Solder powder doped with tin-plated alloyed powder and soldering paste containing solder powder

A technology of alloy powder and solder powder, which is applied in the field of processing of welding and surface treatment materials for electronic device assembly, which can solve the problems of high price and achieve the effects of reducing the cost of solder paste, consistent appearance and excellent soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

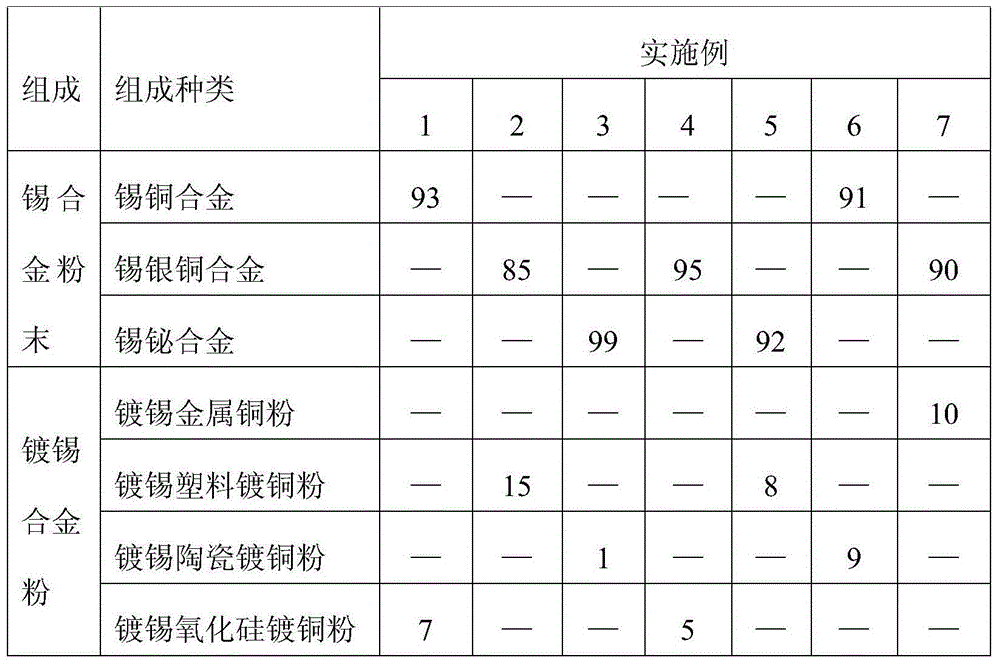

Examples

Embodiment 1

[0029] Table 3 Performance test of solder paste containing commercially available 305 tin powder and solder paste containing solder powder of Example 1

[0030]

[0031]As can be seen from the above data, the tin-plated alloy powder of the present invention can be well mixed with the tin alloy powder to achieve an excellent welding effect, satisfying the performance after solder paste welding, and because these tin-plated alloy powders have a layer of tin-plated , when it is mixed with the existing tin alloy powder on the market, the wettability between the two is good, the bonding force is good, the appearance after welding is consistent, and there will be no small tin beads in the solder joints after welding, or residues outside the pads The situation of small tin ball, and can find out from above-mentioned data and comparison, the soldering tin effect behind the solder paste that contains solder powder of the present invention is better than commercially available solder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com