Preparation method of hydroxy apatite / polylactic acid / chitosan composite microballoon

A technology of hydroxyapatite and composite microspheres, applied in the field of materials science, can solve problems such as the preparation method of composite microspheres without three components, and achieve the effects of good three-phase bonding, good mechanical properties of materials, and mild implementation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh polylactic acid, chitosan, and hydroxyapatite according to the proportioning in Example 1 in Table 1 for subsequent use.

[0030]Measure 25 mL of glacial acetic acid to dissolve polylactic acid, add spare chitosan, stir and mix for 20 minutes, keep the ultrasonic water temperature not exceeding 25°C, and ultrasonically oscillate for 2 hours until chitosan is completely dissolved, add spare hydroxyapatite, keep Ultrasonic water temperature does not exceed 25 ° C, ultrasonic vibration 2h, until the mixture is milky white and no hydroxyapatite particles are precipitated.

[0031] According to the ratio of Example 1 in Table 1, measure liquid paraffin, petroleum ether, and Span80 and add them to the beaker, and stir and mix evenly, inject the hydroxyapatite / polylactic acid / chitosan mixture with a 0.8mm diameter injection needle , drop into the liquid paraffin / petroleum ether mixture with a stirring speed of 1500r / min, and continue to stir for 40 minutes; le...

Embodiment 2

[0033] Accurately weigh polylactic acid, chitosan, and hydroxyapatite according to the proportioning in Example 2 in Table 1 for subsequent use.

[0034] Measure 10 mL of glacial acetic acid to dissolve polylactic acid, add spare chitosan, stir and mix for 15 minutes, keep the ultrasonic water temperature not exceeding 25°C, and ultrasonically oscillate for 1 hour. The following operations are the same as in Example 1.

[0035] According to the ratio of Example 2 in Table 1, measure liquid paraffin, petroleum ether, and Span80 and add them to the beaker, and stir and mix evenly, inject the hydroxyapatite / polylactic acid / chitosan mixture with a needle with a diameter of 0.6mm , drop into the liquid paraffin / petroleum ether mixed solution with a stirring speed of 1500r / min, and continue to stir for 35min; operate according to Example 1 to obtain hydroxyapatite HA / polylactic acid PLA / chitosan CS composite microspheres, see figure 2 . The particle size of the product is mainly b...

Embodiment 3

[0039] Accurately weigh polylactic acid, chitosan, and hydroxyapatite according to the proportioning in Example 3 in Table 1 for subsequent use.

[0040] Measure 10 mL of glacial acetic acid to dissolve polylactic acid, add spare chitosan, stir and mix for 10 minutes, keep the ultrasonic water temperature not exceeding 25°C, and ultrasonically oscillate for 1.5 hours. The following operations are the same as in Example 1.

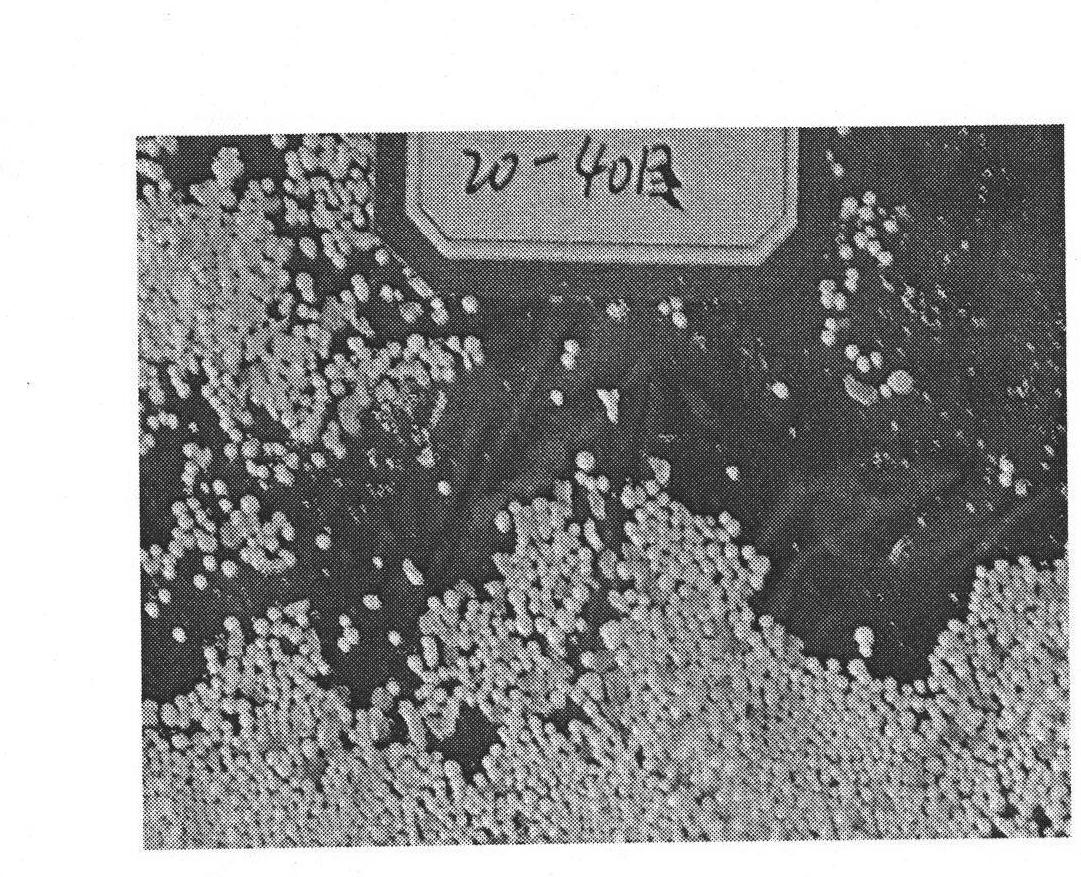

[0041] According to the ratio of Example 2 in Table 1, measure liquid paraffin, petroleum ether, and Span80 and add them to the beaker, and stir and mix evenly, inject the hydroxyapatite / polylactic acid / chitosan mixture with a needle with a diameter of 0.6mm , drop into the liquid paraffin / petroleum ether mixed solution with a stirring speed of 1500r / min, and continue to stir for 35min; operate according to Example 1 to obtain hydroxyapatite HA / polylactic acid PLA / chitosan CS composite microspheres, see Figure 4 . The particle size of the product is mainly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com