Charging pressing forming method for variable-cross-section special-shaped pipe

A technology of special-shaped pipe fittings and variable cross-section, which is applied in the field of pipe filling hydraulic forming and metal pipe fitting manufacturing. It can solve problems such as mold wear, high pressure, and large springback, and achieve improved efficiency, improved thinning, and ring direction. The effect of uniform distribution of wall thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

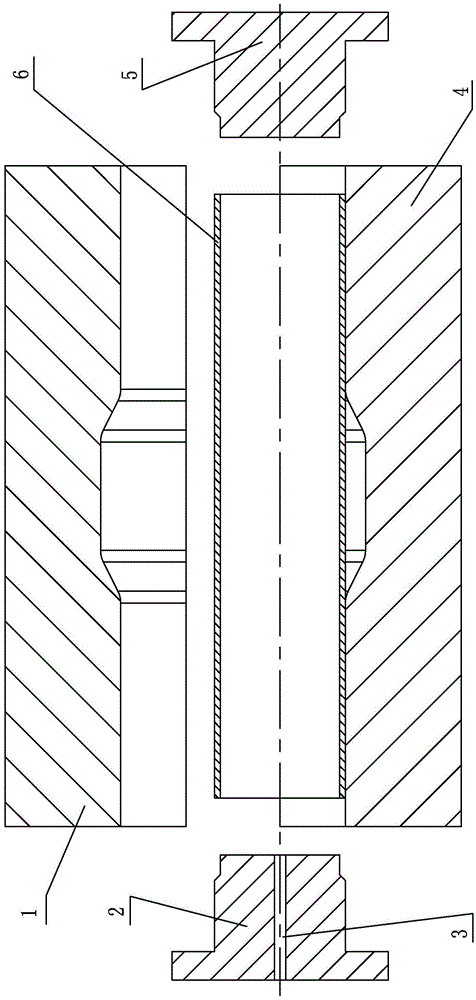

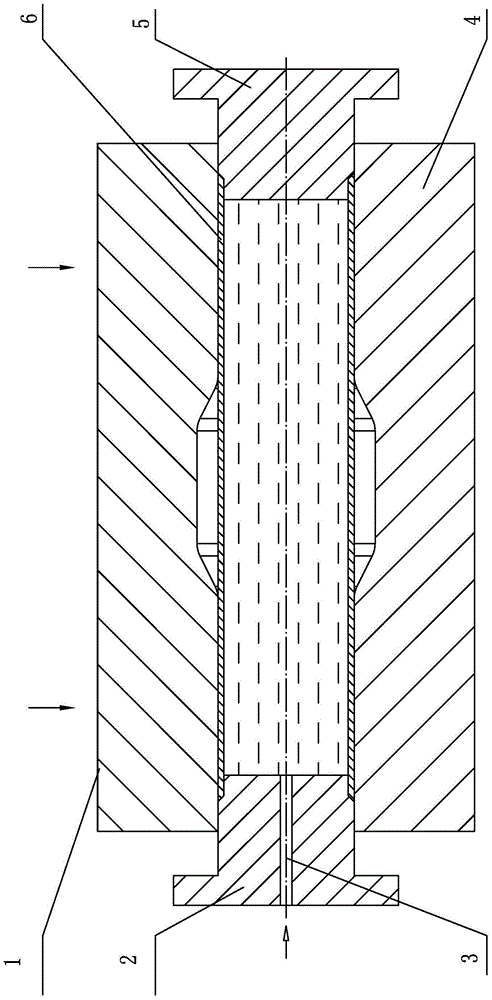

[0046] Specific implementation mode one: combine Figure 2-Figure 21 To illustrate, a method of filling hydraulic forming of variable cross-section special-shaped pipe fittings in this embodiment is carried out in accordance with the following steps:

[0047] Step 1. Assemble the bulging upper die 1 and the bulging lower die 4 on the press according to the design requirements, the bulging lower die 4 is fixed, the bulging upper die 1 goes up to the set height, and the bulging upper die 1 and the bulging The open space of the lower mold 4 is used to place the tube blank 6;

[0048] Step 2. By controlling the movement of the main slider of the press, the bulging upper mold 1 moves downward to close the mold, and the left sealing punch 2 and the right sealing punch 5 move towards each other under the action of the horizontal cylinder, so that the tube blank 6 is respectively in contact with the left sealing punch. The head 2 and the right sealing punch 5 form a closed cavity, th...

specific Embodiment approach 2

[0062] Specific implementation mode 2: In step 5 and step 6 of this embodiment, the set value p is 5MPa-50MPa. The set value p in this embodiment is not enough to cause plastic deformation of the tube blank. Others are the same as in the first embodiment.

specific Embodiment approach 3

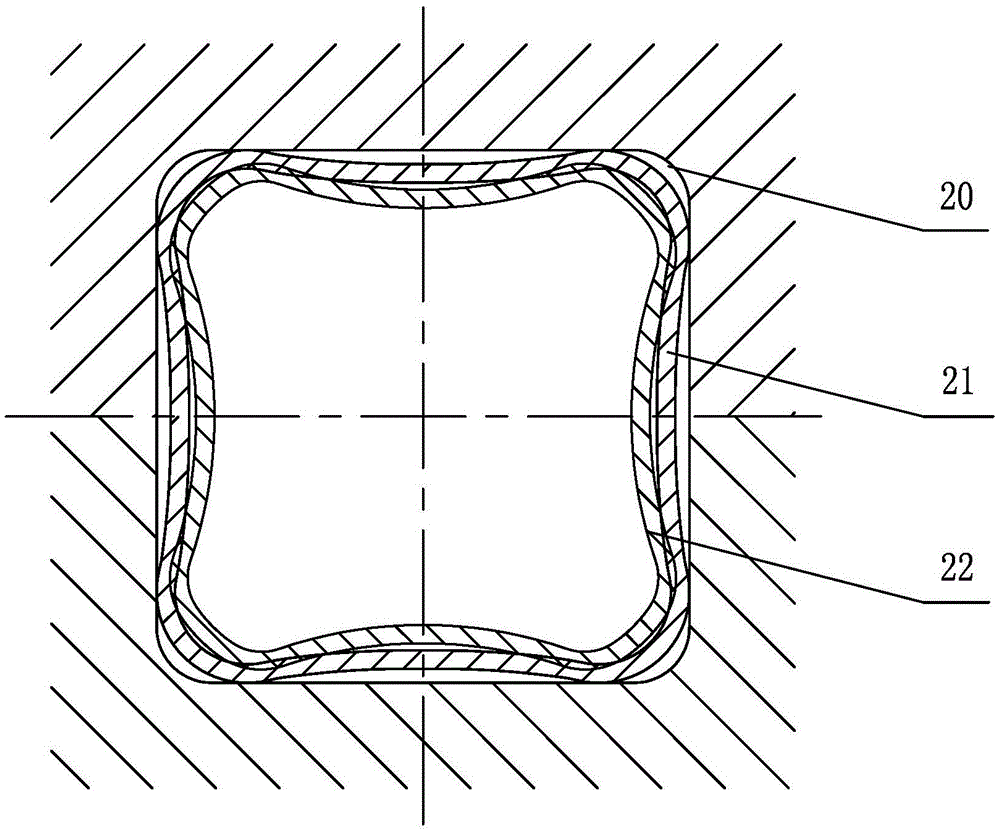

[0063] Specific implementation mode three: combination Figure 2-Figure 12 and Figure 13 , the variable cross-section pipe fitting (62) obtained in step 7 of this embodiment is a variable cross-section rectangular pipe fitting. Such setting meets the design requirements and actual needs. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com