Preparation method of dicyandiamide resin tanning agent

A technology of dicyandiamide and resin, which is applied in the field of preparation of dicyandiamide resin tanning agent, can solve the problems that cannot meet the national environmental protection, human body and environmental hazards, and achieve good napping effect, strong filling effect, and reduced formaldehyde content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

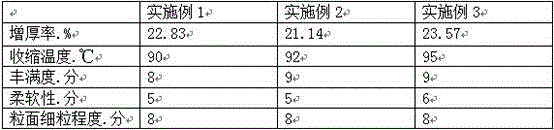

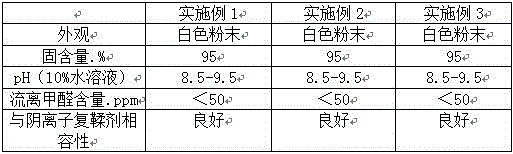

Embodiment 1

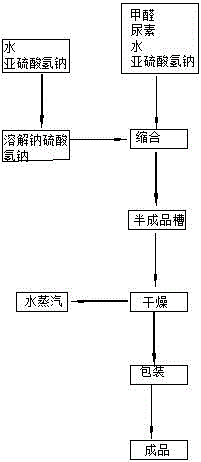

[0017] A kind of preparation method of dicyandiamide resin tanning agent, completes the preparation of dicyandiamide resin tanning agent through preparation sodium bisulfite solution, condensation reaction and drying step; Concrete steps are as follows:

[0018] (1) Prepare ammonium bisulfite solution: add 80Kg of water to the dissolution kettle, start stirring, then add 50Kg of sodium bisulfite, and stir until completely dissolved;

[0019] (2) Condensation reaction: Transfer the above-prepared sodium bisulfite solution into the condensation kettle, start stirring, add 80Kg of formaldehyde, then add 80Kg of dicyandiamide from the manhole, raise the temperature in the kettle to 75°C, and Insulate the reaction at high temperature for 2 hours. After the reaction, add 40Kg of urea from the manhole, and keep the reaction at 75°C for 1h. After the reaction, the temperature in the lower kettle is lowered to 60°C, and add 170Kg of water and 130-Kg of sulfurous acid from the manhole. ...

Embodiment 2

[0022] A kind of preparation method of dicyandiamide resin tanning agent, completes the preparation of dicyandiamide resin tanning agent through preparation sodium bisulfite solution, condensation reaction and drying step; Concrete steps are as follows:

[0023] (1) Prepare ammonium bisulfite solution: add 100Kg of water to the dissolution kettle, start stirring, then add 60Kg of sodium bisulfite, and stir until completely dissolved;

[0024] (2) Condensation reaction: transfer the above-prepared sodium bisulfite solution into the condensation kettle, start stirring, add 90Kg of formaldehyde, then add 100Kg of dicyandiamide from the manhole, raise the temperature in the kettle to 80°C, and Keep the reaction at high temperature for 4 hours. After the reaction, add 45Kg of urea from the manhole, and keep the temperature at 80°C for 3h. After the reaction, the temperature in the lowering kettle is lowered to 60°C, and add 190Kg of water and 150Kg of sodium bisulfite from the manho...

Embodiment 3

[0027] A kind of preparation method of dicyandiamide resin tanning agent, completes the preparation of dicyandiamide resin tanning agent through preparation sodium bisulfite solution, condensation reaction and drying step; Concrete steps are as follows:

[0028] (1) Prepare ammonium bisulfite solution: add 90Kg of water to the dissolution kettle, start stirring, then add 56Kg of sodium bisulfite, and stir until completely dissolved;

[0029] (2) Condensation reaction: Transfer the above-prepared sodium bisulfite solution into the condensation kettle, start stirring, add 86Kg of formaldehyde, then add 90Kg of dicyandiamide from the manhole, raise the temperature in the kettle to 77°C, and Insulate the reaction at high temperature for 3 hours. After the reaction, add 43Kg urea from the manhole, and keep the temperature at 77°C for 2h. After the reaction, the temperature in the lowering kettle drops to 60°C, and add 180Kg water and 140Kg sodium bisulfite from the manhole. , react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com