Oil feeding propeller of scroll compressor

A scroll compressor and thruster technology, applied in the field of scroll compressors, can solve problems such as damage to the compression part, oil supply, failure to lift oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

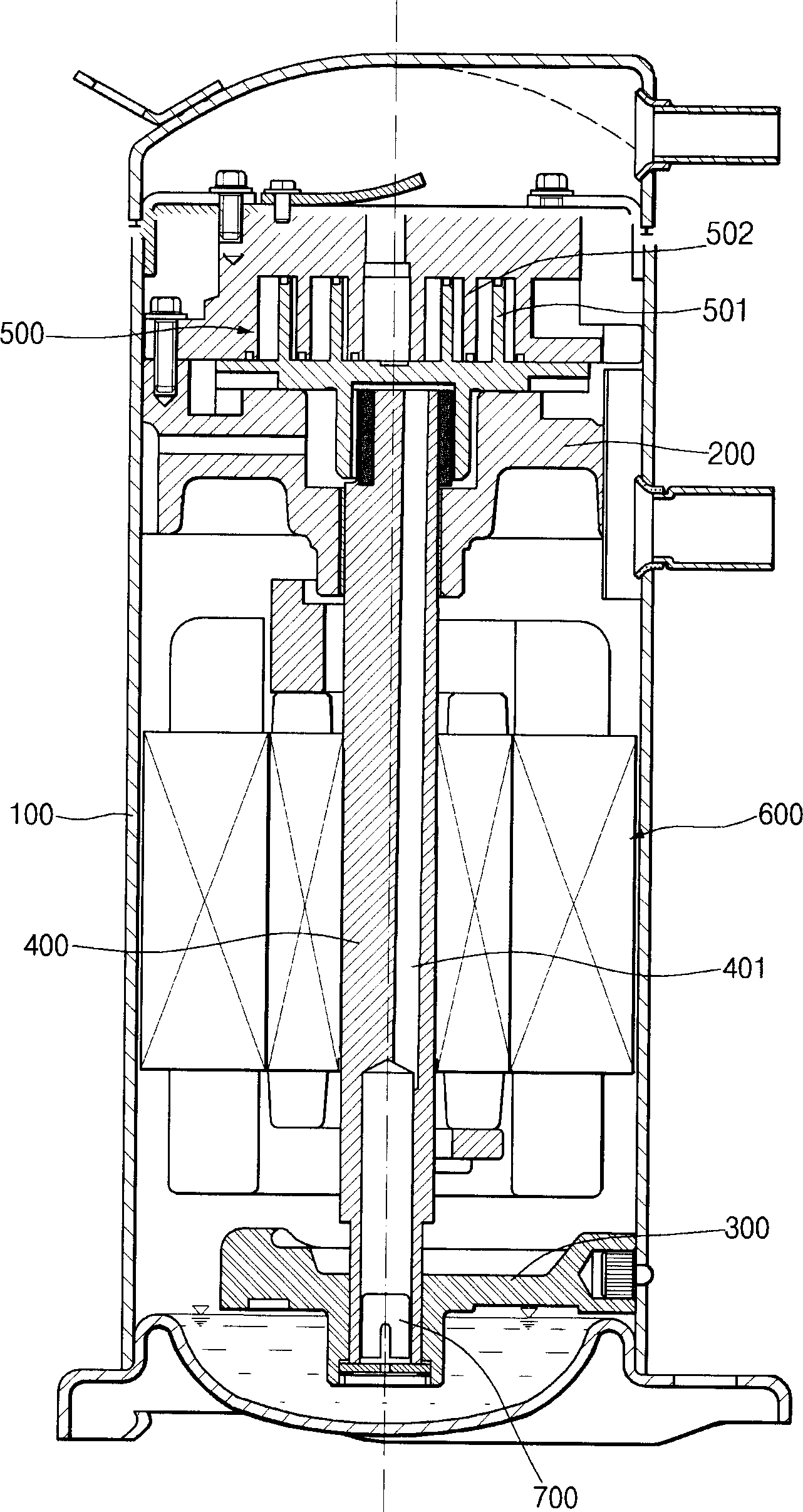

[0054] Hereinafter, an oil-feeding propeller of a scroll compressor according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

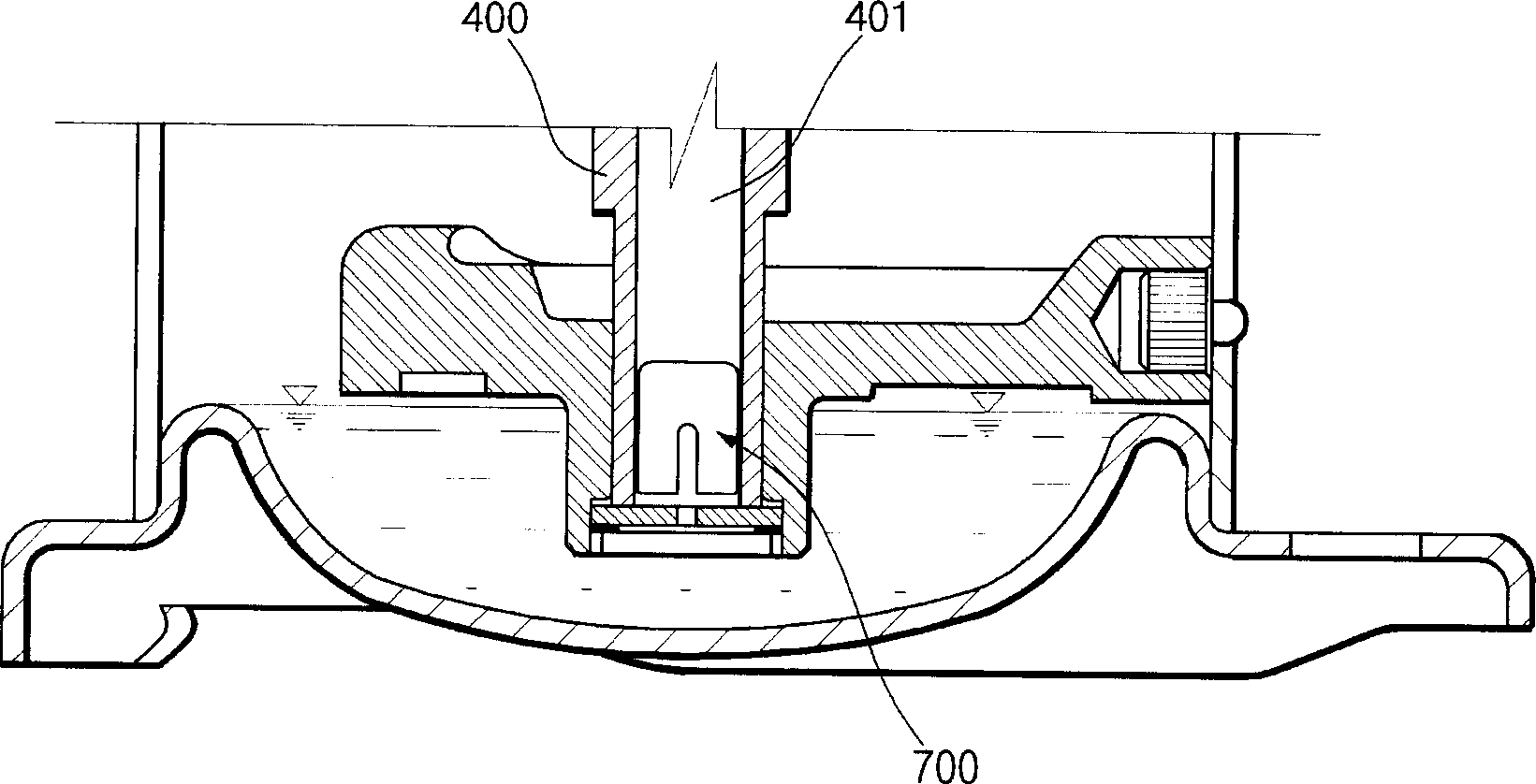

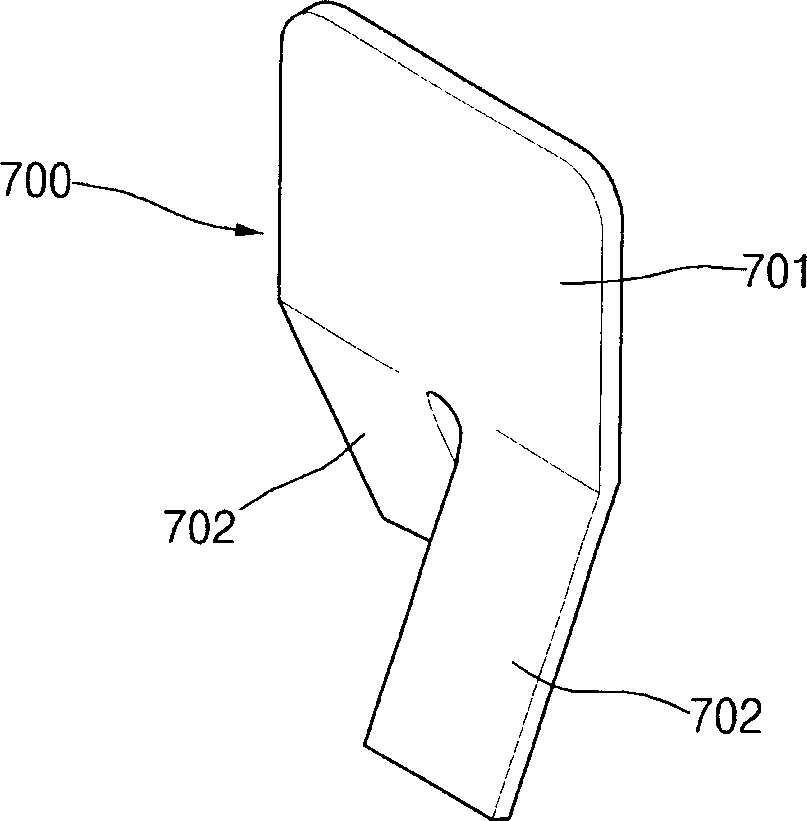

[0055] Figure 4 This is an enlarged cross-sectional view of a scroll compressor employing an oil-supplied thruster according to a first preferred embodiment of the present invention. Figure 5 It is a perspective view of the oil-supplied thruster of the scroll compressor according to the first preferred embodiment of the present invention.

[0056] like Figure 4 and Figure 5 As shown, the oil supply propeller 1 of the scroll compressor according to the first preferred embodiment of the present invention is tightly fitted on the lower side of the oil passage 3 formed in the rotating shaft 2 in the axial direction. And when the rotating shaft 2 rotates, the oil supply propeller 1 absorbs the oil stored in the casing 4 and lifts it to the compression part through the oil pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com