Production molding technique of steel wire mesh/fiber mesh framework dual-resistance PP composite pipe used underground coal mine

A molding process, steel wire mesh technology, applied in applications, household utensils, tubular objects, etc., can solve the problems of impact, poor surface finish of pipes, high melt viscosity, etc., and meet safety requirements, good antistatic effect, and bonding strength big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

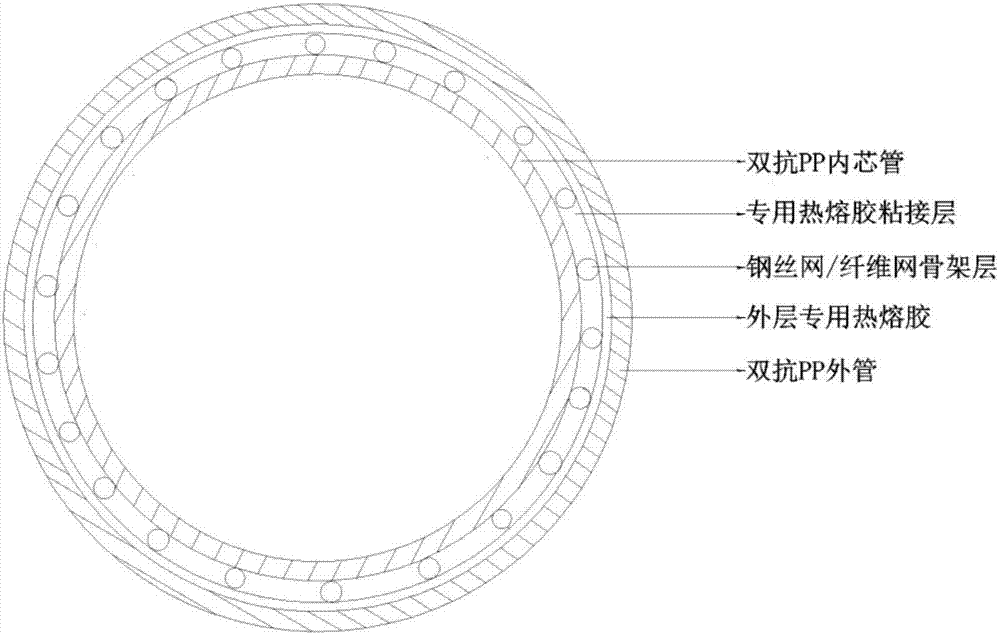

[0048] Raw materials for steel wire mesh / fiber mesh skeleton double-resistant PP composite pipes used in coal mines

[0049] The steel mesh / fiber mesh skeleton double-resistant PP composite pipe used in underground coal mines is made of double-resistant PP modified materials, special heat-resistant hot-melt adhesive for bonding steel materials and double-resistant PP materials, steel wire (copper-plated) ), fiber bundles, etc.

[0050] 1. Double anti-PP modified polymer material

[0051] The patent of this application - the double-resistant PP modified material used in the double-resistant PP composite pipe of steel mesh / fiber mesh skeleton, especially the double-resistant PP modified material developed and produced by China Shenhua Beijing Low Carbon Clean Energy Research Institute, as the steel wire The inner core tube and the outer layer of the net / fiber net skeleton double-resistant PP composite pipe.

[0052] The physical and mechanical performance parameters of the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com