Rapid cooling vacuum cup based on heat absorption solution

A thermos cup and solution technology, which is applied in the direction of drinking water containers, etc., can solve the problems of lower than the suitable drinking temperature, low cooling rate, and long time consumption, and achieve the effects of mature preparation technology, prevention of deterioration, and low freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

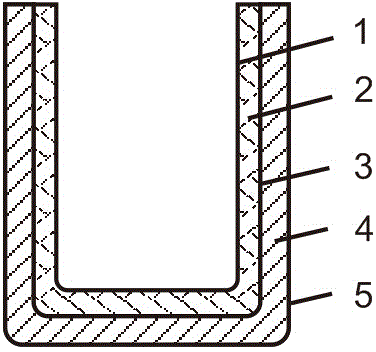

[0033] Such as figure 1 As shown, the heat-absorbing solution-based rapid cooling thermos cup of the present invention includes an inner cup wall 1 , an endothermic solution layer 2 , a middle cup wall 3 , a heat insulation layer 4 and an outer cup wall 5 from inside to outside. The heat-absorbing solution layer 2 contains water, preservatives, emulsifiers and food-grade dyes; the preservatives not only prevent the heat-absorbing solution layer from deteriorating, but also reduce the freezing point of water; the food-grade dyes are mixed with water to form a The heat-absorbing solution of the color, in addition, the food-grade dyeing agent is granular or colloidal, which strengthens the natural convection capacity of water through its own movement, and accelerates the cooling rate; the emulsifier not only makes the coloring agent particles in the heat-absorbing solution Distribute evenly to avoid sedimentation, reduce the viscosity of water at the same time, strengthen the nat...

Embodiment 2

[0037] The inner cup wall 1, the middle cup wall 3 and the outer cup wall 5 of the rapid cooling thermos cup of this embodiment are all made of stainless steel; The agent is soybean milk, and the emulsifier is sorbitan fatty acid ester; the heat insulation layer 4 is high silica cotton.

[0038] When in use, high-temperature hot water is poured into the thermos cup, and the heat-absorbing solution layer 2 absorbs heat immediately, so that the high-temperature hot water is rapidly cooled to reach an appropriate drinking temperature. The heat insulation layer can greatly reduce heat loss and keep hot water at a drinking temperature for a long time.

Embodiment 3

[0040] The inner cup wall 1, the middle cup wall 3 and the outer cup wall 5 of the rapid cooling thermos cup of this embodiment are made of stainless steel; the preservative in the heat-absorbing solution layer 2 is potassium chloride, and the mass fraction of potassium chloride is 1%. , the food-grade dyeing agent is collagen, and the emulsifier is glycerin acetate fatty acid ester; the heat insulation layer 4 is polyurethane foam.

[0041] When in use, high-temperature hot water is poured into the thermos cup, and the heat-absorbing solution layer 2 absorbs heat immediately, so that the high-temperature hot water is rapidly cooled to reach an appropriate drinking temperature. The heat insulation layer can greatly reduce heat loss and keep hot water at a drinking temperature for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com