Intermetallic compound enhanced powder metallurgy friction material and preparing method and application of intermetallic compound enhanced powder metallurgy friction material

An intermetallic compound and powder metallurgy technology, applied in the field of friction materials, can solve the problems of hindering the flow of sintered neck vacancies between powder particles, destroying the unknown structure of pearlite structure, and negatively affecting the comprehensive performance of brake pads, and achieves stable high-temperature friction performance. The effect of improving flexural strength and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

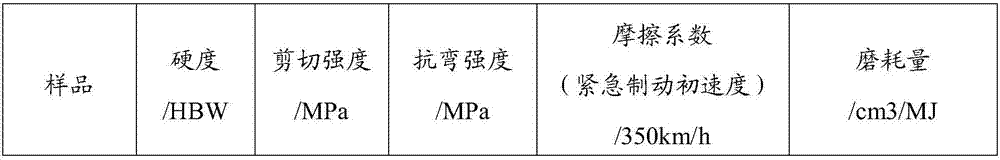

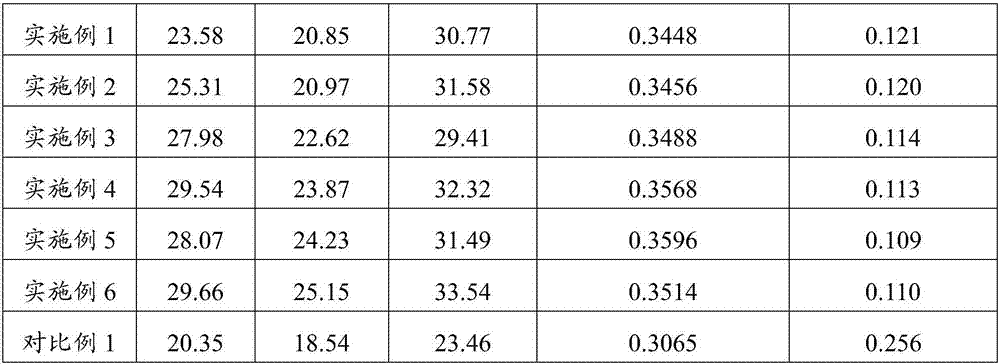

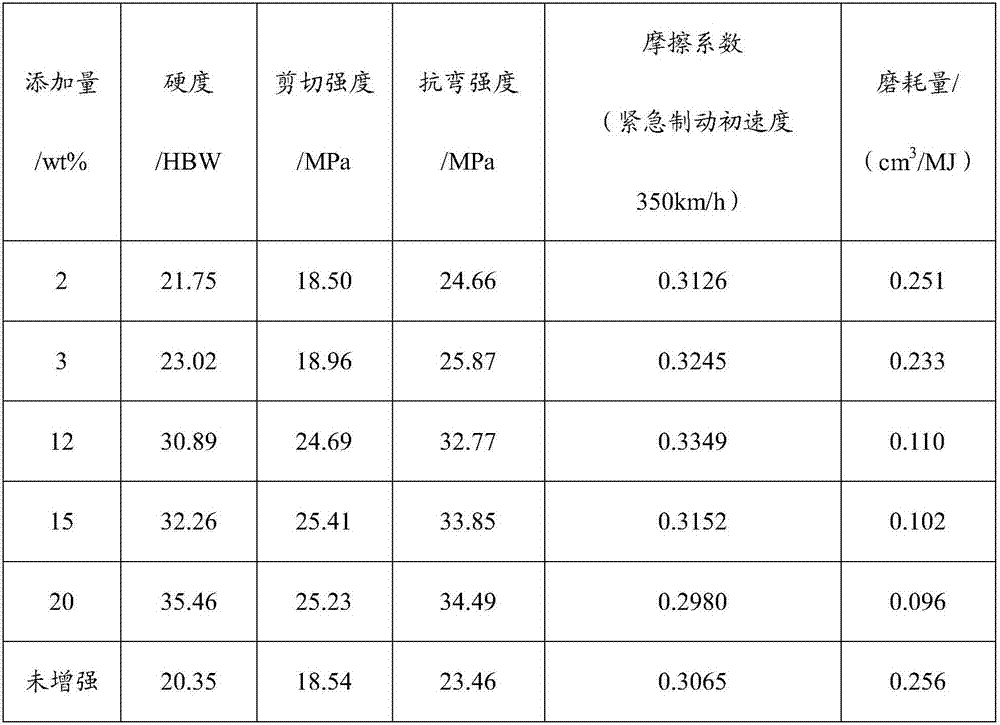

Examples

Embodiment 1

[0044] Example 1: Preparation of intermetallic compound-reinforced powder metallurgy friction material according to the present invention

[0045] 1. Raw materials: copper 400g, iron 200g, iron-aluminum intermetallic compound powder 50g, ferrochrome 100g, graphite 110g, molybdenum disulfide 30g, barium sulfate 10g, silicon dioxide 40g, aluminum oxide 20g, silicon nitride 40g, kerosene 10g ;

[0046] 2. The preparation of iron-aluminum intermetallic compound powder is prepared by solid-liquid reaction ball milling method: Weigh 130g of pure iron (purity>99.8%) and 70g of aluminum (purity>99.8%); put pure iron and aluminum powder into a ball mill tank , filled with argon protection, ball milled at a temperature of 670°C at a speed of 80r / min for 48 hours, then taken out and sieved to obtain iron-aluminum intermetallic compound powder with a particle size of 600-800 mesh;

[0047] 3. Preparation of intermetallic compound-reinforced powder metallurgy friction material: put each ...

Embodiment 2

[0048] Example 2: Preparation of intermetallic compound-reinforced powder metallurgy friction material according to the present invention

[0049] 1. Raw materials: copper 500g, iron 150g, iron-aluminum intermetallic compound powder 60g, ferrochrome 80g, graphite 80g, molybdenum disulfide 40g, barium sulfate 10g, silicon dioxide 20g, aluminum oxide 30g, silicon nitride 30g, kerosene 10g ;

[0050] 2. The preparation of iron-aluminum intermetallic compound powder is prepared by solid-liquid reaction ball milling method: Weigh 130g of pure iron (purity>99.8%) and 70g of aluminum (purity>99.8%); put pure iron and aluminum powder into a ball mill tank , filled with argon protection, ball milled at a temperature of 690°C at a speed of 80r / min for 48 hours, then taken out and sieved to obtain iron-aluminum intermetallic compound powder with a particle size of 600-800 mesh;

[0051] 3. Preparation of intermetallic compound-reinforced powder metallurgy friction material: put all ra...

Embodiment 3

[0052] Example 3: Preparation of intermetallic compound-reinforced powder metallurgy friction material according to the present invention

[0053] 1. Raw materials: copper 600g, iron 100g, iron-aluminum intermetallic compound powder 70g, ferrochrome 80g, graphite 60g, molybdenum disulfide 30g, barium sulfate 10g, silicon dioxide 20g, aluminum oxide 10g, silicon nitride 20g, kerosene 20g ;

[0054] 2. The preparation of iron-aluminum intermetallic compound powder is prepared by solid-liquid reaction ball milling method: Weigh 140g of pure iron (purity>99.8%) and 60g of aluminum (purity>99.8%); put pure iron and aluminum powder into a ball mill tank , filled with argon protection, ball milled at a temperature of 720°C at a speed of 80r / min for 48 hours, then taken out and sieved to obtain iron-aluminum intermetallic compound powder with a particle size of 600-800 mesh;

[0055] 3. Preparation of intermetallic compound-reinforced powder metallurgy friction material: put each r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com