Section-variable hollow component forming device and method

A hollow component and variable cross-section technology, which is applied in the field of processing and forming devices for metal hollow components and forming devices for variable cross-section hollow components, can solve the problems of poor deformation uniformity and difficulty in feeding materials in the axial direction, so as to achieve easy feeding and avoid partial Effect of excessive thinning and uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

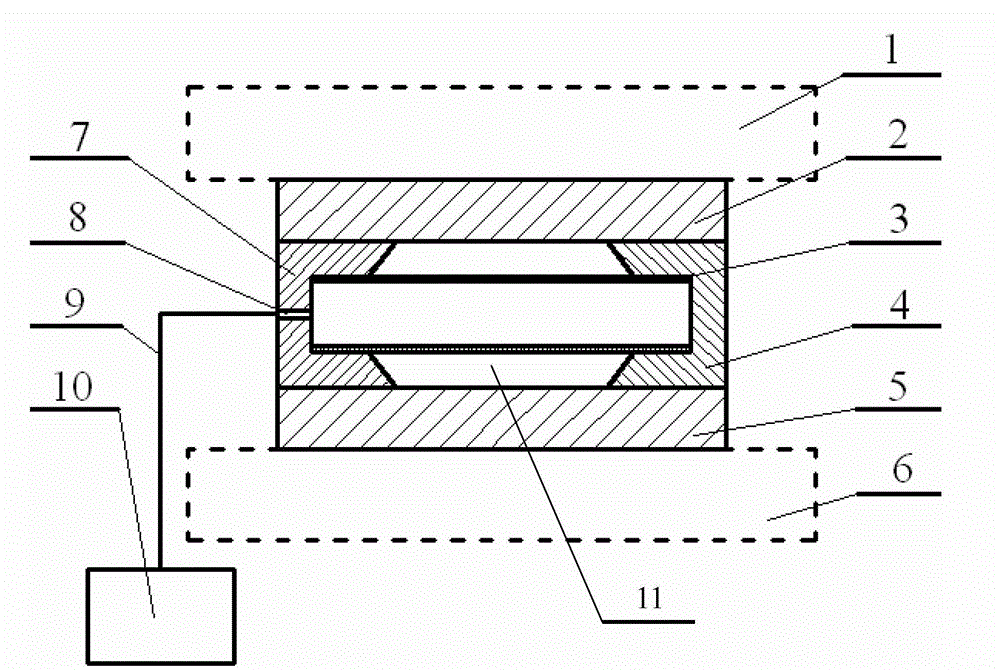

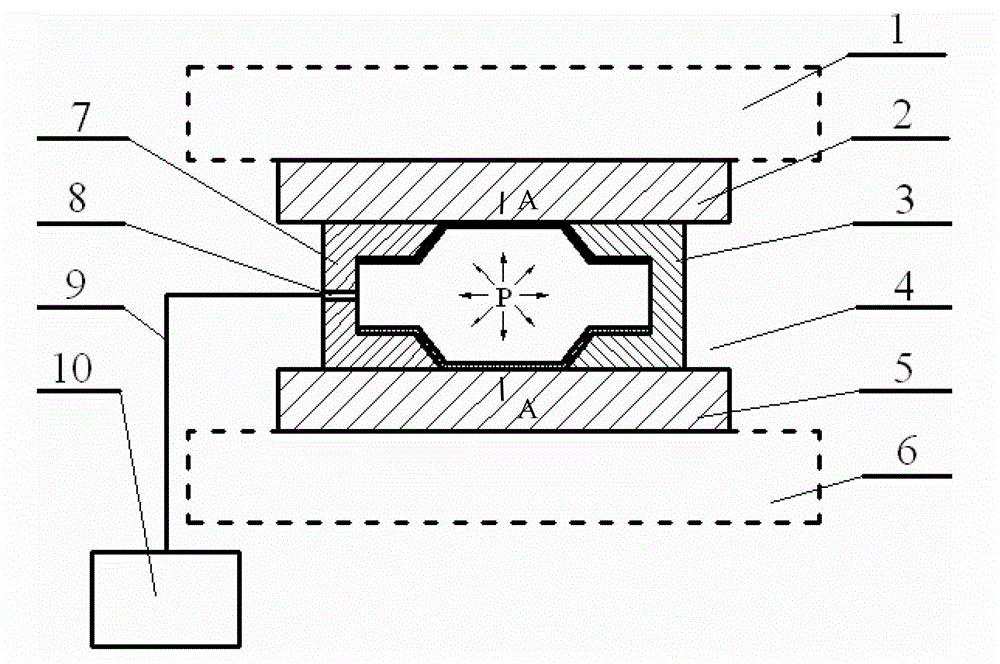

[0019] Specific implementation mode one: as Figure 1-4 As shown, the variable cross-section hollow member internal pressure forming device includes an upper die base 2, a left punch 7, a right punch 4, a lower die base 5, a liquid channel 9 and a supercharger 10, a left punch 7, a right punch The head 4 is located between the upper die base 2 and the lower die base 5, and the upper die base 2, the left punch 7, the right punch 4 and the lower die base 5 form a closed cavity 11, and the left punch 7 or There is a punch liquid injection hole 8 on the right punch 4, the supercharger 10 communicates with the punch liquid injection hole 8 through the liquid channel 9, and the punch liquid injection hole 8 is used to place the left punch 7 and the right punch. Liquid medium is injected into the tube blank 3 on the punch.

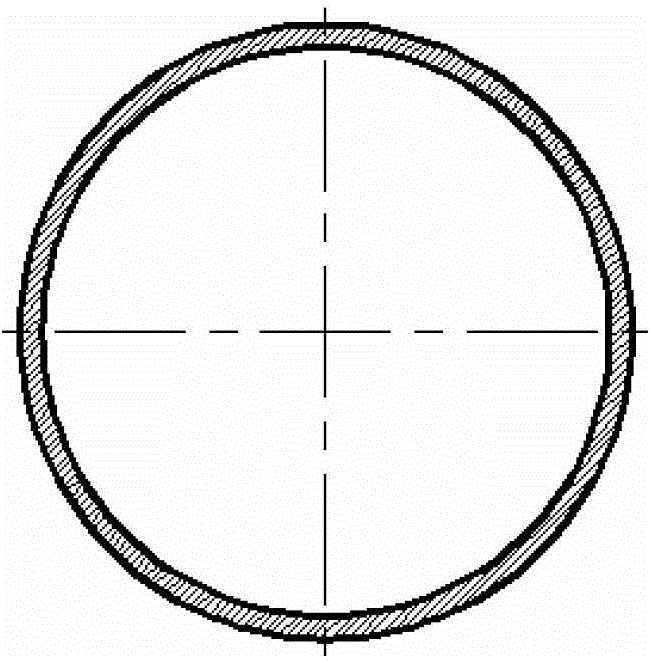

[0020] The cross section of the diameter reducing portion of the closed cavity 11 may be circular, rhombus, square or rectangular.

specific Embodiment approach 2

[0021] Specific implementation mode two: as Figure 1-4 As shown, this embodiment is a method for internal pressure forming of a hollow member with a variable cross-section using the above-mentioned forming device. The method is realized according to the following steps: Step 1. Fix the lower mold base 5 on the lower workbench 6 of the press; step 2. Move the right punch 4 to the right end of the lower mold base 5, and place one end of the tube blank 3 in the mold cavity of the right punch 4; step 3, move the left punch 7 to the lower mold base 5 and place the other end of the tube blank 3 in the mold cavity of the left punch 7; step 4, move down the upper worktable 1 of the press, so that the upper die base 2 is aligned with the left punch 7 and the right punch 4 Form a closed cavity 11 with the lower mold base 5; step five, pressurize the tube material 3 through the supercharger 10; step six, the left punch 7 and the right punch 4 simultaneously push the tube material 3 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com