Purple bronze brass tube and manufacturing method and production line thereof

A manufacturing method and technology for brass pipes, which are applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of connecting pipes and pipe fittings that cannot be produced, and reduce equipment renovation expenses and manufacturing costs. Reduce and eliminate the effect of pickling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

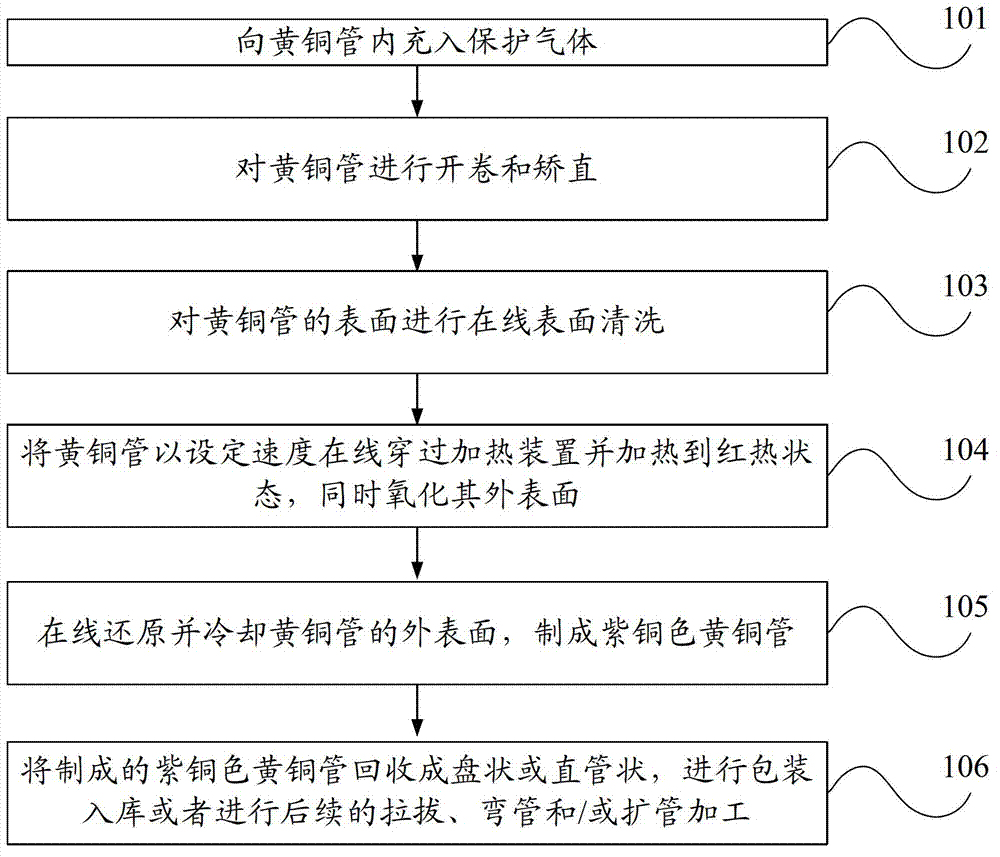

Embodiment 1

[0069] Select the H80 brass coil pipe with the specification of Φ9.52×0.65mm, fill the inner wall with protective gas, and enter the online induction annealing unit model XR-GT400 after the inner wall is filled with protective gas. The set speed is 100m / min, and the heating temperature of the pipe is 650-800℃ , the proportion of ethanol in the cooling liquid is 3%; the cooling liquid is supplied by the circulation system, and the tube blank enters the coil and quickly heats up to 650-800 ° C. When heating, the outer surface of the tube is in contact with the air, and the surface is red and bright red In the hot state, the outer surface of the brass tube is oxidized while being heated, and then enters the reducing cooling liquid containing ethanol to cool to room temperature; the oxide layer on the surface of the brass tube that exits the cooling liquid is reduced to copper. The annealed pipe is of good quality and the surface is copper-colored.

Embodiment 2

[0071]Select the H90 brass coil with a specification of Φ12.7×0.70mm, and uncoil it into the online induction annealing unit model XR-GT200. Oxygen is introduced into the induction coil, the annealing speed is 150m / min, and the heating temperature of the pipe is 750-900°C , the proportion of ethanol in the cooling liquid is 2%; after entering the coil, the temperature of the tube blank rises rapidly to about 750-900 °C, and the surface is red and bright after exiting the coil, and turns black after passing through the oxidation section as long as about 4 meters Bright red hot state; then enter the reduction cooling liquid containing ethanol and cool to room temperature; the oxide layer on the surface of the brass tube that exits the cooling liquid is reduced to copper. The annealed pipe is of good quality and the surface is copper-colored.

Embodiment 3

[0073] Select the H65 brass coil with the specification of Φ6.35×0.65mm, and uncoil it into the online induction annealing unit of model XR-GT400. 700°C, the proportion of ethanol in the cooling liquid is 5%; after the tube blank enters the coil, the temperature rises rapidly to about 550-700°C, and the surface of the coil is in a dark red hot state after passing through the oxidation section of about 5 meters. It is a black and bright red hot state; then it enters the reduction cooling liquid containing ethanol and cools to room temperature; the oxide layer on the surface of the brass tube that exits the cooling liquid is reduced to copper. The annealed pipe is of good quality and the surface is copper-colored.

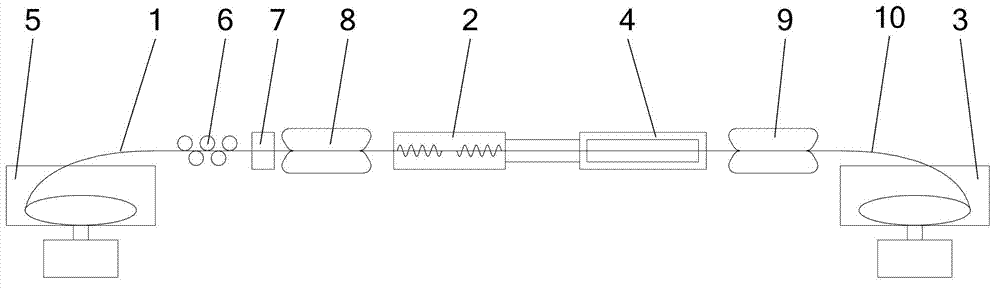

[0074] The present invention also provides a production line of copper-colored brass tubes, such as figure 1 As shown, it includes a heating device 2 and a reduction tank 4, and the reduction tank 4 is filled with reducing cooling liquid; the brass tube 1 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com