Patents

Literature

67results about How to "Reduce oil supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

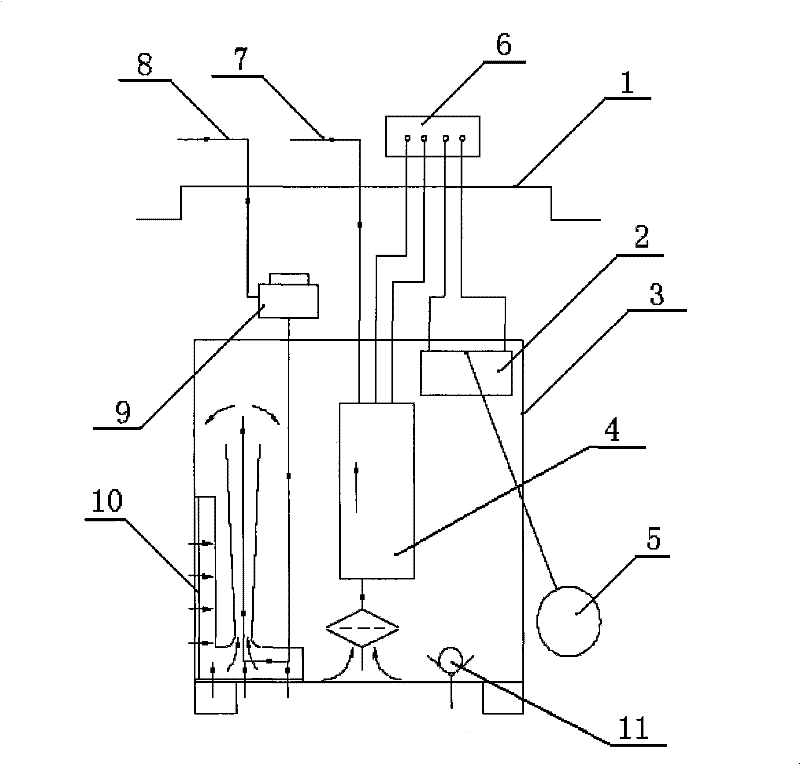

Energy regeneration system of excavator and excavator

InactiveCN103851040ALow calorific valueImprove stabilitySoil-shifting machines/dredgersFluid-pressure actuator componentsEnergy regenerationEngineering

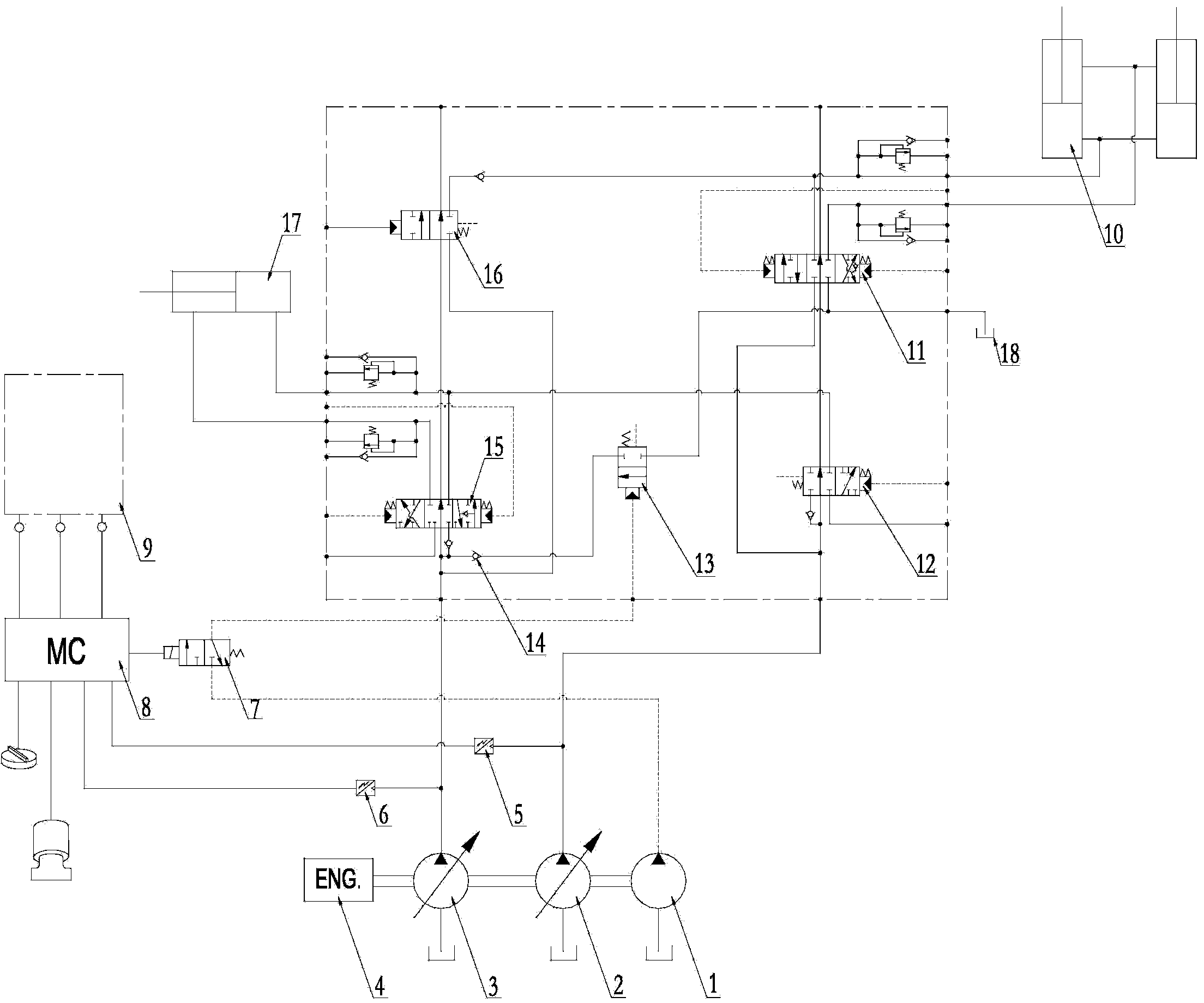

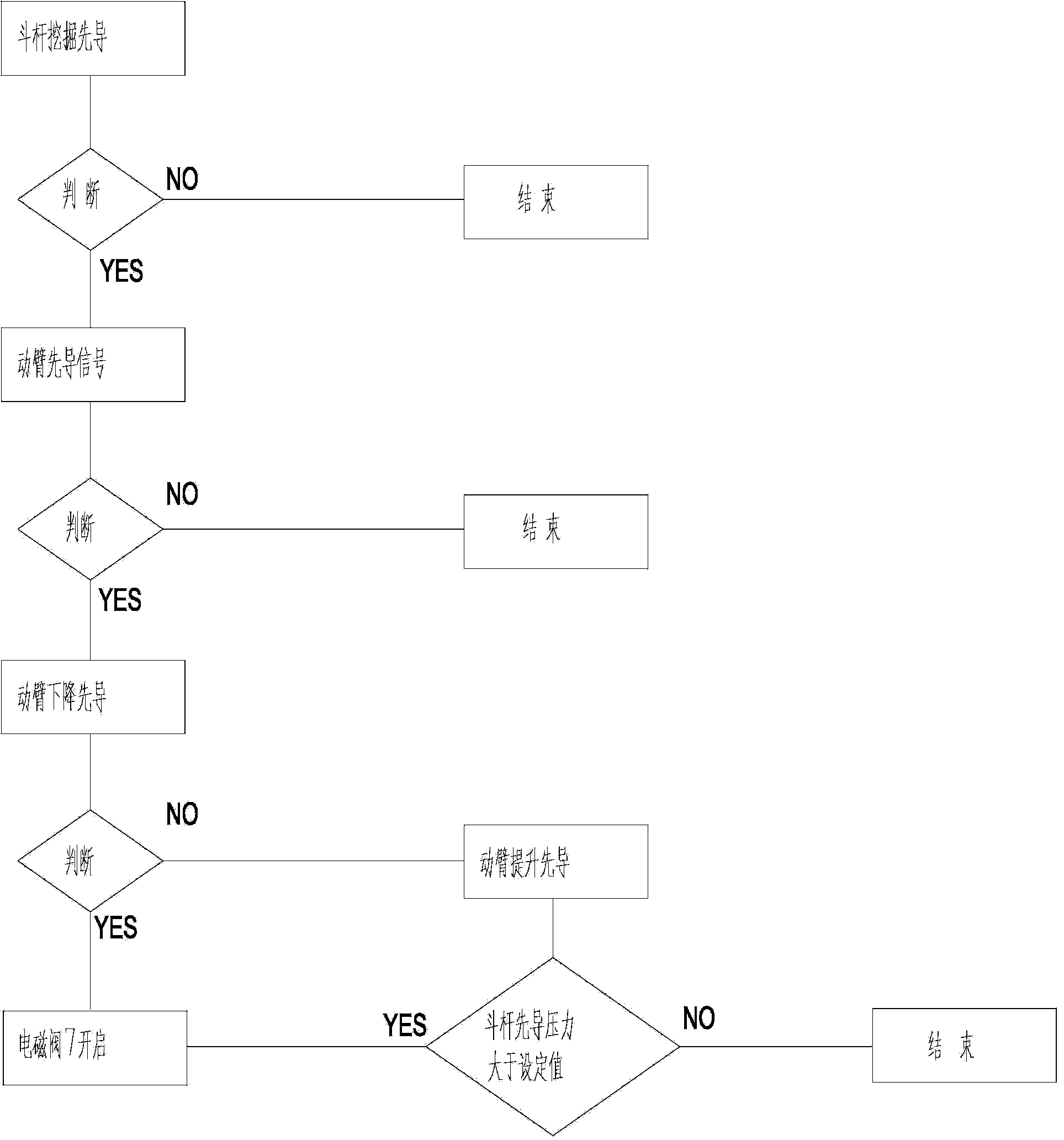

The invention discloses an energy regeneration system of an excavator and the excavator. The system comprises a main hydraulic oil line, a pilot hydraulic oil line, a pilot pump, a first pump, a second pump, an engine, a first sensor, a second sensor, an electromagnetic valve, a main controller, an operation handle, a movable arm oil cylinder, a first movable arm valve core, a first stick valve core, a switch valve, a one-way valve, a second stick valve core, a second movable arm valve core, a stick oil cylinder and a hydraulic oil tank, wherein the pilot pump, the first pump, the second pump and the engine are sequentially connected, the first pump is connected with the main controller through the first sensor, the second pump is connected with the main controller through the second sensor, the first stick valve core is respectively connected with the second pump, the second movable arm valve core and the one-way valve, the one-way valve, the switch valve and the first movable arm valve core are sequentially connected, and the movable arm oil cylinder is sequentially connected with the second movable arm valve core and the first movable arm valve core. The system has the advantages that the working efficiency of the excavator is improved, the fuel consumption is reduced, and the operation convenience of the integral excavator is improved.

Owner:SANY HEAVY MACHINERY

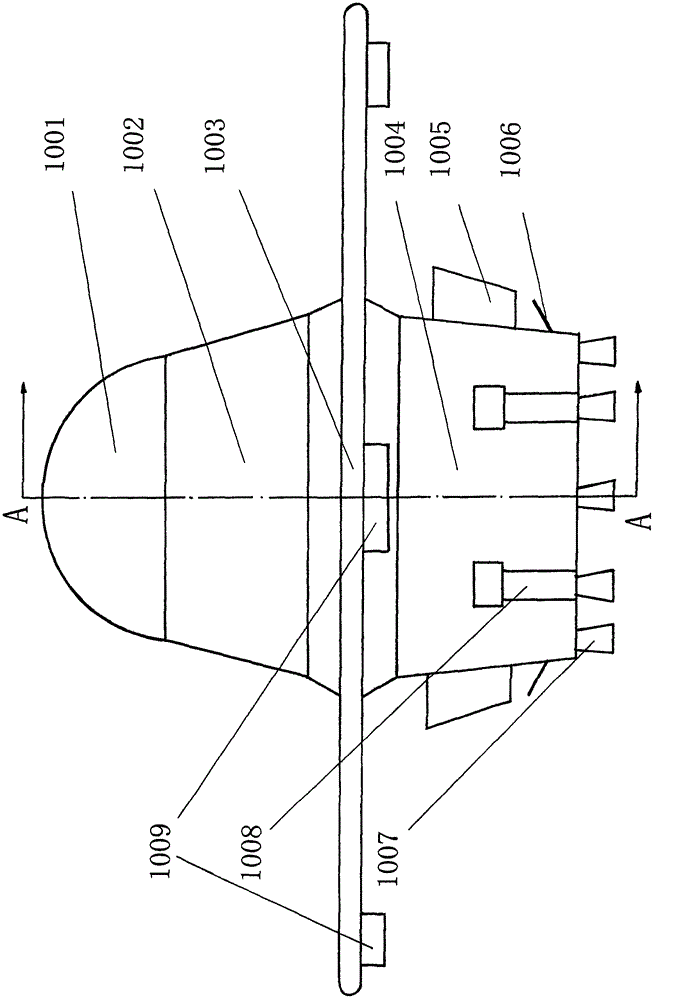

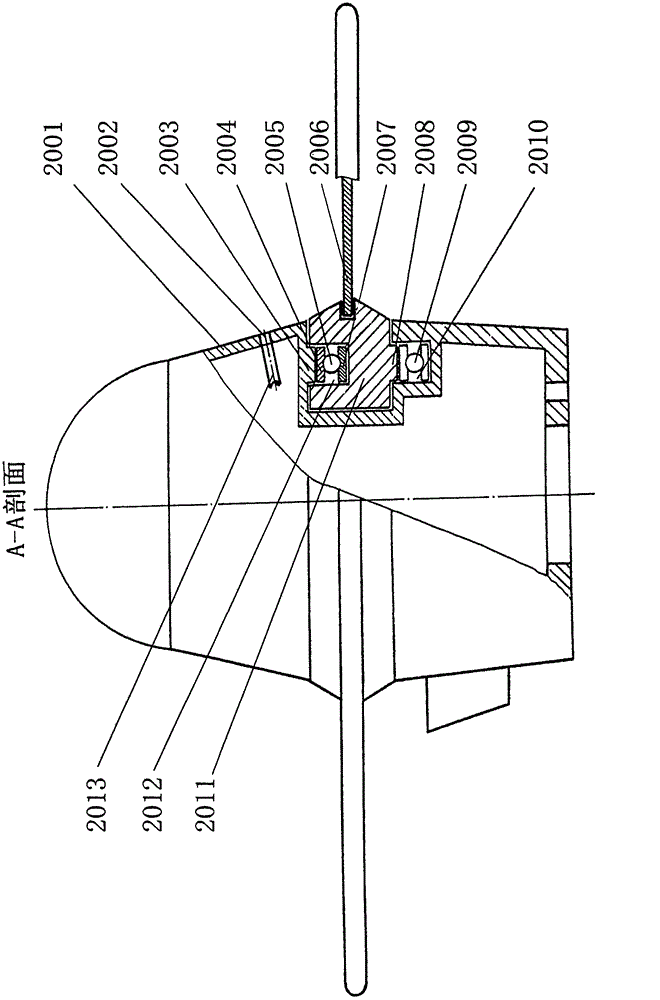

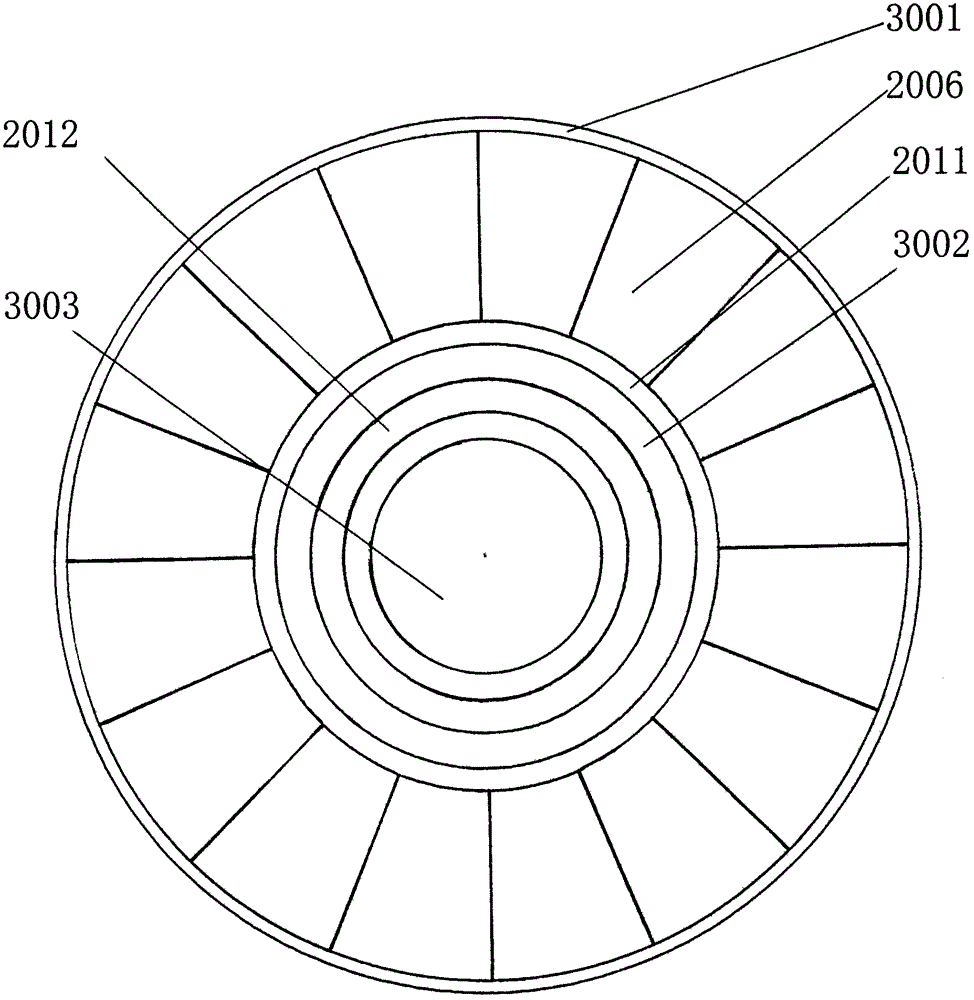

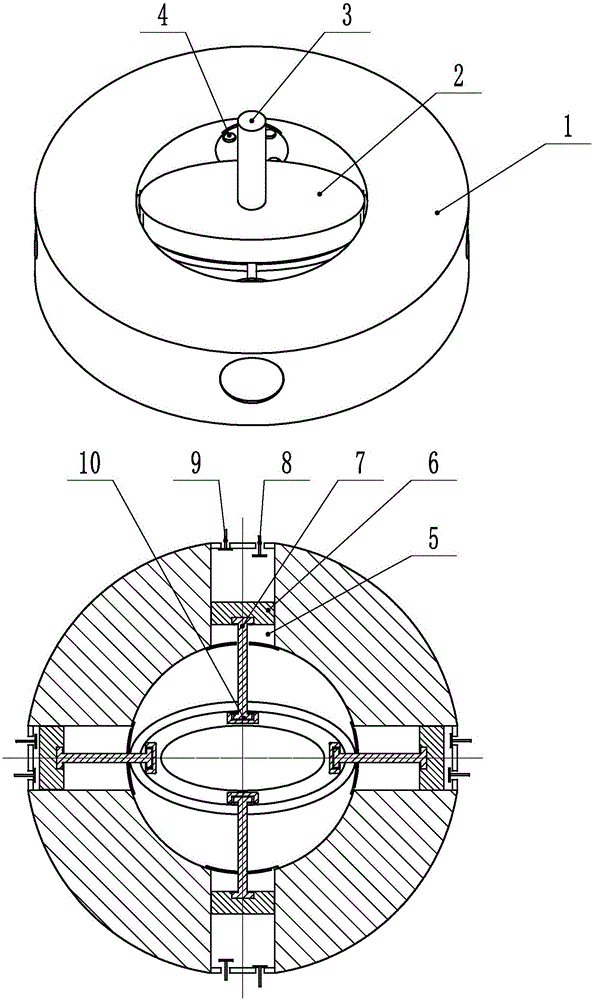

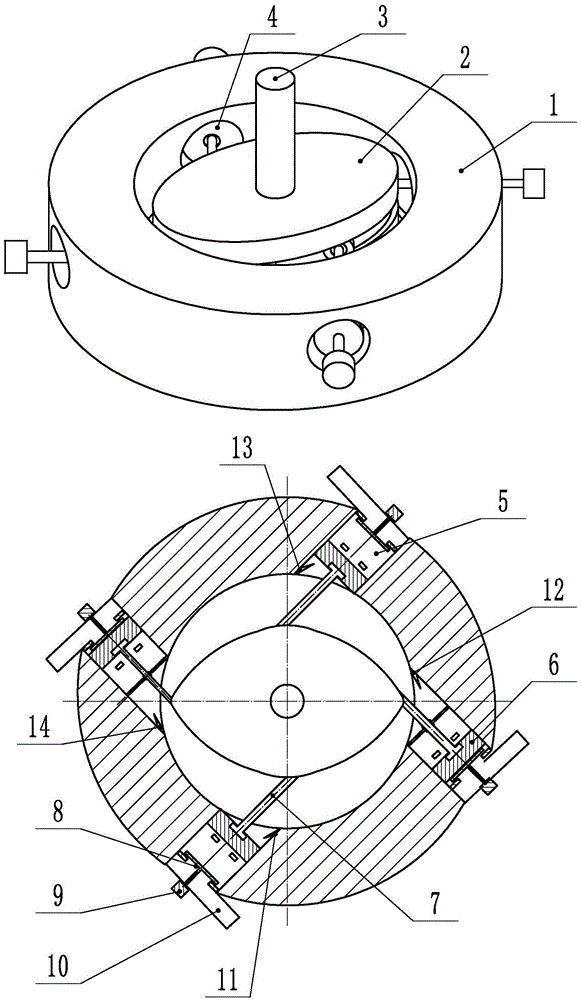

Large-size high-speed invisible flying saucer

InactiveCN105314111AIncrease the moment of inertiaReduce oil supplyAircraft navigation controlJet type power plantsCircular discNacelle

The invention discloses a flying saucer and two smoke- and fire-free engines. The flying saucer is composed of a cabin and a disk which rotates round the cabin. The disk includes a disk-shaped wing and a rotary engine. The cabin includes a driving cabin, a passenger cabin and a device cabin. The rotary engine sucks air which is mixed with water, and then the mixture is jetted out horizontally through jet tubes installed on the edge of the disk according to the sprayer principle, so that a generated reactive force enables the disk to rotate at a high speed, thereby generating an upward raising force on the disk. Four fixing wings are installed outside the device cabin to eliminate reverse rotation of the cabin. A vector engine and a diesel power generating set are installed in the device cabin under the disk. The vector engine sucks large amount of air through an air inlet duct in the passenger cabin to form vacuum above the passenger cabin, which enables air pressure difference between an upper surface and a lower surface of the disk to be increased, thereby generating a huge raising force. The sucked air is compressed to form high-pressure gas which is discharged into vector jet tubes and is jetted out, wherein the directions and the angles of the vector jet tubes are adjustable to generate pushing forces in different directions, thereby achieving maneuvering flight of the flying saucer.

Owner:周彦辉

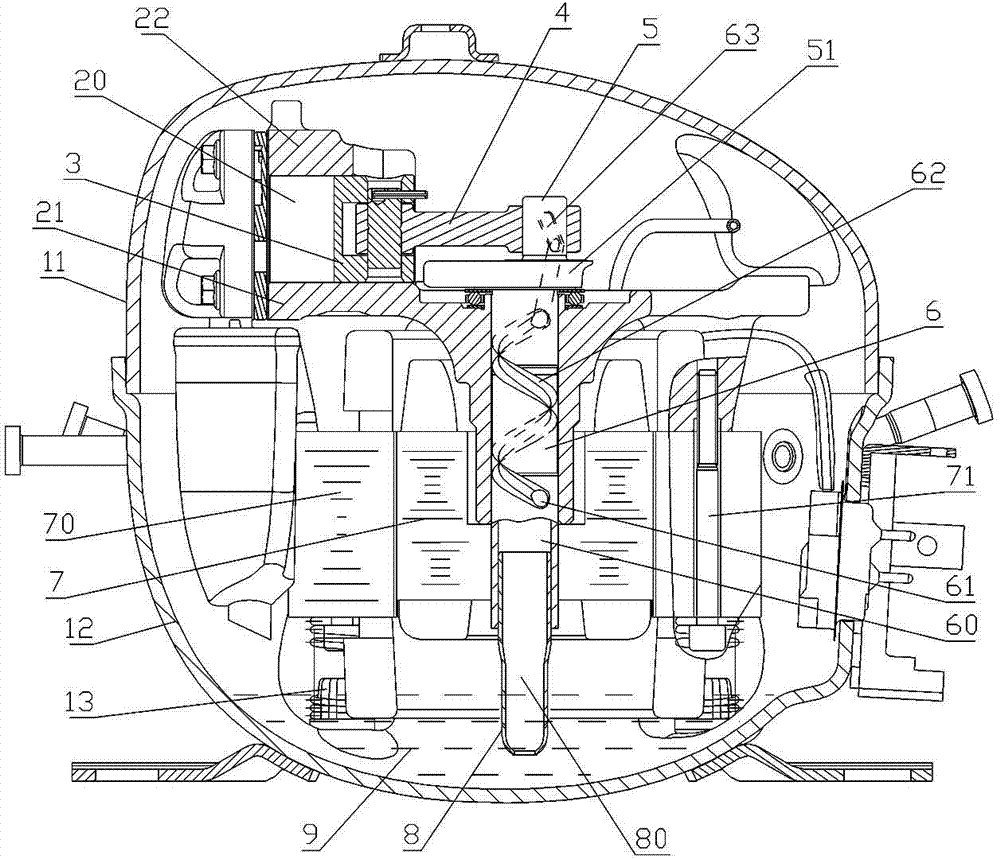

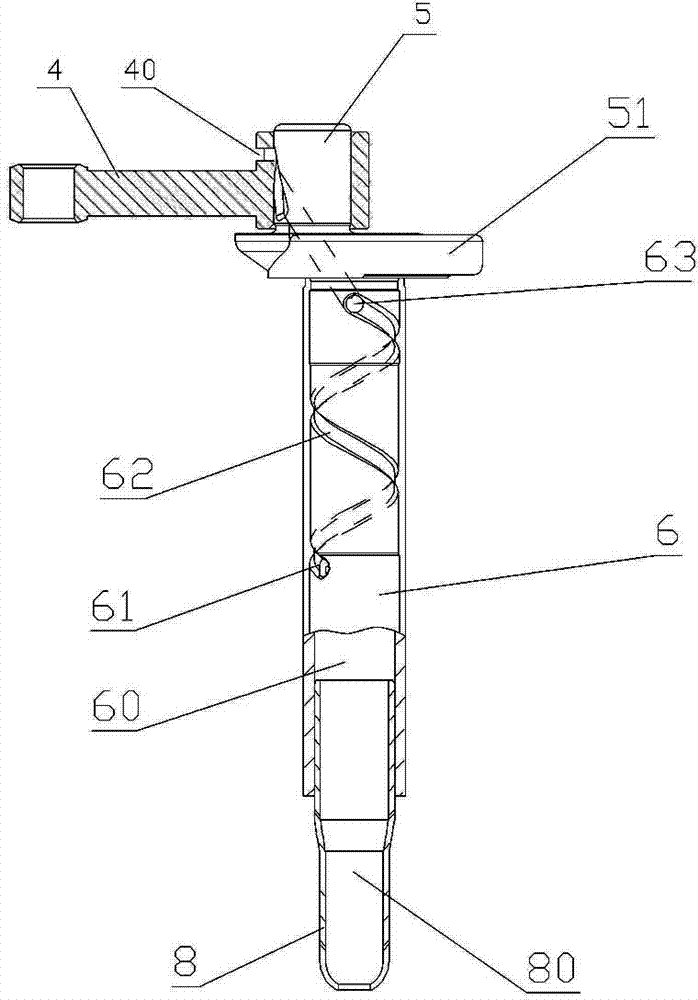

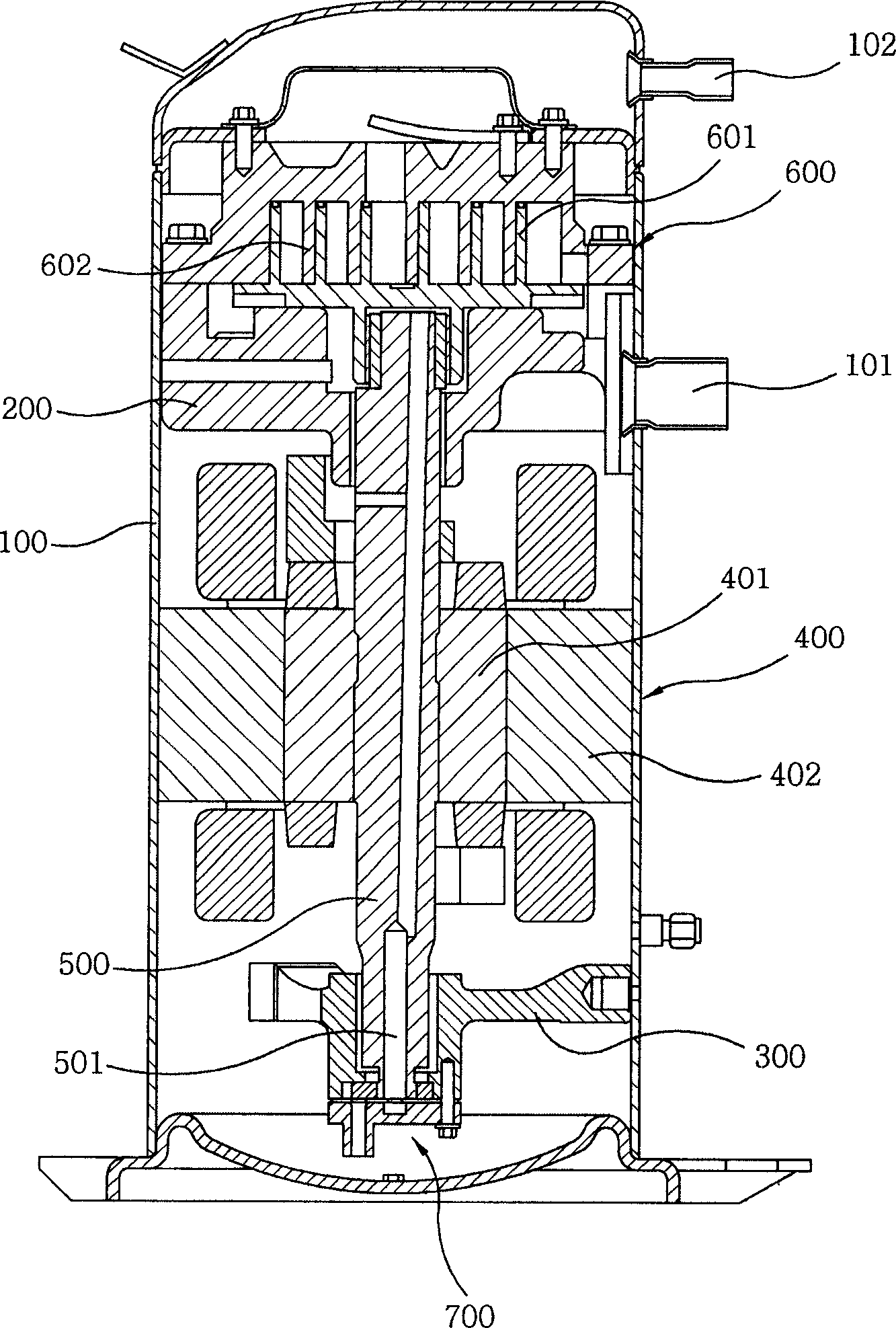

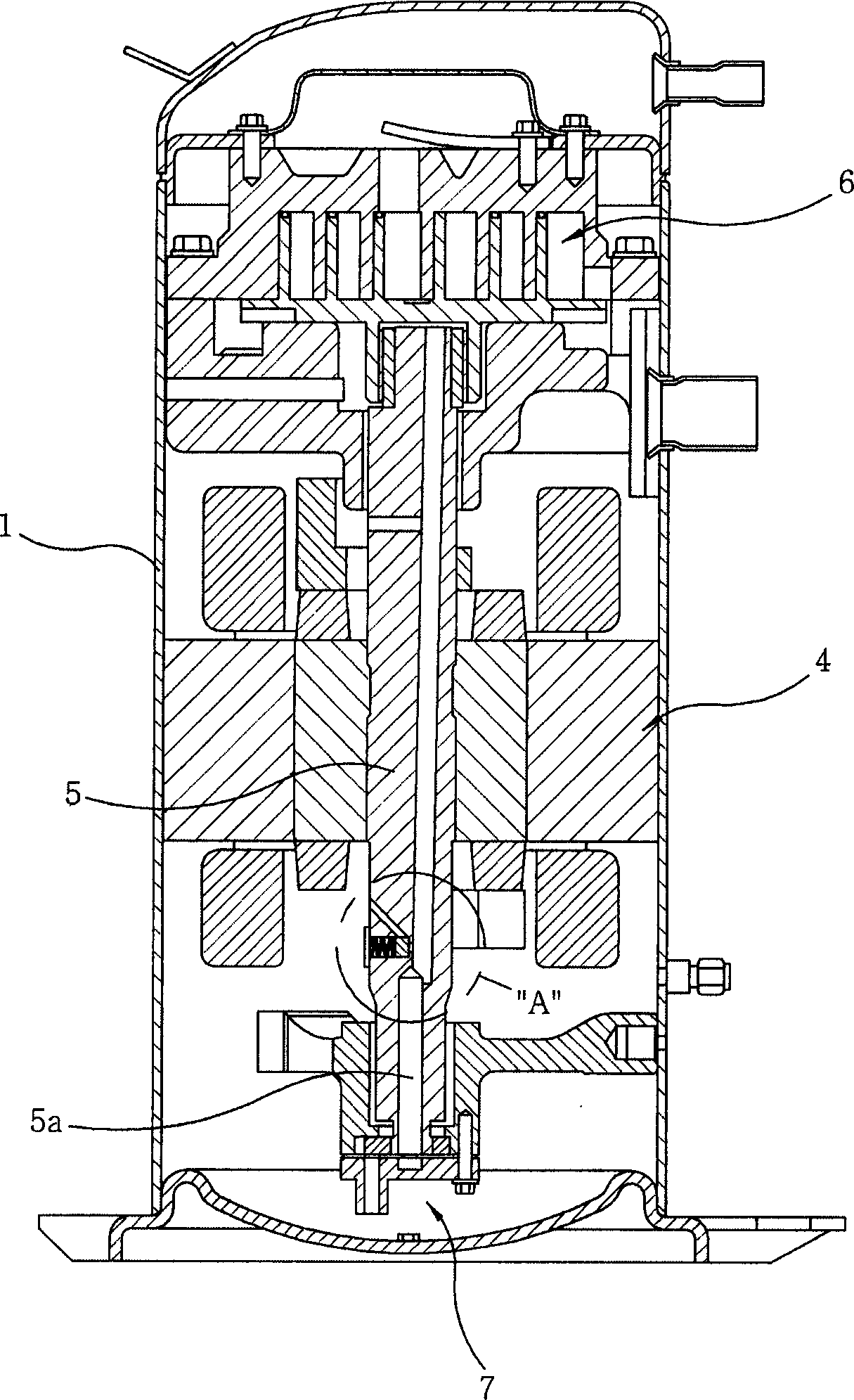

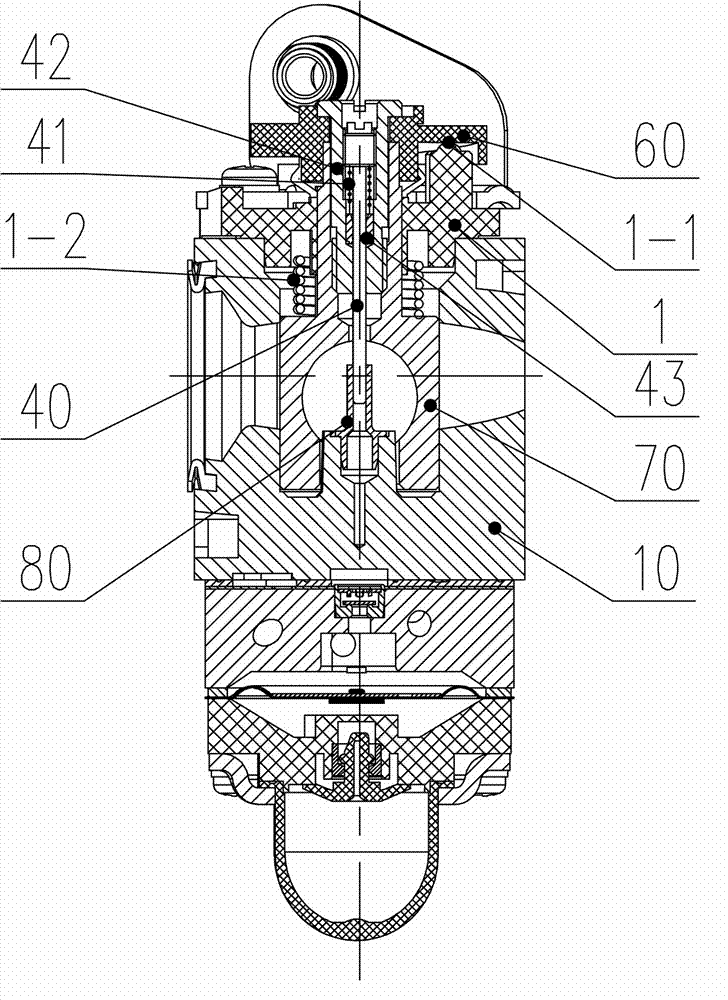

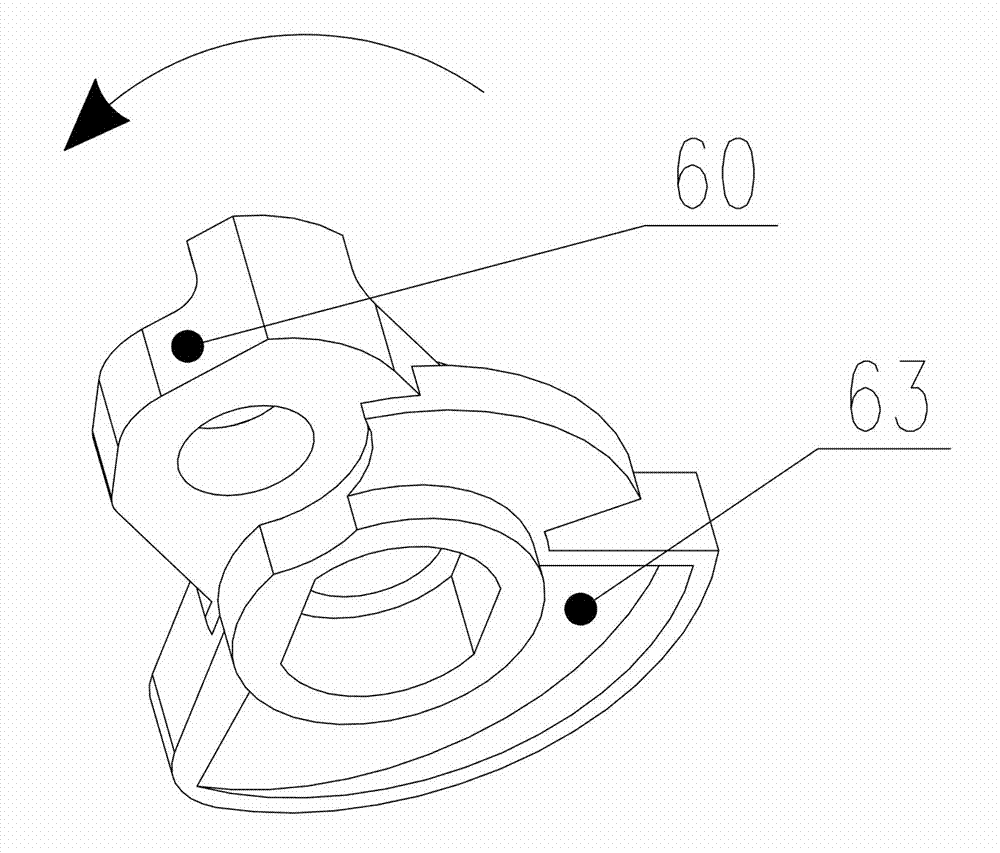

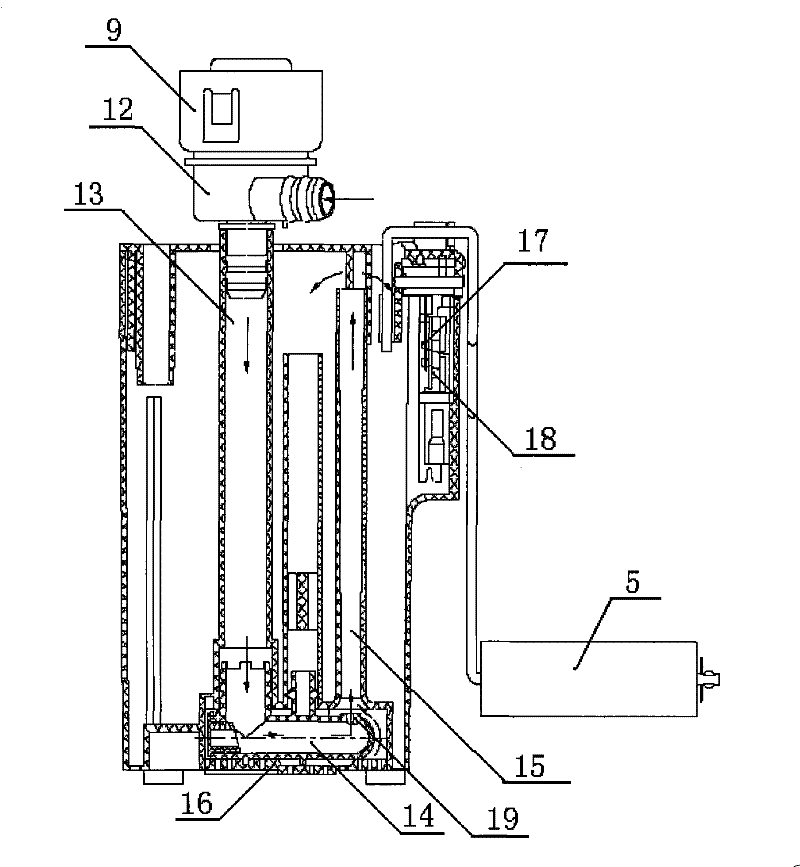

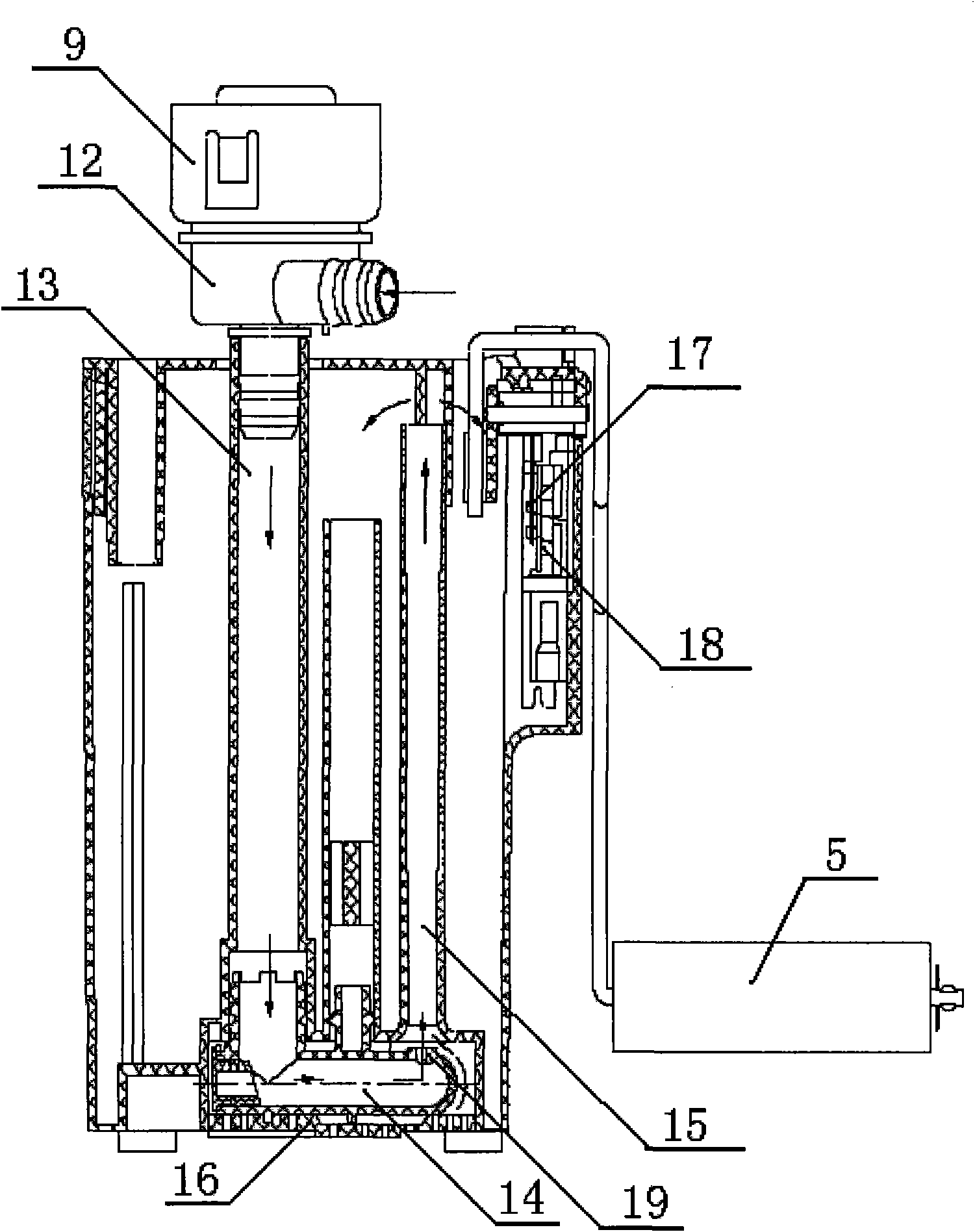

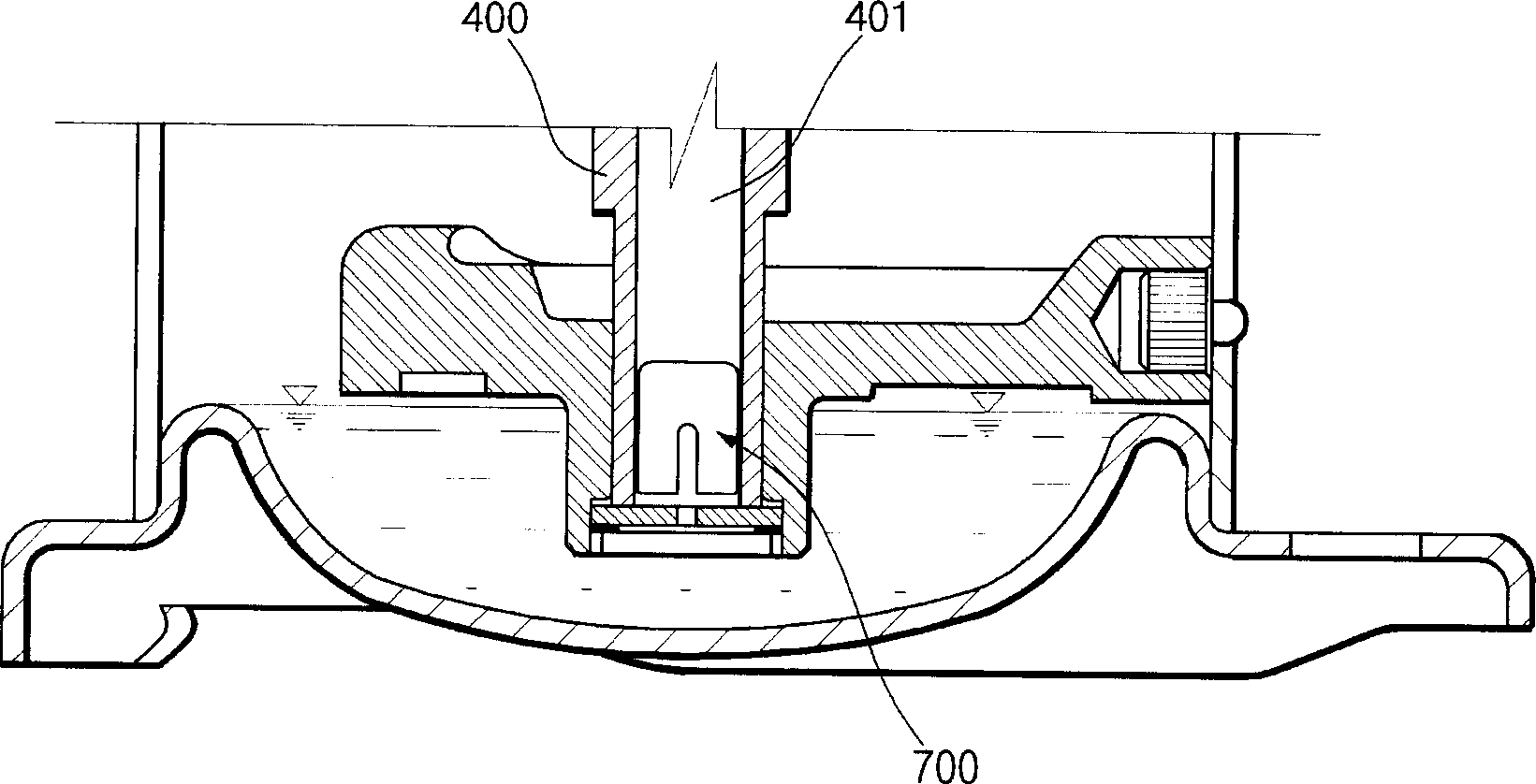

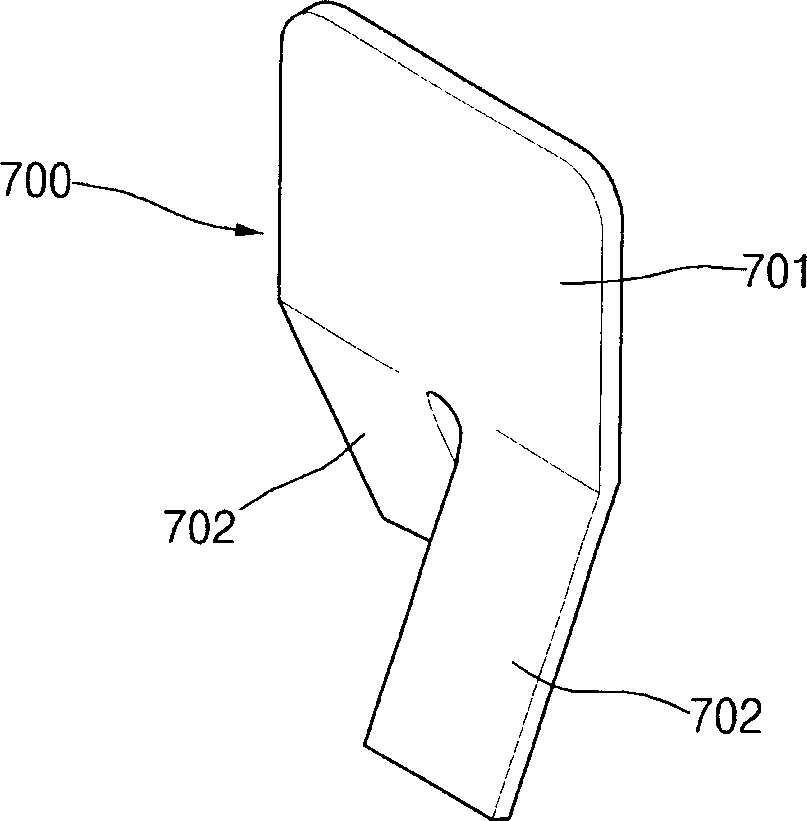

Refrigerator compressor and lubricating-oil supplying device

InactiveCN102953961AReduce oil supplyImprove the lubrication effectPositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionCentrifugal force

The invention relates to a refrigerator compressor and provides a lubricating-oil supplying device of the refrigerator compressor. The lubricating-oil supplying device comprises a connecting rod, a crank shaft and an oil suctioning pipe, wherein the crank shaft is provided with an oil supplying channel, an upper port of the oil supplying channel is positioned on the outer wall of the crank shaft part and a lower port of the oil supplying channel is positioned at the lower-tail end of a main shaft part; the two ends of the connecting rod are provided with a large ring-shaped column, a connecting rod and a small ring-shaped column; the large ring-shaped column of the connecting rod is provided with an exceeding part higher than the connecting rod; the exceeding part is provided with a horizontal oil supplying hole in the direction of the connecting rod; and the horizontal oil supplying hole corresponds the position of an upper oil hole of the crank shaft part. When the refrigerator compressor is in working, the lubricating oil reaches to the upper port through the oil supplying channel from an oil pool under the action of the centrifugal force; and when the large ring-shaped column of the connecting rod rotates to the horizontal oil supplying hole to be butted with the upper oil hole of the crank shaft, the lubricating oil penetrates through the horizontal oil supplying hole on the large ring-shaped column from the crank shaft and then is sprayed quickly and directionally towards the direction of the connecting rod so as to play a role of lubrication for the reciprocating movement of a piston. The invention has the following substantial characteristics and obvious progress that 1, the oil supplying amount of the lubricating oil supplying device is less, and good lubricating action can be achieved for relative movement of the piston, the connecting rod and the crank shaft; and 2, since the oil supplying amount of the lubricating oil supplying device is less, the rotating load of the crank shaft and a motor rotor is reduced, the energy consumption of the motor is reduced and the working efficiency of the compressor is increased.

Owner:WANBAO GROUP COMPRESSOR CO LTD

Novel aircraft carrier flying-off deck

InactiveCN102862684AIncrease takeoff weightImprove combat effectivenessLaunching/towing gearFuel tankEngineering

The invention discloses a novel aircraft carrier flying-off deck, which comprises an ascending flying-off desk section, wherein a carrier plane flying-off acceleration equipment cabin is arranged below a starting section, a brake is arranged outside two tank wheels which are installed on a support through a wheel shaft inside the cabin, the two tank wheels are connected, a rubber plate is hung on the inner surface of a reinforced crawler belt, and the crawler belt is provided with a special crawler belt plate with a towing hook. Two tank engines with an independent oil box and an independent water box respectively are arranged on an engine support at the side of each tank wheel, the tank engines are connected with the tank wheels through a clutch and a transmission case, and a crawler belt tension wheel installation support is provided with a crawler belt tension wheel with a crawler belt traction motor. The starting section of the ascending flying-off deck is provided with a deck narrow seam, and a telescopic automatic switch, a brake releasing switch and a brake anchoring rod are respectively arranged on the middle-rear section and nearby the end of the deck narrow seam and on flying-off station deck on the rear part. The novel aircraft carrier flying-off deck integrates the advantages of a flat ejection flying-off deck and an ascending flying-off deck, and is also free from the defects of the two flying-off decks.

Owner:王长存

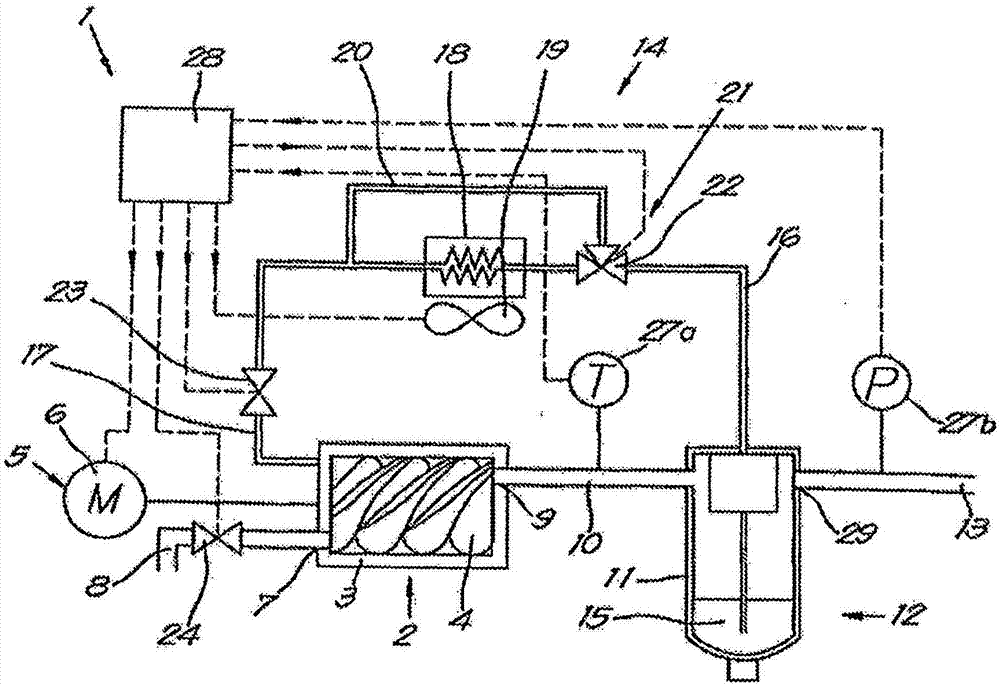

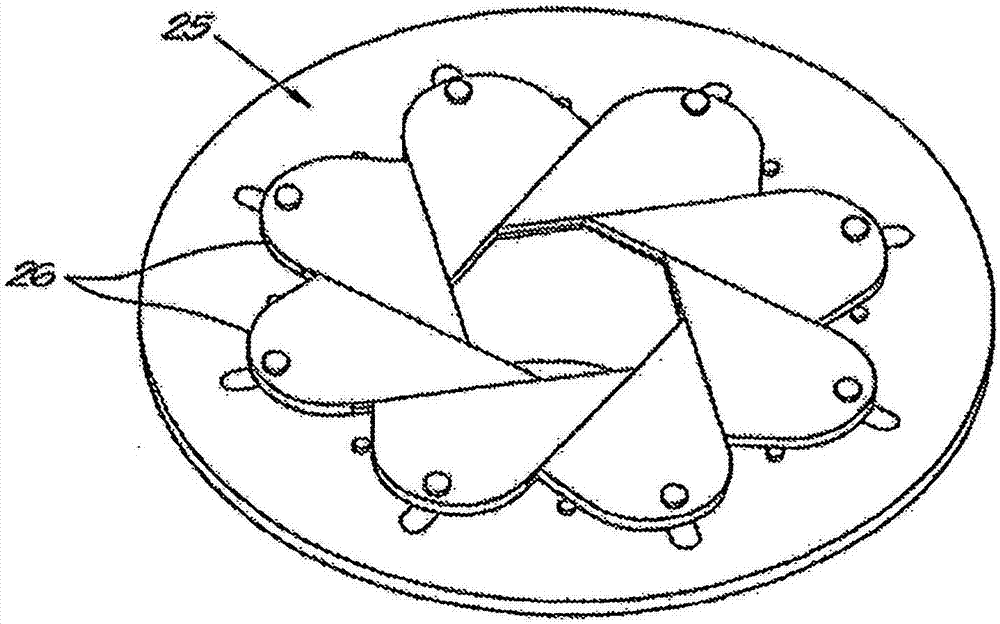

Method for controlling an oil-injected compressor device

ActiveCN107002683ALow powerReduce the temperatureRotary piston pumpsRotary piston liquid enginesEngineering

Method for controlling a compressor device (1) with a compressor element (2) and oil circuit (14) with oil (15) that is injected into the compressor element (2) by a fan (19) via a cooler (18), with a bypass pipe (20) across the cooler (18), whereby when the temperature (T) of the compressor element (2) is less than a value (Tset) the method consists of taking the following steps: the fan (19) is switched off; when the temperature (T) is still less than Tset, the oil (15) is driven via the bypass pipe (20); when the temperature (T) is still less than Tset, the quantity of oil (15) that is injected into the compressor element (2) is decreased until the temperature (T) is equal to Tset.

Owner:ATLAS COPCO AIRPOWER NV

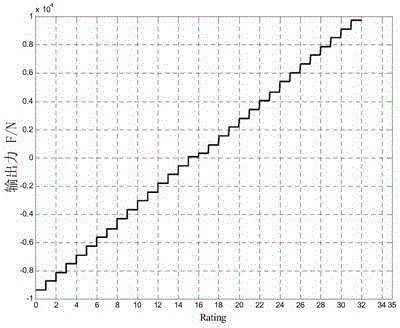

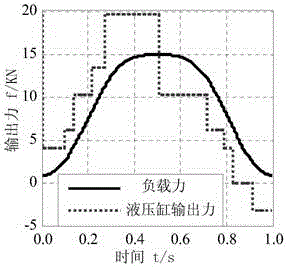

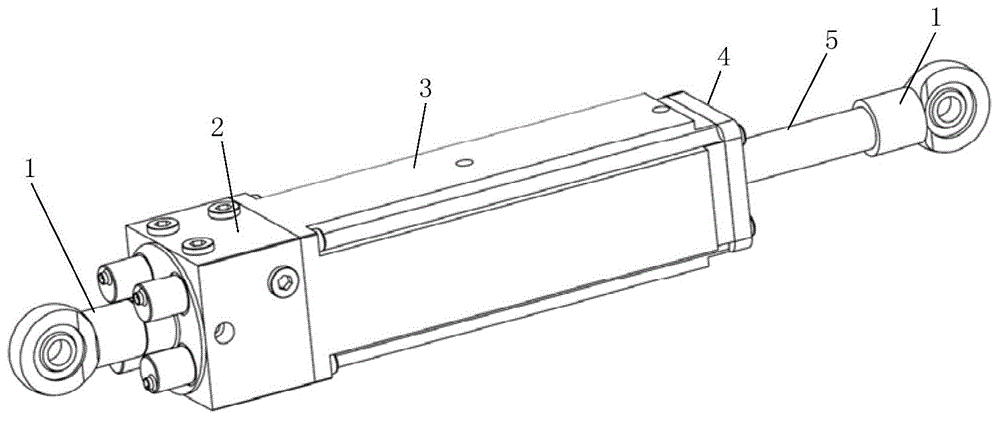

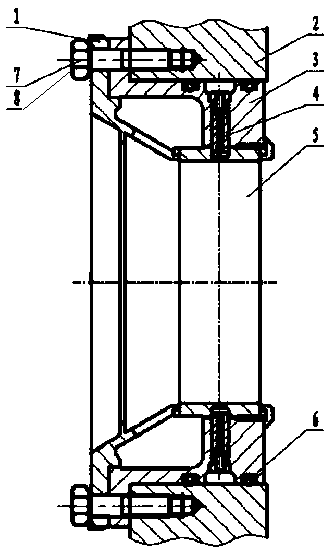

Hydraulic cylinder with variable sections, hydraulic control system and control method of hydraulic cylinder

ActiveCN103557199AImprove hydraulic system efficiencyGood economic benefitsFluid-pressure actuatorsHigh pressureVariable load

The invention discloses a hydraulic cylinder with variable sections. The hydraulic cylinder comprises a piston rod, a cylinder barrel, a left end cover and a right end cover, wherein the left end cover and the right end cover are used for sealing the cylinder barrel; the piston rod comprises a main piston rod and plunger rods; the main piston rod is hermetically mounted on the cylinder barrel through the left end cover and the right end cover; a main piston is arranged at the end part of the main piston rod; a plurality of plunger rods are mounted on the main piston; secondary pistons are arranged at the end parts of the plunger rods; the main piston is mounted in the main piston cavity which is in the cylinder barrel and corresponds to the main piston; the secondary pistons are mounted in the plunger cavities which are in the cylinder barrel and correspond to the secondary pistons. The hydraulic cylinder has a certain capacity of load matching, and is a linear hydraulic cylinder capable of improving the efficiency of a hydraulic system with variable loads. When the hydraulic cylinder is under a loading condition with variable loads, a user can select different small cavities to be communicated with a high-pressure oil circuit or a low-pressure oil circuit to realize load matching so as to finally achieve the purpose of improving the efficiency of the hydraulic system.

Owner:NAT UNIV OF DEFENSE TECH

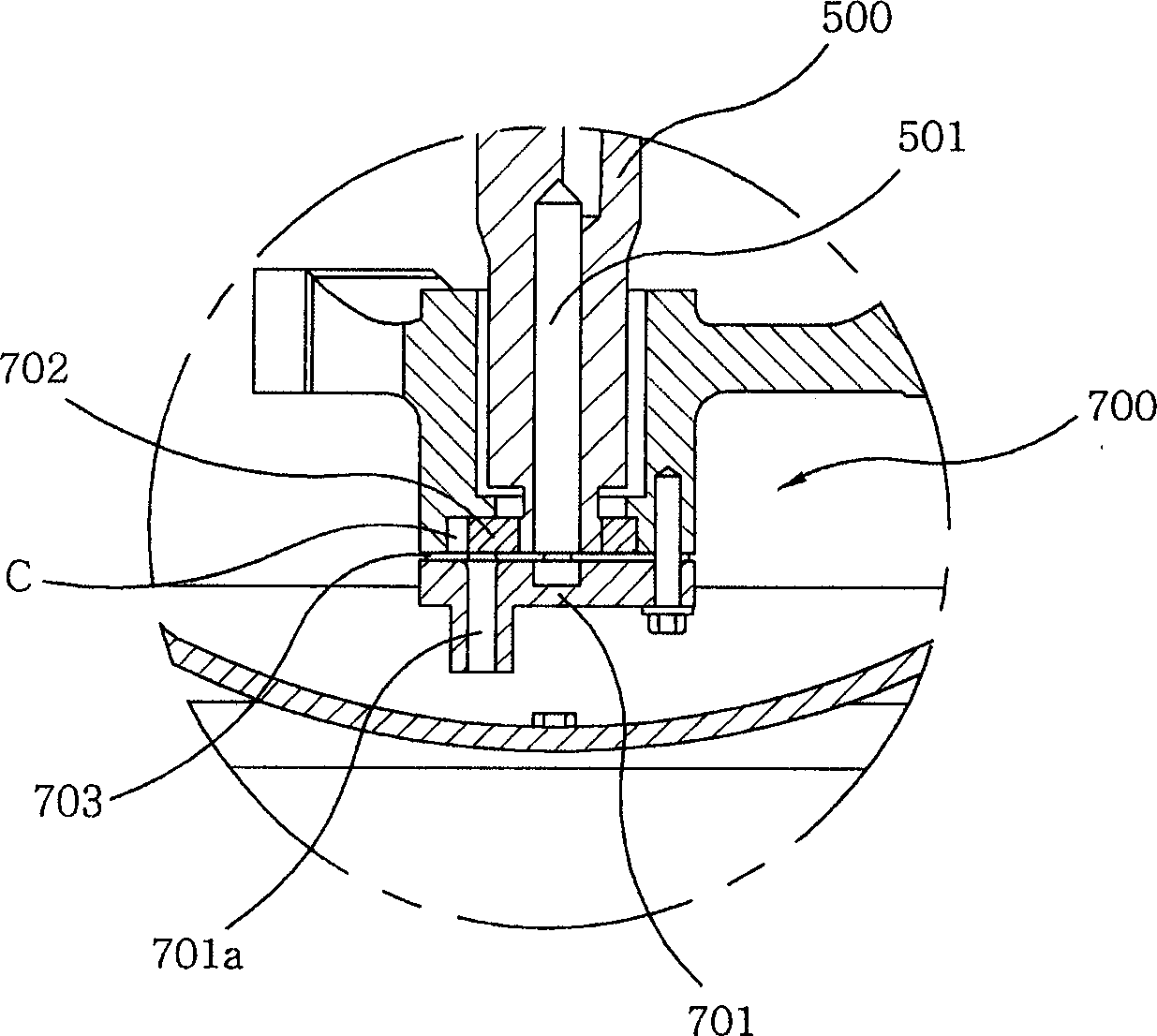

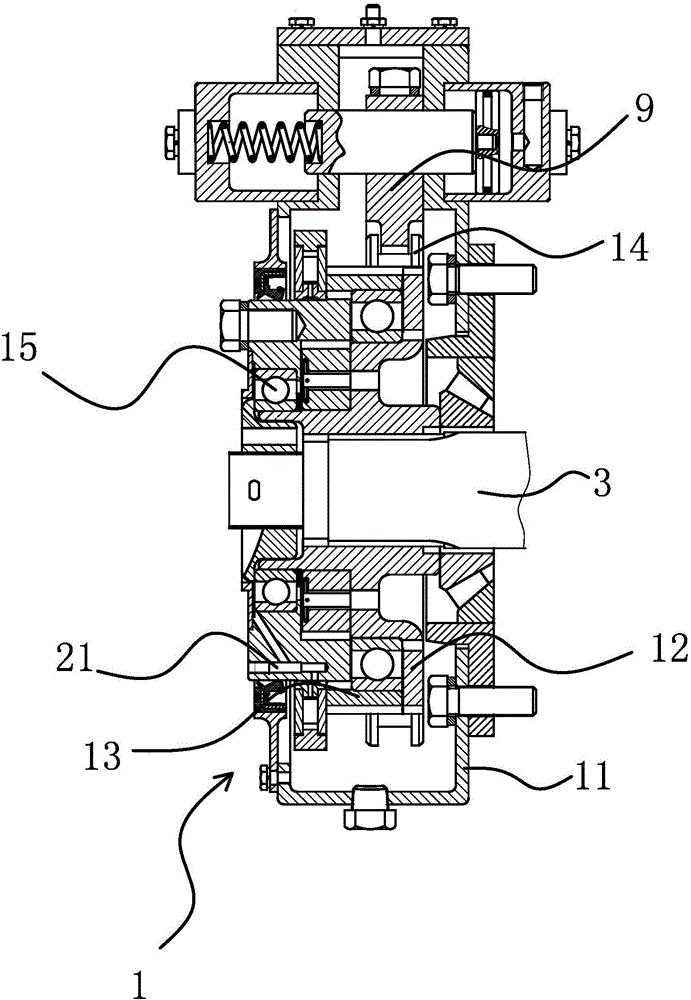

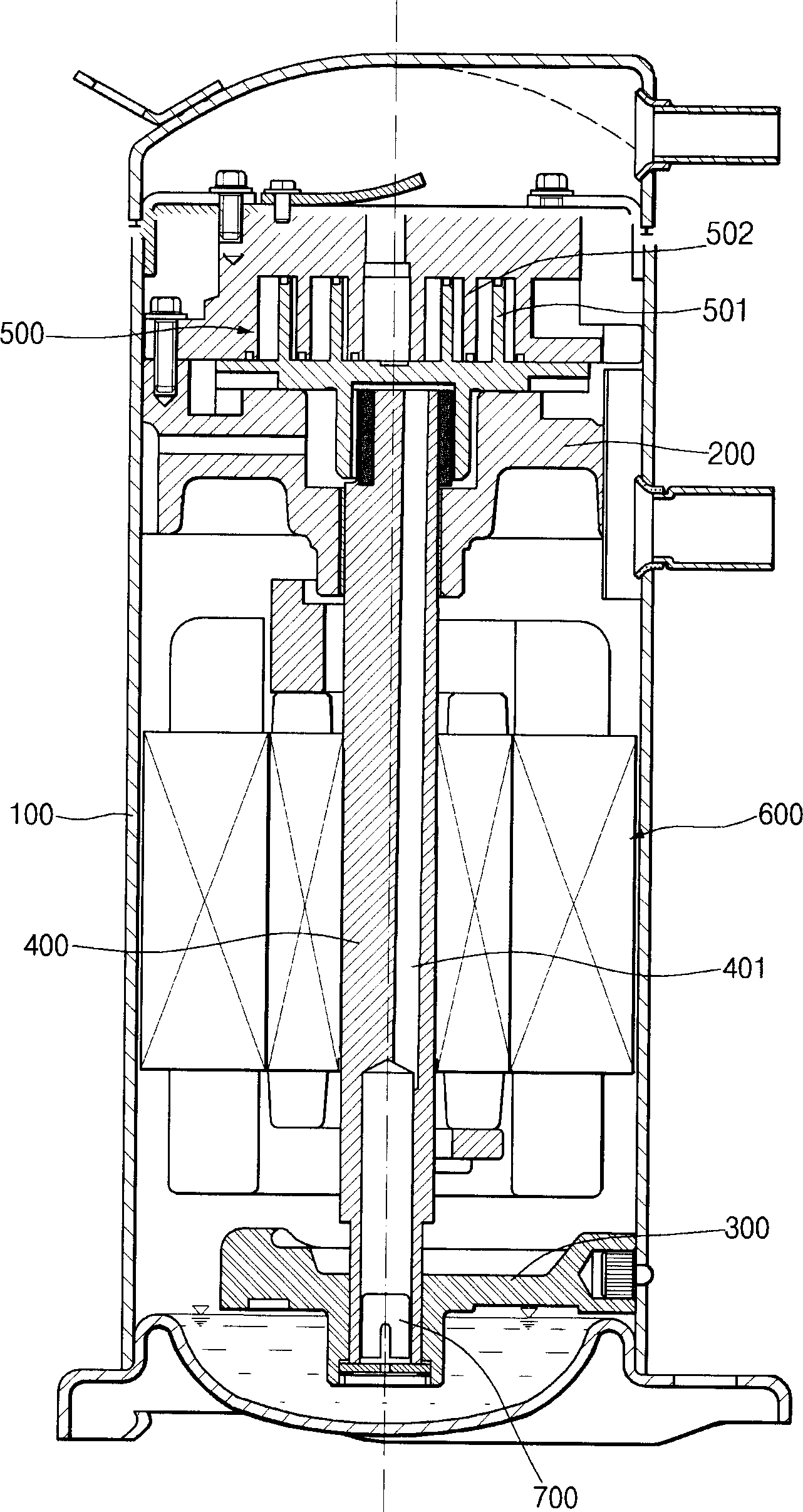

Apparatus for controlling quantity of feeding oil of inverter compressor

InactiveCN1840910ASmooth dischargePrevent supplyWalking sticksMountaineeringLow speedInverter compressor

An oil feed controller of an inverter compressor controls the quantity of feeding oil to prevent excess oil from being fed to a compression part when rotational speed of a rotation shaft is increased. The oil feed controller includes an installation hole formed in the rotation shaft to communicate with an oil passage of the rotation shaft, a bypass formed in the rotation shaft to communicate with the leading end of the installation hole, and an oil feeding controlling part installed in the installation hole to close the bypass when the rotation shaft rotates at low speed and to open the bypass when the rotation shaft rotates at high speed such that the quantity of oil ascending to the compression part through the oil passage is controlled.

Owner:LG ELECTRONICS INC

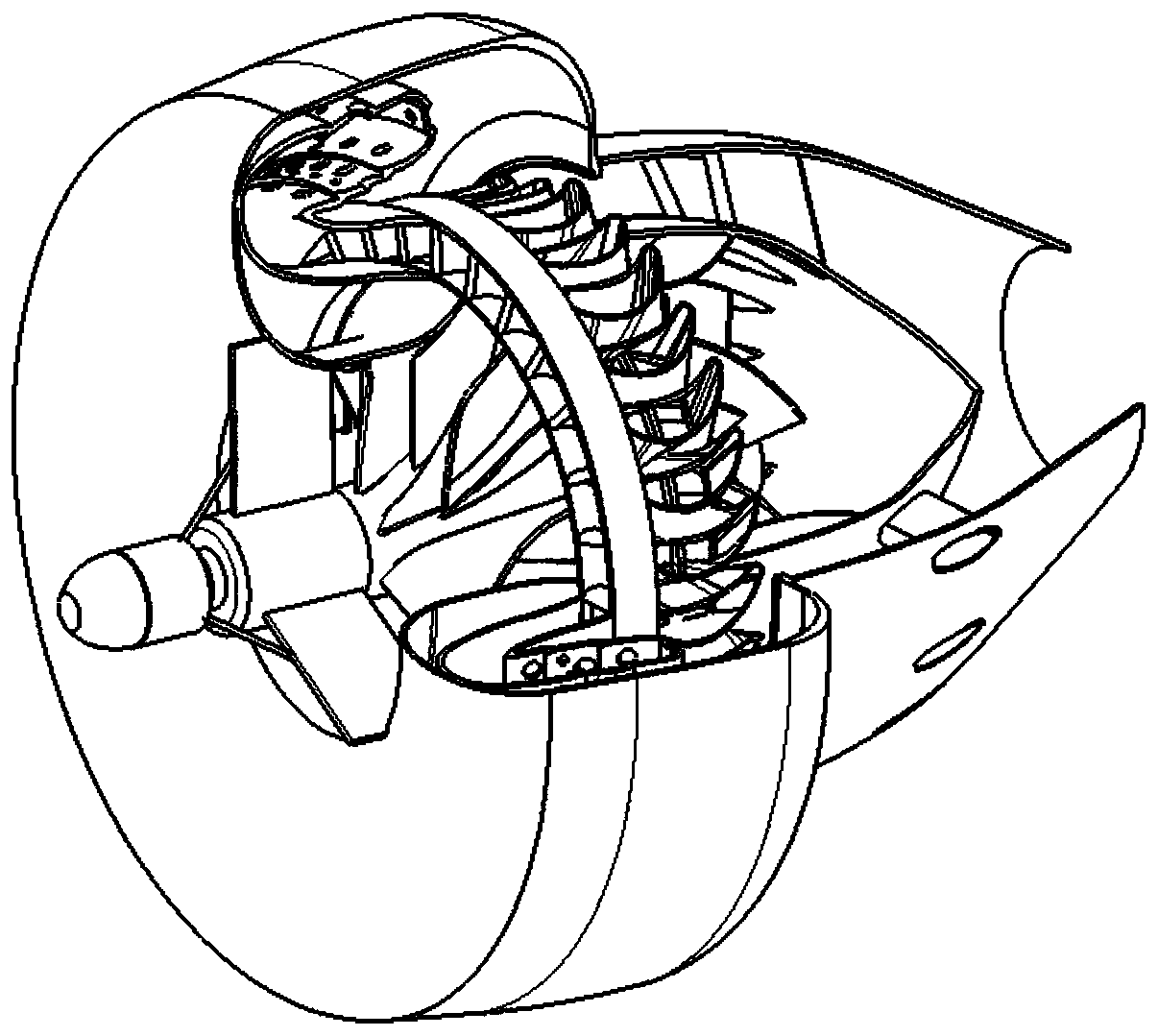

Micro-turbojet engine for novel double-face compound impeller

InactiveCN110273782AIncrease temperatureReduce axial sizePump componentsTurbine/propulsion engine ignitionTurbineTurbojet engine

The invention discloses a micro-turbojet engine for a novel double-face compound impeller. The micro-turbojet engine comprises a starting part, a rotary part, a casing part and a rectification part. The starting part is arranged in front of the casing part. The rotary part is arranged behind the starting part. The rectification part is arranged behind the casing part. The rotary part comprises the novel double-face compound impeller, a spindle and a bearing. The spindle and the novel double-face compound impeller are connected seamlessly fixedly. The novel double-face compound impeller comprises a double-face centrifugal gas compressor. A hollow axial flow turbine is arranged in the outer extending position of a rim of the double-face centrifugal gas compressor. The double-face centrifugal gas compressor comprises two single centrifugal gas compressors which are fixedly connected back to back. The micro-turbojet engine has the advantages that heat efficiency is improved, and the oil consumption rate is lowered; the axial dimension of the micro-turbojet engine is reduced, the vibration degree is lowered, and stability is improved; and turbine front temperature can be increased with hollow turbine cooling design.

Owner:NANCHANG HANGKONG UNIVERSITY

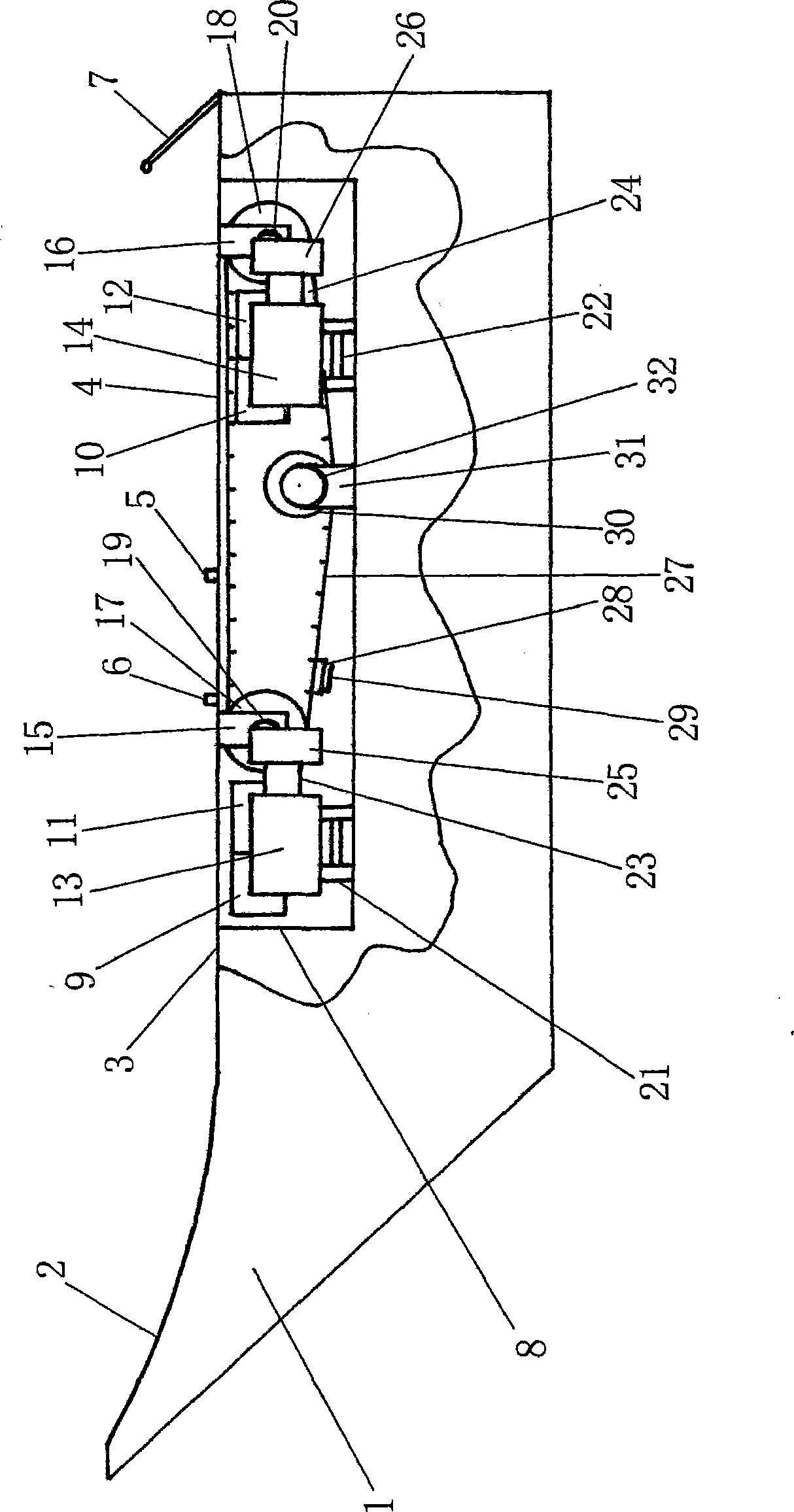

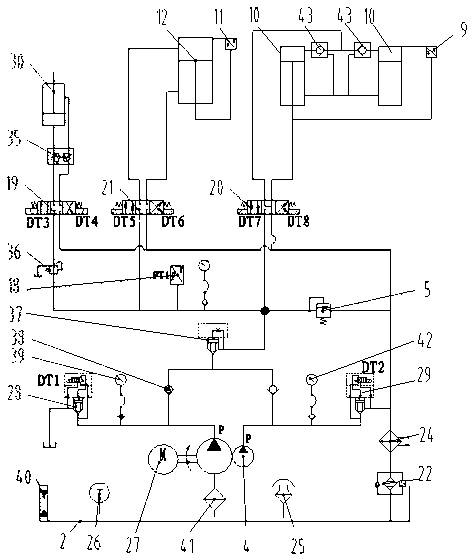

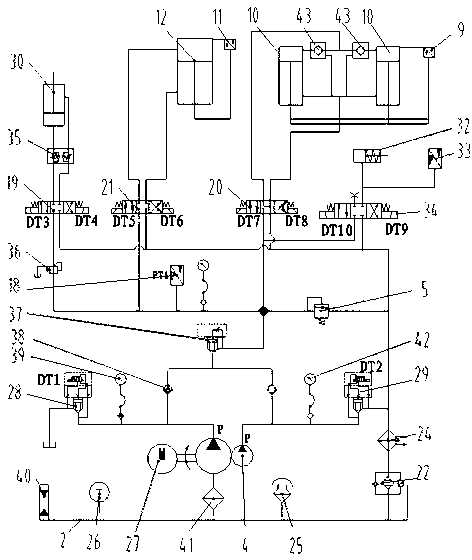

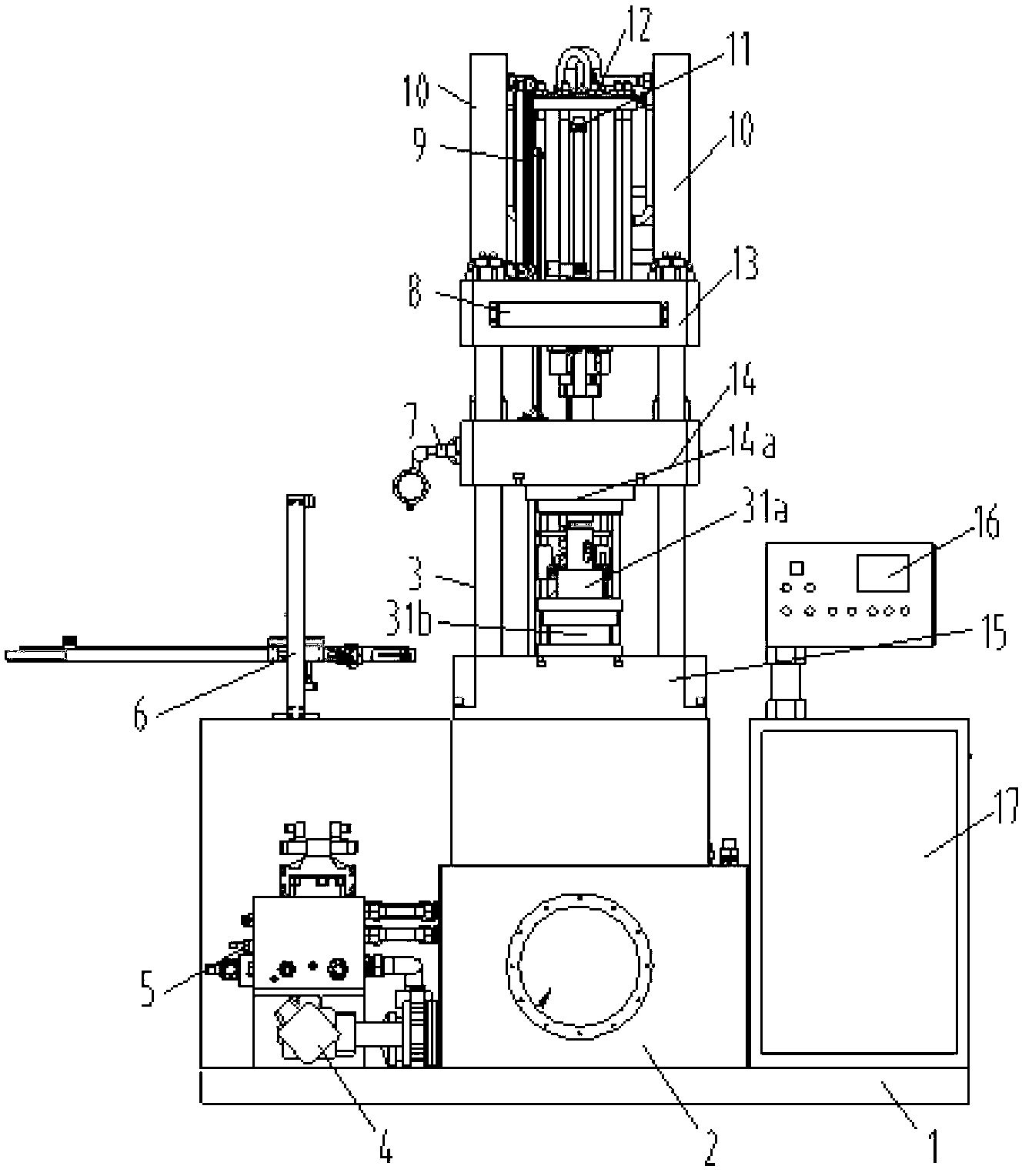

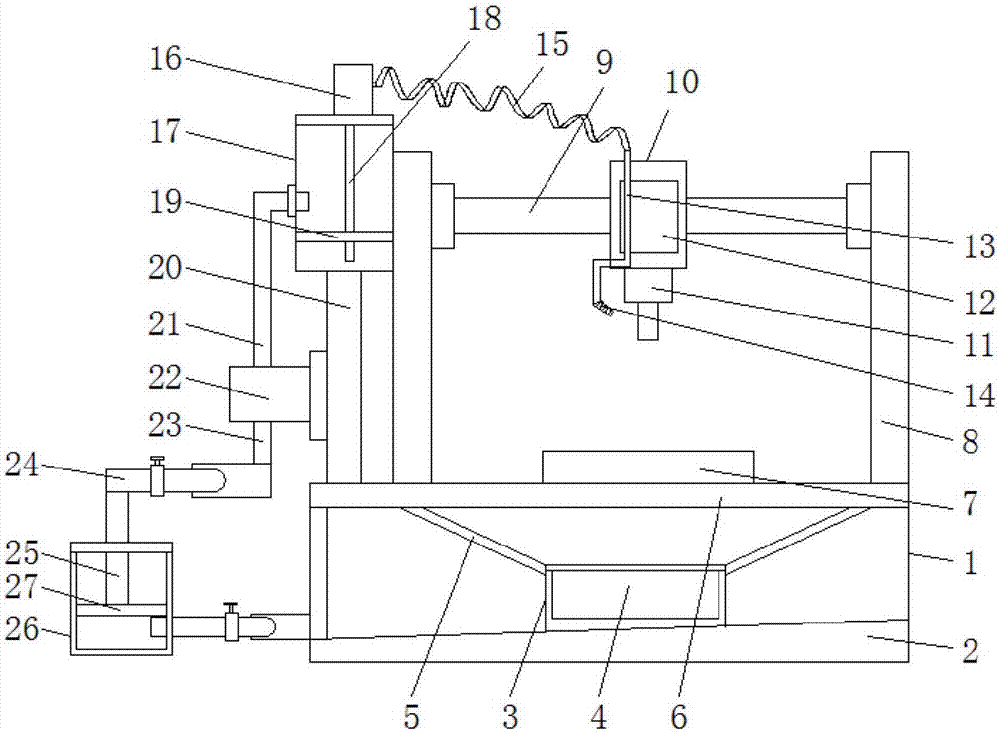

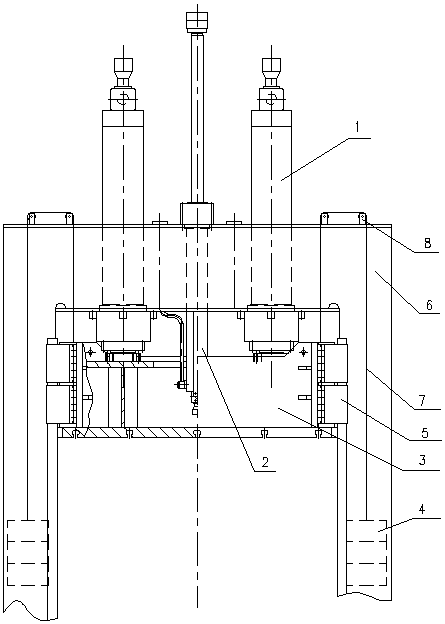

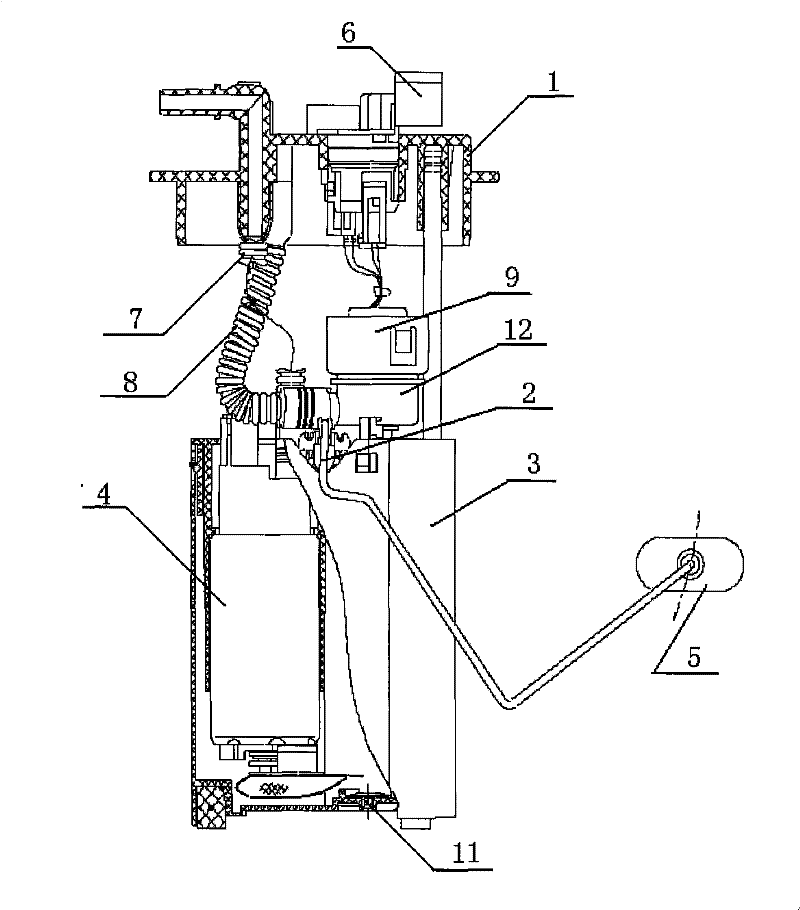

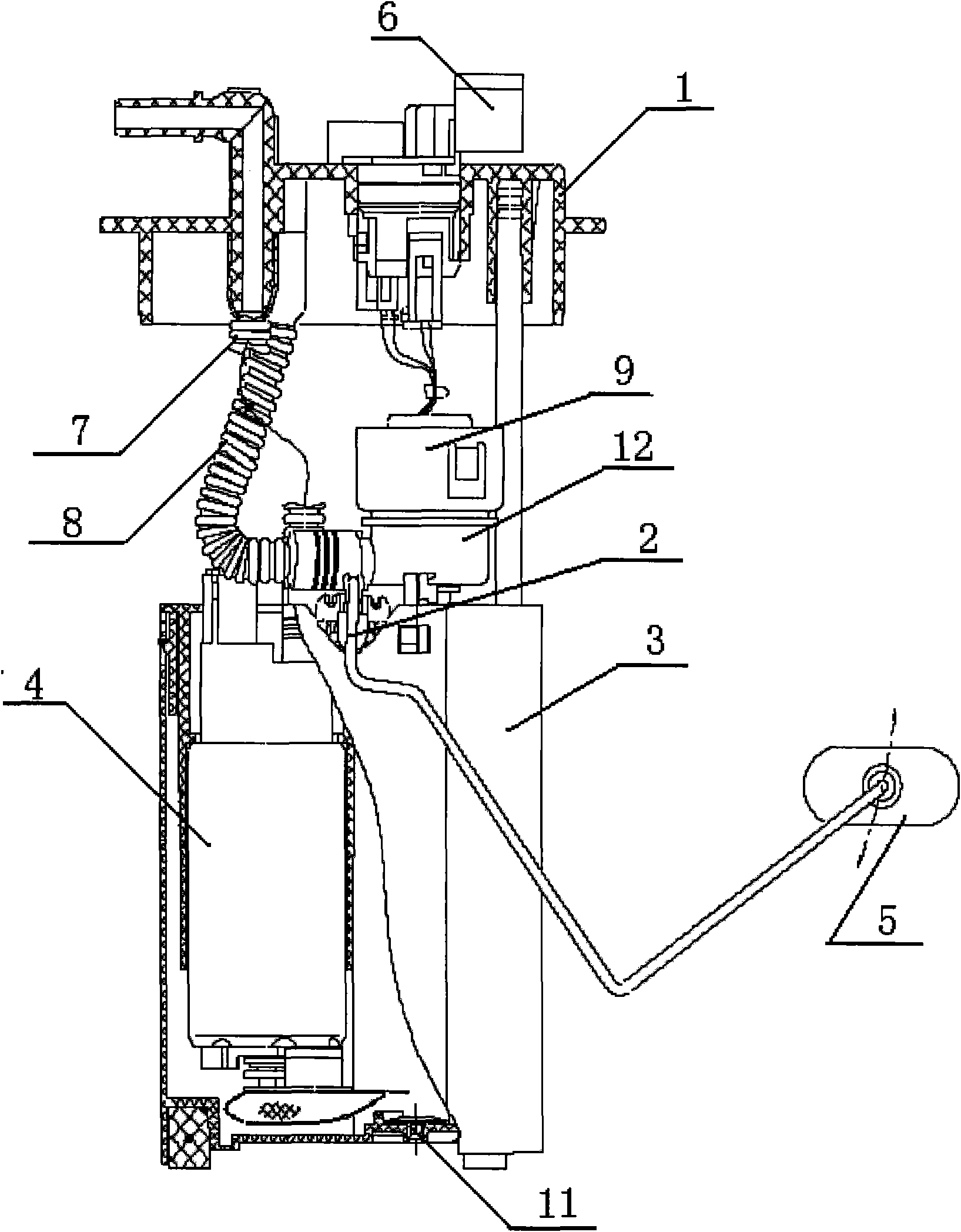

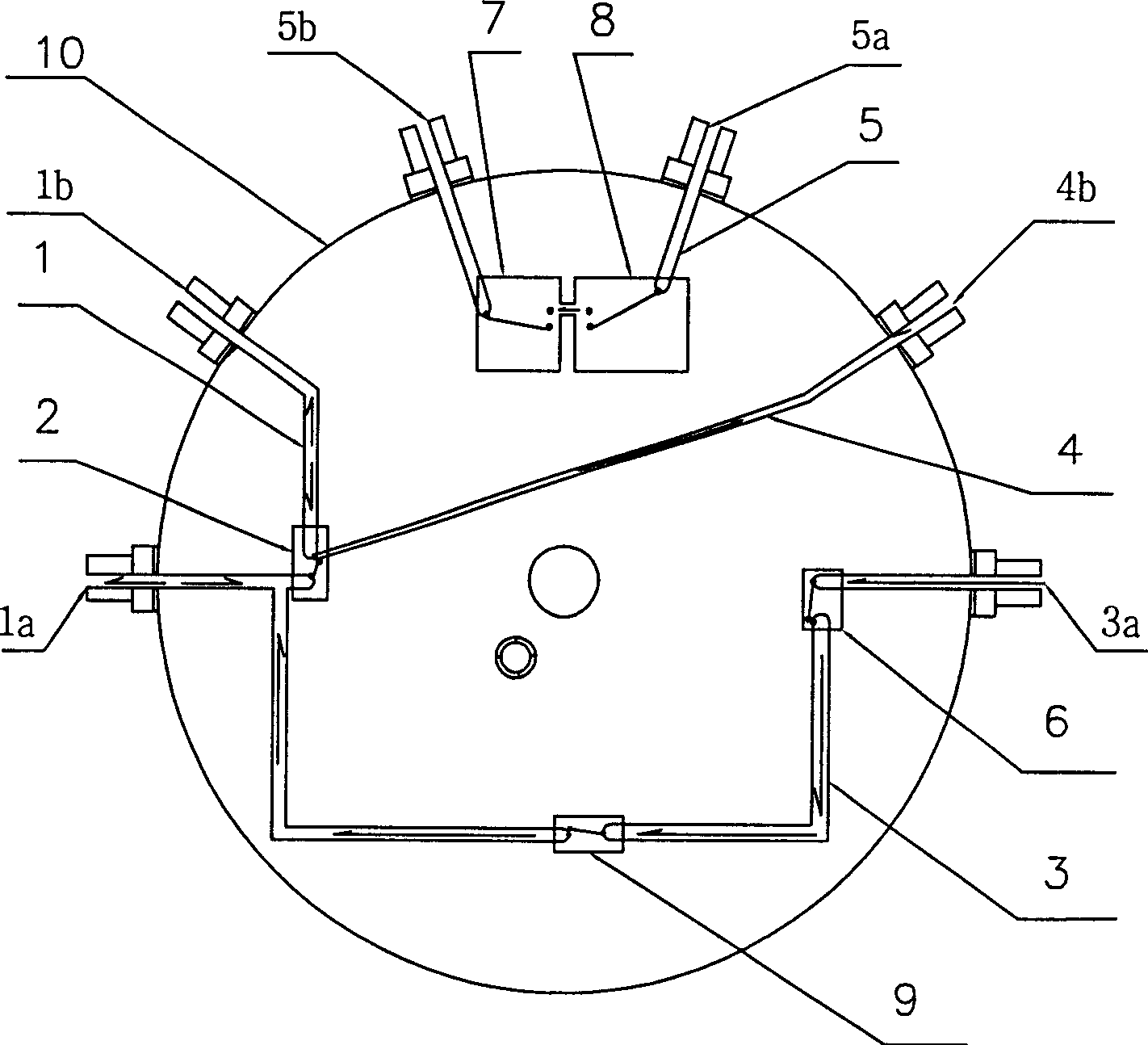

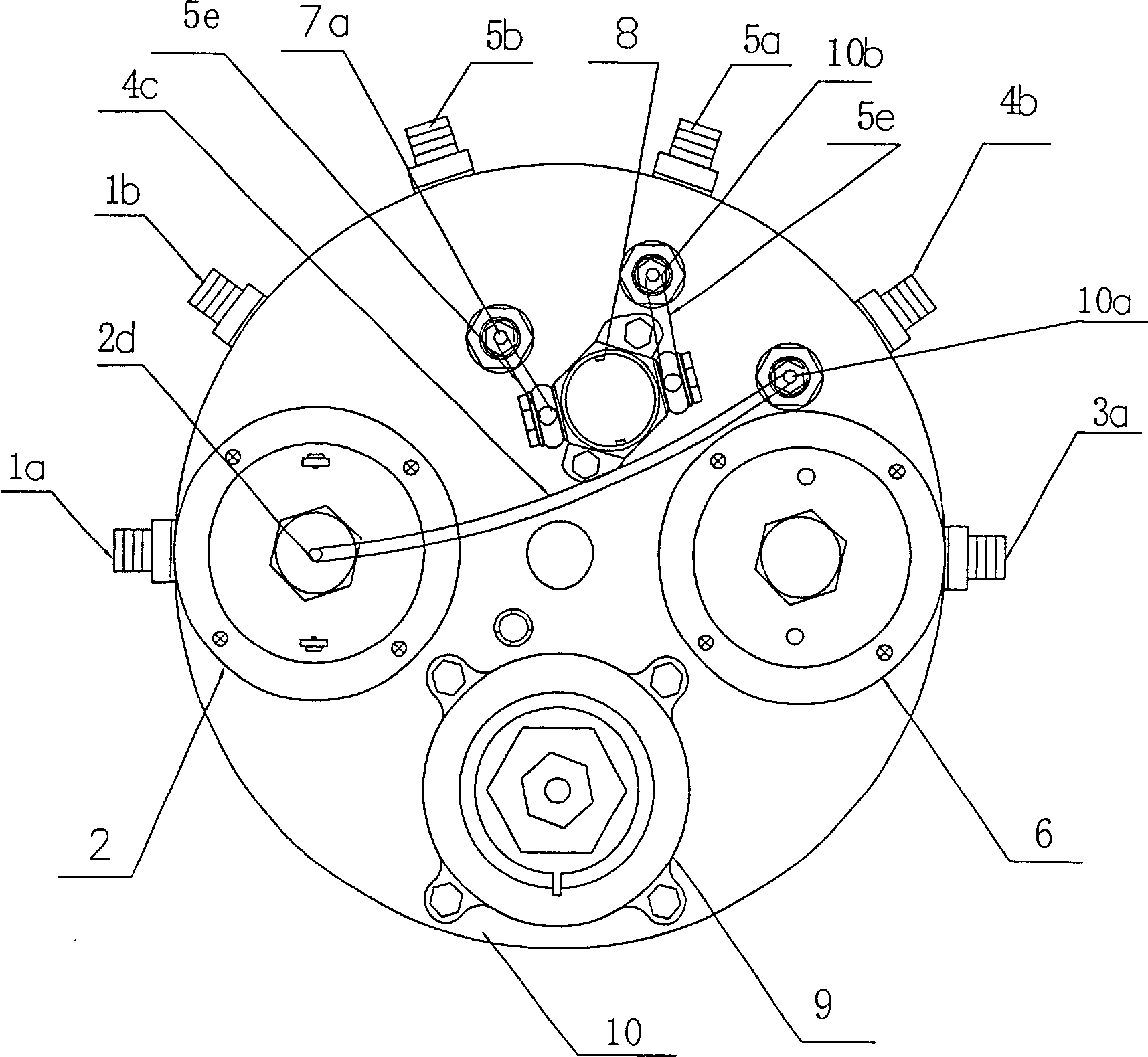

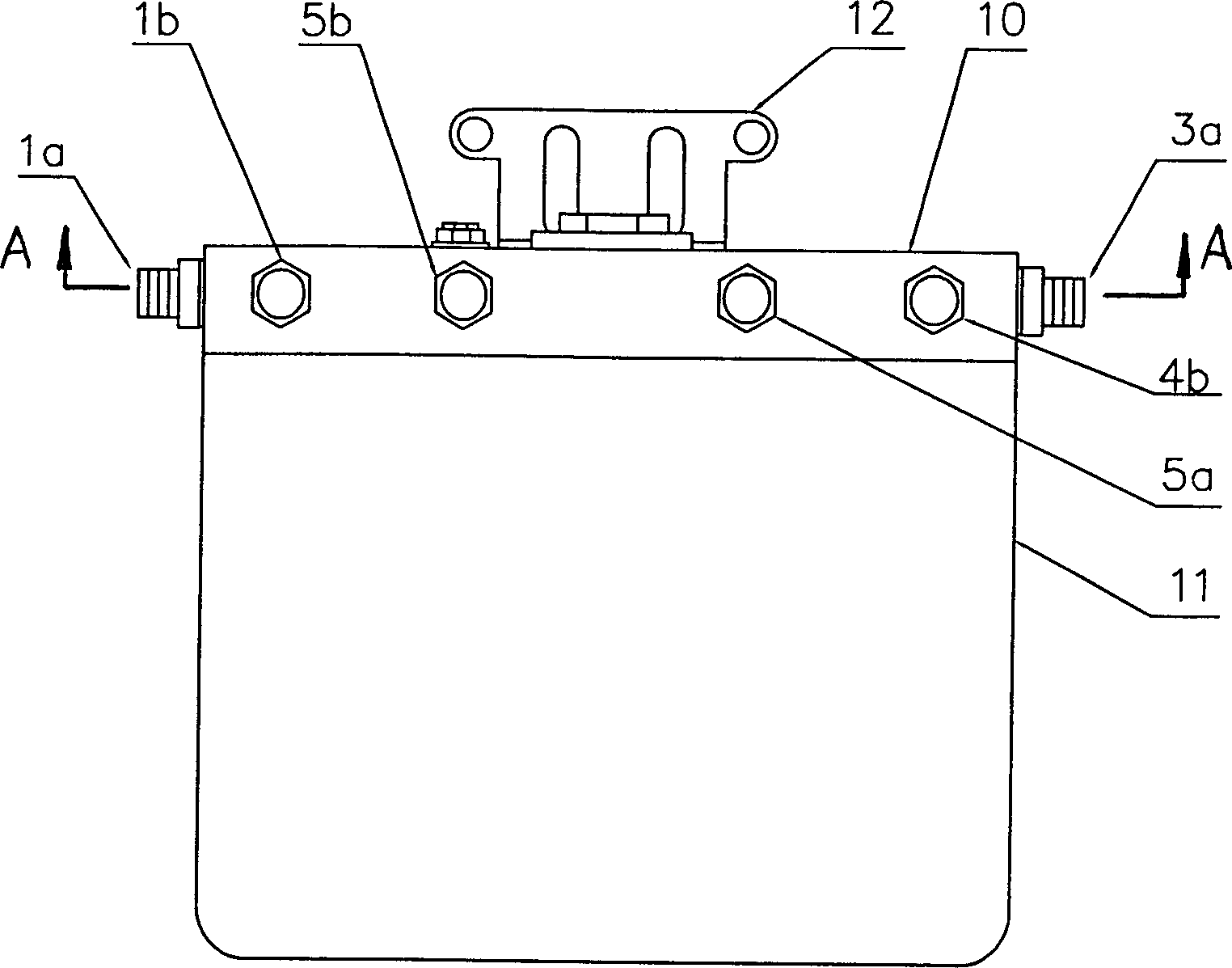

Intelligent metal plate molding machine

ActiveCN103316988AGuaranteed clampingGuarantee product qualityMetal-working feeding devicesPositioning devicesAutomatic controlEngineering

The invention discloses an intelligent metal plate molding machine. The intelligent metal plate molding machine comprises a base, an upper mold plate, a lower mold plate, an ejection oil cylinder, stand columns, an edge pressing module, a molding oil cylinder and edge pressing oil cylinders, wherein the lower mold plate is fixedly mounted on the base, the piston rod of every edge pressing oil cylinder penetrates the upper mold plate and is connected with the upper mold plate, and the molding oil cylinder, the edge pressing oil cylinders and the ejection oil cylinder are all connected with a pump control hydraulic system. The pump control hydraulic system comprises a plurality of hydraulic control check valves and a first electro-hydraulic directional control valve, wherein the plurality of hydraulic control check valves are used for respectively locking the oil supply pipelines of the plurality of edge pressing oil cylinders during the edge pressing process, and the first electro-hydraulic directional control valve is connected with the hydraulic control check valves. The pump control hydraulic system is connected with an automatic control system which is used for adjusting the output pressure of the pump control hydraulic system. The intelligent metal plate molding machine can automatically adjust the pressure of the pump control hydraulic system according to the drawing force needed during the workpiece drawing process, can guarantee the product quality, is low in power loss and good in energy-saving performance, can automatically achieve feeding and blanking and has a high production efficiency, low production costs and a low accident occurrence rate.

Owner:SHANXI SCENERY MACHINE MFG

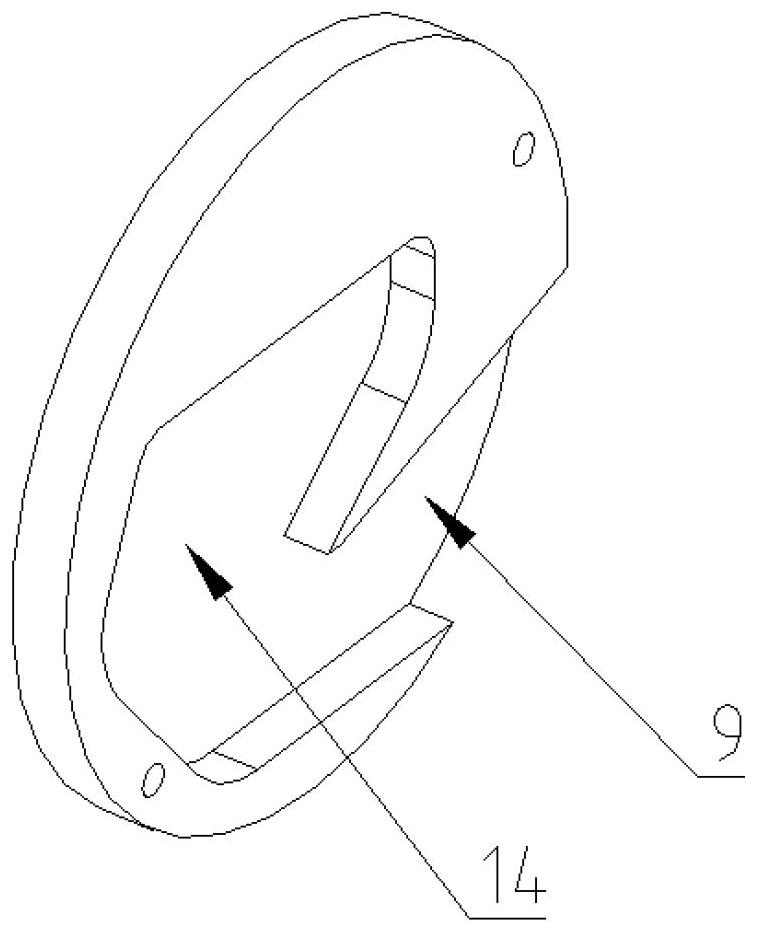

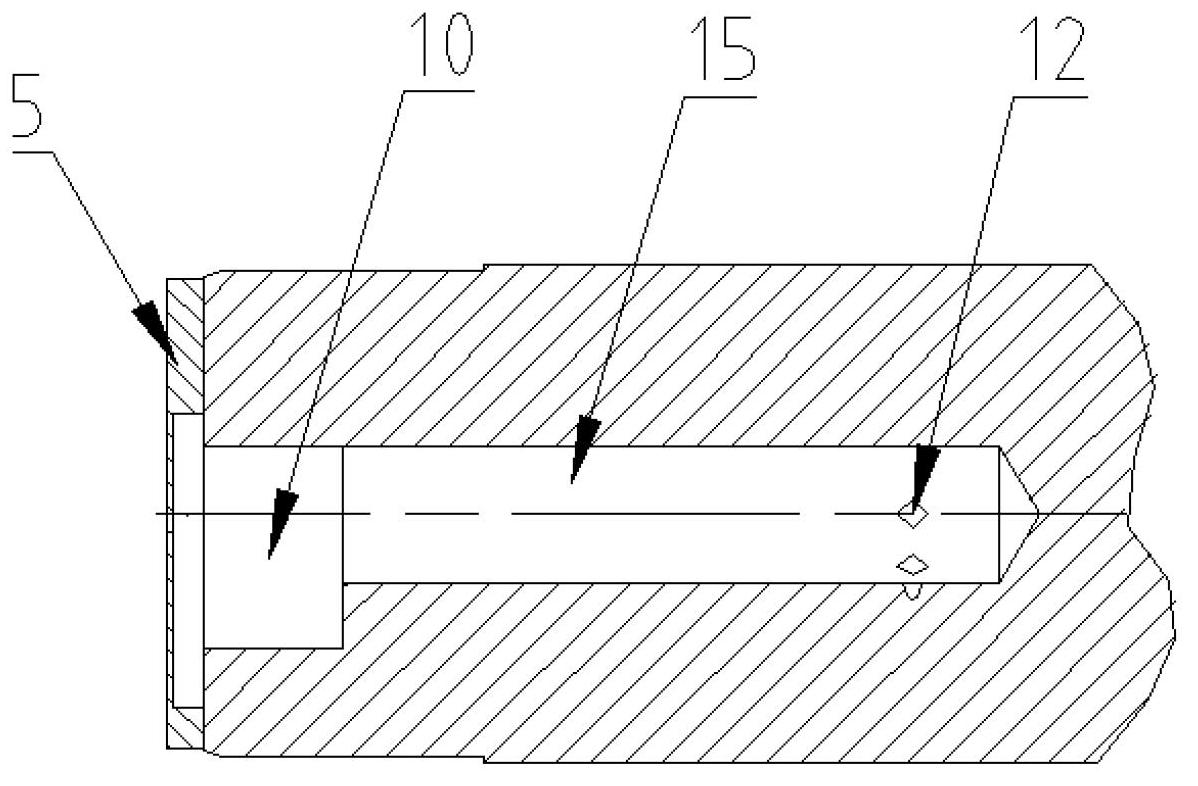

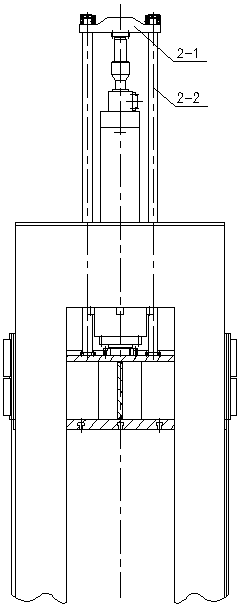

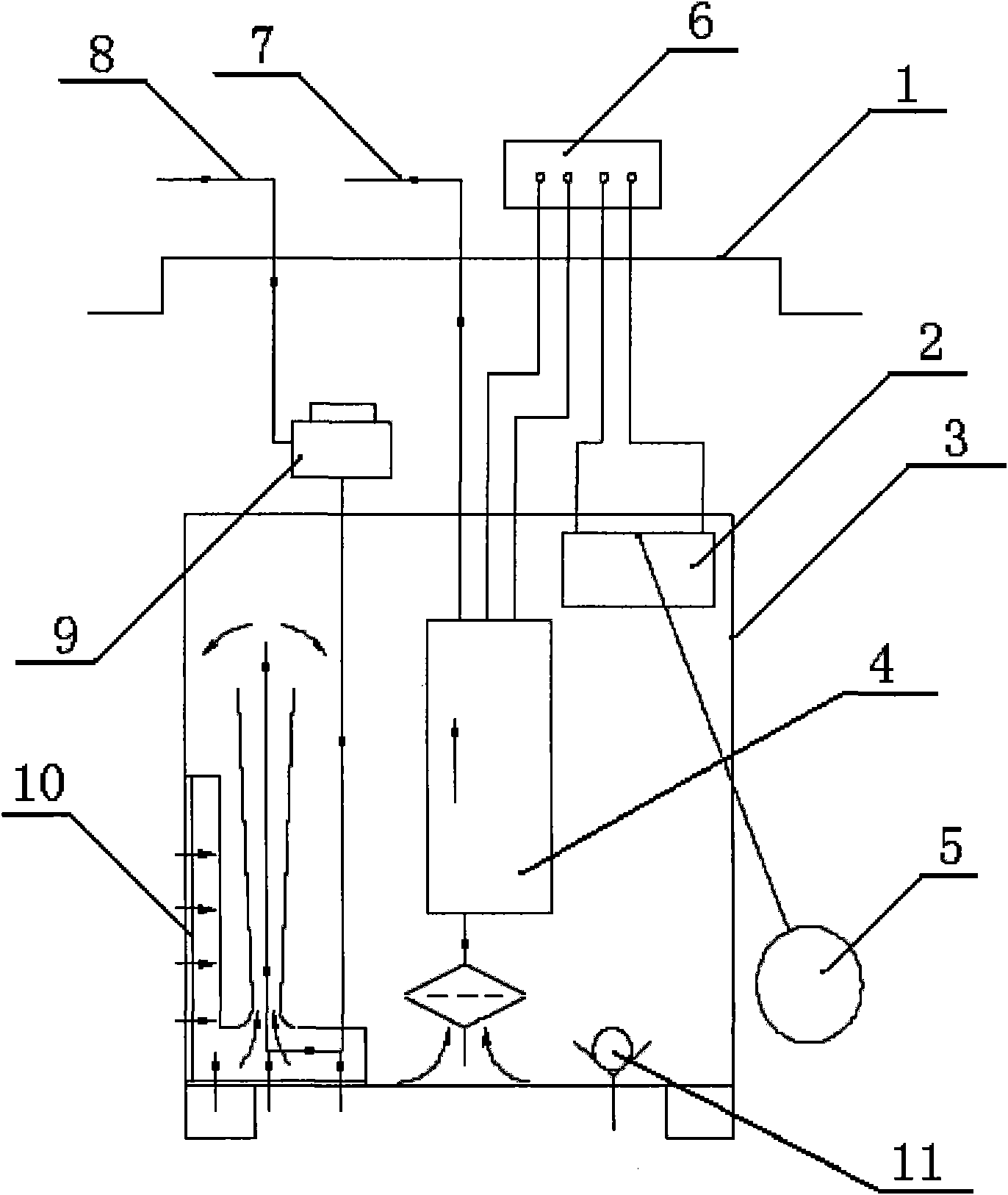

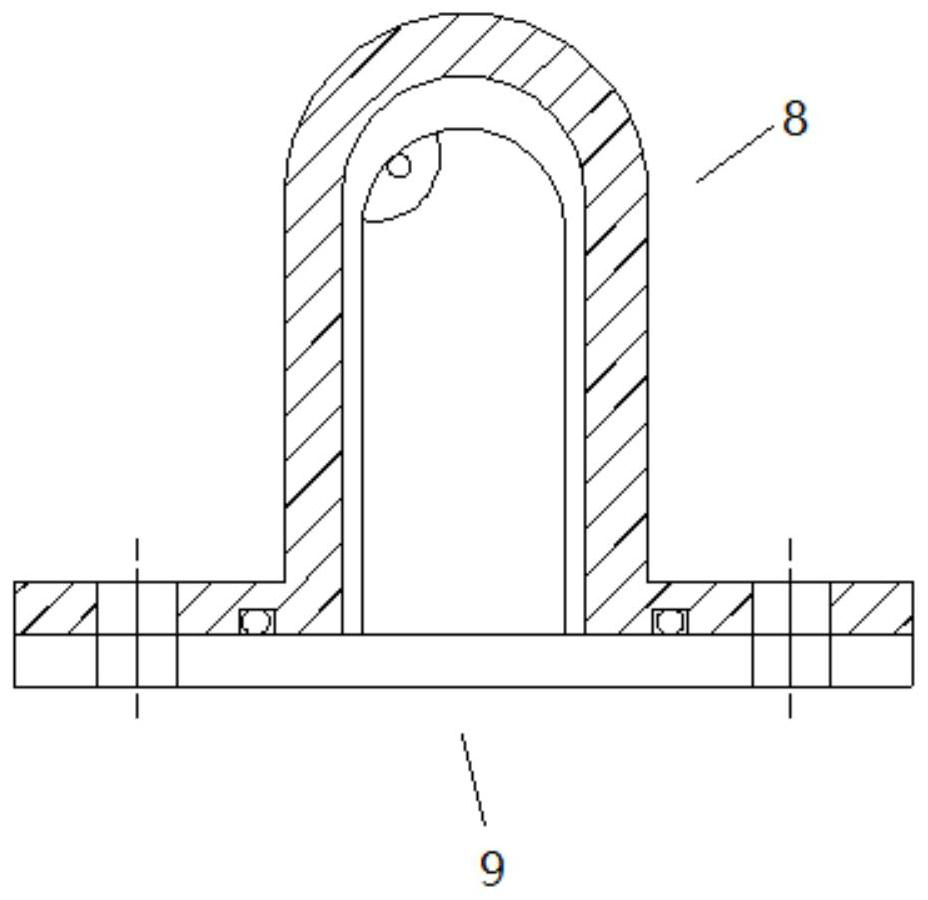

Planet bearing lubricating device in gear box

The invention provides a planet bearing lubricating device in a gear box, comprising a planet frame, a planet wheel, a planet shaft, a planet bearing, an oil shoveling plate, a bearing inner ring space ring and a bearing outer ring space ring, wherein the oil shoveling plate is mounted at the end part of the planet shaft; the oil shoveling plate is provided with an oil shoveling opening and an oil shoveling chamber; the planet shaft is internally provided with an oil storage chamber and an oil conveying hole; one end of the oil storage chamber is communicated with the oil shoveling chamber and the other end of the oil storage chamber is communicated with the oil conveying hole; an inner annular groove is arranged in the middle of the bearing inner ring space ring; and a plurality of oil supplying holes communicated with the annular grooves are arranged at the tail part of the oil conveying hole. According to the invention, with the adoption of a non-forced lubricating manner, the oil supplying amount can be reduced and the cost is greatly saved; the structure of the lubricating device is simple, the risk that the oil supply is insufficient due to the fact that oil supplying equipment is invalid is reduced, and the equipment reliability is greatly improved; and the lubricating device can be designed by adjusting the oil shoveling amount through the size of an oil shoveling region and the thickness of the oil shoveling plate; and the calculation is simple and the design difficulty is small.

Owner:ZHEJIANG TONGLI HEAVY GEAR

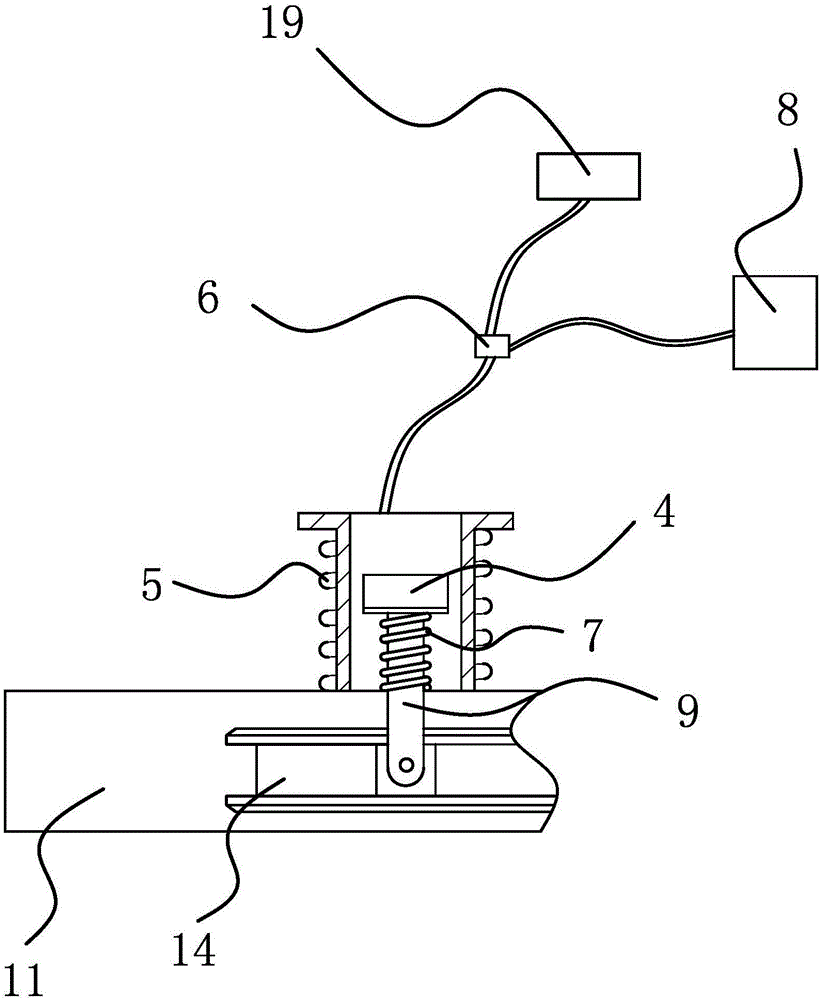

Lubricating device for lathe machining

InactiveCN107414589AValid importAffect precisionMaintainance and safety accessoriesEngineeringMachining

The invention discloses a lubricating device for lathe machining. The lubricating device for lathe machining comprises a machine table, wherein an internal plate is fixedly mounted at the bottom end of a cavity of the machine table; a fixed rack is fixedly mounted in the middle of the top end of the internal plate; an impurity collecting barrel is movably inserted in the fixed rack; side surfaces of the fixed rack are fixedly connected with sloping plates; the top ends of the sloping plates are fixedly connected with the bottom end of a supporting table; the supporting table is fixedly mounted at the top end of the machine table; and a machining table is fixedly mounted in the middle of the top end of the supporting table. According to the lubricating device for lathe machining, two precipitating tanks are matched with two flow distributing devices, collected lubricating oil is precipitated, tiny impurities which are doped in the lubricating oil are precipitated, by independent control of the other flow distributing device, the precipitated lubricating oil is guided out and used, precipitation is implemented by the two precipitating tanks alternately, therefore, the content of the impurities in the lubricating oil is greatly reduced, the purity of reused lubricating oil is improved, and the lubricating effect and long-time supply efficiency and effect are ensured.

Owner:周晓红

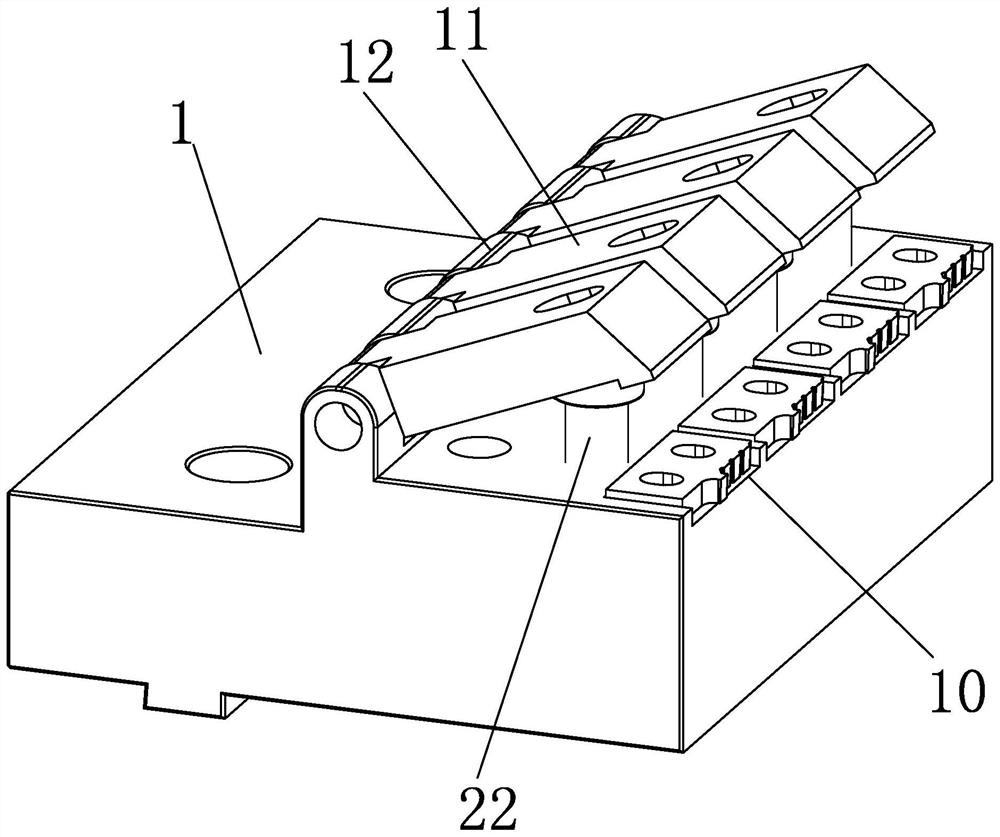

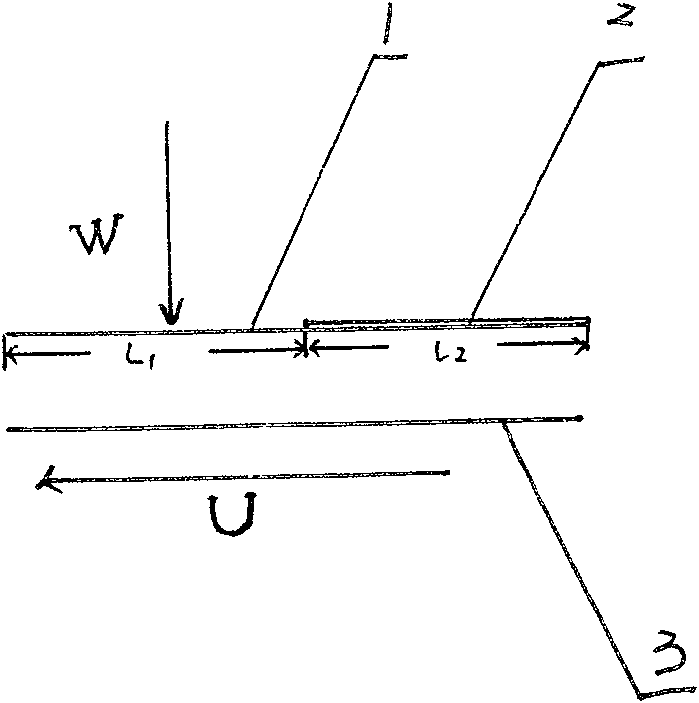

Blade grinding tool fixture and control method thereof

ActiveCN111922798AEasy to placeSimple structureGrinding feed controlOther manufacturing equipments/toolsStructural engineeringKnife blades

The invention discloses a blade grinding tool fixture and a control method thereof for providing the blade grinding tool fixture with the high stability, simple structure, high practicability and goodcontrol effect. According to the key points of the technical scheme, the blade grinding tool fixture is arranged to comprise a base, a blade storing area arranged on the base and used for storing blades, a plurality of upper pressing plates arranged on the base and used for blanking fixing of the blades, and a driving part used for driving all the upper pressing plates to press down or release. By adopting the structure set, the arranged blade storing area can facilitate storing of the blades, the shape of the blade storing area can be changed, thus cutters of different structures can be placed, a lower pressing plate is matched with the driving part to clamp the cutters, the structure is simple, practicability is high, and the blade grinding tool fixture and the control method thereof are suitable for the technical field of machining.

Owner:ZHEJIANG ANDEKAI FLUID EQUIP TECH CO LTD

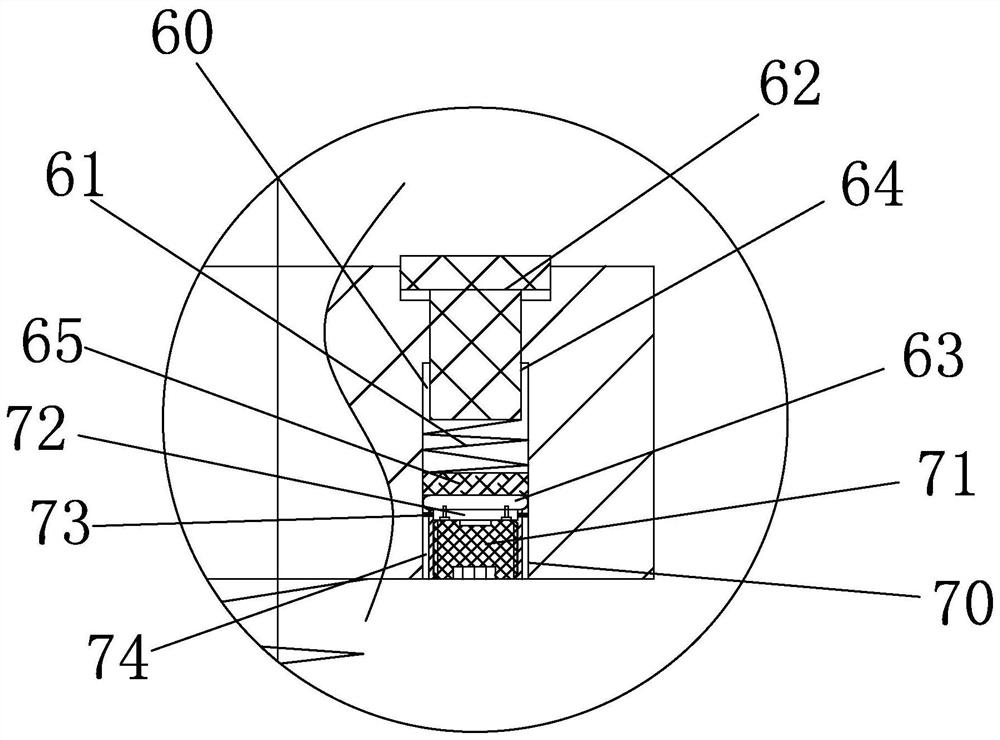

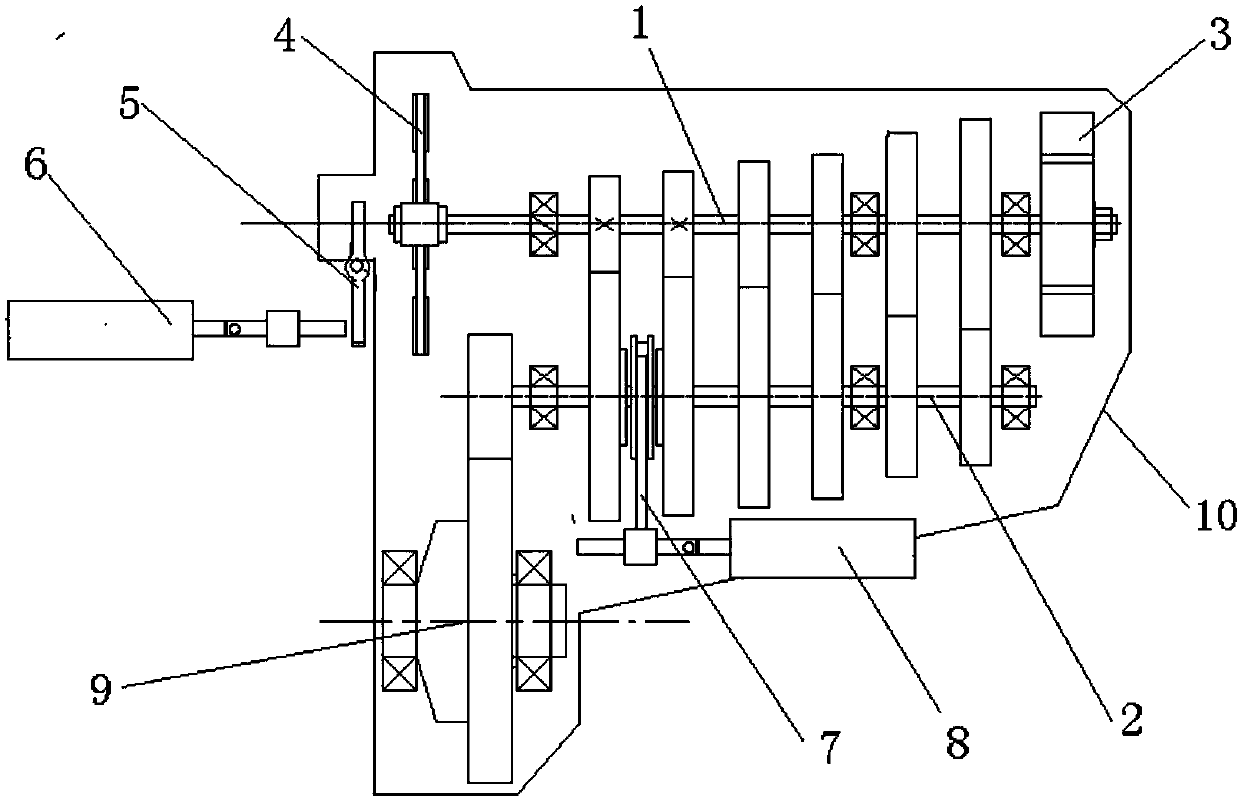

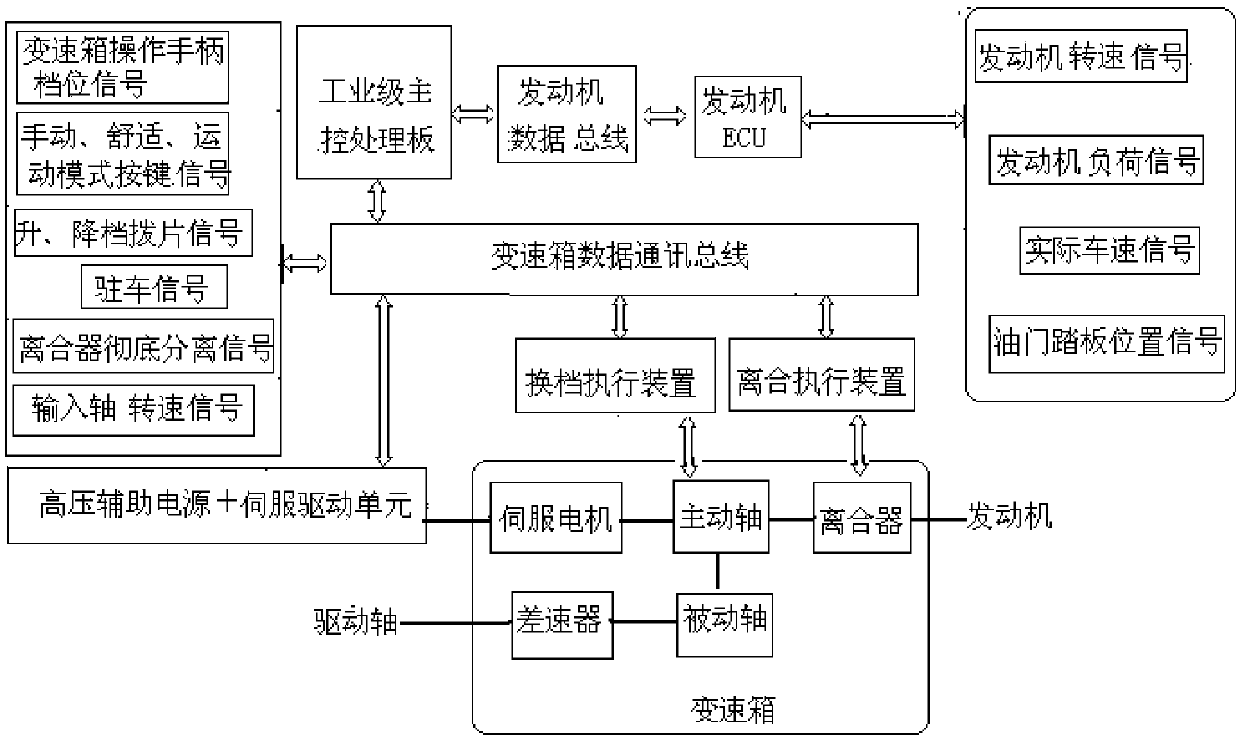

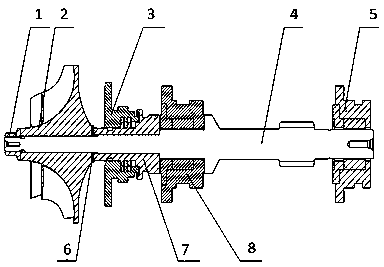

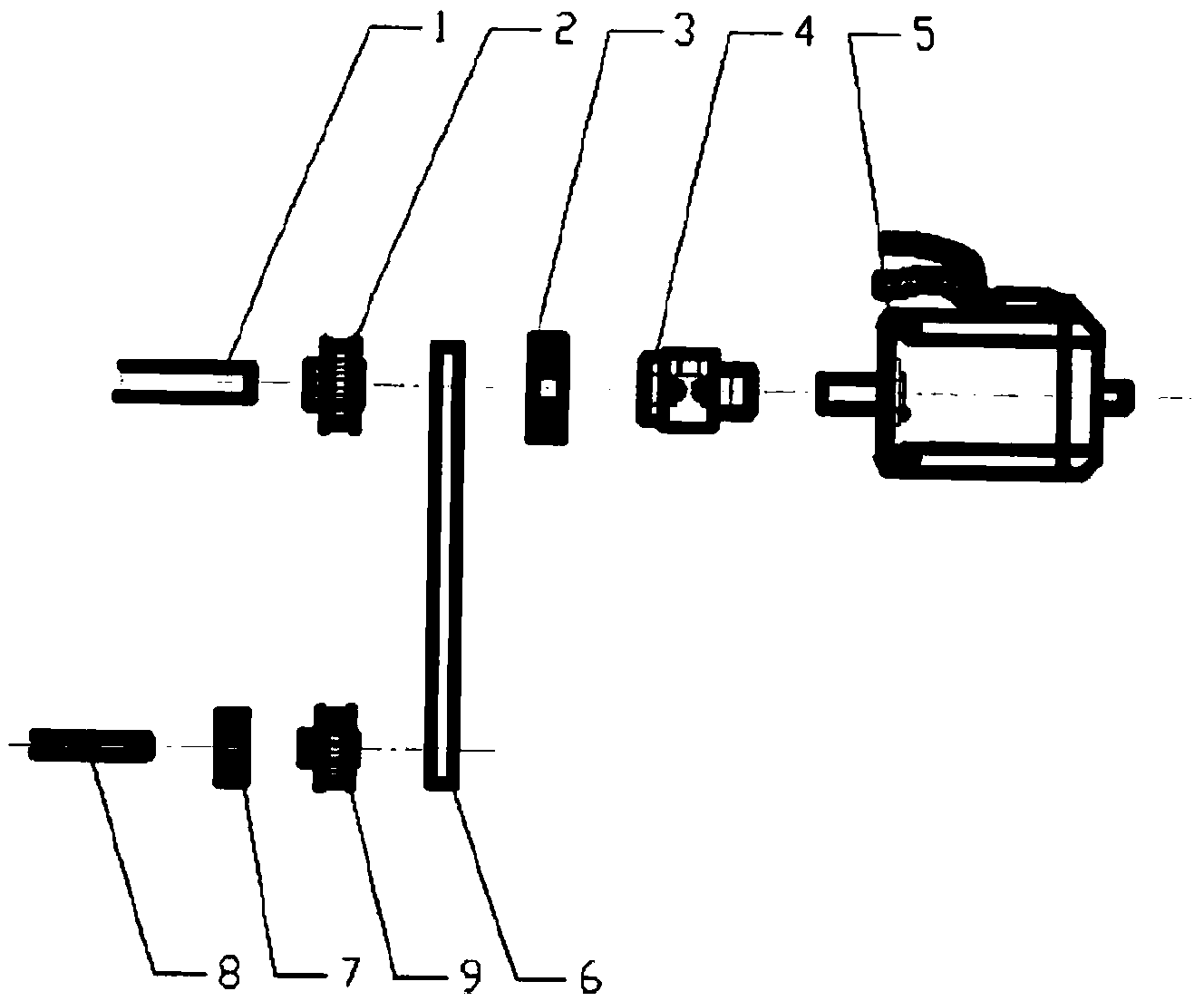

Intelligent automatic speed change system based on manual speed change box and working method thereof

InactiveCN109681625AAvoid abnormal wear and tearAvoid damageControlled membersGearing controlFuel efficiencyWorking set

The invention discloses an intelligent automatic speed change system based on a manual speed change box and a working method thereof. The system comprises a manual speed change box body and an intelligent control device. The intelligent control device is composed of an electromechanical execution part and an intelligent control module part. The electromechanical execution part comprises a speed change execution device, a clutch execution device and a gear shifting execution device. According to the system, by means of combination of all mechanisms, the rapid automatic gear shifting process andthe better gear shifting corresponding characteristic of a car are achieved, thus an engine and the speed change box are at the optimal operation state, good fuel efficiency is obtained, abnormal wear and damage caused by manual operation are avoided, and operation and use efficiency of vehicles are improved.

Owner:SHANDONG UNIV OF SCI & TECH

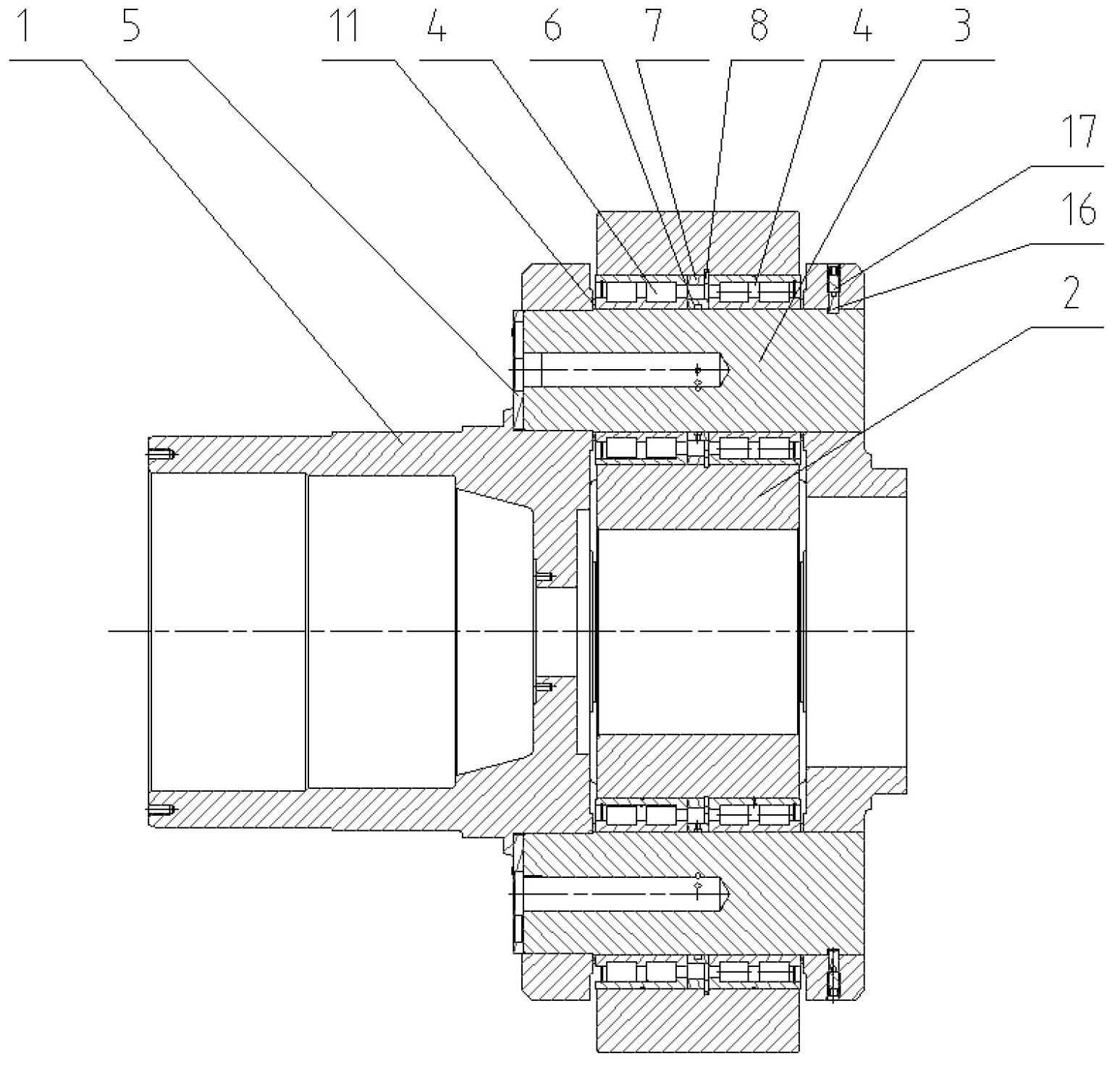

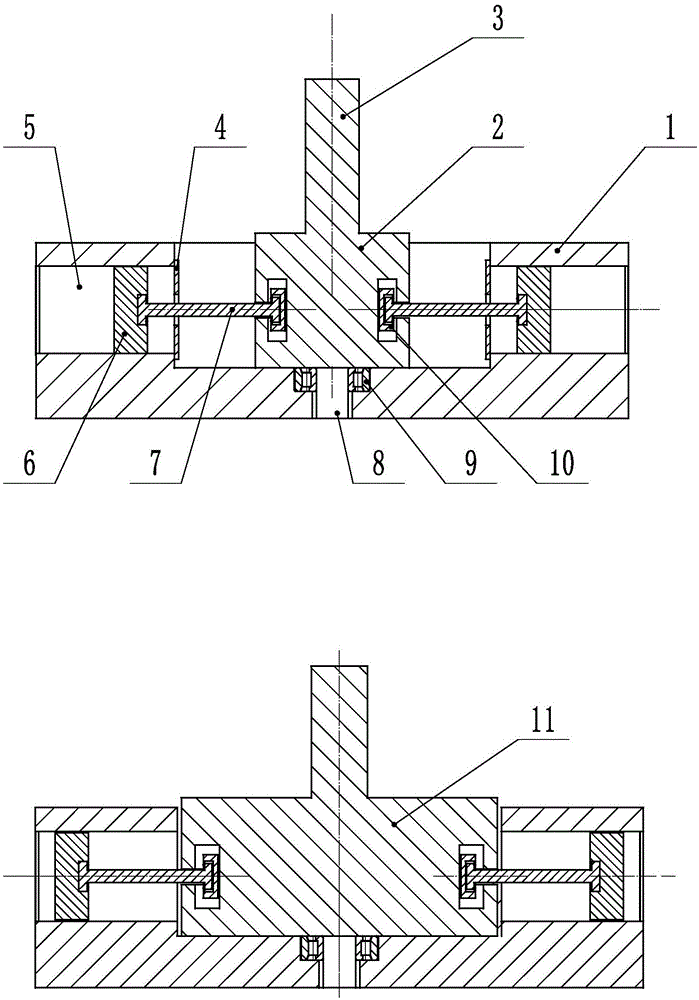

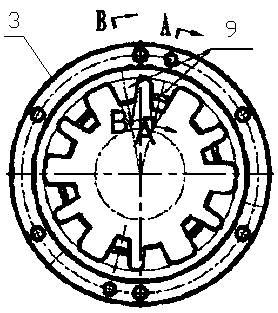

High-speed floating ring bearing and rotor system support manner

ActiveCN109027002AReduce heat generationReduce oil supplyLiquid cushion bearingsMechanical energy handlingHollow cylinderDynamic pressure

The invention discloses a high-speed floating ring bearing sleeving a rotor. The high-speed floating ring bearing comprises a bearing block and a floating ring. The bearing block is of a hollow cylinder structure. The floating ring is arranged in the hollow cylinder structure. When the rotor runs, the floating ring and the rotor relatively rotate, and the bearing block is provided with a bearing block oil passing hole and a bearing block oil passing groove. The floating ring is provided with a floating ring oil passing hole and a floating ring oil groove. Lubricating media enter the bearing block oil passing groove through the bearing block oil passing hole and enter the floating ring oil groove through the floating ring oil passing hole, and when the rotor rotates, a dynamic pressure oilfilm is formed to support the rotor. A high-speed floating ring bearing-rotor supporting system comprises the above high-speed floating ring bearing, and further comprises a floating ring and thrust combined bearing, a rotor system and an oil supply system.

Owner:湖南泛航智能装备有限公司

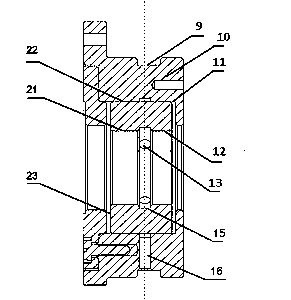

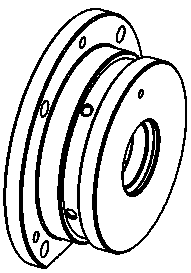

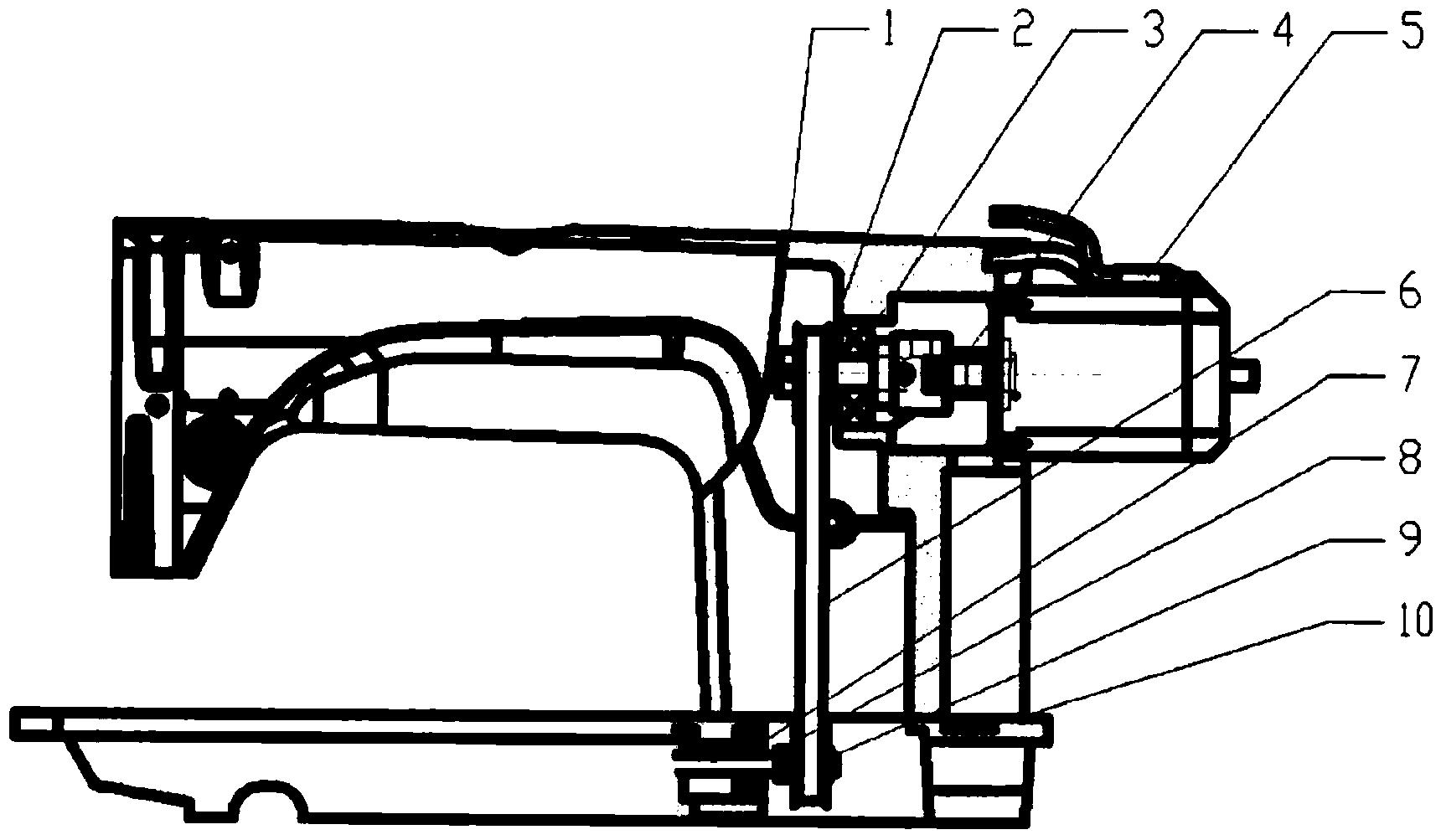

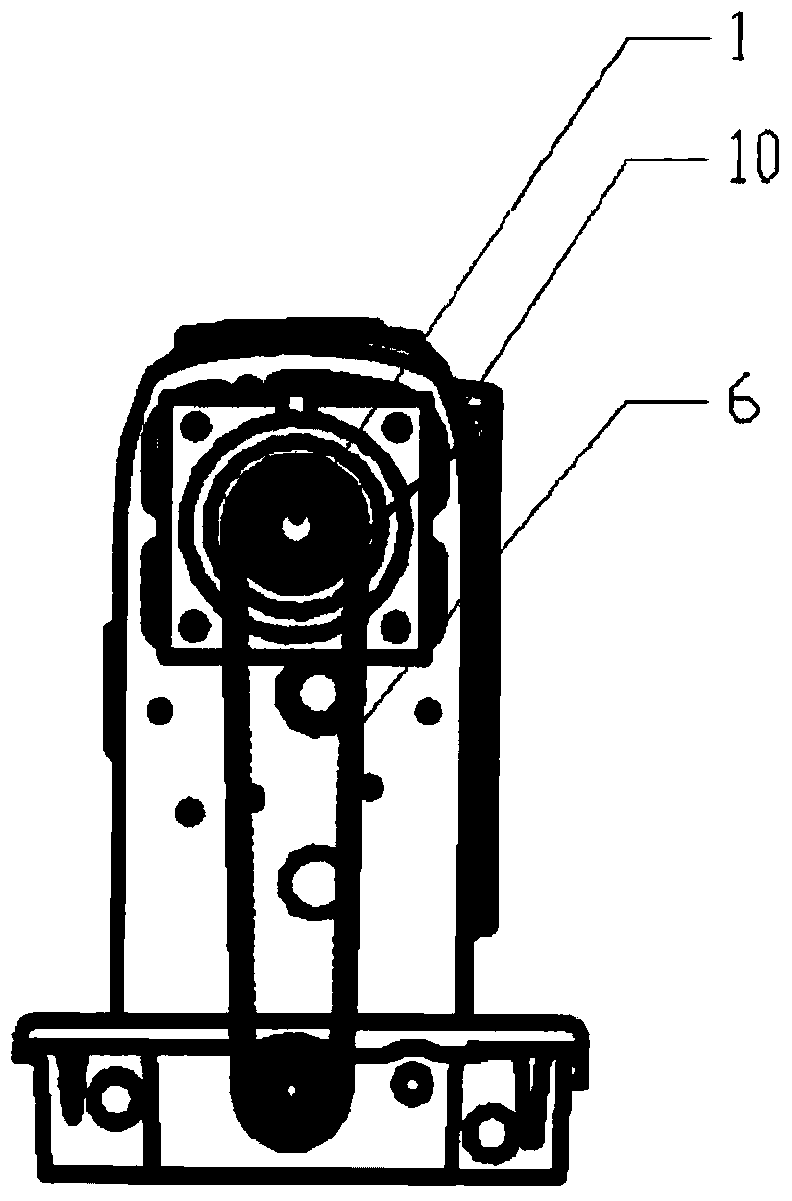

Component transmission gear of sewing machine

ActiveCN103556408AReduce oil supplyReduce pollutionSewing-machine control devicesMotor driveEngineering

The invention relates to a component transmission gear of a sewing machine. The component transmission gear comprises a frame, an upper spindle, a lower spindle, a belt transmission system, a needle bar crank, a take-up connecting rod, a take-up strut, a take-up crank component, a needle bar connecting rod, a take-up connecting rod bearing and a needle bar, wherein the upper spindle is arranged on the upper part of the frame; a motor drives the upper spindle so as to drive a main belt pulley to rotate, a driven belt pulley on the lower spindle of the lower part of the frame is driven to rotate through belt transmission, so that the synchronous rotation of the upper spindle and the lower spindle is realized. According to the component transmission gear, through a take-up pin transmission mechanism, the motion time sequence and the position of the take-up pin transmission mechanism are ensured to be the same as the original forward operation state under the condition of inversion of the motor, a crank and rocker mechanism is formed by the needle bar crank, the take-up connecting rod and the take-up strut in the take-up pin transmission mechanism, and meanwhile, a turning-block linkage is formed by the needle bar crank, the take-up crank component, the needle bar connecting rod and the needle bar. By adopting the component transmission gear, the working rotation direction of the lower spindle, and the motion matching time sequence of cloth feeding, sewing, take-up and shuttling of the sewing machine are unchanged.

Owner:ZHEJIANG DUMA SEWING MACHINE

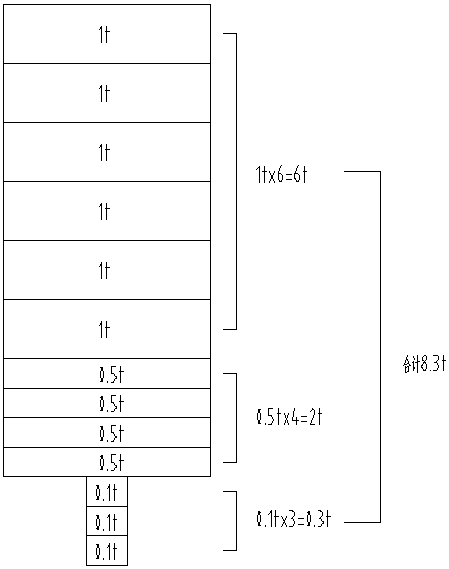

Safe and energy-saving hydraulic press

The invention discloses a safe and energy-saving hydraulic press which comprises a main cylinder, a fast cylinder, a sliding block and a counterweight, wherein the main cylinder is used for meeting the main tonnage requirements; the fast cylinder is used for realizing sliding-down, demolding and fast return of the sliding block; both the main cylinder and the fast cylinder are connected with the sliding block; the counterweight is connected with the sliding block through a lifting actuator, the minimum total weight Tz of the counterweight is equal to sliding block weight Th plus total weight Tm of a die on a hydraulic press plus friction force overcome by sliding block return. In such a manner, the safe and energy-saving hydraulic press disclosed by the invention has the benefits that the self weight of the sliding block is eliminated, the return force is reduced, the overall power and the energy consumption are greatly reduced, the oil supply quantity of equipment is reduced, and the overall heat productivity is reduced; as the sliding block has an upward movement trend in an initial state, the equipment safety is greatly improved; the complex safety protection design in mechanical design, electrical programming and hydraulic design can be omitted.

Owner:WUXI PENGDA HYDRAULIC MACHINE FACTORY

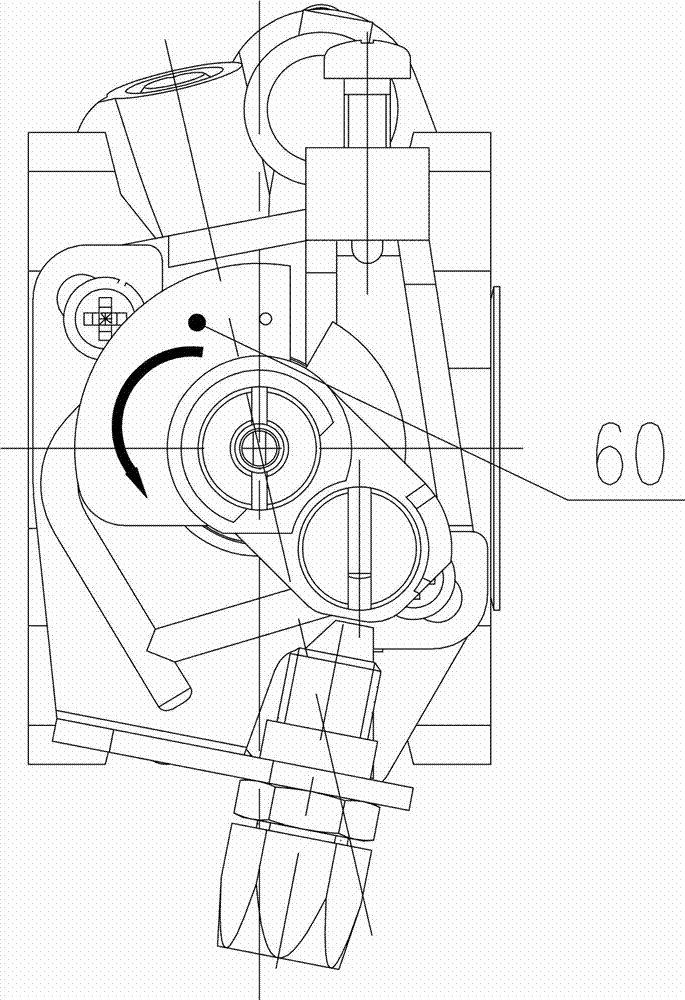

Plunger lifting mechanism of rotary valve type diaphragm carburetor

InactiveCN103047053AReduce oil supplyImprove use reliabilityMachines/enginesControl engineeringRotary valve

The invention relates to a carburetor lifting mechanism, in particular to a plunger lifting mechanism of a rotary valve type diaphragm carburetor. The lifting mechanism comprises a torsion spring, a sealing cap, a cam, a plunger and a main nozzle. An oil return pipe and an oil inlet pipe are arranged in a middle section of the carburetor, and an oil cup is mounted at the bottom of a lower section of the carburetor. The plunger is disposed in the inner cavity of the body; and the cam is arranged in the inner cavity of the body through the limit groove. When in rotating of the throttle cable bracket on the top of the body, the wheel on the plunger is driven to roll along the helical surface on the cam, so that a major gauge pin in a major pin sleeve is driven to make up and down movements in the plunger. The cam is disposed in the inner cavity of the body, so that dust generated in the operation of the engine does not enter the cam to affect the normal work of the plunger, the reliability of the use of the carburetor is increased, and the proper engine work is guaranteed.

Owner:ZHEJIANG RUIXING CARBURETOR MFG

An electric fuel pump assembly

ActiveCN101865057BReduce the chance of leaksAvoid life-shortening situationsMachines/enginesLiquid fuel feedersLevel sensorFuel tank

The invention provides an electric fuel pump assembly, including a bottom barrel, an electric fuel pump, an oil level sensor, an oil outlet pipeline, and an oil return pipeline; the electric fuel pump is arranged in the bottom barrel; the bottom of the bottom barrel is provided with a one-way oil inlet valve; the oil outlet pipeline is connected to the oil outlet of the electric fuel pump; the top of the electric fuel pump assembly is provided with an upper cover that matches the fuel tank port, and the oil outlet of the oil outlet pipeline and the oil inlet of the oil return pipeline are set on the upper cover of the fuel tank port ;The oil return pipeline is connected with a pressure regulating valve; the oil level sensor is fixed on the inner shell of the bottom barrel; the upper cover of the fuel tank port is provided with a combined junction box, and the wiring of the oil level sensor and the electric fuel pump are connected to the combined junction box through connectors middle. The invention centrally arranges the pressure regulating valve and the oil level sensor, and also has the oil storage function, has a compact structure, is convenient for installation and maintenance, saves costs, and reduces the probability of fuel leakage.

Owner:SDZ AUTO PARTS

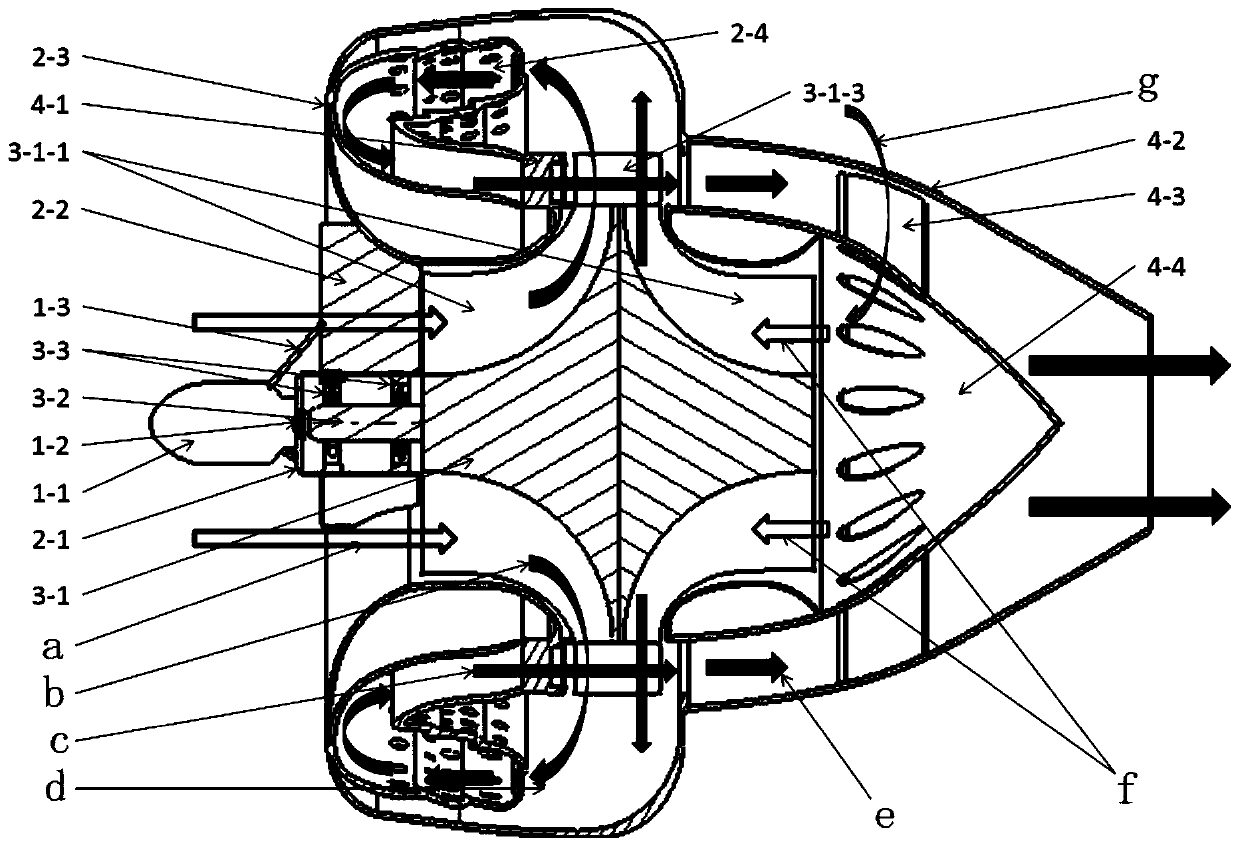

Contraposition double-eccentric-wheel sliding groove push-pull reciprocating compressed air pressurizing homogeneity compression ignition internal combustion engine

InactiveCN105156207AIncreased effective work pressureIncrease effective pressureMachines/enginesPush and pullPush pull

The invention provides a contraposition double-eccentric-wheel sliding groove push-pull reciprocating compressed air pressurizing homogeneity compression ignition internal combustion engine. The eccentric distance of a rotating double-eccentric-wheel serves as a reciprocating stroke to drive pistons to complete air suction, compression, acting pressure gas discharging, pressurized air is supplied to a coaxial double-eccentric-wheel sliding groove type power output internal combustion engine, and the pressurized air flows quickly into all air cylinders of the internal combustion engine through an air intake branch; the air flowing into the air cylinder is the pressurized air 2-5 times larger than the atmospheric pressure, the air exchange efficiency, air inlet density, air inflation and effective internal combustion engine pressure are greatly improved, and the internal combustion engine is a real pressurizing homogeneity compression ignition two-stroke internal combustion engine; even numbers of air cylinders are correspondingly arranged in pairs and evenly embedded into the periphery of the same circular-ring-shaped cylinder body; the inner circle center is the rotating double-eccentric-wheel sliding groove provided with an integrated power shaft and precisely assembled to and connected with a T-shaped sliding mechanism at a big end of connection rod in a sliding mode to transfer power, the rotating double-eccentric-wheel sliding groove provided with the integrated power shaft rotates by a circle, the big end of the connection rod slides in a limiting sliding groove with the eccentric distance as the stroke, and all the air cylinder pistons are pushed and pulled by two reciprocating strokes, in other words, the pistons act twice when the power shaft rotates by a circle.

Owner:高阳

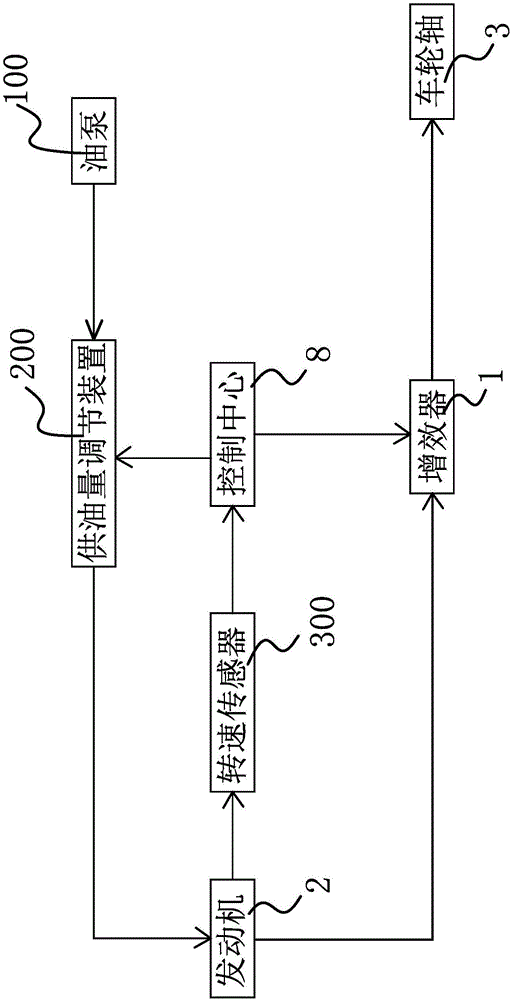

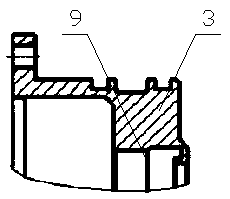

Automotive oil economization control system

InactiveCN106593669AReduce oil supplyReduce consumptionElectrical controlFluid actuated clutchesAutomatic train controlAutomatic control

The invention provides an automotive oil economization control system, belongs to the technical field of automatic control and solves the problem of inconvenient operation of the existing automotive oil economization control system. The automotive oil economization control system comprises a control center, an augmenter, an oil supply quantity adjusting device and a rotation speed sensor; the augmenter is arranged between an engine output shaft and a wheel shaft and is connected with the control center; the oil supply quantity adjusting device is arranged in an oil way between an oil pump and an engine and is connected to the control center; the rotation speed sensor is arranged on the engine output shaft and is connected to the control center; the control center is capable of controlling the augmenter to enable the engine output shaft to not drive the wheel shaft to rotate again when the rotation speed sensor detects that the rotation speed of the engine output shaft reaches the set value; meanwhile, the control center is capable of controlling the oil supply quantity adjusting device to reduce the oil supply quantity of the oil way or enable the oil way to be in cut-off state. The automotive oil economization control system has the advantages of simple structure, automatic operation and high reliability.

Owner:潘云清

Light load sliding bearing

PendingCN109236861AReduce oil supplyStable speedConduits/junctionsBearing unit rigid supportEngineeringPlain bearing

The invention discloses a light load sliding bearing and relates to the technical field of bearings. The light load sliding bearing comprises a front support, a casing, a rear support, a fuel supply pipe, a bearing bush, a rubber seal ring, a bolt and a locking plate, wherein a radial mounting hole and a boss are arranged on both sides of the bearing bush, hooks are arranged on the front support and the rear support, six pads are arranged on the bearing bush, a radial hole is arranged on each of the pads, one end of the fuel supply pipe is installed in each of the radial holes, the other end of the fuel supply pipe is arranged in a radial hole of the rear support, the front support and the rear support are respectively connected with the casing, and a fuel supply circular groove arranged on the rear support is sealed with the rubber seal ring on both sides; each pad is provided with a fuel supply chute. The light load sliding bearing solves problems of poor stability, low structural interchangeability, inconvenient installation, disassembly and maintenance of light load sliding bearings for high-speed rotating machinery in high-speed operation.

Owner:中国船舶重工集团公司第七0三研究所

Electric fuel pump assembly

ActiveCN101865057AReduce the chance of leaksAvoid life-shortening situationsMachines/enginesLiquid fuel feedersLevel sensorInlet valve

The invention provides an electric fuel pump assembly, which comprises a bottom barrel, an electric fuel pump, a fuel level sensor, a fuel outlet pipe and a fuel return pipe. The electric fuel pump is arranged in the bottom barrel; the bottom of the bottom barrel is provided with a one-way fuel inlet valve; the fuel outlet pipe is connected with the fuel outlet of the electric fuel pump; the top end of the electric fuel pump assembly is provided with an upper cover which is matched with a fuel tank port, and the fuel outlet of the fuel outlet pipe and the fuel inlet of the fuel return pipe are arranged on the upper cover of the fuel tank port; the fuel return pipe is connected with a pressure regulating valve; the fuel level sensor is fixed on the inner shell of the bottom barrel; and a combined wiring box is arranged on the upper cover of the fuel tank port, and the wire of the fuel level sensor and the wire of the electric fuel pump are connected into the combined wiring box through connector clips. The invention not only realizes the centralized arrangement of the pressure regulating valve and the fuel level sensor, but also has the function of fuel storage. Moreover, the invention has the advantages of compact structure and convenient installation and maintenance, saves the cost and reduces the chance of fuel leakage.

Owner:SDZ AUTO PARTS

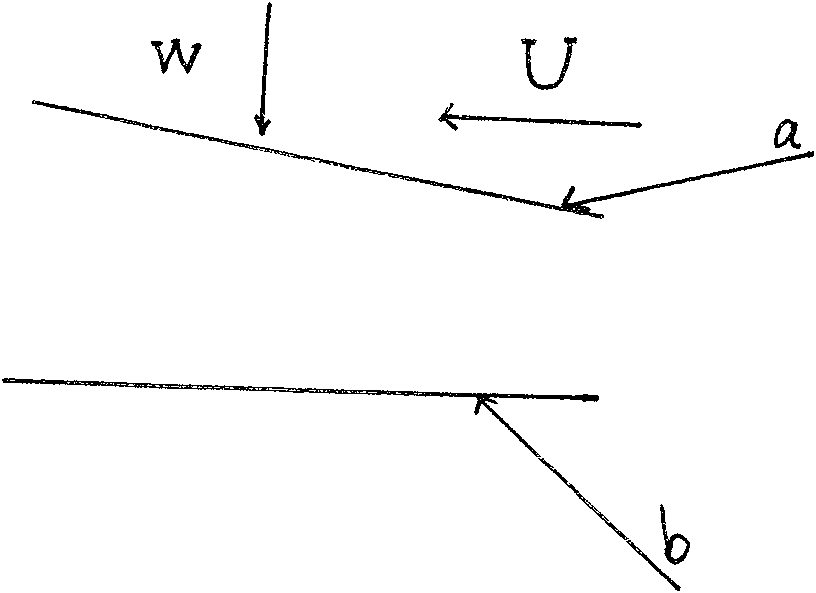

Thrust bearing applying interface adsorption technology

The present invention is a thrust bearing using interface adsorption technology, which is characterized in that it includes a stationary flat plate and a moving flat plate parallel to each other, a certain amount of fluid lubricating oil is filled in the gap between the stationary flat plate and the moving flat plate, and the stationary flat plate The mating surface of the moving plate is smooth and smooth, and a coating is provided on part of the surface of the stationary plate. The moving direction of the moving plate relative to the stationary plate is from one end of the coating on the stationary plate to the other end of the stationary plate, so that there is a certain distance between the two plates. The relative movement of these two flat plates constitutes a thrust bearing; the coating is a mica powder coating modified by a silane coupling agent. The bearing of the present invention is a thrust plate sliding bearing with considerable bearing capacity and good anti-friction and wear-resistance properties; its realization method is simple, no geometric shape processing is required on the mating surface, the structure is simple and compact, and the size is small; the manufacturing cost is low.

Owner:张永斌

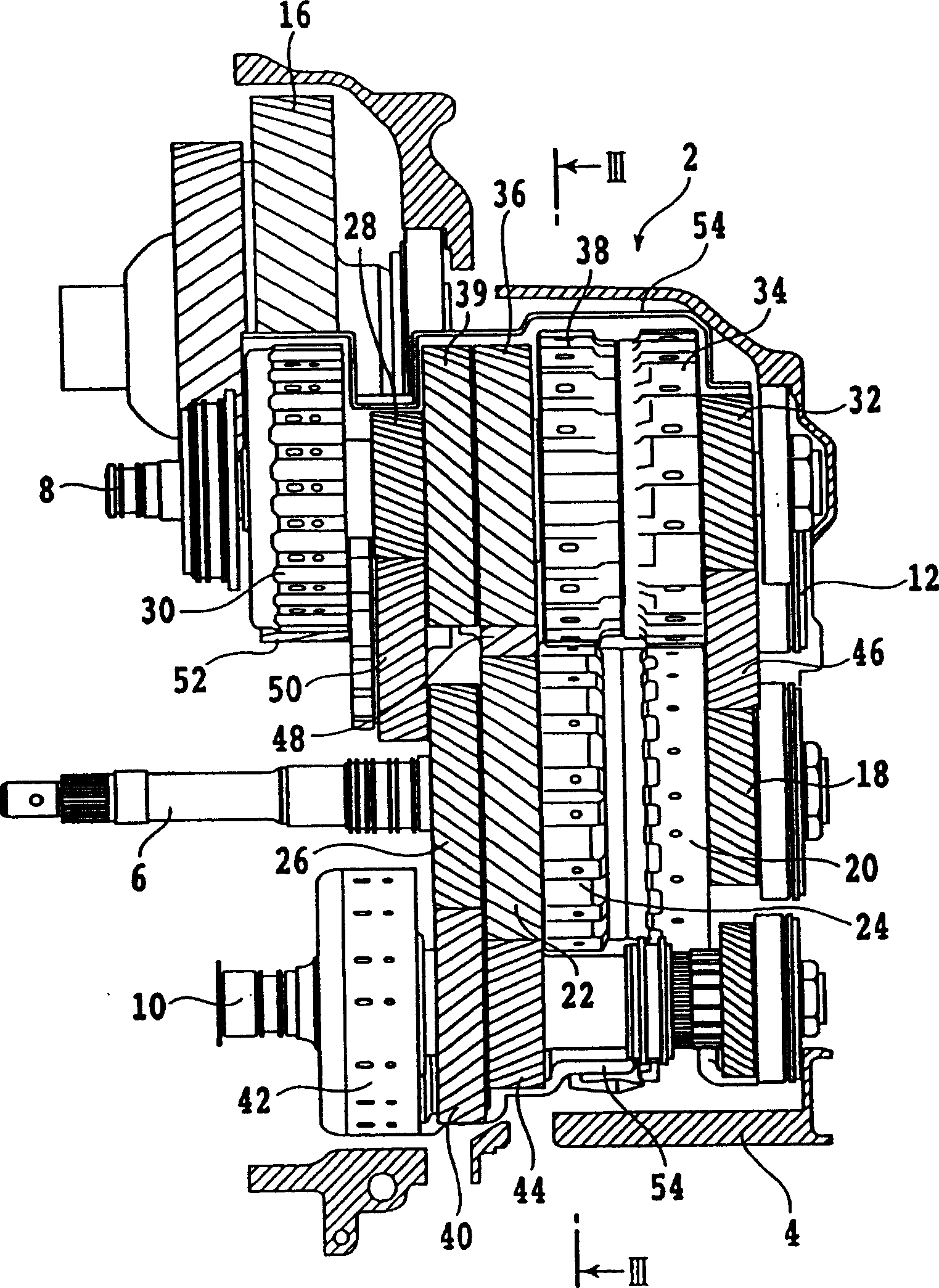

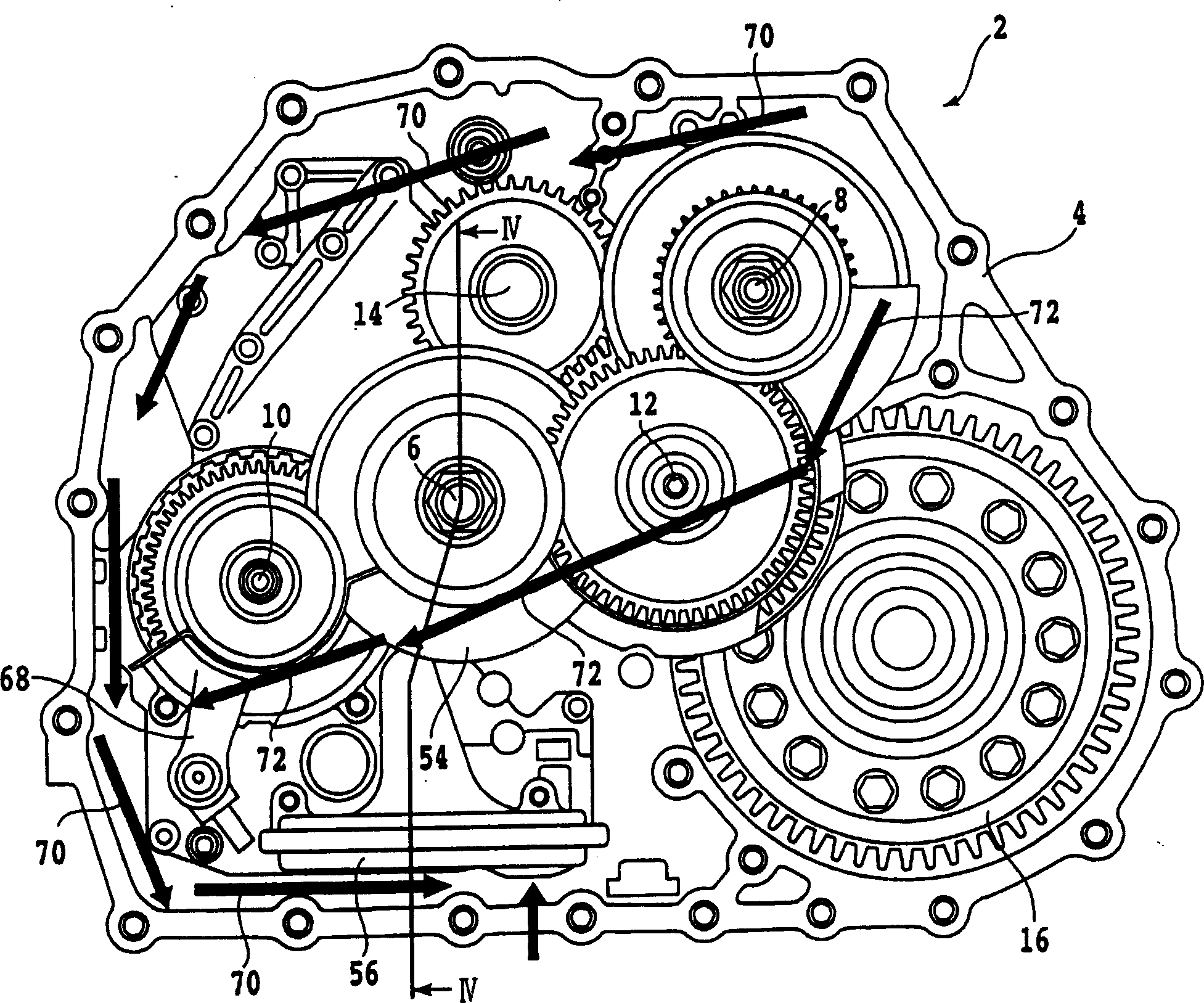

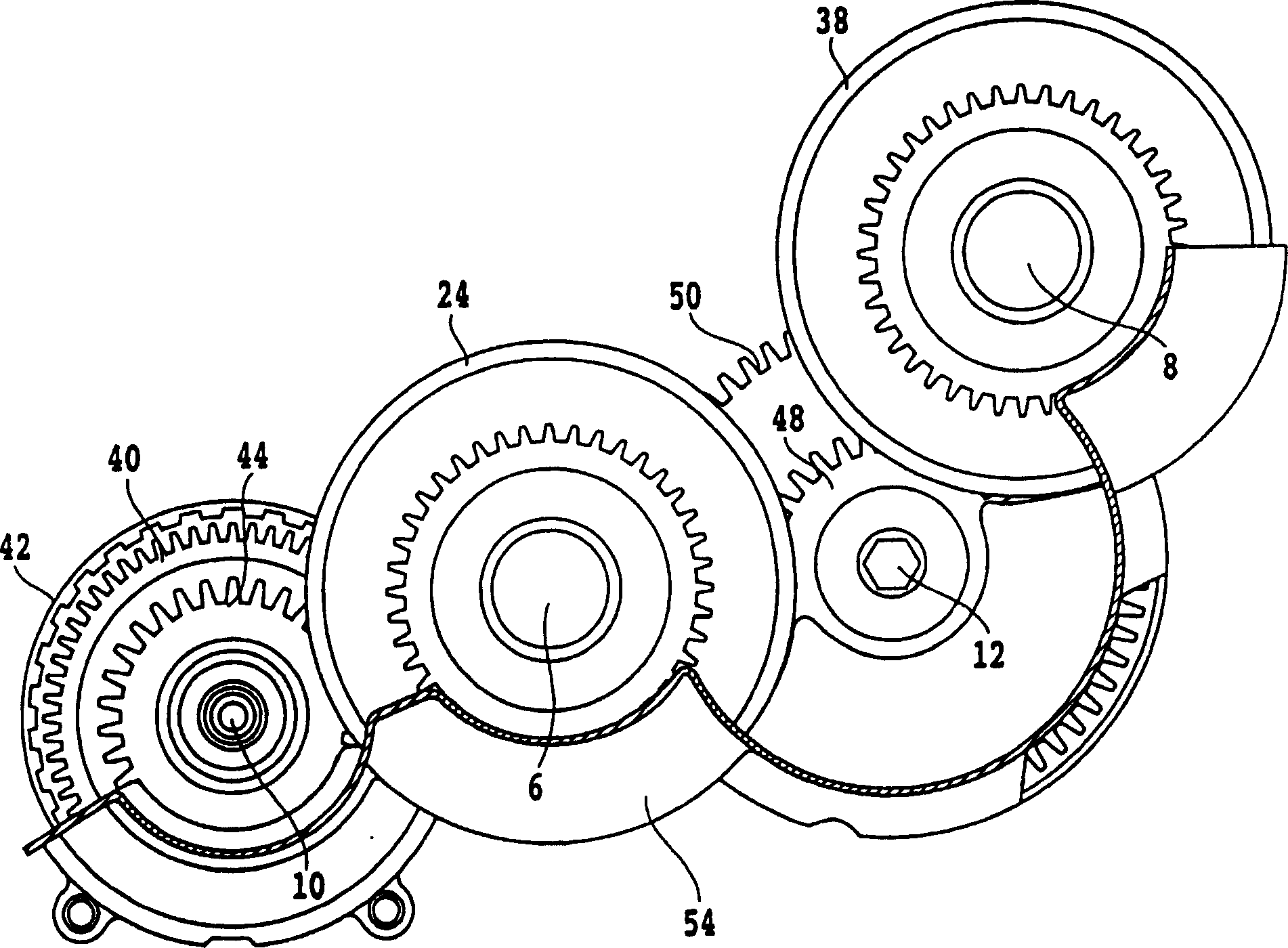

Parallel axes type automatic transmission

InactiveCN1690479AReduce oil supplyReduce loadToothed gearingsGear lubrication/coolingAutomatic transmissionControl theory

The present invention provides a three-input-axis and one-output-axis parallel axis type automatic speed variator which can reduce the amount of the lubricant oil dispersing in the casing and can be miniaturized, and the automatic speed variator comprises a first input axis (6) which inputs the power from the power source, a second input axis which inputs the power through the first input axis (6) and a third input axis (10), and an output shaft. A plurality of wet-type multiple disc clutch for varying velocity are dispersedly arranged on the input axis, each input axis is axially supported with a driving gear connected with the wet-type multiple disc clutch arranged on each input axis, and a plurality of driven gears are fixed on the output axis. The number of the wet-type multiple disc clutches which are arranged on each input axis for speed varying is as follows: the number on the first input axis is above m, the number on the second input axis is above n, the number on the third input axis is less than m, wherein m is an integer above 2, and n is an integer above 3. The second input axis is arranged at the highest position, the first input is arranged at the middle position and the third input axis is arranged at the lowest position.

Owner:HONDA MOTOR CO LTD

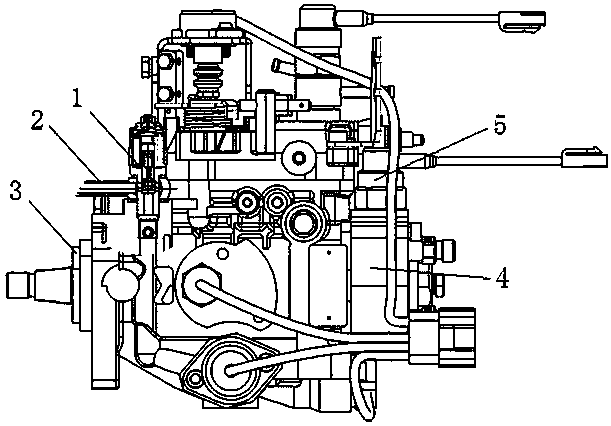

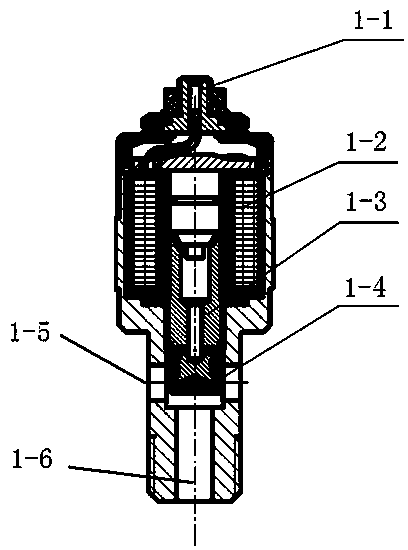

Electronic control VE type distribution pump and a flameout method thereof

PendingCN108194239AFast shutdownOil-filled reductionEngine controllersMachines/enginesSolenoid valveFlameout

The invention discloses an electronic control VE type distribution pump and a flameout method thereof. The electronic control VE type distribution pump comprises an oil pump assembly, an oil inlet pipe and an oil inlet screw, wherein an oil inlet of a pump body of the oil pump assembly is connected with the oil inlet screw, the oil inlet screw is connected to one end of the oil inlet pipe, the other end of the oil inlet pipe is connected to an oil tank, an oil inlet electromagnetic valve is arranged on a pump head of the oil pump assembly, an oil inlet hole, an oil outlet hole and a guide holewhich is formed between the oil inlet hole and the oil outlet hole are formed in the oil inlet screw, an oil cut-off electromagnetic valve is arranged at the upper part, located at of the guide hole,in the oil inlet screw, and an armature of the oil cut-off electromagnetic valve is arranged in the guide hole to move back and forth so as to enable the oil inlet hole and the oil outlet hole of theoil inlet screw to communicate with each other or to be closed. According to the electronic control VE type distribution pump and the flameout method thereof, the oil inlet screw is designed to be the provided with the oil cut-off electromagnetic valve capable of cutting off oil inlet of the electronic control VE type distribution pump, when the electromagnetic valve is powered off, oil inlet ofthe electronic control VE type distribution pump can be cut off, and by means of the coordination of the power failure and oil cut-off of an oil inlet electromagnetic valve of the pump head, the powerfailure of the electronic control VE type distribution pump can be realized so that an engine can be rapidly stopped.

Owner:NANJING WEIFU JINNING

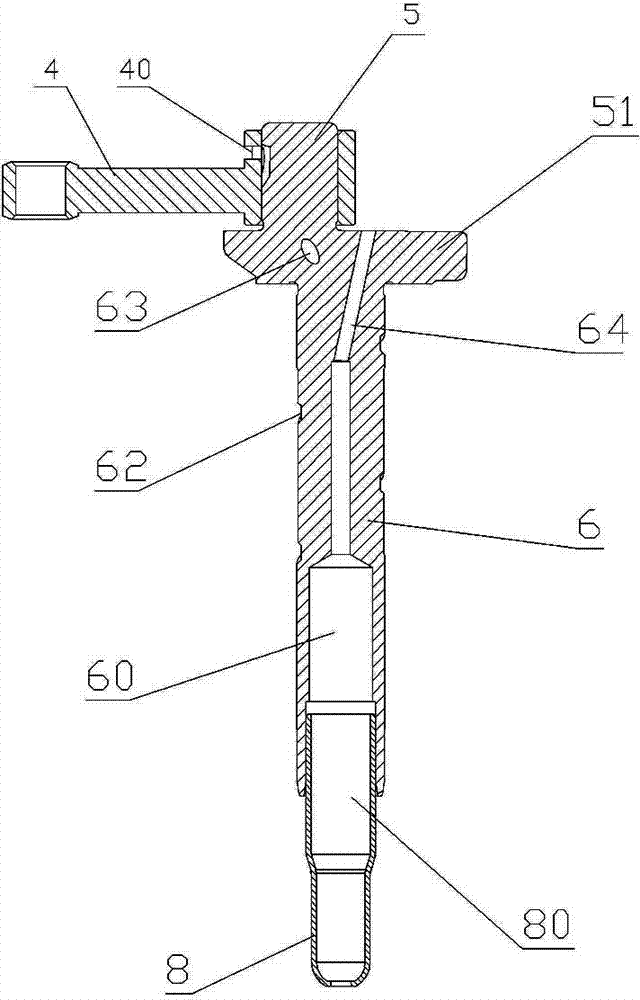

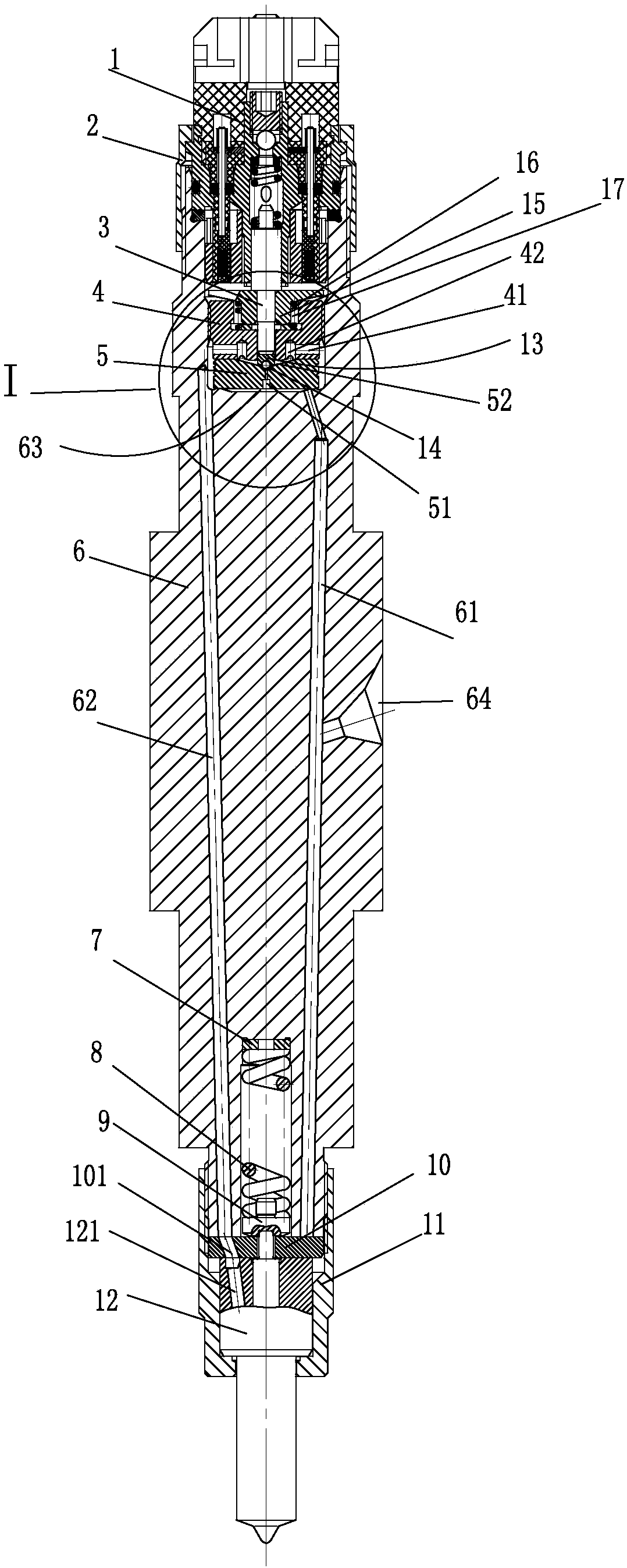

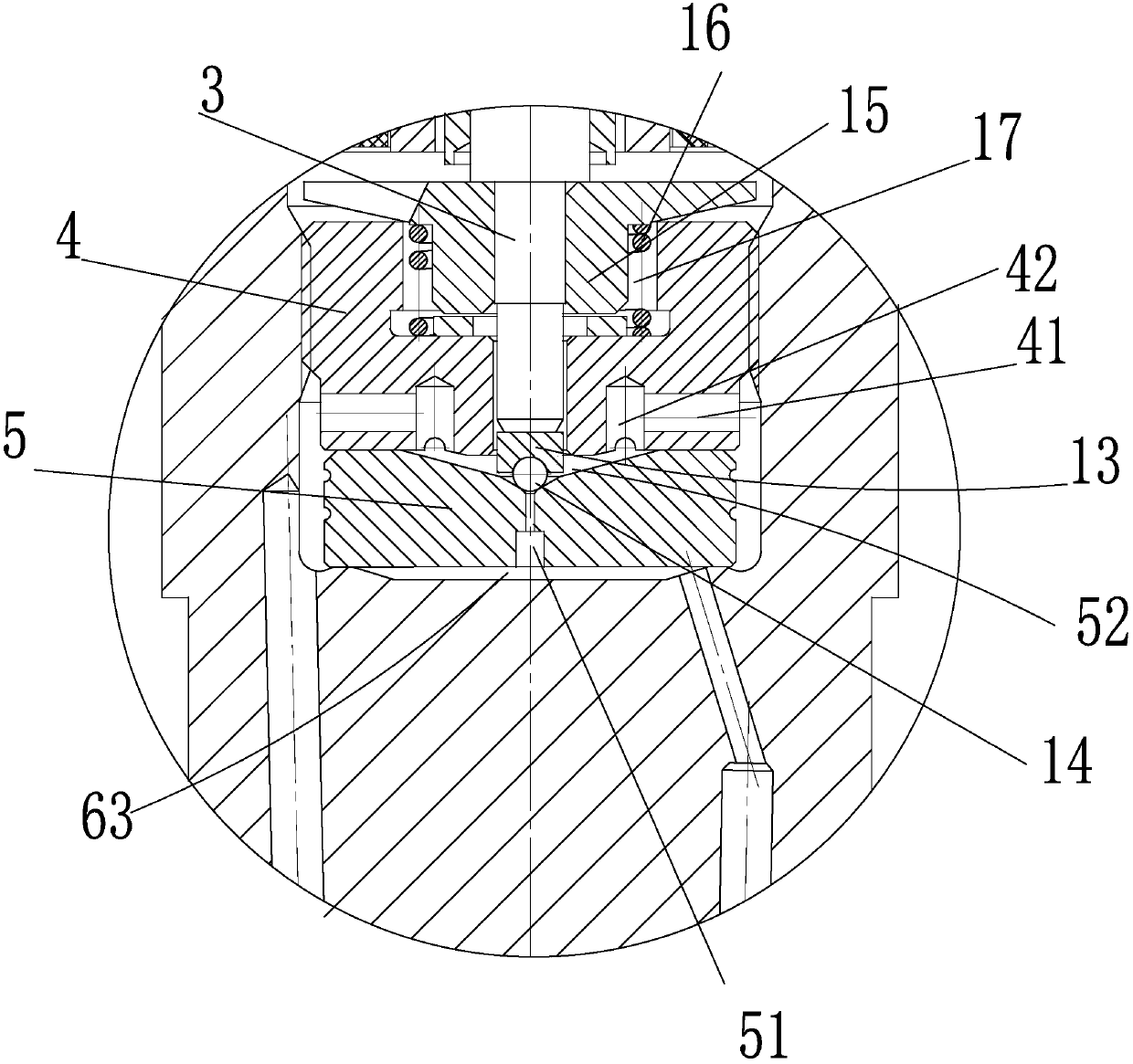

Oil-return-free common-rail oil sprayer

ActiveCN107905931ALow failure rateReduce maintenance costsFuel injection apparatusMachines/enginesCommon railSprayer

The invention discloses an oil-return-free common-rail oil sprayer. The oil-return-free common-rail oil sprayer comprises an electromagnetic valve component, an oil sprayer body, an electromagnetic valve locking nut, a control valve matching part, a locking seat, a flow control mechanism, a pressure adjusting gasket, a pressure adjusting spring, a spring seat, a middle block, an oil spray nozzle matching part and a locking nut. The electromagnetic valve component is arranged at the upper end of the oil sprayer body, the control valve matching part, the locking seat and the flow control mechanism are arranged on an upper groove of the oil sprayer body, and the pressure adjusting gasket, the pressure adjusting spring and the spring seat are arranged in a lower groove of the oil sprayer body.The upper end face of the middle block is matched with the lower end face of the oil sprayer body, the lower end face of the middle block is matched with the oil spray nozzle matching part, and the lower portion of the locking seat is matched with the upper portion of the flow control mechanism. The lower portion of the flow control mechanism is matched with the bottom wall of the upper groove ofthe oil sprayer body, and the locking seat is connected with the oil sprayer body. A first inner open hole is formed in the position, between one side of the bottom wall of the upper groove and the lower end face of the oil sprayer body, of the oil sprayer body, and a second inner open hole is formed in the other side, close to the bottom wall, of the oil sprayer body and communicates with a lower oil channel of the locking seat.

Owner:龙口龙泵柴油喷射高科有限公司

Automobile power regulator

InactiveCN1782347AIncrease oil volumeReduce output powerEngine controllersMachines/enginesSolenoid valveTurbocharger

The automobile power regulator includes one first gas pipeline connected between the air intake boosting pipe of the engine and the boosting pipe of the high pressure oil pump, and features the first gas pipeline with boosting gas pressure controlling solenoid valve communicated with the pipeline. The present invention can regulate the output power of the engine based on practical requirement, increase the output power of engine, save fuel, reduce waste gas exhaust and reduce air pollution, has reasonable structure and compact arrangement, and is especially suitable for automobile with diesel engine adopting turbocharger.

Owner:牟方成

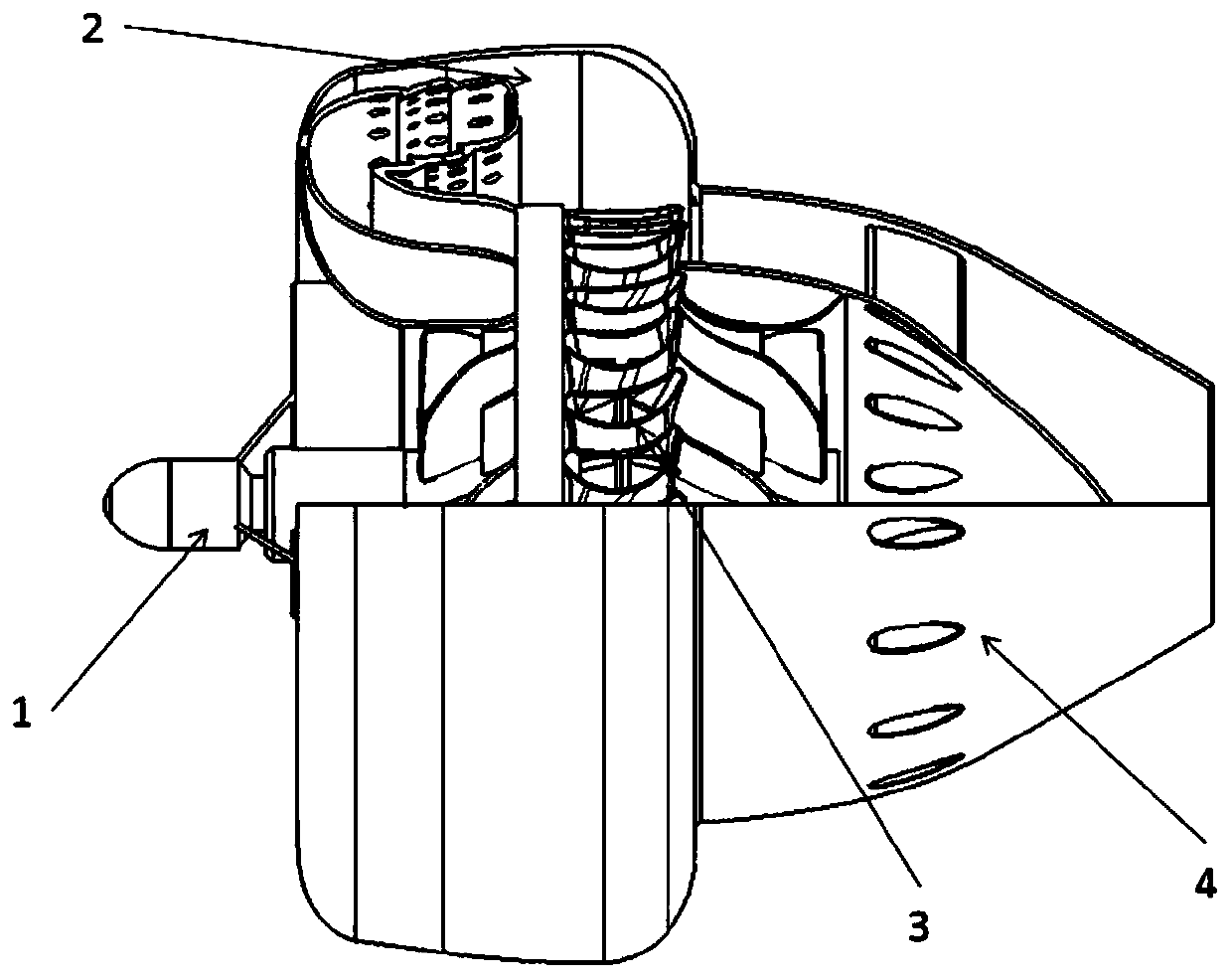

Oil feeding propeller of scroll compressor

InactiveCN1840908AAvoid oil supply deteriorationSmall flow resistanceRotary piston pumpsRotary piston liquid enginesPropellerPetroleum engineering

An oil feeding propeller of a scroll compressor for preventing deterioration of oil feeding generated when a rotation shaft is rotated in reverse is disclosed. The propeller is tightly fitted into the lower side of the oil passage of the rotation shaft, sucks oil into the shell due to rotation shaft of shaft to raise oil to a compression part of the scroll compressor. The propeller includes a plate without operative direction for feeding oil in a predetermined direction so as to raise a predetermined quantity of oil regardless of the rotation direction shaft.

Owner:LG ELECTRONICS INC

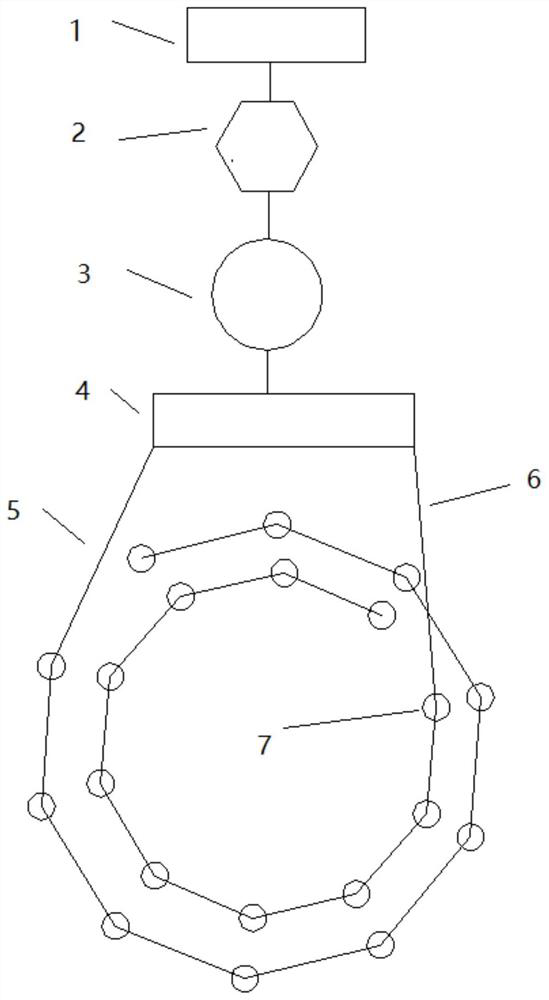

Fuel nozzle and header pipe combined sealing test device and method

PendingCN112964427AReduce oil supplyLower requirementDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringFuel oil

The invention belongs to an aero-engine fuel oil sealing test, and particularly relates to a fuel oil nozzle and header pipe combined sealing test device and a sealing test method. The fuel nozzle and header pipe combined sealing test device comprises an oil inlet pipe joint (1), a valve (2), a pressure gauge (3), a one-to-two adapter (4) and a nozzle cover (8). According to the fuel nozzle and header pipe combined sealing test device, a nozzle is sealed through the nozzle cover, so that the oil supply pressure required by a sealing test is reduced, the requirements on oil supply and oil return capabilities of a tester are reduced, the risk of detonation of atomized fuel oil is thoroughly avoided, and the device is safe and reliable. After the specified fuel pressure is reached, the valve is closed to maintain the pressure, the equipment can be closed to reduce the energy consumption, and whether the fuel leaks or not can be intuitively judged through the reading of the pressure gauge. According to needs, the test device can be placed in water to be heated so as to simulate the working temperature of the nozzle and the header pipe. Meanwhile, fuel is not discharged during the test, the pollution is less, a plurality of fuel nozzles and a header pipe can be simultaneously subjected to a combined sealing test, and the test efficiency is high.

Owner:HARBIN DONGAN ENGINE GRP

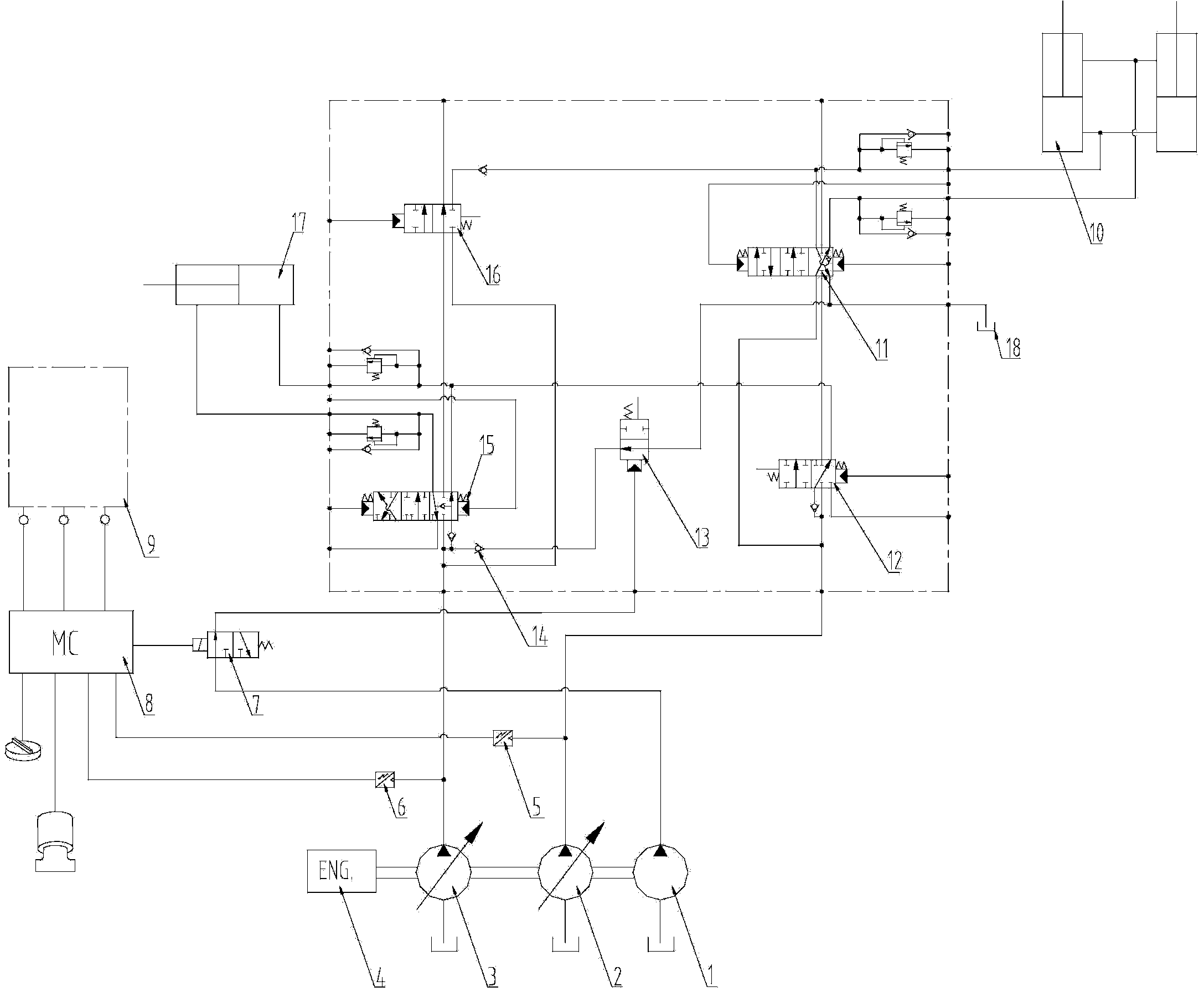

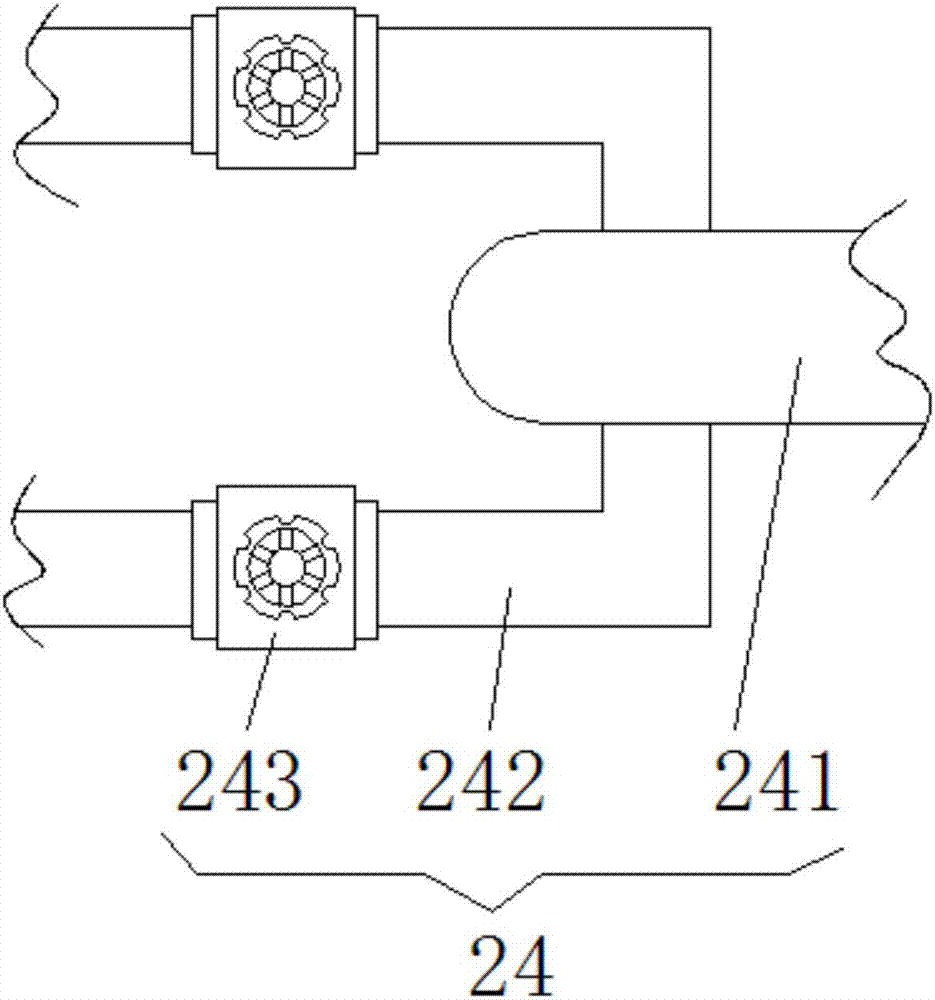

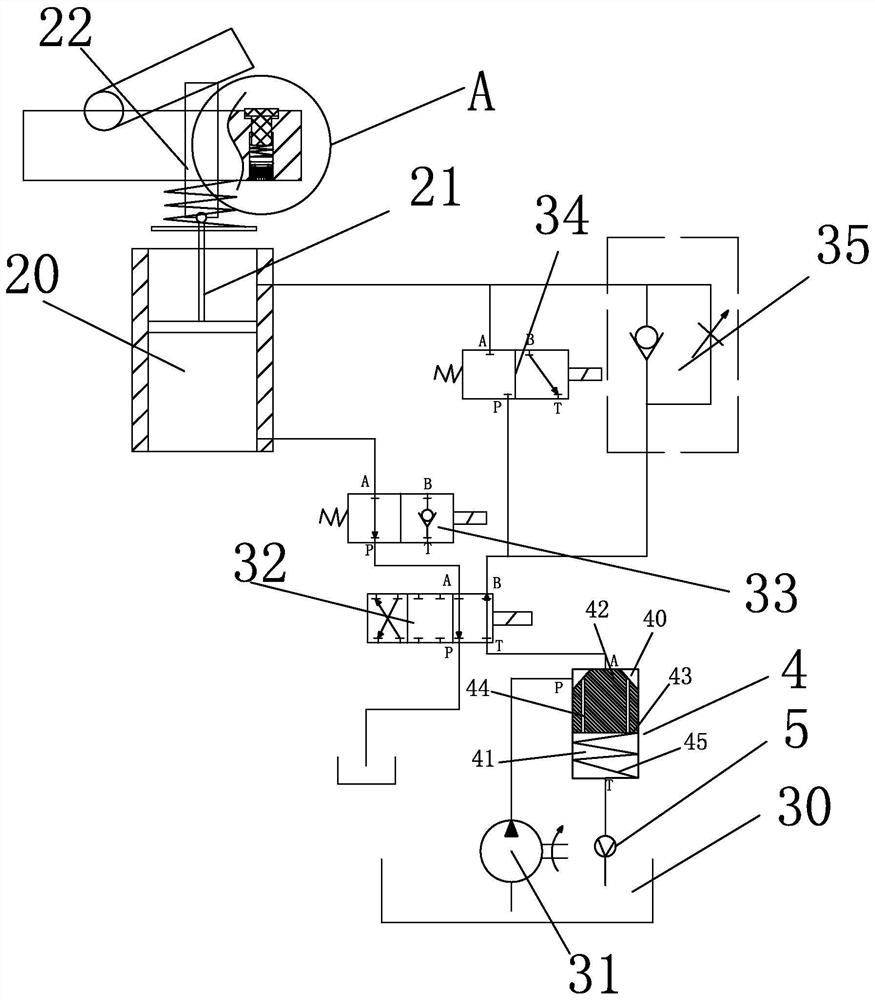

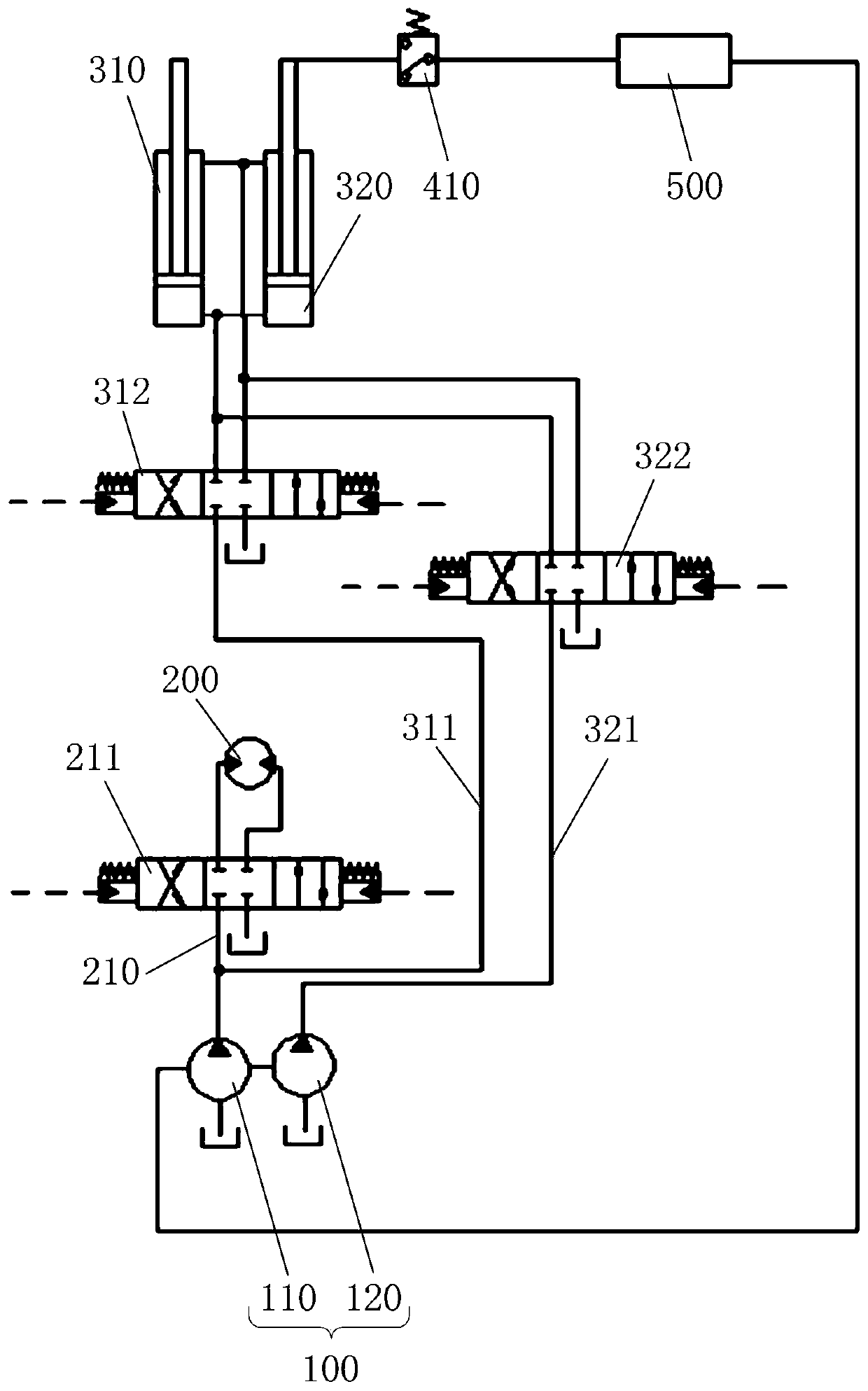

Excavator hydraulic system, excavator and excavator control method

ActiveCN111364536AMitigate uncoordinated technical issuesReduce oil supplyFluid-pressure actuator testingMechanical machines/dredgersControl engineeringControl theory

The invention provides an excavator hydraulic system, an excavator and an excavator control method, and relates to the technical field of engineering machinery. The excavator hydraulic system comprises an oil supply assembly, a rotary motor, a boom cylinder, a detection assembly and a controller, wherein the oil supply assembly communicates with the rotary motor and the boom cylinder respectively;the detection assembly is used for detecting whether a piston rod of the boom cylinder moves to the highest position or not and transmitting a detection signal to the controller; and the controller is used for controlling the oil supply amount of the oil supply assembly to the rotary motor according to the detection signal. According to the excavator hydraulic system, the technical problem that the compound actions of an excavator are not coordinated in the related art is solved.

Owner:SANY HEAVY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com