Parallel axes type automatic transmission

An automatic transmission, parallel shaft technology, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of insufficient miniaturization and increased friction of automatic transmission, and achieve the effect of preventing air from entering and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

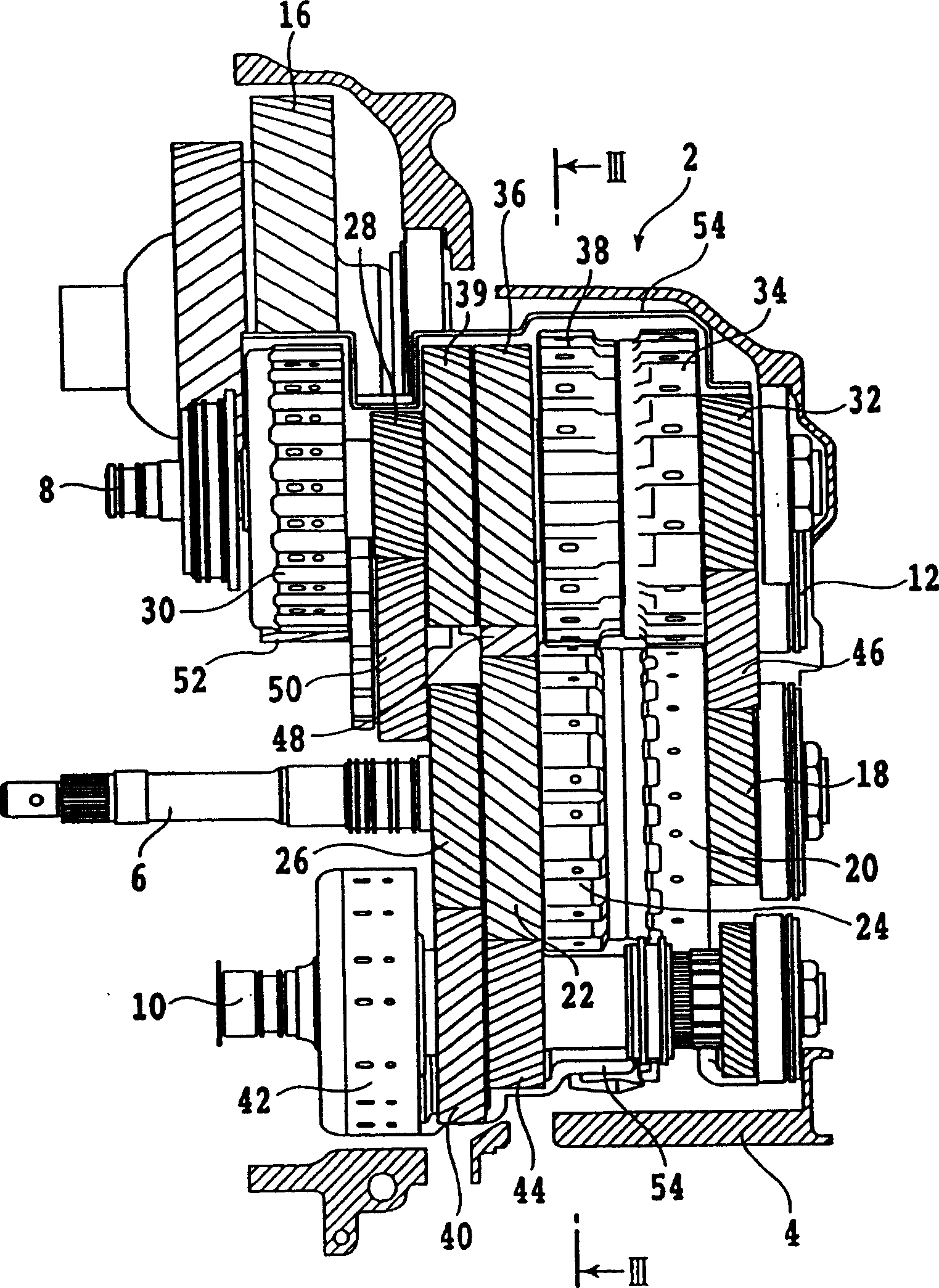

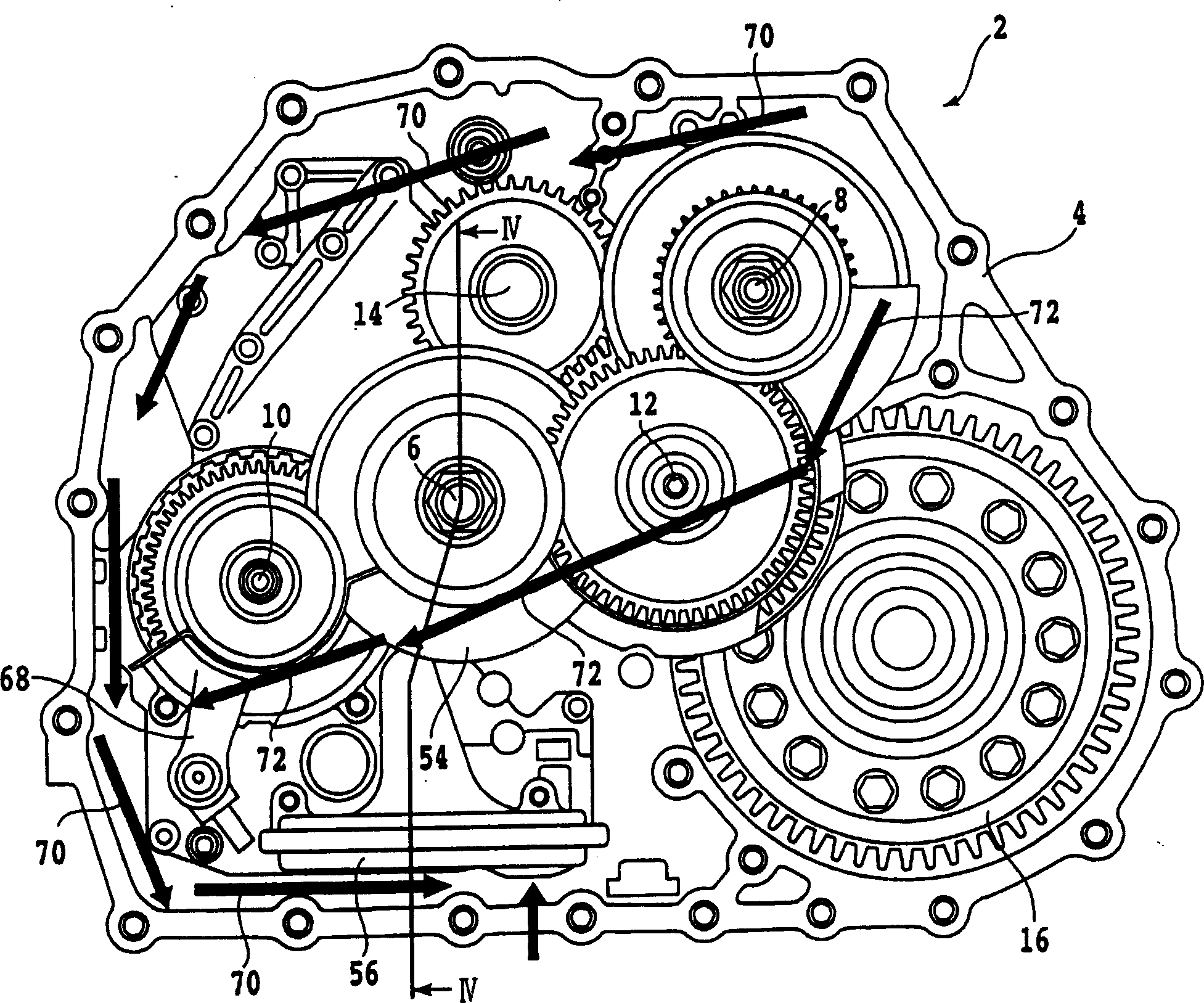

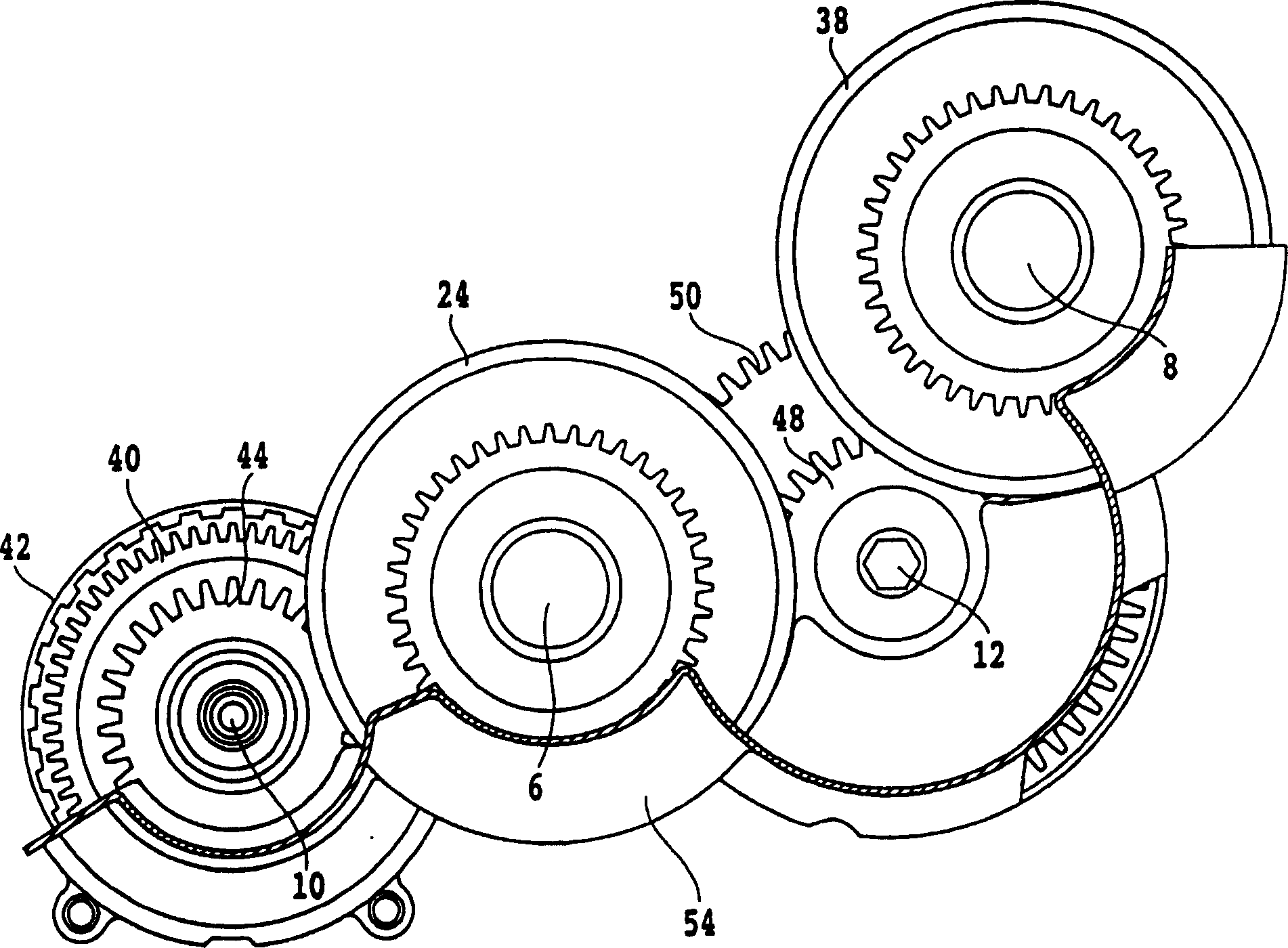

[0016] A parallel shaft automatic transmission according to an embodiment of the present invention will be described below with reference to the drawings. like figure 2 As clearly shown in the side view, the parallel shaft automatic transmission 2 has a first input shaft 6, a second input shaft 8, a third input shaft 10, an output shaft 12, and an idle shaft arranged parallel to each other in the transmission housing 4. Shaft 14.16 is the final reduction driven gear.

[0017] like Figure 4 As shown, the power of an engine (not shown) as a power source is input to the first input shaft 6 through a torque converter 62 connected to a crankshaft 60 of the engine. And, if figure 1 and Figure 4 As shown, a wet multi-disc clutch 20 for 3rd gear and a wet multi-disc clutch 24 for 6th gear as the highest gear are installed on the first input shaft 6, and a 3-disc clutch connected to the wet multi-disc clutch 20 is supported on the shaft. The first gear drive gear 18 and the six...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com