Pulse electroplating method for solving color difference of appearance of thin plate

A pulse electroplating, thin plate technology, applied in jewelry and other directions, can solve the problem of thin plate appearance color difference, and achieve the effect of reducing wrinkles and uniform appearance color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

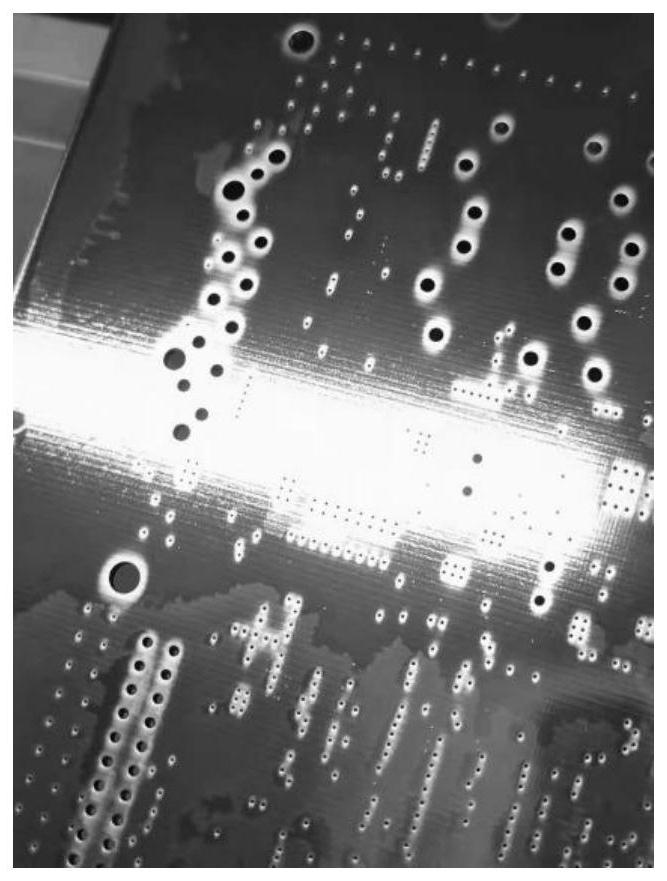

Problems solved by technology

Method used

Image

Examples

Embodiment 1

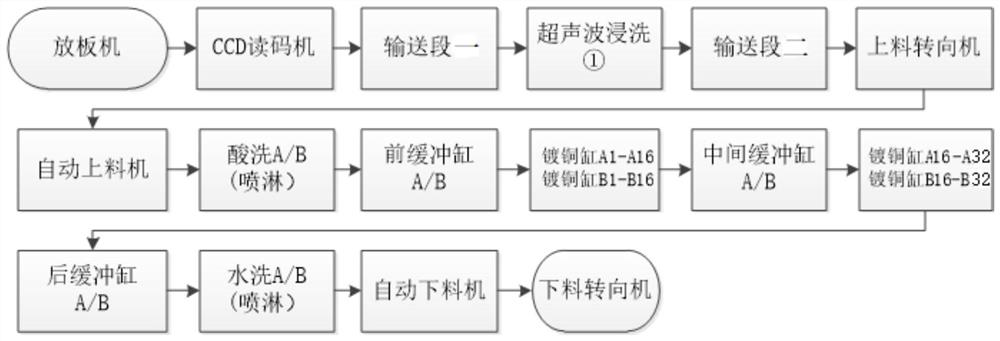

[0024] A pulse electroplating method for solving thin plate appearance color difference, said method comprises the following steps,

[0025] (1) The thin plate is placed in the conveying section through the plate placing machine, and then transported to the ultrasonic immersion section for immersion;

[0026] (2) After the dipping is completed, it is transported to the feeding steering machine through the second conveying section, and after the thin plate is turned, it is transported to the pickling section through the automatic feeding machine for pickling;

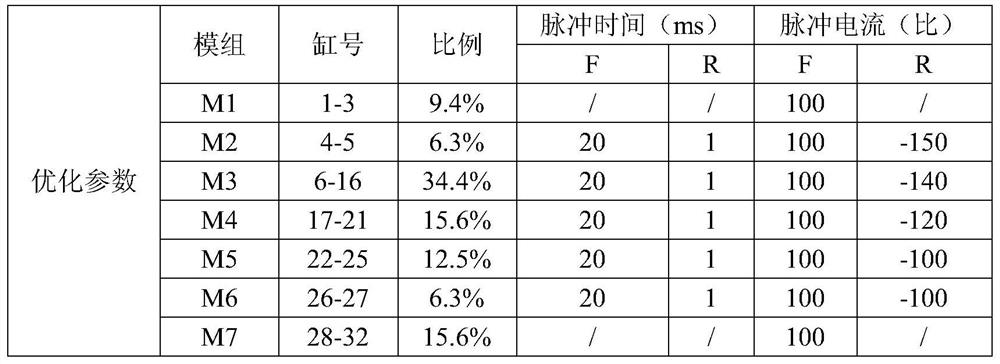

[0027] (3) After pickling, it is transported to the copper plating cylinder. The copper plating cylinder is divided into 7 sections. The waveform parameters are set separately for each section. The reverse current intensity in the waveform parameters is from strong to weak. Among them, the copper plating cylinder of the first section is not Apply reverse current, the positive and negative current ratio of the second copp...

Embodiment 2

[0037] A pulse electroplating method for solving thin plate appearance color difference, said method comprises the following steps,

[0038] (1) The thin plate is placed in the conveying section through the plate placing machine, and then transported to the ultrasonic immersion section for immersion;

[0039] (2) After the dipping is completed, it is transported to the feeding steering machine through the second conveying section, and after the thin plate is turned, it is transported to the pickling section through the automatic feeding machine for pickling;

[0040] (3) After pickling, it is transported to the copper plating cylinder. The copper plating cylinder is divided into 7 sections. The waveform parameters are set separately for each section. The reverse current intensity in the waveform parameters is from strong to weak. Among them, the copper plating cylinder of the first section is not Apply reverse current, the positive and negative current ratio of the second copp...

Embodiment 3

[0048] A pulse electroplating method for solving thin plate appearance color difference, said method comprises the following steps,

[0049] (1) The thin plate is placed in the conveying section through the plate placing machine, and then transported to the ultrasonic immersion section for immersion;

[0050] (2) After the dipping is completed, it is transported to the feeding steering machine through the second conveying section, and after the thin plate is turned, it is transported to the pickling section through the automatic feeding machine for pickling;

[0051] (3) After pickling, it is transported to the copper plating cylinder. The copper plating cylinder is divided into 7 sections. The waveform parameters are set separately for each section. The reverse current intensity in the waveform parameters is from strong to weak. Among them, the copper plating cylinder of the first section is not Apply reverse current, the positive and negative current ratio of the second copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com