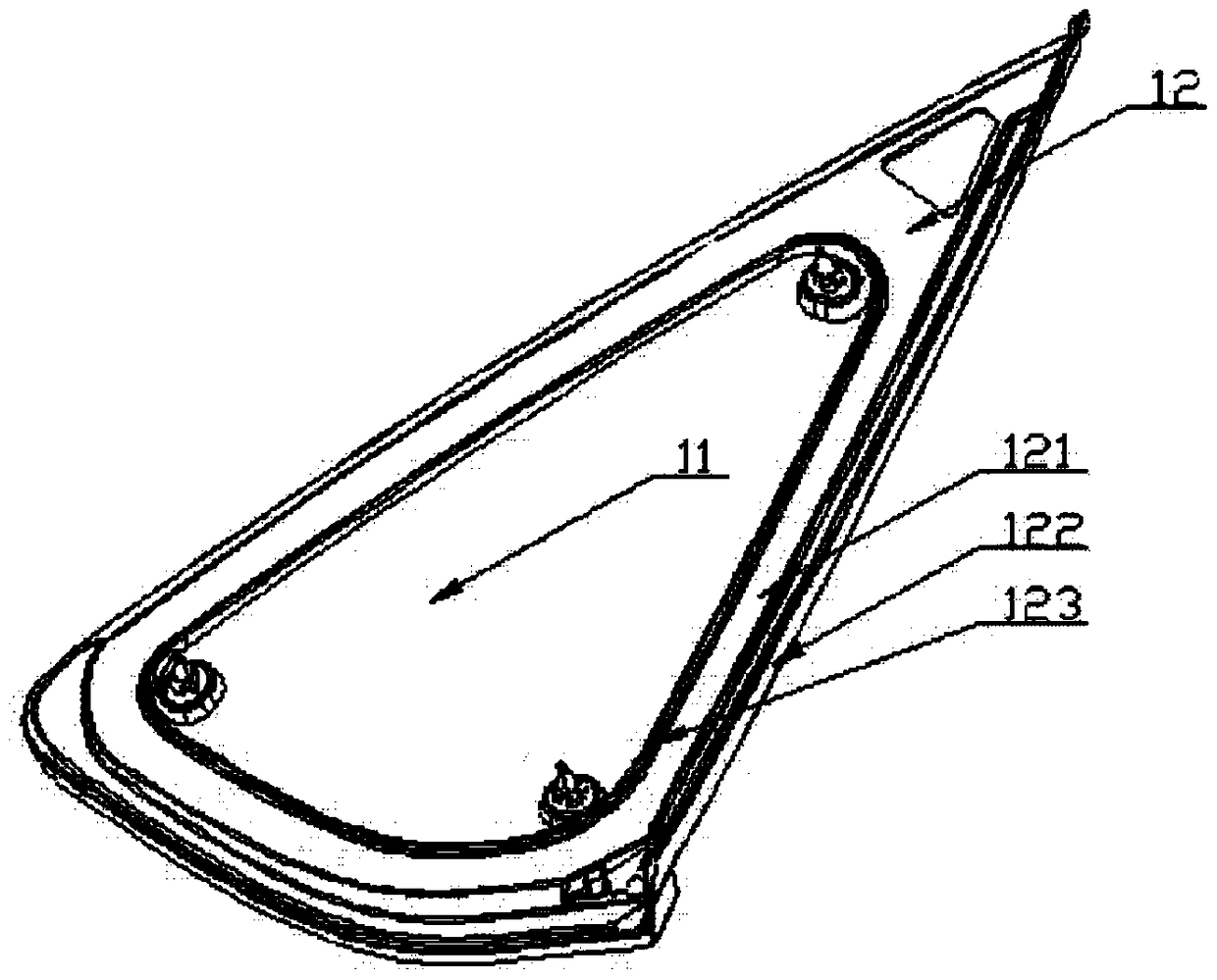

Method for forming automotive glass bezel, window and mold

An automotive glass and mold technology, applied in windshields, windows, home appliances, etc., can solve the problems of glass edging manufacturing yield decline, injection pressure glass cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

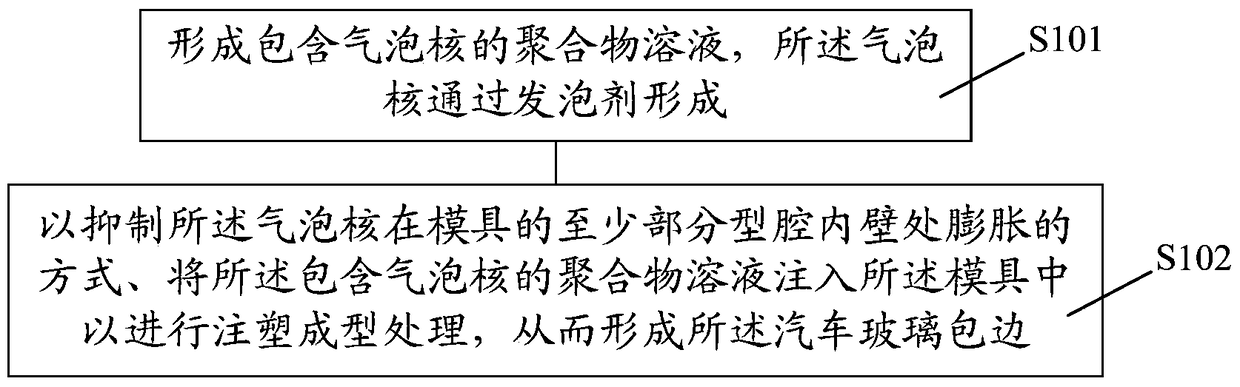

[0022] The following defects usually exist in the plasticizing and encapsulating of automotive glass: the plasticizing solution shrinks due to cooling in the mold cavity, so that the size of the glass encapsulation formed by injection molding is smaller than the design specification and sink marks are generated on the product surface. However, in the prior art, the method of increasing the injection pressure is used to suppress the shrinkage, but the increase of the injection pressure easily leads to glass breakage.

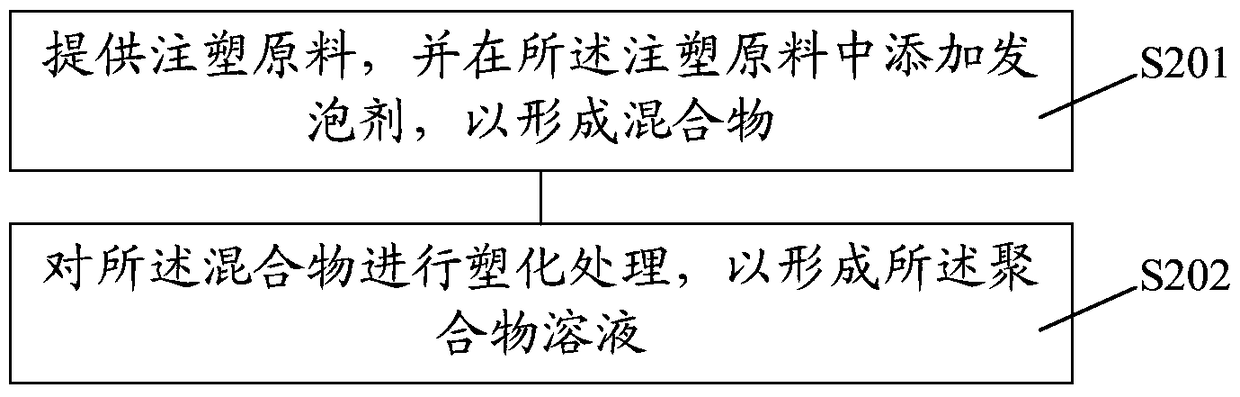

[0023] In order to overcome the above drawbacks, the inventors of the present invention formed a plasticized solution (polymer solution) containing bubble nuclei, injected the plasticized solution into a mold for injection molding processing, and formed an automotive glass encapsulation. Due to the existence of bubble nuclei in the plasticizing solution, the fluidity of the solution is high, which reduces the molding temperature during the plasticizing process, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com