Section-variable hollow component forming device and method

A technology of hollow components and variable cross-sections, which is applied in the field of forming devices for hollow components with variable cross-sections and processing and forming devices for metal hollow components. It is easy to feed materials and avoid the effect of high requirements for pipe end sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

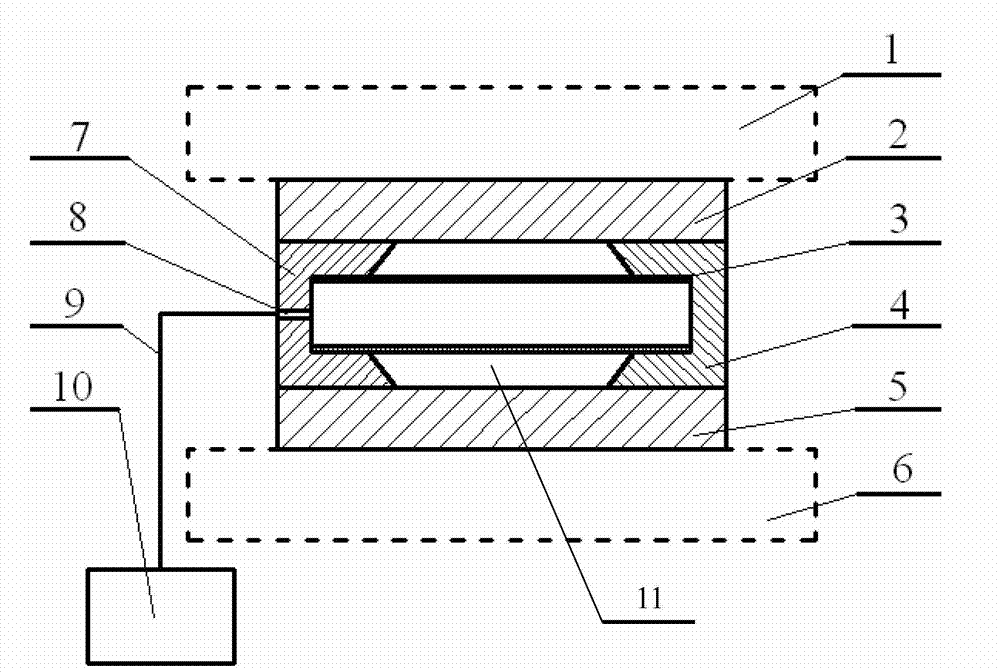

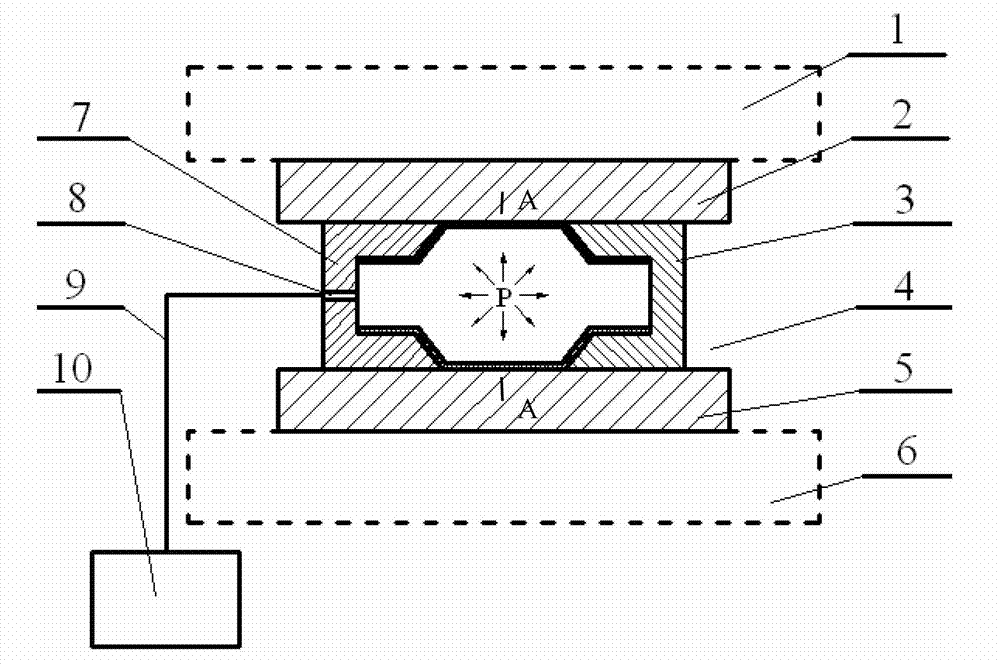

[0019] Specific implementation mode one: as Figure 1-4 As shown, the variable cross-section hollow member forming device includes an upper die base 2, a left punch 7, a right punch 4, a lower die base 5, a liquid channel 9 and a booster 10, a left punch 7, a right punch 4 Located between the upper die base 2 and the lower die base 5, the upper die base 2, the left punch 7, the right punch 4 and the lower die base 5 form a closed cavity 11, and the left punch 7 or the right punch There is a punch liquid injection hole 8 on the head 4, the supercharger 10 communicates with the punch liquid injection hole 8 through the liquid channel 9, and the punch liquid injection hole 8 is used to place the left punch 7 and the right punch Liquid medium is injected into the upper tube blank 3 .

[0020] The cross section of the diameter reducing portion of the closed cavity 11 can be circular, rhombus, square or rectangular.

specific Embodiment approach 2

[0021] Specific implementation mode two: as Figure 1-4 As shown, the present embodiment is a method for forming a variable-section hollow member using the above-mentioned forming device, and the method is realized according to the following steps: Step 1, fixing the lower mold base 5 on the lower workbench 6 of the press; Step 2 1. Move the right punch 4 to the right end of the lower mold base 5, and place one end of the tube blank 3 in the mold cavity of the right punch 4; step 3, move the left punch 7 to the lower mold base 5 the left end, and place the other end of the tube blank 3 in the mold cavity of the left punch 7; step 4, move down the upper worktable 1 of the press, so that the upper die base 2 and the left punch 7, the right punch 4 and The lower mold base 5 forms a closed cavity 11; step five, pressurize the pipe material 3 through the supercharger 10; step six, the left punch 7 and the right punch 4 simultaneously push the pipe material 3 to move to the middle; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com