Oil-return-free common-rail oil sprayer

A common rail fuel injector and fuel injector technology, which is applied in the directions of machines/engines, fuel injection devices, engine components, etc., can solve the problem of high maintenance cost of valve components, achieve simple structure, save user costs, and reduce failure rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

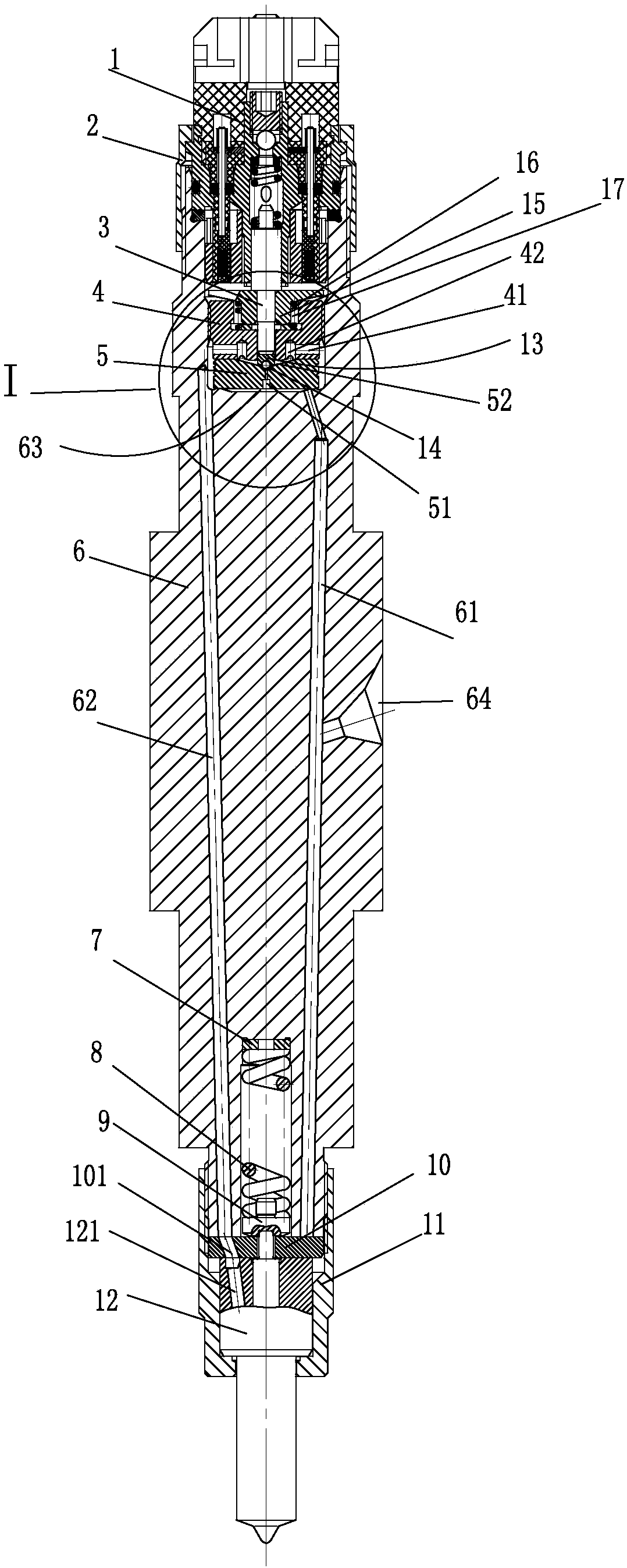

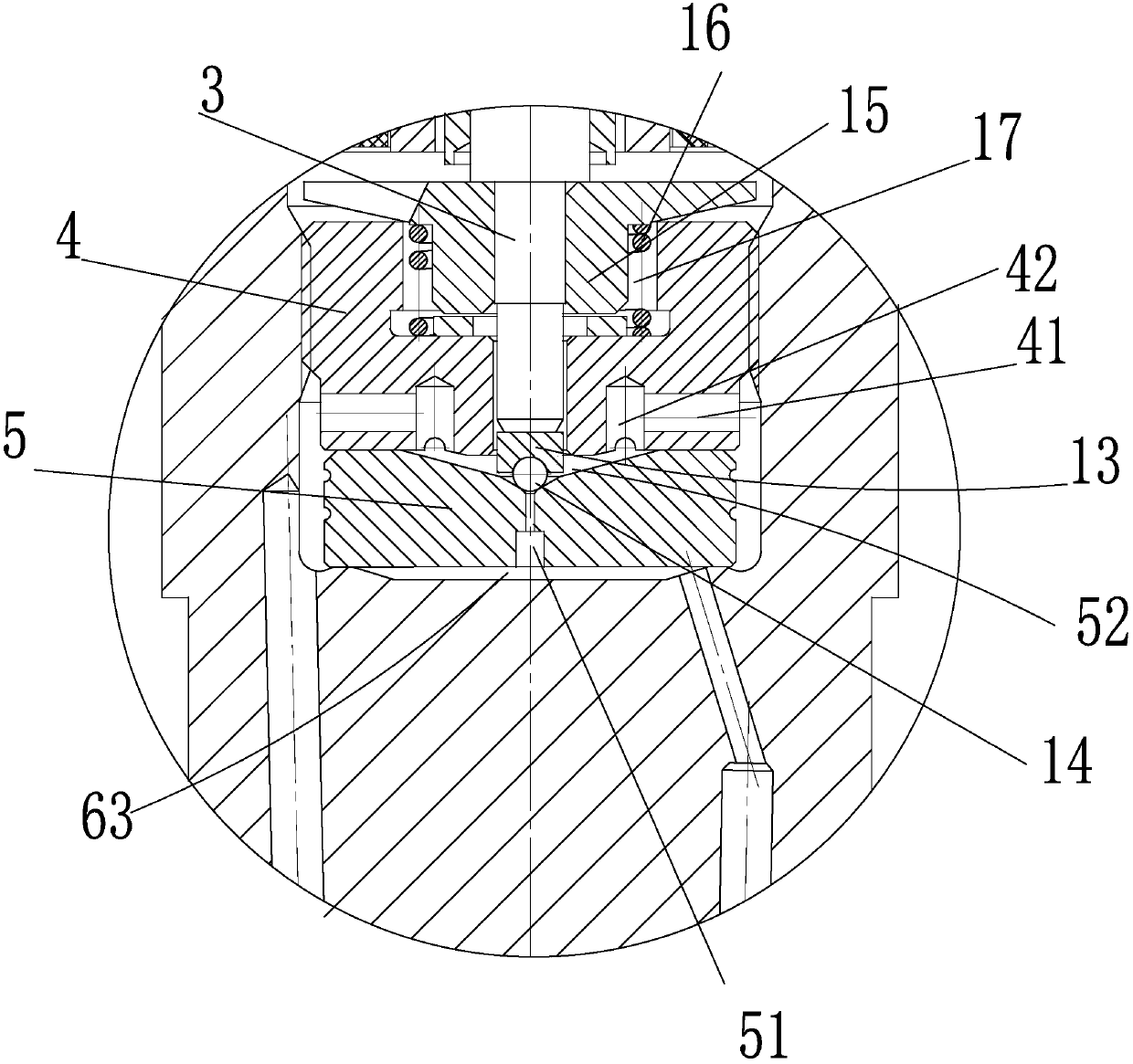

[0020] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0021] combine figure 1 , figure 2 , the present invention relates to a common rail fuel injector without valve assembly and oil return, comprising a solenoid valve component 1, a fuel injector body 6, a solenoid valve tight cap 2, a control valve coupler 3, a tight seat 4, a flow control Plate 5, pressure regulating gasket 7, pressure regulating spring 8, spring seat 9, middle block 10, fuel injector coupler 12, tight cap 11. The solenoid valve part 1 is set on the upper end of the injector body 6, and is fastened to the injector body 6 through the solenoid valve tight cap 2; The upper groove, the pressure regulating gasket 7, the pressure regulating spring 8 and the spring seat 9 are set in the lower groove of the lower end of the injector body 6, the upper end surface of the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com