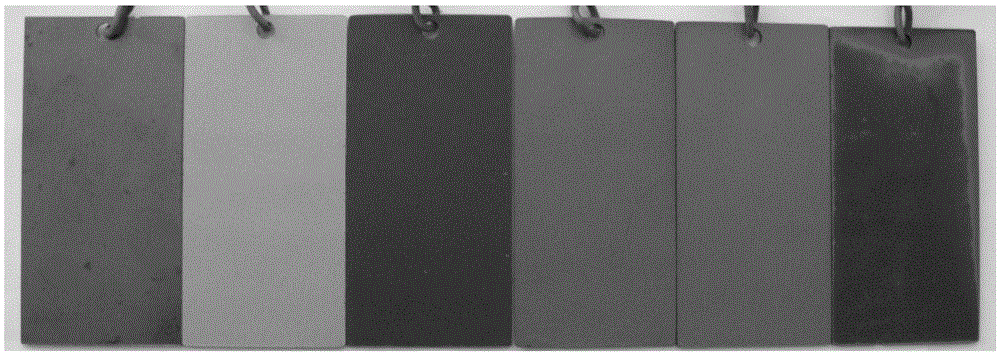

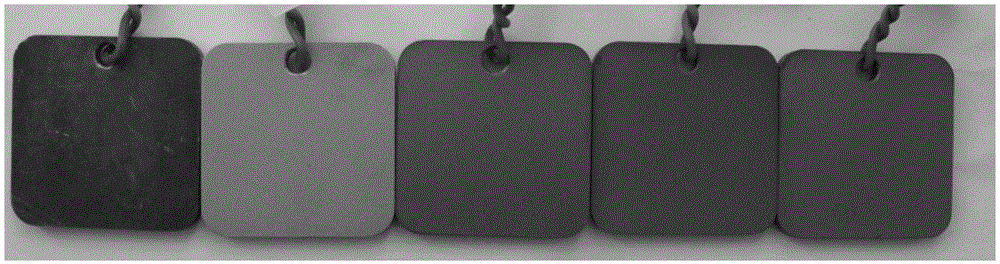

Preparation method for aluminum-based transition coating of die-casting aluminum alloy shell

ActiveCN105506567AUniform appearance and colorImprove wear resistanceVacuum evaporation coatingSputtering coatingSputteringSalt spray test

The invention discloses a preparation method for an aluminum-based transition coating of a die-casting aluminum alloy shell. The preparation method comprises the steps that a Cr basal layer or Ti basal layer is deposited on the surface of a die-casting aluminum alloy mobile telephone shell by adopting multiple electric arc Cr-based targets or Ti-based targets through vacuum magnetron sputtering ion plating equipment; the pure Al coating is prepared on the Cr basal layer or Ti basal layer by taking multiple pairs of planar Al targets evenly installed on the inner wall of a furnace body as an Al source, taking pure Ar as sputtering gas and ensuring the effective glow discharge process and target material sputtering. The prepared die-casting aluminum alloy shell is processed through follow-up anodic oxidation and then tested, the appearance of an oxidation layer is uniform in color and luster and presents various colors and luster, the microhardness of the oxidation layer is Hv500, the coating does not fall off after a sample is bent 180 degrees, the corrosion resistance of a neutral salt spray test exceeds 48 hours, and the oxidation coating quality and technique index requirements of the aluminum alloy shell are completely met.

Owner:晨光真空技术(东莞)有限公司

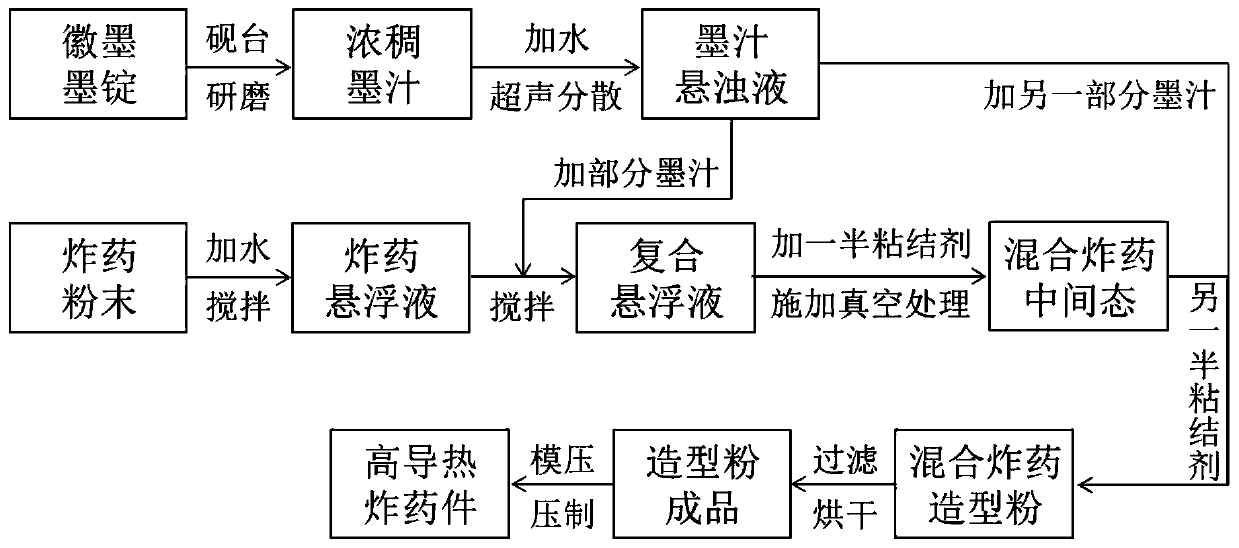

Method for improving heat conduction performance of mixed explosive

ActiveCN110183291AGood dispersionImprove thermal conductivityNon-explosive fillers/gelling/thickening agentsStarch/sugar nitrate explosive compositionsEngineeringCarbon nanomaterials

The invention discloses a method for improving heat conduction performance of a mixed explosive, and belongs to the technical field of energetic composite materials. The method comprises the followingsteps: step 1, adding water into an ink stick for grinding the ink stick in a inkstone, adding a proper amount of a surfactant, and carrying out ultrasonic dispersing to obtain an ink turbid liquid;and step 2, adding the ink turbid liquid into an explosive by two stages, dropwise adding a high polymer binder to prepare explosive molding powder by a water suspension granulation method, carrying out filtering, water washing and drying, and pressing the explosive molding powder into a reagent column to obtain the mixed explosive with heat conduction performance. According to the invention, a natural hybrid carbon nano material in the ink stick is used as heat conduction filler, and meanwhile, good adhesion capability of the natural hybrid carbon nano material is fully utilized, so that heatconduction performance of the mixed explosive is improved. The method disclosed by the invention has the advantages that the effect is remarkable, the preparation process is simple, amplification iseasy, universality is strong, and the method is suitable for all types of mixed explosives.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

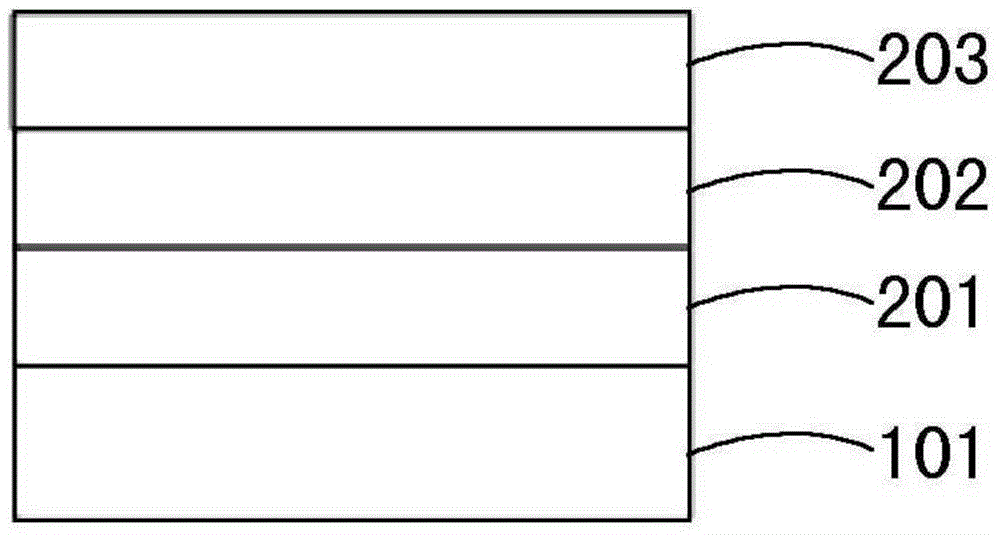

Antireflective film for solar cell piece and manufacturing method thereof

InactiveCN104091839AGood passivation effectIncrease short circuit currentFinal product manufactureChemical vapor deposition coatingPower flowPhotovoltaic conversion efficiency

The invention provides an antireflective film for a solar cell piece and a manufacturing method of the antireflective film. The antireflective film for the solar cell piece comprises a first silicon nitride layer covering the surface of the solar cell piece, a second silicon nitride layer covering the upper surface of the first silicon nitride layer and a third silicon nitride layer covering the upper surface of the second silicon nitride layer. By means of the antireflective film for the solar cell piece, the three layers of silicon nitride antireflective films are adopted, the good passivating effect can be achieved, the short-circuit current of the metallurgical polycrystalline silicon cell pieces can be improved, the reverse leakage current can be reduced, and photovoltaic conversion efficiency is improved. Meanwhile, according to the manufacturing method of the antireflective film, an intermittent deposition technology is adopted, that is, a certain dead time is added between depositions of the two layers of silicon nitride thin films, so that the growth of all layers of silicon nitride thin films is complete as much as possible, the manufactured metallurgical polycrystalline silicon cells are more even in color of appearance, the chromatic aberration rate of the surfaces of the cell pieces is reduced by about 5% from the original 30%, and the yield of the metallurgical polycrystalline silicon cells is improved greatly.

Owner:INNER MONGOLIA RIYUE SOLAR ENERGY TECH +1

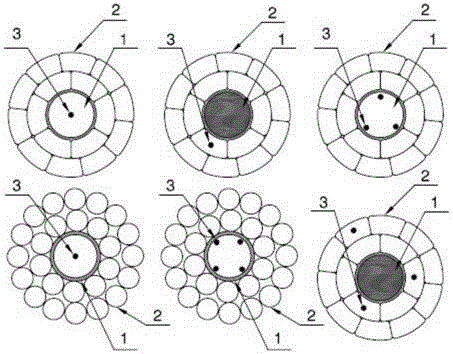

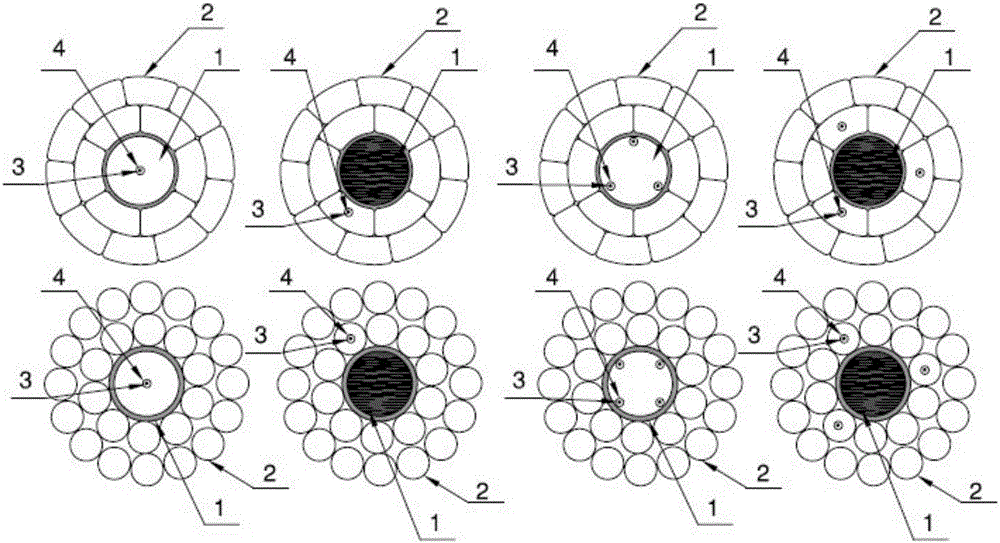

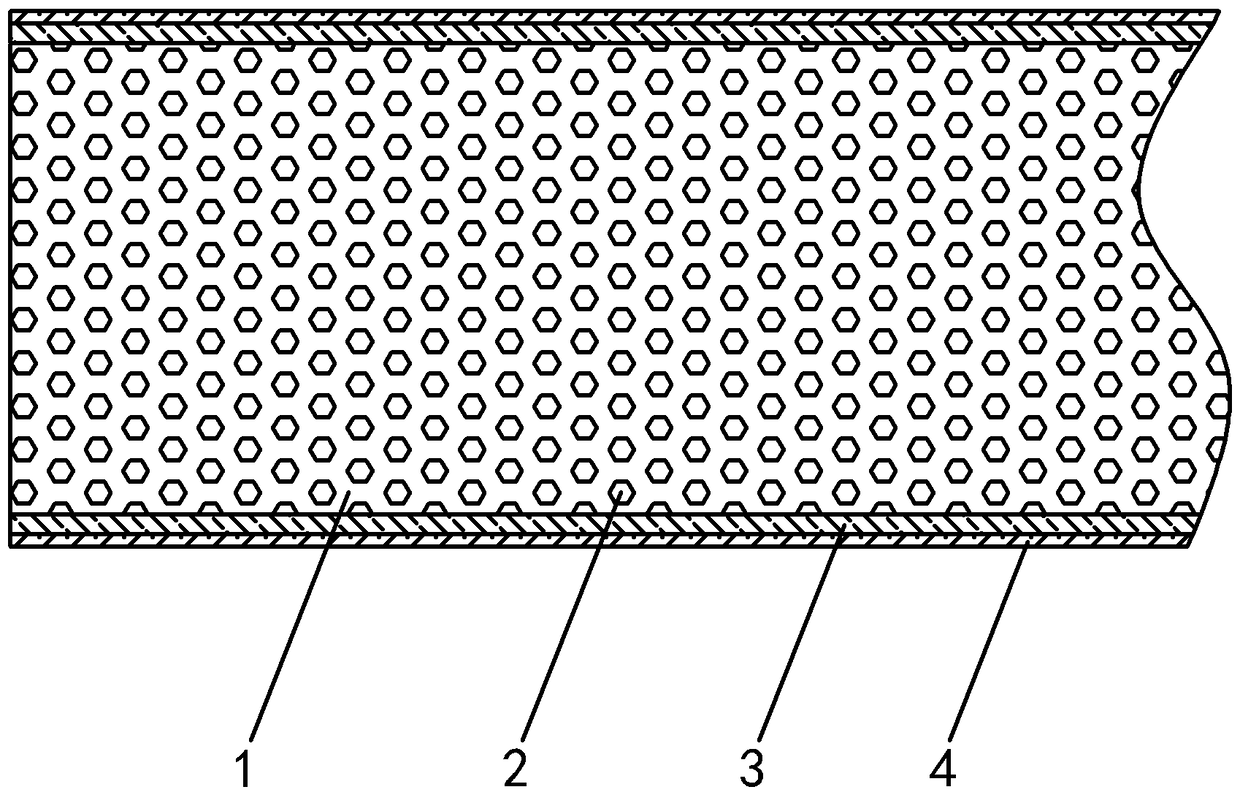

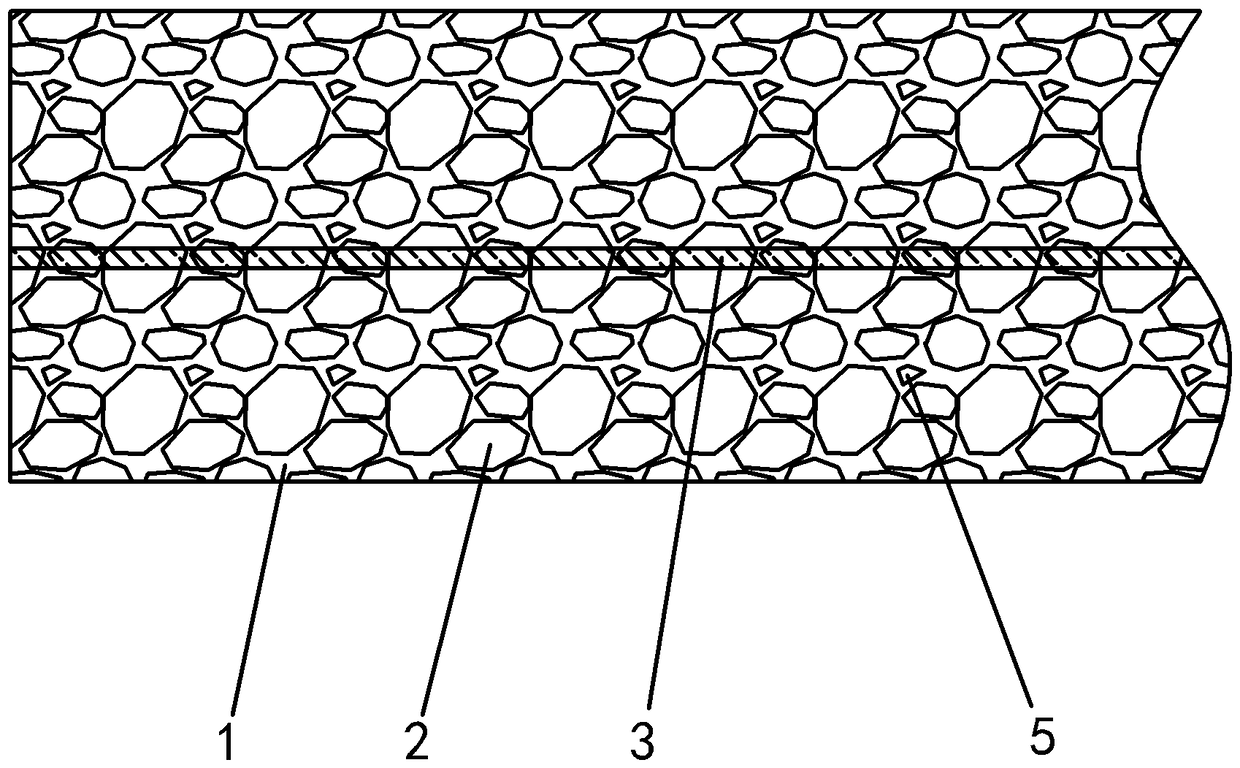

Intelligent composite material core wire and preparation method thereof

ActiveCN105825945AReasonable structural designHigh temperature resistantNon-insulated conductorsPower cables including optical transmission elementsCarrying capacityAging resistance

The invention discloses an intelligent composite material core wire and a preparation method thereof. The intelligent composite material core wire includes a composite material core (1) and single conductor wires (2) stranded at the periphery of the composite material core (1), wherein the composite material core (1) or the single conductor wires (2) are internally provided with optical fibers (3) or optical fiber protection pipes (4) for communication or monitoring; and the optical fibers (3) are arranged in the optical fiber protection pipes (4). The preparation method of the intelligent composite material core wire includes the steps of preparing the composite material core and stranding the single conductor wires (2) at the periphery of the composite material core (1). The preparation method of the intelligent composite material core wire has the advantages of being high in operability, being higher in production efficiency, being able to save a lot of manpower and material resources, and being low in production cost; the prepared composite material core has the advantages of being high in linearity and roundness, having no bending, being high in color consistency, being high in intensity, being long in the service life, having no eccentricity, and being high in aging resistance; and the prepared intelligent composite material core wire has the advantages of being higher in the wire compactness and filling rate, being resistant to high temperature, being high in current-carrying capacity and being small in sag.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

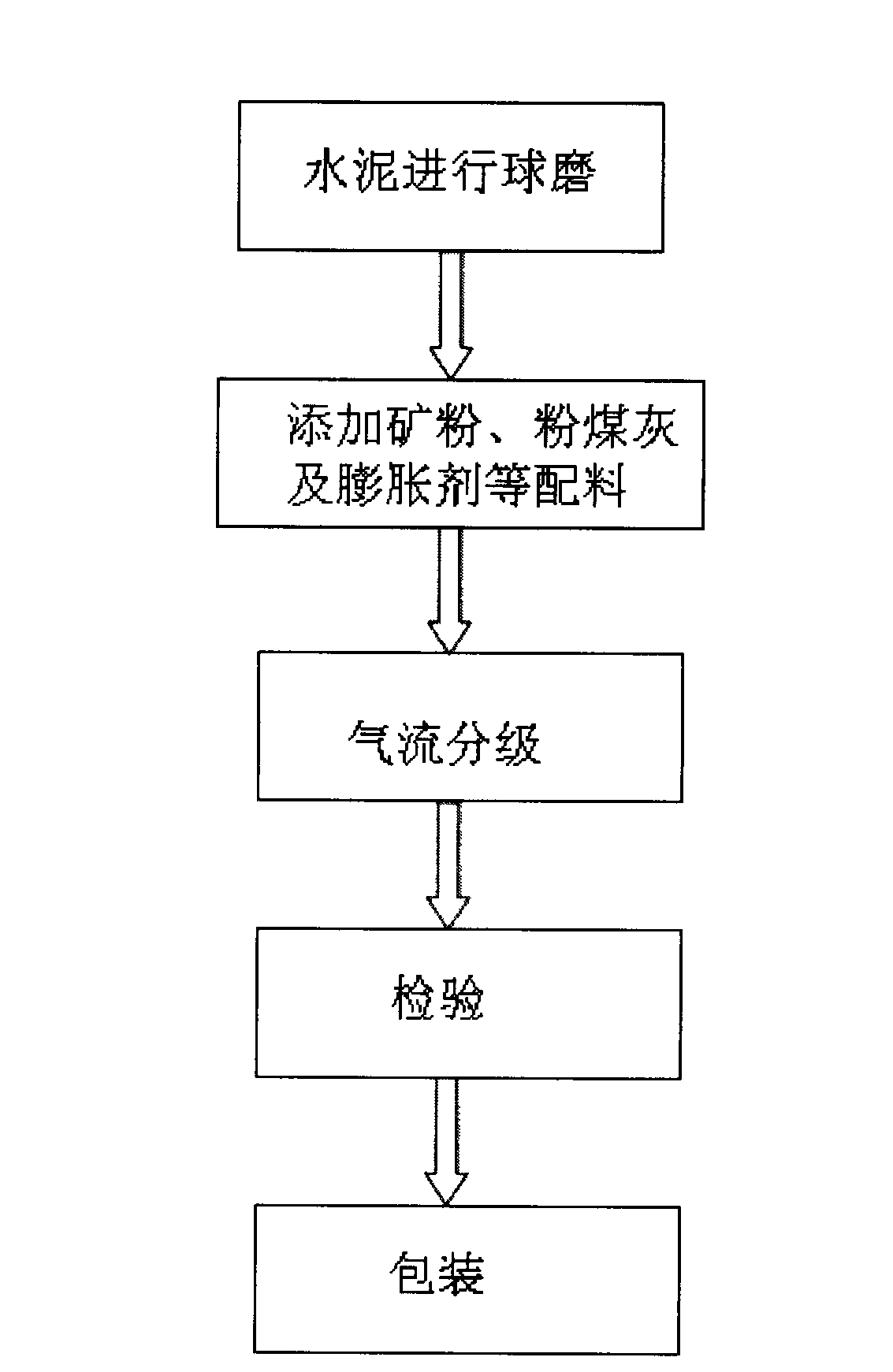

Ultra-fine powder cement admixture and manufacturing method thereof

InactiveCN103964712AIncreased durabilityAvoid crackingCement productionUltra finePulverised fuel ash

The invention relates to an ultra-fine powder cement admixture and a manufacturing method thereof. In the ultra-fine powder cement admixture, 700-to-900-mesh cement accounts for 65 to 75% and has an average particle size of 5.4 mu m; 1100-to-1200-mesh ore powder accounts for 20 to 30% and has an average particle size of 4.5 mu m; a 700-to-900-mesh expanding agent accounts for 2% and has an average particle size of 5.4 mu m; and fly ash accounts for 3% and has an average particle size of 4.5 mu m; and the particle sizes of the above-mentioned materials are controlled by using wind power. The ultra-fine powder cement admixture provided by the invention has the advantages of good workability, high durability, low hydration heat and good thermal stability and is more than 5 times finer than materials of a same kind.

Owner:王诗友

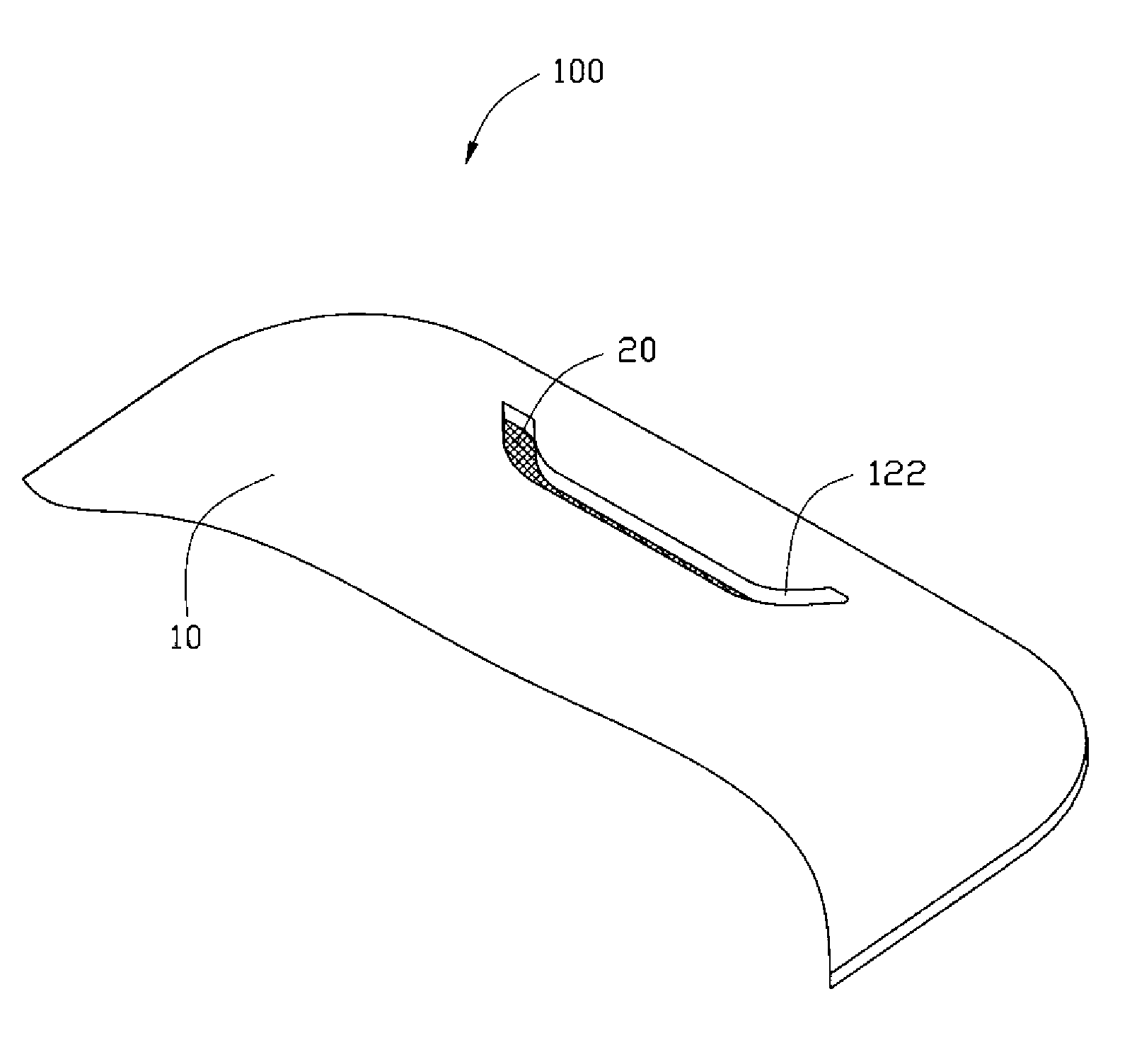

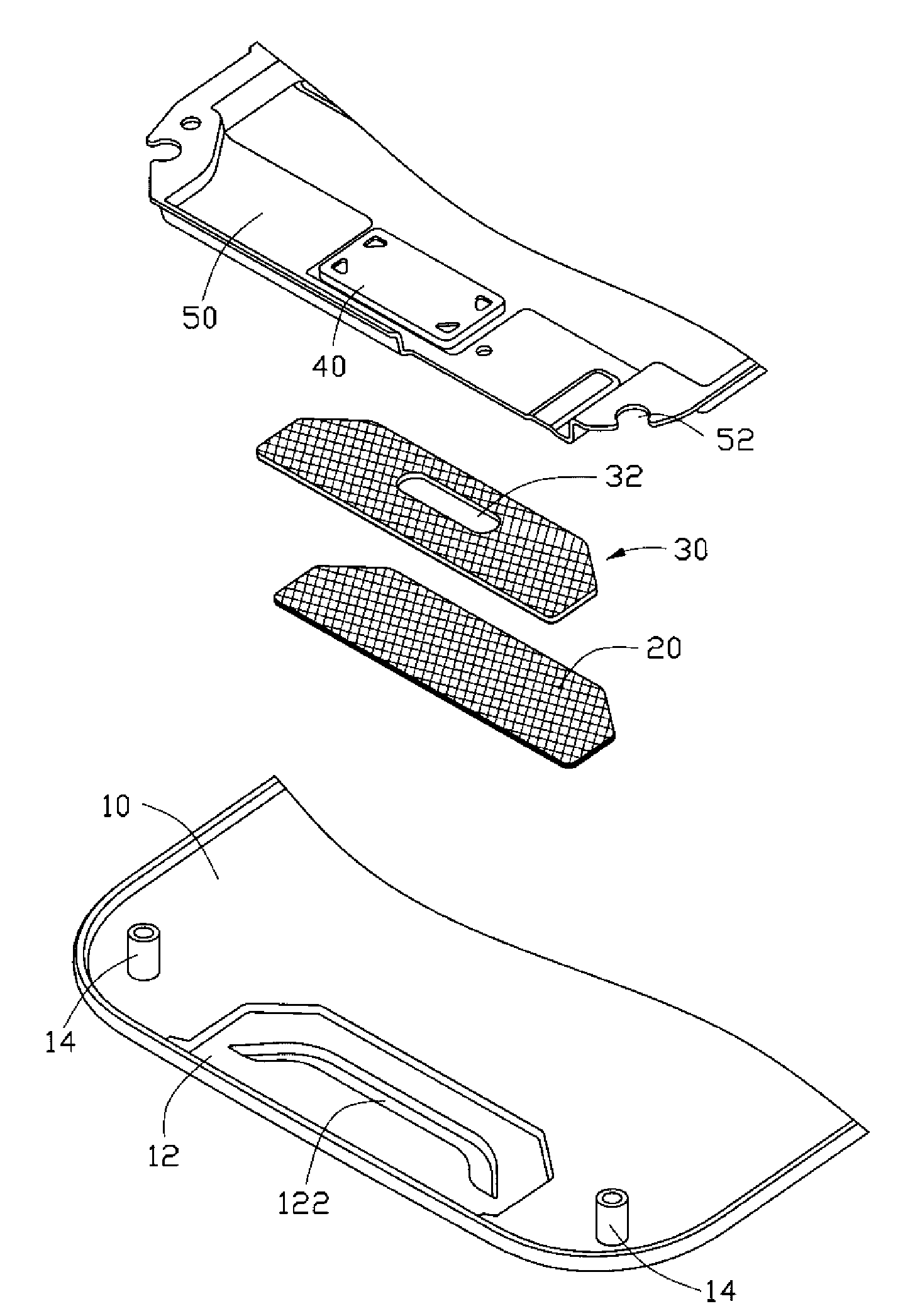

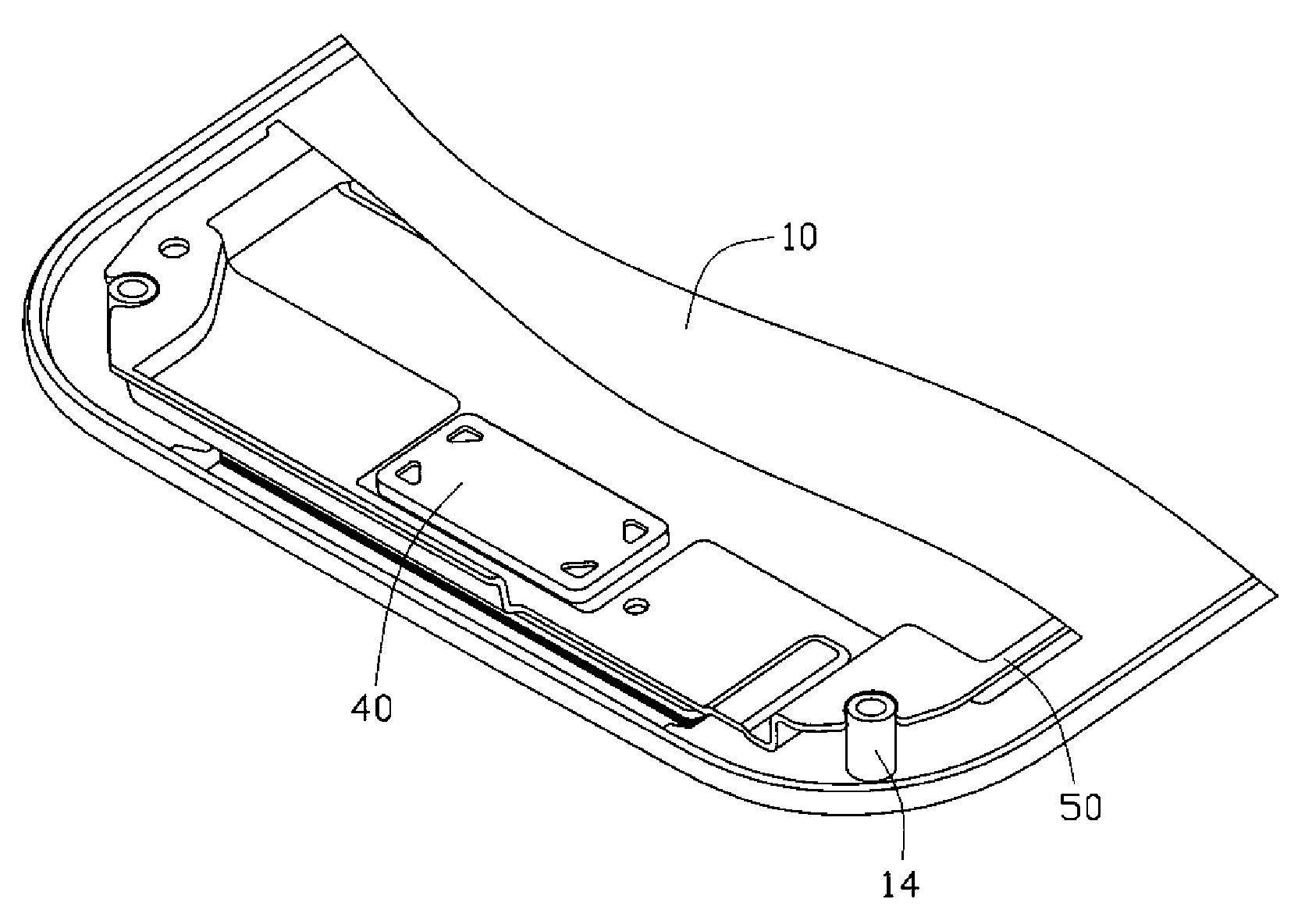

Telephone receiver structure of electronic device

InactiveCN101646113AAvoid enteringAvoid uneven colorLoudspeaker screensEarpiece/earphone attachmentsEngineeringLoudspeaker

The invention discloses a telephone receiver structure of an electronic device. The telephone receiver structure comprises a shell, a first net layer, a second net layer and a loudspeaker, wherein anaccommodating frame is formed on the shell, and the bottom of the accommodating frame is provided with a first sound diffusing hole; the first net layer is attached to the bottom of the accommodatingframe and covers the first sound diffusing hole; the second net layer is provided with a second sound diffusing hole which is attached to the first net layer and is aligned to the first sound diffusing hole; the loudspeaker is attached to the second net layer; and a loudspeaking surface of the loudspeaker is aligned to the second sound diffusing hole. The invention has dust proof structure, good sound diffusing effect and ideal visual effect.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Cattail pollen sauting method, sauted cattail pollen and application thereof

ActiveCN102233066AUniform appearance and colorQuality is easy to controlBlood disorderExtracellular fluid disorderHemostaticsEnergy consumption

The invention provides a cattail pollen sauting method, sauted cattail pollen and application thereof. The sauting method comprises the following steps of: preheating a medicament sauting machine, adding cattail pollen and auxiliary materials in a weight ratio of 4:2-5:2 into the medicament sauting machine, sauting for 8-12 minutes at the temperature between 200 DEG C and 220 DEG C and the revolving speed of 14-24r.min<-1>, taking out the sauted cattail pollen and auxiliary materials, screening the auxiliary materials, and cooling to obtain the sauted cattail pollen. The sauted cattail pollenis applied in preparation of hemostatic and medicaments for treating hematemesis, hemoptysis, hemorrhinia, bloody dysentery, hemafecia, metrorrhagia and metrostaxis, bleeding from injuries and / or vaginal wet and itching. The method is low in energy consumption and high in yield in unit time, and meets the requirement of modern Chinese medicinal clinical application; the sauted cattail pollen is not stuck to a pot, and the produced sauted cattail pollen product has uniform appearance and color and controllable quality; and the method is simple and reasonable.

Owner:KANGMEI PHARMA +1

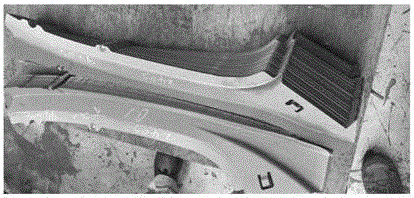

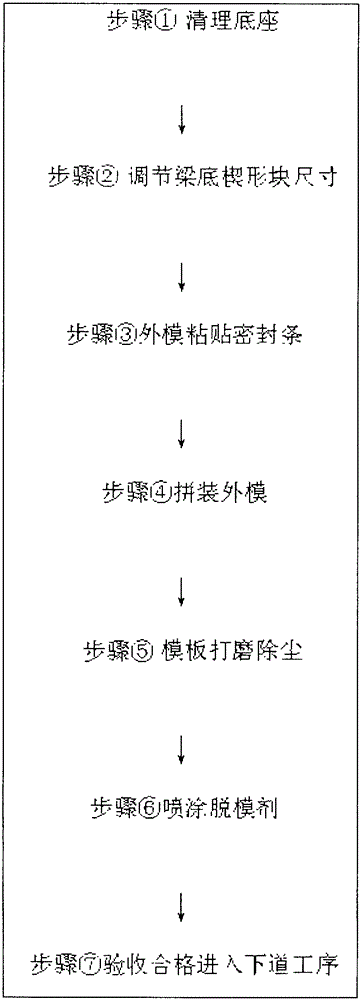

Construction method for polishing outer mold of precast box beam

ActiveCN105113421AUniform appearance and colorShorten turnaround timeBridge erection/assemblyHigh pressureAir compressor

The invention discloses a construction method for polishing an outer mold of a precast box beam. The construction method is used for polishing an inner mold and the outer mold of a precast concrete structural component, brushing a demolding agent on the polished inner mold and the polished outer mold of the precast concrete structural component, and casting a concrete structural article of which the construction period is short in place. The construction method sequentially comprises the following steps: cleaning a base; regulating the size of a wedge block at the bottom of the beam; sticking sealing strips on the outer mold; assembling the outer mold; polishing a formwork, and removing dust; spraying the demolding agent; and after acceptance inspection is qualified, sending semi-finished products into following operation procedures. Handheld polishing equipment is utilized to cleanly polish a staggered platform on the surface of the formwork and residual concrete, an air compressor is used for continuous pressurization so as to spray the demolding agent in a handheld oil tank through a high pressure, the brushing thickness of the demolding agent sprayed in the manner is easier to control than the brushing thickness of the demolding agent sprayed manually, an oil path runoff is not formed in the surface of the formwork, and the color of the outer surface of the box beam can be effectively controlled; the air compressor is adopted to be combined with a spray gun so as to perform pressurized spraying, a uniform isolating layer is formed on the surface of the formwork, and the situation that runoff is formed because too much oil is brushed by using a traditional roller brush is avoided; the concrete surface is smooth after the mold is disassembled, and the appearance color is uniform.

Owner:CR10BG NO 3 CONSTR

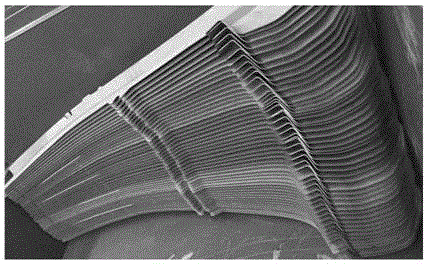

Steel hot stamping product with aluminum or aluminum alloy coating and manufacturing method thereof

ActiveCN106466697BUniform appearance and colorUniform shapeHot-dipping/immersion processesVehicle componentsHot stampingPunching

The invention discloses a manufacturing method of a steel hot-stamped product with an aluminum or aluminum alloy plating layer. The manufacturing method comprises the following steps: 1) blanking: a steel plate with the aluminum or aluminum alloy plating layer is machined to a part blank with a needed shape by a blanking or laser cutting method; and the thickness of the steel plate with the plating layer is not more than 2.8 mm; 2) blank heat treatment: the blank is put in a heating furnace for heating and insulation; the temperature of the heating furnace is 900-950 DEG C; the atmosphere in the heating furnace guarantees the oxygen content to be more than 15%; and the total stop time of the blank in the heating furnace is 2.5-10 minutes; 3) blank transmission: the heated blank is quickly conveyed into a mold for punching; the conveying time is 4-12 seconds; and the temperature of the blank before punching is 680-750 DEG C; and 4) blank hot stamping: the heated blank is directly punched in the mold; the mold is cooled in the punching process; and the surface temperature of the mold before punching is lower than 100 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

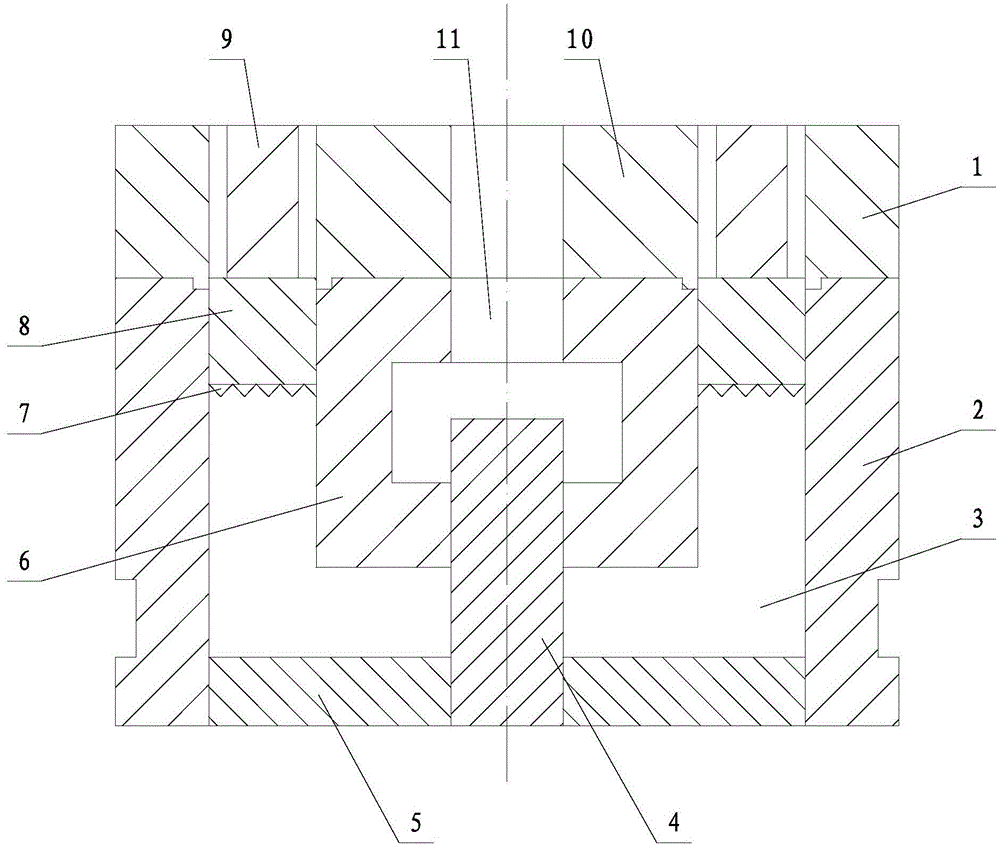

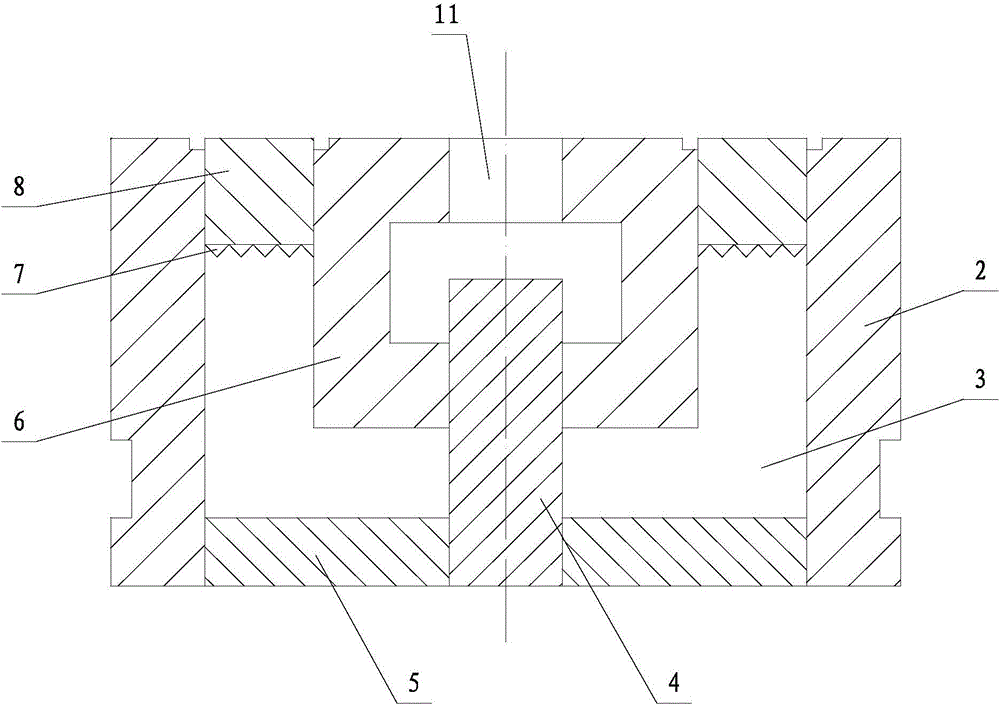

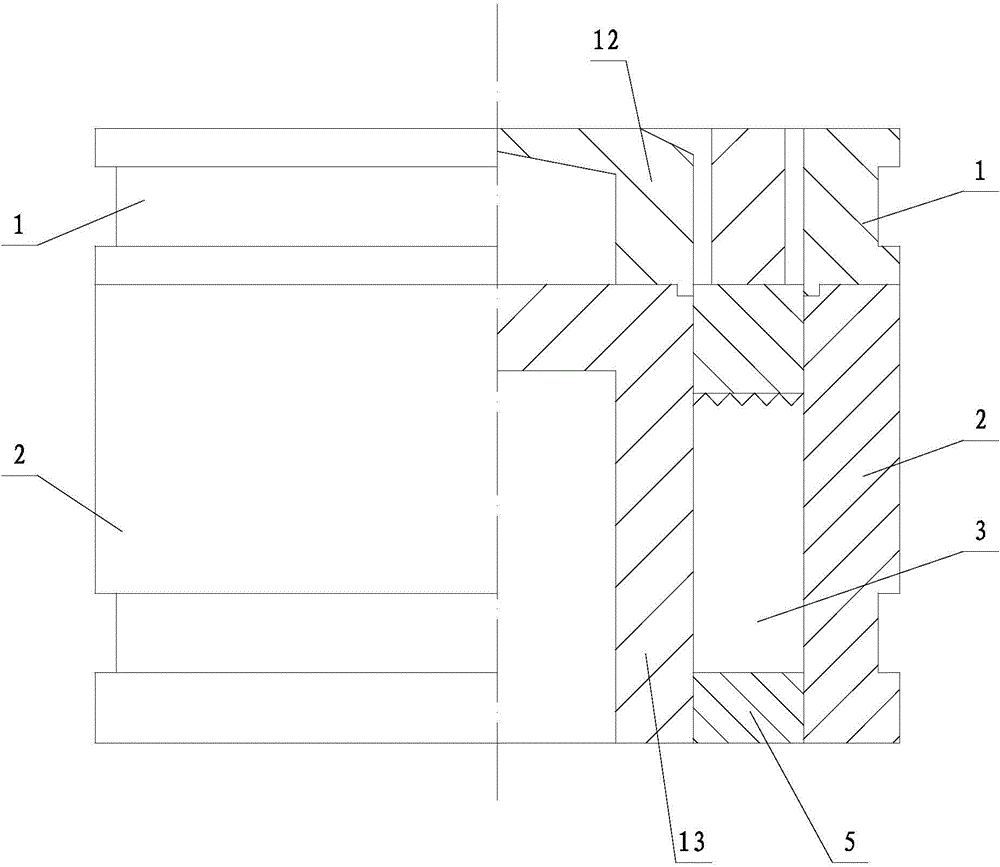

Grindstone hot press molding die and hot press molding technology thereof

InactiveCN105751092ASimple structureLower the altitudeGrinding devicesEngineeringMechanical engineering

The invention relates to a grindstone hot press molding die and a hot press molding technology thereof. The die comprises an upper die and a lower die which can be separated. The lower die is on the bottom in a die sleeve. A core mold and a mandril are combined with a lower mold plate. A space for holding a hot-press workpiece blank is formed among the inner walls of the die sleeve. An upper mold plate is on the upper part in the die sleeve, and is placed on the blank of the hot-press workpiece. The lower surface of the upper mold plate is provided with a peck plate. A connecting sleeve and an upper connecting core mold are respectively combined with the die sleeve and the core mold. The upper mold plate and a pressing ring are placed between the connecting sleeve and the upper connecting core mold. The technology comprises: assembling the upper die and the lower die, installing the lower mold plate, installing the mandril, combining the core molds, putting into a blank to strike off a comb material, adding the upper mold plate and the pressing ring, performing prepressing, removing a sizing block, the connecting sleeve, the upper connecting core mold, and the pressing ring, and starting pressing; maintaining pressure, deflating, and repressing to complete pressing, and then unloading the die, and transferring a hot press workpiece blank on a drying rack. The grindstone hot press molding die is characterized by simple structure, easy operation, fast die heat conduction, even heated, and low heat energy loss.

Owner:FUXIN SHENGDA ABRASIVES MFG CO LTD

Firing-free ceramic wood chip board (ceramic-wood board)

The invention relates to a firing-free ceramic wood chip board (ceramic-wood board), and relates to the technical field of boards. The firing-free ceramic wood chip board is prepared from the following raw materials and net ribs in parts by mass: 100 parts of firing-free ceramic, 5 to 25 parts of wood chip, and 0 to 160 parts of sand; the firing-free ceramic is prepared by adding 0.1 to 10 parts of porcelainizing agent into 100 parts of cement; the wood chip is plant crushed chip. The firing-free ceramic wood chip board has the advantages that the firing-free ceramic wood chip board can be sawed and nailed; the weight is light, the environment-friendly, fireproof and mothproof properties are realized, the water-proof, mildew-proof and acid and alkaline-resistant properties are realized, the poison, odor and irritation are avoided, the metal is not corroded, and the anti-aging life reaches 50 years or above; the cost is low, and the raw materials for preparation are easy to obtain; thefiring-free ceramic wood chip board can be widely applied to the floors, walls, skeletons, slabs, roofings, furniture, toilets, pipelines, windows and doors and the like in the fields of buildings, furniture and decoration.

Owner:GUANGZHOU QINGNENG BUILDING MATERIALS CO LTD

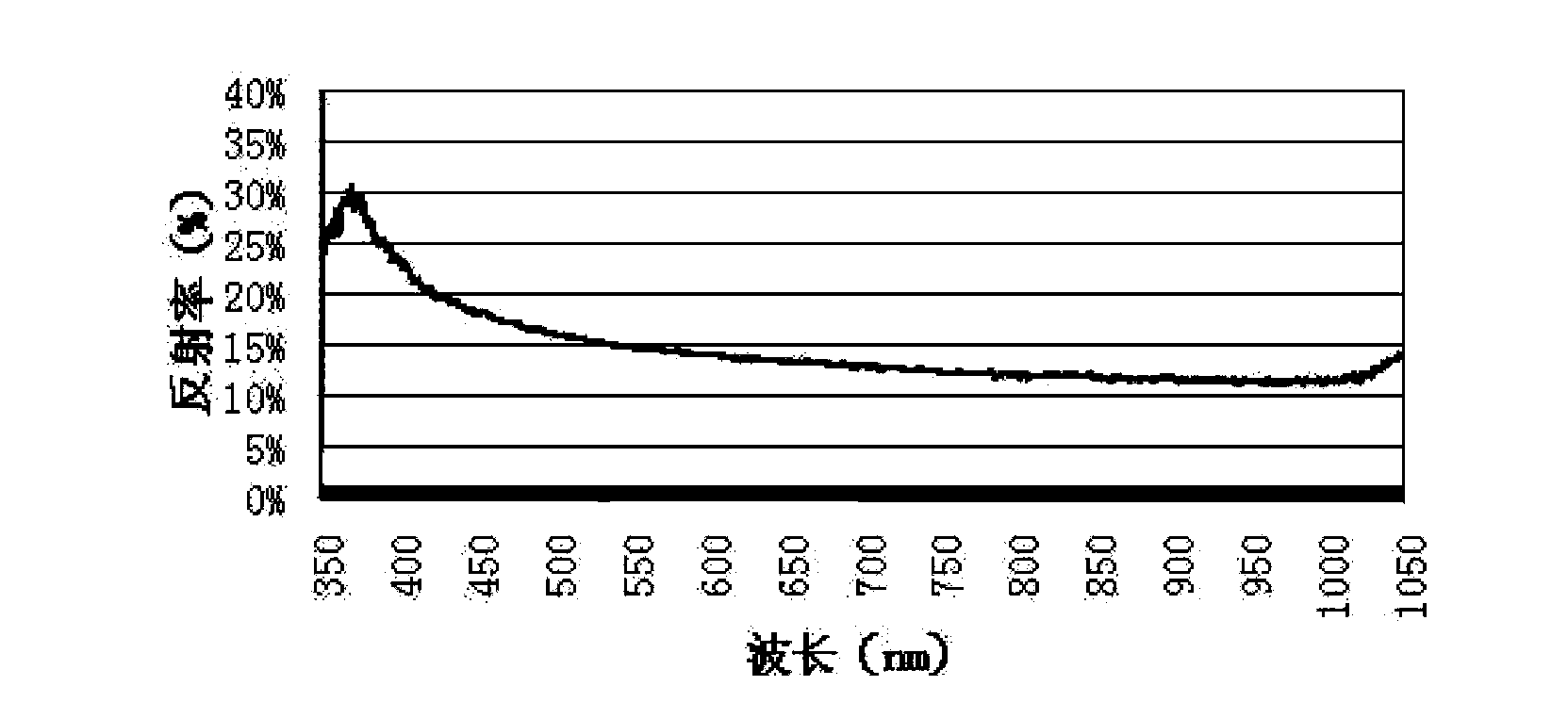

Monocrystalline silicon system flocking additive for crystalline silicon solar battery

The invention aims to disclose a monocrystalline silicon system flocking additive for a crystalline silicon solar battery. The monocrystalline silicon system flocking additive comprises the following components in percentage by mass: 1-2% of poly(propylene glycol), 0.01-0.05% of fatty amine polyoxyethylene ether, 0.5-5% of methyl pyruvate, 0.1-5% of vitamin C, 0.1-3% of oxalic acid, 0.1-5% of lactic acid, 0.1-2% of alkali and the balance of deionized water. Compared with the prior art, the monocrystalline silicon system flocking additive with the formula has the advantages that the size of a monocrystalline suede coating pyramid can be well controlled, and a suede coating structure with good uniformity and high density is obtained; the etching thinning weight of a monocrystalline silicon chip is stable and can be controlled at 5-8%; the appearance of the silicon chip is uniform in color, and the average reflectivity is lower than 15%, so that the requirements for industrial production are met, and the aim of the invention is achieved.

Owner:SHANGHAI HANYAO NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com