Patents

Literature

229results about How to "Mature manufacturing technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

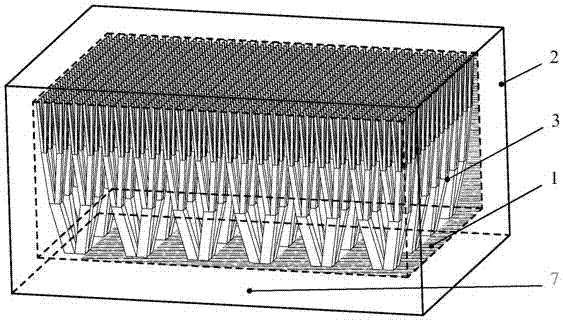

Charging pressing forming method for variable-cross-section special-shaped pipe

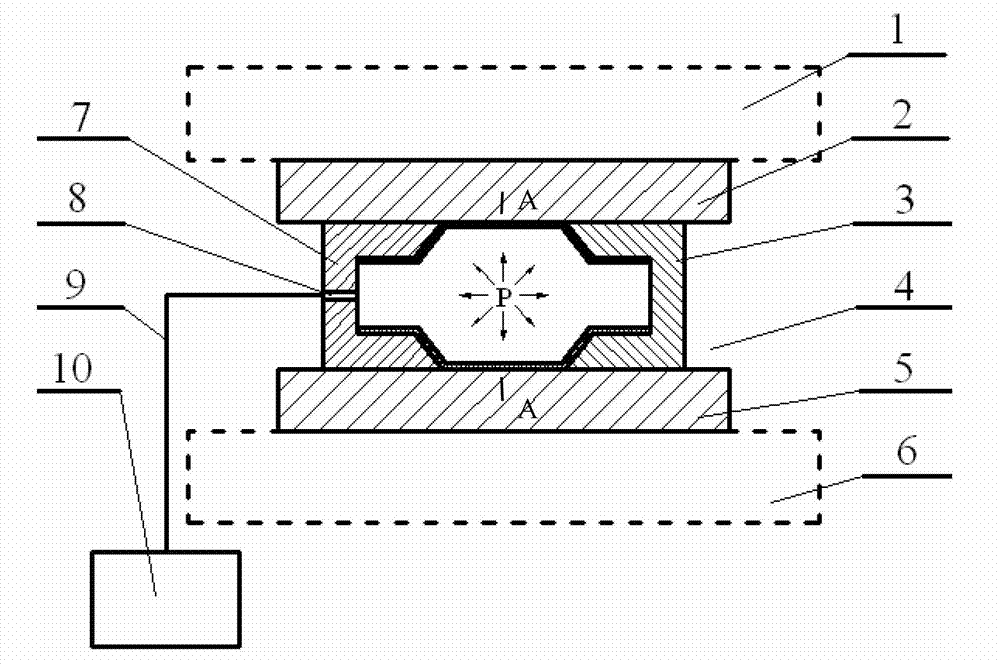

The invention discloses a charging pressing forming method for a variable-cross-section special-shaped pipe, and relates to a forming manufacturing method of a metal pipe. The problems that an existing low-internal-pressure forming technology only can form a pipe with the unchangeable section perimeter, and meanwhile, in the internal-high-pressure forming process of an advanced high-strength steel variable-cross-section pipe, the pressure is high, springback is large, and a mold is seriously worn are solved. The forming method comprises the steps that firstly, an upper expansion mold and a lower expansion mold are assembled on a pressure machine; secondly, the upper expansion mold descends to perform mold assembly, a pipe blank is subject to charging, and the pipe blank expands until the pipe blank is attached to the mold; thirdly, the internal pressure of the pipe blank is relieved; fourthly, an upper pressing block and a lower pressing mold are assembled on a pressure machine; fifthly, the upper pressing block descends to perform mold assembly; sixthly, under the joint action of mechanical pressure of the mold and hydraulic pressure of an inner cavity of a variable-cross-section round pipe, mold attaching is carried out, the variable-cross-section round pipe is formed into the variable-cross-section special-shaped pipe, and the forming process is finished; and seventhly, the internal pressure of the variable-cross-section special-shaped pipe is relieved, and the variable-cross-section special-shaped pipe is cut, so that the variable-cross-section special-shaped pipe meeting the design requirement is obtained. The method is used for forming the variable-cross-section special-shaped pipe.

Owner:HARBIN INST OF TECH

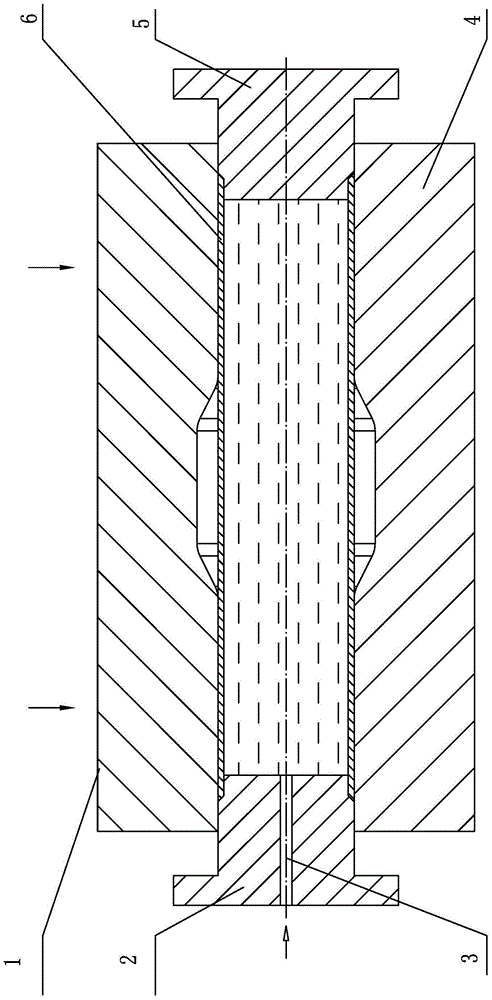

Variable-gradient fractal lattice sandwiched reinforcement phase change heat sink

ActiveCN106940148AUniform absorptionSmooth releaseHeat storage plantsSemiconductor/solid-state device detailsEngineeringHeat sink

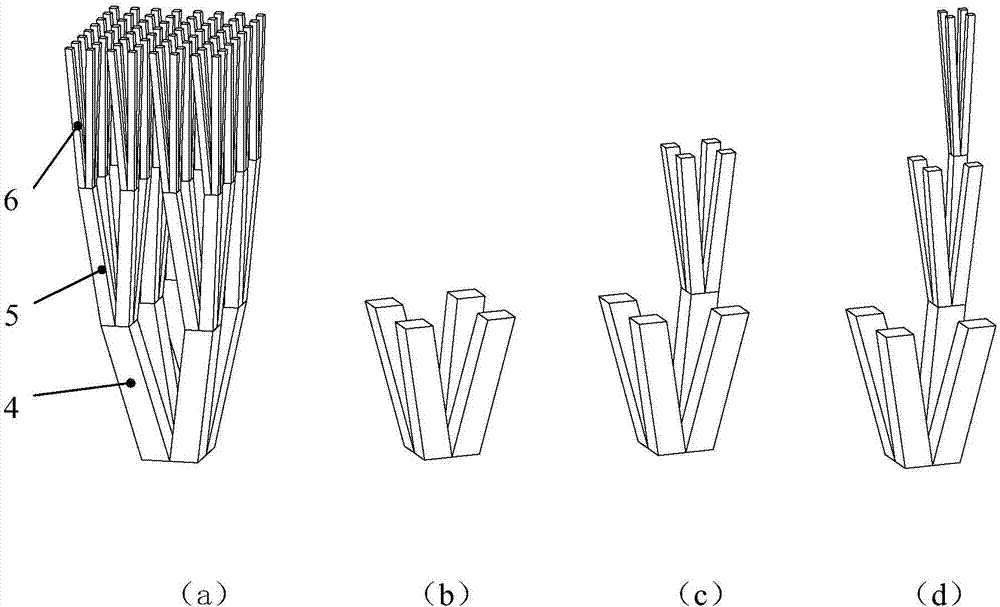

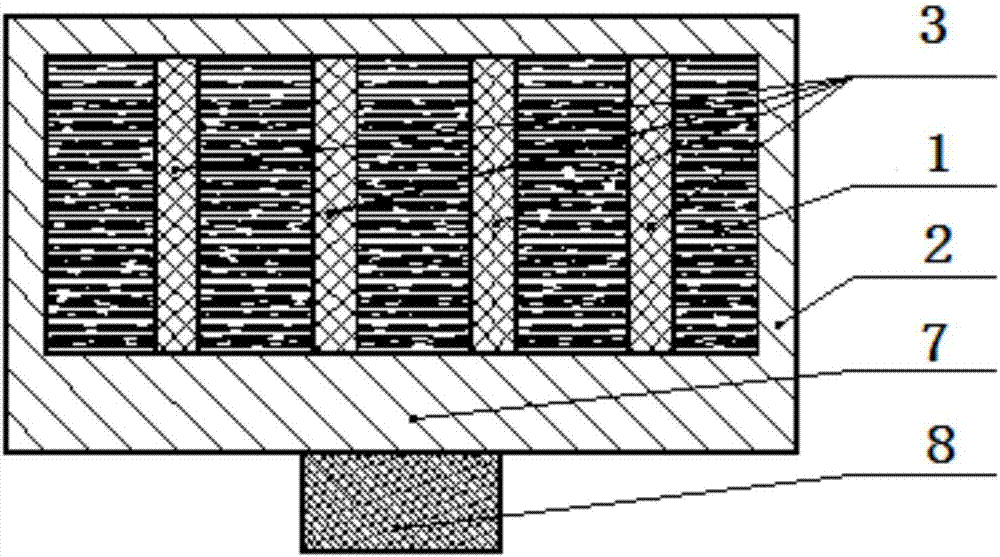

The invention discloses a variable-gradient fractal lattice sandwiched reinforcement phase change heat sink and aims to provide an efficient phase change heat sink which is high in heat exchange efficiency, has certain universality and can be developed in a serialization mode. The variable-gradient fractal lattice sandwiched reinforcement phase change heat sink is realized according to the following technical scheme: reinforcement heat transfer structures are distributed in a phase change heat sink shell in an array; each variable-gradient fractal lattice sandwiched unit takes a variable-gradient V structure as a first-stage reinforcement heat transfer structure (4) according to the heat transfer and heat exchange characteristics of the phase change heat sink; on this basis, at variable-gradient V-shaped ends of the first-stage reinforcement heat transfer structures, the variable-gradient V structures in the same shape are gradually increased to form multiple stages of reinforcement heat transfer structures, and the specific surface areas of the multiple stages of reinforcement heat transfer structures are multiplied in sequence; the first-stage reinforcement heat transfer structures can transfer heat to an area far away from a heat radiation bottom plate rapidly in a reinforcement mode, and the second-stage reinforcement heat transfer structures (5) and the third-stage reinforcement heat transfer structures can transfer heat to phase change material far away from the heat radiation bottom plate rapidly to complete heat exchange.

Owner:10TH RES INST OF CETC

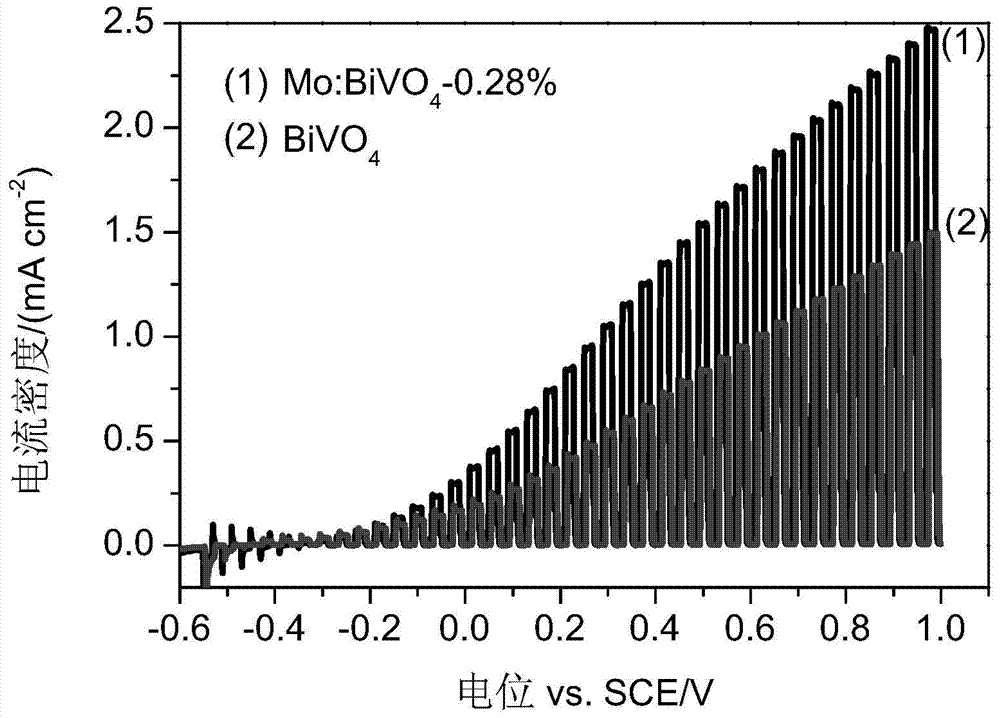

Method for preparing hydrogen through photoanode-photovoltaic battery coupled dual-illumination fully-photic-driven decomposition of water

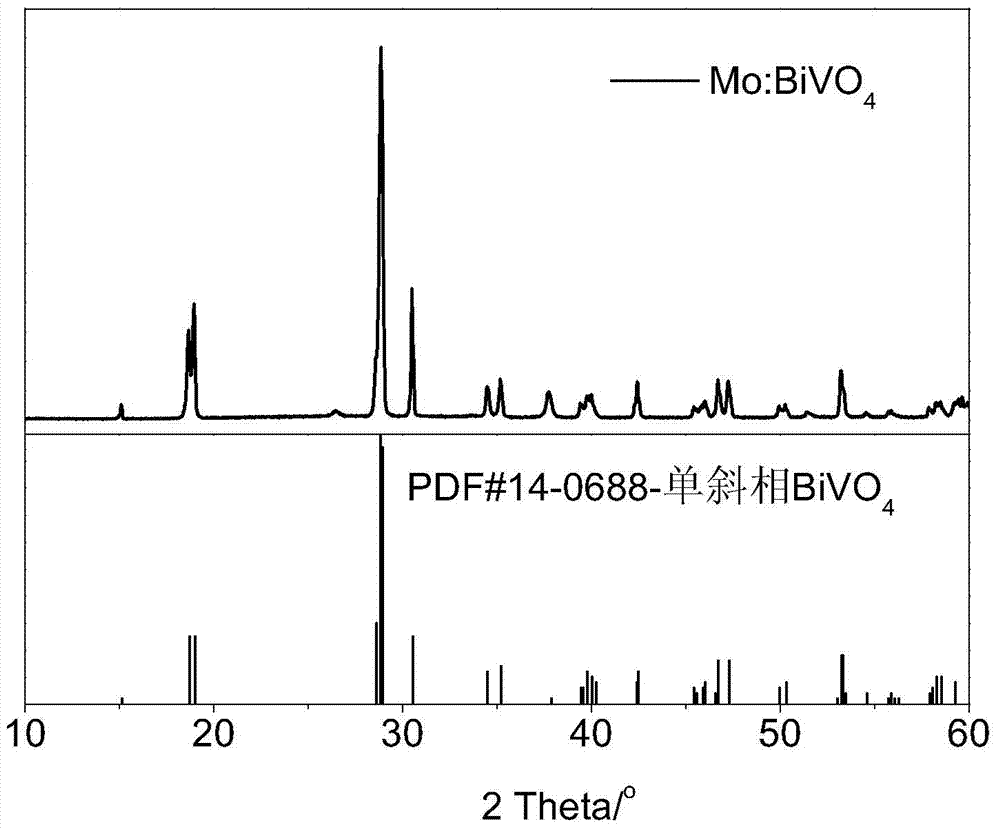

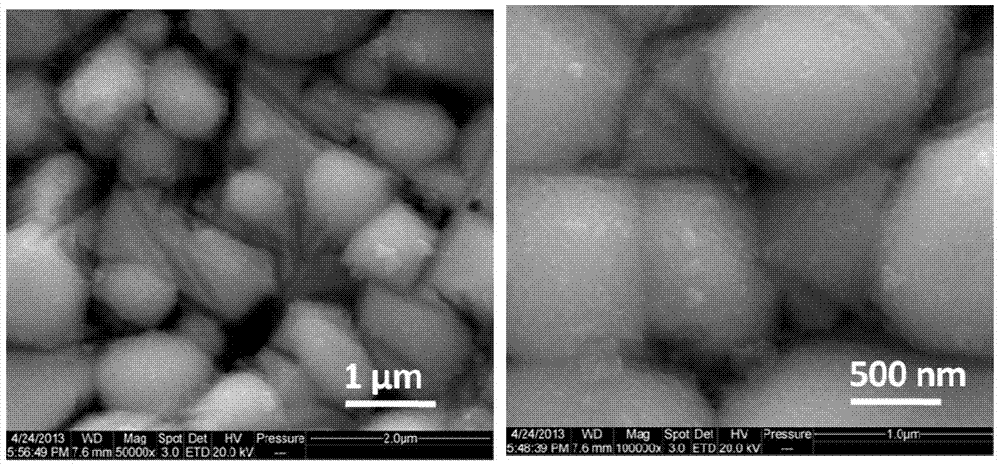

InactiveCN104711627AImprove visible light absorptionHigh catalytic activityElectrolysis componentsLight-sensitive devicesSemiconductor materialsHydrogen

The invention relates to a method for preparing hydrogen through photoanode-photovoltaic battery coupled dual-illumination fully-photic-driven decomposition of water. Efficient decomposition of water is realized under sunlight illumination conditions by using coupling of a photoelectrocatalysis technology with a photovoltaic battery technology, adopting a water oxidation cocatalsyt modified semiconductor material as a photoanode, placing a proton reduction cocatalyst modified Si battery in an electrolyte as a photocathode, directly connecting the positive electrode of the Si battery with the anode through a lead and allowing the surface of the cathode to contact with the electrolyte. The method realizes fully photic driven decomposition of water without applied bias conditions, and the solar energy utilization efficiency STH of the method reaches 2.2% or above.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

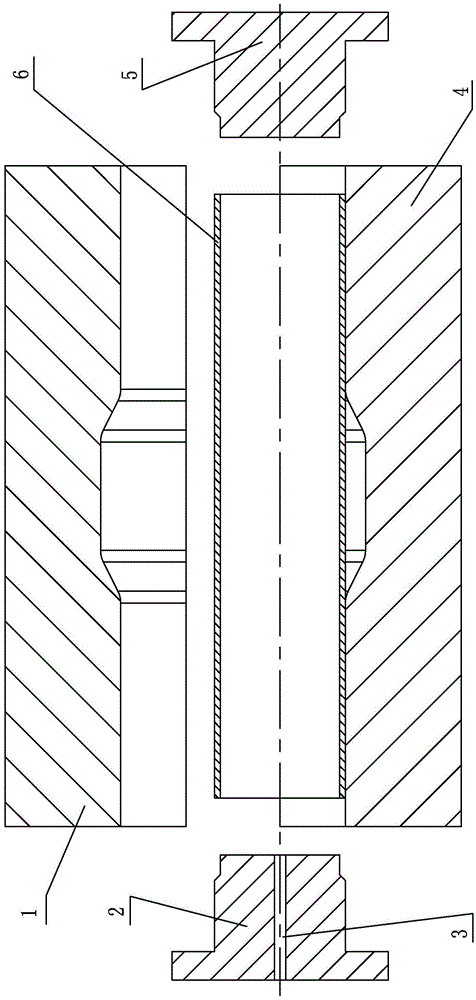

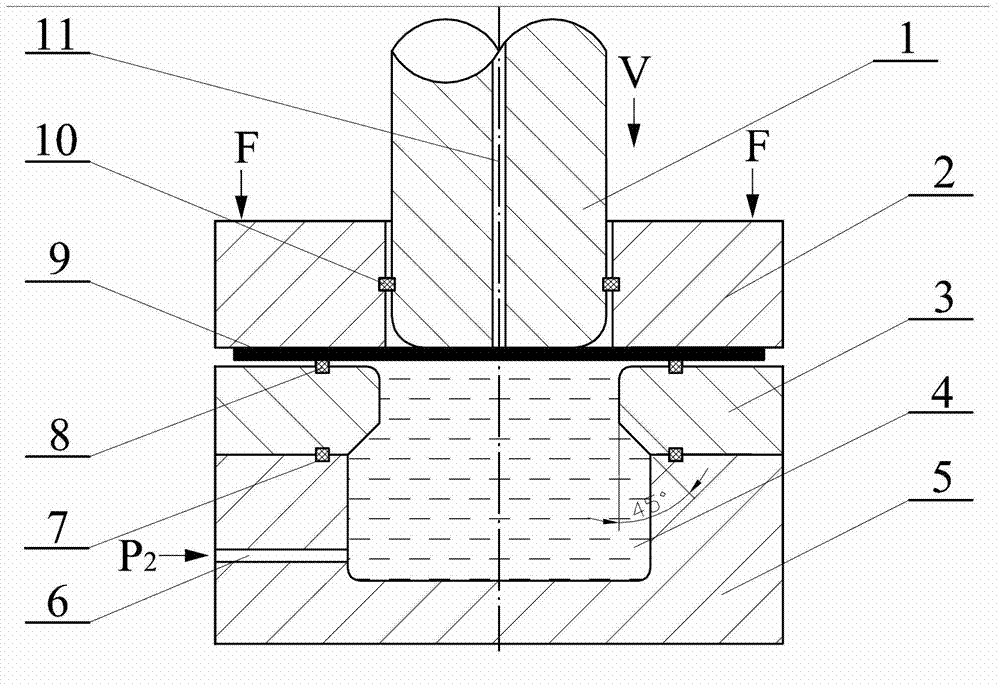

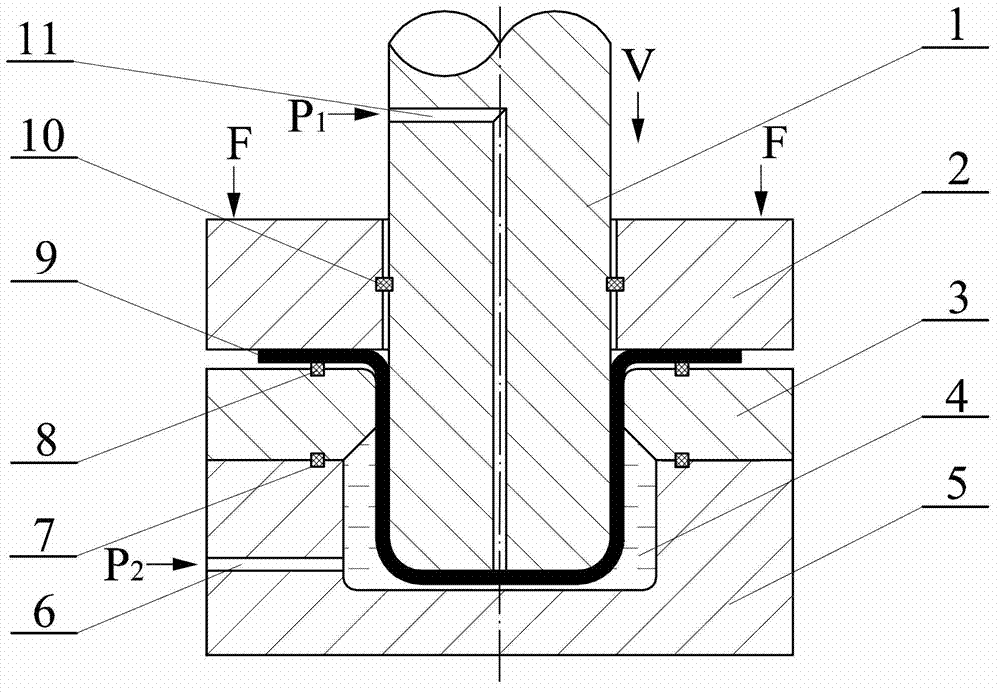

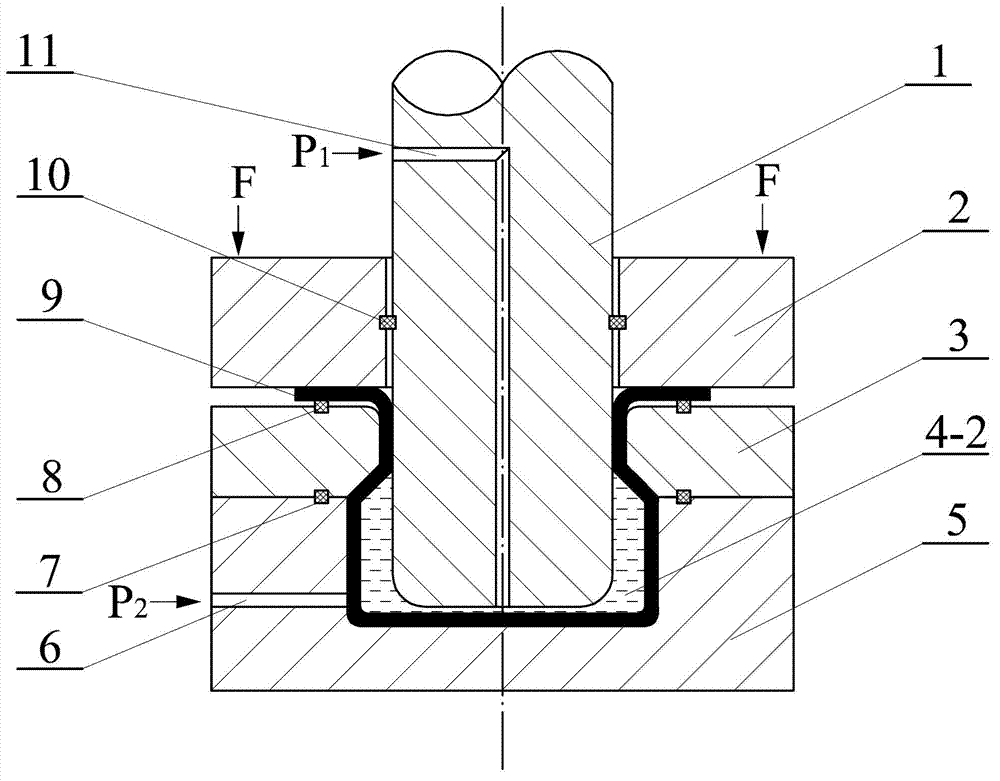

Hydraulic forming device and method of reducing cylindrical part

A hydraulic forming device and method of a reducing cylindrical part relate to a hydraulic forming device and method of a metal plate. Aiming at the bottleneck problems of high cost, long cycle and poor forming property in a roll welding process used due to the fact that the reducing cylindrical part, the section of an axis part of which is of a bottle shape with a small upper part and a big lower part, is difficult to machine by using the traditional plate hydraulic forming method, the device comprises a lower concave die and an upper concave die; a blank holder and a convex die are arranged above the upper concave die; the shape of a cavity in the concave die is in accordance with the shape of the outer outline of a finally-formed cylindrical part, namely the cavity is configured into a reducing cylinder with the aperture gradually reduced from the bottom to the top or reducing in a stepped form; and the lower concave die and the convex die are respectively provided with an injection hole. The forming method sequentially comprises the following steps of: injecting medium in the cavity, arranging blanks, pressing the blanks, applying backpressure, downwards moving the convex die, and pressing in the inner cavity of a pre-formed part in order to close to the die. The blanks are under the action of a pressure difference of inner and outer dynamic fluids in the forming process due to the injection holes arranged in the convex die, the die-close forming of the blanks is finished at one step, and the formed part can be smoothly taken out due to the design of the combined concave die.

Owner:HARBIN INST OF TECH

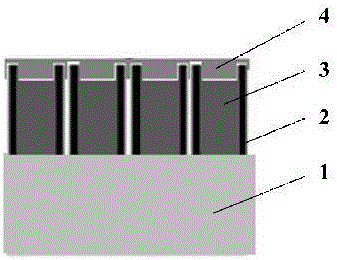

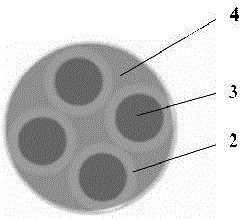

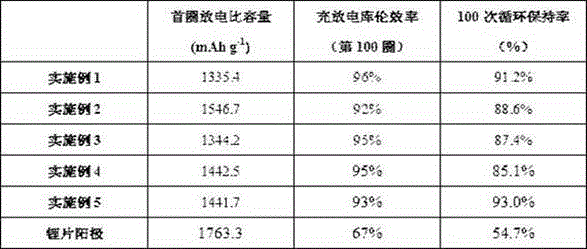

Lithium anode for high-specific-energy secondary battery

InactiveCN106025230AGuaranteed stabilityOvercoming breakageFuel and primary cellsMaterial nanotechnologyPhysicsMetallic lithium

The invention discloses a lithium anode for a high-specific-energy secondary battery. The lithium anode for the high-specific-energy secondary battery consists of a conductive substrate, a nanotube array, lithium metal and a barrier layer, wherein the nanotube array grows on the conductive substrate in an oriented manner; the lithium metal exists in the nanotube array; the barrier layer covers the nanotube structure. The lithium anode for the high-specific-energy secondary battery has the advantages that the lithium metal exists in a pipeline structure in a sealed manner, lithium dendrites can be prevented effectively, and a metal organic frame (MOF) which is rich in electrolyte or another lithium conducting material is used as the barrier layer, so that overgrowth of the lithium dendrites in local nanotubes can be prevented effectively, and the safety of the battery is ensured.

Owner:SHENZHEN RES INST CENT SOUTH UNIV

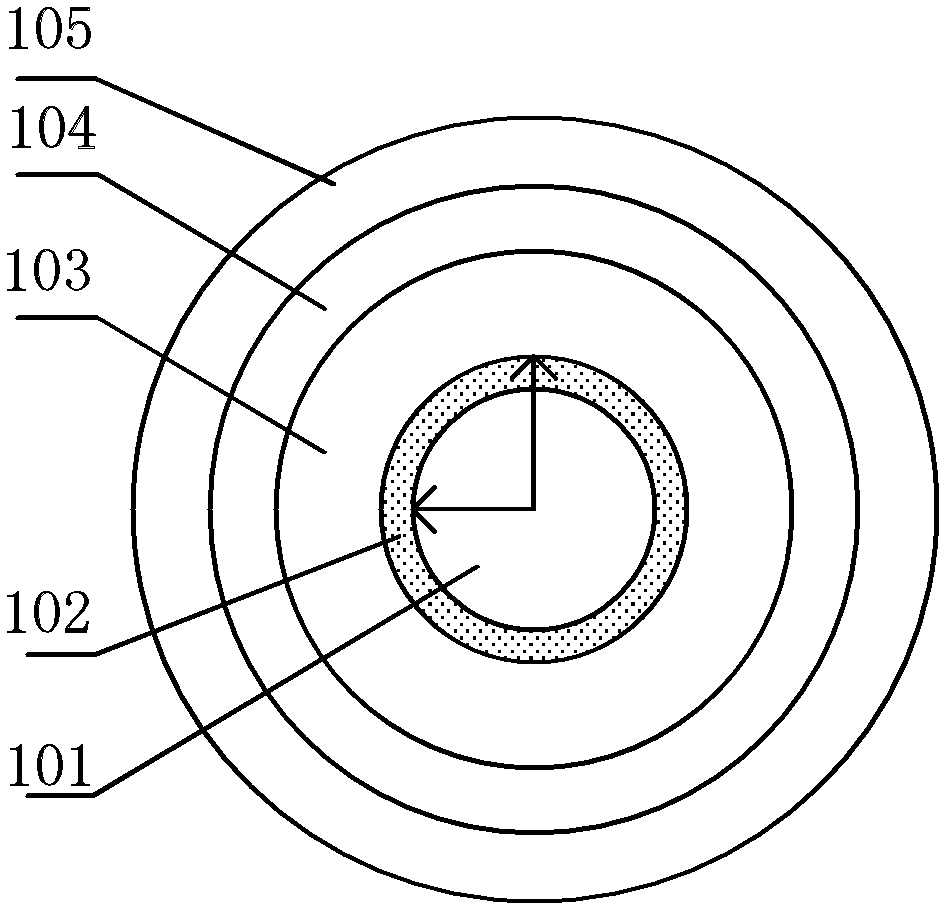

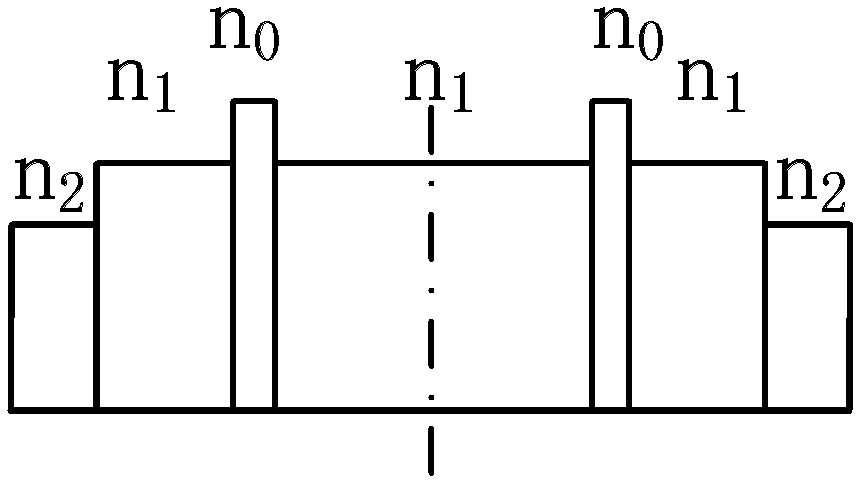

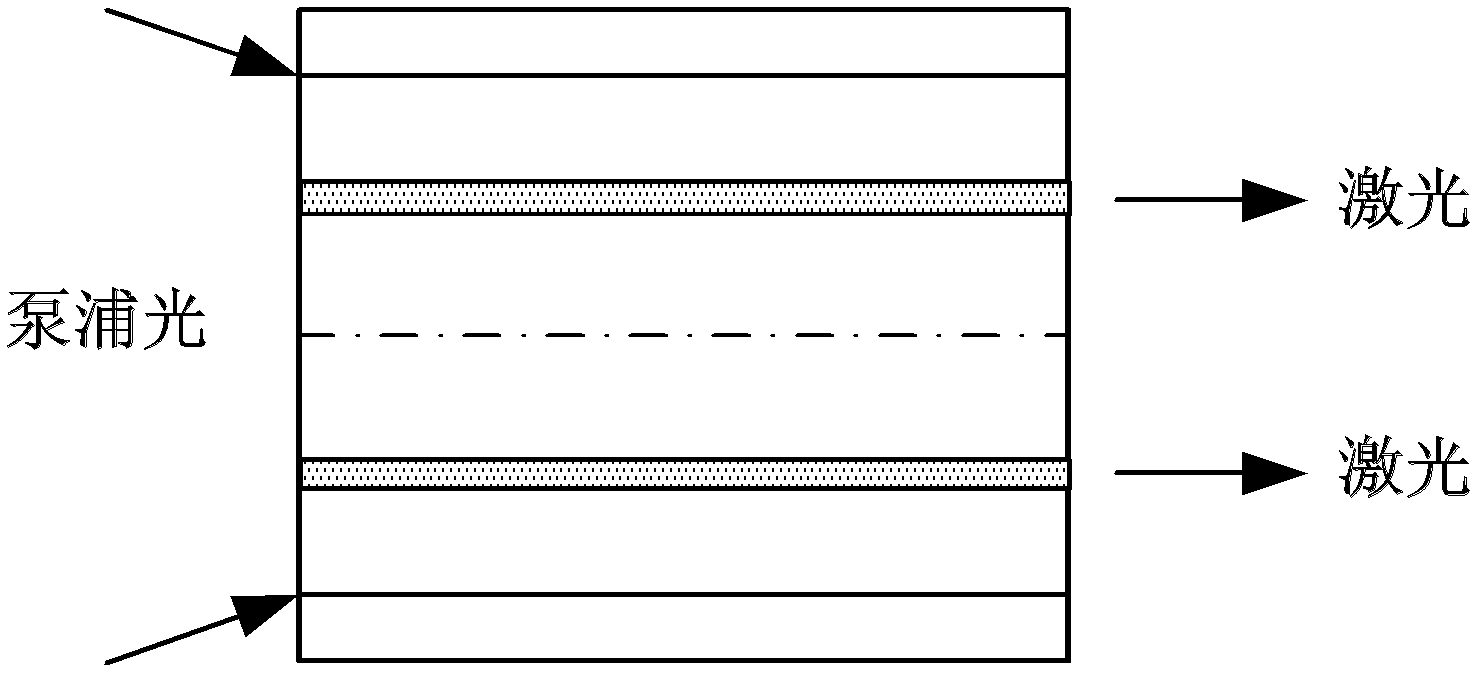

Optical fiber with ring-shaped doped layer and preparation method thereof and laser containing optical fiber

InactiveCN102621628AMature preparation technologyIncrease laser powerGlass making apparatusOptical fibre with multilayer core/claddingOptical fiber cableWaveguide

The invention discloses an optical fiber with a ring-shaped doped layer, which is used in an optical fiber laser and composed of an inner clad layer (101), a ring-shaped doped layer (102), a middle clad layer (103), an outer clad layer (104) and a protective layer (105), wherein the ring doped layer (102), the middle clad layer (103), the outer clad layer (104) and the protective layer (105) are, from inside to outside, sequentially clad on the inner clad layer (101), and the inner clad layer (101) is an undoped optical fire core. The invention also discloses a method for preparing the optical fiber with a ring-shaped doped layer, and a laser taking the optical fiber with a ring-shaped doped layer as a gain medium. According to the invention, the traditional fiber core doping is changed into a ring-shaped doped layer, so that the laser oscillation is actually performed in a ring-shaped waveguide, and then through reasonably designing the thickness of the ring-shaped waveguide, a single-mode operation can be kept; meanwhile, because the cross section area of the doped layer is large, the optical fiber with a ring-shaped doped layer is suitable to high-power output, therefore, the output power of the optical fiber laser using the optical fiber can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

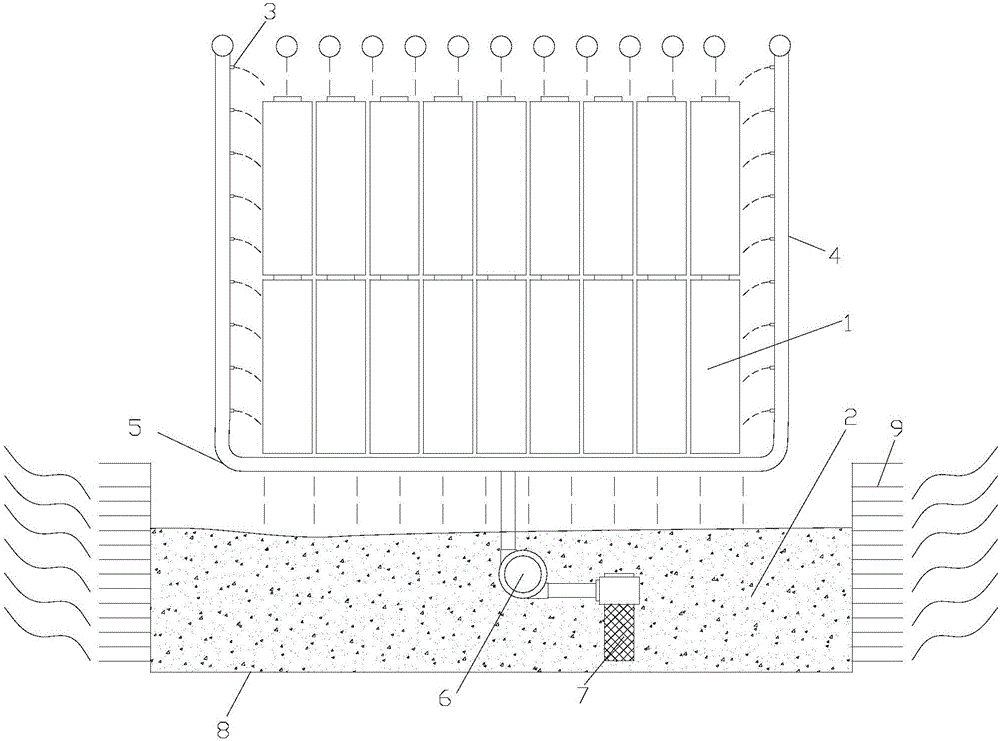

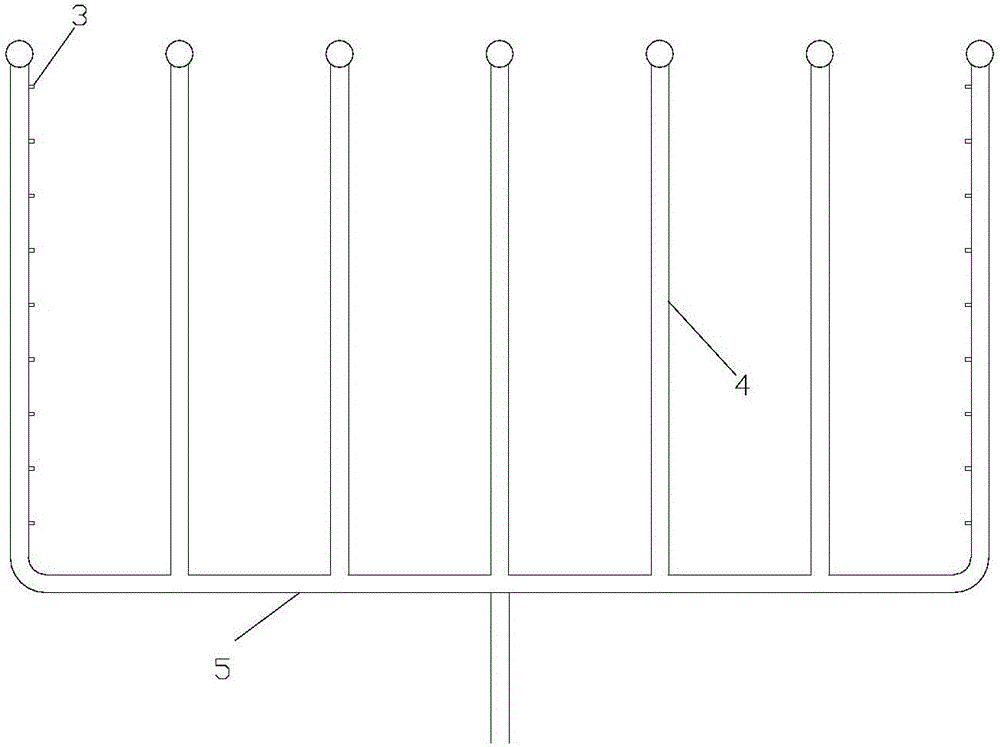

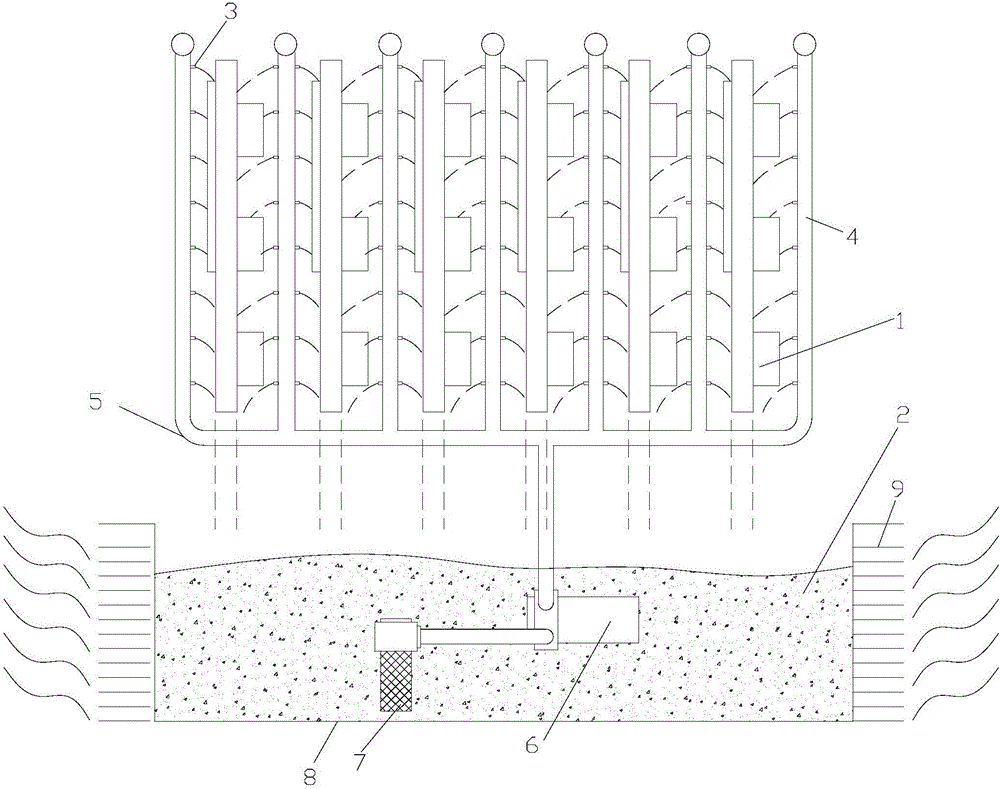

Working medium contact cooling system of power batteries and working method of working medium contact cooling system

ActiveCN105977572AReduce thermal contact resistanceImprove heat transfer efficiencySecondary cellsBatteriesPower batteryHeat conducting

The invention discloses a working medium contact cooling system of power batteries. An insulating liquid heat-conducting working medium is contained in a working medium box; a working medium pump sinks into the insulating liquid heat-conducting working medium; a filter is arranged at an inlet of the working medium pump; the working medium pump is connected with a spray main pipe; a plurality of spray branch pipes are connected with the spray main pipe in parallel; each spray branch pipe is provided with a plurality of nozzles; the nozzles are opposite to a high-power battery pack; the spray branch pipes and the spray main pipe form a cage frame; the high-power battery pack is placed in the cage frame; the spray branch pipes are distributed on the side surfaces and the upper part of the high-power battery pack to form a relatively open spray structure; and the insulating liquid heat-conducting working medium is a nonpolar substance and is free of a phase change in the spray process. The invention further provides a working method of the working medium contact cooling system of the power batteries. According to the working medium contact cooling system, the cooling structure is reasonable and the cooling efficiency is high.

Owner:佛山久安储能科技有限公司

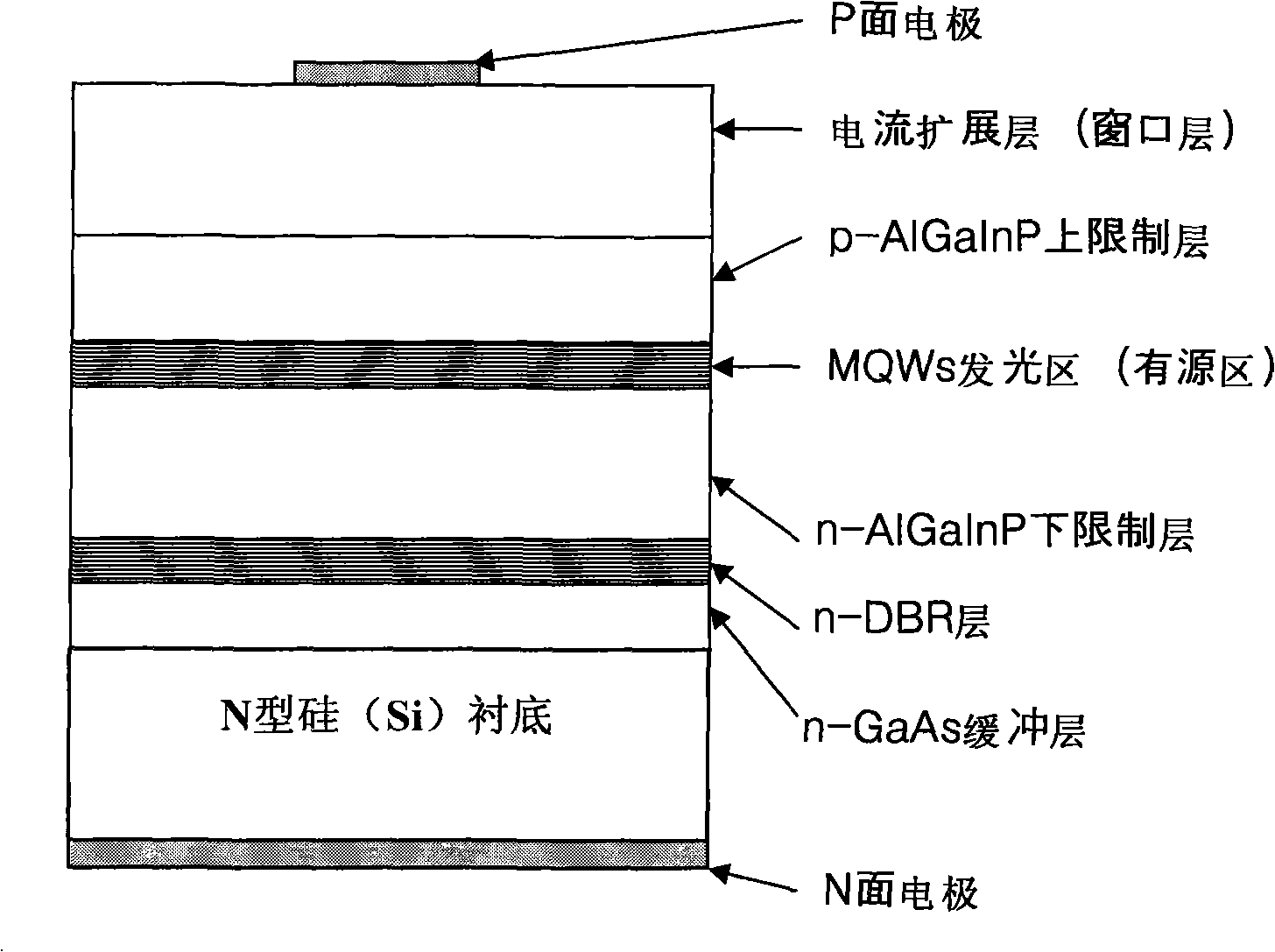

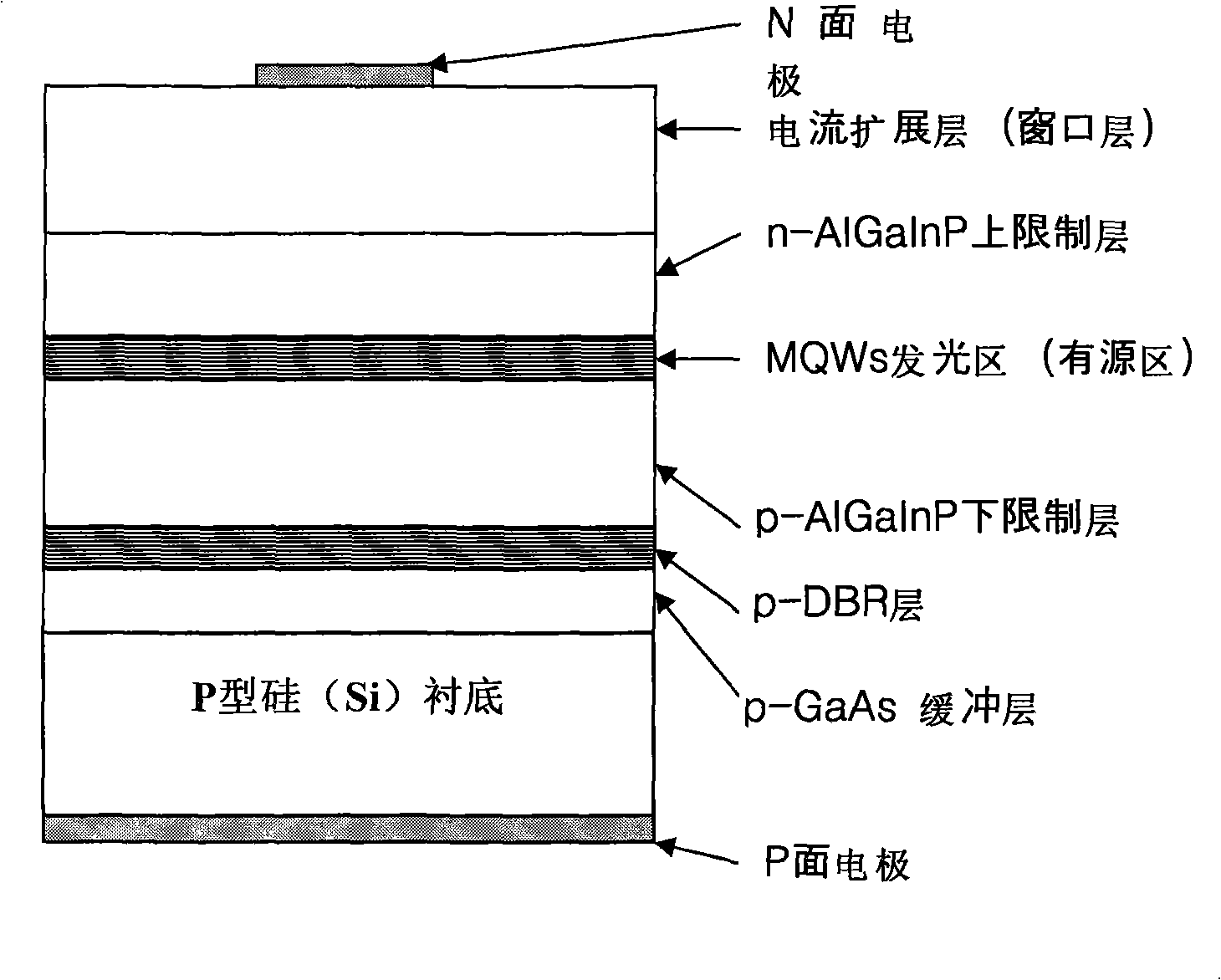

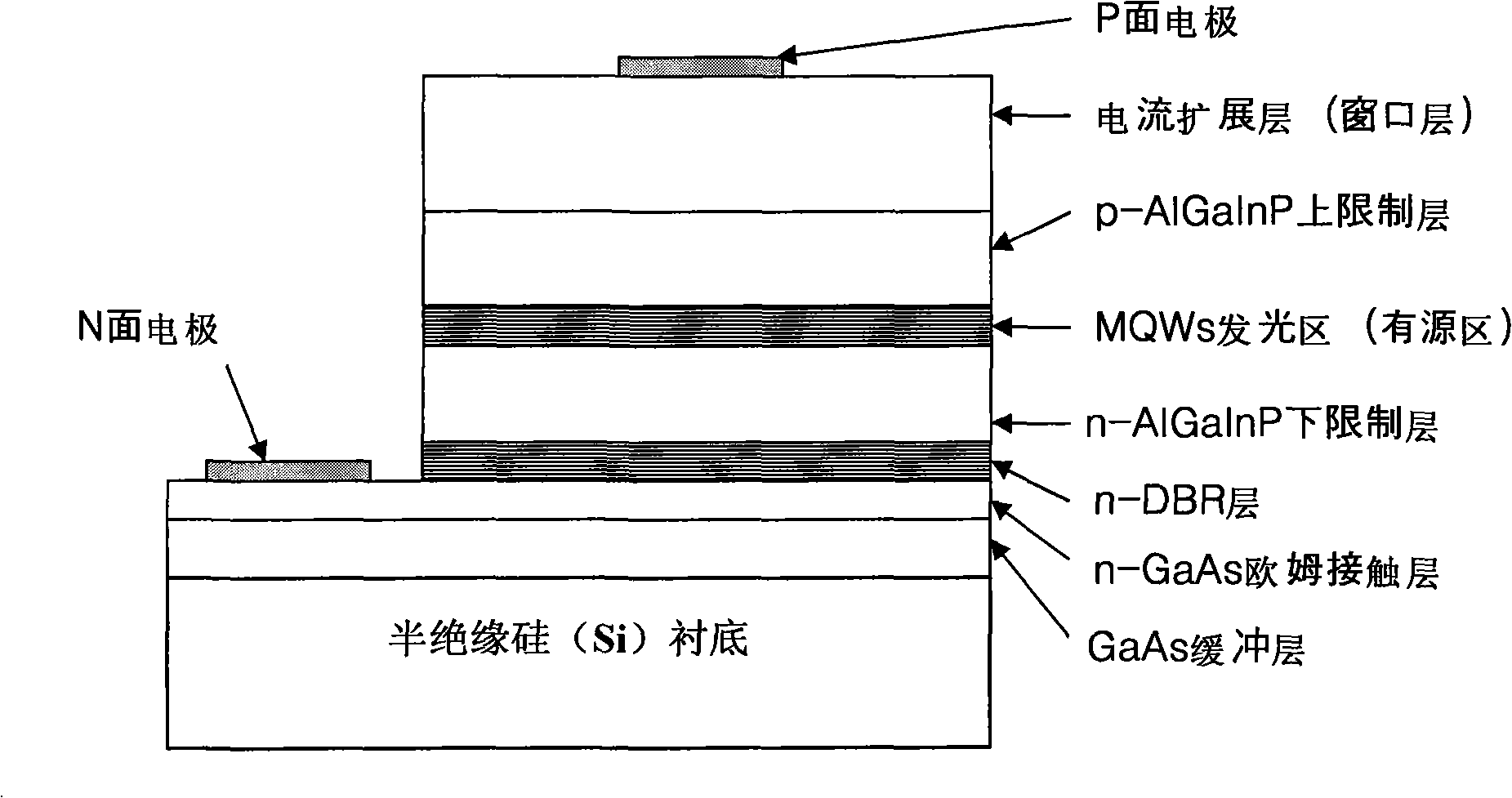

Silicon base grown AlGaInP LED epitaxial wafer and preparation method thereof

InactiveCN101540361ASolving CTE Mismatch ProblemsMature manufacturing technologySemiconductor devicesEpitaxial materialGallium arsenide

The invention discloses a silicon base grown AlGaInP LED epitaxial wafer and a preparation method thereof. The LED epitaxial wafer adopts a silicon base which sequentially comprises a gallium arsenide low-temperature buffer layer, a gallium arsenide high-temperature buffer layer, a DBR reflecting layer, an AlGaInP lower limiting layer, a multiple quantum well light emitting area, an AlGaInP upper limiting layer and a current expansion layer from bottom to top. The preparation method comprises the steps that metal organic chemical vapor deposition equipment is directly used for sequentially growing layer by layer. The AlGaInP LED epitaxial wafer solves the problem of heat expansion coefficient mismatch between the silicon base and the AlGaInP light emitting layer and directly and epitaxially grows the epitaxial material on the silicon base. The heat conductivity of silicon (145.7W / m. K) is 3.3 times of that of the AlGaInP base (44W / m. K) so as to improve the heavy current working capability of the silicon.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Preparation method of human adipose-derived MSCs (mesenchymal stem cells) and application of human adipose-derived mesenchymal stem cell in preparation of medicine for treating diseases

InactiveCN104357383ABroad basic researchSolid basic researchAntipyreticMetabolism disorderAutoimmune conditionSide effect

The invention discloses a preparation method of human adipose-derived MSCs (mesenchymal stem cells) and an application of the human adipose-derived MSCs in preparation of medicine for treating diseases. The preparation method of the human adipose-derived MSCs comprises steps as follows: adipose tissue collection, adipose tissue transportation, adipose tissue connection, adipose tissue microblock preparation, SVF (stromal vascular fraction) extraction, primary culture, subculturing, cell cryopreservation, cell bank establishment and cell recovery. The human adipose-derived MSCs have a powerful immunity regulation function and can be applied to preparation of medicine for treating autoimmune diseases, and compared with conventional medicine, the human adipose-derived MSCs have the advantages as follows: 1, the treatment is convenient, the curative effect is lasting, the variety and the number of medicine for treatment and toxic and side effects caused by medicine treatment can be reduced, even the medicine such as immunosuppressant and the like for treatment is out of service, the death rate and the disability rate are reduced, and life quality is improved; 2, the safety is good, and toxic and side effects are avoided; 3, the source of adipose tissue is wide, the collection is convenient, fundamental research of the human adipose-derived MSCs is solid, the preparation technology is mature, the popularization degree is high, and the technology is controllable; and 4, the preparation cost of the human adipose-derived MSCs is lower than that of other biological preparation and can be accepted by most patients.

Owner:张炳强

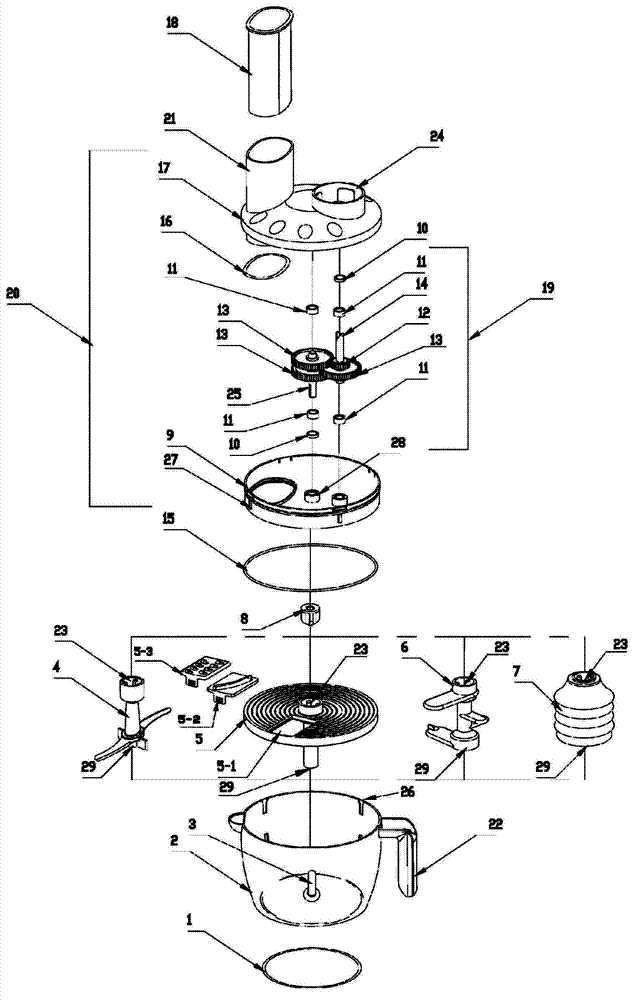

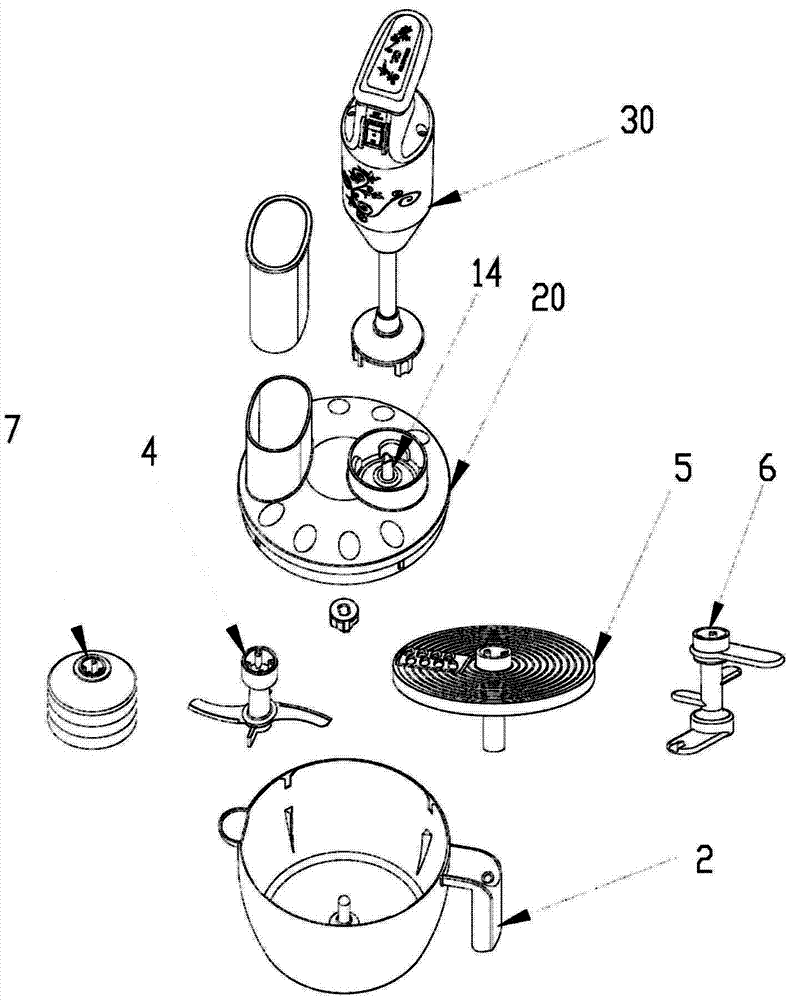

Handheld multifunctional food processing device

The invention belongs to the technical field of food processing equipment, and relates to a handheld multifunctional food processing device. The main structure of the handheld multifunctional food processing device comprises a sliding cushion, a barrel body, a vertical shaft, a grinding cutter, a cutting disk, a cutter groove, a splicing cutter, a shredding cutter, a dough kneader, a garlic peeler, a connector, a lower barrel cover, pipe rubber, a copper shaft, a speed-reducing pinion, a speed-reducing gearwheel, a rotary shaft, a barrel cover lower sealing ring, a barrel cover upper sealing ring, a barrel cover, a press-in rod, a speed reducing device, a transmission cover, a feeding hole, a handle, a transmission shaft seat, a power seat, a transmission shaft, a clamping groove, a convex clamp, a transmission shaft hole and a hollow rotary shaft, and functionally comprises a handheld motor, the transmission cover, the barrel body and processing parts, wherein the processing parts comprise the grinding cutter, the cutting disk, the dough kneader and the garlic peeler. The handheld multifunctional food processing device is scientific in design principle, fashion in appearance, mature in preparation technology, easy to use and operate, good in processing effect, high in efficiency, easy to assemble and disassemble, convenient to clean, high in performance, multifunctional, wide in application, environmentally-friendly, safe and reliable.

Owner:QINGDAO LEKANG ELECTRONICS

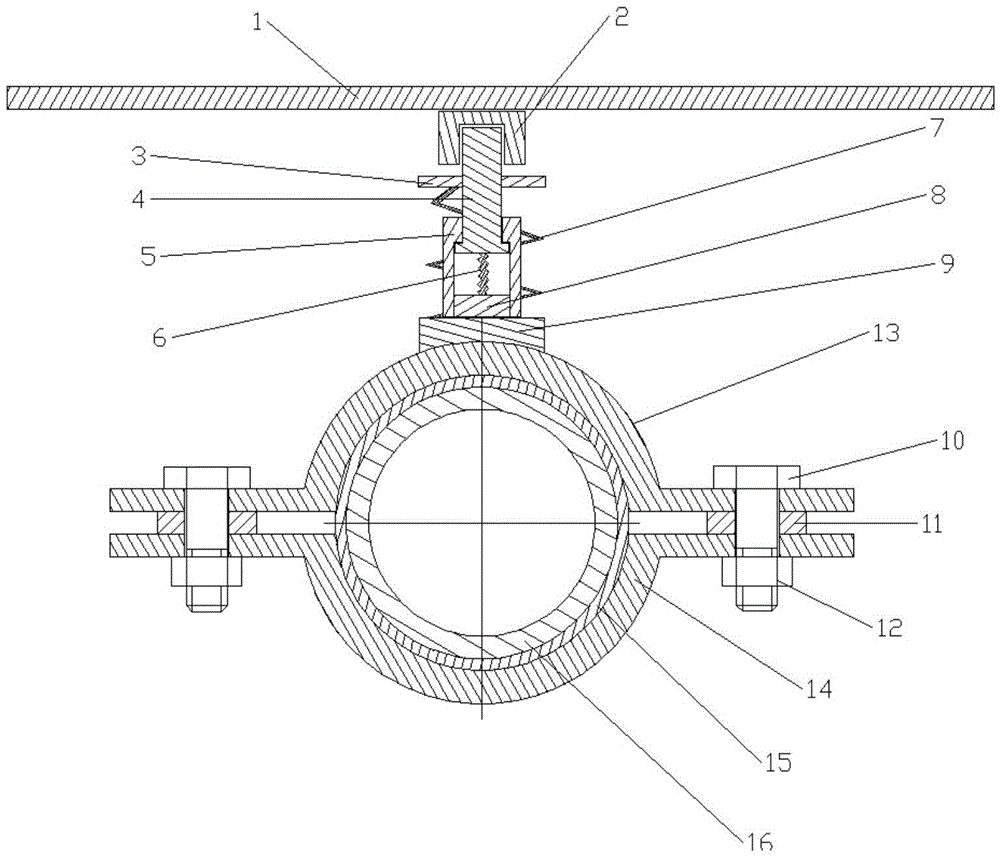

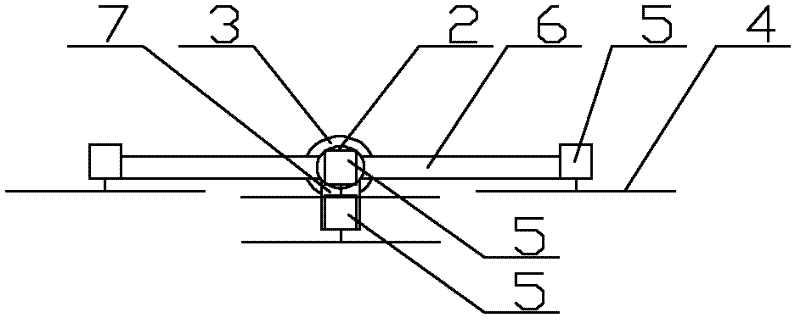

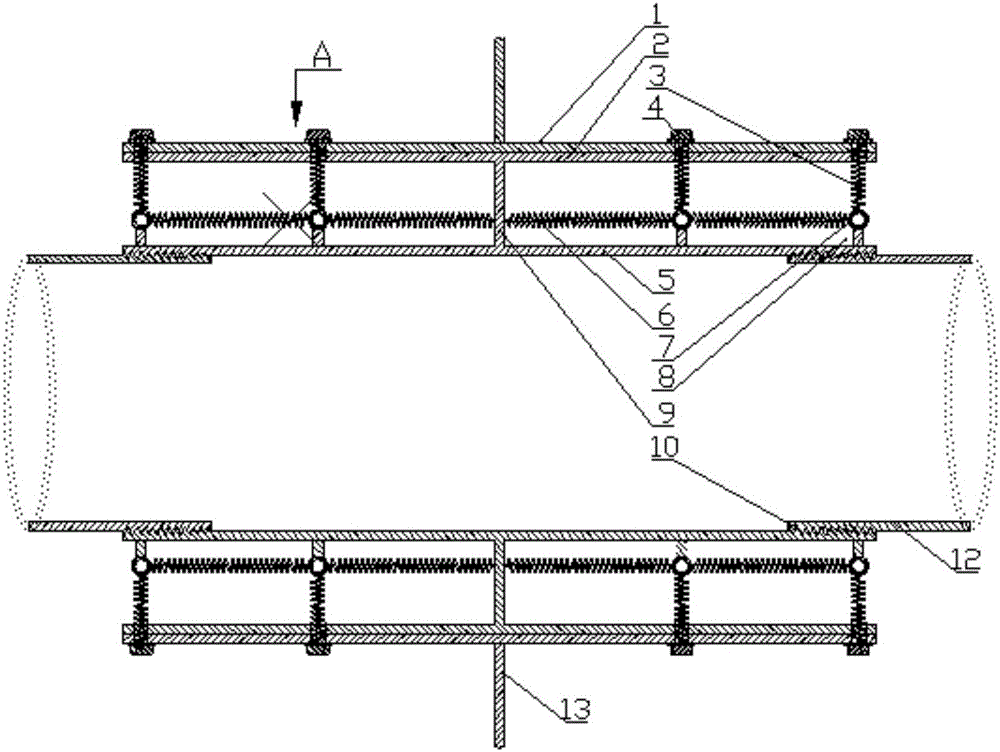

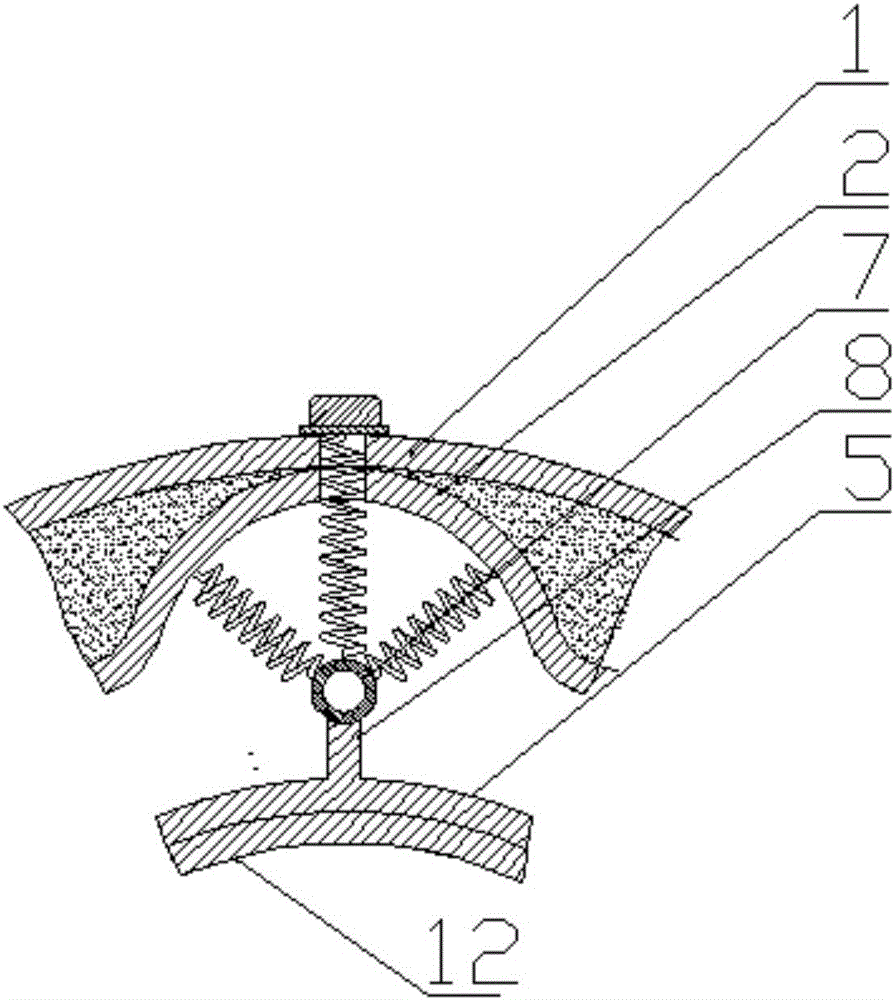

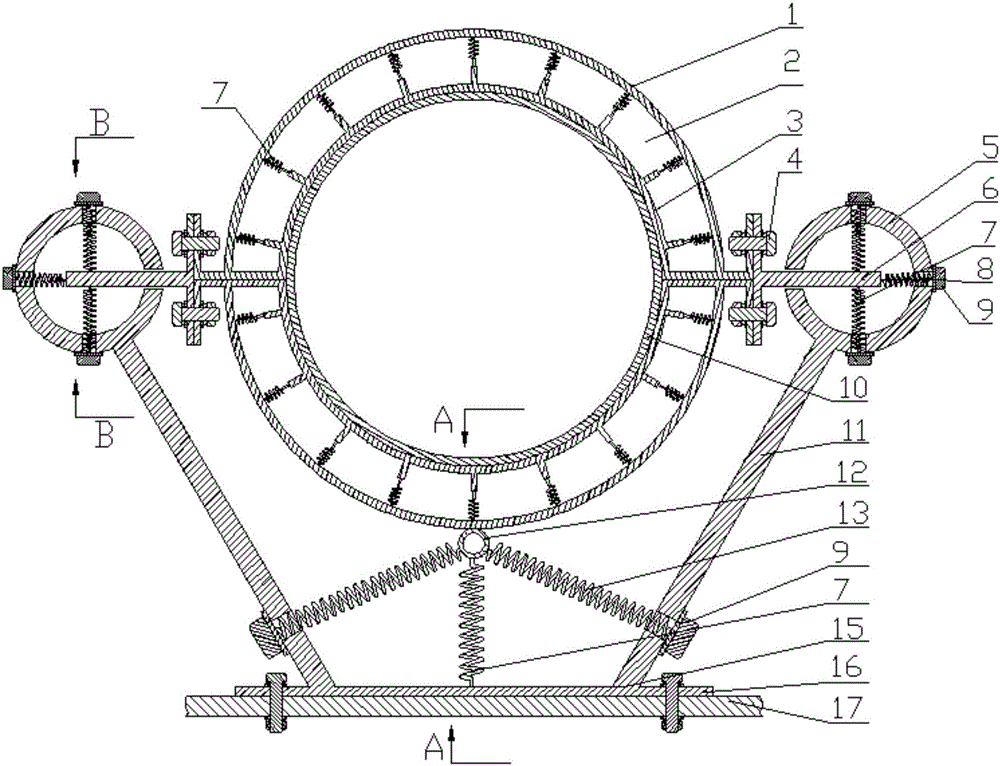

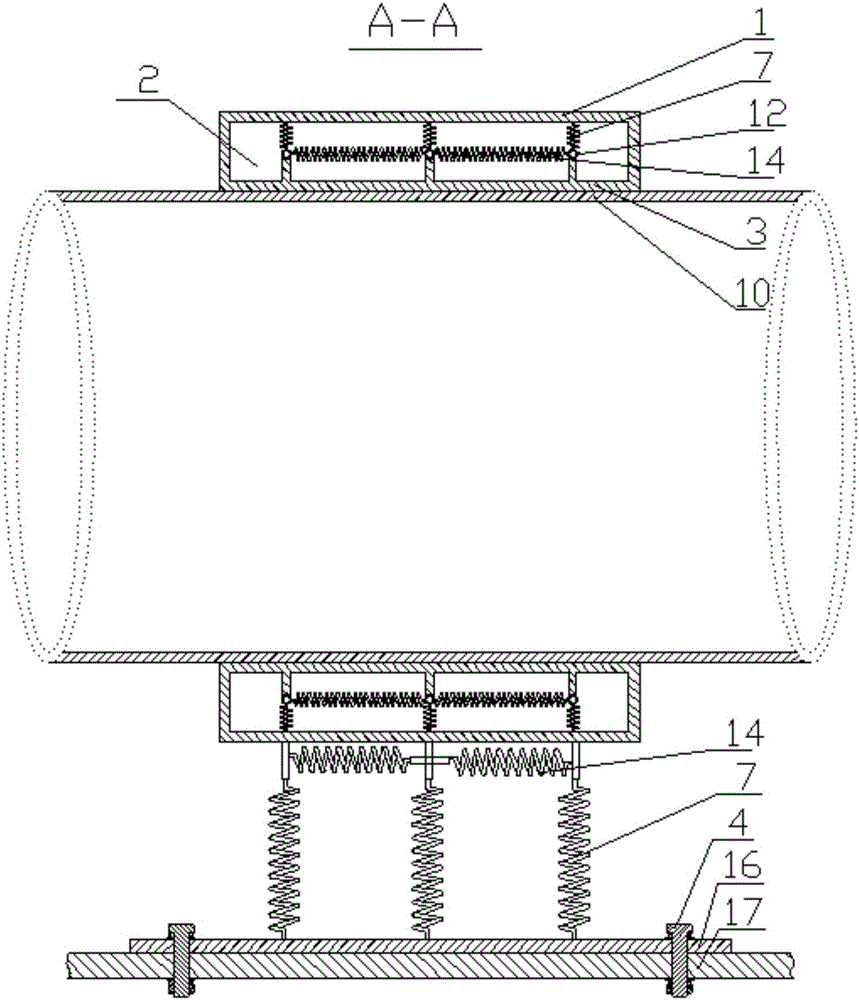

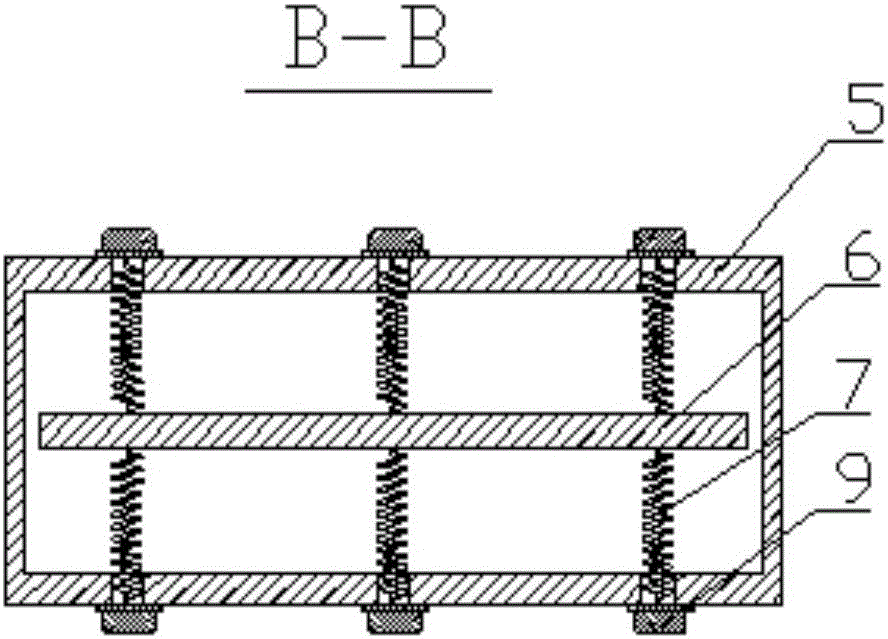

Vibration-reducing anti-impact pipeline hanging rack

ActiveCN105650350AImprove vibration damping effectImprove impact resistancePipe supportsMechanical engineeringPiston rod

The invention discloses a vibration-reducing anti-impact pipeline hanging rack which comprises an upper pipe clamping body and a lower pipe clamping body. The upper pipe clamping body and the lower pipe clamping body are connected through bolts and nuts which are arranged at the clamping ends of the clamping bodies, a gasket is further arranged between the clamping ends of the upper pipe clamping body and the lower pipe clamping body, a base is arranged at the top of the upper pipe clamping body, a vibration-reducing cylinder provided with a vibration-reducing spring in the inside is fixedly connected to the base, a cylinder body of the vibration-reducing cylinder is fixedly connected with the base, the vibration-reducing spring is arranged between the cylinder body and a piston rod of the vibration-reducing cylinder, the piston rod is sleeved with a movable baffle, the outer side of the vibration-reducing cylinder is sleeved with an anti-impact spring, one end of the anti-impact spring is connected with the base, the other end of the anti-impact spring is connected with the movable baffle, and the top of the piston rod is fixedly connected with a machine body through a cap. The vibration-reducing anti-impact pipeline hanging rack can support a pipeline like other hanging racks during normal working, meanwhile can reduce small-amplitude vibration and can further make the advantages prominent when working in a severe environment suffering from a strong impact load.

Owner:江苏圣大中远电力科技有限公司

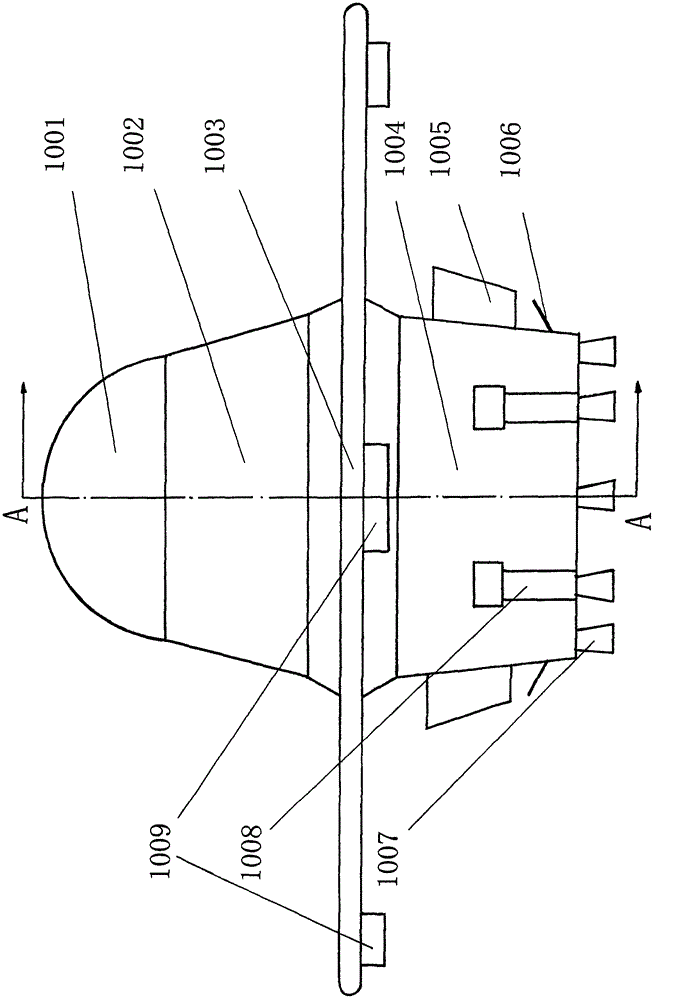

Large-size high-speed invisible flying saucer

InactiveCN105314111AIncrease the moment of inertiaReduce oil supplyAircraft navigation controlJet type power plantsCircular discNacelle

The invention discloses a flying saucer and two smoke- and fire-free engines. The flying saucer is composed of a cabin and a disk which rotates round the cabin. The disk includes a disk-shaped wing and a rotary engine. The cabin includes a driving cabin, a passenger cabin and a device cabin. The rotary engine sucks air which is mixed with water, and then the mixture is jetted out horizontally through jet tubes installed on the edge of the disk according to the sprayer principle, so that a generated reactive force enables the disk to rotate at a high speed, thereby generating an upward raising force on the disk. Four fixing wings are installed outside the device cabin to eliminate reverse rotation of the cabin. A vector engine and a diesel power generating set are installed in the device cabin under the disk. The vector engine sucks large amount of air through an air inlet duct in the passenger cabin to form vacuum above the passenger cabin, which enables air pressure difference between an upper surface and a lower surface of the disk to be increased, thereby generating a huge raising force. The sucked air is compressed to form high-pressure gas which is discharged into vector jet tubes and is jetted out, wherein the directions and the angles of the vector jet tubes are adjustable to generate pushing forces in different directions, thereby achieving maneuvering flight of the flying saucer.

Owner:周彦辉

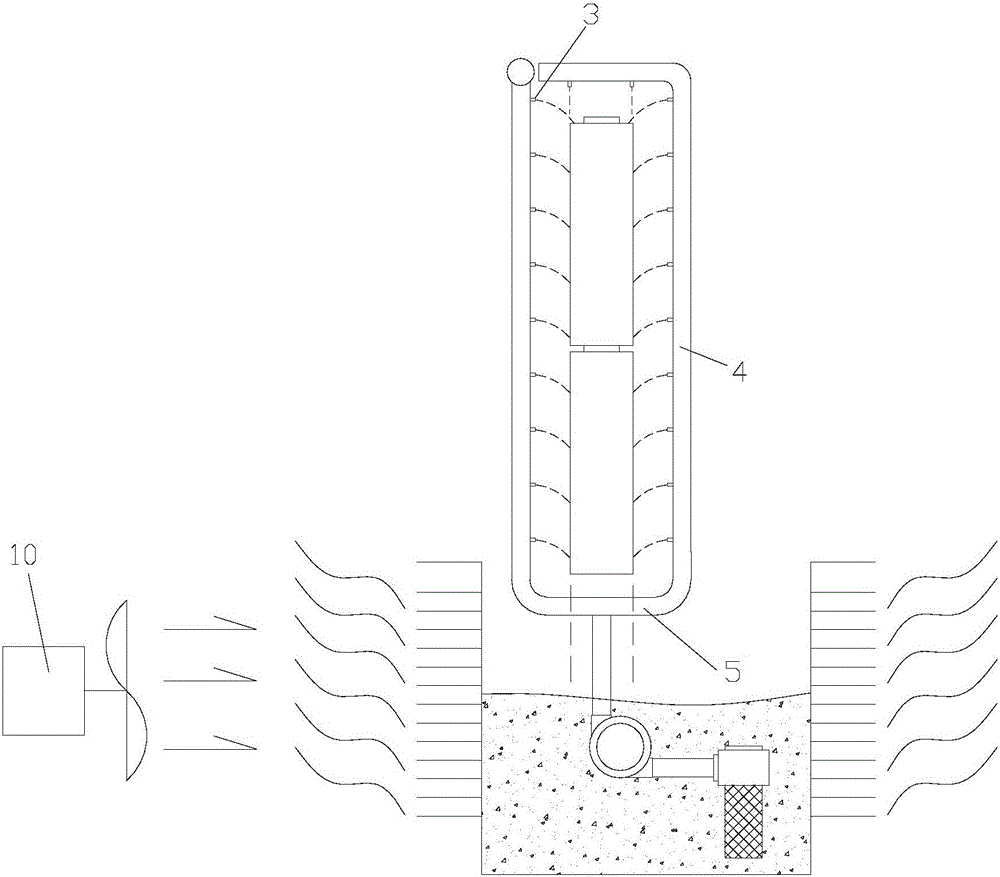

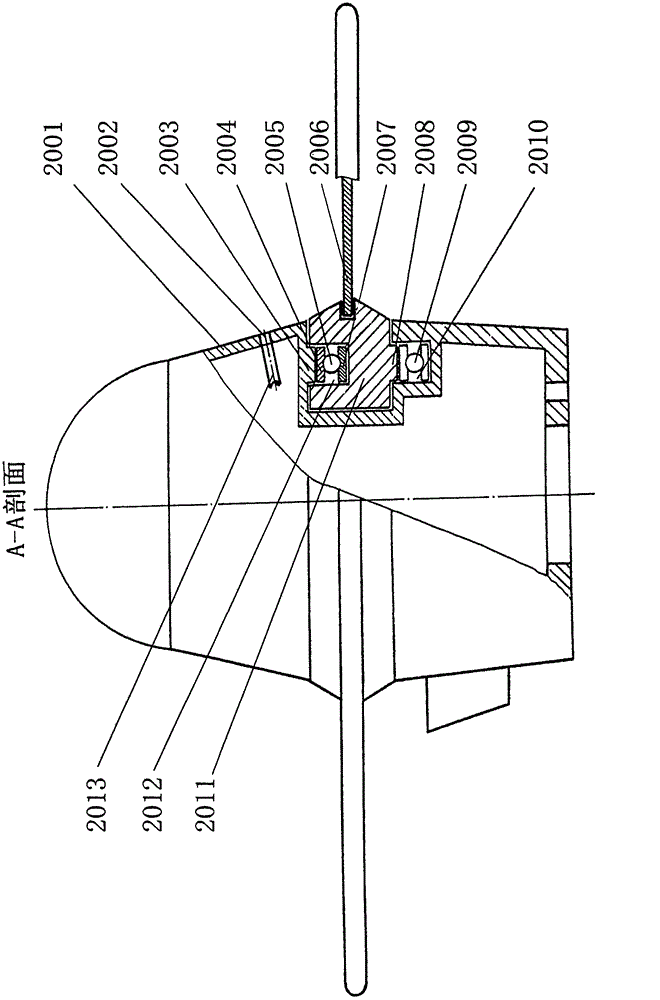

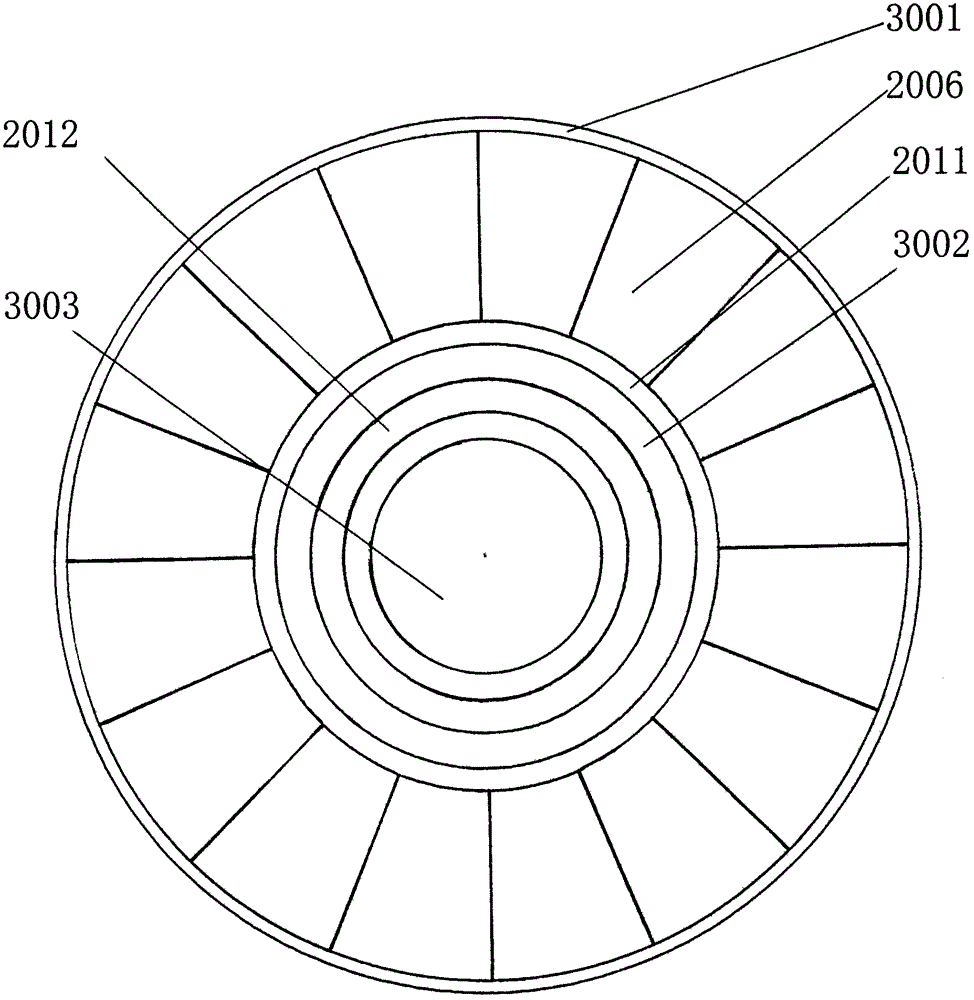

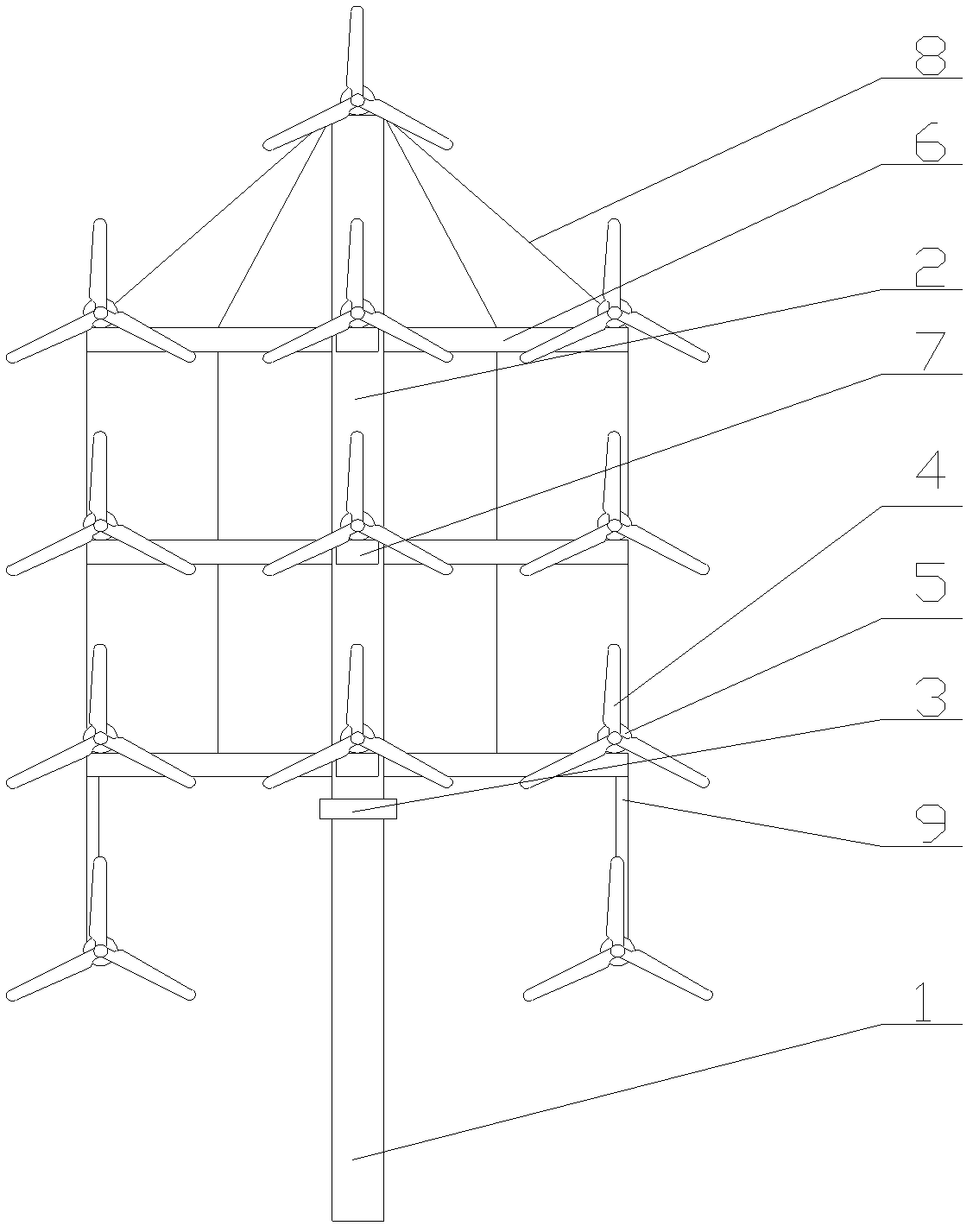

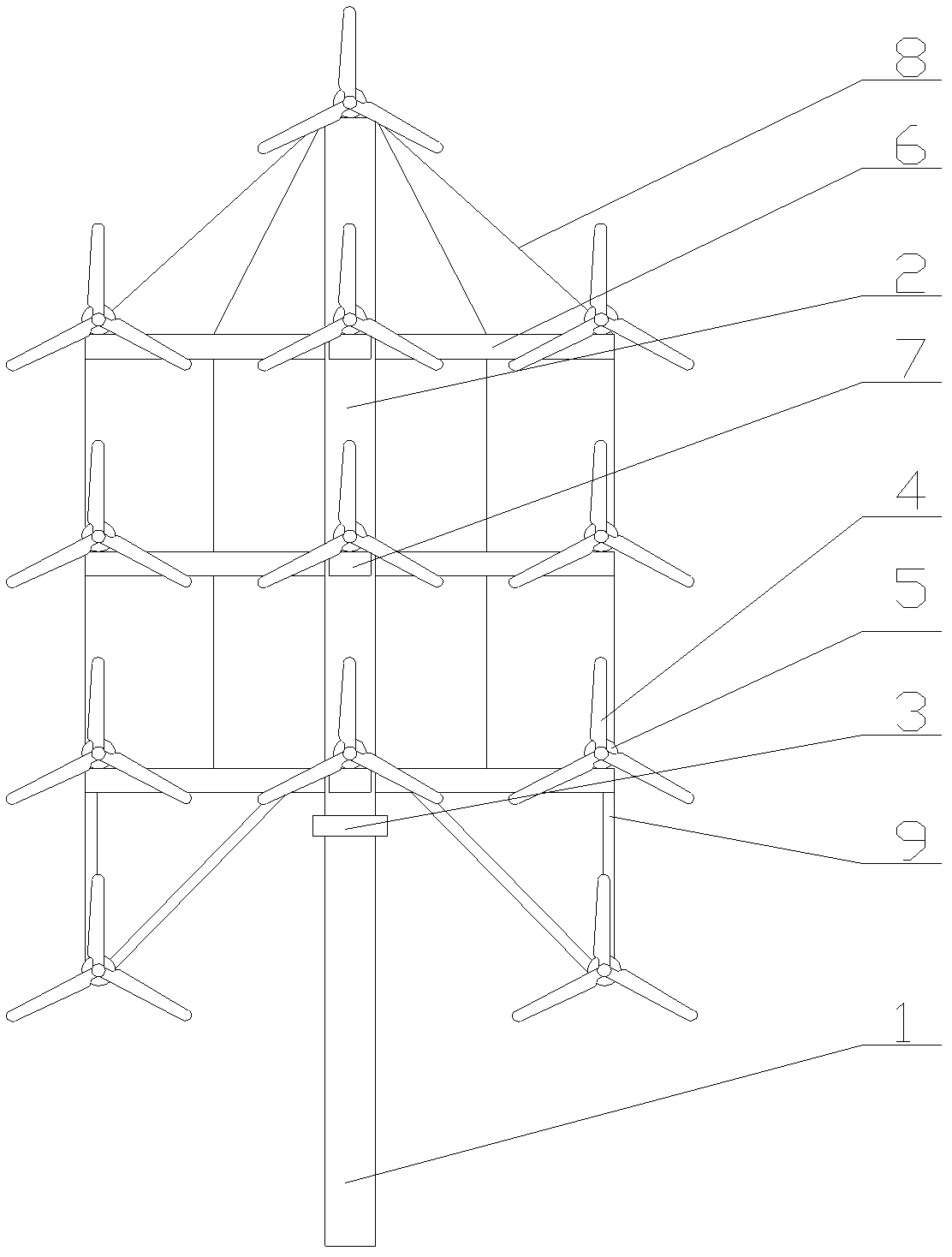

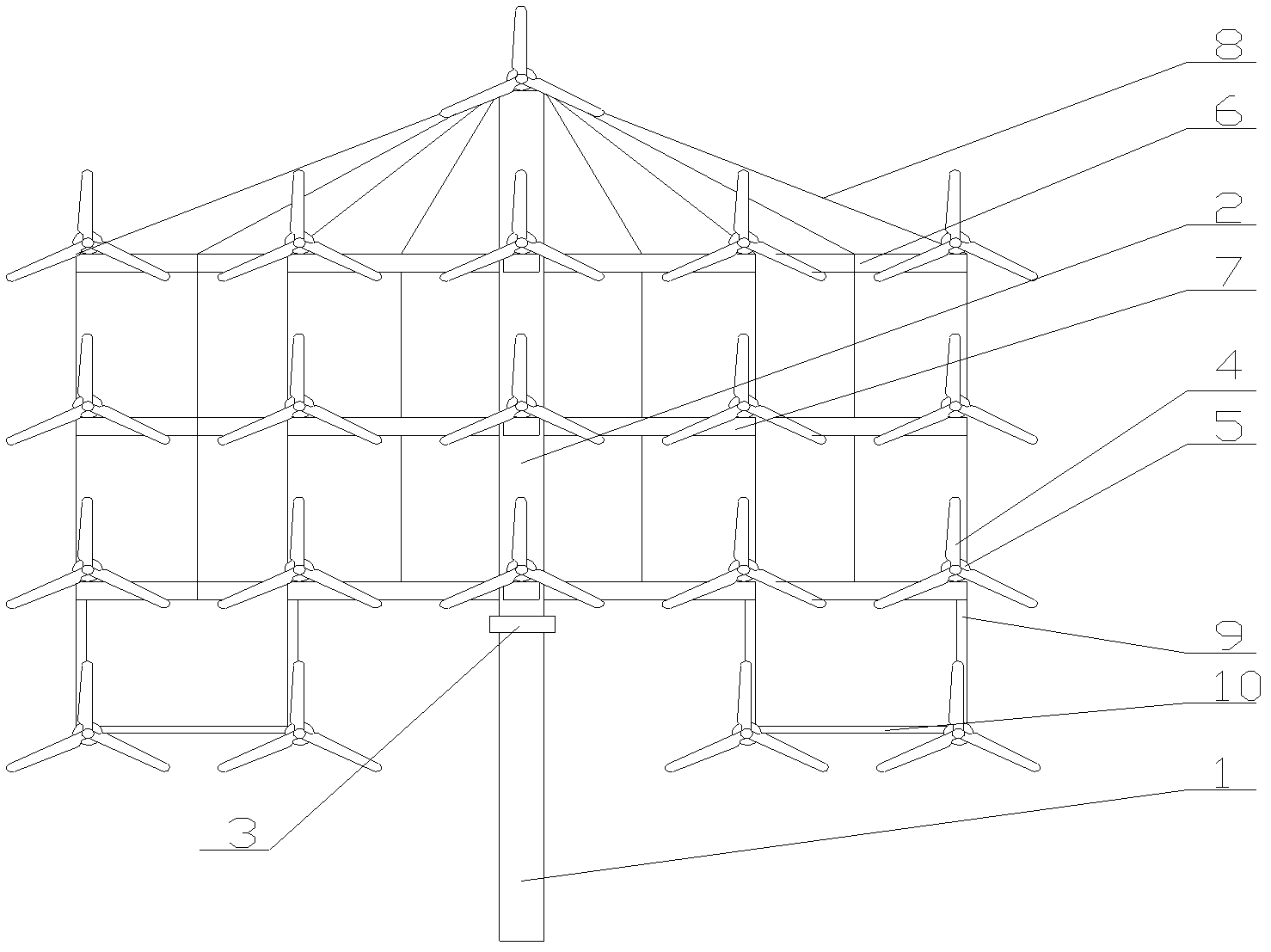

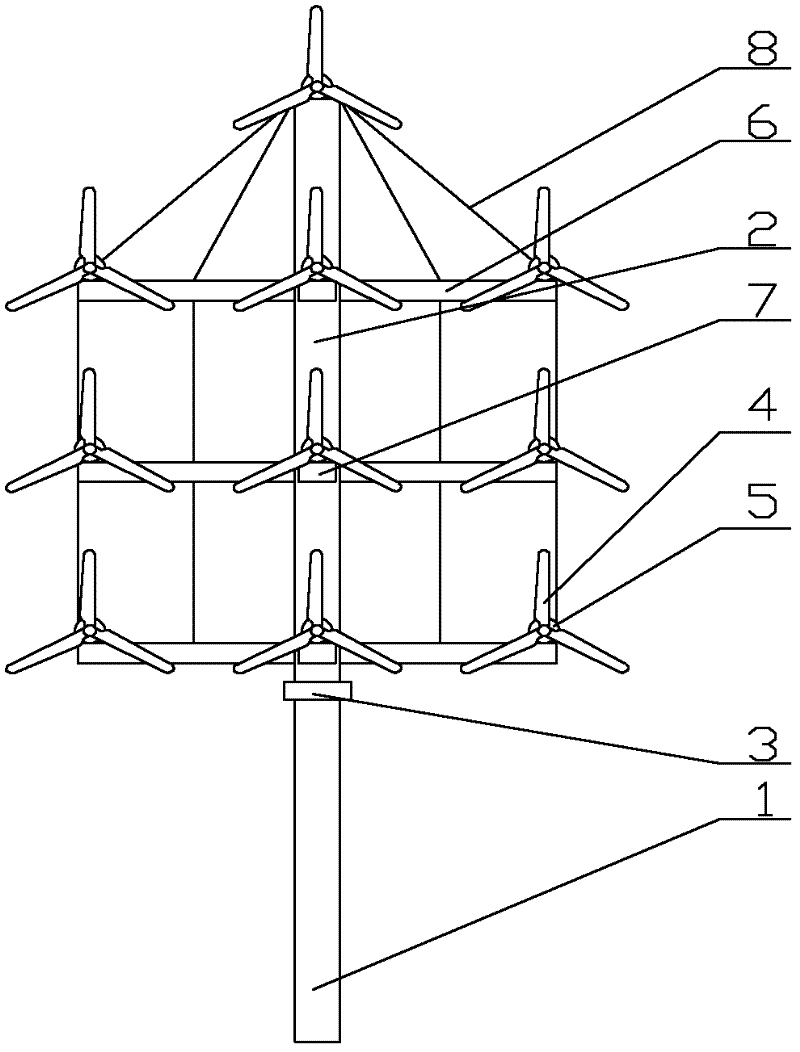

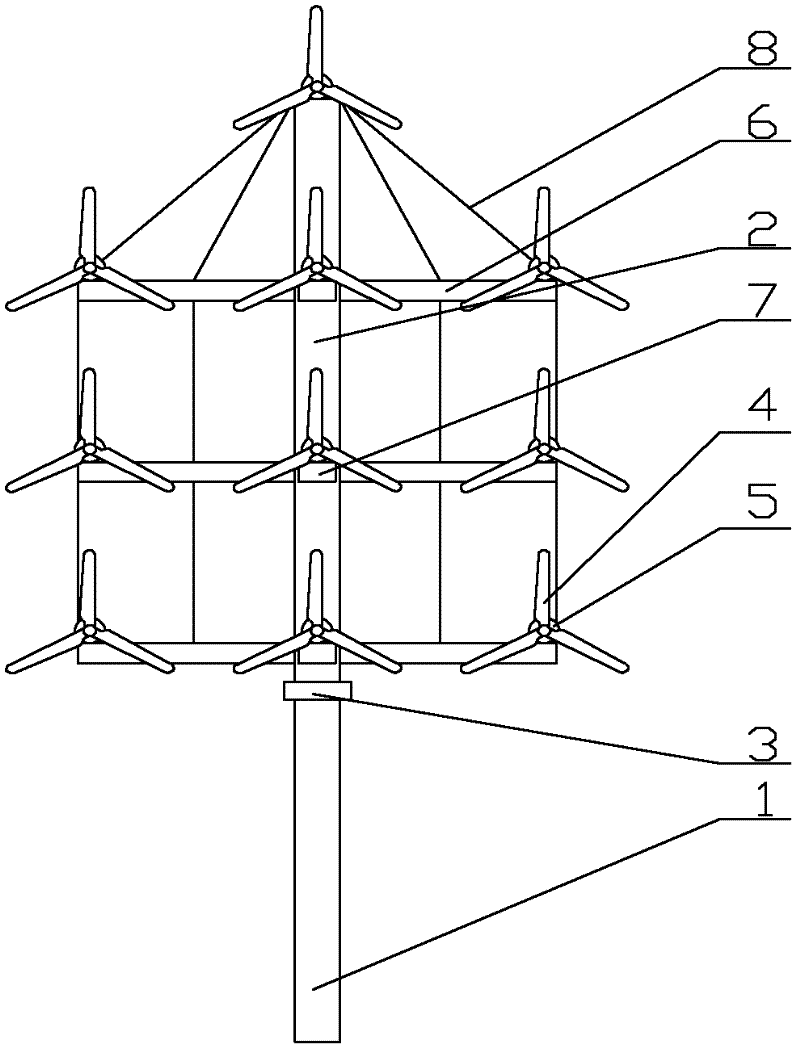

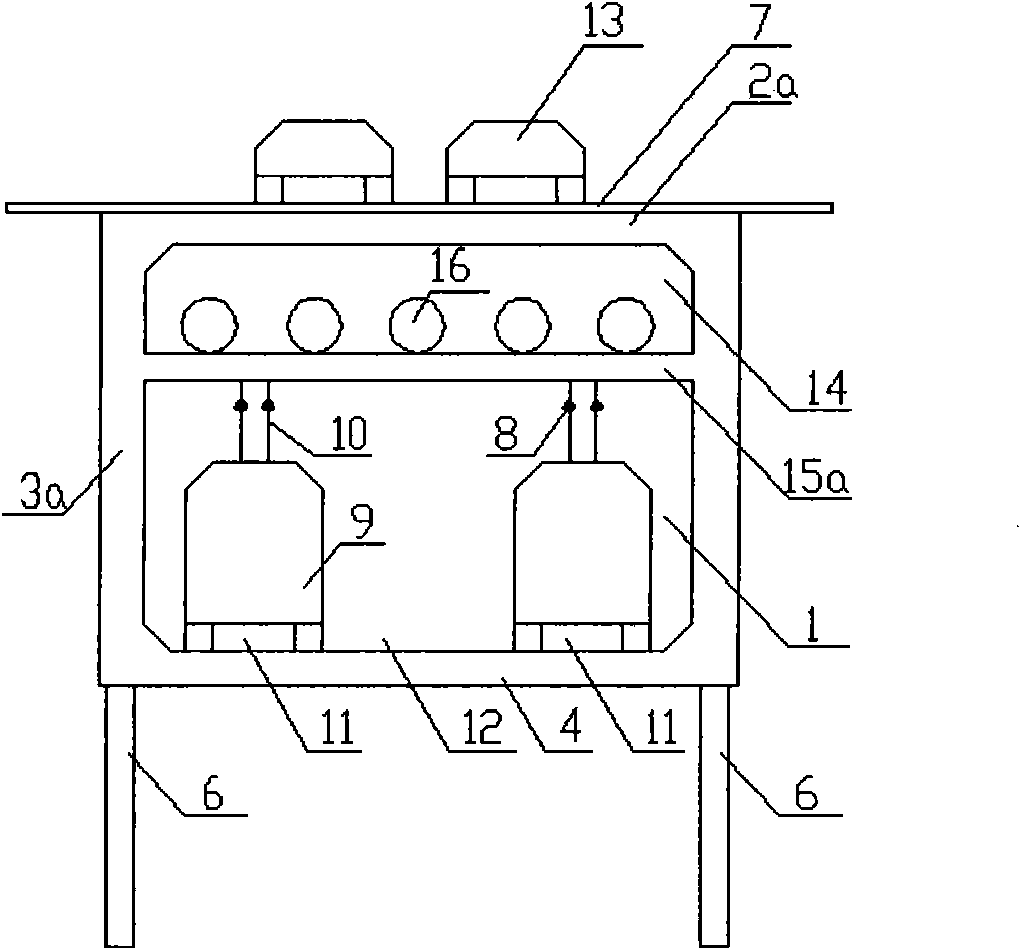

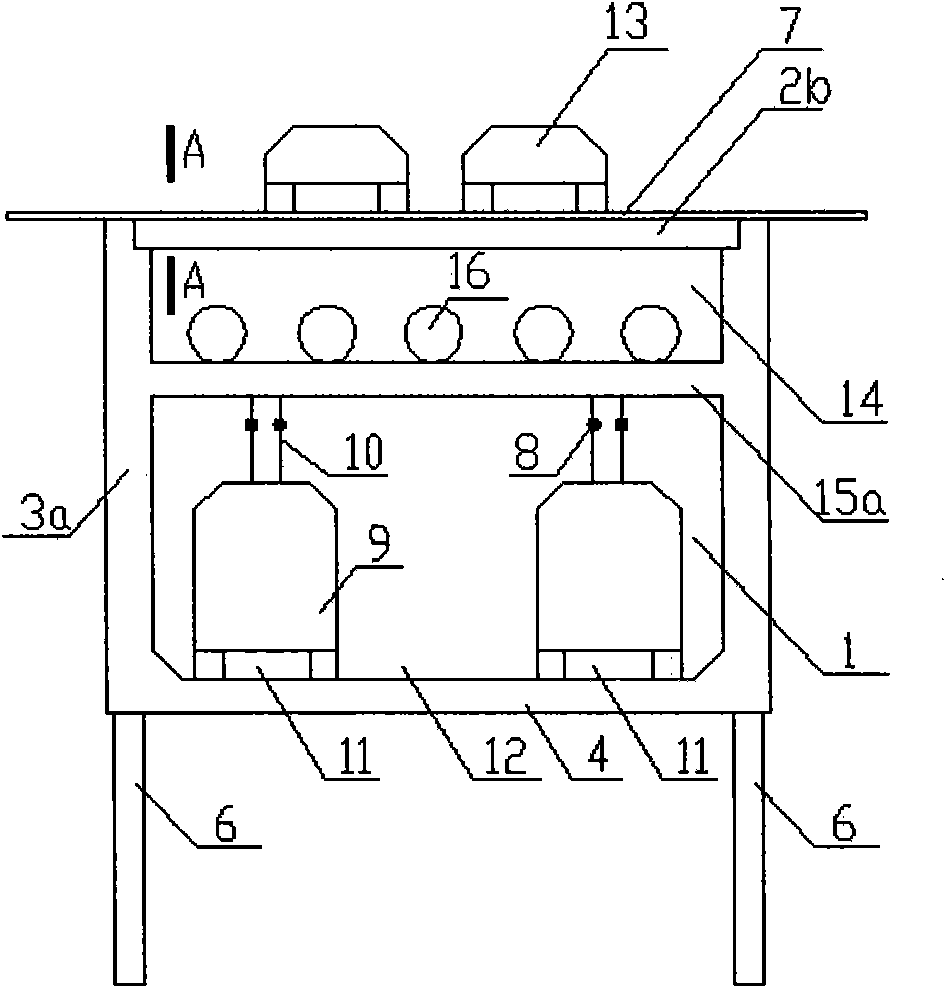

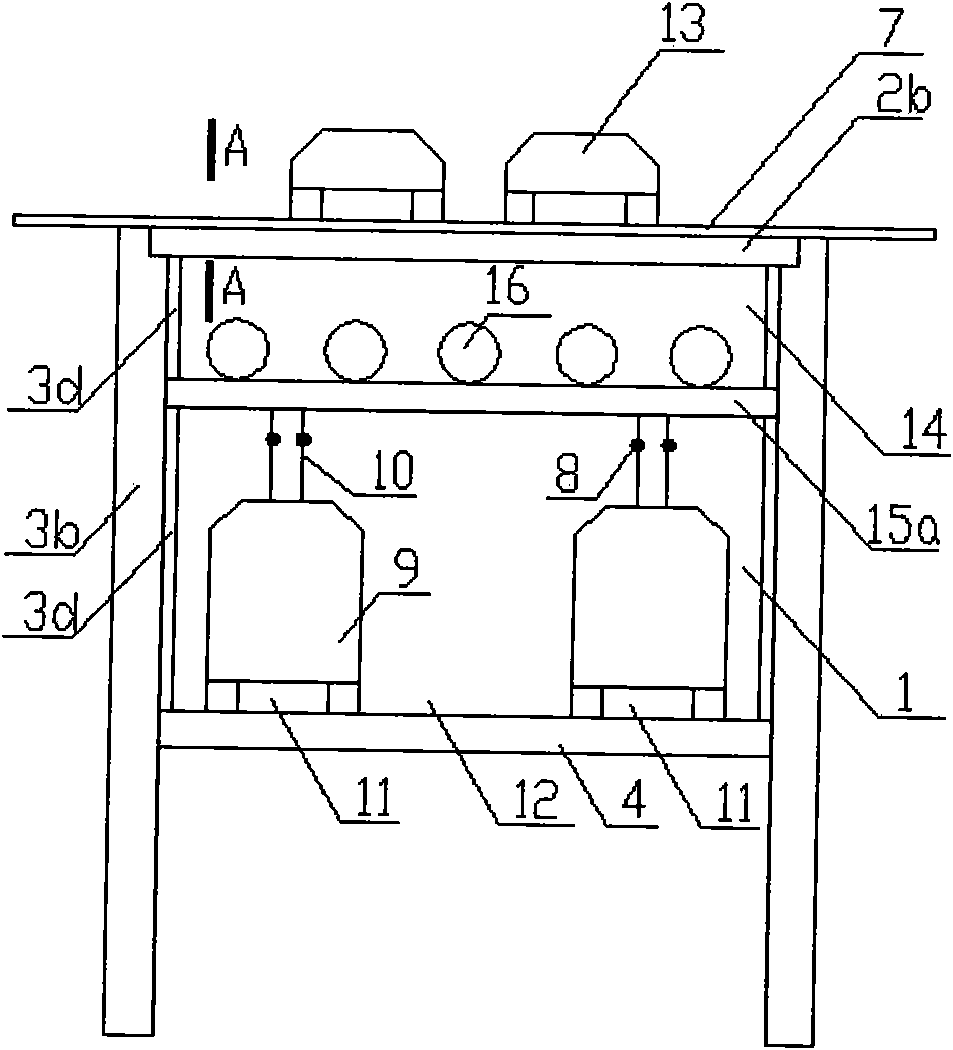

Multi-rotor wind generating system with suspenders

InactiveCN102305185ASolution to short lifeMature manufacturing technologyWind motor controlMachines/enginesWind forceNacelle

The invention discloses a multi-rotor wind generating system with suspenders. The multi-rotor wind generating system comprises a lower tower 1, a rotary driving device 3, wind turbines, an upper tower 2, ropes and / or connecting rods 8, beams 6, a cabin frame 7 and the suspenders 9, wherein the rotary driving device is arranged between the upper tower and the lower tower; two sides of the upper tower are connected with one end of each beam; the outer end and the middle part of the uppermost beam are connected with the top of the upper tower through the ropes and / or the connecting rods; outer ends of adjacent beams are connected through the ropes and / or the connecting rods; middle parts of the adjacent beams are connected through the ropes and / or the connecting rods; the upper ends of the suspenders are fixedly connected with the lowermost beam; the cabin frame is arranged on the upper tower; the wind turbines are arranged on the upper tower; and the wind turbines are fixedly connected with the top of the upper tower, the beams, the cabin frame or / and the lower ends of the suspenders. The multi-rotor wind generating system has the advantages of long service life, small floor area, low installation and maintenance cost, high reliability, wide application range, no rotary driving device in a cabin, and low bearing overturning moment.

Owner:TIANJIN UNIV

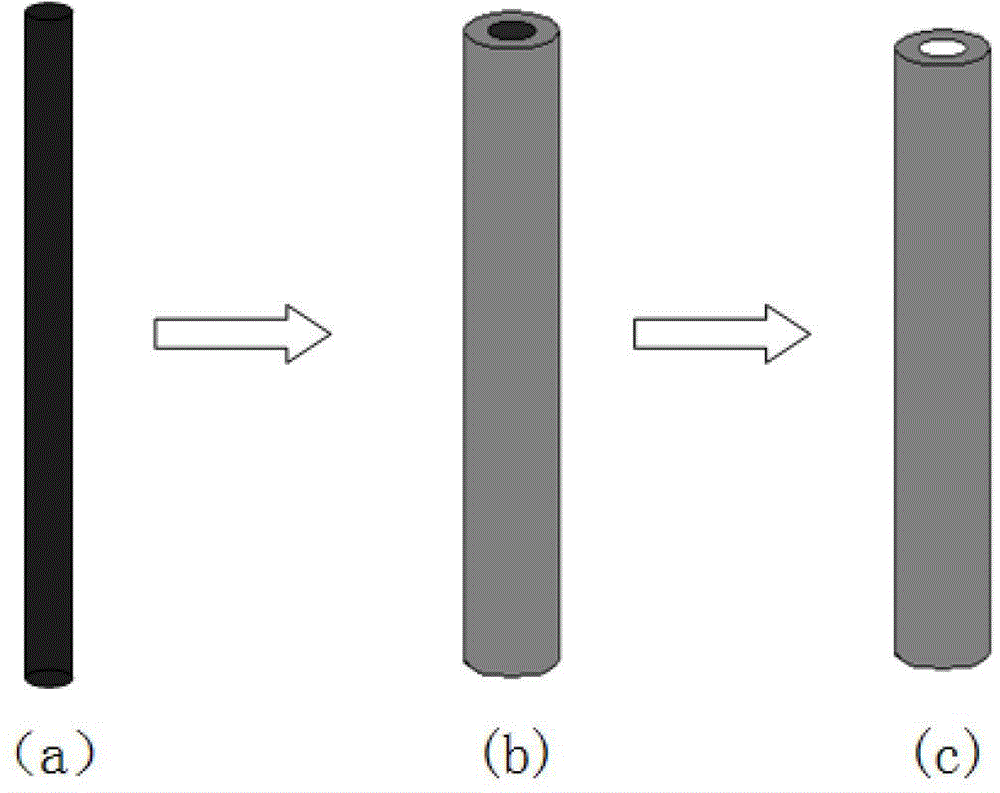

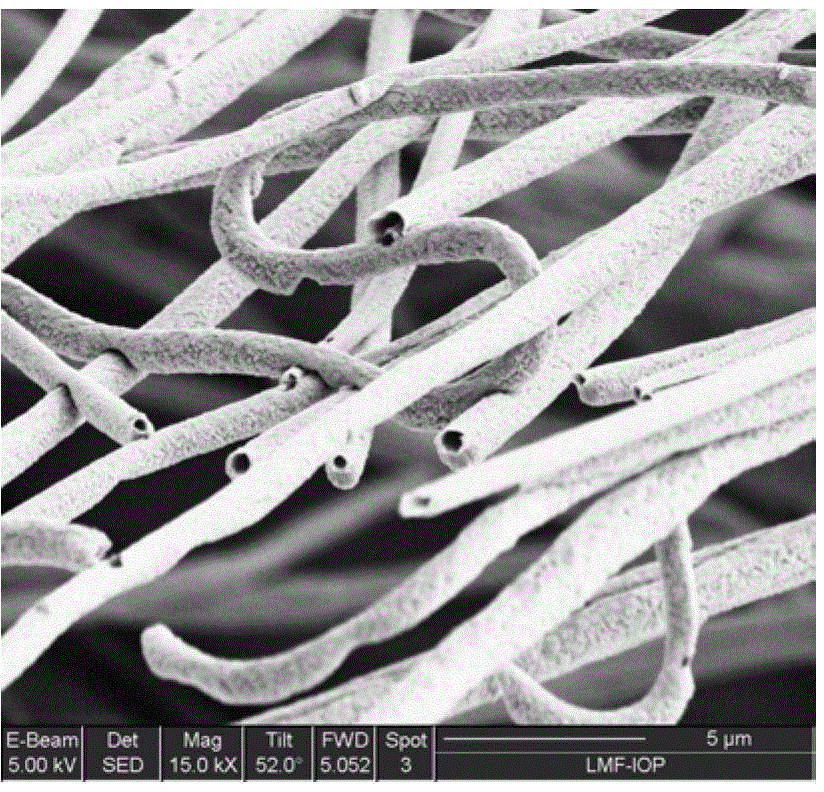

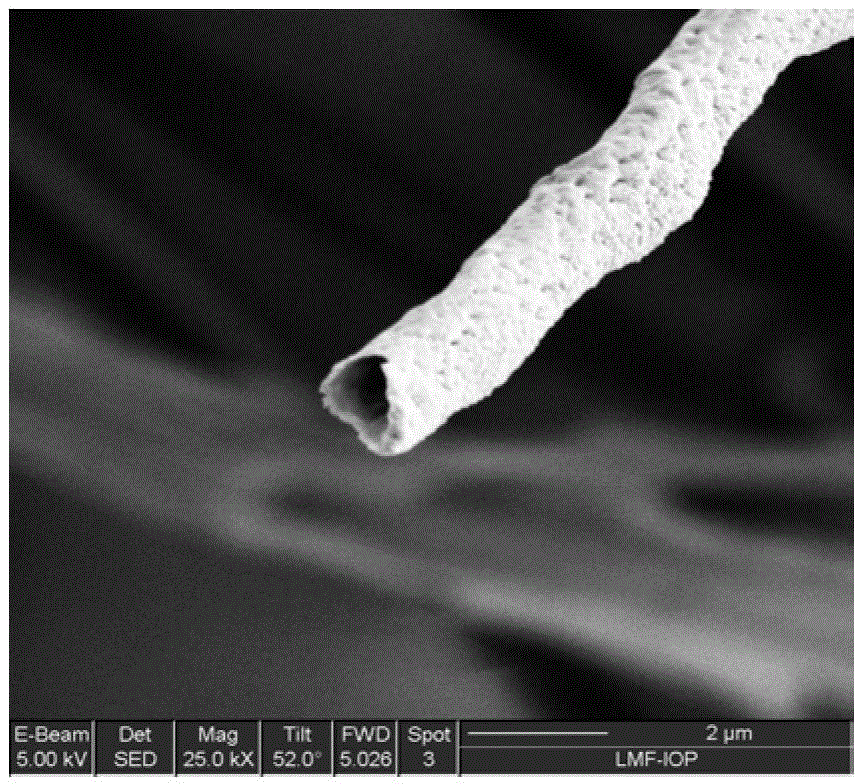

Hollow structure indium oxide nanometer fiber preparation method

InactiveCN103334179AThe hollow structure is obviousLarge specific surface areaInorganic material artificial filamentsFibre typesFiberMaterials preparation

The invention belongs to the technical field of nanometer fiber material preparation, and relates to a hollow structure indium oxide nanometer fiber preparation method, which comprises the following three steps: preparing polyvinylidene difluoride (PVDF) nanometer fibers, wrapping indium oxide, and carrying out high temperature sintering to remove PVDF, wherein a PVDF solution is prepared, an electrostatic spinning device is adopted to carry out electrostatic spinning according to the conventional operation method to prepare PVDF nanometer fibers, the conventional magnetron sputtering method is adopted to wrap a layer of indium oxide on the surface of the PVDF fibers, the indium oxide wrapped PVDF fibers are placed in a muffle furnace to sinter, and the PVDF is completely decomposed to form the hollow structure indium oxide nanometer fibers. The preparation method has characteristics of simpleness, reliable principle, mature preparation technology, convenient operation, high yield, low cost, good product performance, and environmental protection.

Owner:QINGDAO UNIV

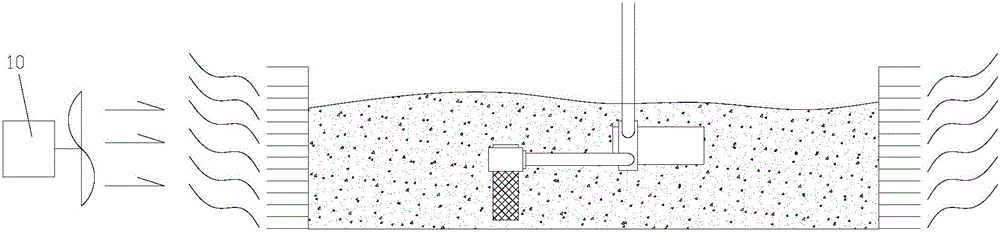

Working medium contact cooling system for high-power electromagnetic generators and working method of working medium contact cooling system

ActiveCN105934138AReduce thermal contact resistanceImprove heat transfer efficiencyCooling/ventilation/heating modificationsElectromagnetic generatorHeat conducting

The invention discloses a working medium contact cooling system for high-power electromagnetic generators. The working medium contact cooling system comprises the high-power electromagnetic generators, an insulating liquid heat-conducting working medium, nozzles, spray branch pipes, a spray master pipe, a working medium pump, a filter and a working medium box, wherein the insulating liquid heat-conducting working medium is contained in the working medium box; the working medium pump sinks into the insulating liquid heat-conducting working medium; the filter is arranged at an inlet of the working medium pump; the working medium pump is connected with the spray master pipe; a plurality of spray branch pipes are connected with the spray master pipe in parallel; each spray branch pipe is provided with a plurality of nozzles; the nozzles are opposite to the high-power electromagnetic generators and spray towards the front surfaces and the back surfaces of the high-power electromagnetic generators to form a relatively open spray structure; the insulating liquid heat-conducting working medium is a non-polar substance; and the insulating liquid heat-conducting working medium is free of a phase change in the spraying process. The invention further provides a working method of the working medium contact cooling system for the high-power electromagnetic generators. The heat dissipation structure is reasonable and the heat dissipation efficiency is high.

Owner:GUANGDONG HI 1 NEW MATERIALS TECH RES INST CO LTD

Multi-rotor wind power generation system

InactiveCN102269113ASolution to short lifeMature manufacturing technologyMachines/enginesWind energy generationWind forceNacelle

The invention discloses a multi-rotor wind power generation system, which includes a lower tower 1, a rotary drive device 3 and a wind turbine, and also includes an upper tower 2, ropes and / or rods 8, beams 6 and a nacelle frame 7, and the rotary drive device is arranged on Between the upper tower and the lower tower, the beams located on both sides of the upper tower are connected to the upper tower through one end of the beam, and the outer end and middle part of the uppermost beam are respectively connected to the upper tower by ropes and / or rods The top ends of the adjacent beams are connected by ropes and / or rods, and the middle parts of adjacent beams are connected by ropes and / or rods. The nacelle frame is set on the upper tower, and the wind turbine is connected to the top of the upper tower. , the beam or / and the nacelle frame are fixedly connected, the wind turbine includes the wind wheel 4 and the nacelle 5, and there are 2-100 wind turbines. The blade of the invention has long service life, small occupied area, low installation and maintenance cost, good system reliability and wide application range, cancels the slewing bearing or slewing driving device in the nacelle, and improves the stress of the beam.

Owner:TIANJIN UNIV

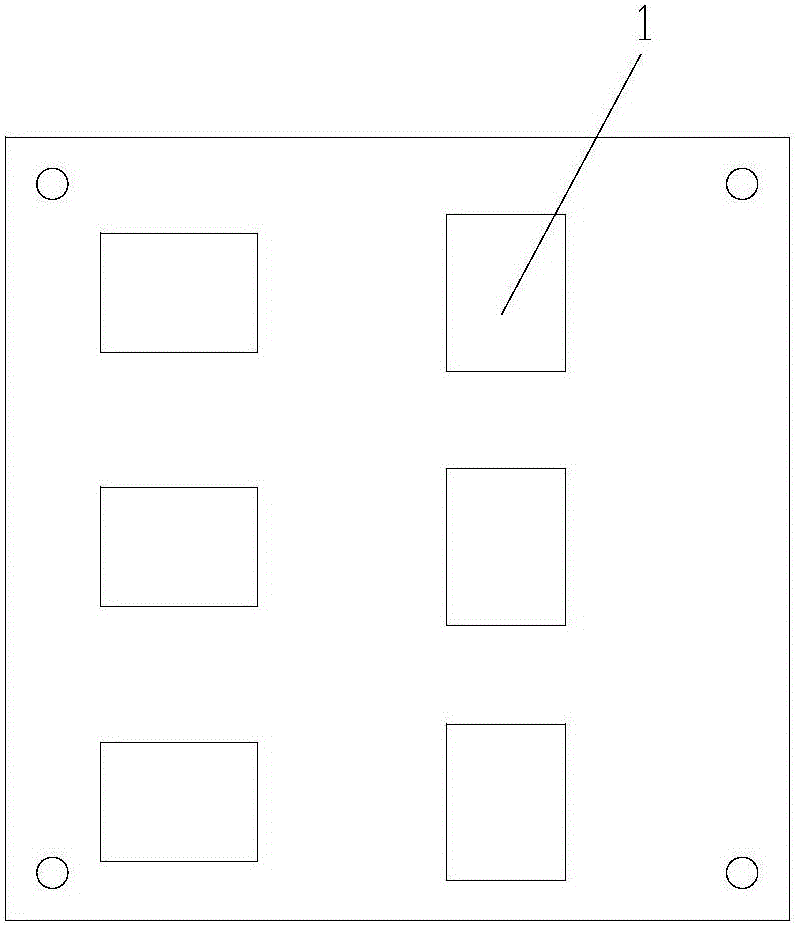

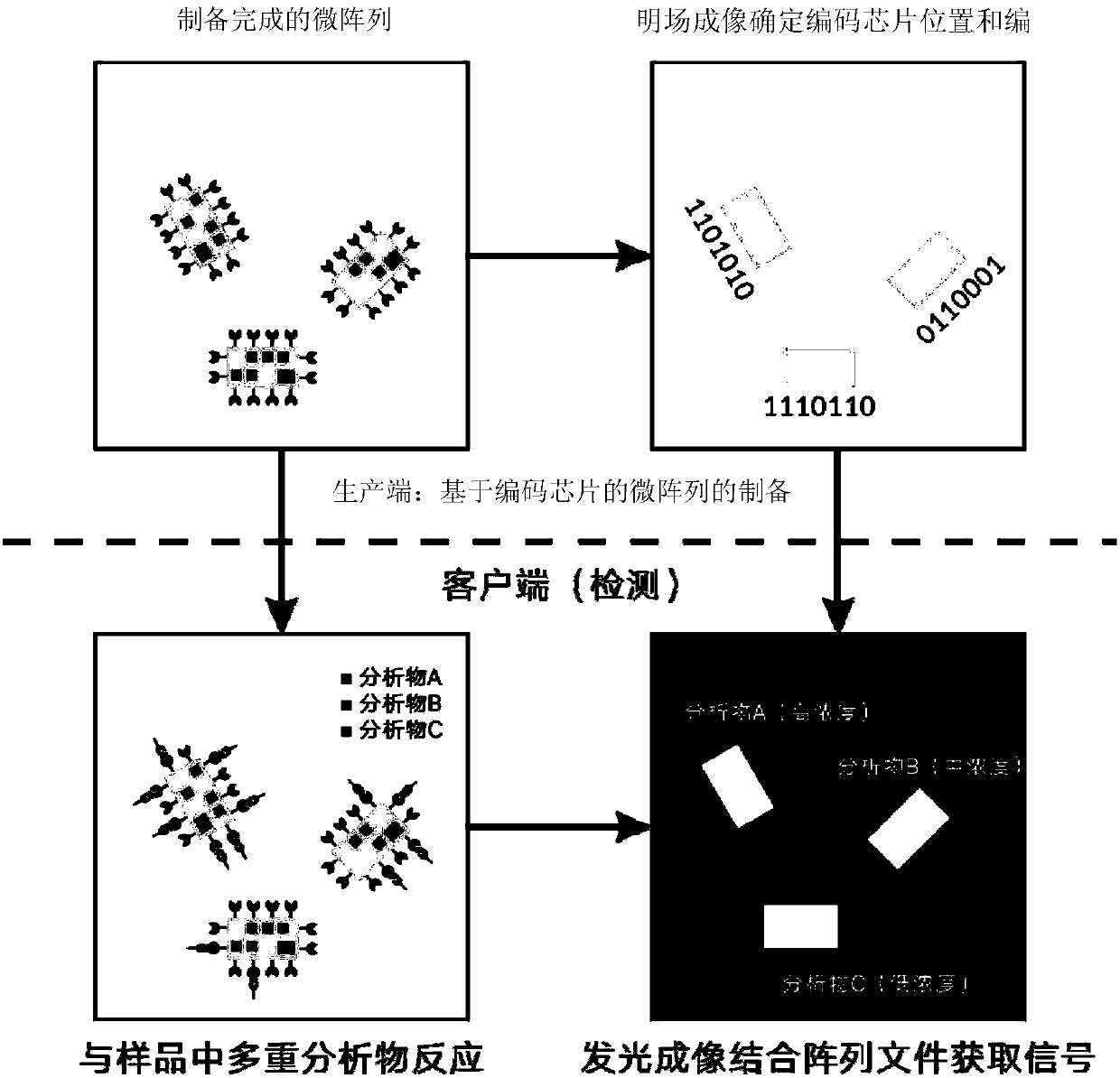

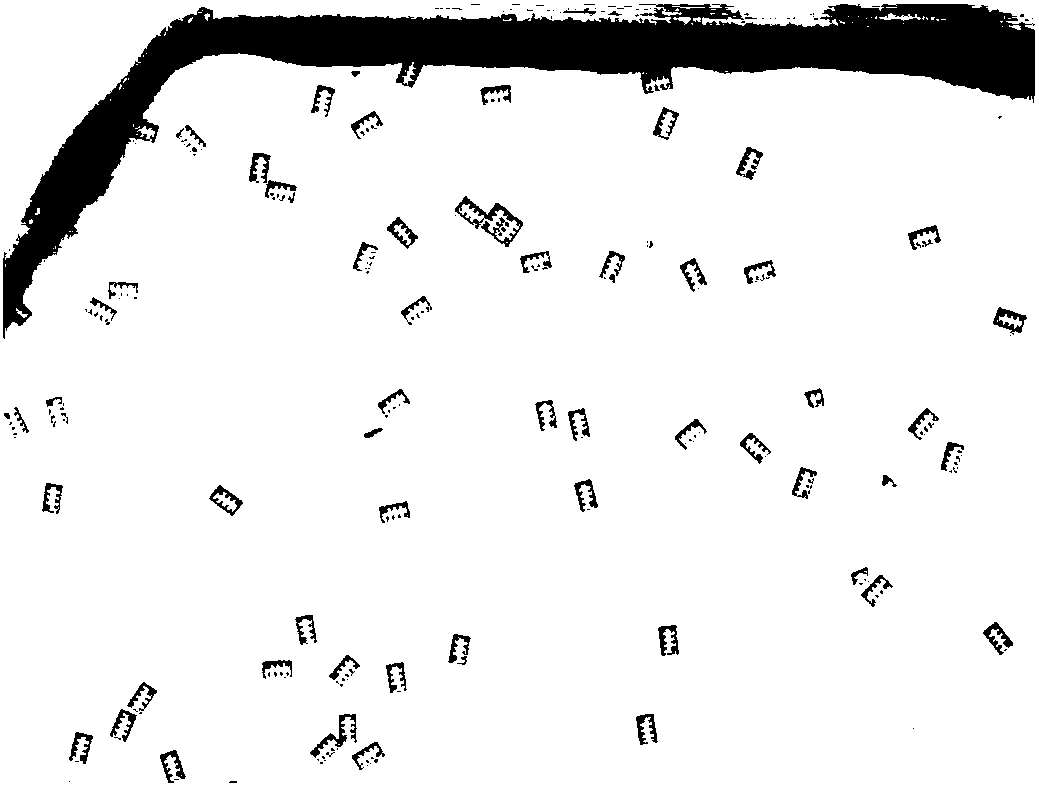

Coding chip based microarray, preparation method and application thereof

ActiveCN107694649AImprove throughputImprove accuracyMicrobiological testing/measurementChemiluminescene/bioluminescenceAdhesiveHigh flux

The invention discloses a coding chip based microarray and a preparation method thereof. In a typical embodiment, the preparation method includes: providing a carrier, which has at least one fluid accommodating cavity, in which at least one bearing surface is distributed; coating the bearing surface with an adhesive evenly; adding a selected fluid into the fluid accommodating cavity till immersionof the bearing surface with the selected fluid; depositing coding microchips dispersed in the selected fluid to the bearing surface, and performing combination with the adhesive distributed on the bearing surface; and curing the adhesive so as to fix the microchips on the bearing surface. The invention also discloses a biochemical kit based on the microarray, a detection system, a method and thelike. Compared with the prior art, the coding chip based microarray provided by the invention shows outstanding advantages in detection multiplicity, high efficiency, sensitivity and other aspects, can achieve high flux and high accuracy sample detection, also is simple in operation, and has manufacturing simplicity and economical efficiency.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

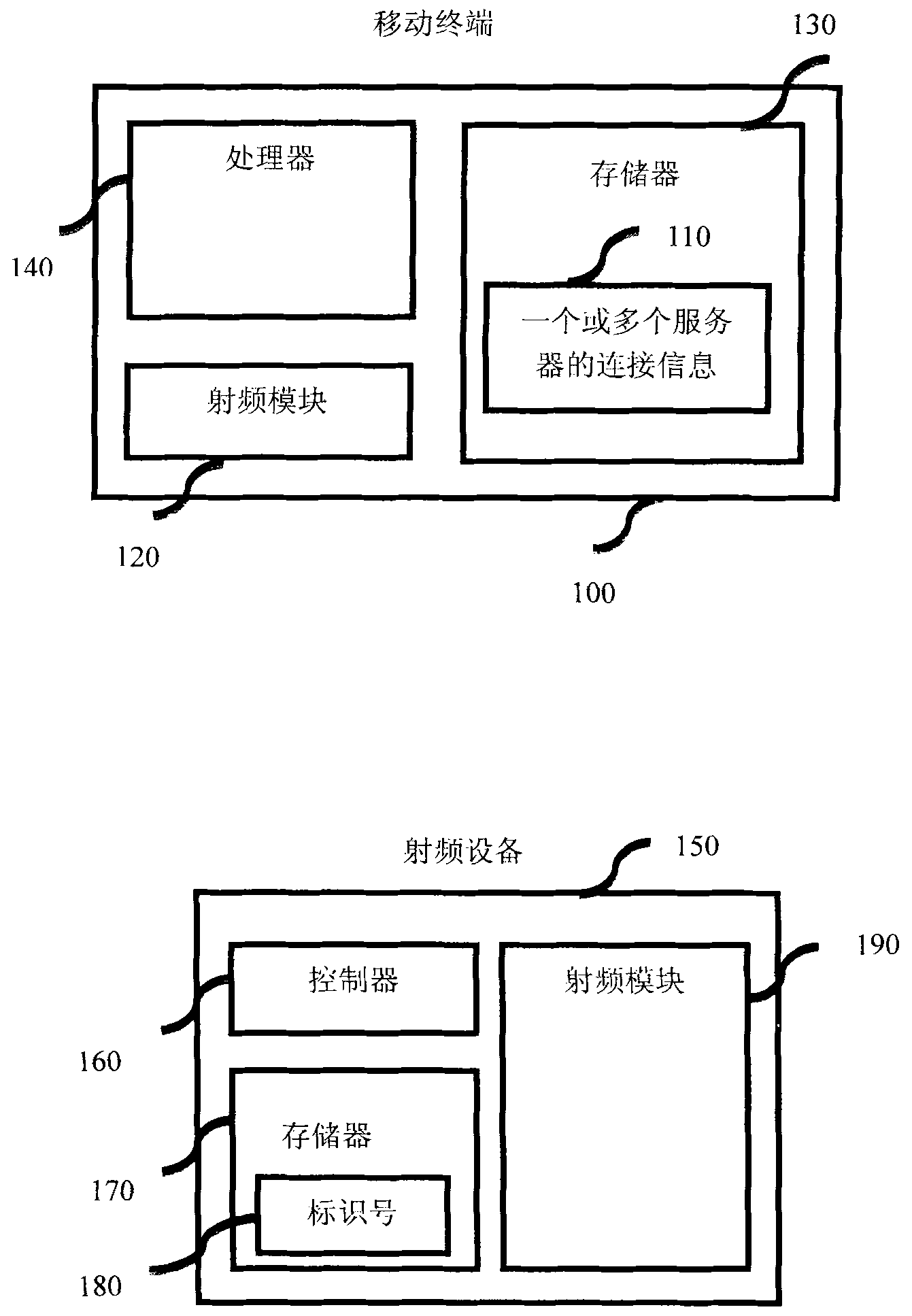

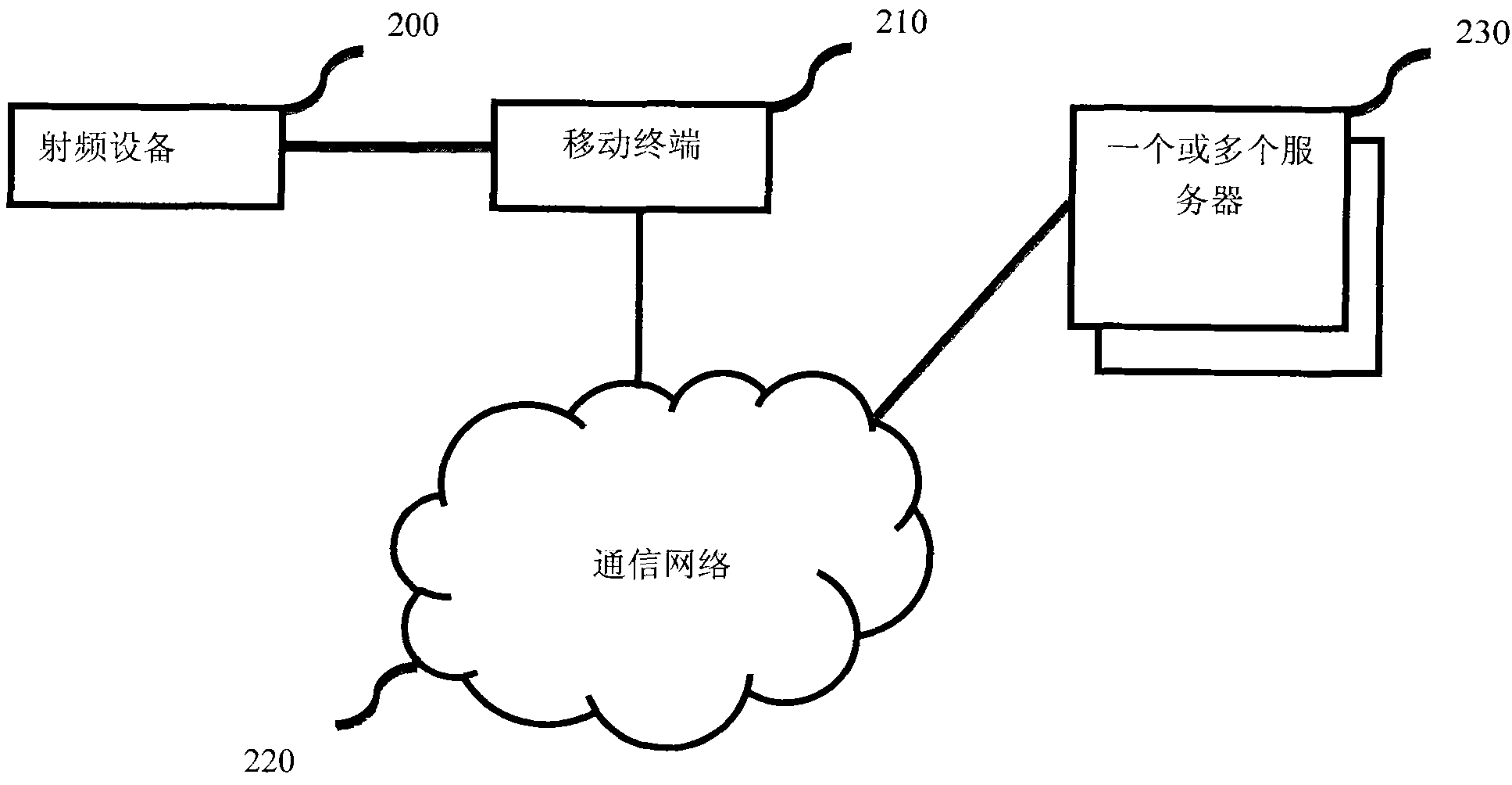

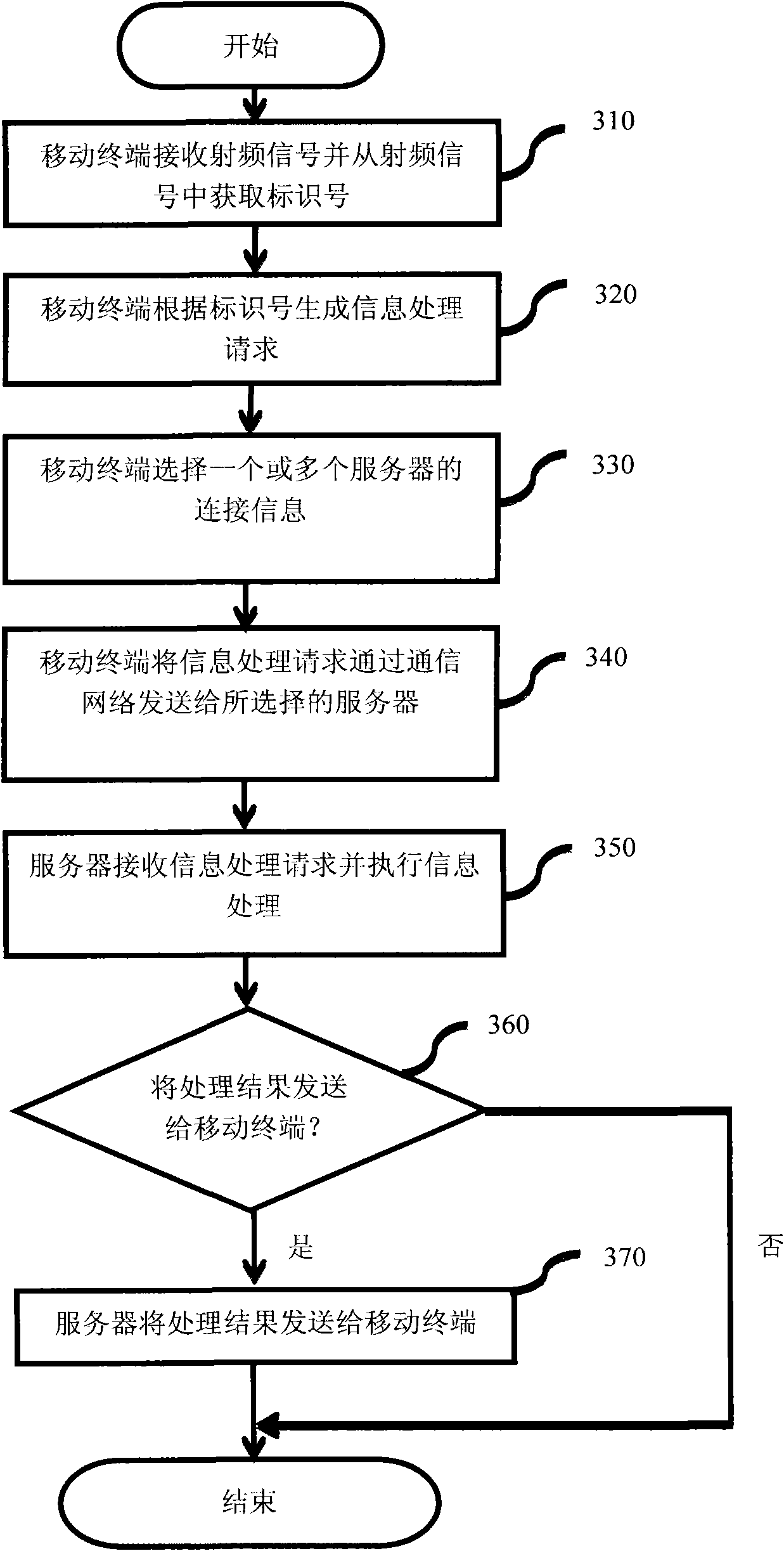

Information processing method

InactiveCN102123142AMature manufacturing technologyLow costNear-field systems using receiversSensing record carriersRadio frequency signalInformation processing

The invention relates to an information processing method based on an identification number, comprising: (a), a mobile terminal receives a radio-frequency signal which is transmitted by a radio-frequency device and contains the identification number, and extracts the identification number from the radio-frequency signal; (b), the mobile terminal generates an information processing request according to the identification number; and (c), the mobile terminal selects one or more servers according to the server information obtained by the mobile terminal and sends the information processing request to the one or more servers; and (d), the one or more servers respond to the information processing request so as to carry out information processing. The invention further relates to a system used for implementing the information processing method.

Owner:金锰 +1

Ground-road combined comprehensive tunnel for underground pipeline and trolley bus

InactiveCN101634126AImprove traffic capacityIncrease carrying capacityArtificial islandsRoadwaysUnderground tunnelOxygen

The invention belongs to the field of municipal and traffic engineering and relates to a ground-road comprehensive tunnel for underground pipelines and trolley buses. The technical scheme is that the underground compressive tunnel is set by combining with the ground roads, wherein the underground compressive tunnel has a rectangular cross section, and is vertically divided into two layers and is transversely provided with one single pore or multiple pores, the lower layer is used as a trolley bus comprehensive tunnel, the upper layer is used as a pipeline tunnel, the top plates are used as the ground roads, and the lower layer is only provided with ventilating facilities by which drivers and conductors can breathe. The technical effects include: the traffic of the underground trolley buses becomes a brand new public transport mode in which the special roads are set, and the traffic speed and ability are greatly improved; the oxygen is not consumed, no waste gas discharges, and the ventilating facilities only need to meet the breathing requirements of the drivers and conductors, so that the operating cost of ventilation is saved; the ground traffic space is saved; and the ground roads, the underground tunnels of the trolley buses and the pipeline tunnels are organically combined. The comprehensive tunnel is suitably used for developing underground trolley bus transportation in cities, and can also solve the problems of laying and maintaining the pipelines at the same time.

Owner:马兴华

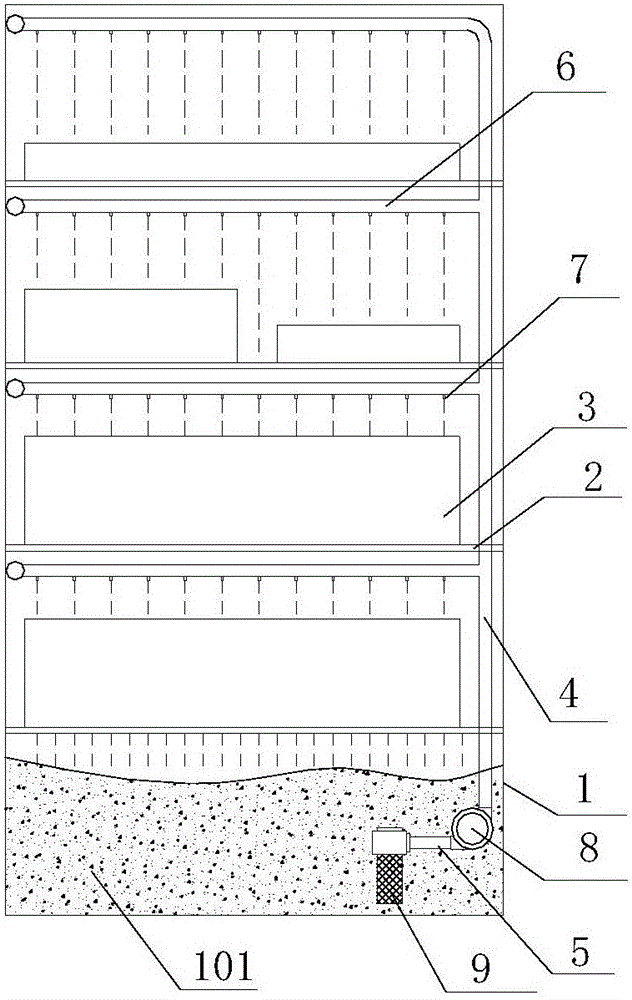

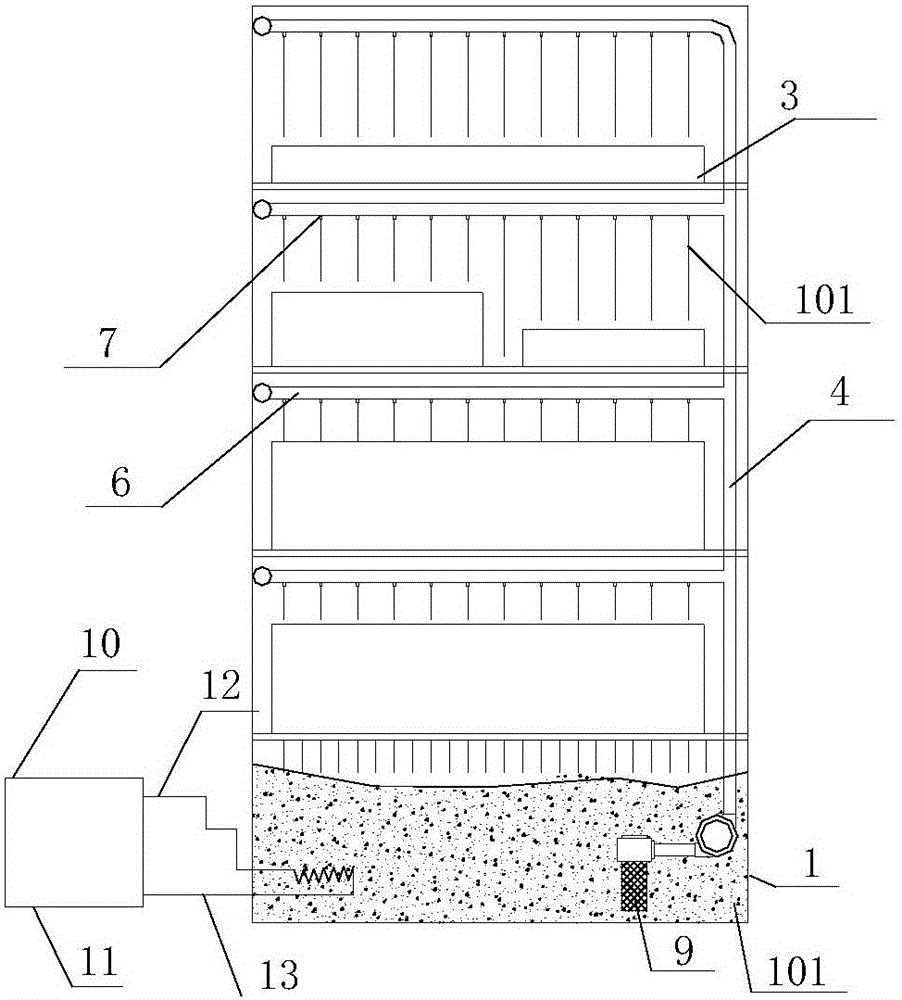

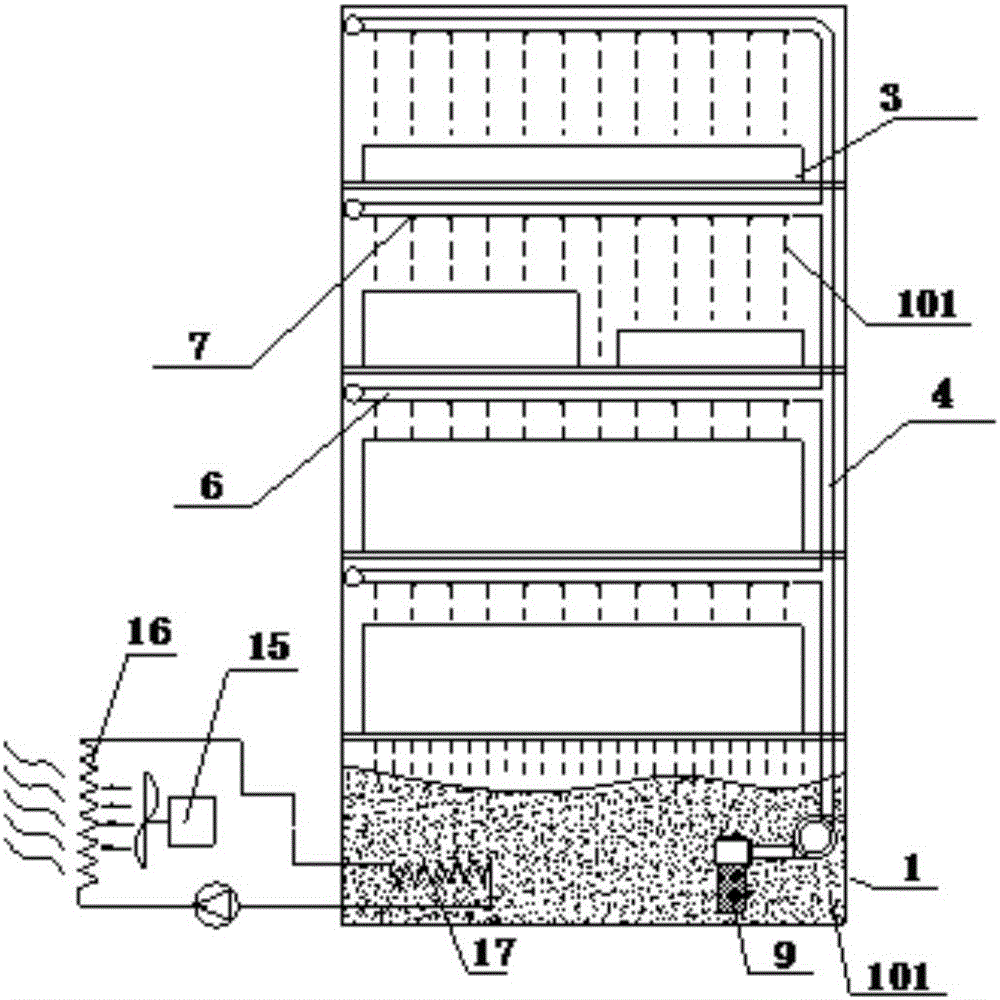

Working medium contact cooling system for computer and data center heat radiation

ActiveCN106413338AReduce trafficSmall temperature differenceDigital data processing detailsCooling/ventilation/heating modificationsLiquid stateData center

The present invention relates to a working medium contact cooling system for computer and data center heat radiation. The system comprises: a server cabinet; a liquid working medium case located at the bottom of the server cabinet; multiple layers of clapboards which are mutually paralleled and horizontally arranged and are hollow or have backflow channels, wherein the server assembly is arranged on the clapboards; a main pipe liquid dispenser being vertically arranged and being communicated with the liquid working medium case through a main pipe; and a plurality of liquid working medium shower pipes which are uniformly provided with a plurality of spraying ports, are horizontally arranged and located above each server assembly, and are communicated with the main pipe liquid dispenser, wherein the spraying directions of the spraying ports correspond to the position of the server assemblies, and the spraying ports spray the liquid working medium on the sever assemblies back to the liquid working medium case. The foggy liquid-state heat conduction working medium is directly contacted with the heating surface of the server assemblies without any intermediate medium and heat transferring links so as to substantially improve the heat exchange efficiency.

Owner:GUANGDONG HI 1 NEW MATERIALS TECH RES INST CO LTD

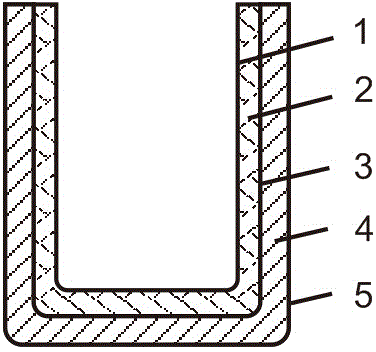

Rapid cooling vacuum cup based on heat absorption solution

The invention relates to a rapid cooling vacuum cup based on a heat absorption solution. The rapid cooling vacuum cup based on the heat absorption solution is characterized by sequentially comprising an inner cup wall, a heat absorption solution layer, a middle cup wall, a heat insulation layer and an outer cup wall from inside to outside. The rapid cooling vacuum cup can cool high-temperature hot water and keep an appropriate drinking temperature for a long time as required; the heat absorption solution contains water, a preservative, an emulsifying agent and a food-stage dying agent, and absorbs heat of high-temperature hot water, so that high-temperature hot water is cooled rapidly to reach the appropriate drinking temperature; the heat insulation layer can prevent heat loss and keep the appropriate drinking temperature for a long time. The rapid cooling vacuum cup based on the heat absorption solution, which is provided by the invention, is simple in structure, is obvious in cooling velocity, and can be widely applied to the field of daily supplies of water cups and the like.

Owner:BEIJING EMIKON TECH DEV

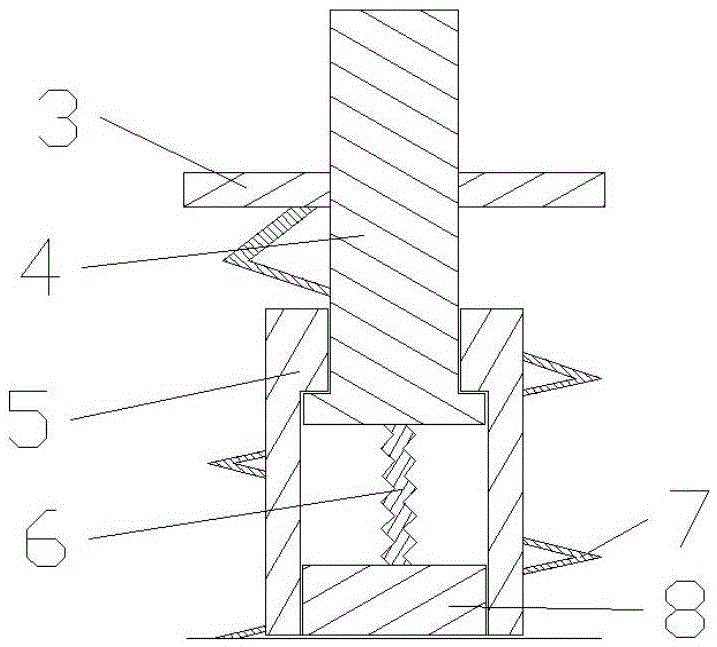

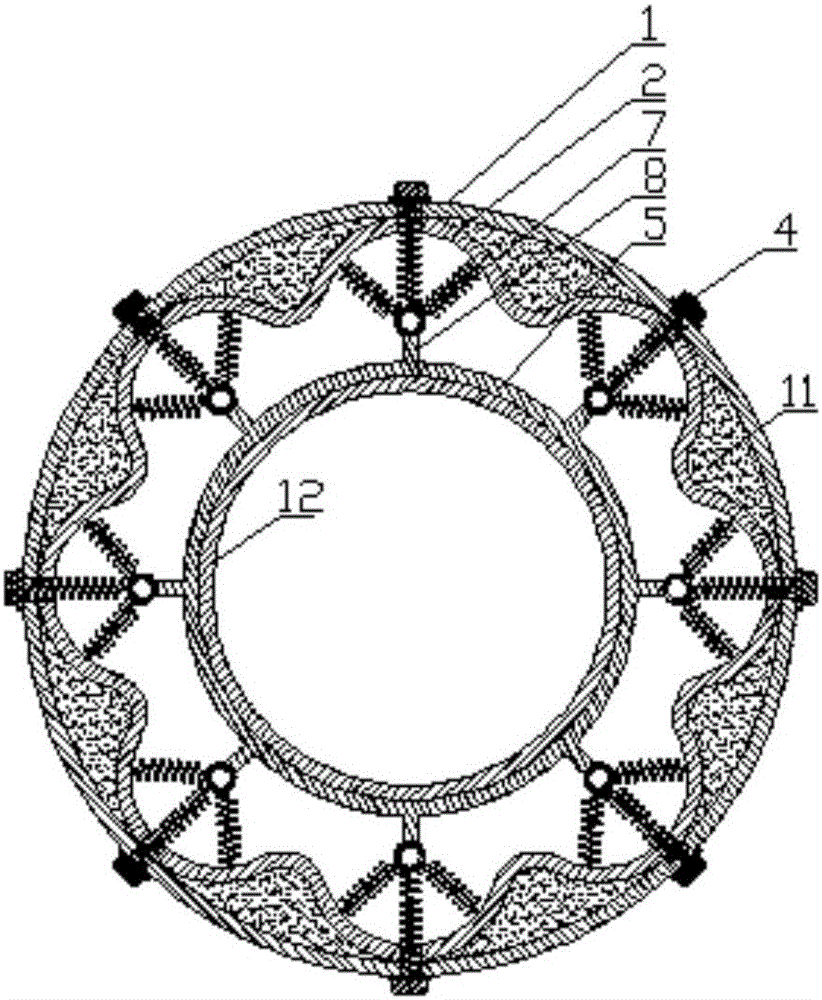

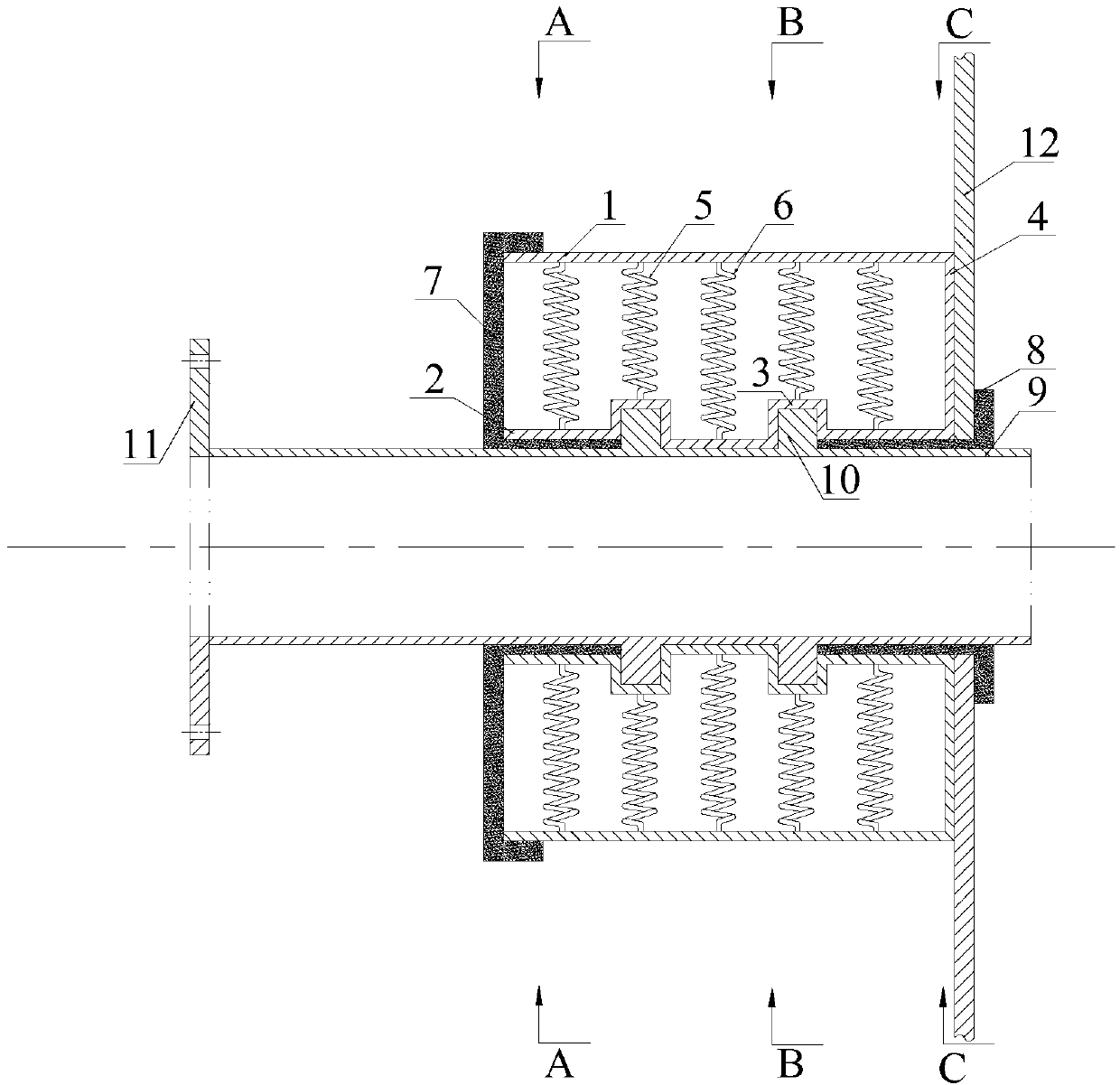

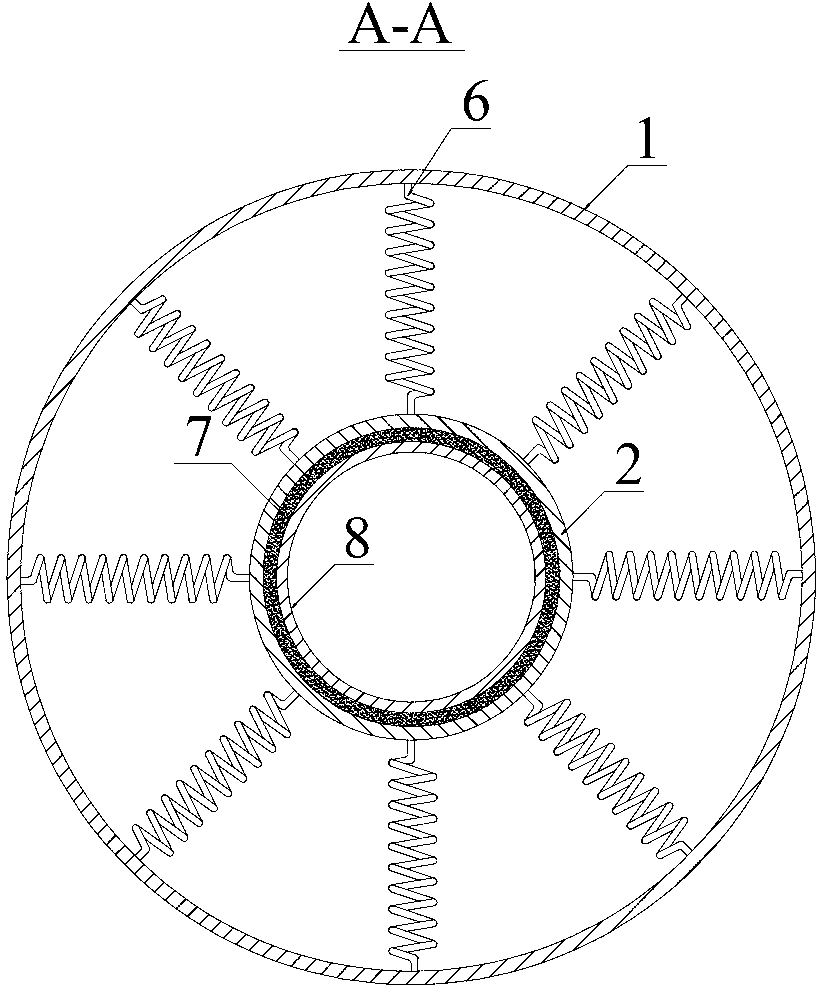

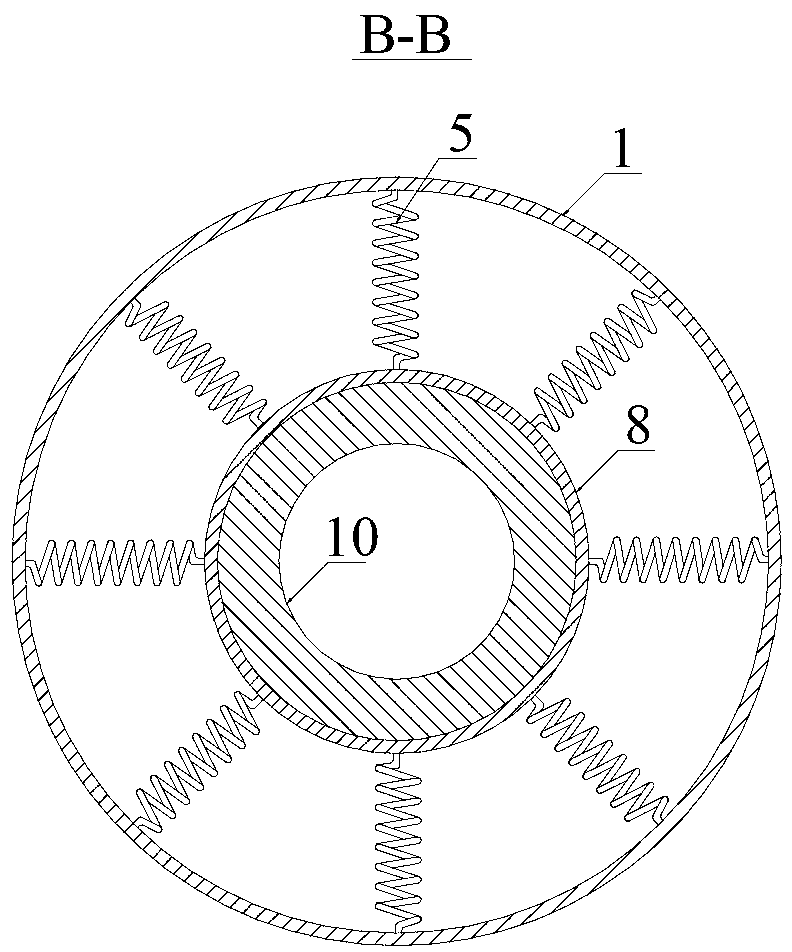

Vibration reduction ship pipeline cabin penetrating piece

ActiveCN106015761AImprove vibration damping effectAdjust the damping capacityNon-rotating vibration suppressionPipesStress concentrationMechanical engineering

The invention discloses a vibration reduction ship pipeline cabin penetrating piece which comprises a pipeline and a cabin wallboard. The pipeline is externally provided with a cabin penetrating piece shell. The cabin penetrating piece shell is divided into an outer cabin penetrating piece shell body, a wavy shell body and an inner cabin penetrating piece shell body. The outer cabin penetrating piece shell body is connected with the cabin wallboard, the wavy shell body is connected with the outer cabin penetrating piece shell body at crest positions, and wavy fireproof rubber is arranged between the wavy shell body and the outer cabin penetrating piece shell body. Perpendicular connecting pieces are arranged on the inner cabin penetrating piece shell body and are provided with connecting rings, and parallel springs are arranged between the connecting rings and are parallel to the outer cabin penetrating piece shell body and the inner cabin penetrating piece shell body. Perpendicular springs perpendicular to the wavy shell body are arranged on the crests, and the parts, at the joint of the crests and the outer cabin penetrating piece shell body and at the outer portion of the outer cabin penetrating piece shell body, of the perpendicular springs are provided with bolts. A transverse partition plate is arranged at the middle portion of the cabin penetrating piece shell and is connected with the parallel springs. The vibration reduction ship pipeline cabin penetrating piece has the following beneficial effects that firstly, the vibration reduction capability of the pipeline cabin penetrating piece under collisions is improved; secondly, the vibration reduction capability of the cabin penetrating piece can be adjusted according to needs of different pipeline systems; and thirdly, the wavy shell body in the cabin penetrating piece can well reduce stress concentration.

Owner:HUAIHAI INST OF TECH

Impact-resistant connecting device of pipeline and equipment

InactiveCN102809007AReduce the risk of large displacementRealize flexible connectionAdjustable jointsPipe protection against damage/wearEngineeringLarge deformation

The invention provides an impact-resistant connecting device of a pipeline and equipment. The impact-resistant connecting device comprises an outer barrel, a cylindrical helical spring, a rubber gasket, a rubber barrel cover, a connecting pipe and a flange, wherein one end of the connecting device is connected with the equipment through the outer barrel which is internally provided with springs, while the other end is connected with the pipeline through the flange and the connecting pipe; at the connecting end with the equipment, the connecting pipe is inserted into the equipment through the rubber gasket to realize the flexible connection of the pipeline and the equipment; the interior of the outer barrel of the connecting device is provided with a plurality of groups of springs which can be used for bearing larger deformation, and the outer barrel and the connecting pipe are fixed through a clamping trough so as to realize a constraint effect in the axial direction and the vertical direction of the pipeline and guarantee the tightness of the connection of the pipeline and the equipment; and meanwhile, the connecting part of the end part of the barrel, the connecting pipe and the equipment is provided with the rubber gasket so as to play the roles of sealing and flexible connection.

Owner:JIANGSU UNIV OF SCI & TECH

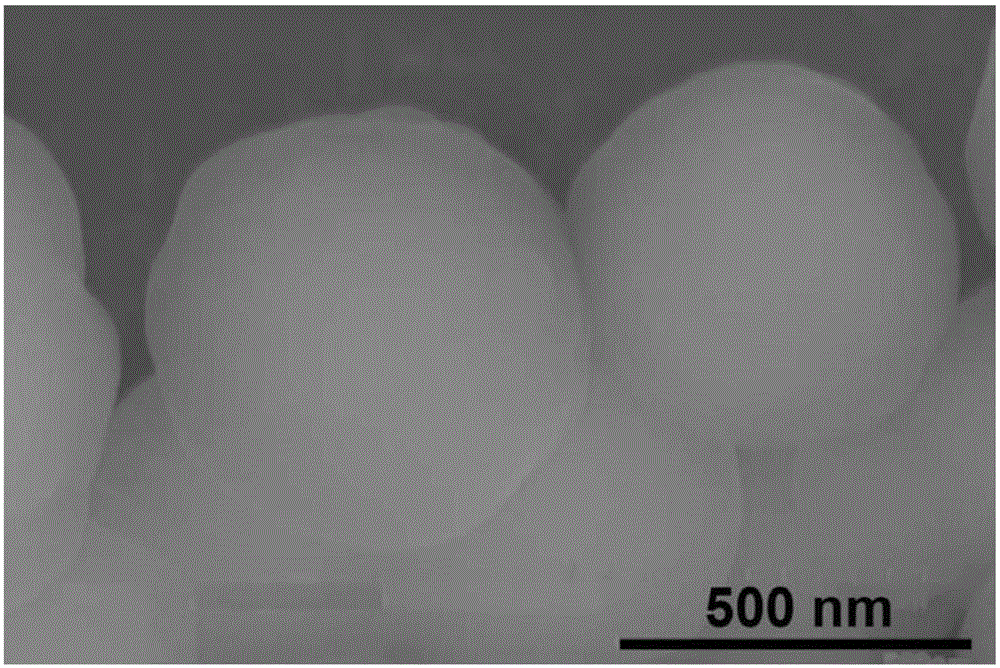

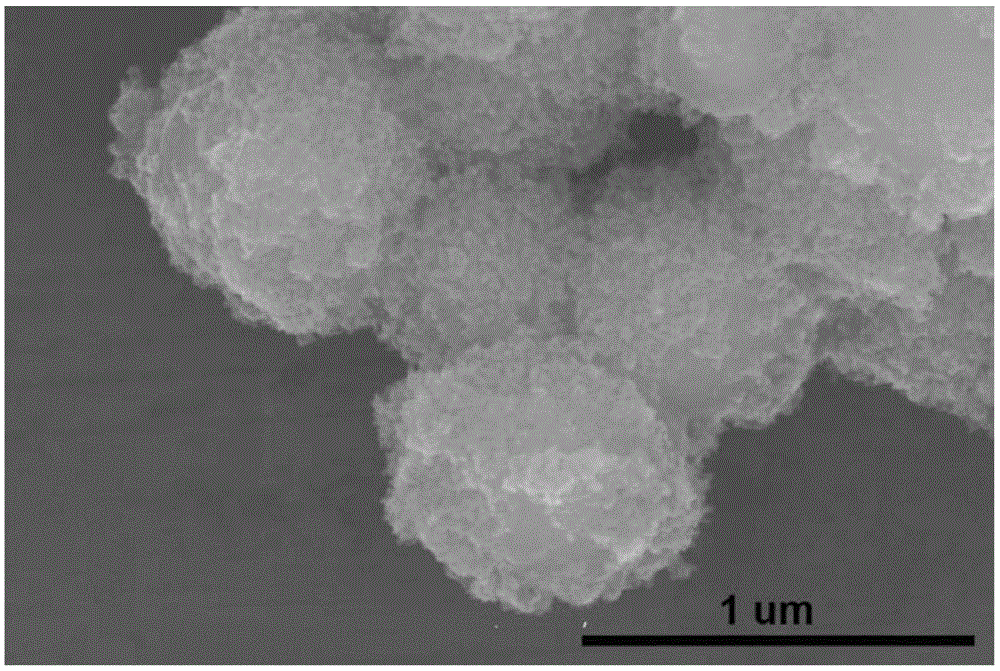

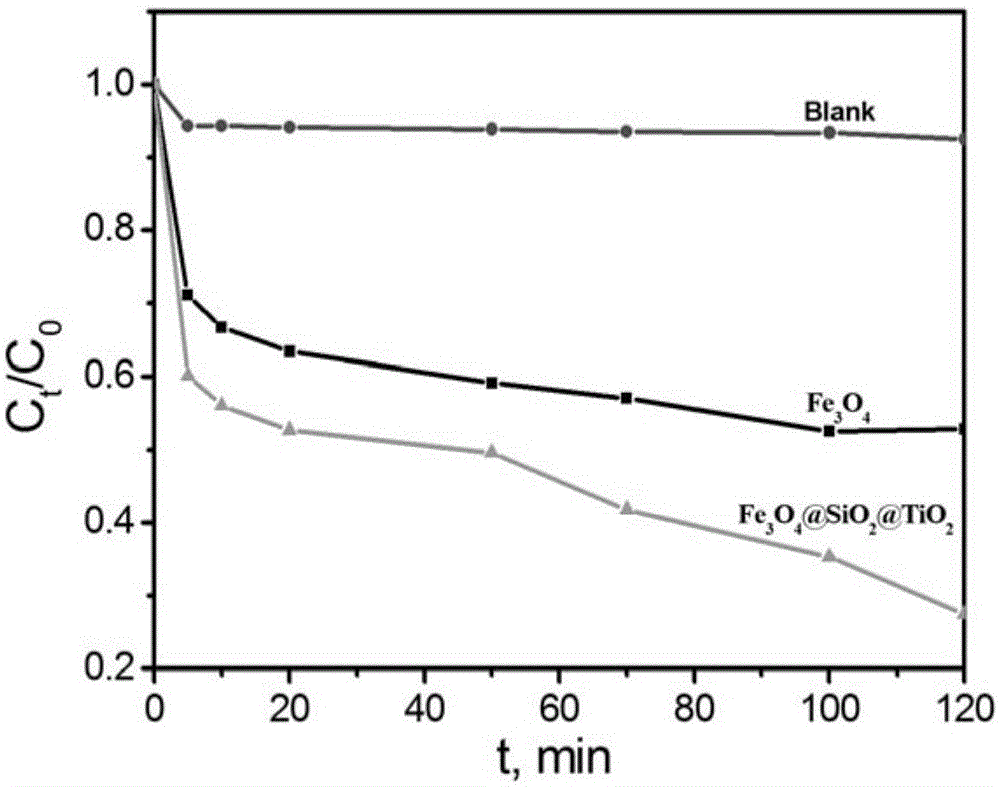

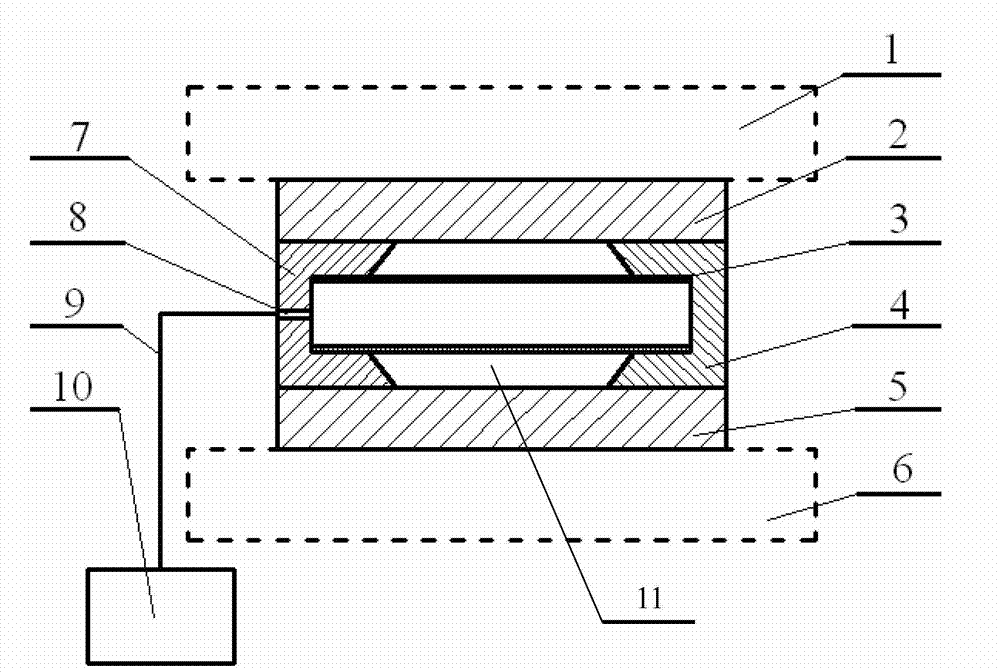

Multiphase magnetic Fenton-photocatalyst and preparation method thereof and application

InactiveCN105032423AEasy to recycleGood superparamagneticMaterial nanotechnologyWater/sewage treatment by irradiationMicrosphereWastewater

The invention relates to a multiphase magnetic Fenton-photocatalyst which is core-shell type microsphere Fe3O4@TiO2 which is of a three-layer structure. A core Fe3O4 microsphere is formed by stacking nanometer small granules of 15-30 nm, the thickness of a transitional SiO2 layer is 50-150 nm, and the thickness of an outermost TiO2 is 100-300 nm. The prepared photocatalyst has good superparamagnetism, can be separated thoroughly in 30 s under the effect of an outside magnetic field, is easy to recycle, can be recycled, and is environmentally friendly. The multiphase magnetic Fenton-photocatalyst can catalyze hydrogen peroxide under visible light to degrade organic pollutants, a multi-channel reaction pathway is formed, and accordingly high catalytic activity is achieved. A composite microsphere is good in monodispersity and can maintain high activity of a catalyst in wastewater treatment and improve utilization rate.

Owner:张少旸

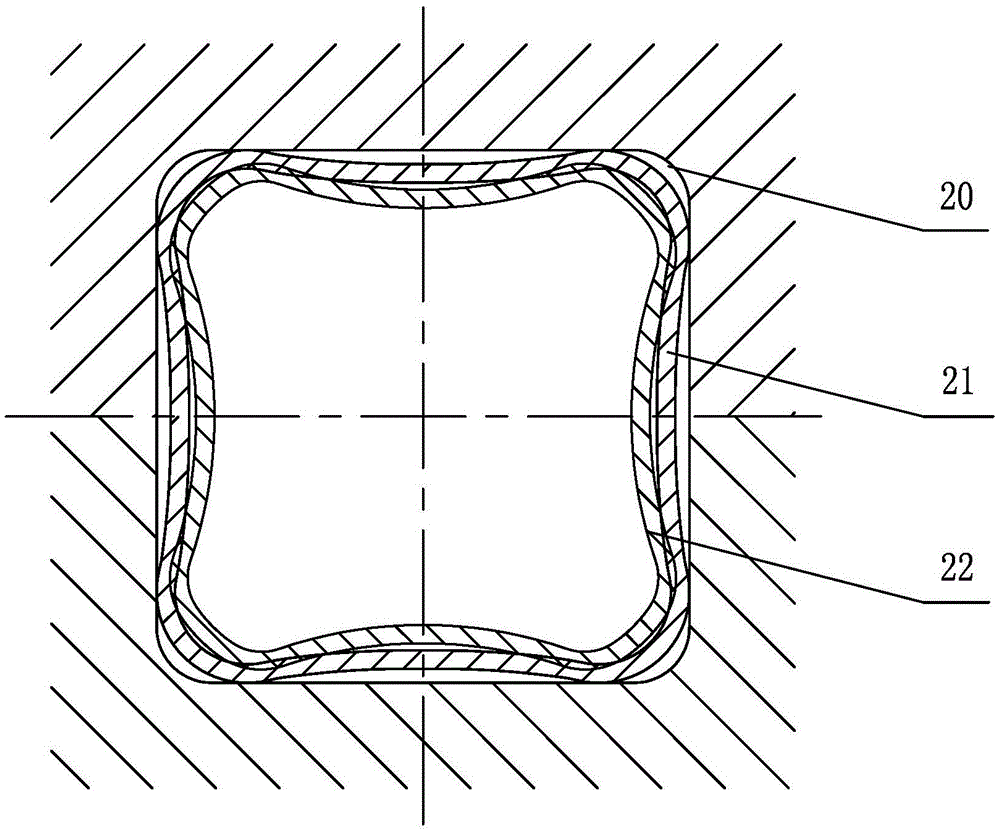

Section-variable hollow component forming device and method

InactiveCN102921791AAvoid technical problems with high sealing requirementsImprove uniformitySize differenceLiquid medium

The invention provides a section-variable hollow component forming device and a section-variable hollow component forming method, belongs to the technical field of hydraulic formation, and solves the problems that when a hollow component with a large hydraulic formation section size difference of a traditional tubular product is formed, axial feeding is difficult, the deformation uniformity is poor and the like. A closed cavity is formed by an upper die base, a left puncher pin, a right puncher pin and a lower die base; a puncher pin liquid injection hole is formed on the left puncher pin or the right puncher pin; a pressurizing device is communicated with the puncher pin liquid injection hole through a liquid channel; and the puncher pin liquid injection hole is used for injecting a liquid medium into a pipe blank. A pipe blank is placed into a die cavity and the puncher pins at the two ends are used for fixing the pipe blank; the upper die base is moved downwards to form a sealed hollow cavity with the lower die base; a force transfer medium is injected into the tubular product from the puncher pin injection hole at one side to pressurize; and the formation of a diameter-changing tube piece is realized under the matching effect of moving the left and right puncher pins to the inner side. After the formation, pressure in the die cavity can be removed after the formation, the upper die base is removed to separate the left and right puncher pins, and the formed piece is taken out. The section-variable hollow component forming device and the section-variable hollow component forming method are suitable for forming the hollow component with the great change of the section size and the circular-section or non-circular-section diameter-changing part.

Owner:哈尔滨松花江汽车座椅有限责任公司

Vibration-damping ship pipe clamp and support frame assembly

ActiveCN106122599AReduce vibration displacementSimple structurePipe supportsManufacturing technologyMarine engineering

The present invention discloses a vibration-damping ship pipe clamp and support frame assembly comprising a pipe, a ship body board and a support frame. A pipe clamp is arranged outside the pipe, and connected to a top cylinder of the support frame by means of a T-shaped connecting piece. A base plate of the support frame is connected to the ship body board. When the pipe vibrates under collision, springs in the pipe clamp, springs in the top cylinder of the support frame and springs in a base of the support frame function in reducing displacements and stresses of the whole assembly in a vertical direction, a lateral direction and a longitudinal direction, thus reducing the vibration displacement of the whole pipe. The vibration-damping ship pipe clamp and support frame assembly is reasonable and simple in structure and low in production cost. Each spring used in the vibration-damping ship pipe clamp and support frame assembly is a cylindrical helical extension spring with centrally curled ring ends, and such a spring is very mature in manufacturing technology and also highly stable in quality.

Owner:连云港苏茂船舶技术服务有限公司

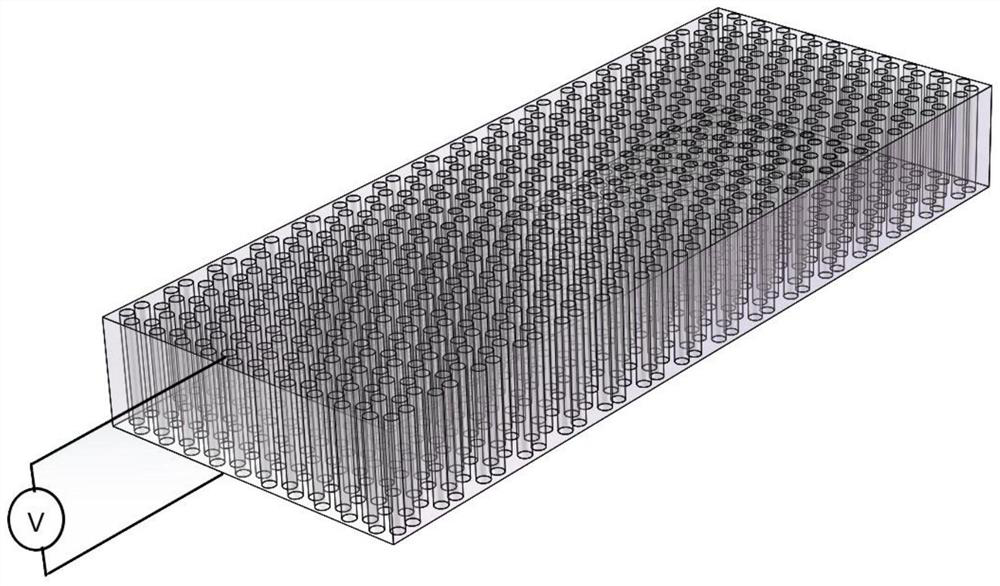

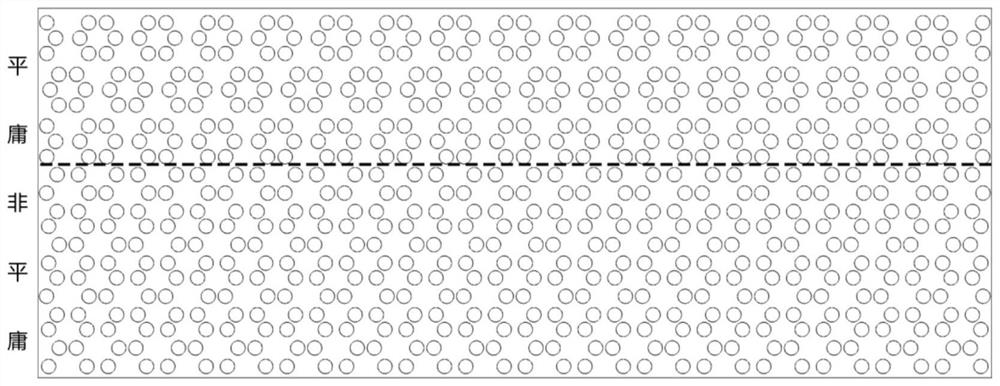

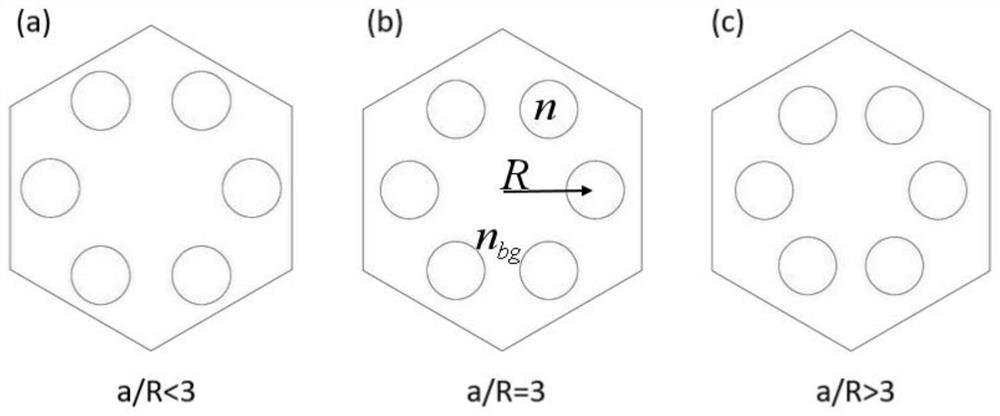

Optical waveguide structure capable of regulating and controlling boundary state of topological photonic crystal

ActiveCN112147805AReduce scatterGood photon localityStatic indicating devicesNon-linear opticsPhotonic crystalDielectric cylinder

The invention provides an optical waveguide structure capable of regulating and controlling the boundary state of a topological photonic crystal. The optical waveguide structure comprises an upper metal plate, a lower metal plate, a waveguide, a background material and a shell, wherein the upper metal plate and the lower metal plate are arranged in the shell, the waveguide is arranged between theupper metal plate and the lower metal plate, the waveguide is composed of a part A and a part B, the part A is formed by arranging unit cells with moderate topological properties, the part B is formedby arranging unit cells with non-moderate topological properties, each unit cell is formed by arranging six cylindrical dielectric cylinders with the radius of 0.12a, the cross section of each unit cell is in a regular hexagon shape, the distance radius from the center of each unit cell to the corresponding cylindrical dielectric cylinder in the unit cell is R, the distance between the centers ofevery two adjacent unit cells is a lattice constant a, the unit cells with the moderate topological property meet a / R=3.36, and the unit cells with the non-moderate topological property meet a / R=2.8.The problems that a traditional waveguide photon is weak in locality and low in transmission efficiency, and the frequency cannot be regulated and controlled are solved.

Owner:JIANGSU UNIV

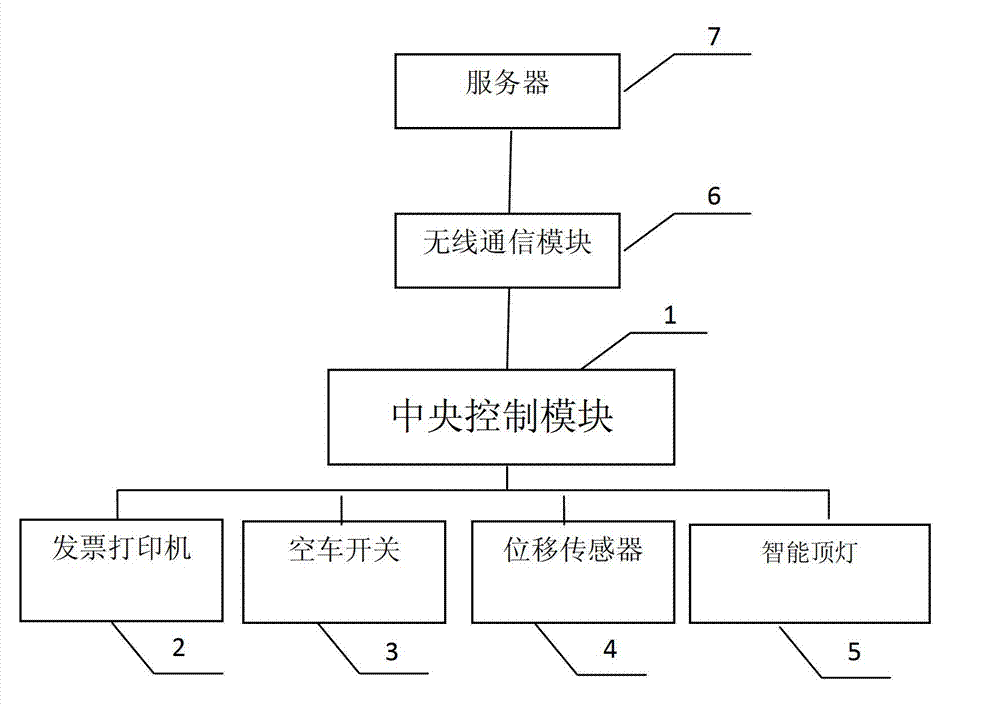

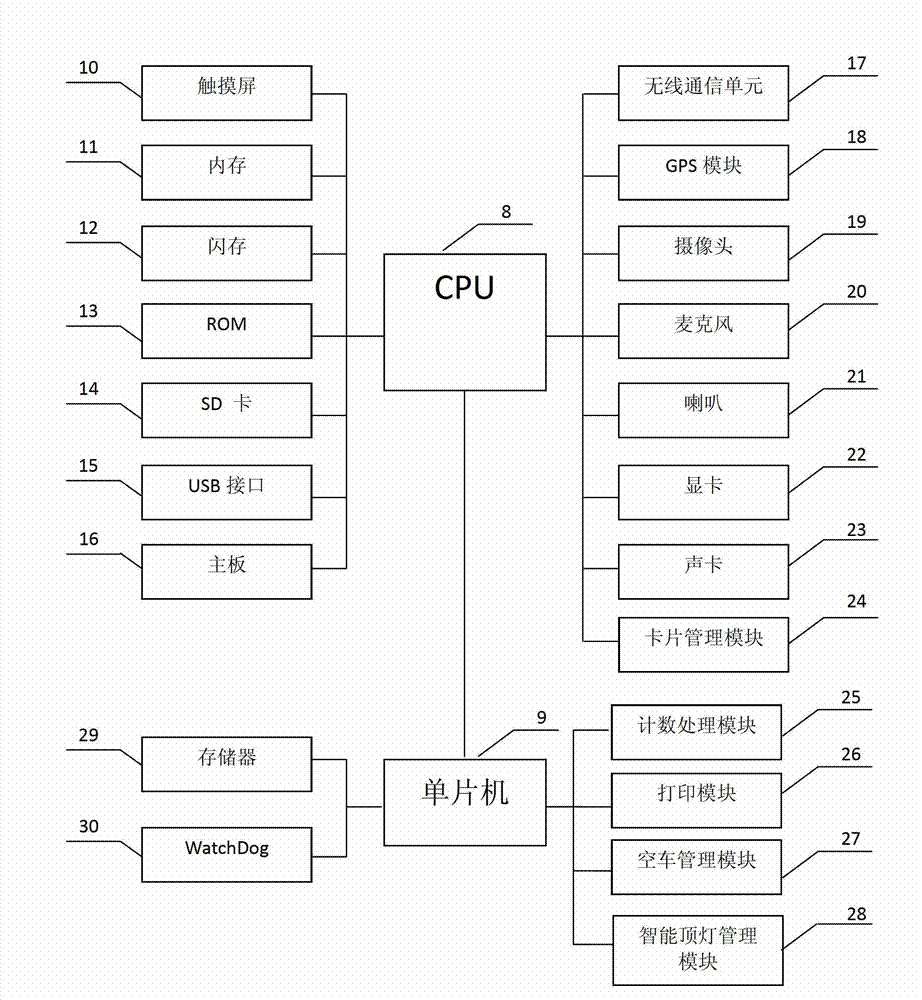

Taxi intelligent terminal device with pricing function

ActiveCN103035037ASimple structure and principleMature manufacturing technologyTaximetersOriginal dataWeb service

The invention belongs to the technical field of taxi pricing and management, and relates to a taxi intelligent terminal device with a pricing function. A wireless mobile network is adopted to serve as an information transmission tool, and when a user decides to adjust price information and parameters of a taxi, a server sends an instruction to modify relevant price information and parameters of the taxi. Peripheral devices of the intelligent terminal device comprise four functional parts of the server, the displacement sensor, an empty taxi display and an intelligent ceiling lamp, wherein the server comprises a WEB server and a data base server, the WEB server utilizes management software to manage the taxi, and the data base server is used for storing original data and other relevant management data of all operation records of the taxi. The system device is simple in structural principle, mature in preparation technology, safe and reliable to operate, flexible to control and monitor, and high in efficiency, saves resources, and facilitates information adjustment and data processing.

Owner:青岛华通智能科技研究院有限公司

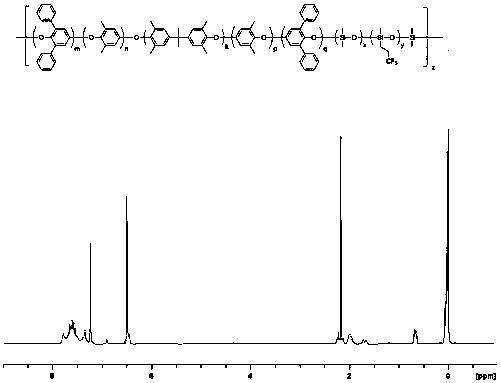

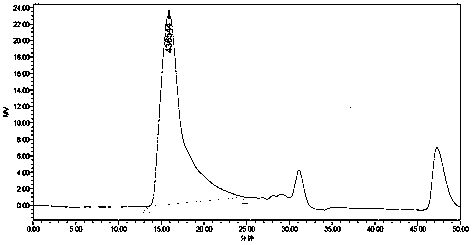

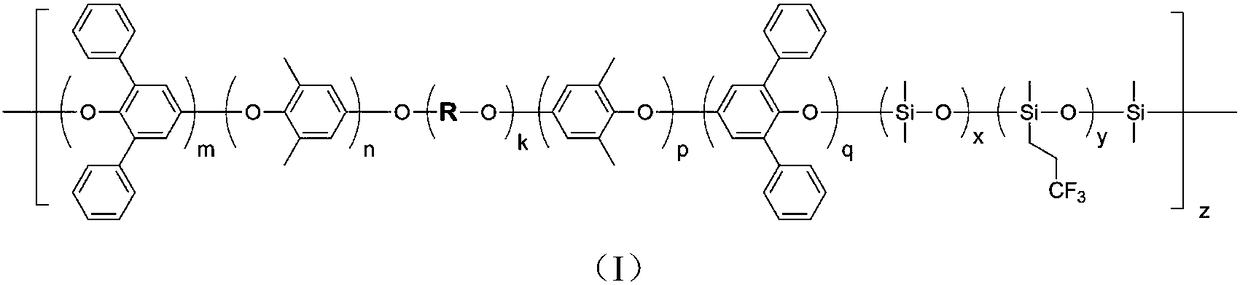

Polyarylether-polysiloxane copolymer and preparation method thereof

The invention relates to the technical field of organosilicone industry, and provides a polyarylether-polysiloxane copolymer and a preparation method thereof in order to overcome defects of the priorart. By taking phenolic hydroxyl group terminated polyarylether and hydrogen terminated polysiloxane as raw materials and by utilizing a catalytic dehydrogenation and polycondensation method, an Si-Hbond at the tail end of a polysiloxane molecular chain is activated through a catalyst, so that the two raw materials are in dehydrogenation coupling reaction, an (AB)n type multi-block copolymer of which the structure is regular is formed through polycondensation, and soft / hard segments are connected together through an Si-O-Ph bond; an obtained (AB)n type polyarylether-polysiloxane multi-block copolymer has good mechanical performance, good heat resistance and good oil and solvent resistance.

Owner:HANGZHOU NORMAL UNIVERSITY

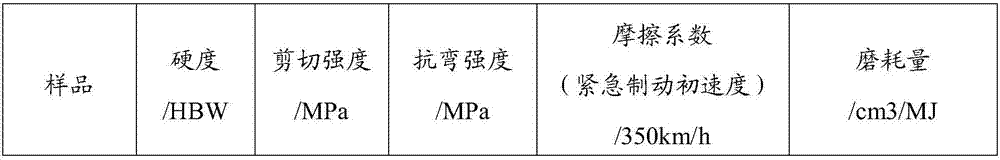

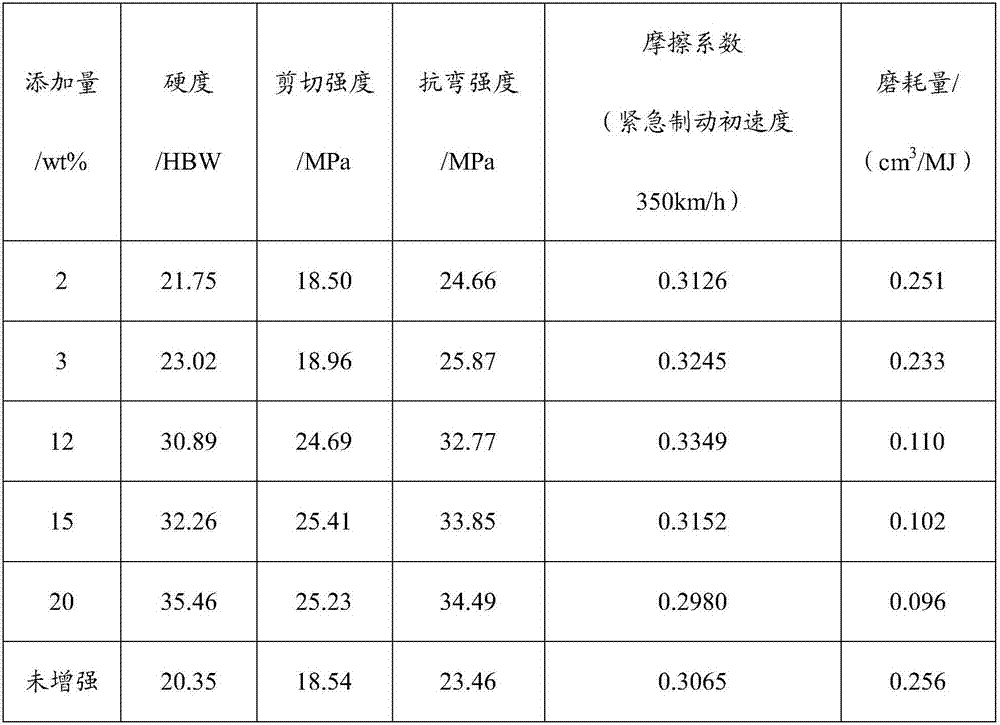

Intermetallic compound enhanced powder metallurgy friction material and preparing method and application of intermetallic compound enhanced powder metallurgy friction material

The invention provides an intermetallic compound enhanced powder metallurgy friction material. The powder metallurgy friction material comprises 40%-60% of copper, 10%-20% of iron, 5%-10% of intermetallic compound powder, 8%-12% of ferrochromium, 5%-12% of graphite, 3%-5% of molybdenum disulfide, 1%-2% of barium sulfate, 2%-4% of silicon dioxide, 1%-3% of aluminum oxide and 2%-4% of silicon nitride. A preparing method for the intermetallic compound powder metallurgy friction material includes the steps that firstly, after all raw materials are weighed and mixed according to the proportion, a binding agent is added, and stirring is conducted; secondly, a mixture obtained in the first step is subjected to cold pressing forming; and thirdly, a pressed blank obtained in the second step is subjected to sintering treatment under the protective atmosphere, and then cooling is conducted. Intermetallic compound particles are adopted as a base reinforcement phase for the intermetallic compound powder metallurgy friction material, defects in the prior art are effectively overcome, the comprehensive performance of a braking pad is greatly improved, and especially the high-temperature friction performance, the shear strength and the wear resistance of the material are greatly improved.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com