Hydraulic cylinder with variable sections, hydraulic control system and control method of hydraulic cylinder

A hydraulic control system and hydraulic cylinder technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of low hydraulic power system efficiency, valve port pressure loss, and inability to change, and achieve the effect of improving hydraulic system efficiency and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present patent will be described in further detail below with reference to the accompanying drawings.

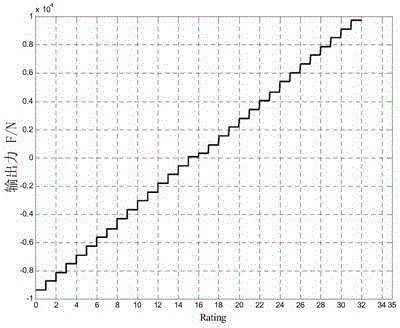

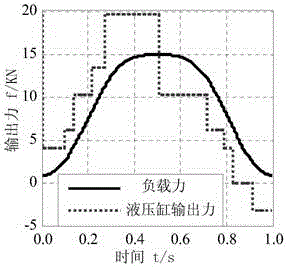

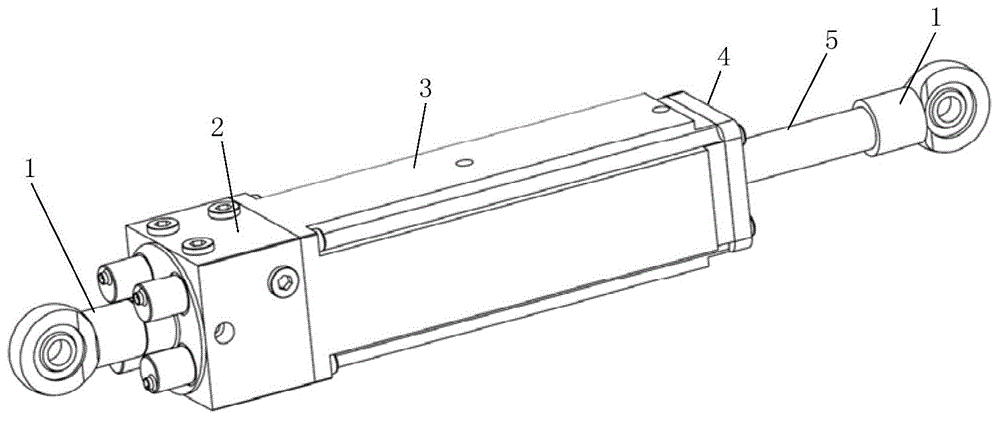

[0025] As shown in Figure 1 to Figure 4 As shown, the variable cross-section hydraulic cylinder is composed of two ends connecting earrings 1, left end cover 2, cylinder barrel 3, right end cover 4, piston rod 5, etc. The left end cover 2 is composed of an integrated block 21 and four two The three-way cartridge valve 22 (including four two-position three-way cartridge valves in this example) and the plug 23 are composed. The left end cover 2 is connected with the cylinder barrel 31 by screws 24, and an O-ring 32 is used to To achieve the sealing between the left end cover 2 and the cylinder barrel 3, in addition to the installation holes and oil inlet and outlet holes required for the two-position three-way cartridge valve 22, the integrated block 21 is also machined with four plunger cavities including the first The plunger cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com