A uniform deposition process of hydroxyapatite coating on medical porous titanium and titanium alloy

A technology of hydroxyapatite and titanium alloy is applied in the field of surface modification treatment of medical materials, which can solve the problems of uneven surface quality and uneven surface modification of porous metal, so as to avoid process asynchrony and improve electrochemical reaction. The effect of mass transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

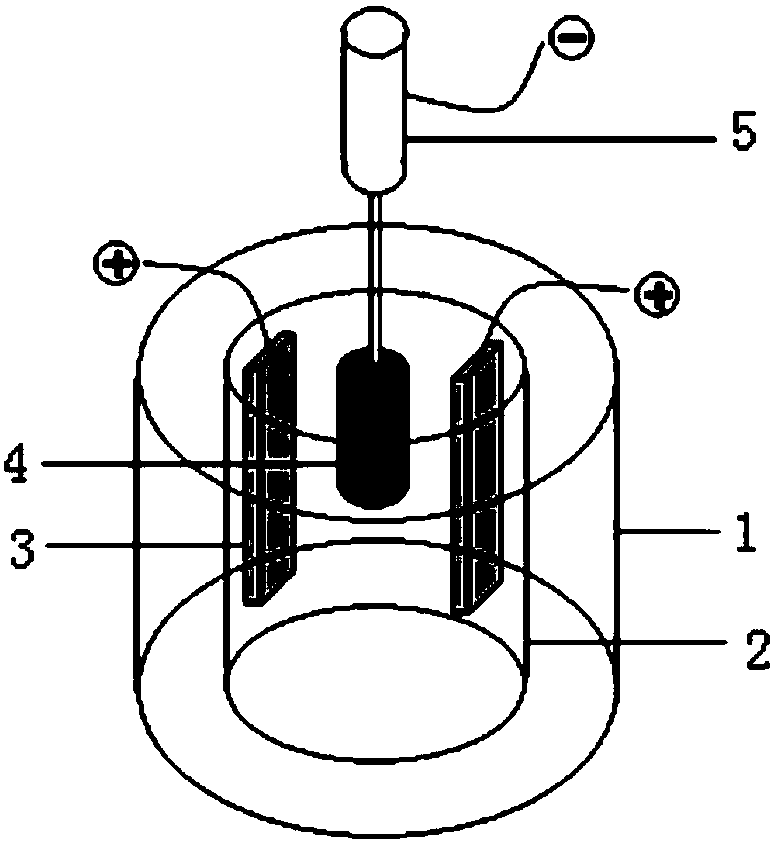

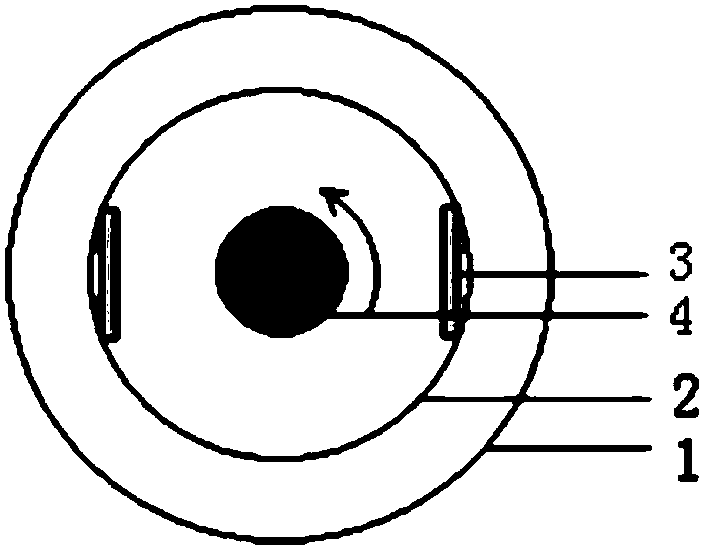

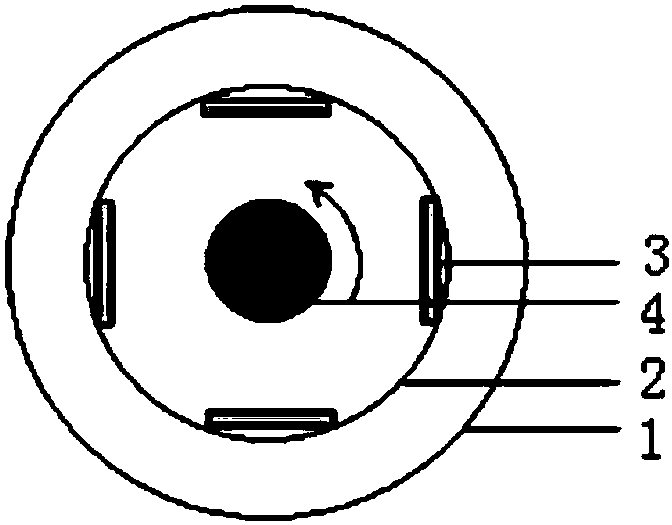

[0038] The uniform deposition process of hydroxyapatite coating on medical porous titanium and titanium alloy of the present invention comprises:

[0039] Step 1: Pretreatment of Porous Metal Substrates

[0040] (1) Mechanical polishing: Use the automatic mode of the drum sandblasting machine to mechanically polish the inner and outer surfaces of porous titanium or titanium alloy samples. Brown corundum or white corundum with a particle size of 100-280 is used as sandblasting abrasive, and sandblasting is performed for 1-5 minutes to remove irregular burrs during the forming process of the inner and outer surfaces of the porous structure;

[0041] (2) Degreasing: Then place the mechanically polished porous titanium or titanium alloy sample in a hot alkali degreasing solution at 70-90°C for 2 to 10 minutes under supergene conditions, then take out the sample and rinse it with deionized water clean. The hot alkali degreasing liquid is 20~40g·L -1 NaH 2 PO 2 ·H 2 O, 10~20g·...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com