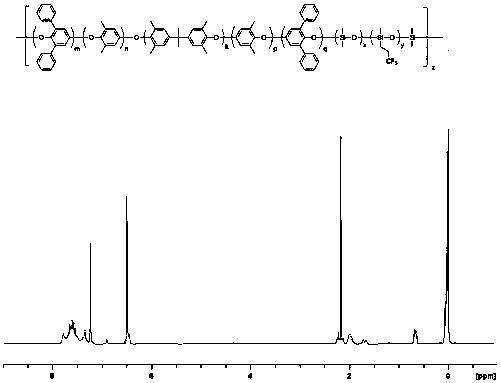

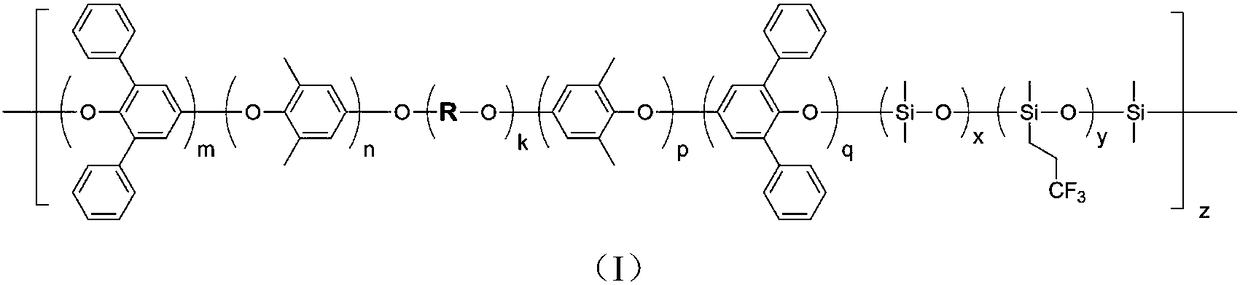

Polyarylether-polysiloxane copolymer and preparation method thereof

A technology of polysiloxane and polyarylether, applied in the field of polyarylether-polysiloxane copolymer and its preparation, can solve the problem of poor oil resistance and solvent resistance, limit the application range of copolymers, reduce the mechanical strength of materials, etc. problems, to achieve the effect of improving mechanical strength, improving physical and chemical properties and processing performance, and the preparation method is mature and simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] In a 1L three-necked flask equipped with a thermometer, mechanical stirring and a constant pressure dropping funnel, add M n Be 5600 PPO-2OH (1a) 5.6g (1mmol), B (C 6 f 5 ) 3 56mg and 300mL of chlorobenzene, stirred and heated to 70°C. Add M to the constant pressure dropping funnel n 11g (1mmol) of PS-2H(2e) at 11000, and then added dropwise to the flask in 12 times (each interval 0.5h, each time about 1mL). As the reaction progressed, it was observed that bubbles escaped slowly from the solution, and the viscosity of the reaction system gradually increased. Continue to react for 3 hours after the dropwise addition, the viscosity of the reaction system has not increased significantly, and there is no gas escape, stop the reaction, cool to room temperature, precipitate the reaction mixture into 1000mL methanol, filter out the white rubber-like product, and vacuum at 80°C Dry to constant weight, the resulting (AB) n The yield of type polyarylether-polysiloxane copol...

Embodiment 2

[0108] In a 1L three-necked flask equipped with a thermometer, mechanical stirring and a constant pressure dropping funnel, add M n 4400 PPO-2OH (1d) 4.4g (1mmol), B (C 6 f 5 ) 3 22mg and 265mL of chlorobenzene, stirred and heated to 80°C. Add M to the constant pressure dropping funnel n 7700 PS-2H (2d) 7.7g (1mmol), and then added dropwise to the flask 5 times (every interval of 1h, each time about 1.5mL). As the reaction progressed, it was observed that bubbles escaped slowly from the solution, and the viscosity of the reaction system gradually increased. Continue to react for 4 hours after the dropwise addition, the viscosity of the reaction system has not increased significantly, and there is no gas escape, stop the reaction, cool to room temperature, precipitate the reaction mixture into 1000mL methanol, filter out the white blocky product, and vacuum at 100°C Dry to constant weight. Earned (AB) n The yield of type polyarylether-polysiloxane copolymer is 98.2%, M ...

Embodiment 3

[0110] Add M n 8300 PPO-2OH (1e) 8.3g (1mmol), B (C 6 f 5 ) 3 17mg and 232mL of chlorobenzene, stirred and heated to 120°C. Add M to the constant pressure dropping funnel n 19g (1mmol) of PS-2H(2k) at 19000 was added dropwise into the flask in 20 times (20min interval between each time, about 1mL each time). After the dropwise addition, the reaction was continued for 1 h, then the reaction was stopped, cooled to room temperature, the reaction mixture was precipitated into 1000 mL of methanol, the white rubbery product was filtered out, and vacuum-dried at 120°C to constant weight. Earned (AB) n The yield of type polyarylether-polysiloxane copolymer is 98.2%, M n : 168800, PDI: 3.45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com