Patents

Literature

48results about How to "Consistent appearance and color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-compaction fair-faced concrete with strength grade of C50

The invention discloses self-compaction fair-faced concrete with the strength grade of C50 used for a stiffness concrete structure, belonging to the field of concrete. The mixed proportion comprises 335kg / m<3> cement, a 110kg / m<3> complex mineral additive, 40kg / m<3> coal ash, 850kg / m<3> fine aggregate sand, 910kg / m<3> coarse aggregate and additive PCA; the water-binder ratio is 0.32, the sand ratio is 48%, the dosage replacement rate of the mineral additive is 29% and the water-powder ratio is 0.82; in the unit volume of concrete, the stone occupies 31%, the sand occupies 32.5%, the stone porosity is 36.5%, the rubber powder occupies 19%, the water occupies 15.5% and the gas content is 2%. The self-compaction fair-faced concrete has the effect that the mobility, the segregation resistance and the self fallibility of the concrete meet the requirement, the appearance and colour of the molded concrete are substantially in consistency with little bubbles and dispersion. The self-compaction fair-faced concrete is simple to operate and is particularly suitable for constructing fair-faced concrete of a vertical or inclined stiffness concrete structure with dense steel bars.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

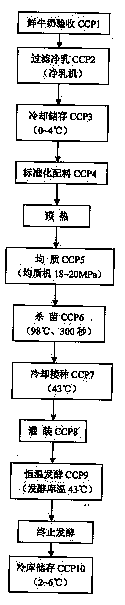

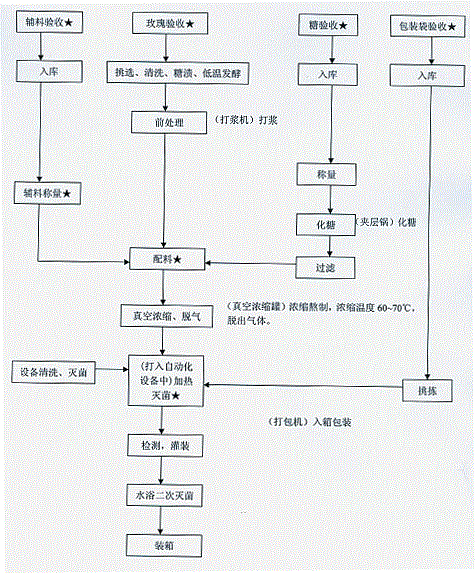

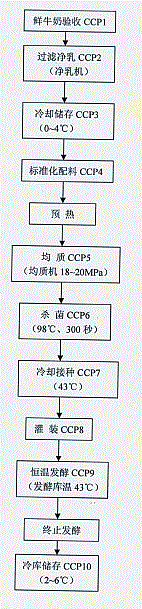

Fresh flower yoghourt and production method

InactiveCN103783158AReasonable process structureConsistent appearance and colorMilk preparationSugarFermentation

The invention relates to fresh flower yoghourt and a production method. The fresh flower yoghourt mainly comprises an isotrope acidification fermented product of edible fresh flower sugaring flower mud and fresh milk and has the unadulterated special flower nourishing smell, and the fresh flower is one or more of rose, arabian jasmine flowers, osmanthus fragrans, lily and lotus. The production method comprises the following steps of cleaning fresh petals, carrying out pickling on the fresh petals by using granulated sugar, carrying out low-temperature fermentation on the fresh petals, pulping, grinding the fresh pedals into mud, carrying out high-temperature sterilization on the fresh petals for later use, filtering and cleaning fresh milk passing acceptance inspection, and storing the fresh milk for later use at 0-4 DEG C; and mixing the flower mud and the fresh milk according to a proportion, simultaneously adding an emulsifying agent to carry out homogenization treatment, introducing fermentation bacteria after sterilization, and carrying out constant-temperature fermentation on the fermentation bacteria to obtain a finished fresh flower yoghourt. The fresh flower yoghourt has the characteristics that the texture is delicate and uniform, uniform fluid is formed after stirring, and can be pulled to be filiform, an appearance does not have fine particles, the luster is bright, the surface is flat, smooth and bright, the fresh flower yoghourt has mellow smell with the combination of fragrance and fermented milk, and the fresh flower yoghourt is tender, sour and sweet.

Owner:HONGHE YUNNIU DAIRY IND

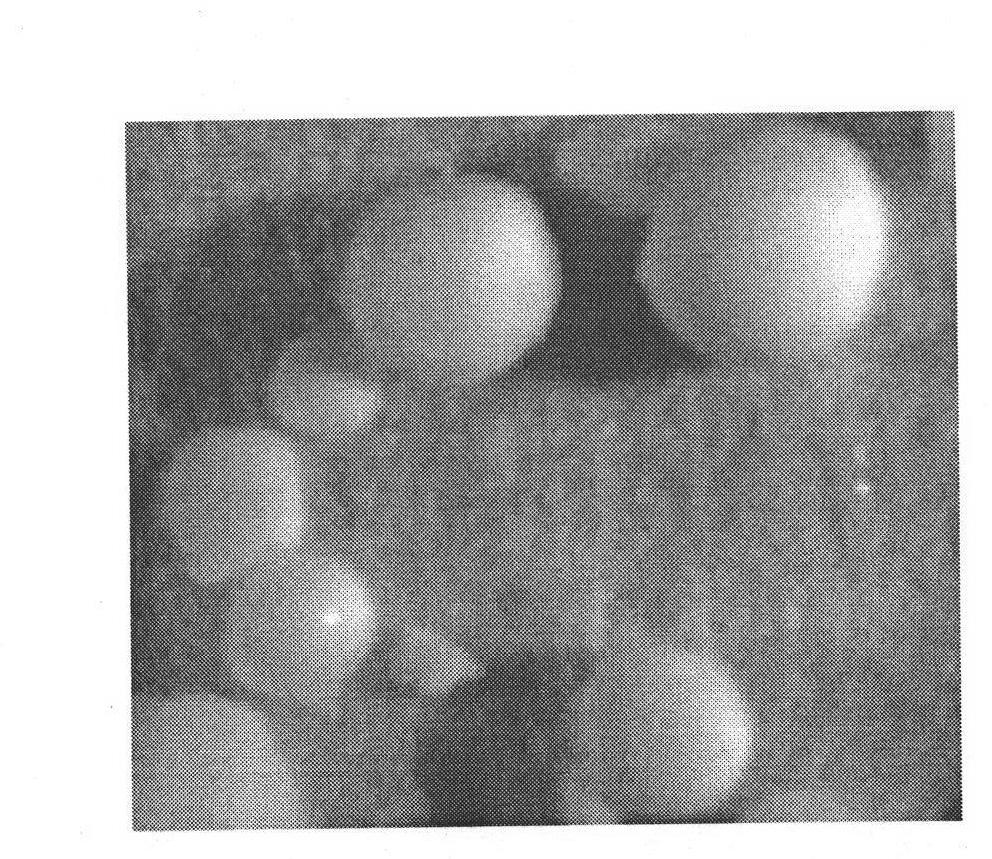

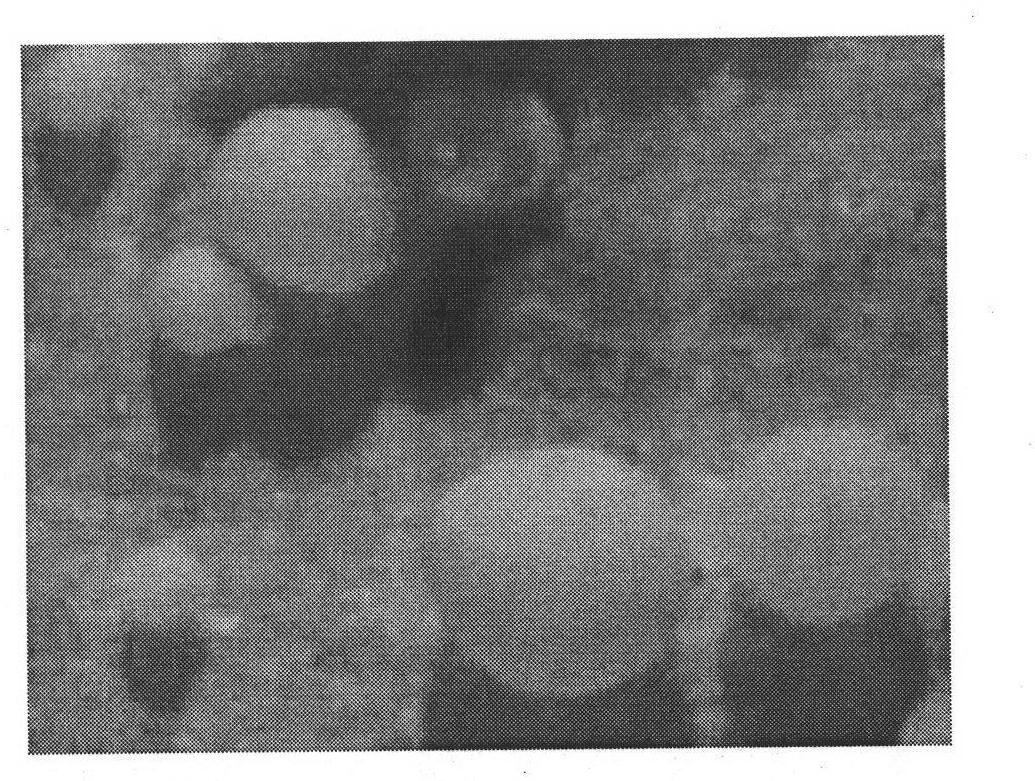

Preparation method of hydroxy apatite / polylactic acid / chitosan composite microballoon

InactiveCN102489231AImprove mechanical propertiesEvenly dispersedPharmaceutical non-active ingredientsMicroballoon preparationMicrosphereApatite

The invention discloses a preparation method of a hydroxy apatite / polylactic acid / chitosan composite microballoon. The hydroxy apatite / polylactic acid / chitosan composite microballoon is prepared by using hydroxy apatite HA, polylactic acid PLA and chitosan CS as raw materials and employing manufacturing principles of a solution blending method and an emulsion method. The method comprises steps of: dropping a prepared apatite / polylactic acid / chitosan acetate acid gracial solution into a stirred liquid paraffin / petroleum ether mixed liquor ; carrying out stewing; removing the liquid paraffin / petroleum ether mixed liquor; washing; carrying out stewing; and refrigerating drying to obtain the composite microballoon product. The hydroxy apatite / polylactic acid / chitosan composite microballoon of the invention compounds three materials with different performances to solve problems of strength, toughness and biocompatibility of the material; and the hydroxy apatite / polylactic acid / chitosan composite microballoon is mainly used in bone tissue restoration material, cell engineering and transmission of medicament and bioactive molecule.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Construction technology of interchange type bare concrete anti-collision guardrails

ActiveCN105755954AIncrease stirringQuality improvementBridge structural detailsSocial benefitsEconomic benefits

The invention relates to the technical field of building construction, in particular to a construction technology of interchange type bare concrete anti-collision guardrails.According to the construction technology of the interchange type bare concrete anti-collision guardrails, concrete template planning is reasonably performed, the template manufacturing and installation technology is improved, the release agent and concrete composition is selected, the concrete mixing and vibrating quality is improved, concrete demolding post-maintenance and protection are enhanced, and other means are adopted, so that the common quality problem of common concrete is eliminated, the overall appearance quality of bridge pier stud concrete is improved, the city appearance and city environment are beautified, and social benefits are improved.According to the construction technology, all construction procedures are improved, the construction scheme is optimized, concrete defects are reduced, the construction period is shortened, resources are saved, economic benefits are improved, and the popularization and application prospects are achieved.The interchange type bare concrete anti-collision guardrails are manufactured and installed, the formed anti-collision guardrails are consistent in color, and no obvious color aberration exists.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

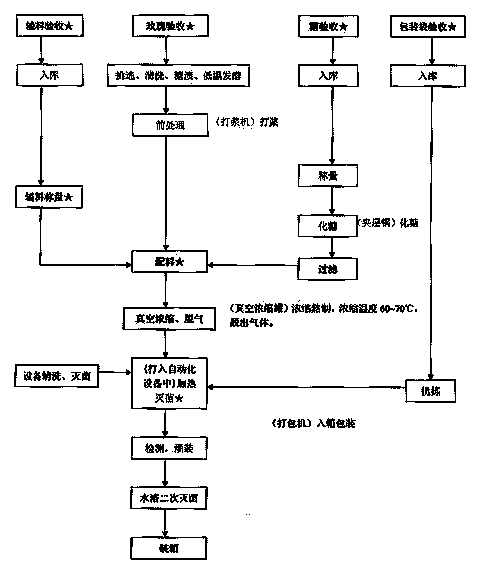

Processing method of tobacco stem and the device thereof

InactiveCN101095556AImprove the quality of sensory inhalationHigh fillingTobacco preparationTobacco treatmentPulp and paper industry

The invention relates to a method for treating tobacco stem, and device used for tobacco stem processing. The stem is stored for 1-6 hours after feeding process, and then is fed into drying and expanding process. The invention can improve tobacco stem quality and reduce cost.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Nickel-chromium-based alloy for porcelain teeth and preparation method thereof

ActiveCN102978445AStrong combinationConsistent appearance and colorImpression capsDentistry preparationsMetal substrateAluminium

The present invention provides a nickel-chromium-based alloy for porcelain teeth and a preparation method thereof. The alloy includes by weight: 22-25%chromium, 4-8% of molybdenum, 2-6% tungsten, 1-2% of aluminum, 0.5-1% of niobium, 1-2% of titanium, 1-2% of silicon, 0.2-0.5% of cerium, 0.1-0.4% of boron, and the balance being nickel. The ingredients in accordance with the chemical compositions of the claim 1 are loaded into a high temperature ceramic crucible and heated to melt in a vacuum intermediate frequency or high frequency furnace. The high-temperature molten solution is stirred for 5-10 seconds. The uniformly stirred molten solution is cast into a square mold or cylindrical mold. An ingot is formed after natural cooling. The surface attachments of the ingot are removed by sandblasting. Lastly the ingot is polished to the nickel-chromium-based alloy for the porcelain teeth. The strength, hardness and toughness of the alloy are moderate, the performances are close to imported products, the glaze layer and the metal substrate are solidly combined after porcelain, and the appearance is consistent in color, lifelike, and perfect.

Owner:洛阳北苑新材料技术有限公司

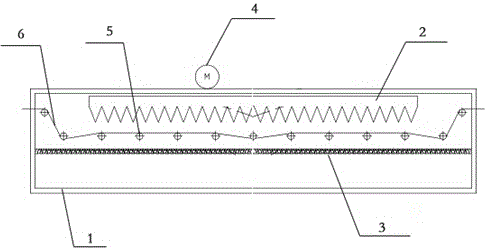

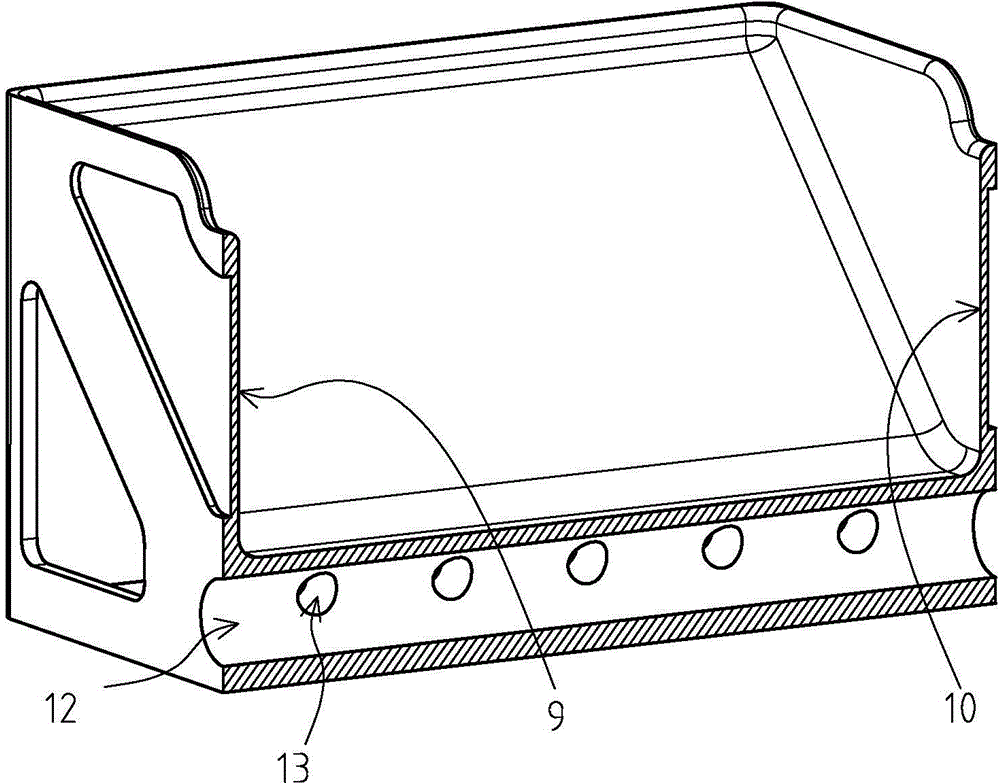

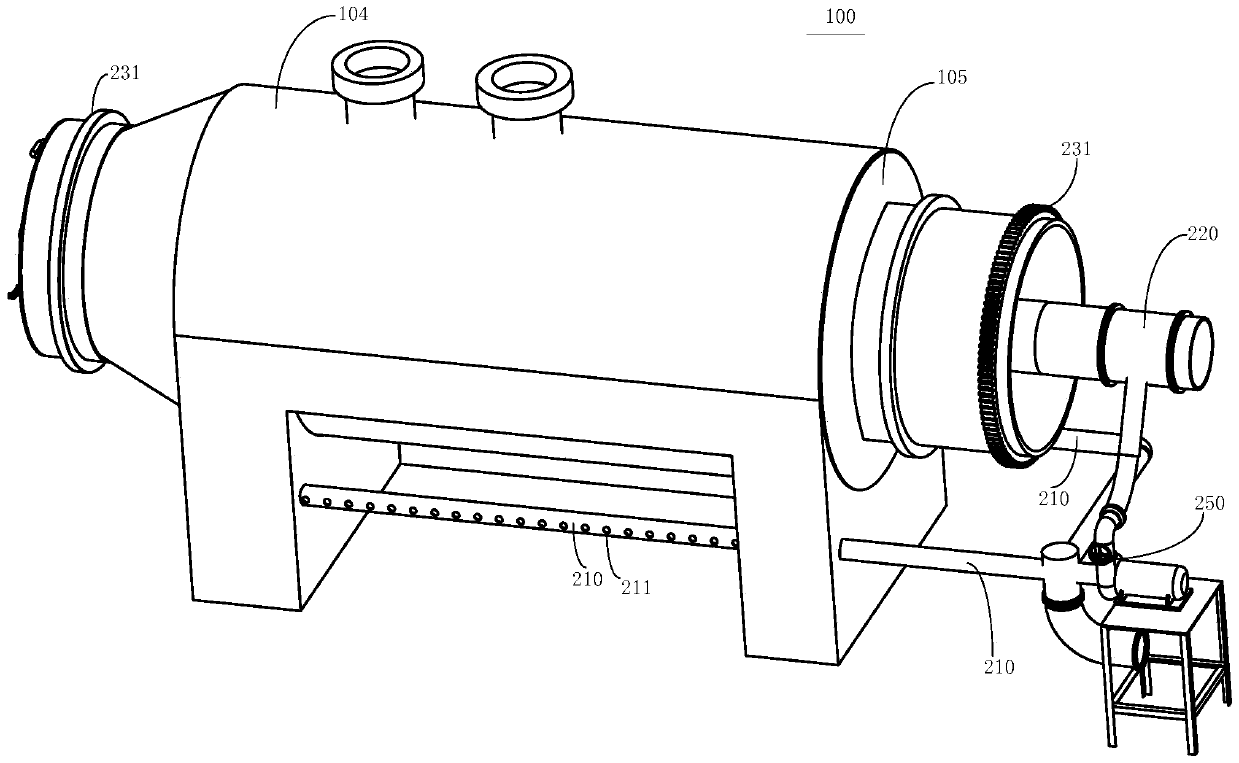

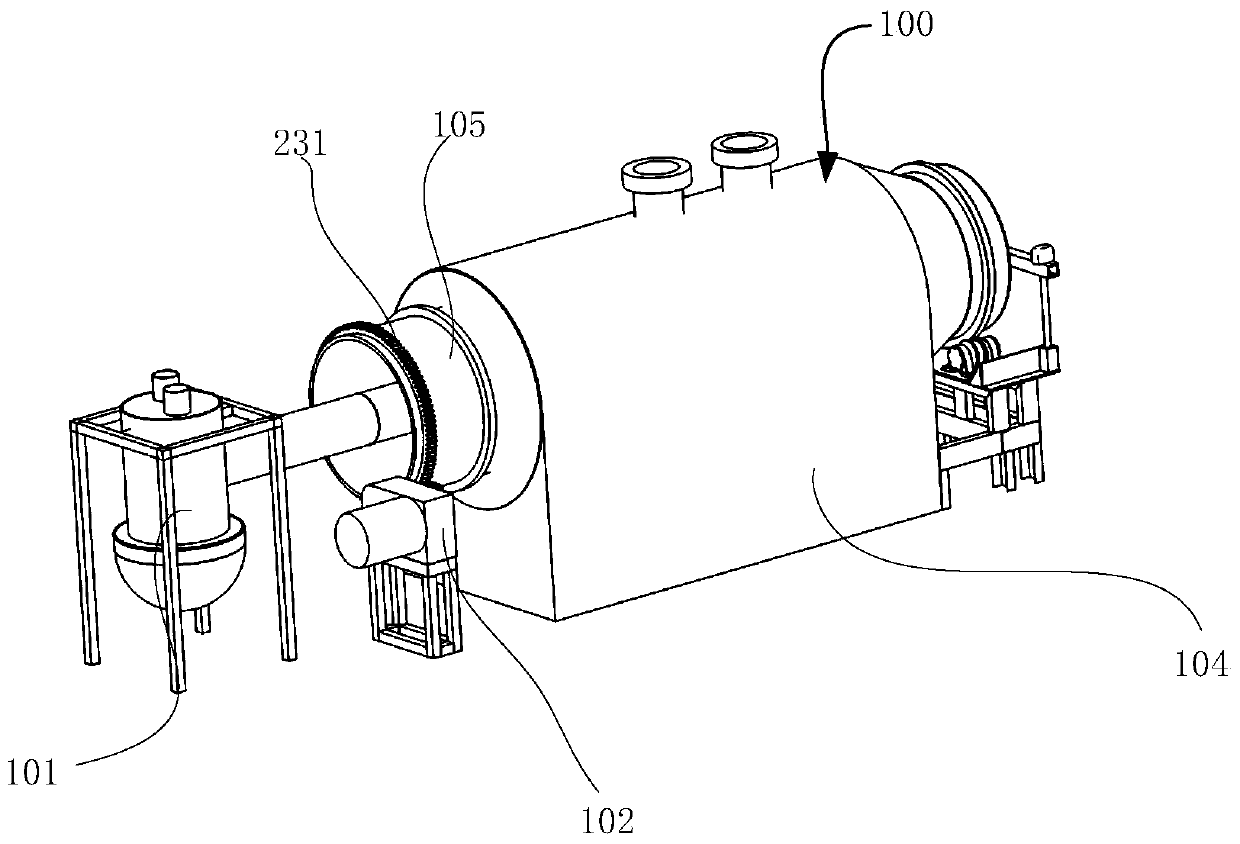

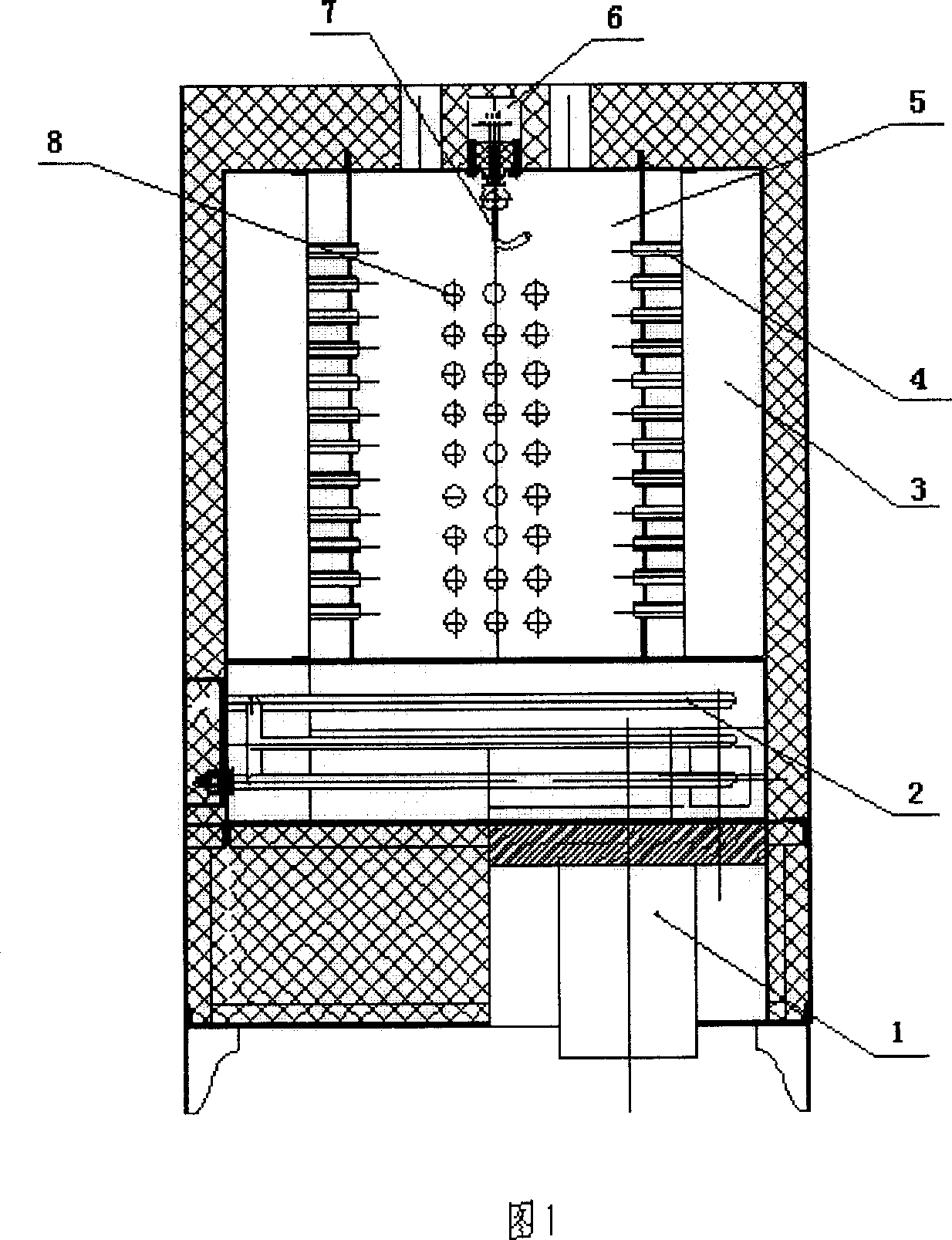

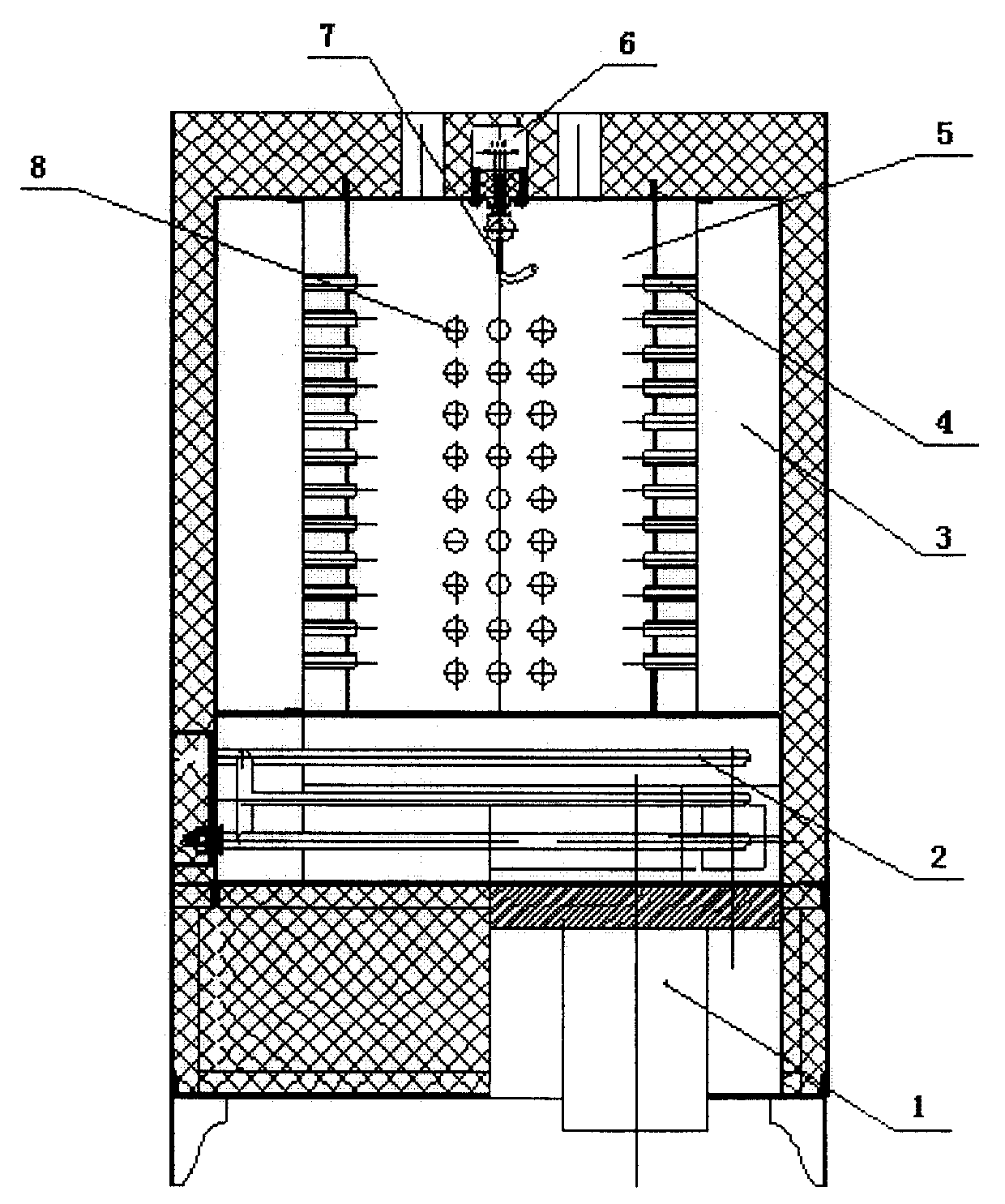

Drying box used for accumulator separator production

InactiveCN104534853AReduce manufacturing costReduce energy consumptionDrying gas arrangementsElectric energyWater pipe

The invention discloses a drying box used for an accumulator separator production. The drying box used for the accumulator separator production comprises a drying box body. A warm-air pipe is arranged on the top side the drying box body. A transferring device is arranged below the warm-air pipe. A condensate pipe is arranged below the transferring device. According to the drying box, drying can be carried out on accumulator separators by using the warm-air pipe, the production cost of the accumulator separators can be greatly lowered, meanwhile the energy consumption can be lowered and the electric energy can be saved. By means of the drying box, drying can be carried out deeply and thoroughly on the accumulator separators, and therefore the color difference of the front sides and the back sides of the accumulator separators is effectively improved so that the consistency in the appearance and color of the accumulator separators can be achieved. According to the drying box, the reaction liquid recycling rate of the accumulator separator production is greatly increased, the waste of the reaction liquid is effectively avoided, the shrinking percentage of the accumulator separators is lowered by 40% to 50%, and porosity characteristics of the accumulator separators are improved.

Owner:镇江奥美机电设备有限公司

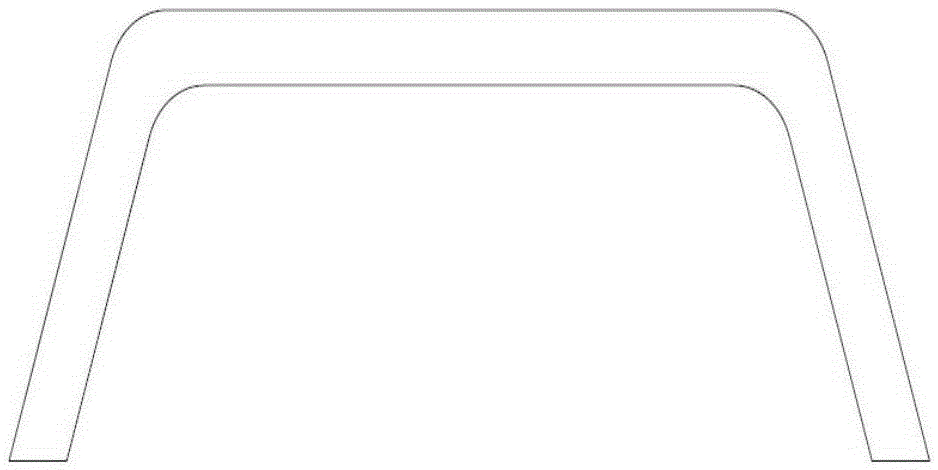

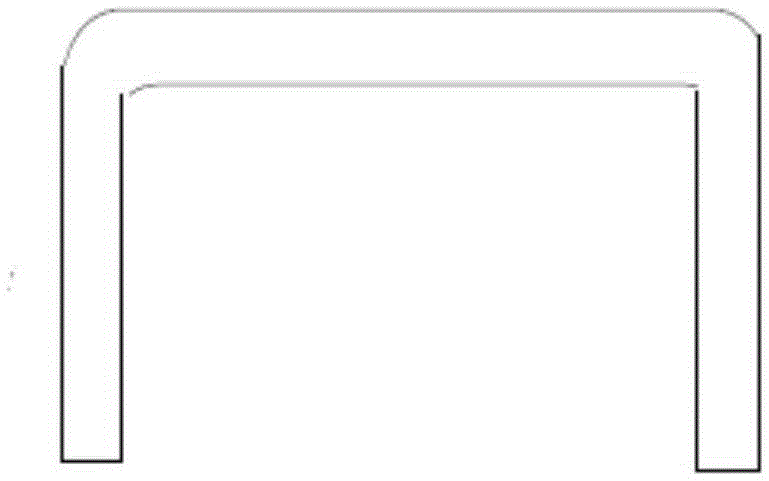

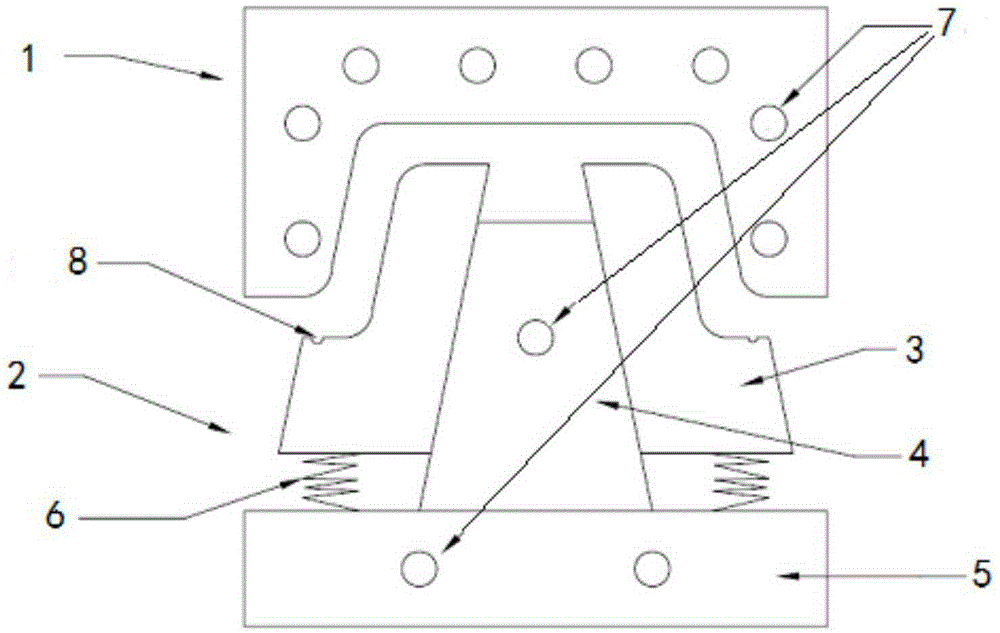

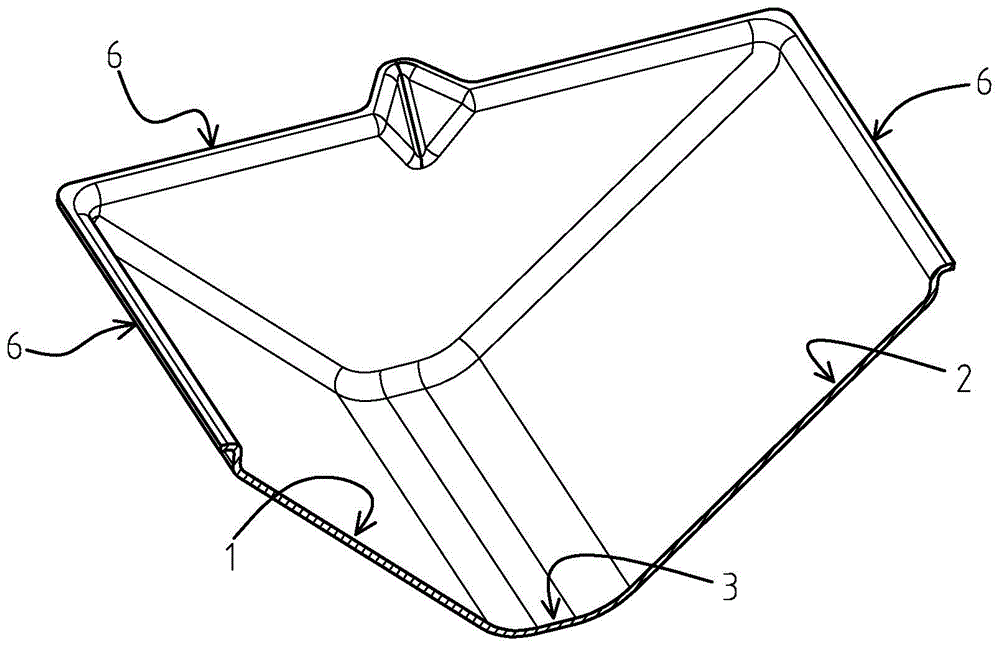

Device for manufacturing large-size U-shaped part

InactiveCN105235238AStable and uniform product sizeConsistent appearance and colorPultrusionEngineering

The invention discloses a device for manufacturing a large-size U-shaped part. As a hot pressing forming process is adopted, tension of the large-size U-shaped part in a traditional pultrusion process is avoided, and the parallel layer direction shearing strength of the large-size U-shaped part meets the requirement. As a sliding block spliced structure is adopted, the top, the left side and the right side of the large-size U-shaped part are stressed simultaneously during the mould pressing forming process; the stress on all the surfaces is gradually increased, so that the forming process requirements of thermosetting compound materials are met. Meanwhile, automatic demoulding of products is achieved, and the obtained products are stable and uniform in size and consistent in appearance color.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

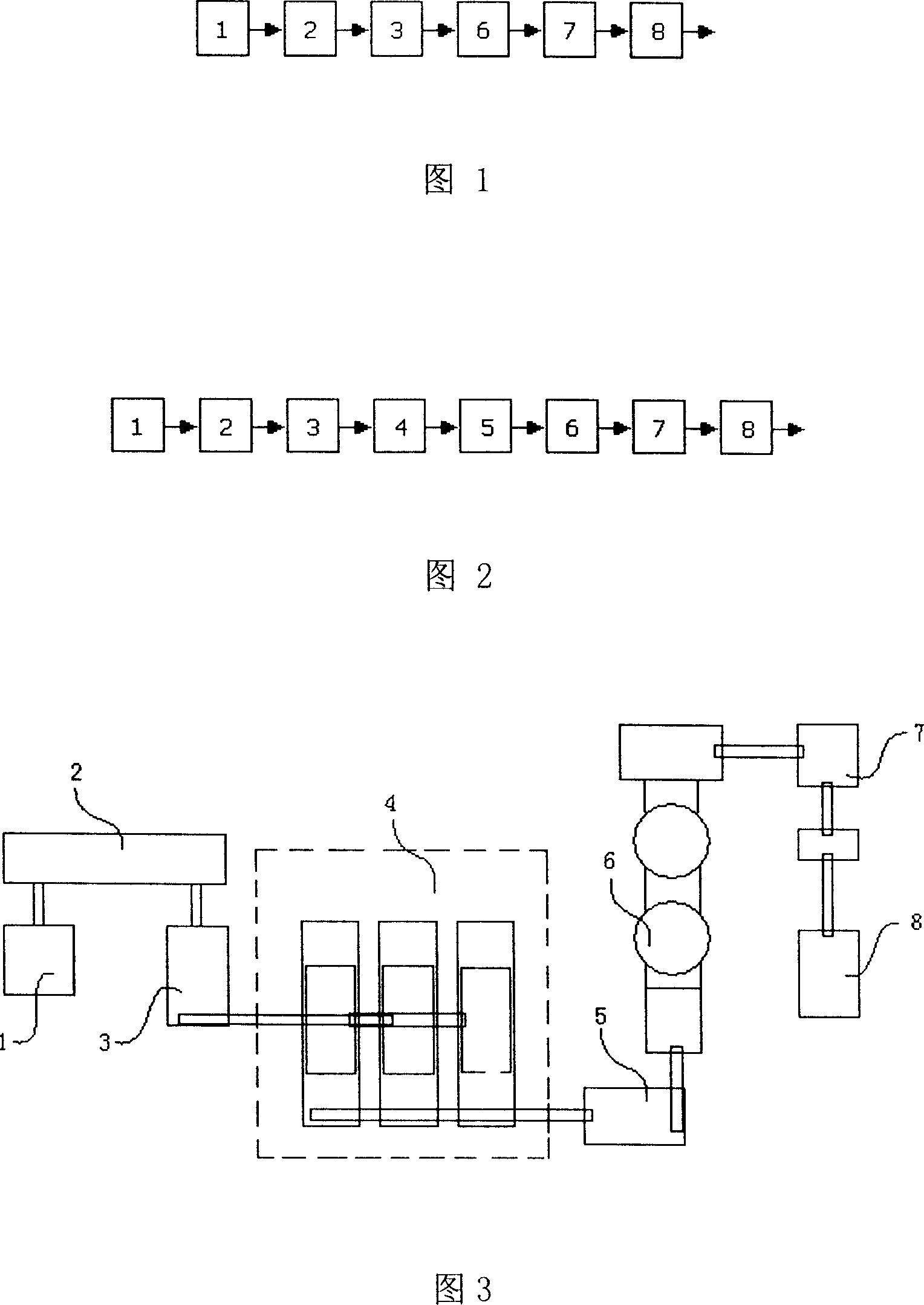

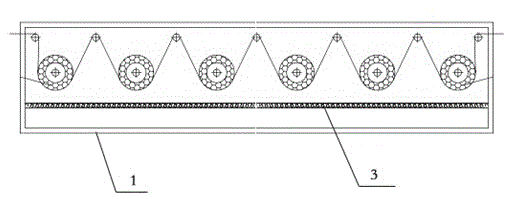

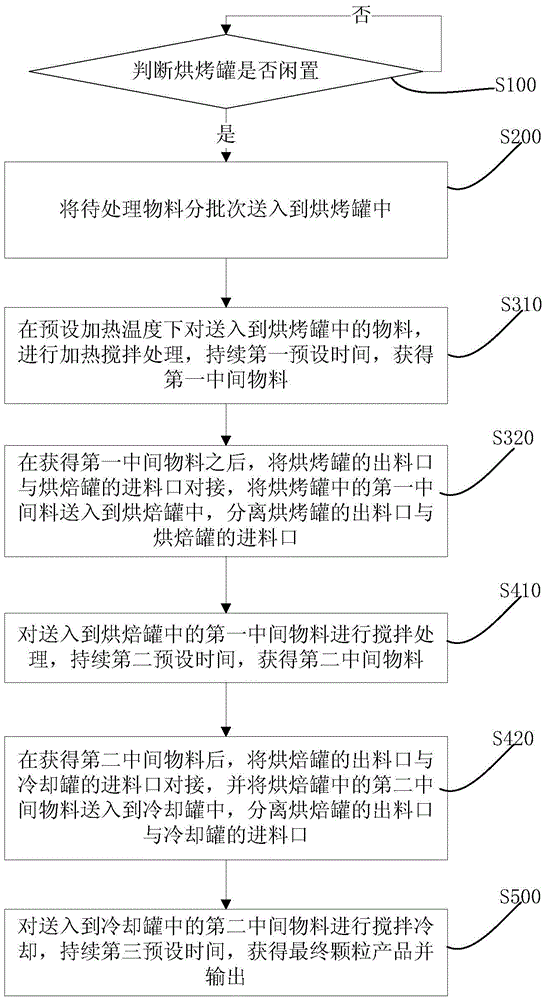

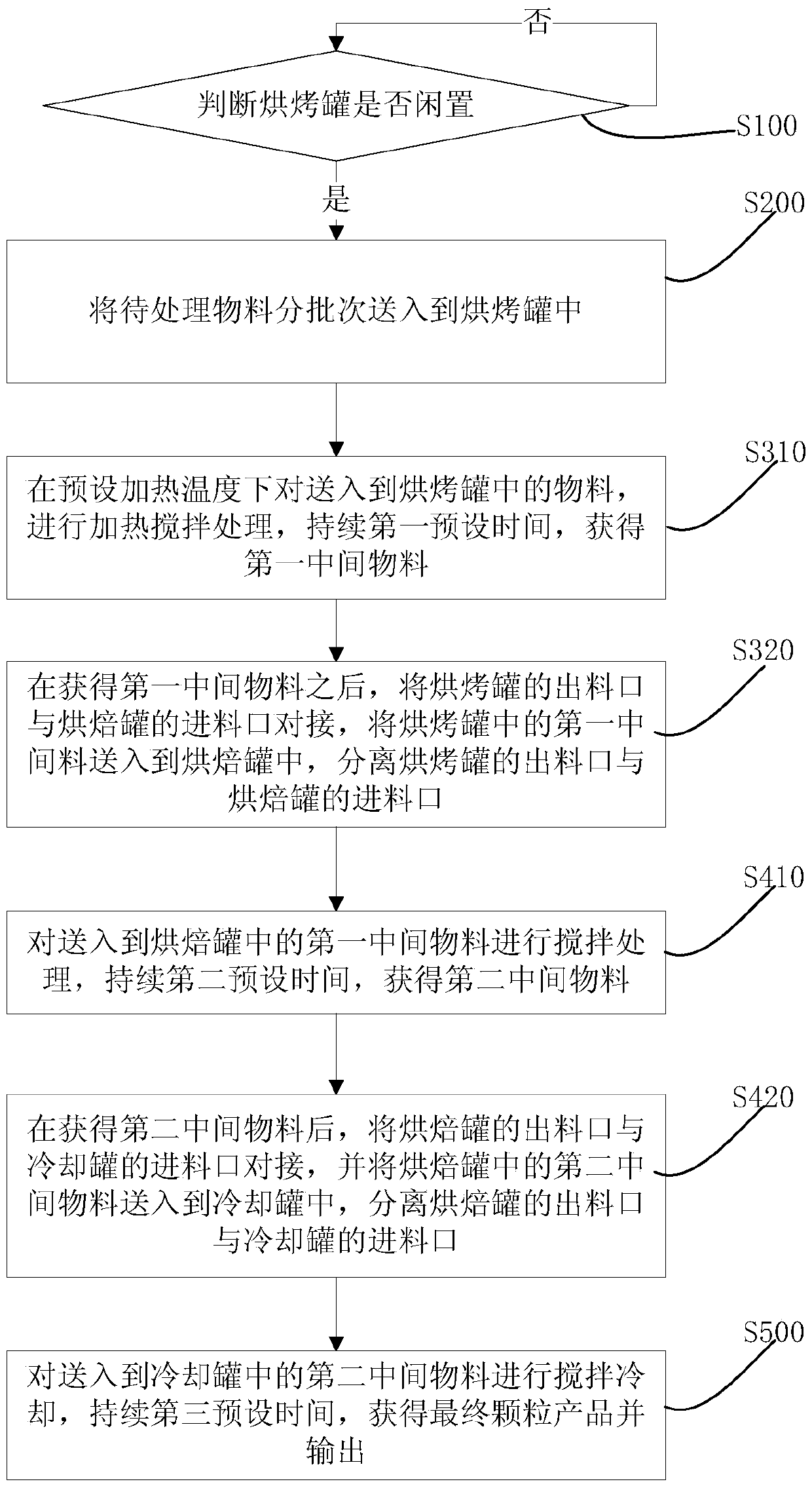

Three-tank type automatic particle production method and system

ActiveCN105536645AReduce waiting timeIncrease productivityBiofuelsGranulation in rotating drumsEngineeringProcess engineering

The invention relates to a three-tank type automatic particle production method and system. The method comprises the following steps: sending to-be-processed materials into a baking tank in batch when the baking tank is idle; heating and stirring the materials sent in the baking tank at a preset heating temperature for a first preset time, so as to obtain a first intermediate material, butting a discharging hole of the baking tank with a feeding hole of a roasting tank, sending the first intermediate material in the baking tank into the roasting tank, and separating a discharging hole of the baking tank from the feeding hole of the roasting tank. The three-tank type automatic particle production system is simple in structure and relatively high in production efficiency.

Owner:柏红梅

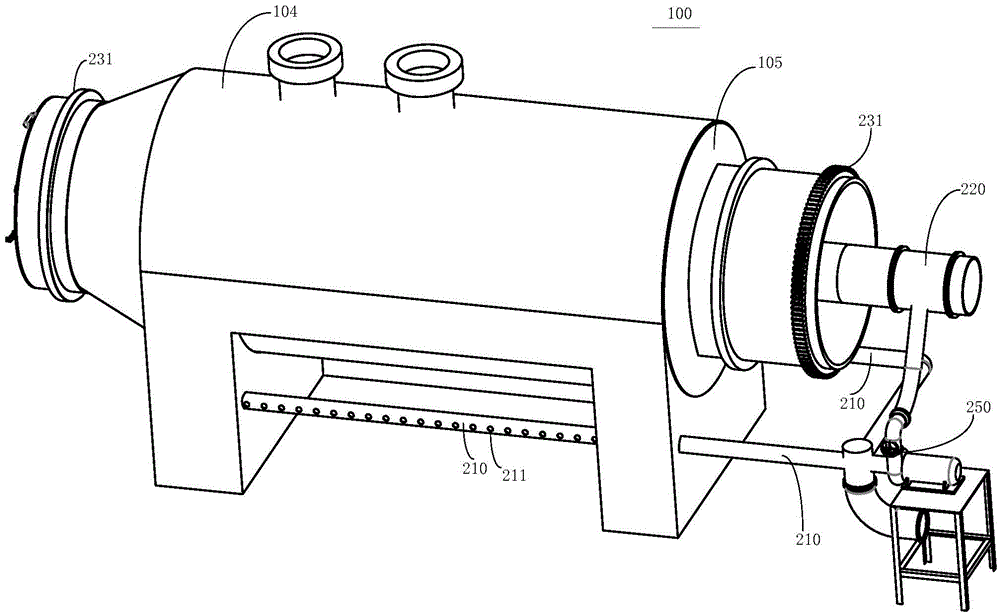

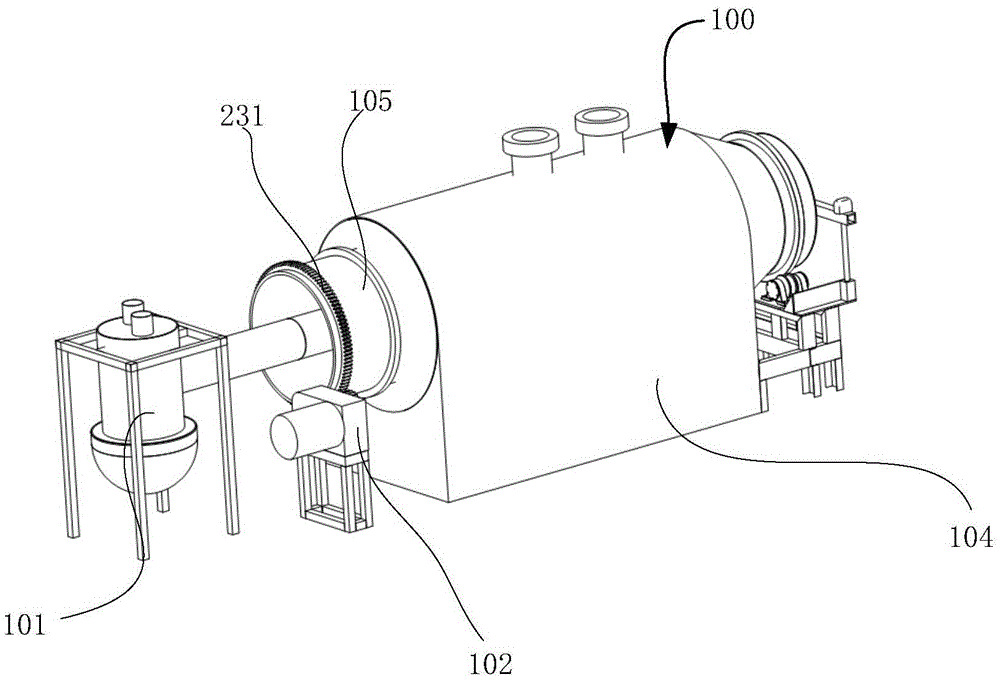

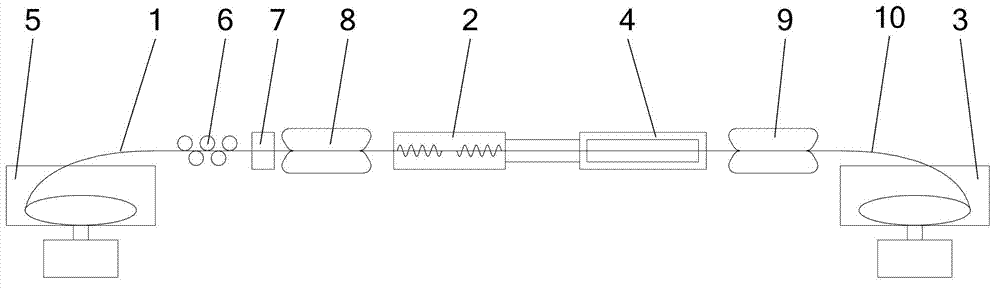

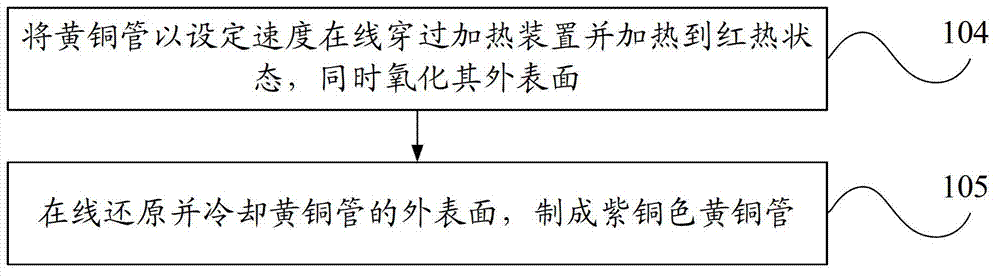

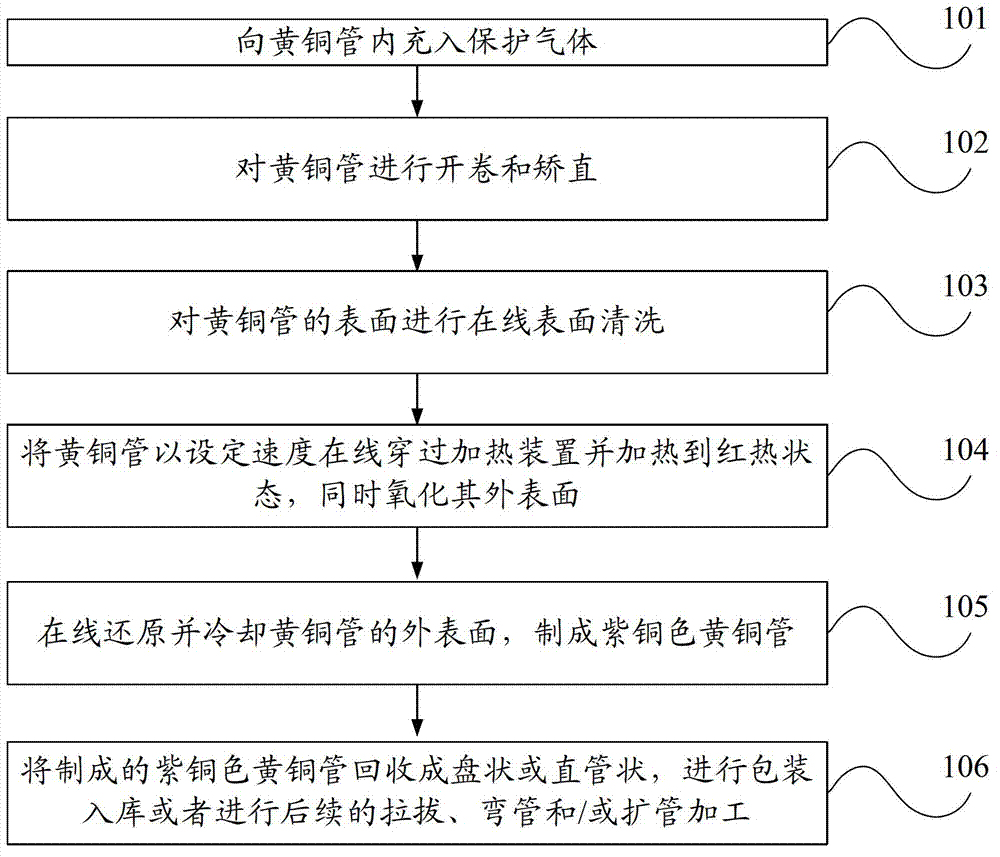

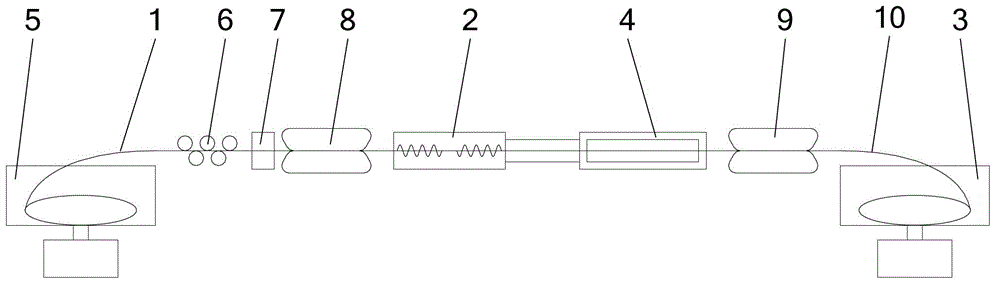

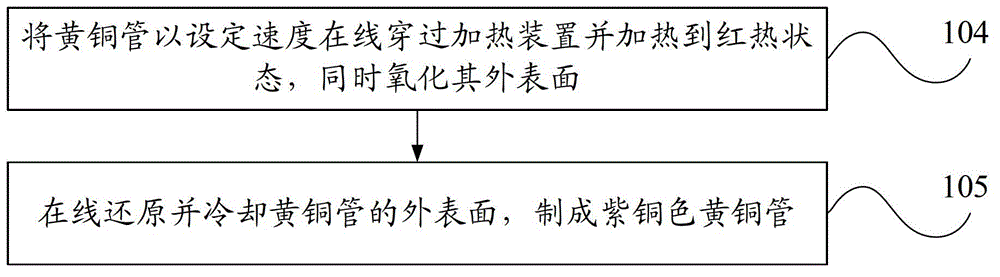

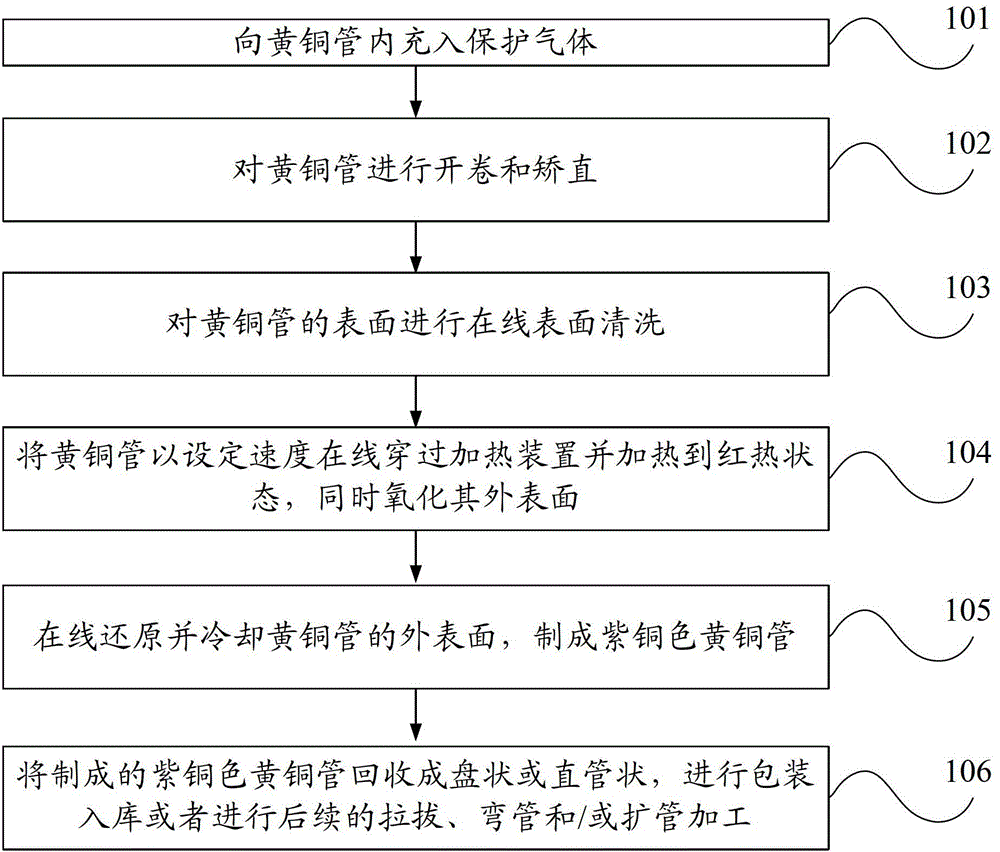

Purple bronze brass tube and manufacturing method and production line thereof

InactiveCN103243291ADense outer surfaceUniform outer surfaceSolid state diffusion coatingProduction lineShielding gas

The invention provides a purple bronze brass tube and a manufacturing method and production line of the purple bronze brass tube. The manufacturing method of the purple bronze brass tube comprises the following steps: allowing the brass tube to penetrate through the heating device on line at a set speed and heating to a red hot state, and oxidizing the outer surface; and reducing and cooling the outer surface of the brass tube on line, and manufacturing the purple bronze brass tube. The purple bronze brass tube production line comprises a heating device and a reduction tank, wherein reducing and cooling liquid is filled in the reduction tank. Compared with the prior art, the manufacturing method of the purple bronze brass tube has the advantages that process steps are less, yield is high, production efficiency of the purple bronze brass tube is high, lots of brass tube pickling process are eliminated in the related technology, the outer protective gas of the brass tube is canceled, the manufacturing cost is obviously reduced, the brass tube is energy-saving and environment-friendly, the manufactured purple bronze brass tube is dense and uniform in outer surface and can serve as a finished tube, drawing, bending, tube expanding and other subsequent treatment can be performed, and the color layer does not drop.

Owner:JIANGSU XINGRONG HI TECH

Novel method for electroplating gold on surface of molybdenum-copper alloy

InactiveCN113445090ADo not deviate from the essenceDo not deviate from the rangeElectrophoretic coatingsElectroless nickelBinding force

The invention relates to a novel method for electroplating gold on the surface of molybdenum-copper alloy, and belongs to the technical field of metal surface treatment. The method comprises the seven steps that acid pickling is conducted through an acid pickling solution composed of nitric acid with the volume fraction being 390-410 ml / L, sulfuric acid with the volume fraction being 390-410 ml / L and water with the volume fraction being 180-220 ml / L, activation is conducted through hydrochloric acid with the volume fraction being 45-55%, and chemical coarsening is conducted through an anode etching coarsening solution of sulfuric acid with the volume fraction being 650-750 ml / L. On the basis that flash nickel plating is directly conducted in a chemical nickel solution and then chemical nickel plating is conducted to form a nickel plating layer, good binding force of the plating layer and a base material is achieved, the binding force of the gold-plated layer and the base material and the welding performance of gold-tin solder to the gold-plated layer are enhanced, the gold-tin solder is good in wettability on the surface of the gold-plated layer after being baked for 10 min at the high temperature of 350 DEG C, the gold-plated layer does not blister or discolor, the thickness is uniform, the color is consistent, the environment is not polluted, and the cost is low. The method is suitable for machining all workpieces including precise workpieces and workpieces with complex shapes.

Owner:JINGZHOU NANHU MACHINERY CO LTD

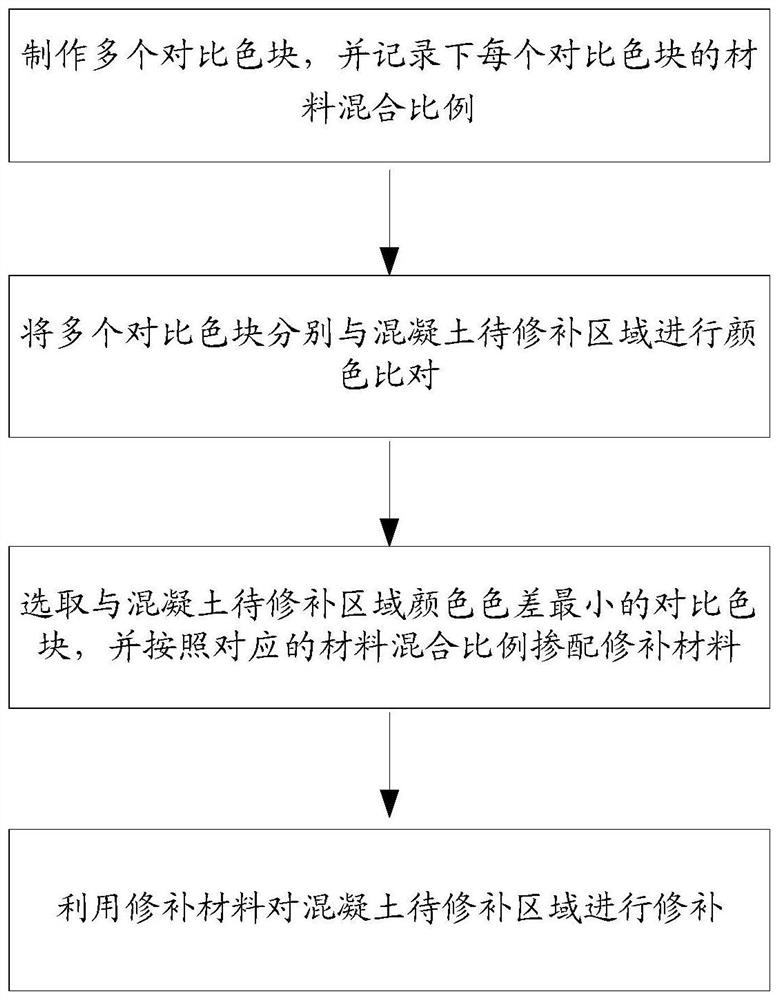

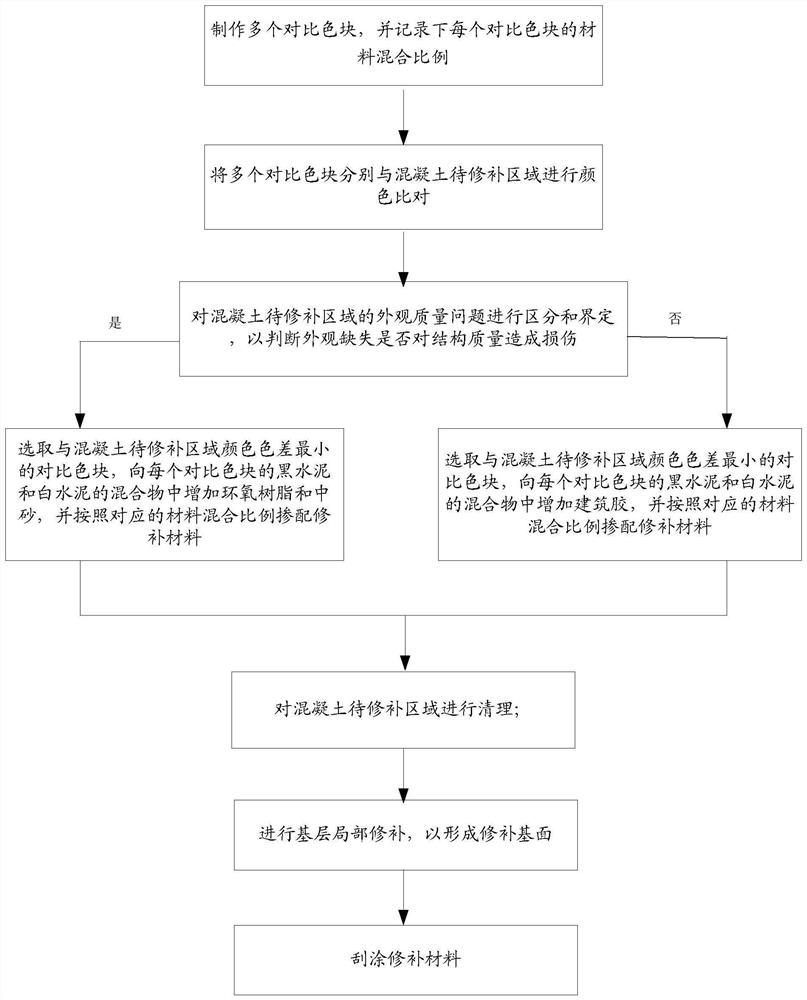

Repair method of concrete structure

InactiveCN111622522AConsistent appearance and colorAlleviate appearance quality issuesBuilding repairsArchitectural engineeringRepair material

The invention provides a repair method of a concrete structure, and relates to the technical field of concrete. The repair method of the concrete structure comprises the steps that multiple contrast color blocks are manufactured, and the material mixing proportion of each contrast color block is recorded; the multiple contrast color blocks and the concrete to-be-repaired area are subjected to color contrasting; the contrast color block with the minimum color difference with the concrete to-be-repaired area is selected, and a repair material is blended according to the corresponding material mixing proportion; and the concrete to-be-repaired area is repaired through the repair material. Due to the fact that the contrast color blocks of different colors are used for being subjected to colorcontrasting with the concrete to-be-repaired area, the color of the repair material can be similar to the color of the concrete to-be-repaired area to the greatest extent, after repair is finished, the appearance colors of the concrete structure can tend to be consistent, and the problem of the appearance quality of the concrete structure is relieved.

Owner:CHINA FIRST HIGHWAY ENG +1

Method for producing corn husks sprayed with corn steep liquor through two-stage technology

PendingCN110089626AReduce contact timeEvenly heatedFood processingAnimal feeding stuffWater contentCorn starch

The invention discloses a method for producing corn husks sprayed with corn steep liquor through a two-stage technology, and belongs to the technical field of processing of corn starch by-products. The method comprises the following steps of drying corn fibers through tube bundle drying until the water content is 8%-12%, adding corn steep liquor to the dried corn fibers, drying the corn fibers through tube bundle drying once again until the water content is 8%-12%, to obtain corn fibers with corn steep liquor addition in advance, performing crushing and screening, adding the corn steep liquoronce again, and performing uniform mixing so as to obtain corn fibers with corn steep liquor addition; and performing airflow drying on the corn fibers with corn steep liquor addition, so that the water content of the corn fibers with corn steep liquor addition, after the airflow drying, is reduced to 8%-12% and the corn husks sprayed with the corn steep liquor can be obtained. According to the method disclosed by the invention, the problem of low protein content caused by product color differences and low corn steep liquor addition quantity can be solved; the products prepared by the method are uniform and consistent in color and free of color differences; and besides, the corn steep liquor addition quantity and the protein content of the products are notably increased than those througha traditional technology, and the corn husks sprayed with the corn steep liquor are suitable for being used as a feed.

Owner:绥化象屿金谷生化科技有限公司

Fertilizer anti-caking wrapping agent and preparation method thereof

InactiveCN110790599ATo achieve the purpose of anti-cakingConsistent appearance and colorSolid/semi-solid fertilisersFertilizer mixturesVegetable oilActive agent

The invention discloses a fertilizer anti-caking wrapping agent which comprises the following components in parts by weight: 25-45 parts of liquid wax oil, 10-20 parts of temperature-resistant black,28-48 parts of fatty acid derivatives, 6-11 parts of multi-carbon alcohol, 5-10 parts of a surfactant, 0.5-1 part of a defoaming agent, 5-10 parts of a phosphate, 20-30 parts of water-soluble macromolecules and 30-40 parts of water. The invention has the beneficial effects that the vegetable fat raw material is used as a basic raw material, is fully degradable, environment-friendly and pollution-free, and has a good anti-caking effect; hydrophilic water-soluble polymer substances are spread on the surface of a fertilizer, so that the activity of water molecules is reduced, the "dissolution-crystallization process" among fertilizer particles is hindered, and the anti-caking purpose of the fertilizer is achieved; the surfactant is used for improving the spreadability of the water-based fertilizer polymer substances on the surface of the chemical fertilizer; low-carbon alcohol and water are mainly used as carriers of the anti-caking agent; and the temperature-resistant black coats the fertilizer by the fertilizer anti-caking agent, so that the fertilizer is black and has strong temperature resistance and covering performance.

Owner:WUHAN QIANGSHENG TECH CO LTD

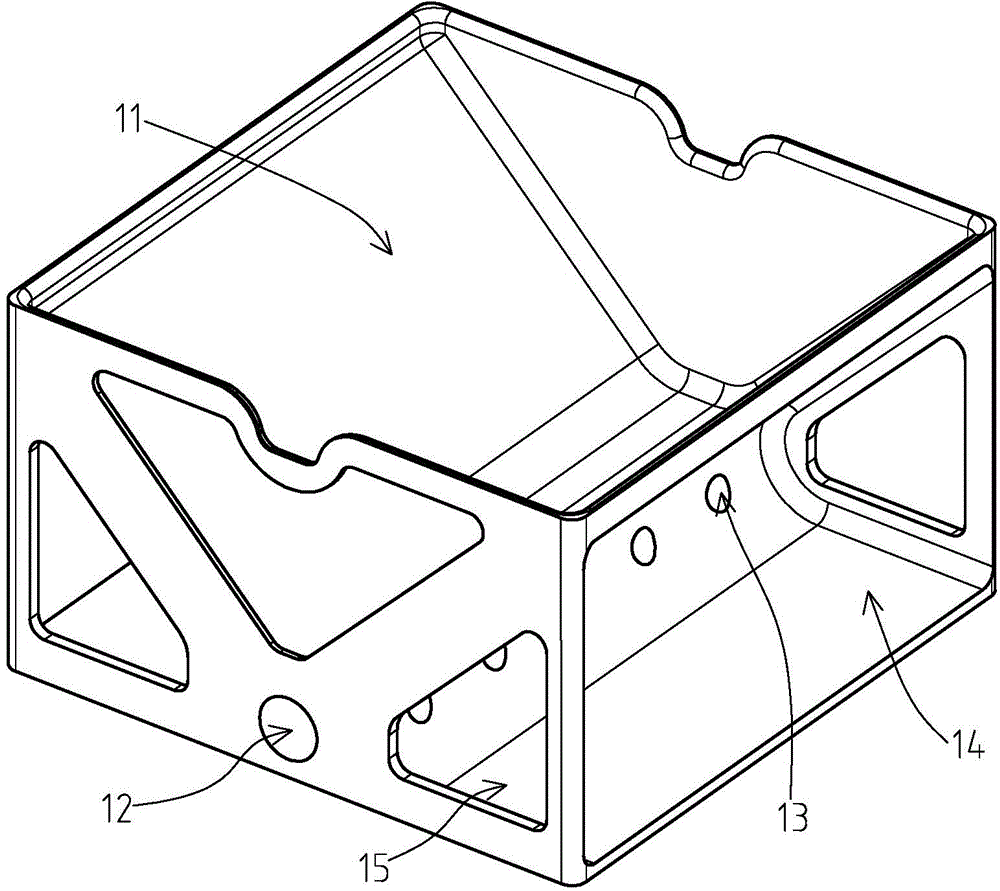

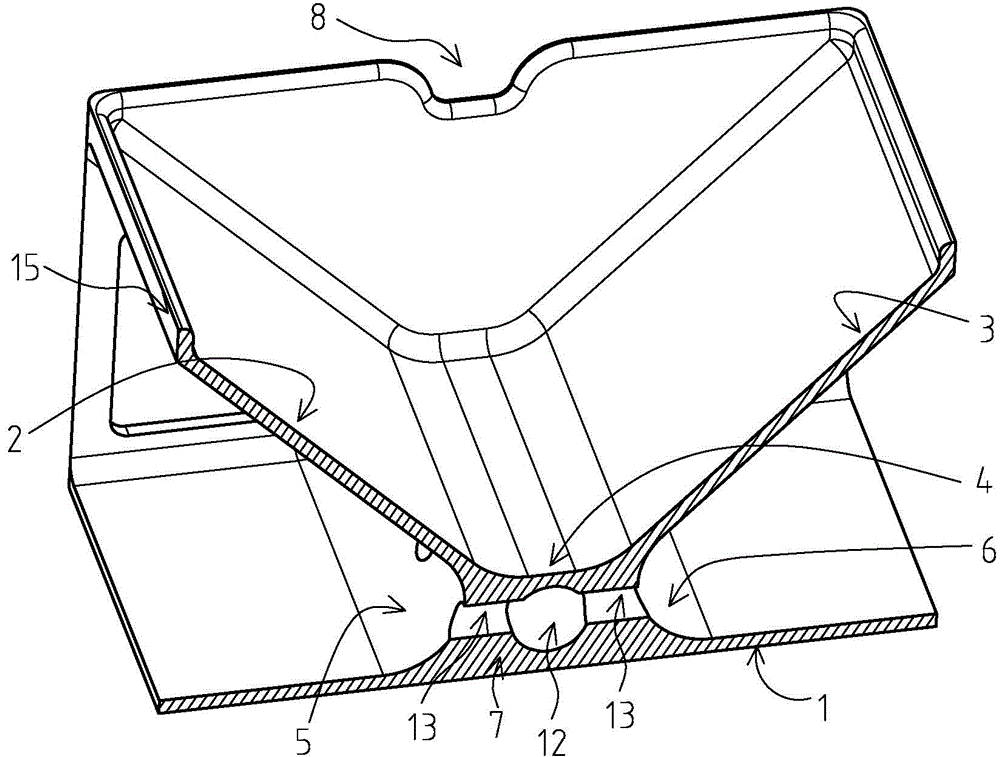

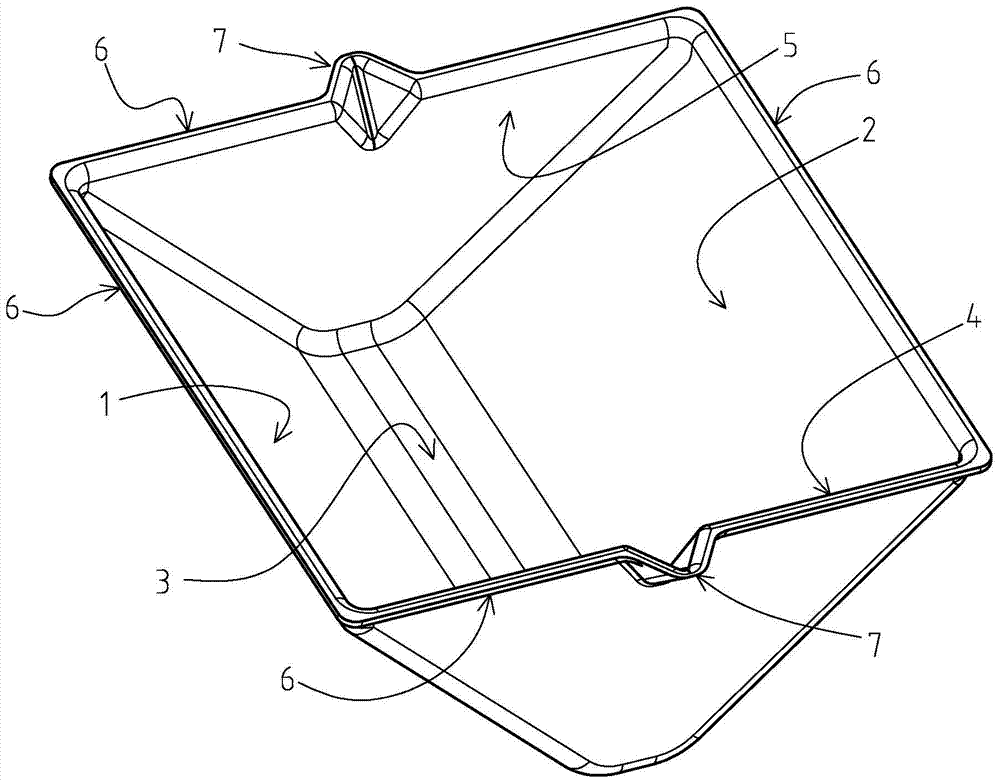

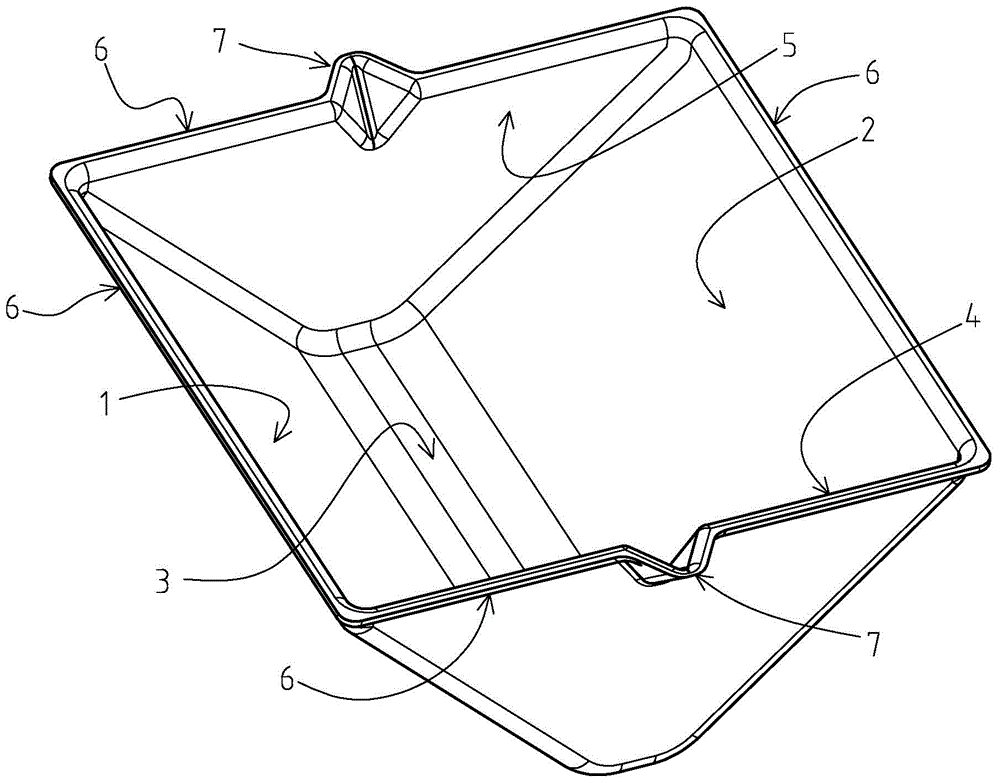

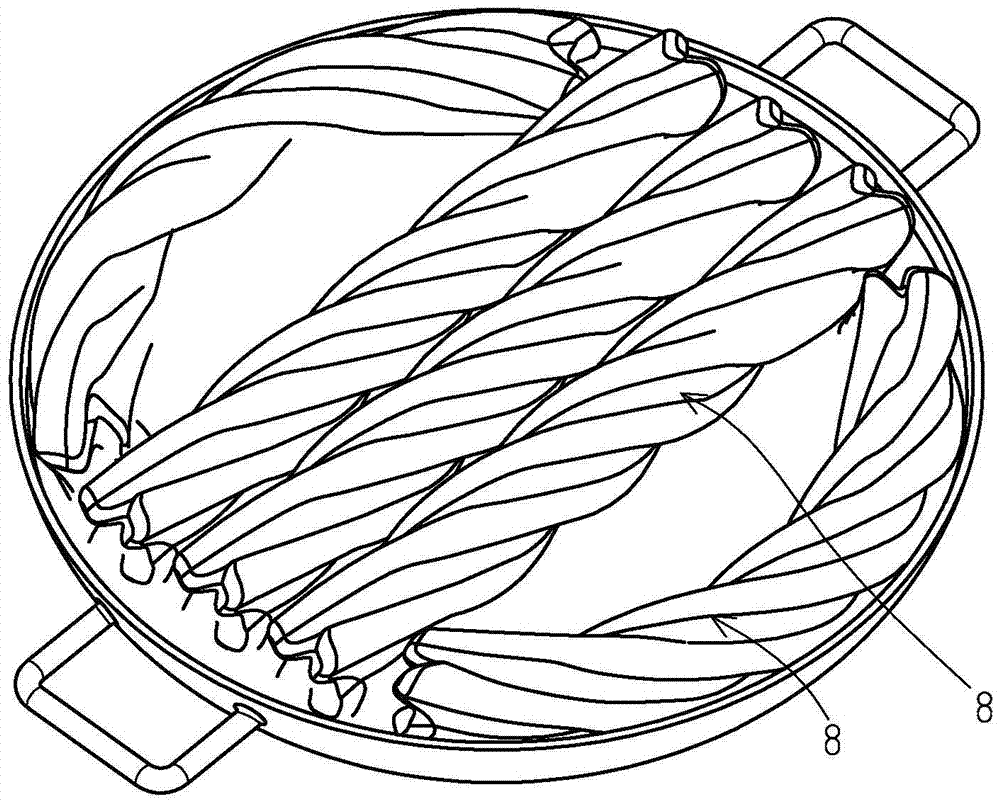

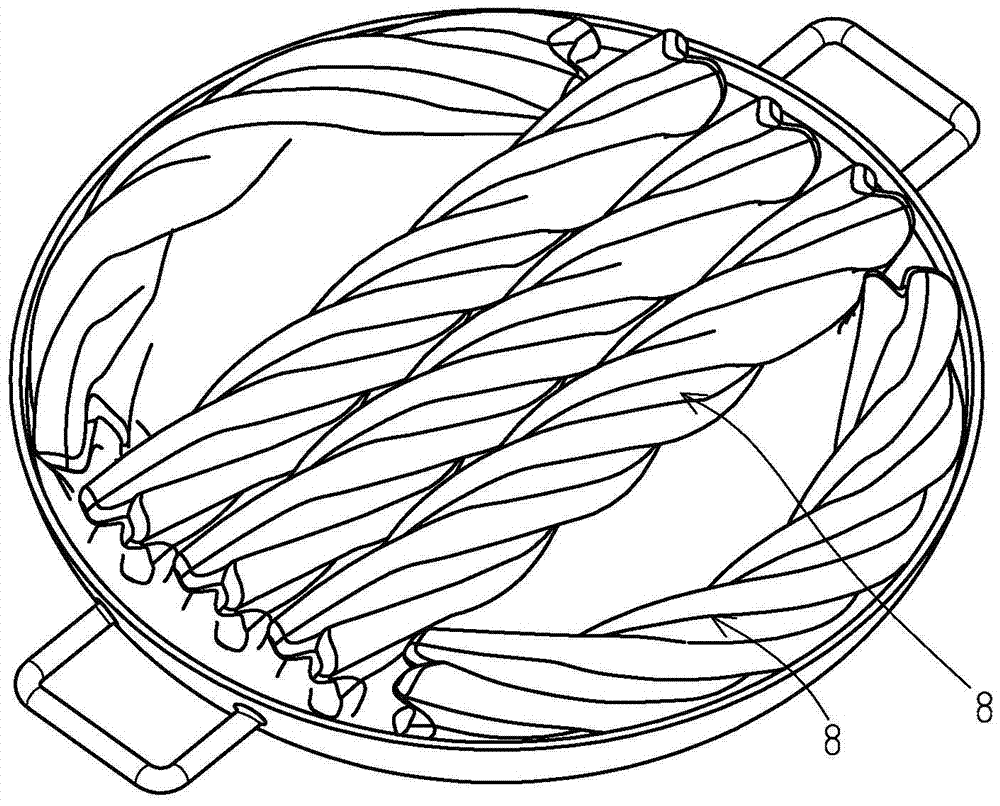

Design method for cooker support of cooker used for manufacturing fried bread sticks

The invention particularly relates to a design method for a cooker support of a cooker used for manufacturing fried bread sticks. The design method for the cooker support of the cooker used for manufacturing the fried bread sticks comprises a first containing cavity used for containing a lining matched with the cooker, and is characterized in that the first containing cavity is arranged to be in a shape with the wide upper portion and the narrow lower portion, a main heating area is arranged at the bottom of the first containing cavity in the longitudinal direction, and auxiliary heating areas are arranged on the two sides of the containing area; a first through hole communicated with the outside is formed in the bottom of the cooker support in the longitudinal direction, a second through hole communicated with the first through hole is formed in the bottom of the cooker support in the transverse direction, and the first through hole and the second through hole are formed in a heat collecting area at the bottom of the cooker support. The cooker support designed with the design method is used for conducting main heating and auxiliary heating, and oil in the lining further generates flow enabling the fried bread sticks to easily overturn; the through holes formed in the bottom of the cooker can be matched with a handle and a cover of the cooker to generate the chimney effect, and airflow enabling the fried bread sticks to easily overturn is further generated.

Owner:龚柱

Preparation method of hydroxy apatite / polylactic acid / chitosan composite microballoon

InactiveCN102489231BSolving Miscibility DifficultiesEasily hydrolyzedPharmaceutical non-active ingredientsMicroballoon preparationMicrosphereApatite

The invention discloses a preparation method of a hydroxy apatite / polylactic acid / chitosan composite microballoon. The hydroxy apatite / polylactic acid / chitosan composite microballoon is prepared by using hydroxy apatite HA, polylactic acid PLA and chitosan CS as raw materials and employing manufacturing principles of a solution blending method and an emulsion method. The method comprises steps of: dropping a prepared apatite / polylactic acid / chitosan acetate acid gracial solution into a stirred liquid paraffin / petroleum ether mixed liquor ; carrying out stewing; removing the liquid paraffin / petroleum ether mixed liquor; washing; carrying out stewing; and refrigerating drying to obtain the composite microballoon product. The hydroxy apatite / polylactic acid / chitosan composite microballoon of the invention compounds three materials with different performances to solve problems of strength, toughness and biocompatibility of the material; and the hydroxy apatite / polylactic acid / chitosan composite microballoon is mainly used in bone tissue restoration material, cell engineering and transmission of medicament and bioactive molecule.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

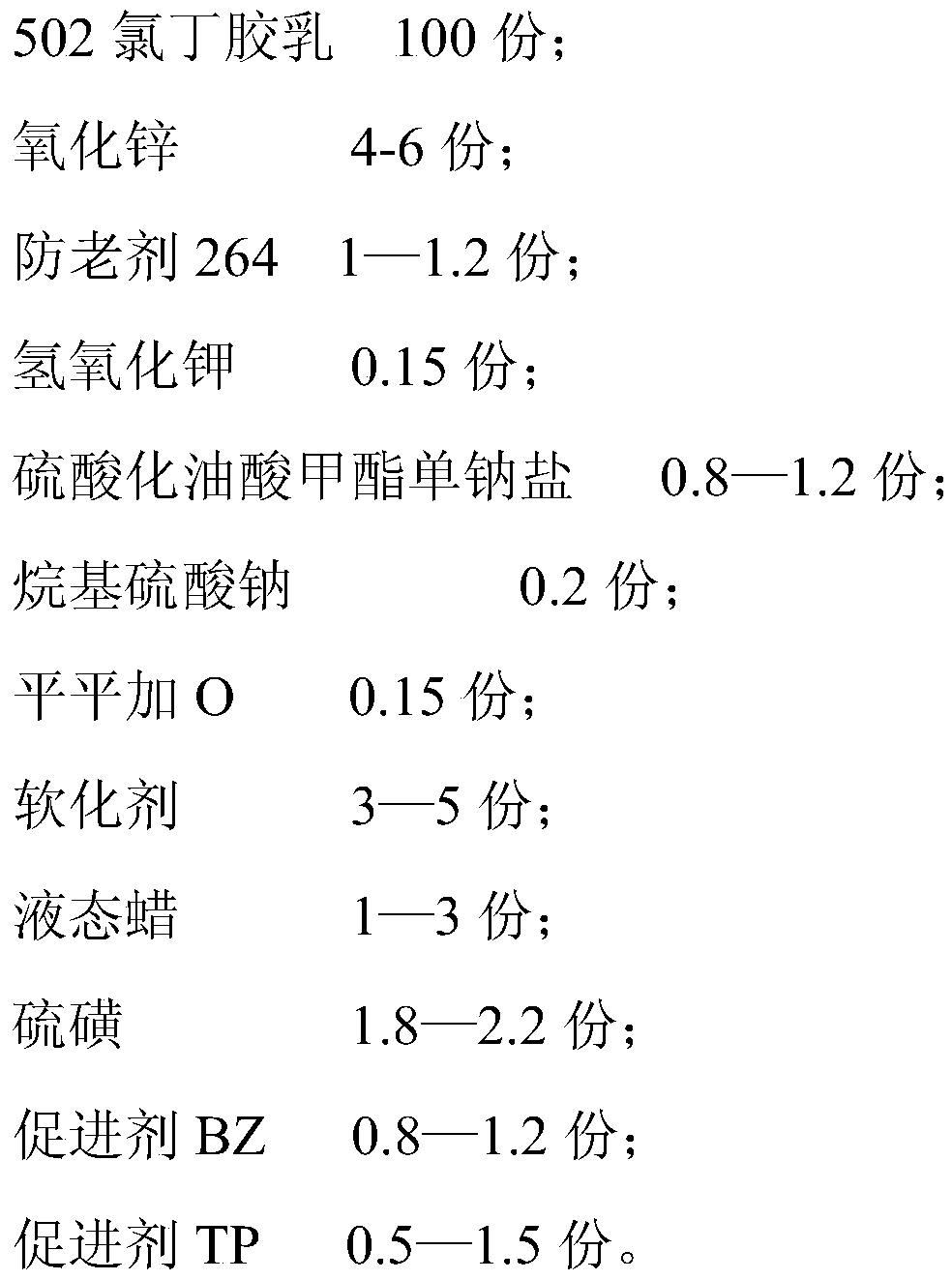

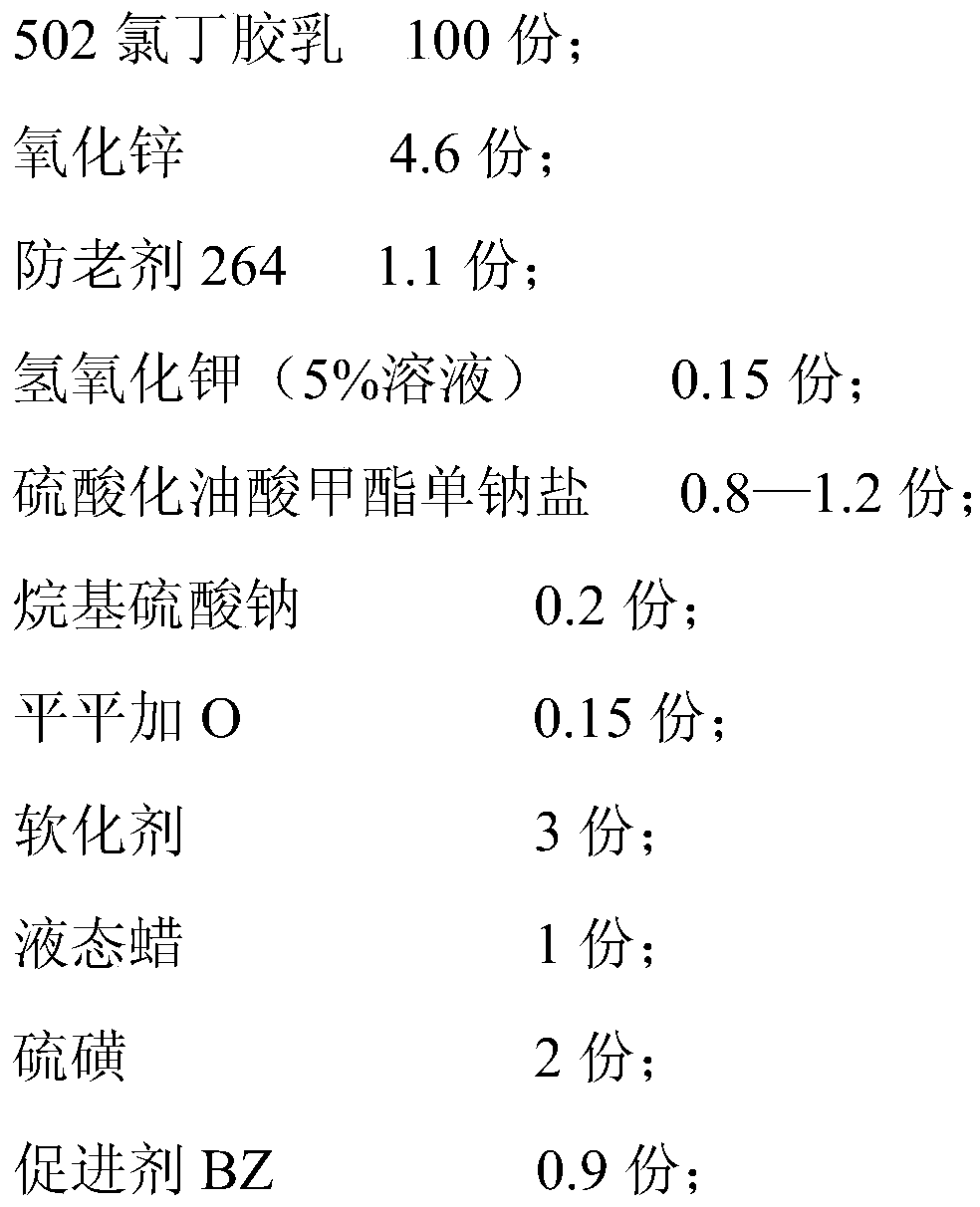

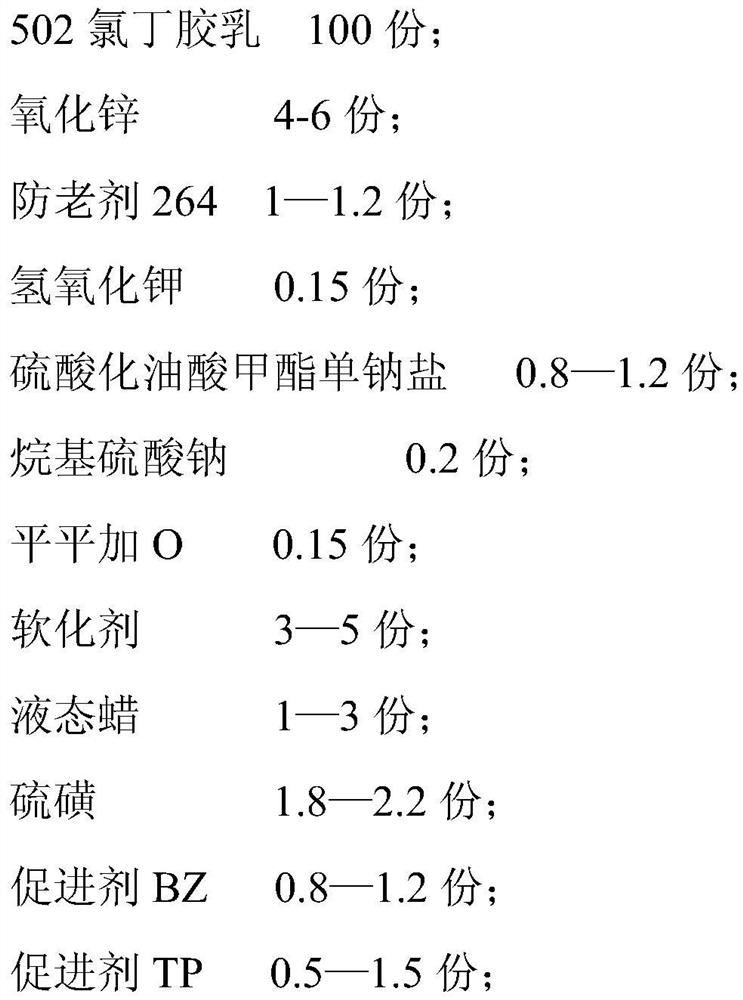

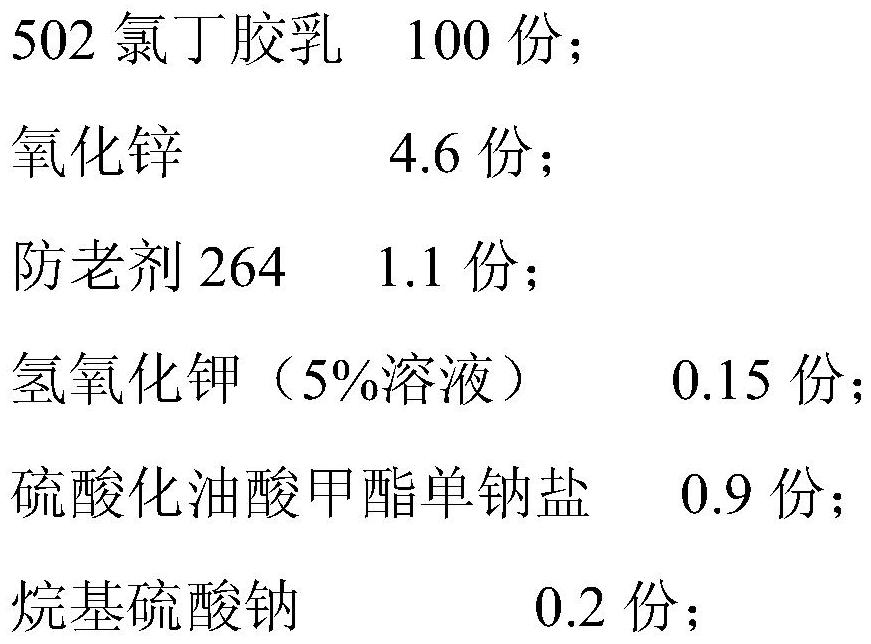

Neoprene anesthesia air storage bag

ActiveCN110054819AConsistent appearance and colorSurface is clean and free from blemishesWaxPotassium hydroxide

The invention relates to a neoprene anesthesia air storage bag, and belongs to the technical field of anesthesia air storage bags. The neoprene anesthesia air storage bag is characterized by comprising, based on 100 parts of dry glue, 100 parts of 502 neoprene latex, 4-6 parts of zinc oxide, 1-1.2 parts of anti-aging agents 264, 0.15 part of potassium hydroxide (5% solution), 0.8-1.2 parts of sulfated methyl oleate monosodium salts, 0.2 part of sodium alkyl sulfate, 0.15 part of peregal O, 3-5 parts of softeners, 1-3 parts of liquid wax, 2 parts of sulphur, 0.5-1.5 parts of accelerants TP and0.9 part of accelerant BZ. The neoprene anesthesia air storage bag has the advantages that the risk that existing natural rubber anesthesia air storage bags causes allergy to patients is avoided, appearance, color and luster are uniform, the surface is clean and flawless, and the like.

Owner:山东津莱环海医疗科技有限公司

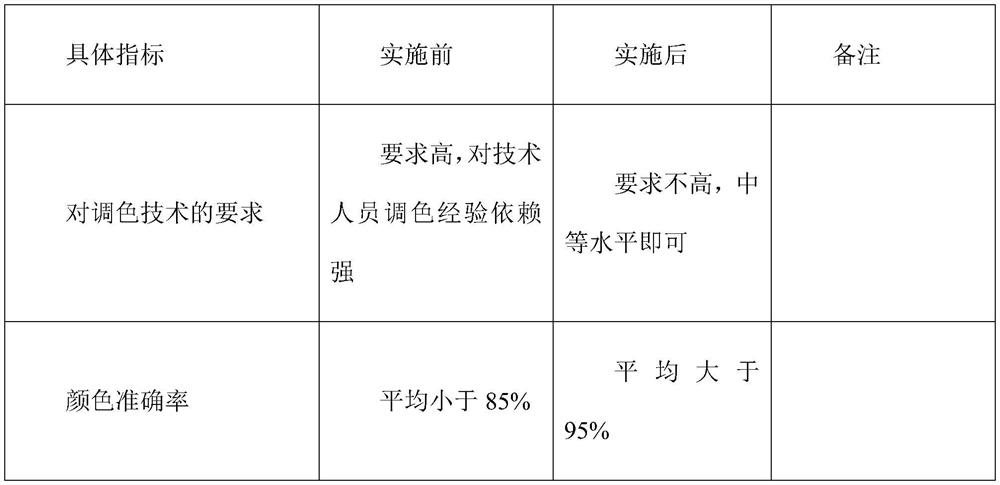

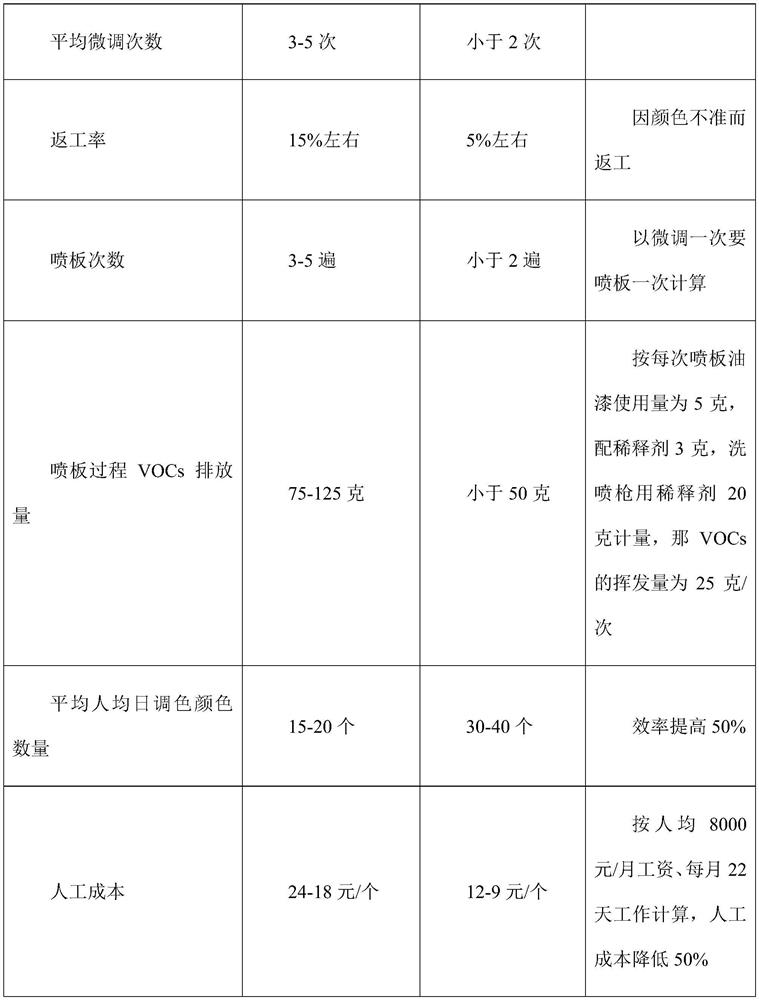

Preparation method of various-color finished paint for vehicle appearance repair

ActiveCN111826039AConsistent appearance and colorMeet repair and repair needsCoatingsCosmetic appearanceMechanical engineering

The invention discloses a preparation method of various-color finished paint for vehicle appearance repair. The preparation method comprises the following steps of: firstly, weighing required paint according to certain weight parts; then acquiring a mixed solution, lifting a paint mixing ruler, respectively observing the color difference between the color and a sample plate from angles of 30 degrees, 45 degrees and 90 degrees, and finely adjusting the color difference; then spraying a sample plate by using a spray gun, drying the sample plate by using an oven, comparing the dried sample platewith an original vehicle plate, and determining that the color is qualified when the color difference is less than 0.5 by using a colorimeter; and finally, adjusting the viscosity by using the mixed solution with qualified test color to obtain the qualified finished paint. The method can be used for preparing the repairing finished paint with the color very close to that of the original vehicle body, the appearance colors are consistent during vehicle repairing, the construction efficiency is improved, the universality and the practicability of the paint are improved, the colors can meet the repairing requirements of various vehicle body colors of various vehicles on the market through preparation of the various-color finished paint for vehicle appearance repair, and the paint can be widely applied to vehicle coatings.

Owner:NANXIONG JIASHENG IND

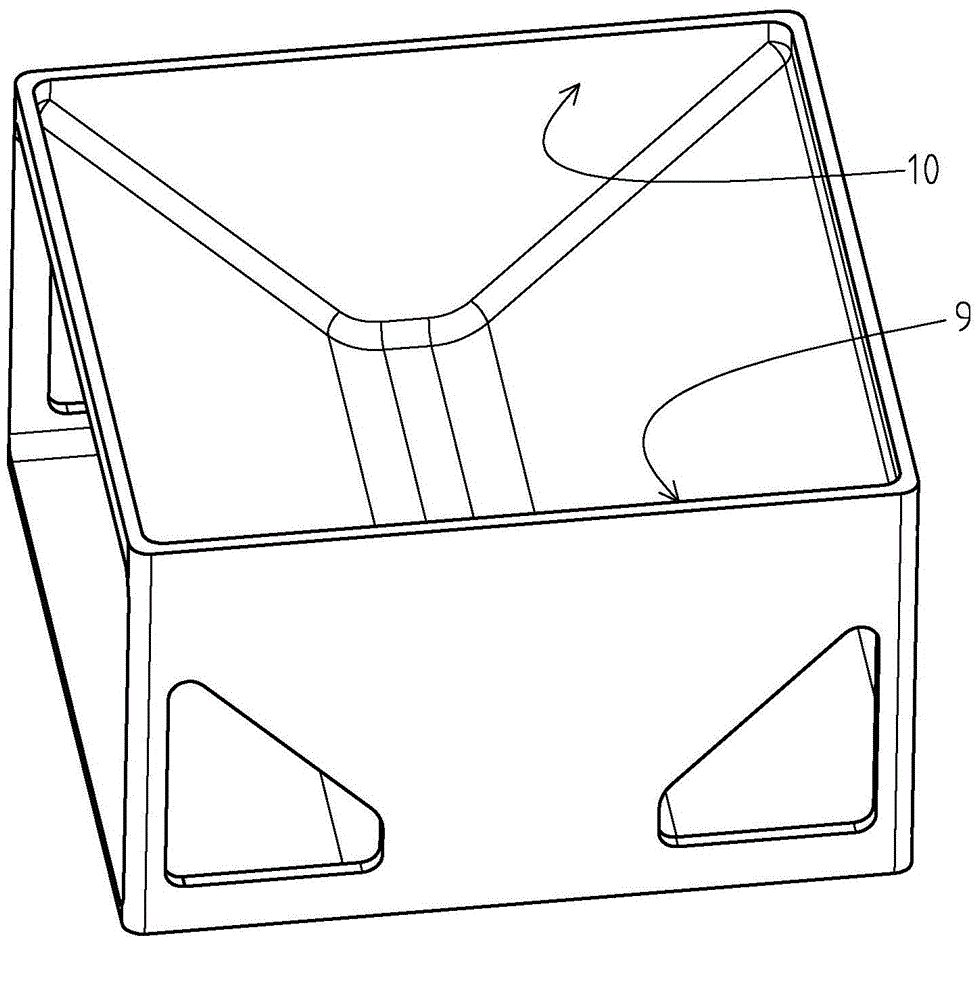

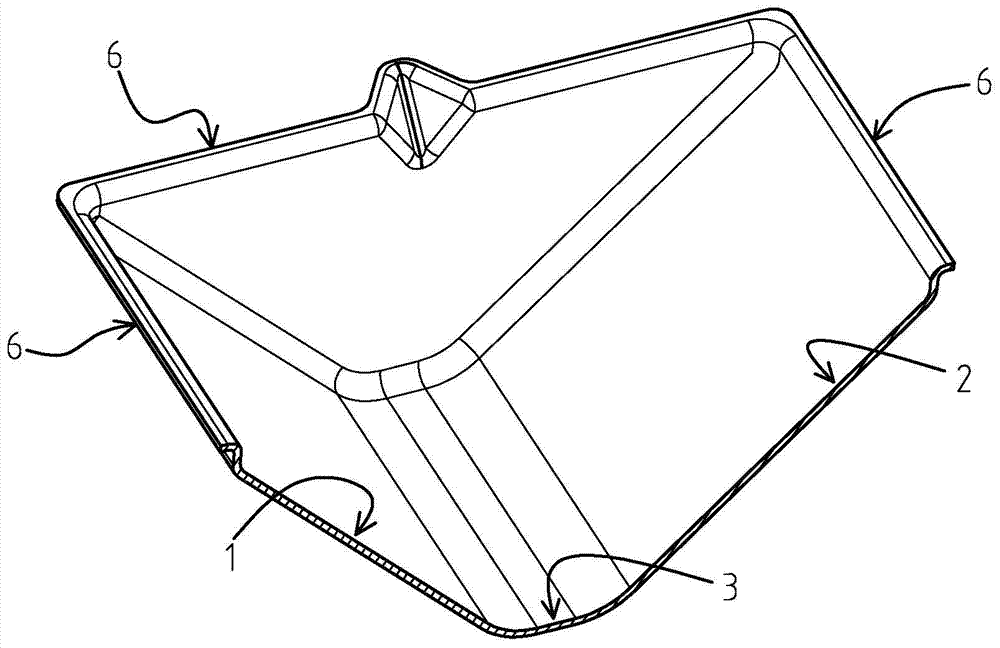

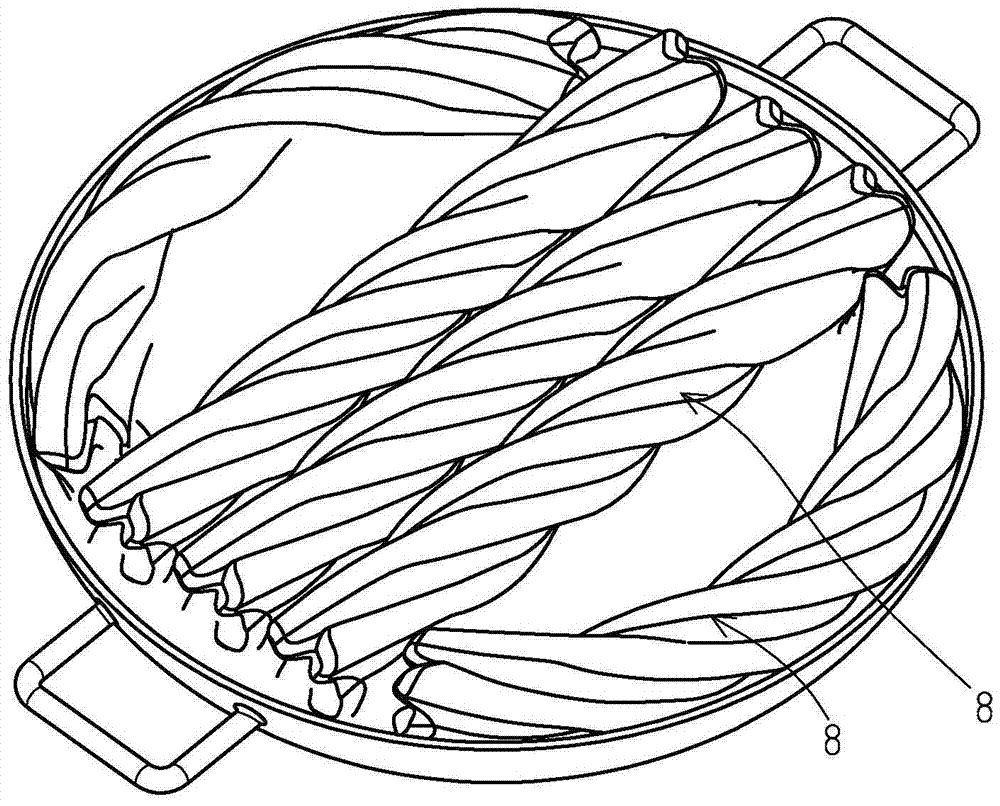

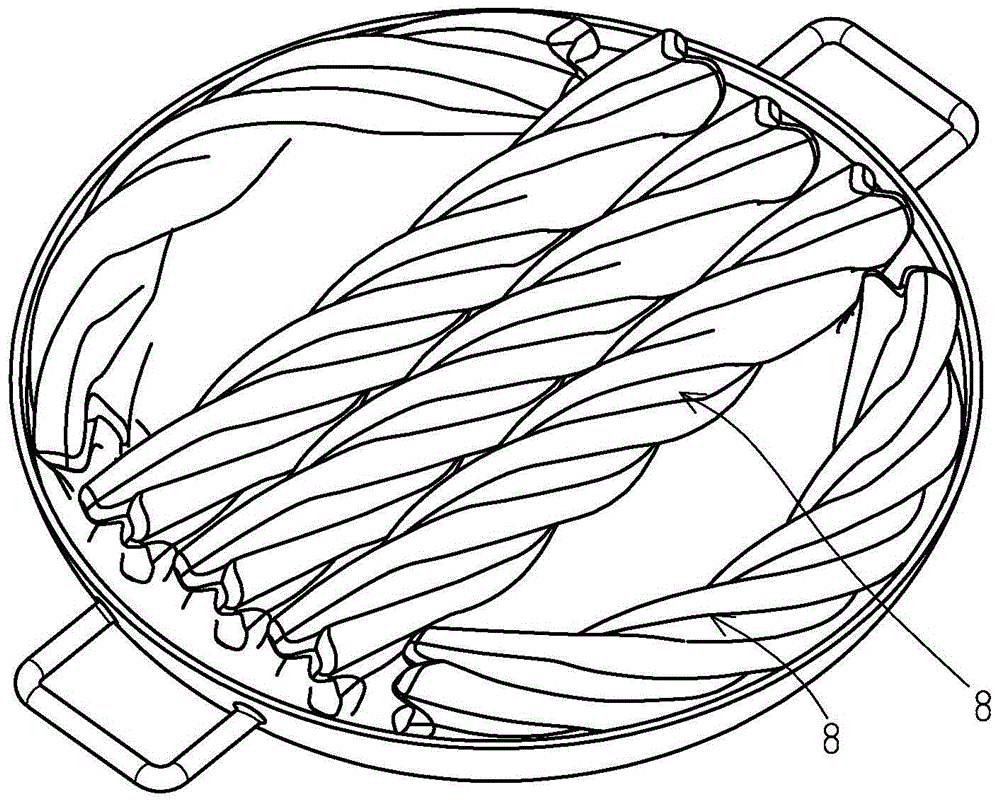

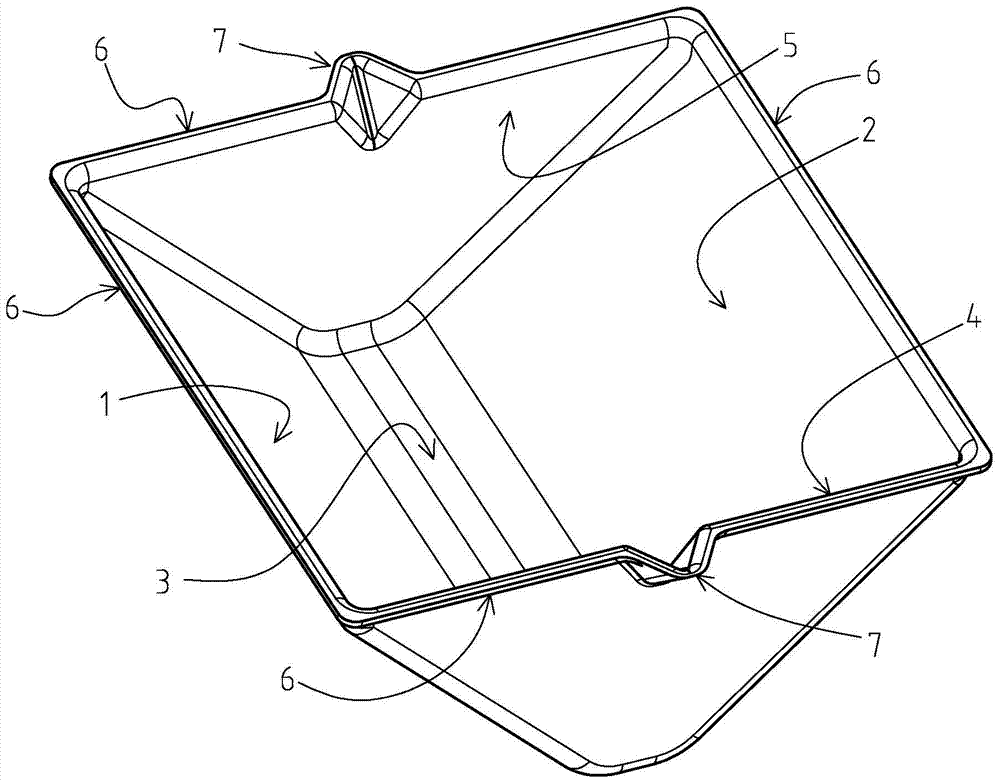

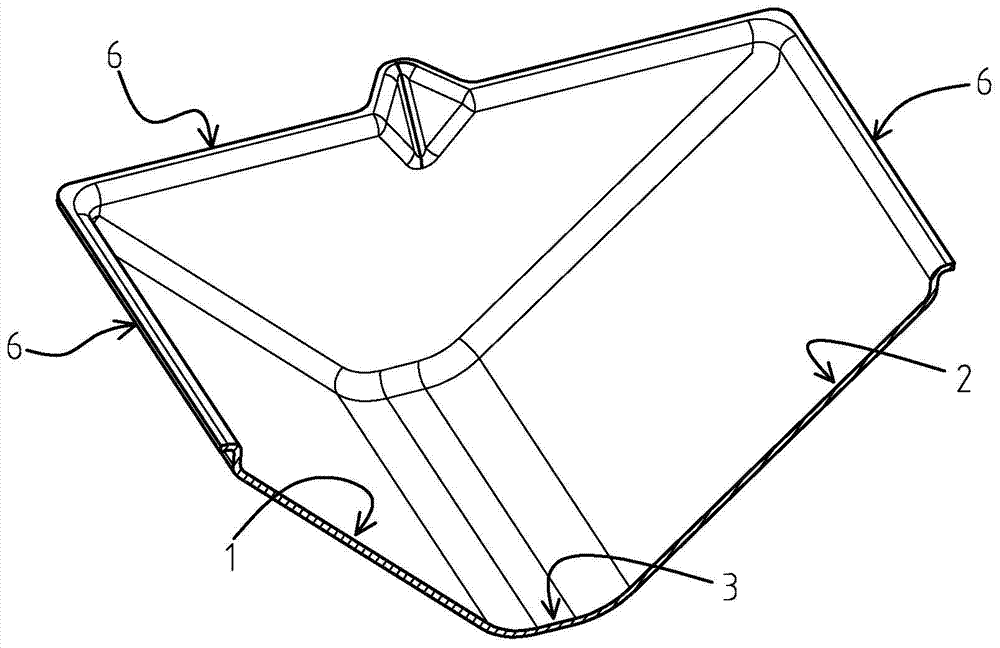

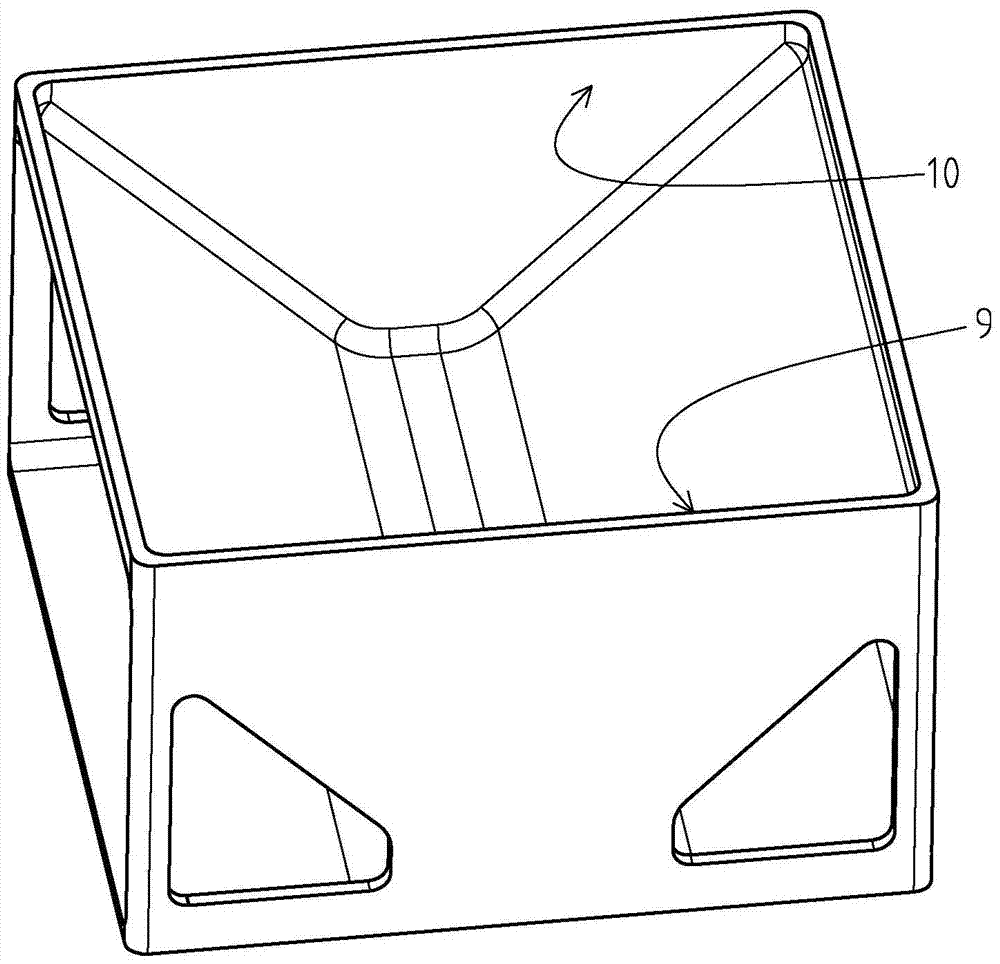

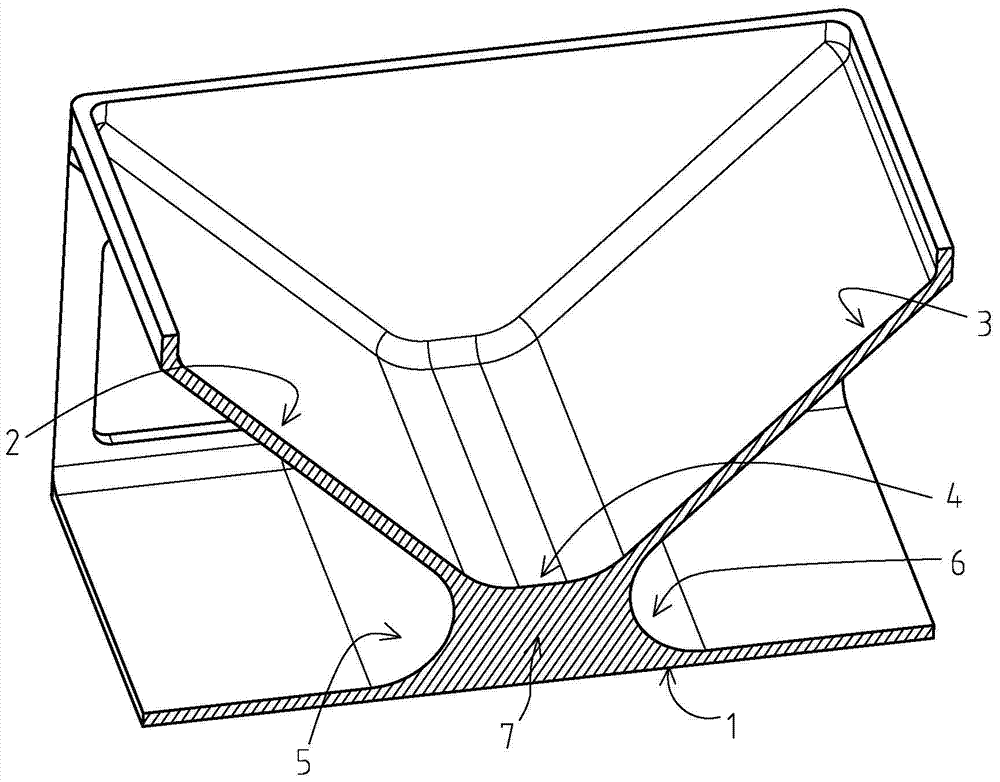

Design method for cooker used for manufacturing fried bread sticks

Design Method for Cookware for Making Youtiao Abstract The invention relates to a design method for a cookware for making youtiao. The method comprises arranging a second plane, a third plane, a first arcuate surface, a second arcuate surface and a third arcuate surface above the first plane; arranging for the second plane 5 to transitioning to the first plane through the second arcuate surface; arranging for the third plane to transitioning to the first plane through the third arcuate surface; arranging for the second plane to transitioning to the third plane through the first arcuate surface; defining the area surrounded by the first plane, the second arcuate 10 surface, the first arcuate surface and the third arcuate surface as a heat collecting area; defining the area with a square opening facing up surrounded by the second plane, the first arcuate surface, the third plane, the front vertical plane and the rear vertical plane as a receiving area; arranging for the receiving area to be with a shape 15 with wide top and narrow bottom. The cookware makes youtiao with a straight shape and can fry a plurality of youtiaoes together at the same time. Fig.1 5 7 Fig.2 -1 / E

Owner:滁州润泰清真食品有限公司

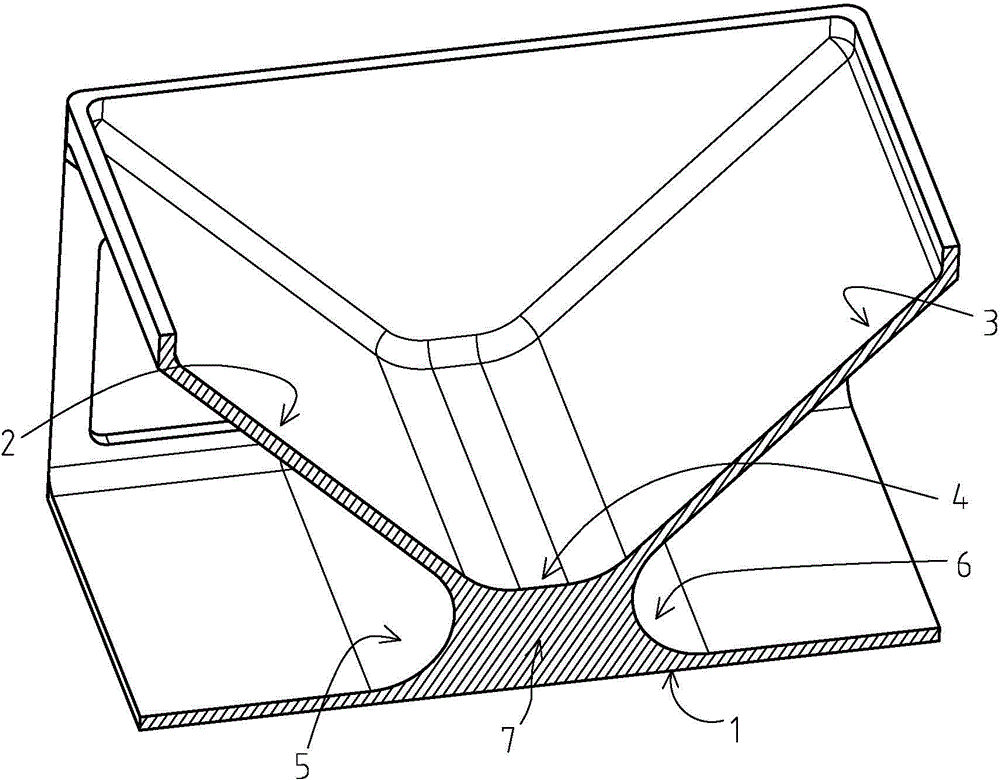

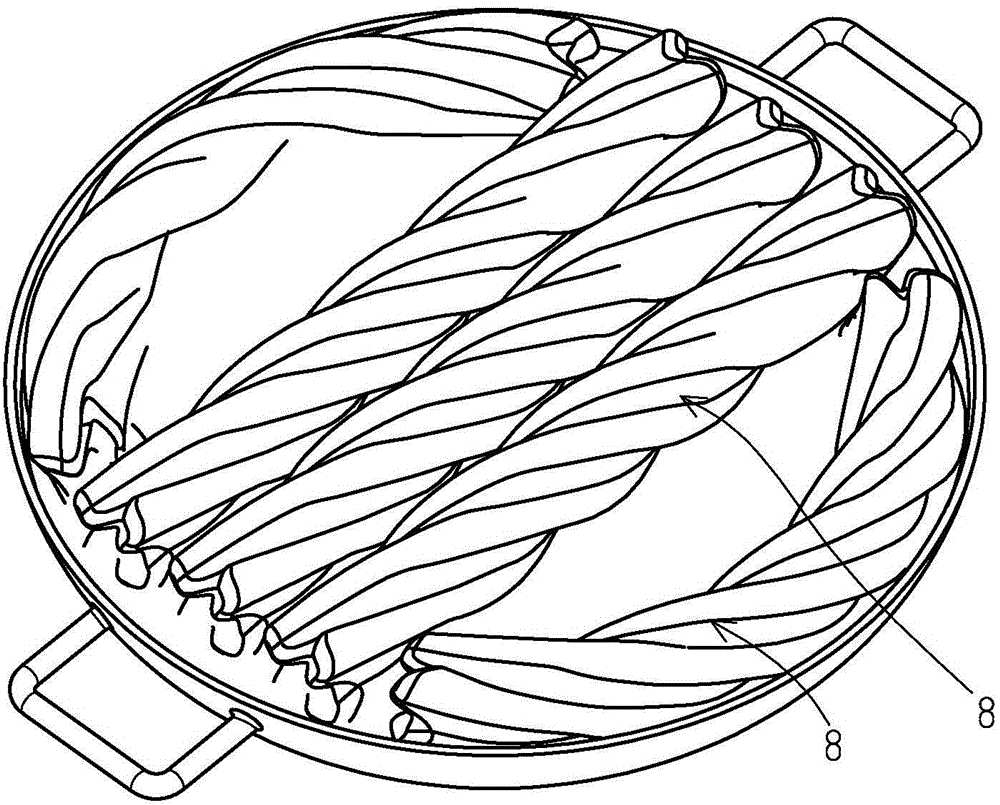

The lining of the pot for making fried dough sticks

The invention relates to a pot for making deep-fried dough sticks, in particular to an inner lining. The invention discloses an inner liner of a pot for making deep-fried dough sticks, which includes a receiving area, and is characterized in that the inner liner is also provided with a first plane, a second plane and a first arc surface, and the first plane and the second plane pass through The transition connection of the first arc surface is defined as the accommodation area by the first plane, the first arc surface, the second plane, and the front and rear facades perpendicular to the first plane and the second plane. The upward area is defined as the accommodation area. The shape is wide at the top and narrow at the bottom, and the opening is square. The deep-fried dough sticks made by the inner lining disclosed by the invention are straight and unbent, have a high pass rate, are evenly heated, have uniform appearance and color, and can simultaneously produce a plurality of qualified deep-fried dough sticks with high efficiency.

Owner:滁州润泰清真食品有限公司

Lining of pot for making fried bread sticks

Owner:滁州润泰清真食品有限公司

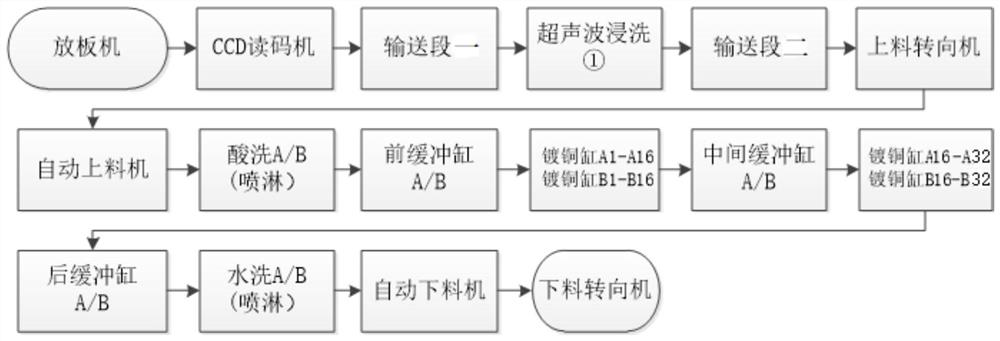

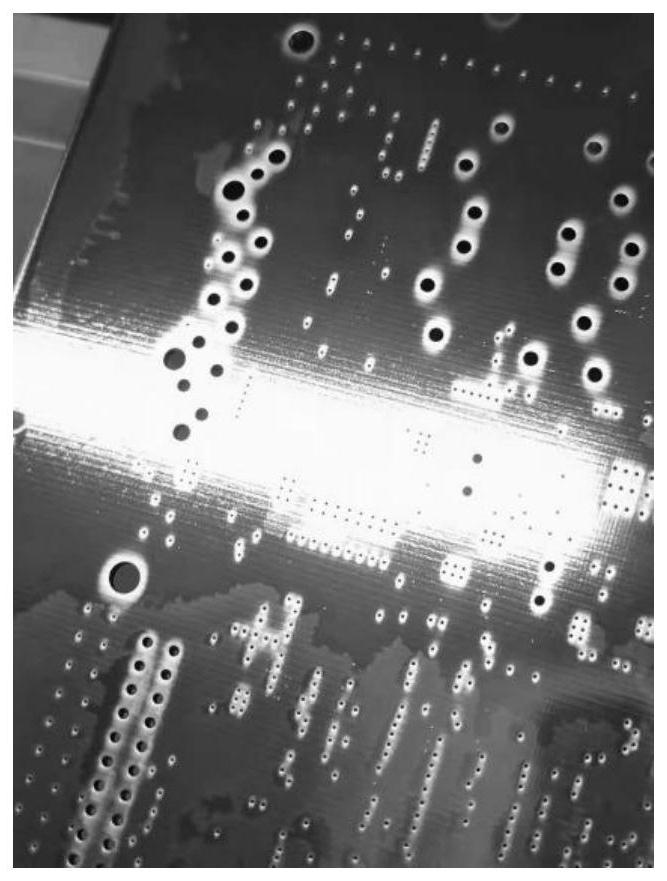

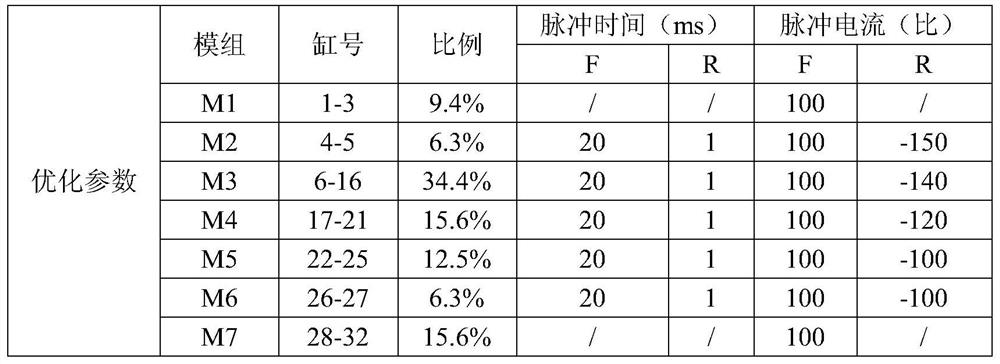

Pulse electroplating method for solving color difference of appearance of thin plate

PendingCN113430601AConsistent appearanceConsistent appearance and colorJewelleryCopper platingPulse electroplating

The invention discloses a pulse electroplating method for solving the color difference of the appearance of a thin plate. The method is characterized by comprising the following steps: (1) placing the thin plate on a conveying section I through a plate placing machine, and conveying the thin plate to an ultrasonic immersion cleaning section for immersion cleaning; (2) after immersion cleaning is completed, the thin plate is conveyed to a feeding steering machine through a second conveying section, and after steering, the thin plate is conveyed to an acid pickling section through an automatic feeding machine for acid pickling; (3) after acid pickling, the copper is conveyed to a copper plating cylinder, the copper plating cylinder is divided into seven sections, waveform parameters are set for the sections separately, and the reverse current intensities in the waveform parameters are decreased from high to low; and (4) after copper plating is completed, the thin plate is conveyed to an automatic discharging machine for discharging. According to the pulse electroplating method, the phenomenon of color difference of appearance is solved by setting different waveform parameters, and the problems of wrinkling and bubbling of the dry film of the outer circuit caused by the phenomenon can be effectively reduced.

Owner:江西景旺精密电路有限公司

Fresh flower yoghourt and production method

InactiveCN103783158BReasonable process structureConsistent appearance and colorMilk preparationPetalCulture fungus

Owner:HONGHE YUNNIU DAIRY IND

Three-tank automatic granule production method and system

ActiveCN105536645BReduce waiting timeIncrease productivityBiofuelsGranulation in rotating drumsCooking & bakingProcess engineering

Provided are three-tank automatic particle production method and system. The method comprises: feeding material to be treated into a heating tank in batches during idle of the heating tank; heating and stirring the material in the heating tank under a preset heating temperature for a first preset time to obtain a first intermediate material; connecting an outlet of the heating tank to an inlet of a baking tank, feeding the first intermediate material in the heating tank into the baking tank, and disengaging the outlet of the heating tank with the inlet of the baking tank.

Owner:柏红梅

A neoprene anesthesia air storage bag

ActiveCN110054819BConsistent appearance and colorSurface is clean and free from blemishesPotassium hydroxideMethyl oleate

The invention relates to a chloroprene rubber anesthesia air storage bag, which belongs to the technical field of anesthesia air storage bags; it is characterized in that, based on 100 parts of dry rubber, 100 parts of 502 neoprene latex; 4-6 parts of zinc oxide; 2641-1.2 parts of anti-aging agent 0.15 parts of potassium hydroxide (5% solution); 0.8-1.2 parts of sulfated methyl oleate monosodium salt; 0.2 parts of sodium alkyl sulfate; 3 parts; 2 parts of sulfur; 0.5-1.5 parts of accelerator TP; 0.9 parts of accelerator BZ. The invention solves the problem that the existing natural rubber anesthesia air storage bag causes the risk of allergy to patients, and has the advantages of consistent appearance and color, clean and flawless surface, and the like.

Owner:山东津莱环海医疗科技有限公司

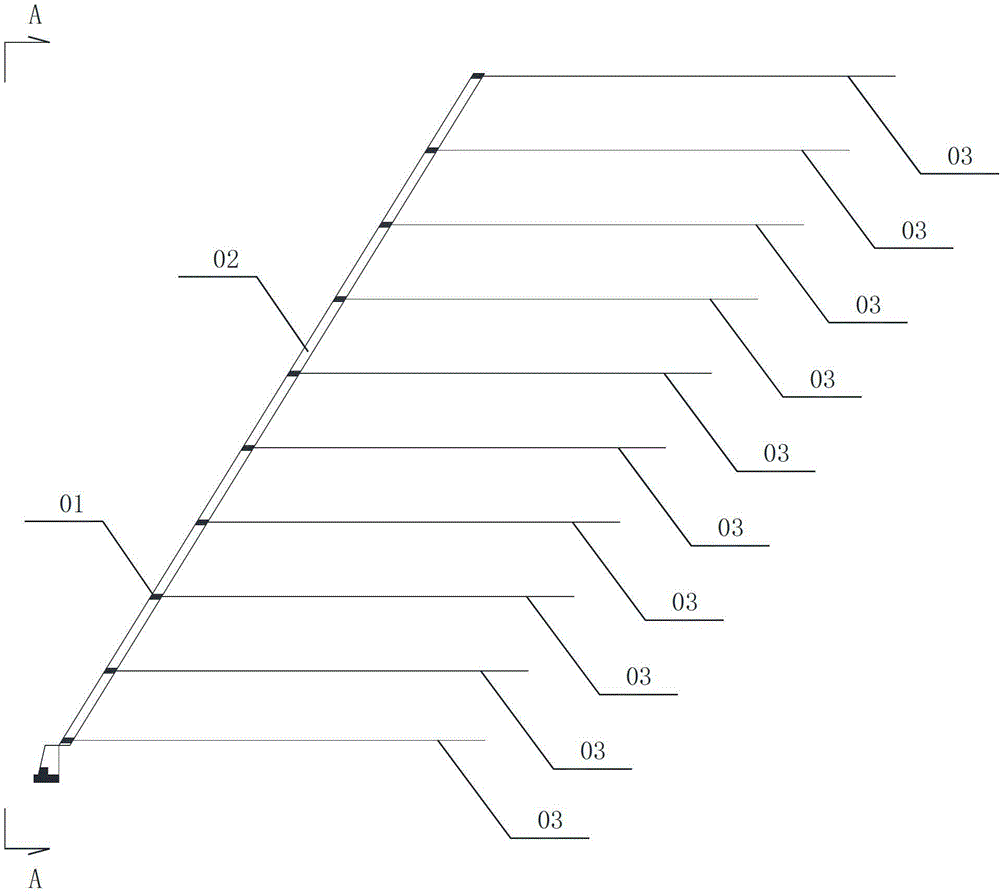

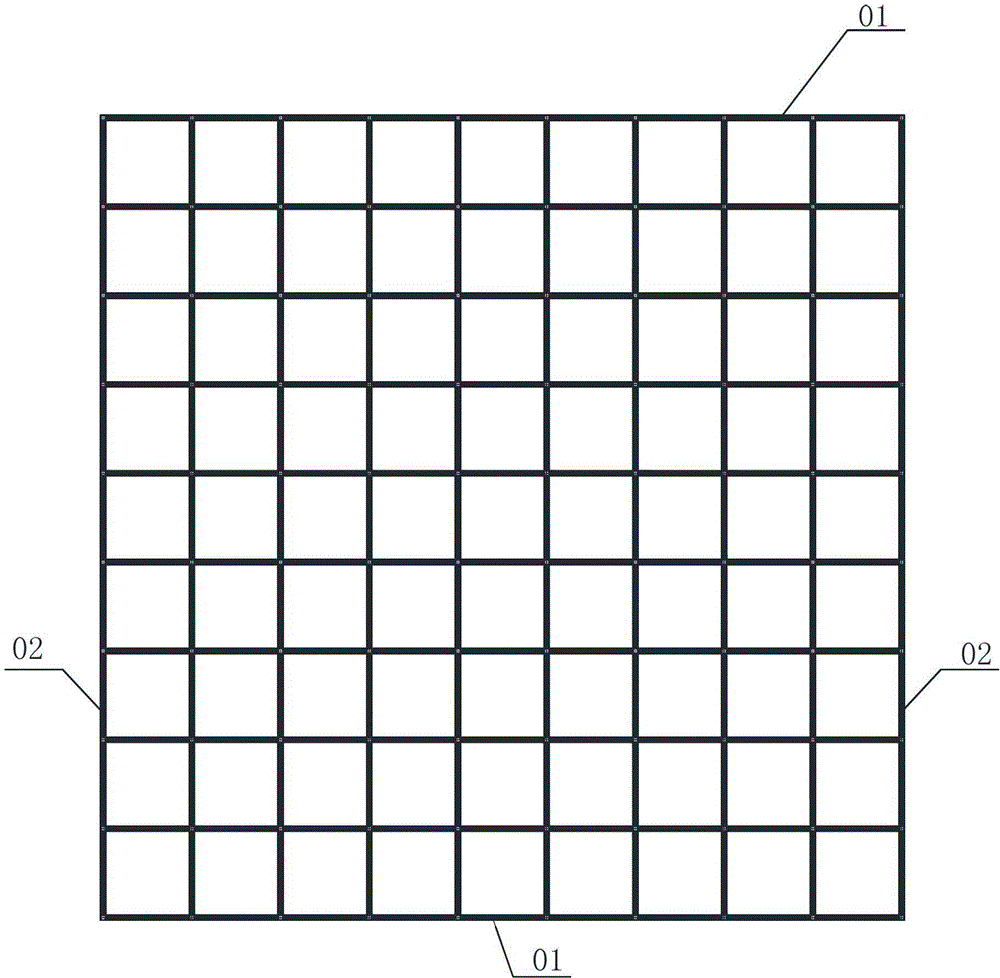

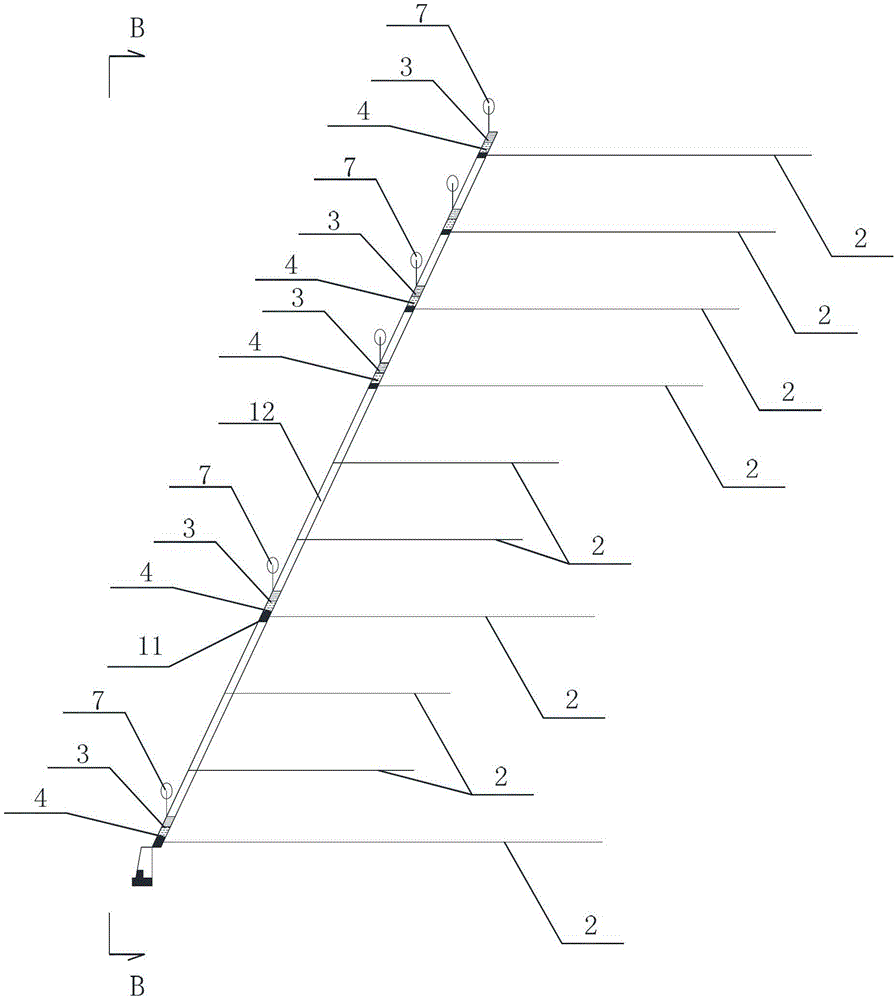

Road slope protecting structure and construction method thereof

InactiveCN103334441BExtended service lifeConsistent appearance and colorExcavationsFiberReinforced concrete

The invention discloses a road slope protecting structure. The road slope protecting structure comprises an anchoring cable, an outer layer of FRP (Fiber Reinforce Plastic) frame grid beam template and an inner reinforcing steel bar concrete frame grid beam, wherein the outer layer of FRP frame grid beam template comprises a cross beam template which is horizontally arranged and a longitudinal beam template which is arranged along a slope in the height direction of the side slope; and the inner reinforcing steel bar concrete frame grid beam comprises reinforcing steel bar concrete cross beams and reinforcing steel bar concrete longitudinal beams which are respectively cast in the cross beam template and the longitudinal beam template. Both the reinforcing steel bar concrete cross beams and the reinforcing steel bar concrete longitudinal beams are wrapped in the outer layer of FRP frame grid beam template to form a combined structure of an FRP structure and a reinforcing steel bar concrete structure, so that the exposed areas of the reinforcing steel bar concrete cross beams and the reinforcing steel bar concrete longitudinal beams are effectively reduced, the cross beams and the longitudinal beams are effectively prevented from being cracked, the service life of the road slope protecting structure is prolonged, and meanwhile, the cost of a large number of steel templates or wood templates and brackets is saved. The invention also discloses a construction method of the road slope protecting structure.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Duck Roasting process and device by air jet impacting

InactiveCN100348130CCreate pollutionNo uneven heatingFood preparationRoast chickenPulp and paper industry

The present invention aims at providing duck roasting process and roaster with homogeneous heating, homogeneous product appearance and color, standard operation and no pollution. The technological process features that the prepared duck is roasted in airflow of 120-150 deg.c temperature and 5-20 m / s speed for 30-60 min inside an airflow impacted duck roaster. The roaster includes roasting chamber with nozzles on two sides and waste air recovering channel, duck suspender, fan assembly and heater in the lower part of the roasting chamber, and rotating unit in the top center of the roasting chamber. The present invention has the features of homogeneous heating, no flame, no pollution, homogeneous color of the roasted product and standard operation. The present invention may be also used in producing roasted chicken, roasted sucking pig, roasted whole sheep, etc.

Owner:CHINA AGRI UNIV

Design method of inner lining of pan for making deep-fried dough sticks

Owner:临泉县白良电子信息技术有限责任公司

Pot for making fritters

Owner:临泉县白良电子信息技术有限责任公司

Purple bronze brass tube and manufacturing method and production line thereof

InactiveCN103243291BNo pollution in the processReduce production processSolid state diffusion coatingProduction lineShielding gas

The invention provides a purple bronze brass tube and a manufacturing method and production line of the purple bronze brass tube. The manufacturing method of the purple bronze brass tube comprises the following steps: allowing the brass tube to penetrate through the heating device on line at a set speed and heating to a red hot state, and oxidizing the outer surface; and reducing and cooling the outer surface of the brass tube on line, and manufacturing the purple bronze brass tube. The purple bronze brass tube production line comprises a heating device and a reduction tank, wherein reducing and cooling liquid is filled in the reduction tank. Compared with the prior art, the manufacturing method of the purple bronze brass tube has the advantages that process steps are less, yield is high, production efficiency of the purple bronze brass tube is high, lots of brass tube pickling process are eliminated in the related technology, the outer protective gas of the brass tube is canceled, the manufacturing cost is obviously reduced, the brass tube is energy-saving and environment-friendly, the manufactured purple bronze brass tube is dense and uniform in outer surface and can serve as a finished tube, drawing, bending, tube expanding and other subsequent treatment can be performed, and the color layer does not drop.

Owner:JIANGSU XINGRONG HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com