Processing method of tobacco stem and the device thereof

A technology of tobacco cut stems and a processing method, which is applied to the processing equipment of tobacco cut stems and the processing field of tobacco cut stems, which can solve the problem that the cut stems absorb moisture and the feed liquid is not uniform and sufficient, increase the expansion resistance of cut stems, and prevent the cut stems from containing water. rate and other problems, to achieve uniform appearance and color, improve the quality of sensory taste absorption, and promote the effect of consistent appearance and color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

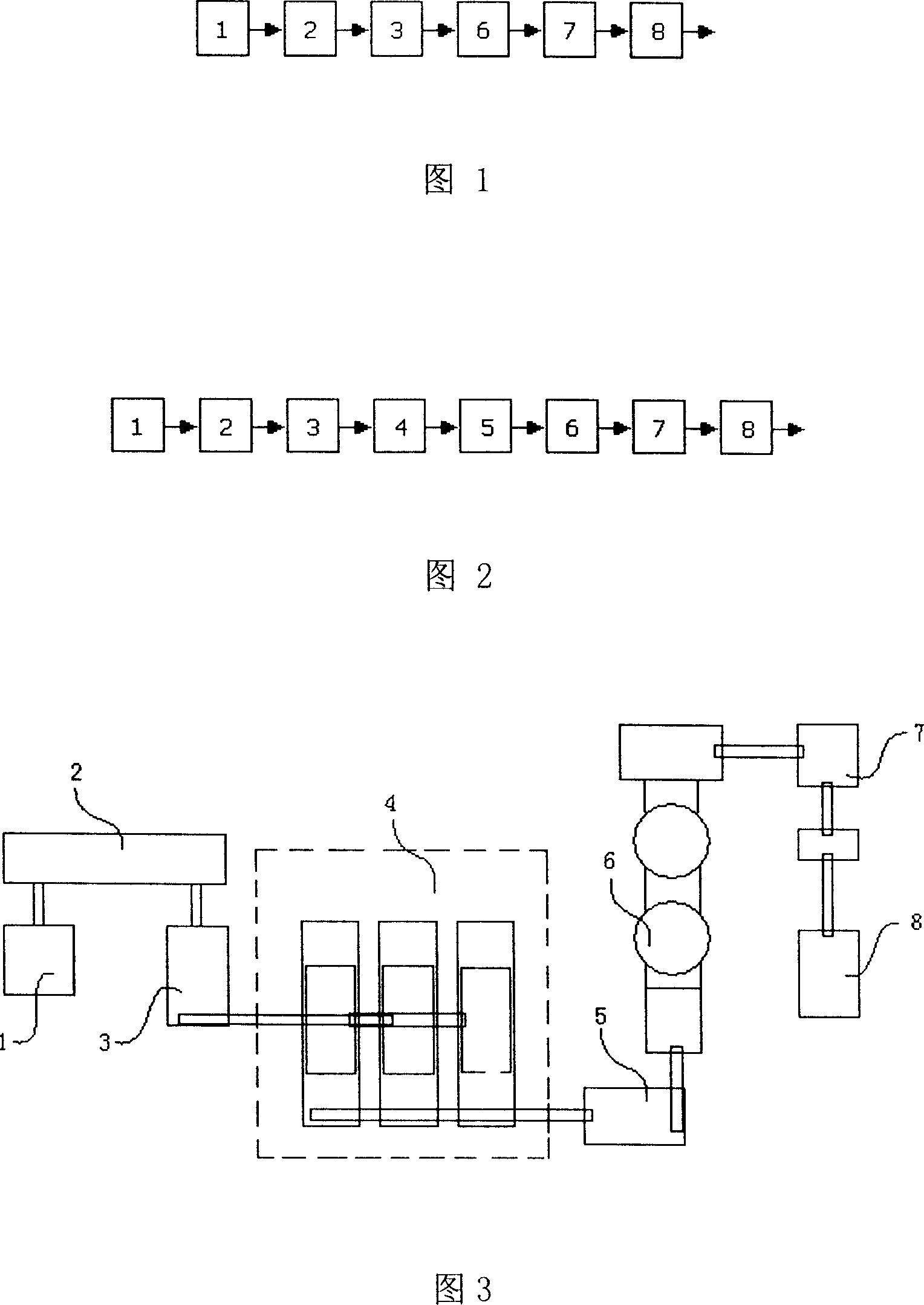

[0033] Referring to Fig. 2, the cut tobacco stem processing method provided by the present invention consists of the following procedures.

[0034] Add material 3 to the shredded stems 1 and flow control 2. After feeding, the temperature of the cut stems is 65±5°C and the moisture content is 38±2%. Then, the process environment temperature is 24±2°C and the humidity is 60 The cut stems are stored at ±5% for 40-8 hours, and then sent to the warming process 5. After the temperature increase, the cut stems have a temperature of 70±5°C and a moisture content of about 38±1%. Finally, the cut stems are subjected to traditional Process processing, including drying and expanding cut stems 6, cooling to remove impurities 7 and flavoring 8.

[0035] Correspondingly, the equipment for implementing this process is shown in Figure 3, including a shredding device 1, a flow control device 2, a feeding device 3, a storage stem cabinet 4, a warming device 5, a drying expansion device 6, a cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com