Design method for cooker support of cooker used for manufacturing fried bread sticks

A design method and pot support technology, which is applied in oil/fat baking, special product baking, baking, etc., can solve the problems of increased labor costs, low yield of round pots, etc., and achieve improved product appearance and appearance color Consistent, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

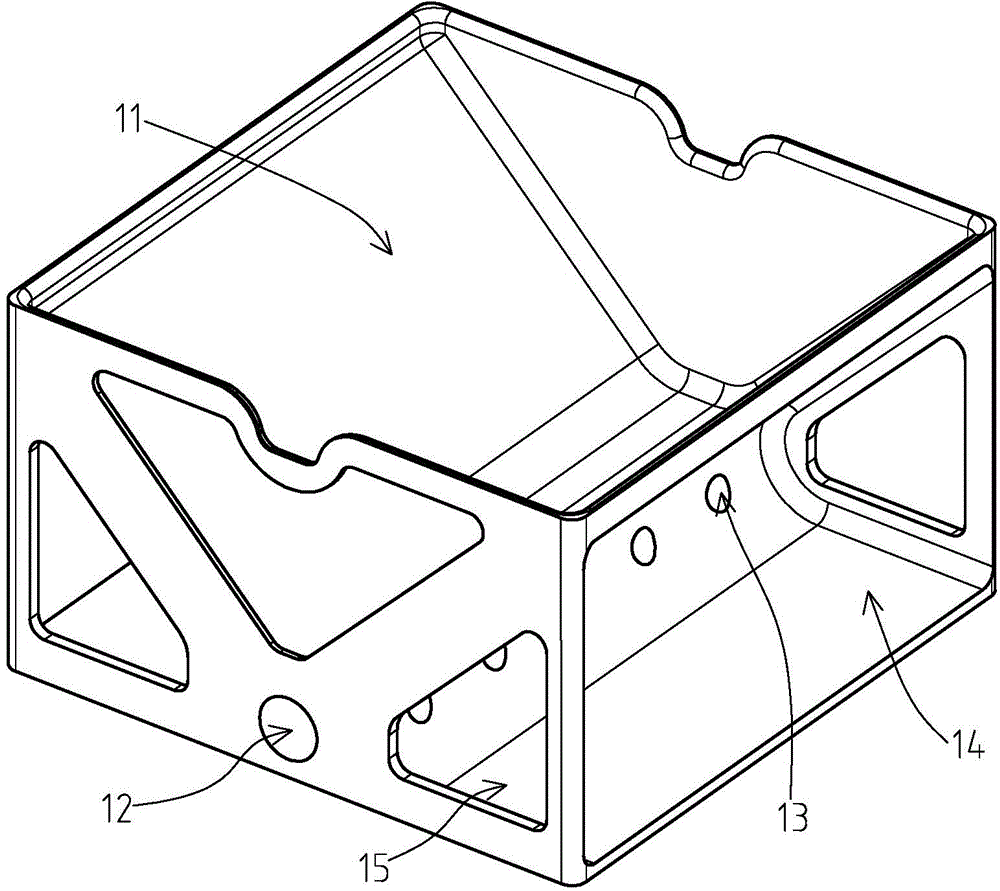

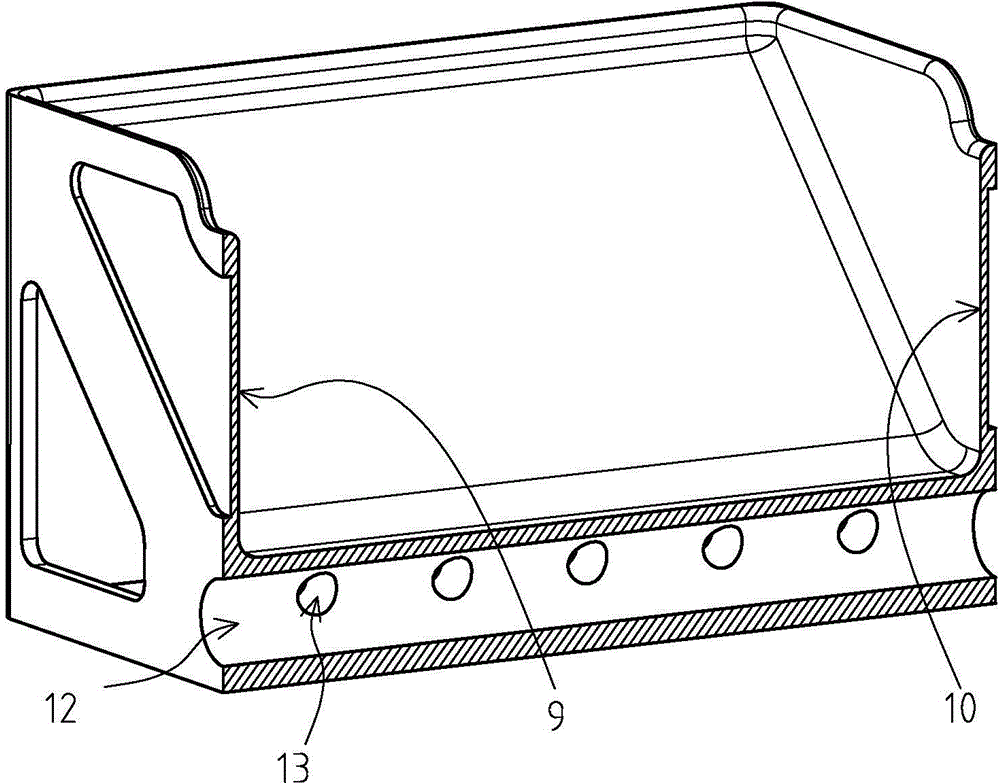

[0021] like figure 1 and image 3 As shown, it is an embodiment of a pan support for a pan for making deep-fried dough sticks disclosed in the present invention, which has a square shape, and a first receiving cavity 11 for receiving a lining is provided in the middle of the pan support. A second receiving cavity 14 for receiving the handle is respectively provided on the left and right sides of the pot support, and two special-shaped through holes for receiving the support plate are respectively provided on the front and rear facades of the pot support.

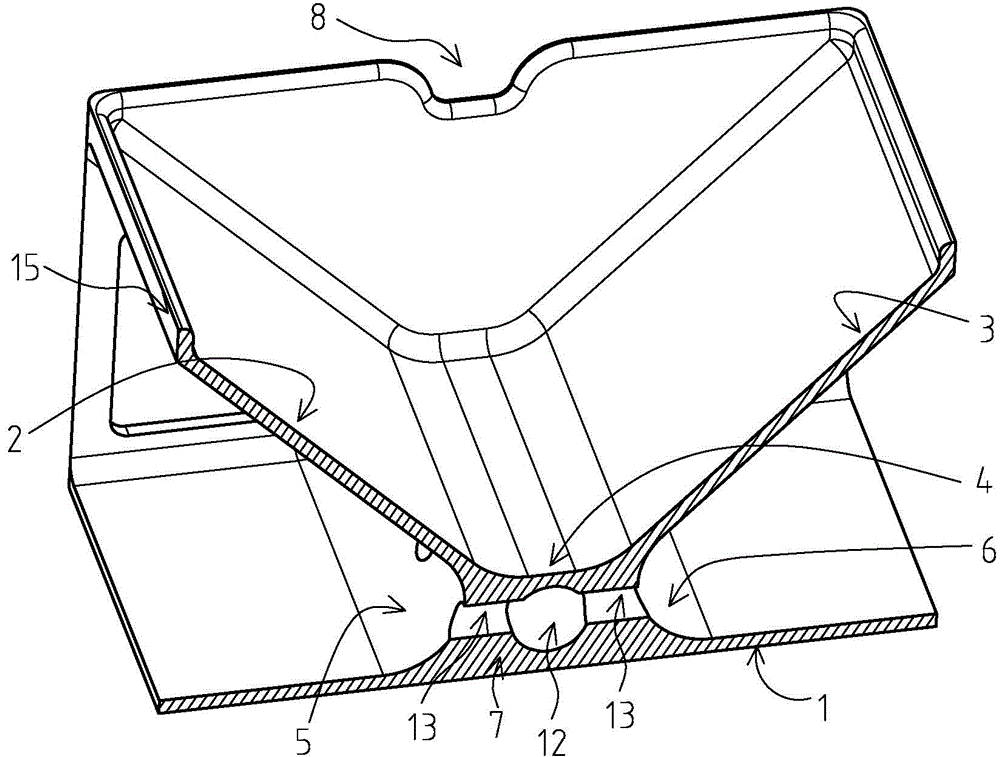

[0022] like figure 2 and image 3 As shown, it is a perspective view of the horizontal and vertical section of the pot stand. The bottom of the pot stand is provided with a first plane 1, and the middle part of the first plane 1 is provided with a protruding entity upward. The top of the entity extends to the left and right sides respectively. They are respectively the first plane 1 and the second plane 2, the first plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com