Solder powder doped with tin-plated alloy powder and solder paste containing same

A technology of alloy powder and solder powder, which is applied in the field of processing of welding and surface treatment materials for electronic device assembly, which can solve the problems of high price and achieve the effects of reducing the cost of solder paste, consistent appearance and excellent soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with specific embodiments of the present application.

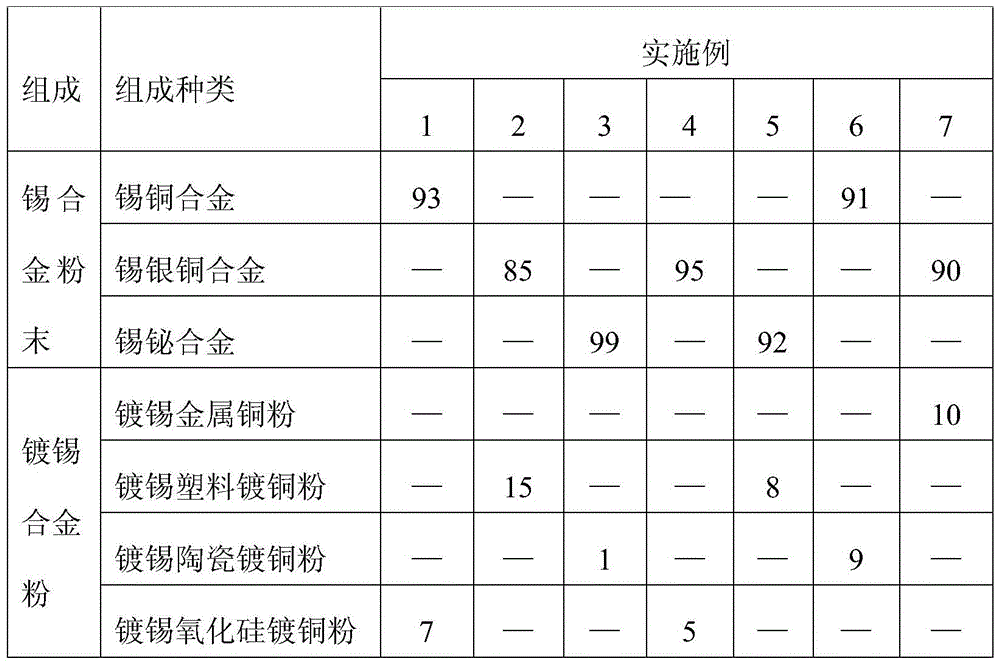

[0018] The solder powder doped with tin-plated alloy powder in the present invention is composed of tin-plated alloy powder and the rest of tin alloy powder, wherein the tin-plated alloy powder is obtained by heating the surface of non-tin alloy powder with a particle diameter of 20-45 μm. Prepared by electroless tin plating, the non-tin alloy powder is at least one of metal copper powder, plastic copper plating powder, ceramic copper plating powder and silicon oxide copper plating powder, and the tin alloy powder is tin-copper alloy, tin-silver-copper At least one of alloys and tin-bismuth alloys. The non-tin alloy powders adopted in this embodiment are all finished products purchased on the market such as metal copper powder, plastic copper-plated powder, ceramic copper-plated powder and silicon oxide copper-plated powder; For example, tin-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com