Grindstone hot press molding die and hot press molding technology thereof

A hot-press forming and mold technology, applied in grinding devices, manufacturing tools, metal processing equipment, etc., can solve the problems of many molds and large heat conduction distance, and achieve the effects of reduced manufacturing cost, uniform heating and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

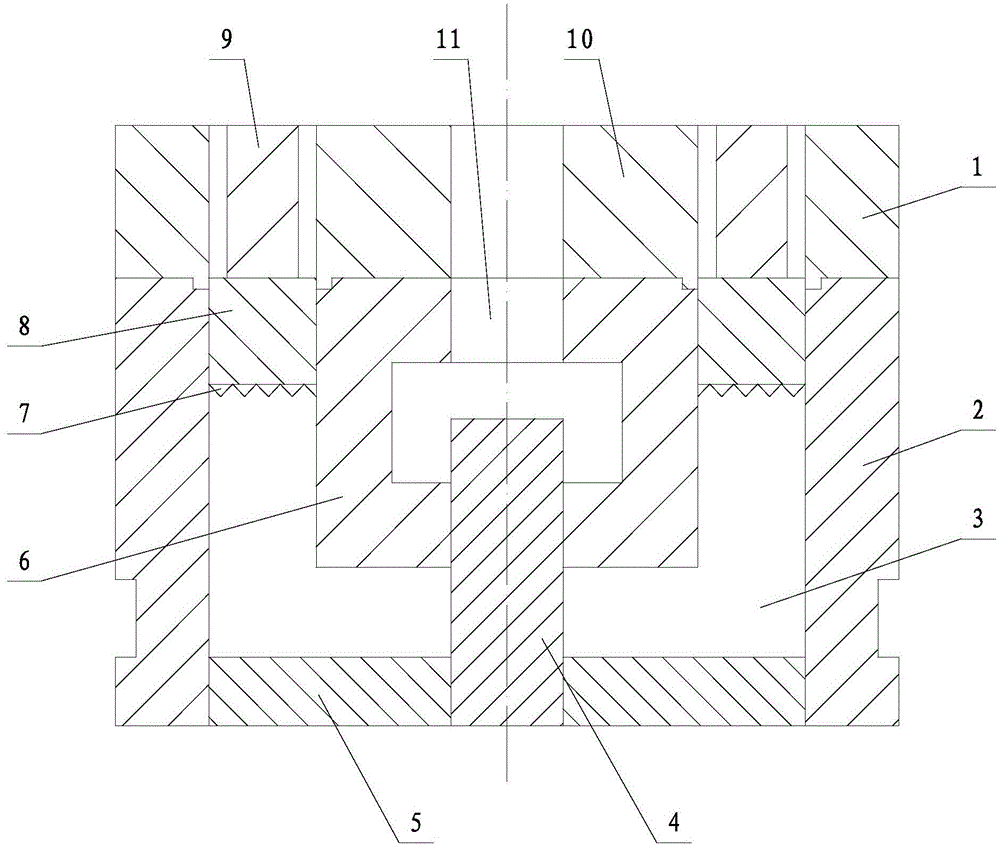

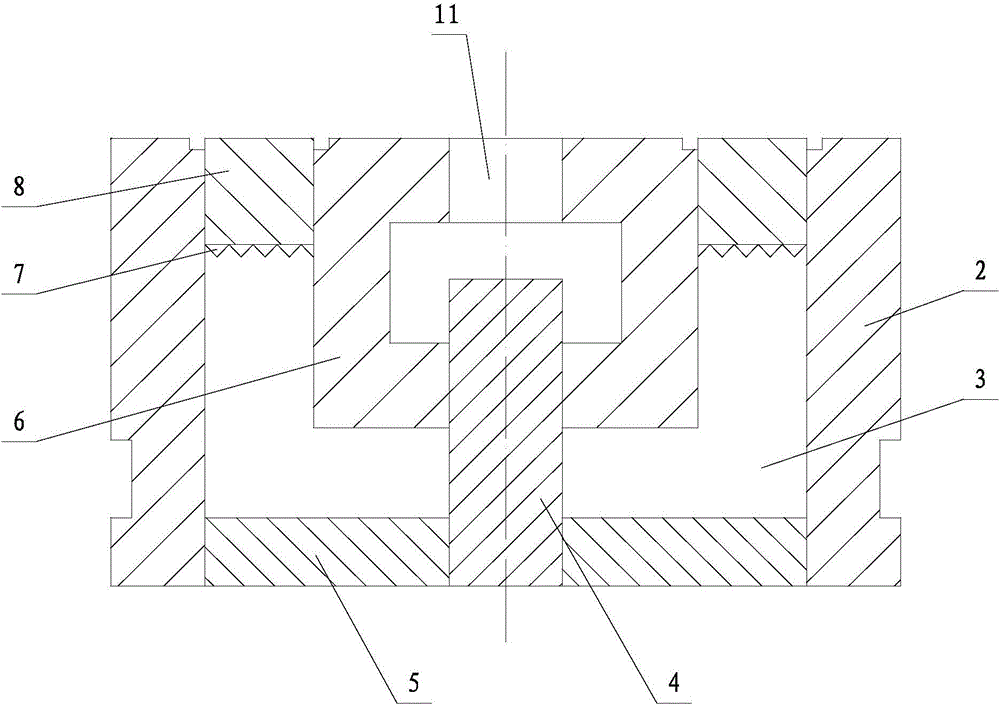

[0032] Such as figure 1 As shown, the thermoforming mold of this embodiment includes a detachable upper mold and a lower mold, wherein the upper mold includes a sleeve 1, a pressure ring 9 and an upper core type 10, and the lower mold includes a die sleeve 2 and a mandrel 4 , the lower template 5, the lower core type 6, the pecking plate 7 and the upper template 8. The core type of this embodiment includes a mandrel 4 and upper and lower core types 10,6. The mold case 2 is cylindrical, with a taper on the inner wall, which shrinks outward from bottom to top; when hot pressing, the big end of the mold case 2 faces upwards (that is, the end with the larger diameter of the inner wall of the mold case 2 faces upwards), and on the top of the die case 1 A socket 1 is installed, and a pad iron is placed under the mold sleeve 2; the lower template 5 is located at the bottom of the mold sleeve 2, and the outer surface of the mandrel 4 has a taper, which shrinks from bottom to top inwa...

Embodiment 2

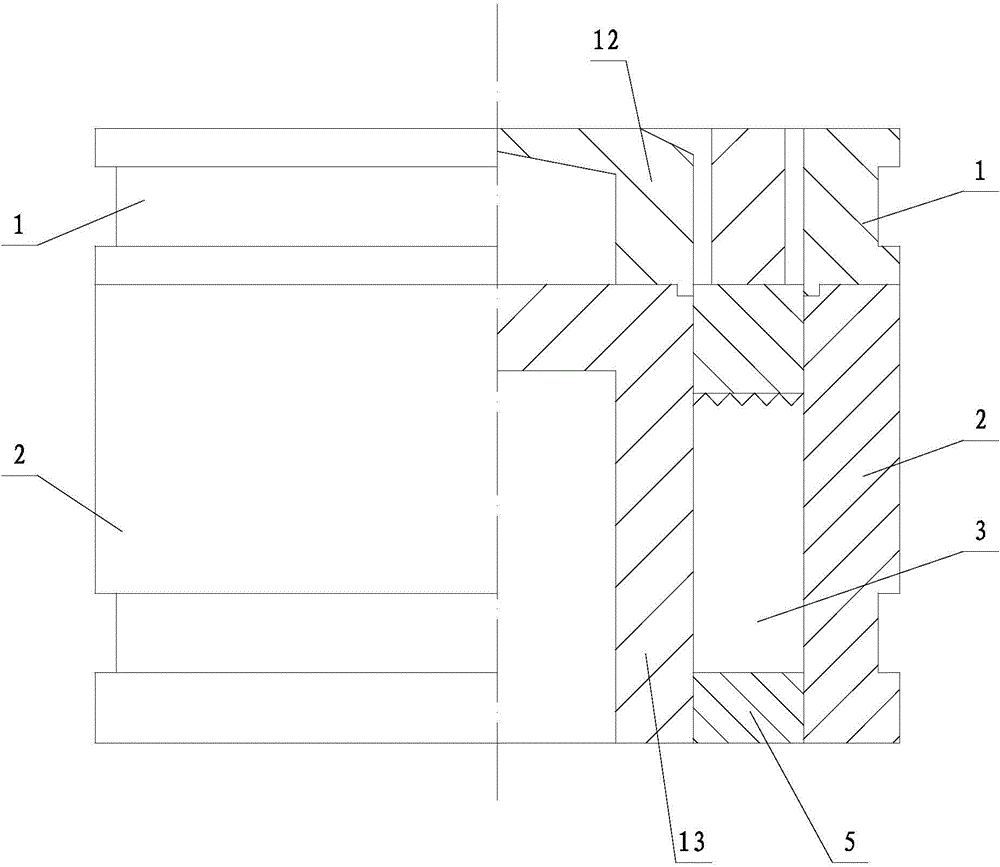

[0035] Such as image 3 As shown, the thermoforming mold of this embodiment includes a detachable upper mold and a lower mold, wherein the upper mold includes a sleeve 1, a pressure ring 9 and an upper connecting mandrel 12, and the lower mold includes a die sleeve 2, a lower connecting core Rod 13, lower template 5, pecking plate 7 and upper template 8. In this embodiment, the grinding stone is a cylindrical grinding wheel, and the core is a cylindrical mandrel structure. The mandrel is divided into an upper mandrel 12 and a lower mandrel 13 which are hollow inside. The mold case 2 is cylindrical, with a taper on the inner wall, which shrinks outward from bottom to top; when hot pressing, the big end of the mold case 2 faces upwards (that is, the end with the larger diameter of the inner wall of the mold case 2 faces upwards), and on the top of the die case 1 Sleeve 1 is installed, and a shim iron is placed under the mold sleeve 2; the lower formwork 5 is located at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com