Firing-free ceramic wood chip board (ceramic-wood board)

A technology of sawdust boards and ceramics, applied in the field of boards, can solve problems such as difficult cleaning, damage to cement strength, and weak impact resistance, and achieve the effects of wide application fields, reduced engineering cost, light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

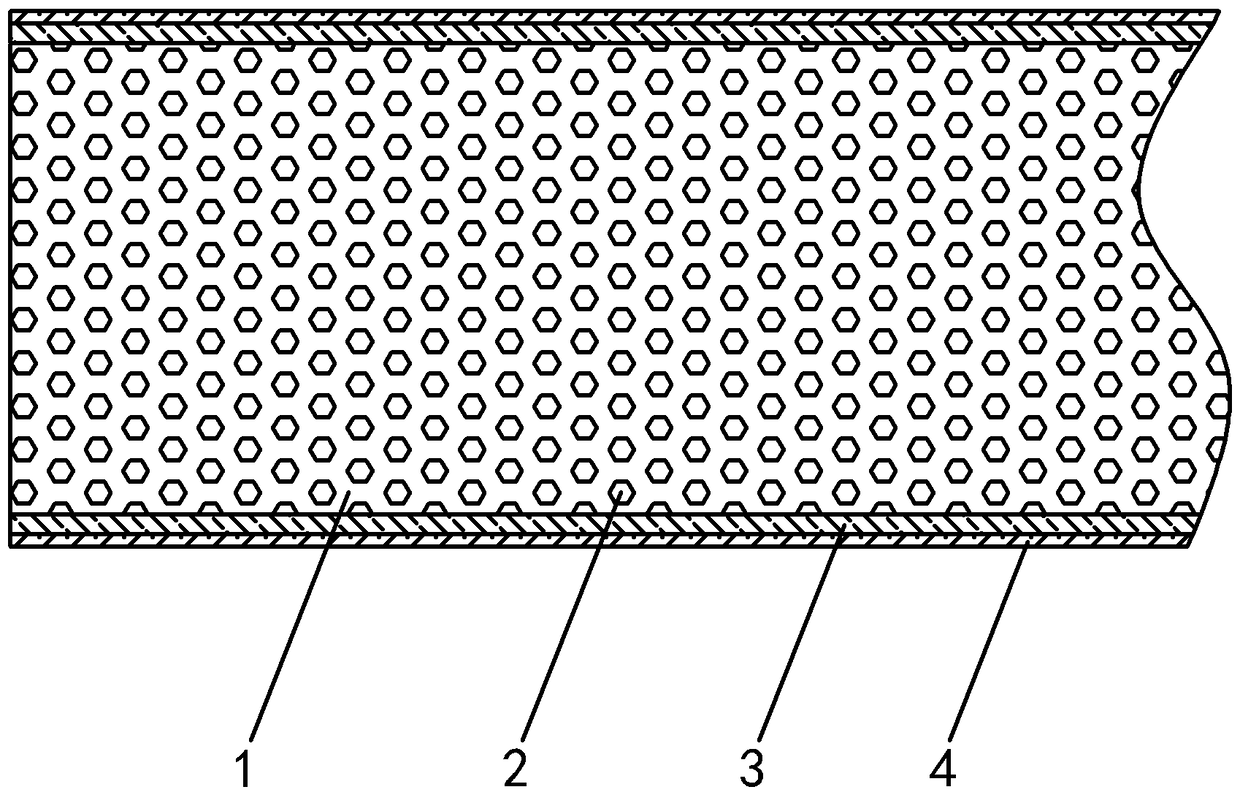

[0021] refer to figure 1 , in this embodiment, the unfired ceramic sawdust board is made of unfired ceramics (1), wood chips (2) and mesh bars (3), and the mass parts of unfired ceramics and wood chips are: 100 parts of unfired ceramics, wood chips 10 servings. After mixing the non-fired ceramics and wood chips, add 50 parts of water, stir and make a plate shape, and lay mesh reinforcement (3) on both sides of the board and add non-fired ceramic pure slurry, which will form pure non-fired ceramic slurry after hardening. After the fired ceramic coating (4), the non-fired ceramic (1) is hardened, it can be made into a non-fired ceramic sawdust board. In addition, a small amount of wood chips or / and sand can also be added to the pure unfired ceramic slurry as needed, so as to improve the performance of the pure unfired ceramic layer (4) and save costs.

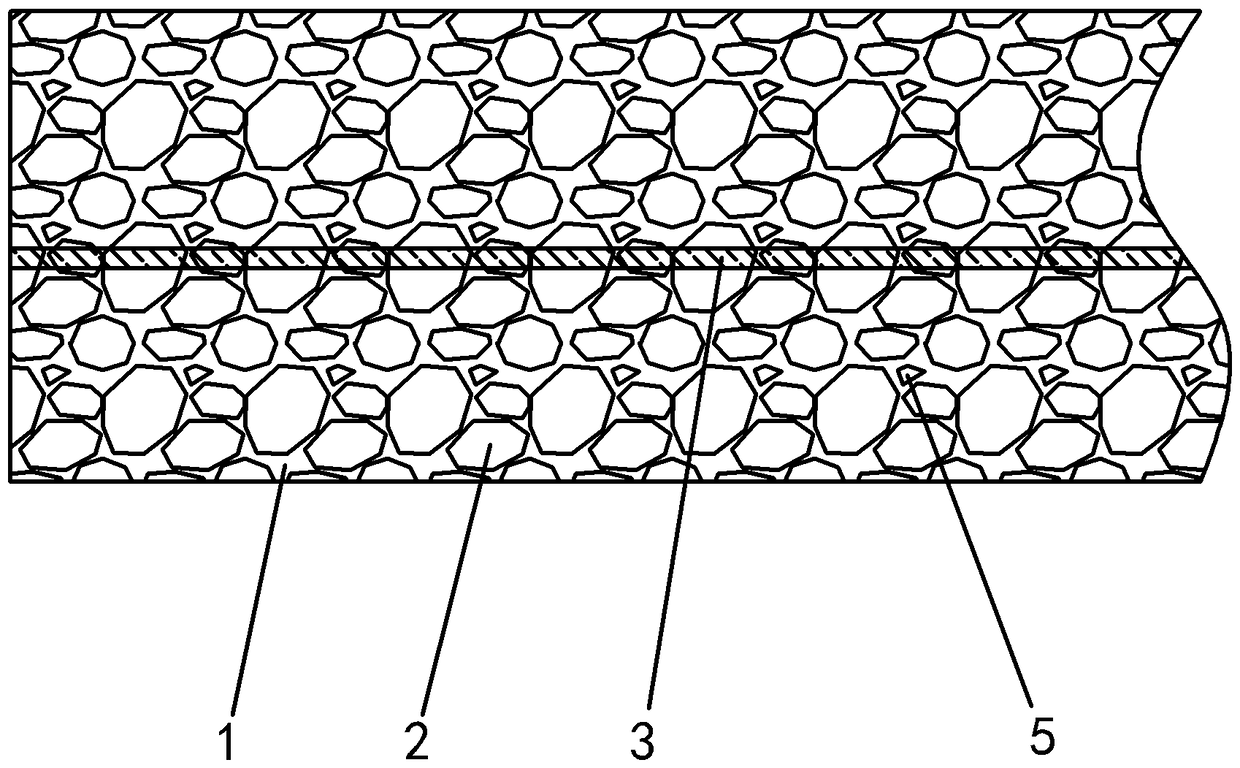

[0022] refer to figure 2 , in this embodiment, the unfired ceramic sawdust board is made of unfired ceramics (1), wood chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com