Patents

Literature

30results about How to "Increase effective pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

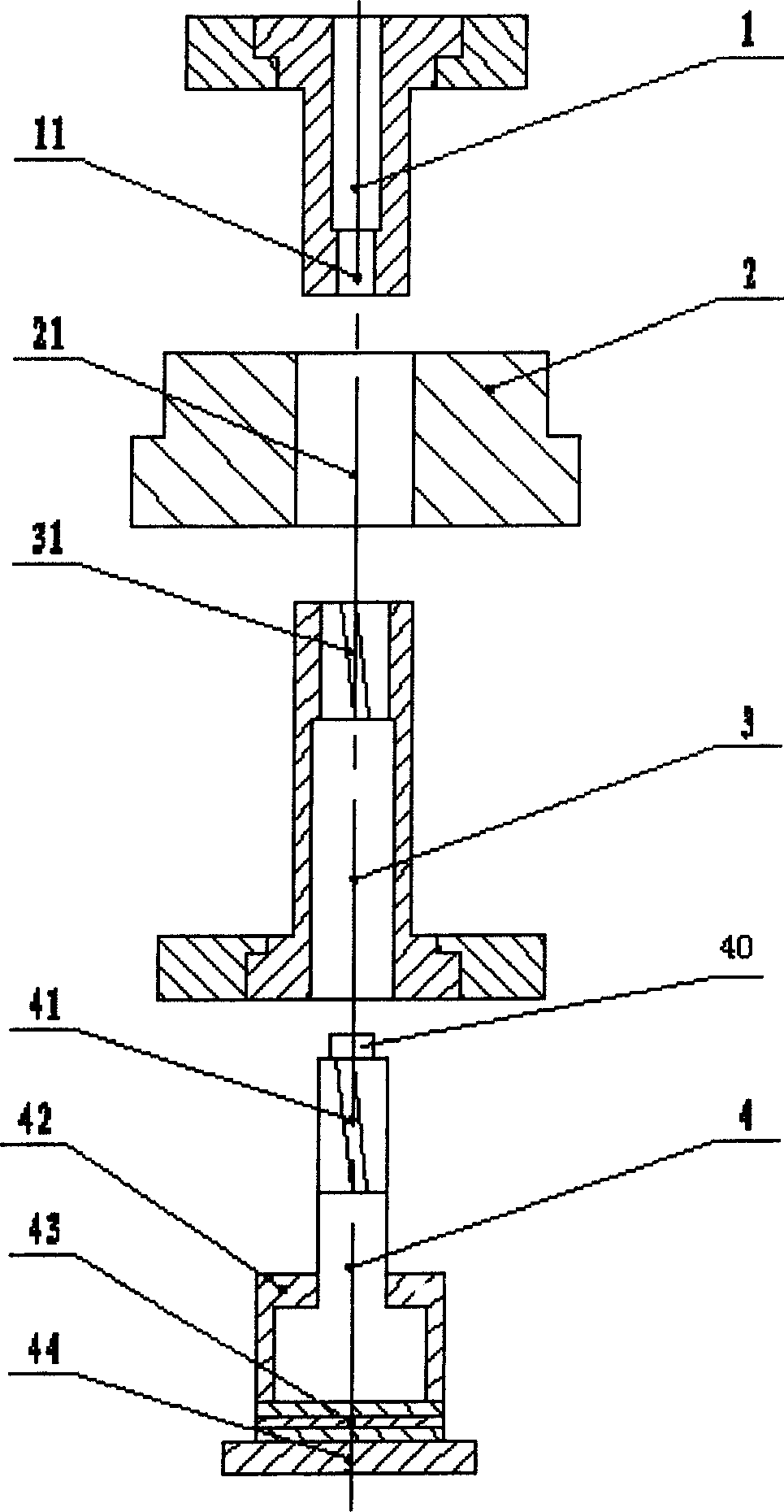

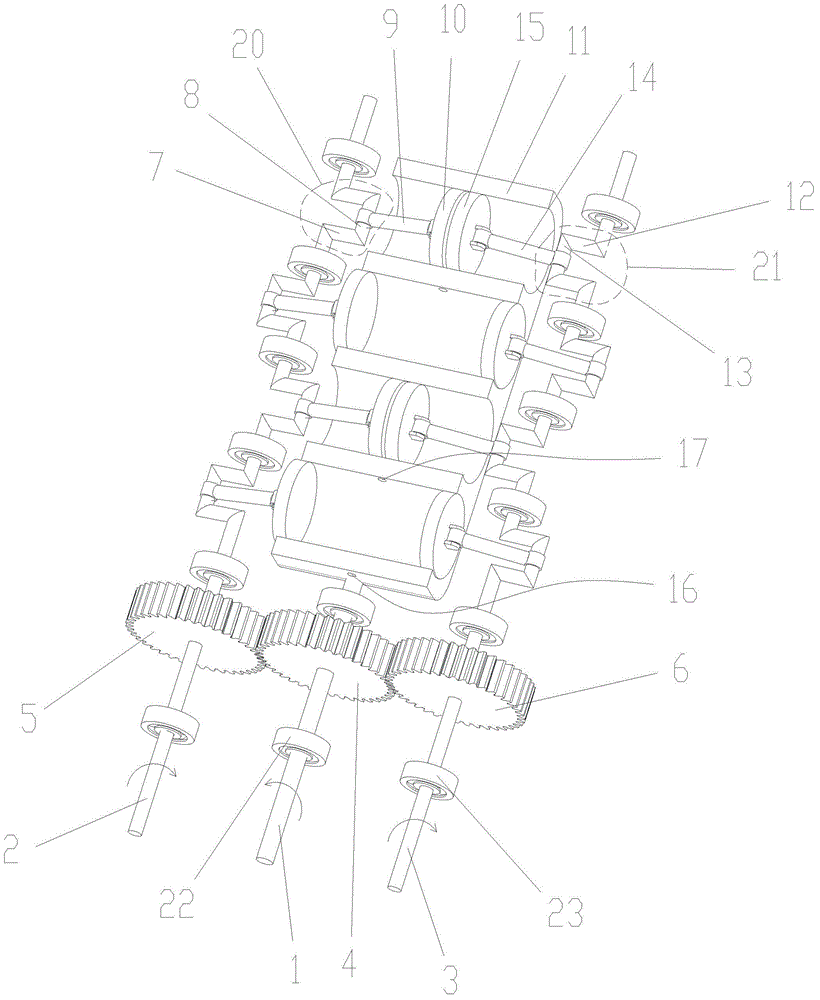

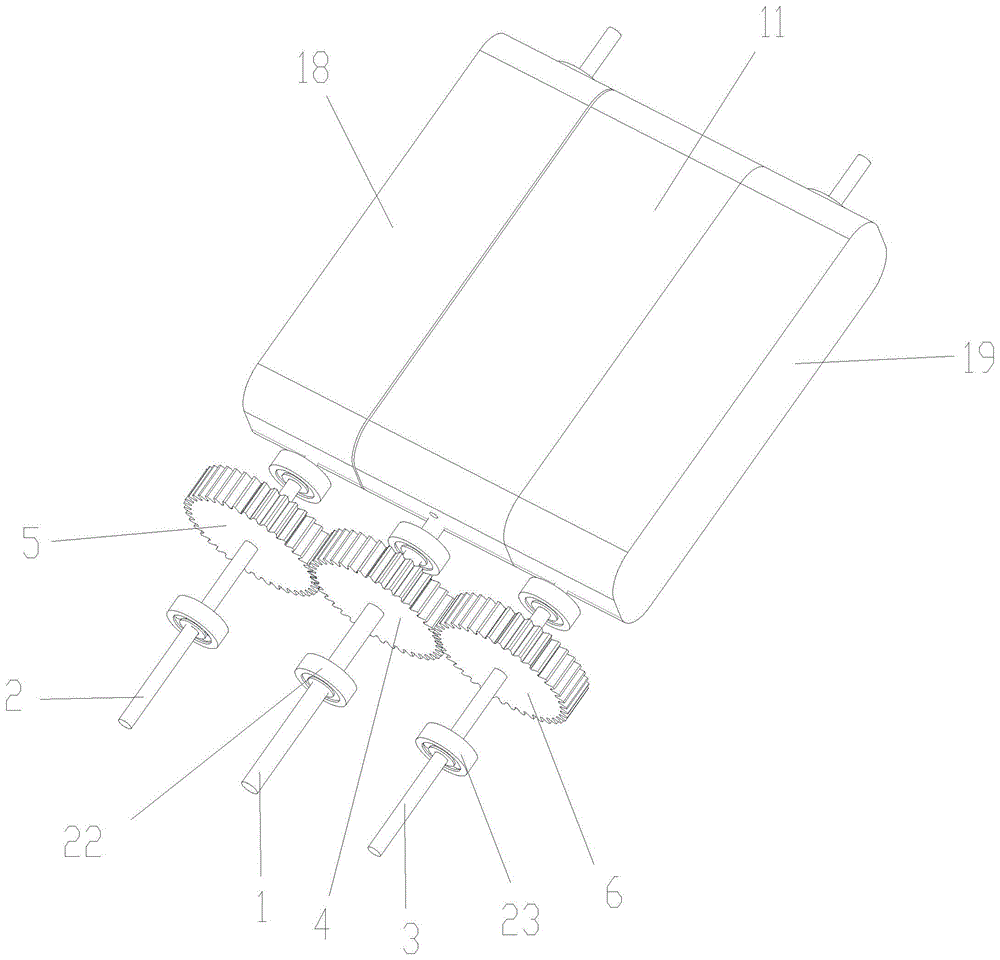

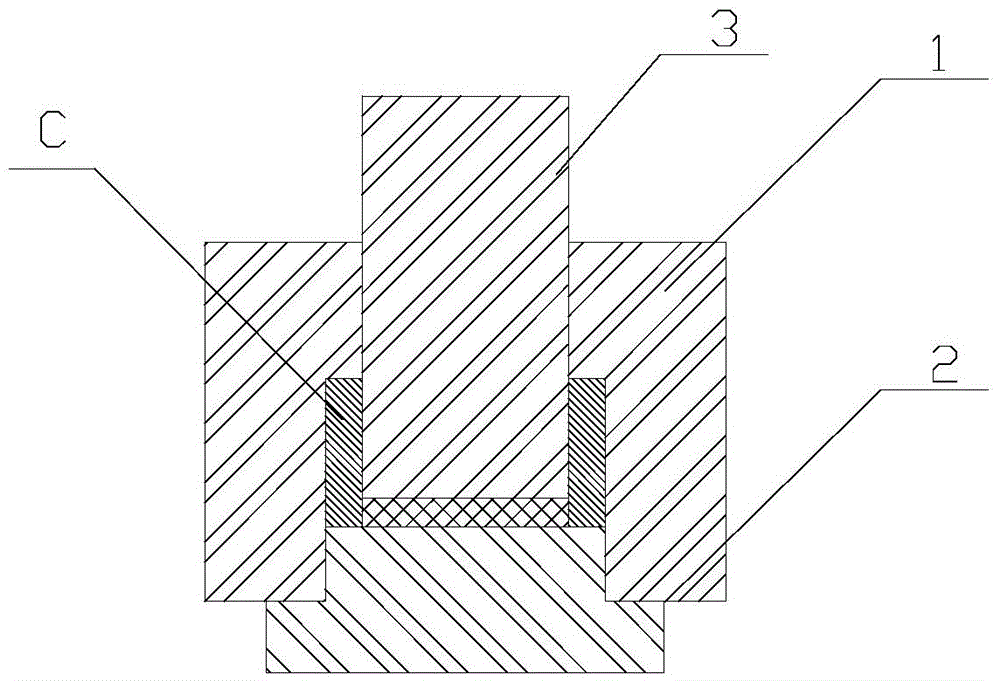

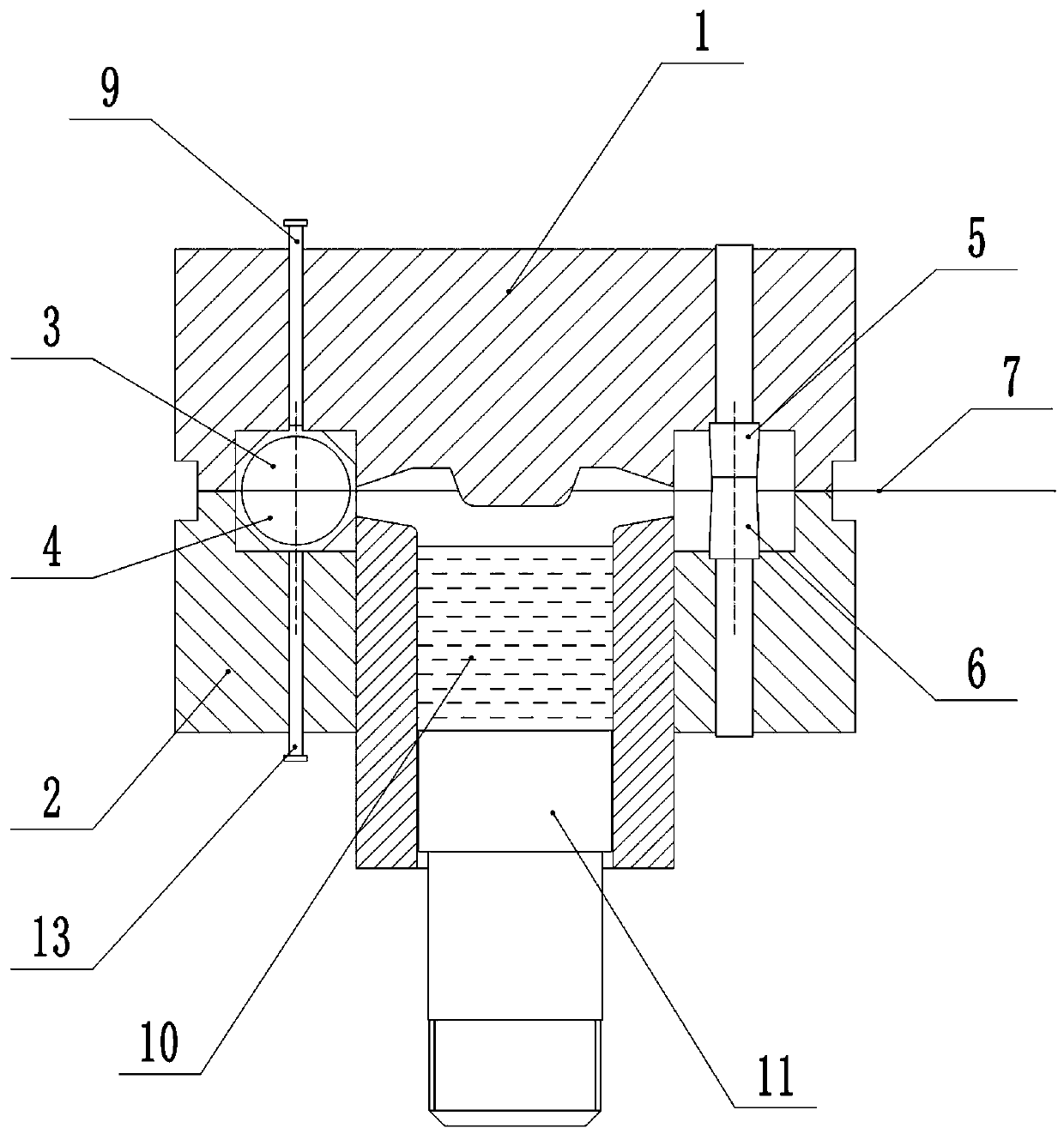

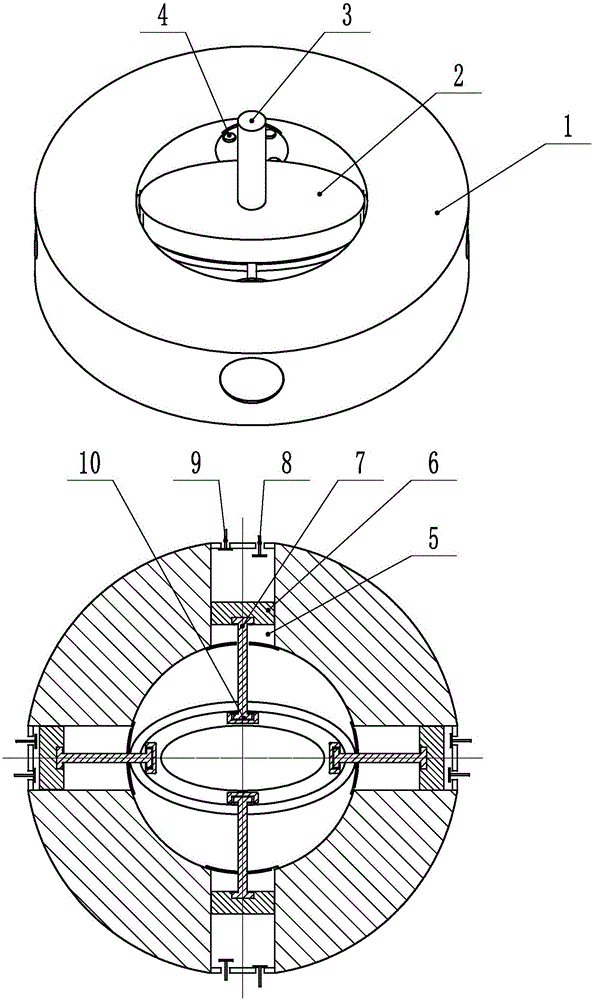

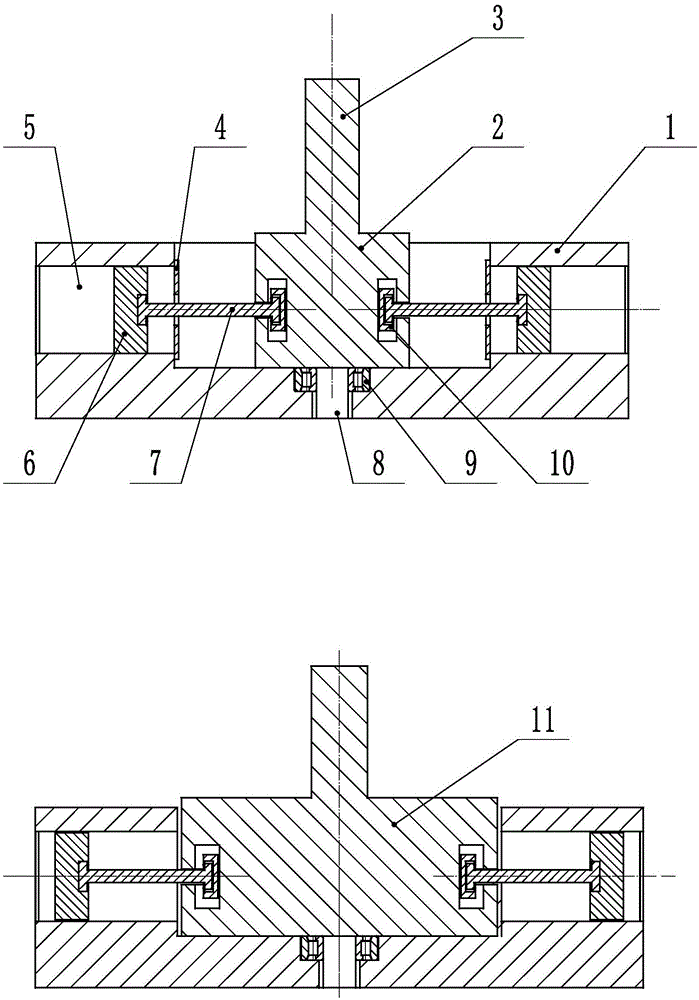

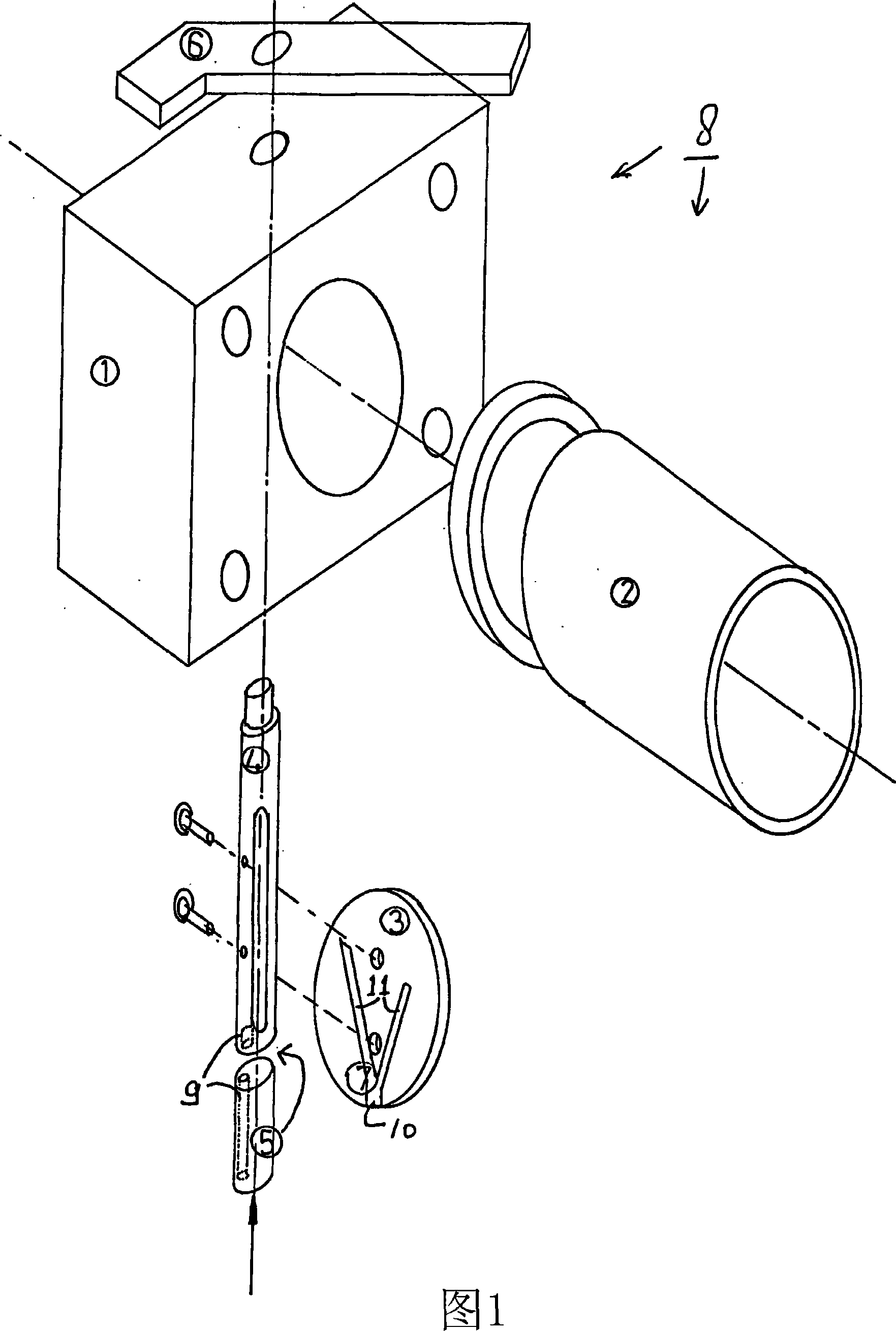

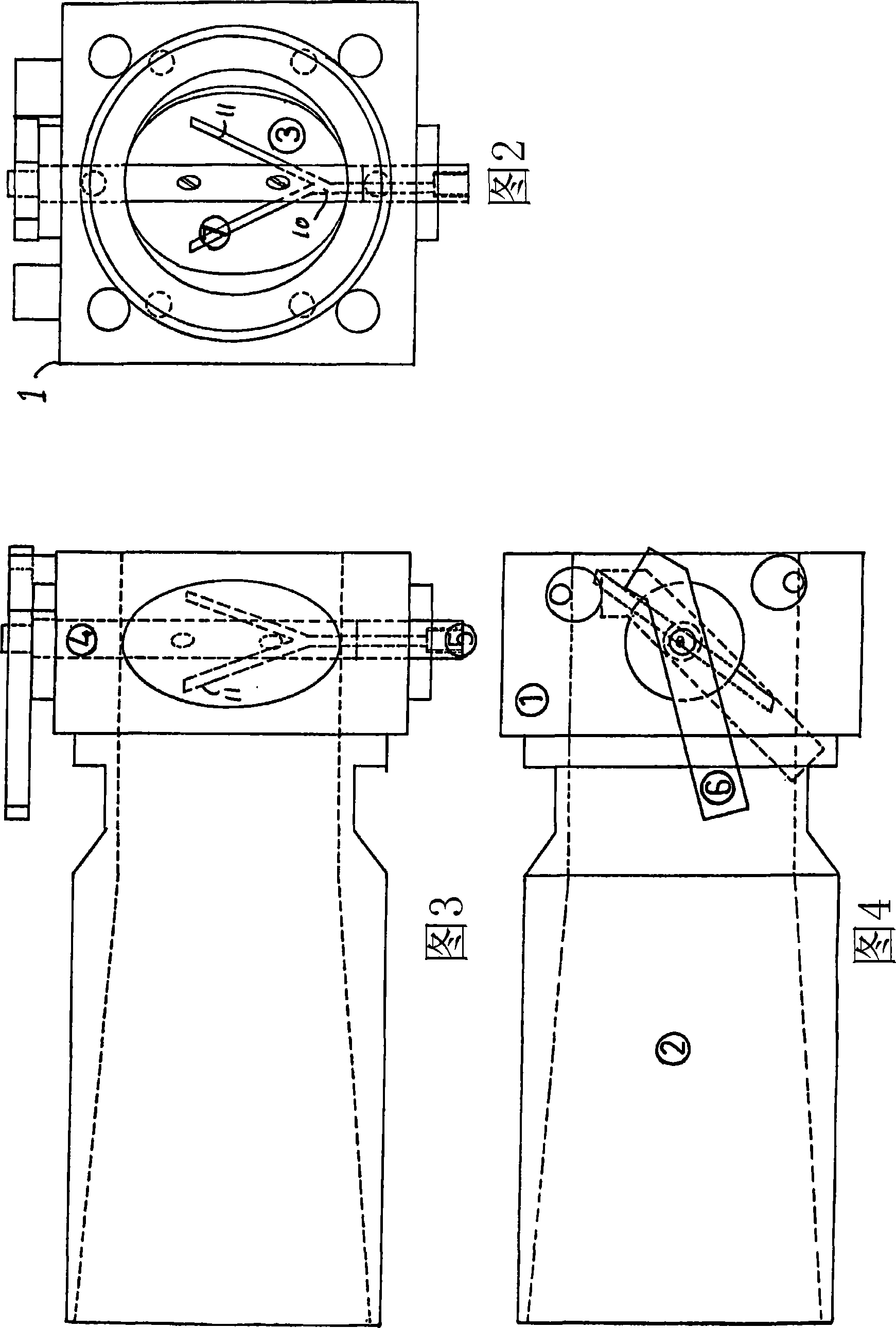

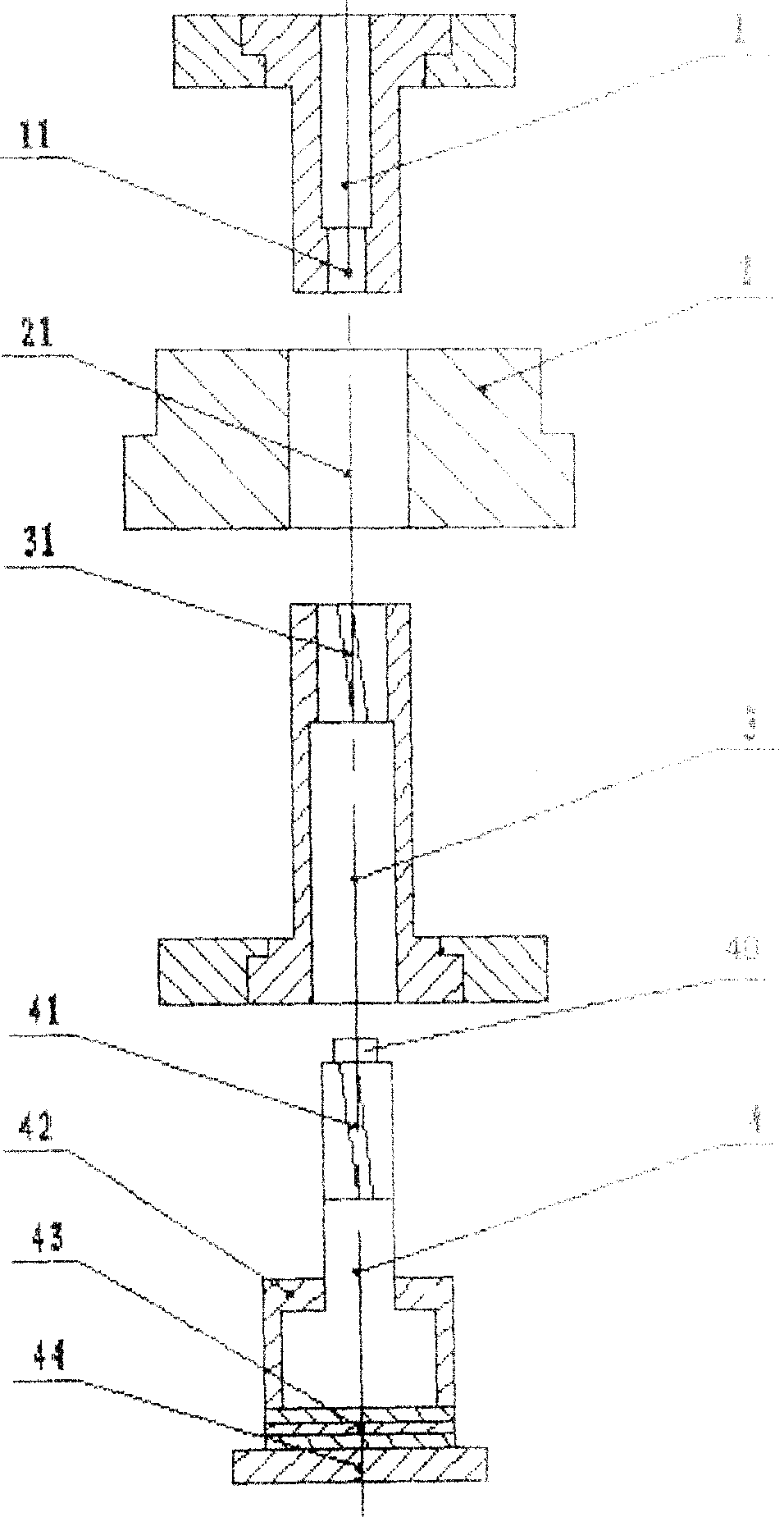

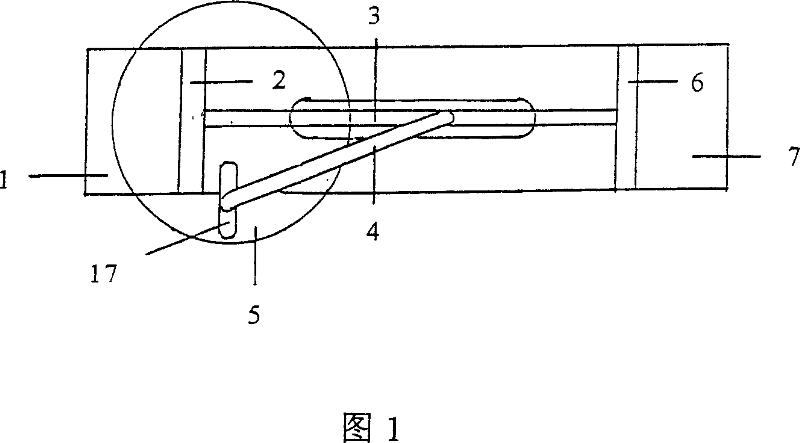

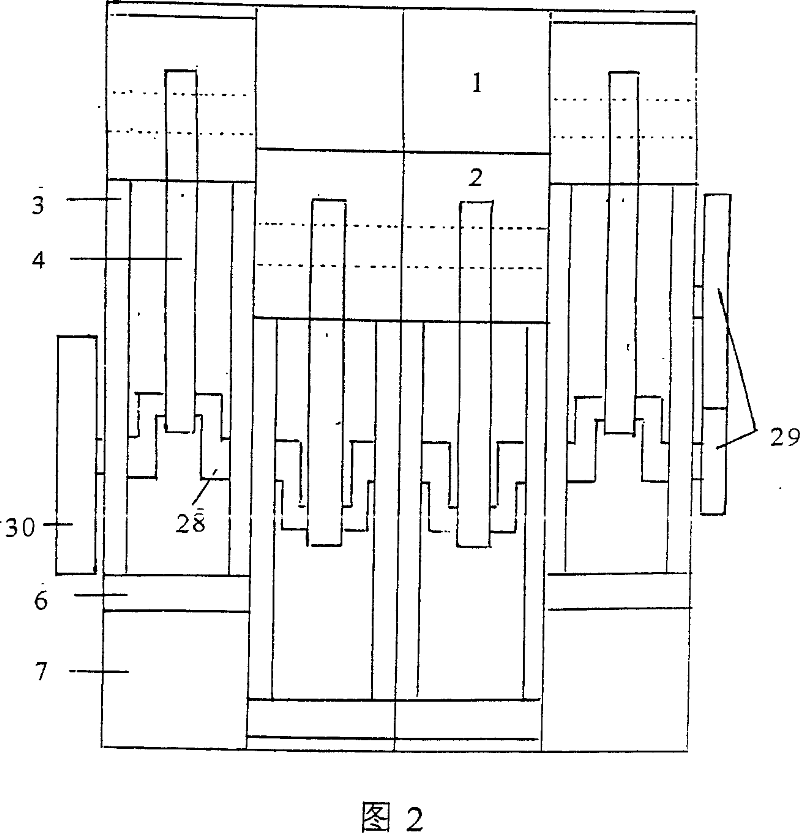

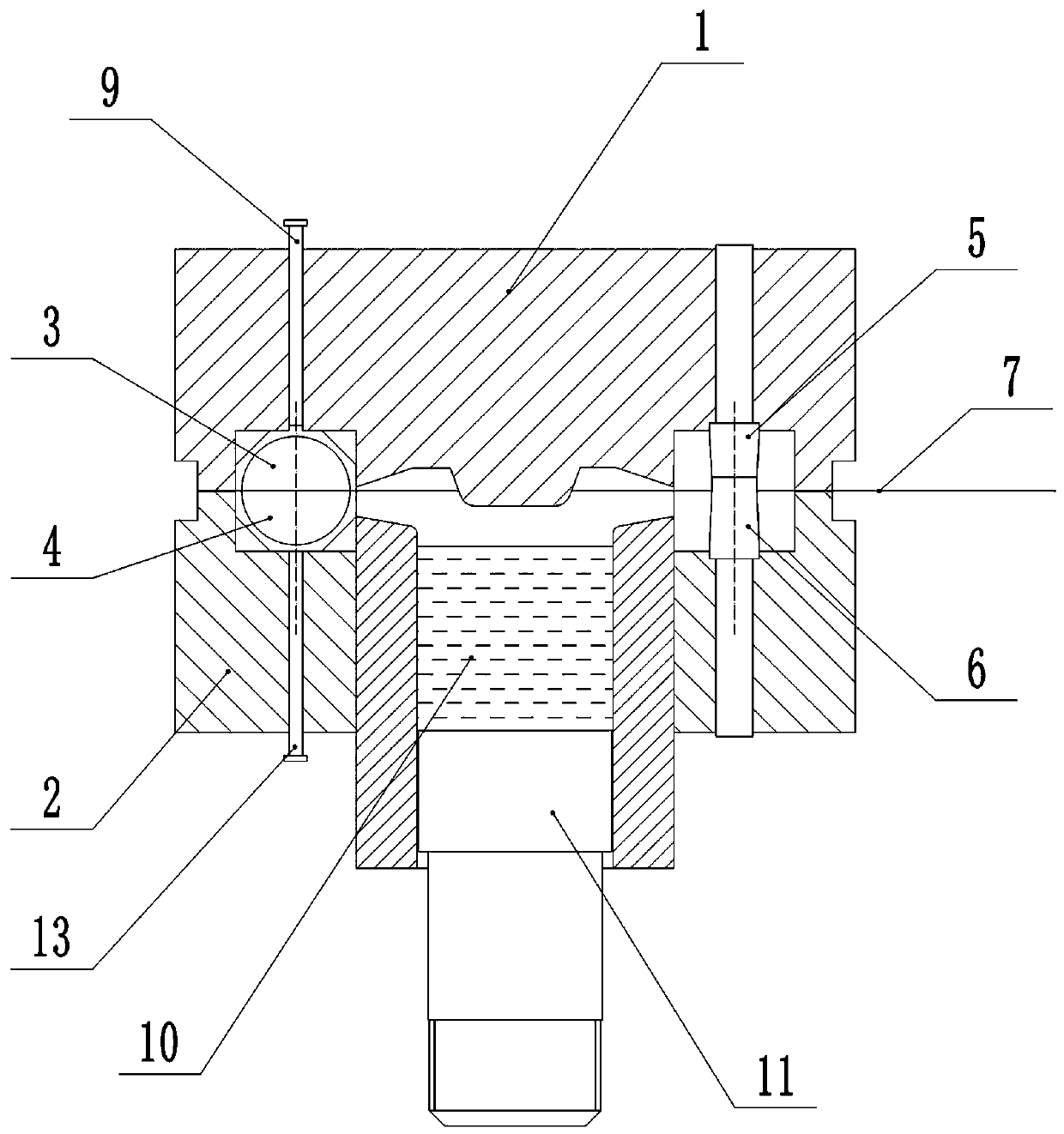

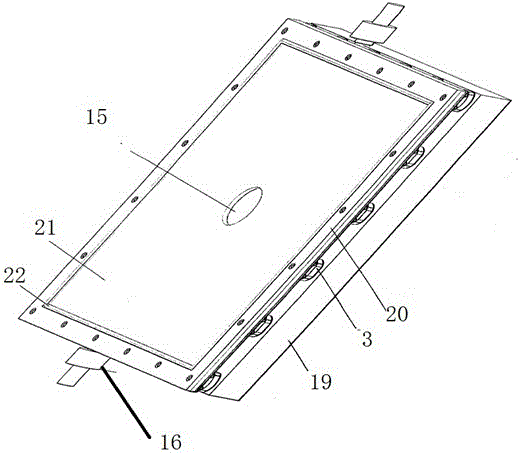

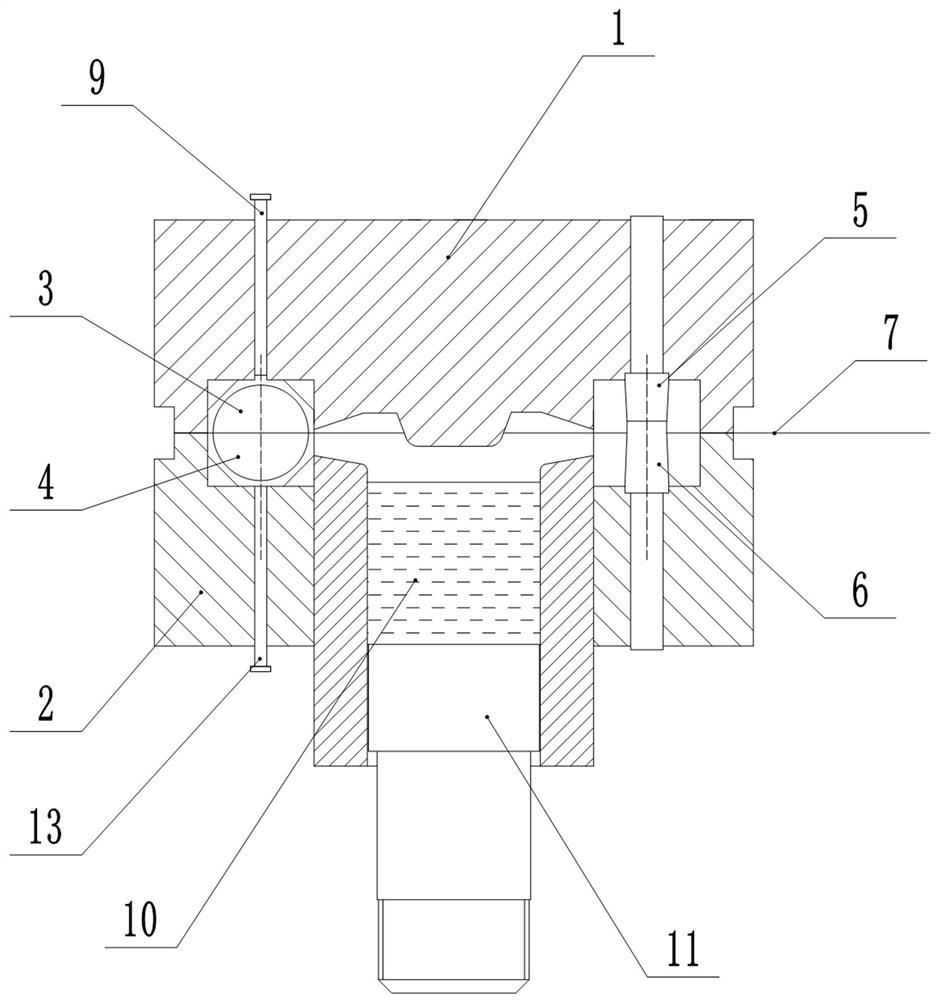

Manufacture method and die for powder metallurgy inside spin ratchet wheel

The invention relates to a method for producing powder smelt screw ratchet, which comprises: mixing the materials, compressing molding, sintering, compressing and shaping, to obtain the ratchet. The invention also discloses a relative mould, which is formed by a compressing upper punch, compressing middle mould, compressing lower punch; the upper part of lower punch has the inner screw tooth matched with the outer screw tooth; the upper punch is sliding matched with the middle mould; the middle mould is sliding matched with the lower mould; the compressing core rod has compressing core rod, friction plate, and rotation element; the upper part of compressing core rod has outer screw tooth; the lower end of core rod and the upper end of rotating element have friction plate between them, while their contact surface has lubricant. The invention, via the rotation of core rod, realizes the one-time molding and demoulding of inner screw ratchet, to improve the yield and reduce the cost.

Owner:南通市海门常乐粉末冶金厂

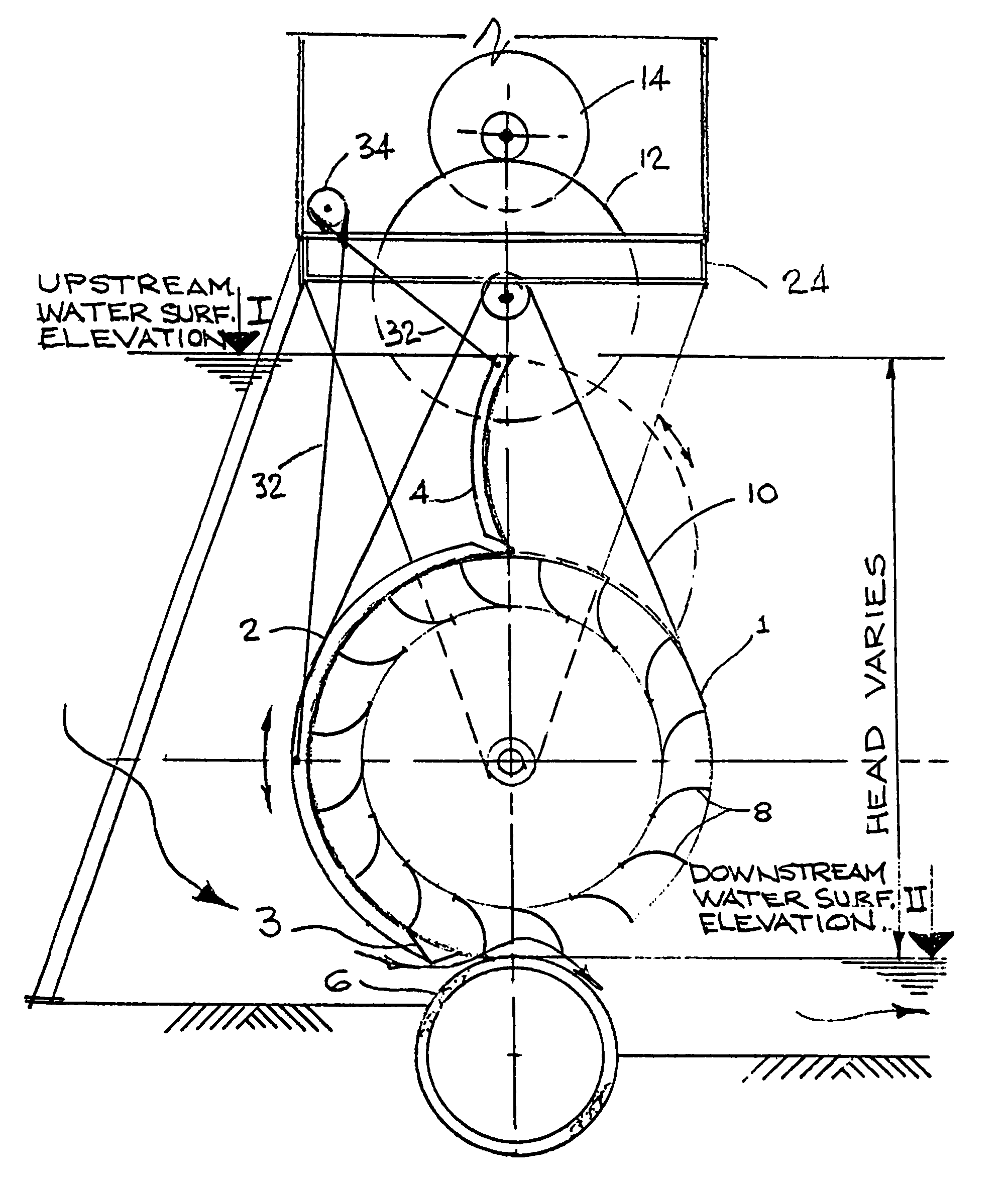

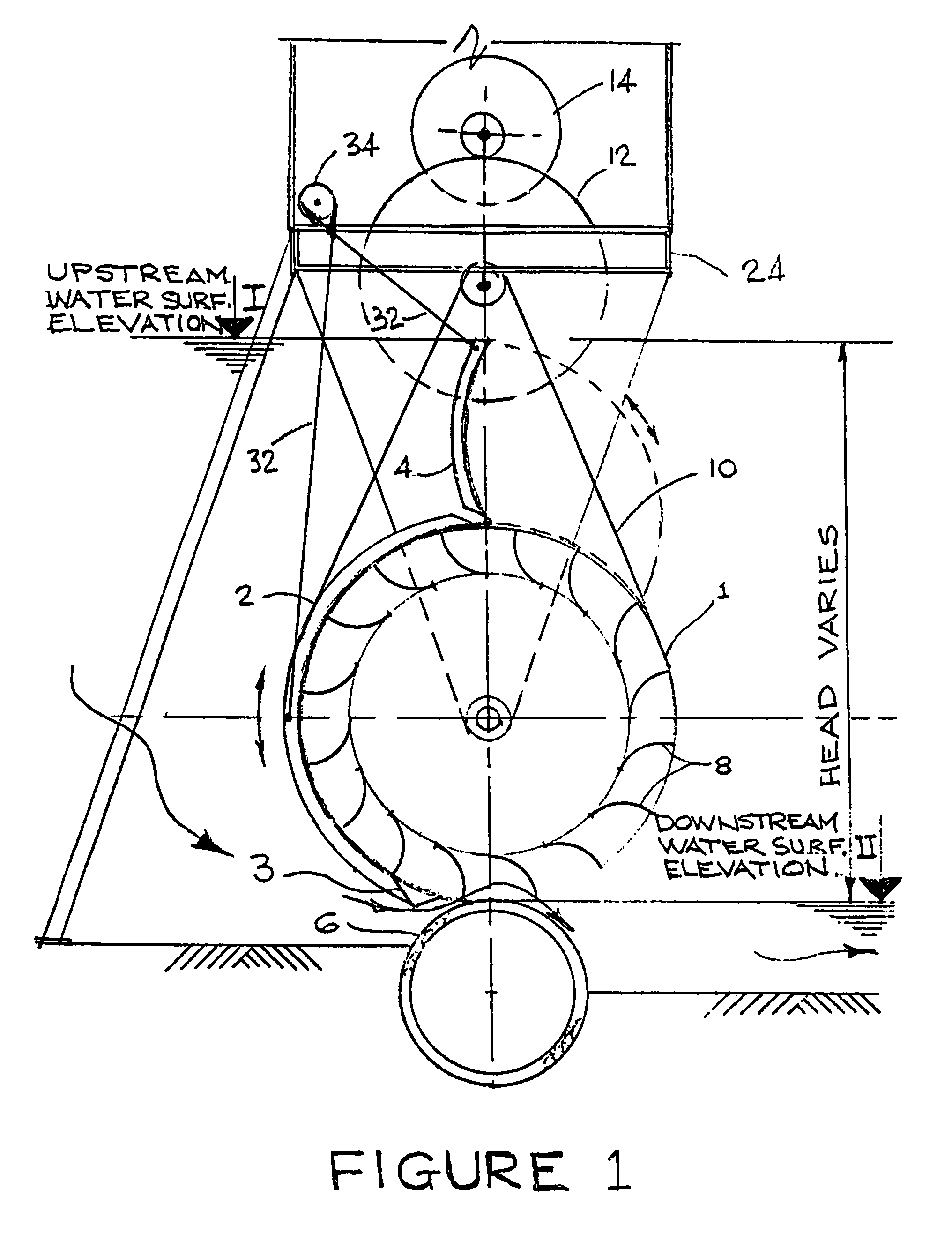

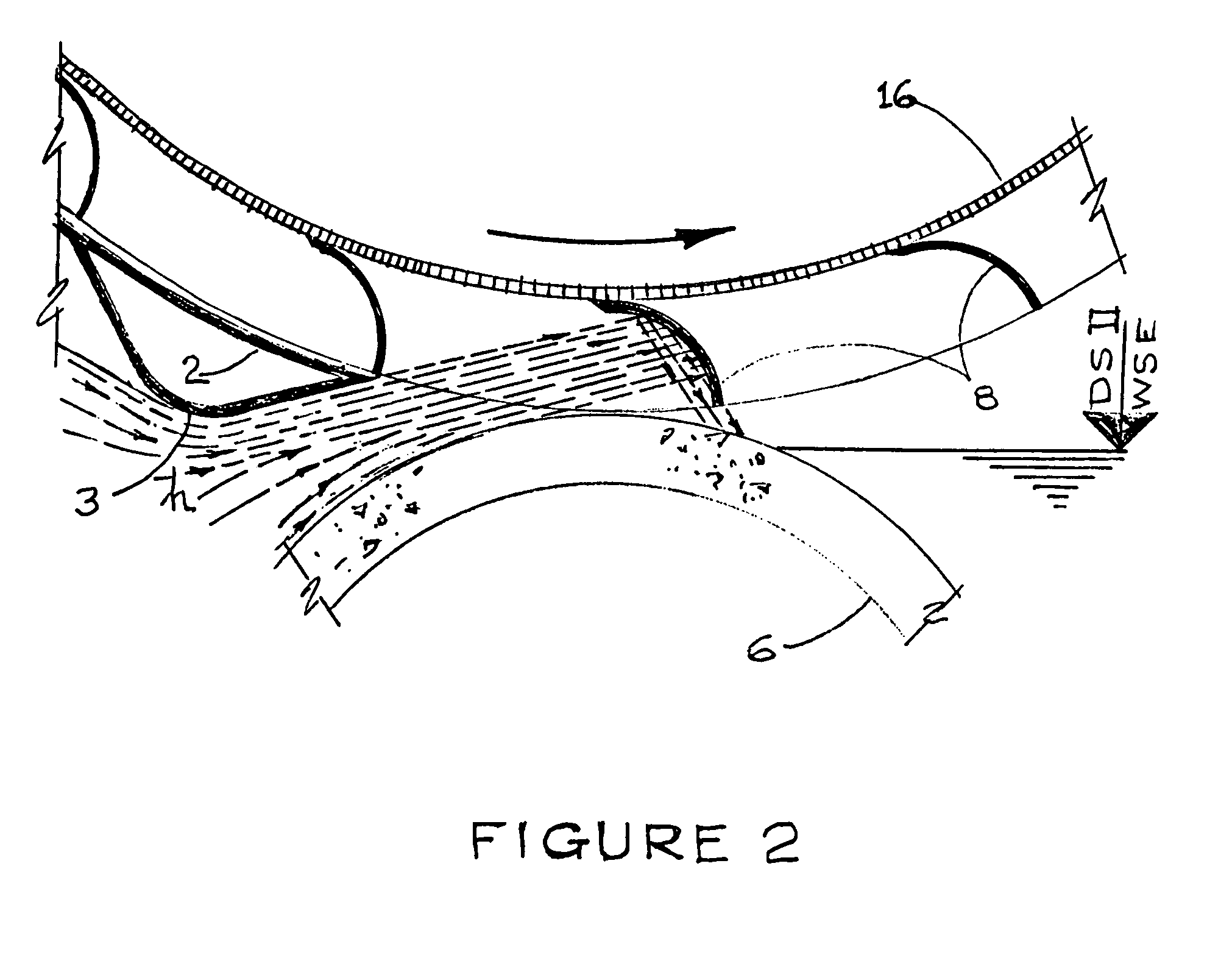

Undershot impulse jet driven waterwheel having an automatically adjustable radial gate for optimal hydroelectric power generation and water level control

InactiveUS7503744B1Maintain water levelRaise transfer toWind motor controlPump componentsDrop structureEngineering

A low-head impulse jet waterwheel for power generation at irrigation canal drop structures and navigation dam spillways achieves renewable electric power generation that has been lost until now due to lack of suitable equipment to convert such energy at competitive cost. Conventional practice has limited use of impulse turbines to heads of more than 50 meters or about 150 feet. However, there is now no need for such a limitation. Kinetic energy of a low-pressure jet is employed in a way that enables numerous locations to generate electricity conveniently near points of use, from a renewable source at minimum cost. The equipment can be pre-assembled for minimum installation cost at sites with no existing impoundment and can be automatically raised clear of flood levels with built-in lifting equipment. Existing multi-span bridges offer convenient access for installation and maintenance. Raising the equipment also provides clear passage for fish migration.

Owner:BROOME FAMILY TRUST DATED DEC 8 2003 KR BROOME TRUSTEE

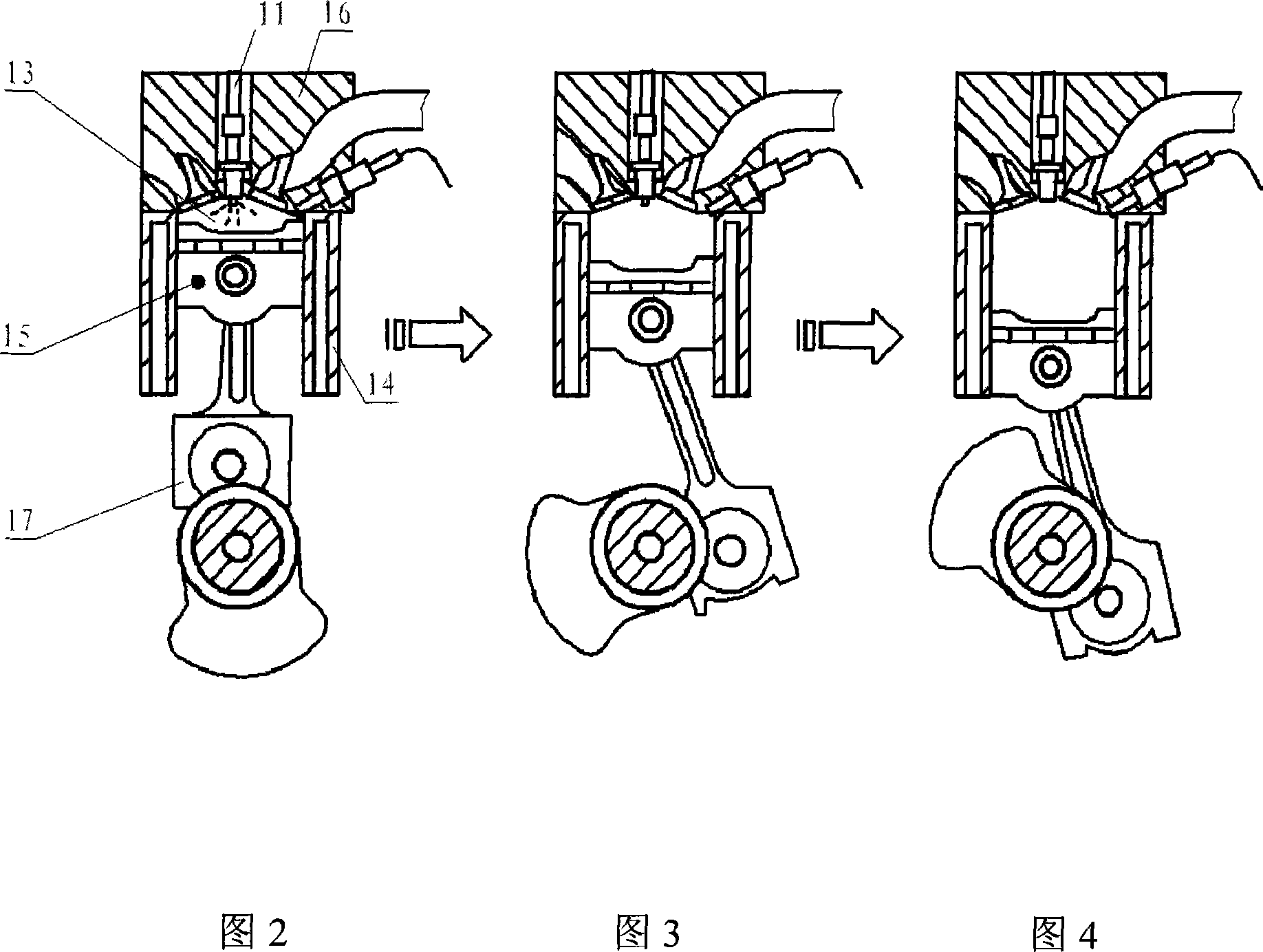

Two-in-one cylinder horizontally-opposed double-crankshaft engine

The invention relates to a two-in-one cylinder horizontally-opposed double-crankshaft engine. The engine comprises an engine spindle, and a first crankshaft spindle and a second crankshaft spindle are symmetrically connected to the two sides of the spindle respectively. The spindle, the first crankshaft spindle and the second crankshaft spindle are sleeved with a spindle gear, a first crankshaft gear and a second crankshaft gear respectively, wherein the spindle gear, the first crankshaft gear and the second crankshaft gear are meshed with one another. The first crankshaft spindle drives first pistons through first crankshaft sets and first connecting rods, and the second crankshaft spindle drives second pistons through second crankshaft sets and second connecting rods. The first pistons and the second pistons are arranged on the two sides of each air cylinder sleeve. Air intake and exhaust systems and oil injection ignition devices are arranged on the middle side walls of the air cylinder sleeves. The two-in-one cylinder horizontally-opposed double-crankshaft engine has the advantages that through the internal combustion engine, the heat losses are greatly lowered, the acting peak value of each cylinder is twice that of an original cylinder, the effective pressure of the pistons is increased, more oil can be saved by the engine, two original sets of air exhaust, air inlet, ignition and oil injection devices are combined into one set, the weight is lowered, the cost is saved, operation is stable and vibration is small.

Owner:邵金彪

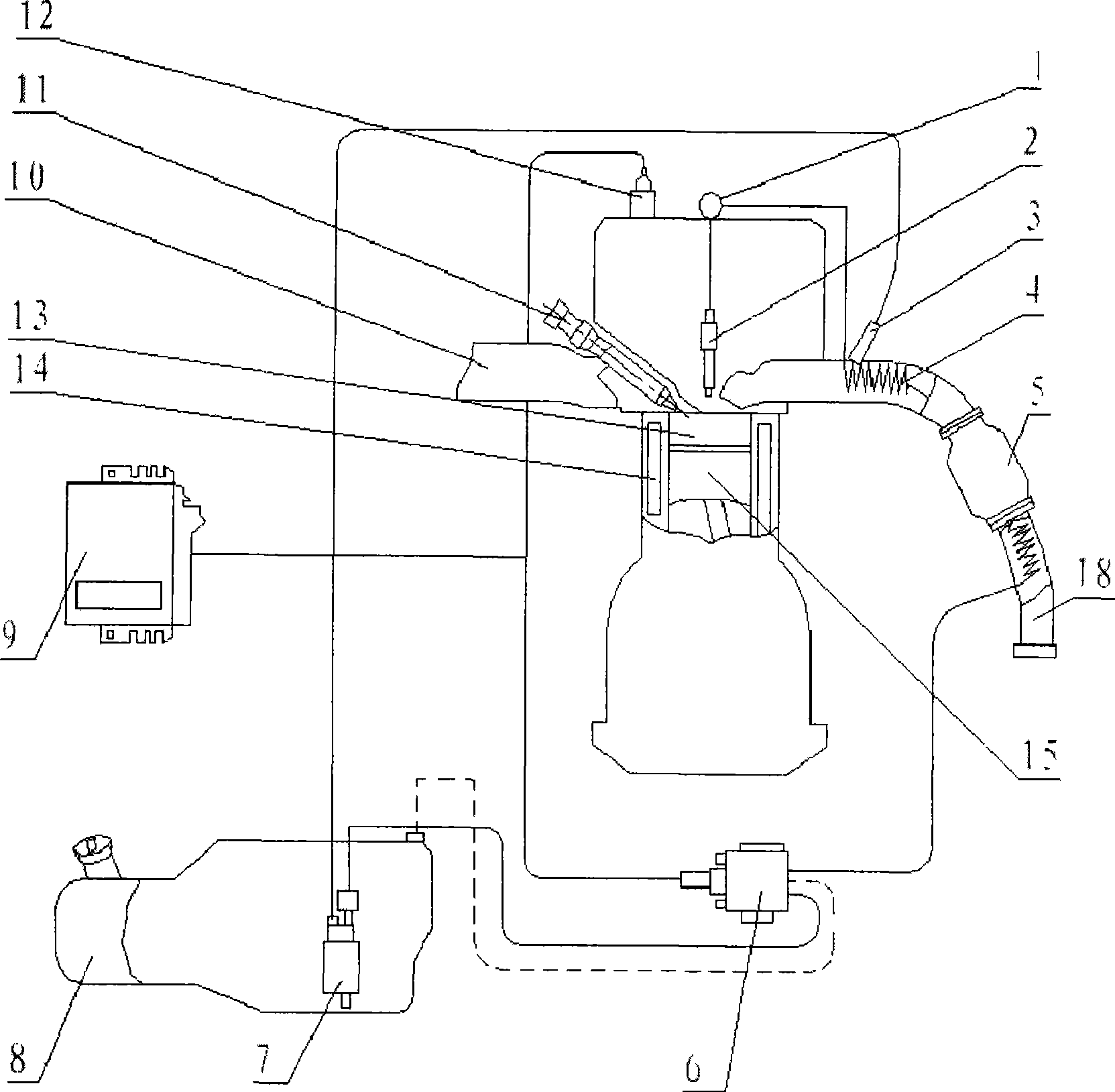

Subcritical steam auxiliary power gasoline engine

InactiveCN101457713AEfficient emissionsReduce fuel consumptionInternal combustion piston enginesNon-fuel substance addition to fuelPipingInjector

The invention relates to a subcritical vapor auxiliary work done gasoline engine which comprises a water injector in a cylinder of the gasoline engine, wherein, the water injector comprises a water tank, an electric control unit, and water pumps, a water guideway, a water injection nozzle and a temperature sensor which are controlled by the electric control unit. The water injector is characterized in that the water pumps comprise a low pressure water pump and a high pressure water pump pressurizing water to be above 200bar, the low pressure water pump is arranged in the water tank and is communicated with the high pressure water pump, the high pressure water pump is communicated with the water guideway by a high pressure water pipe, the water injection nozzle is communicated with the water guideway, and a water injection opening extends into a combustion chamber of the gasoline engine. The gasoline engine also comprises a gasoline engine exhaust pipe used for heating water to above 250 DEG C and not more than 374.2 DEG C, and a high pressure water pipe penetrates through the exhaust pipe and then is communicated with the water guideway. The gasoline engine utilizes the waste heat of engine tail gas to do work circularly, thereby saving oil; the temperature of water injected into the cylinder is in a subcritical state, and the water is instantaneously vaporized in the cylinder under the pressure condition, thereby increasing the explosion pressure of the cylinder; and the torque output and the power are improved under the premise that the oil injection amount is not increased.

Owner:MIANYANG XINCHEN ENGINE

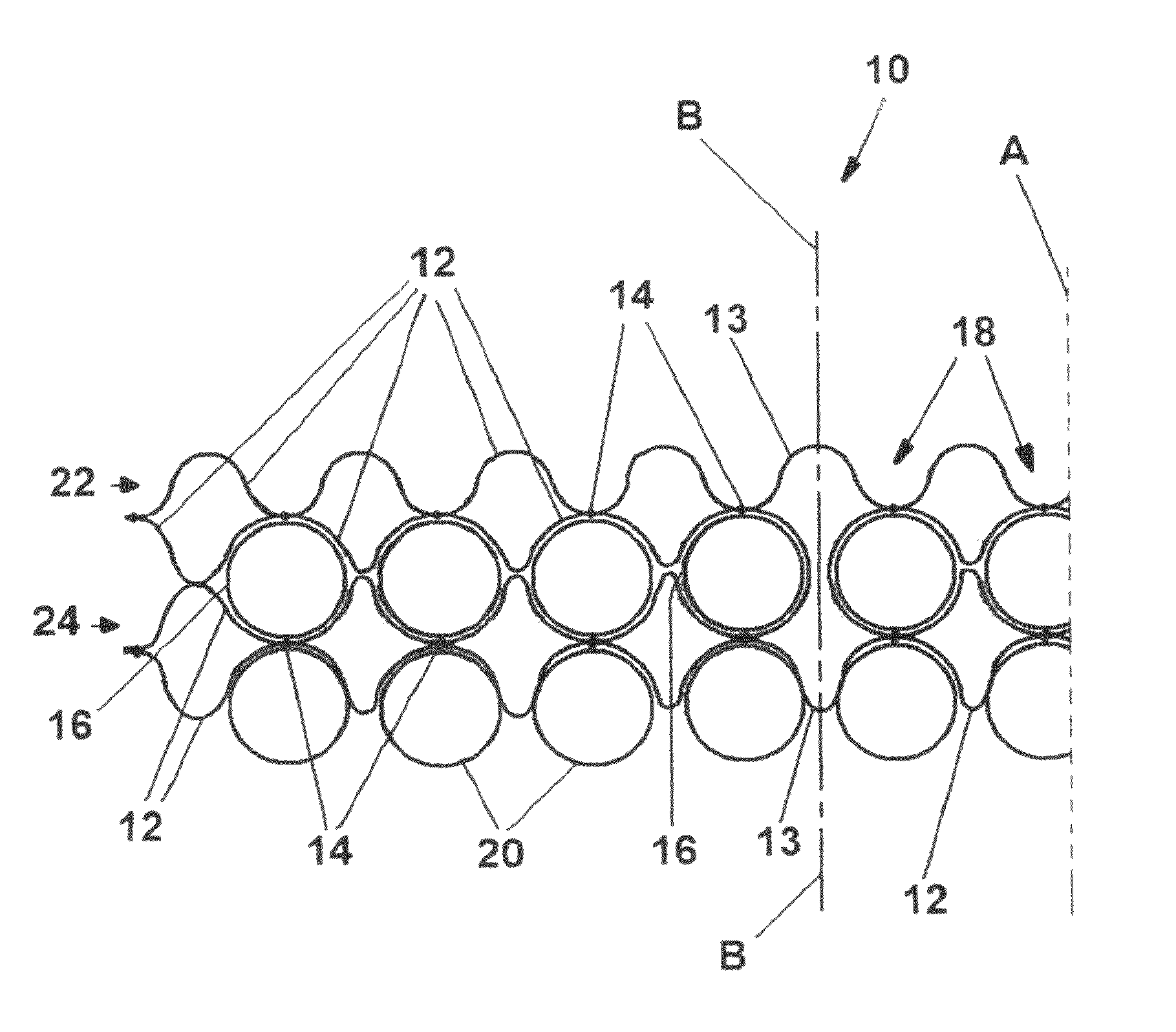

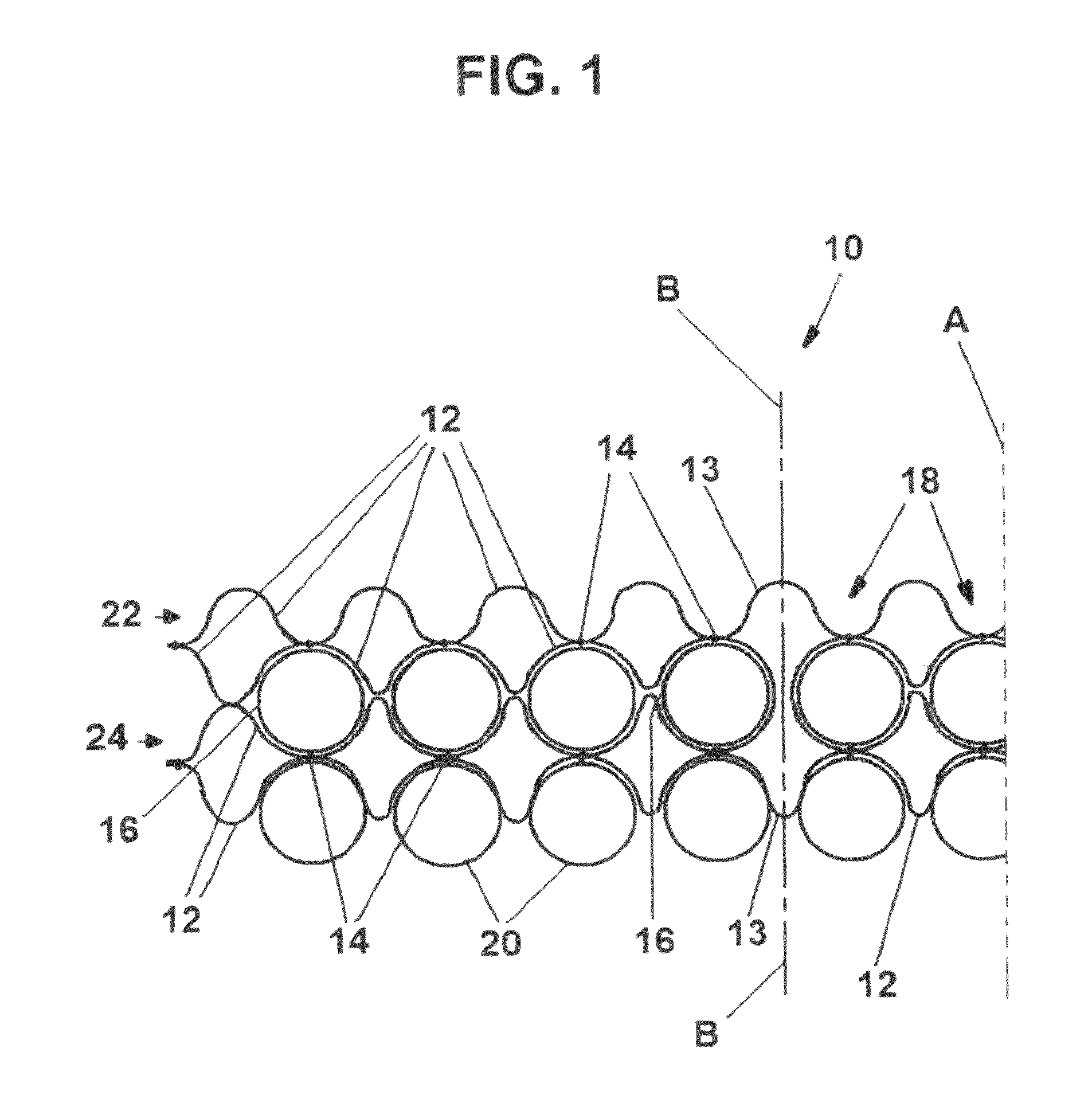

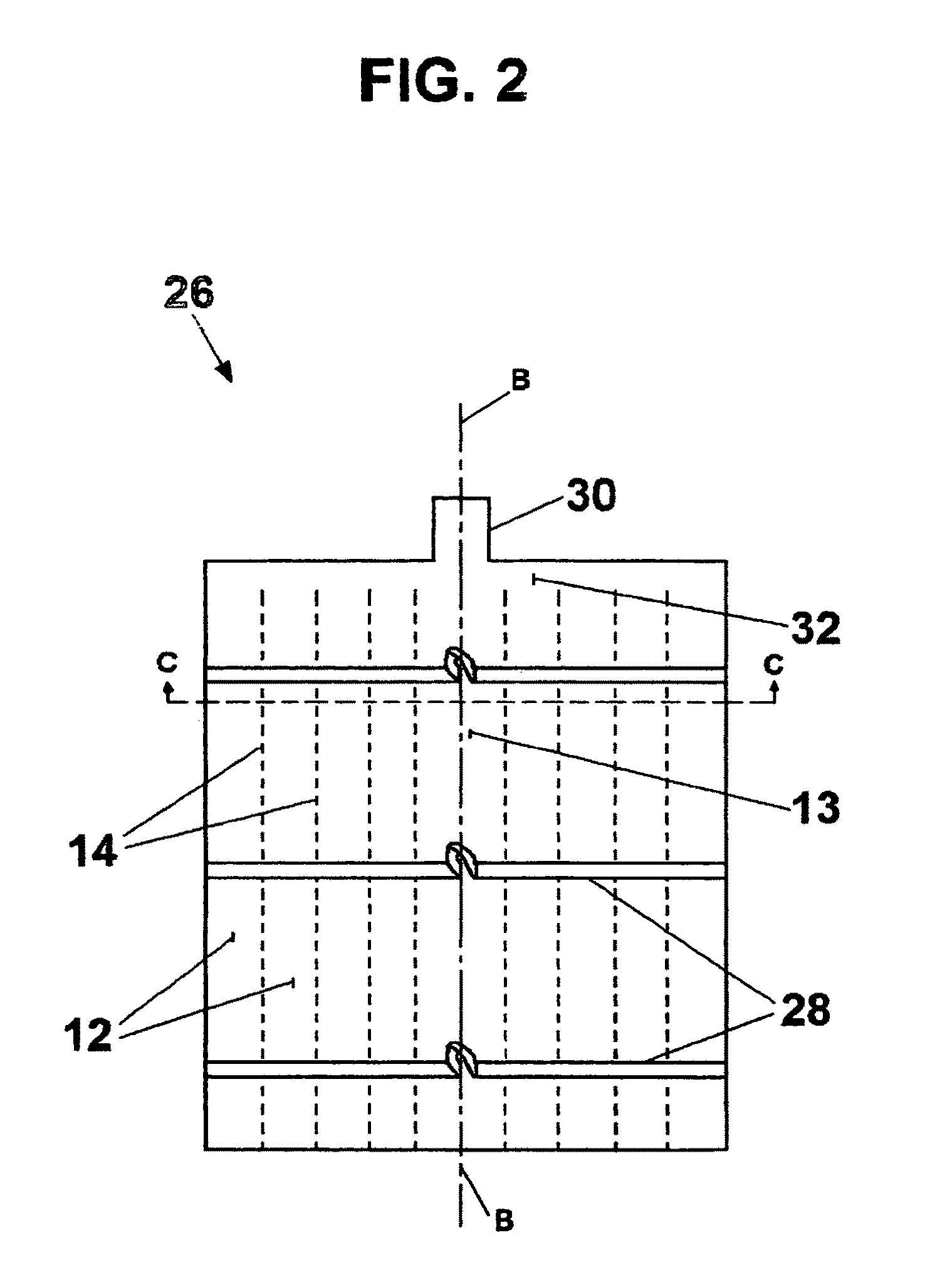

Stormwater filter bag

InactiveUS7918996B1Easy to shipNatural head pressures in collection systems are relatively smallWater cleaningSewerage structuresSediment FilterEngineering

The invention is a particle and sediment filter for stormwater. A long permeable filter bag is laid out horizontally within an enclosure. The bag is formed of at least two layers of parallel tubes that give each layer the pleated look of a typical air mattress. Stormwater is collected from the filter bag by perforated pipes held within the creases between the tubes of the layers of the bag, with the pipes draining to the outside of the enclosure. The bag is also supported above the bottom of the enclosure by additional perforated pipes located within the creases between the tubes, thus allowing the filtered liquid to also drain off beneath the bag. The stormwater input is from a pipe that feeds a manifold formed in the bag and connected to each tube. The top of the enclosure is removable for replacing the filter. The filter bags are constructed of flexible material so that they are flat during initial transport and installation, but they expand as they are filled with liquid and solid material. An assembly of the bags also includes straps for holding the perforated pipes in place against the tubes and for lifting the bag with trapped sediment.

Owner:DE BRUIJN HANS

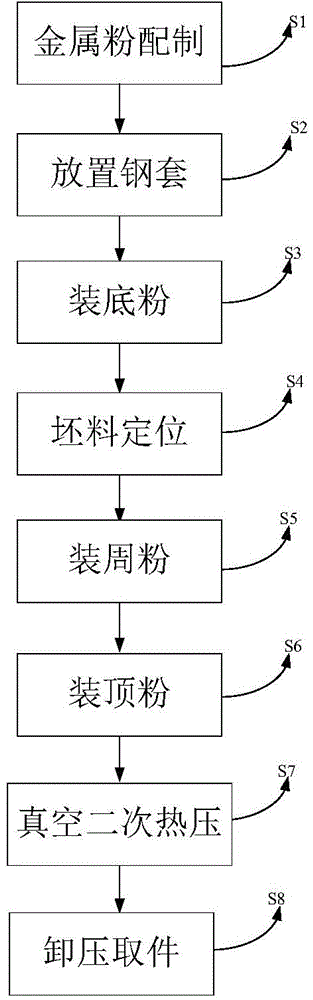

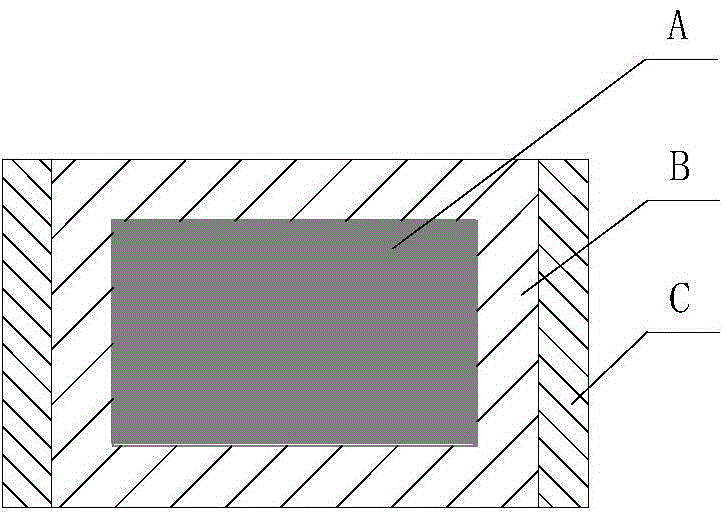

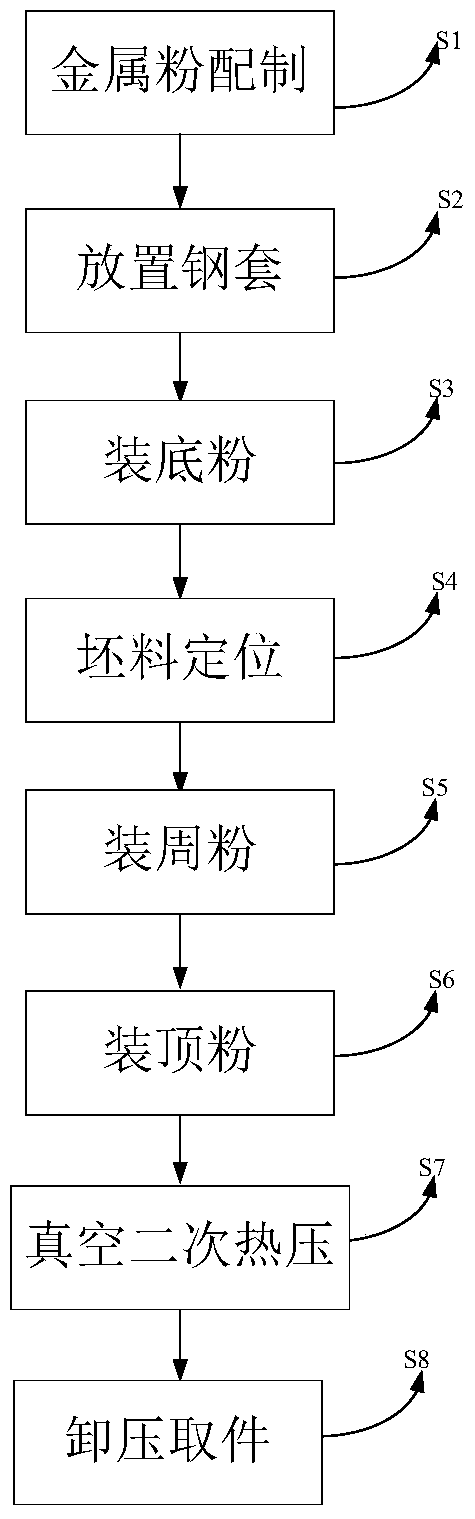

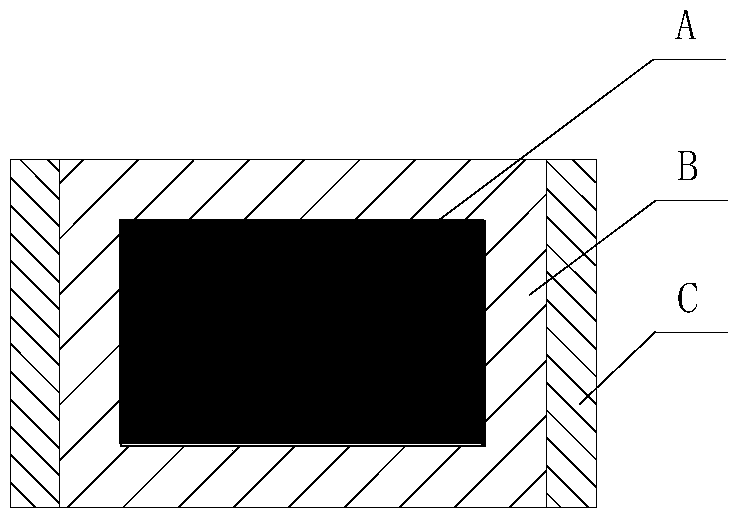

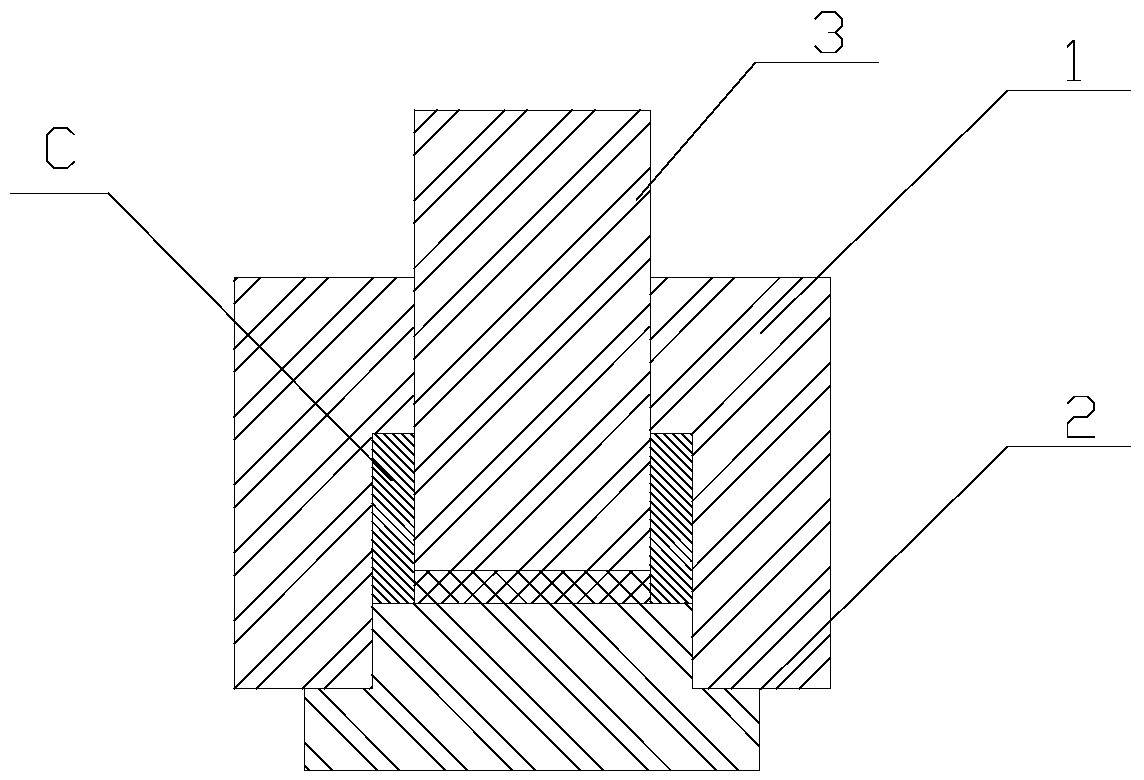

Vacuum secondary hot pressing manufacturing technology for high-strength polycrystalline diamond drawing die

The invention discloses a vacuum secondary hot pressing manufacturing technology for a high-strength polycrystalline diamond drawing die. A bushing is obtained by metal powder through vacuum secondary hot pressing, the vacuum degree is 2*10-3-8*10-3 Pa, the pressing pressure is 20-45 MPa, the temperature is increased to 500-550 DEG with the rate of 20-30 DEG C / min, the temperature and the pressure are kept for 10-20min, the temperature is increased to 600-650 DEG C with the rate of 10-15 DEG C / min, the temperature is kept for 10-15 min, the pressure is kept for 15-20 min, and the drawing die is obtained through cooling. The method of vacuum secondary hot pressing is adopted, particles can be scattered and slide through the surface energy and the external pressure, pores in a sintered body are removed, and the compactness of materials is improved; elastic strain in the cold pressing process can be removed, the density of the sintered body can be increased, the elastic failure does not exist, and the adverse influences generated by size increasing after demolding are reduced; the vacuum sintering is neutral sintering of anaerobic and non-reducing gas, combination of interfaces can be improved, and the obtained drawing die bushing is closely attached to a die core and a steel bushing; the gaps of the sintered body can be fully filled with the particles through secondary hot pressing, obtained material cracks are few, and the utilization rate of the die is increased.

Owner:天长市天屹模具科技发展有限公司

Method for manufacturing beryllium bronze explosion-proof hammer

The invention relates to a method for manufacturing a beryllium bronze explosion-proof hammer. The method is characterized in that a metal casting mold is used for forming, and a metal column comprises an upper half mold and a lower half mold which are horizontally split; an upper casting mold half cavity is formed in the upper half mold, a lower casting mold half cavity corresponding to the uppercasting mold half cavity is correspondingly formed in the lower half mold, an upper half core is arranged in the center of the top surface of the upper casting mold half cavity, and a lower half coreis arranged in the center of the bottom surface of the lower casting mold half cavity; an exhaust channel is formed in the position, positioned on the parting surface of the upper half mold and the parting surface of the lower half mold, of the outer side of an explosion-proof hammer head cavity; an upper pressing head is arranged on the upper half mold; a material storage cavity is formed in thecenter of the lower half mold, and a lower pressing head is arranged at the bottom of the material storage cavity; and a flow channel is formed between the material storage cavity and the lower casting mold half cavity. The invention further relates to the method for manufacturing the beryllium bronze explosion-proof hammer by utilizing the metal casting mold, so that the problems that the density is low, the structure is thick and large, and blocks are prone to jumping in the using process in the process of producing the beryllium bronze explosion-proof hammer by an existing casting technology are solved.

Owner:HEBEI BOTOU SAFETY TOOLS CO LTD +1

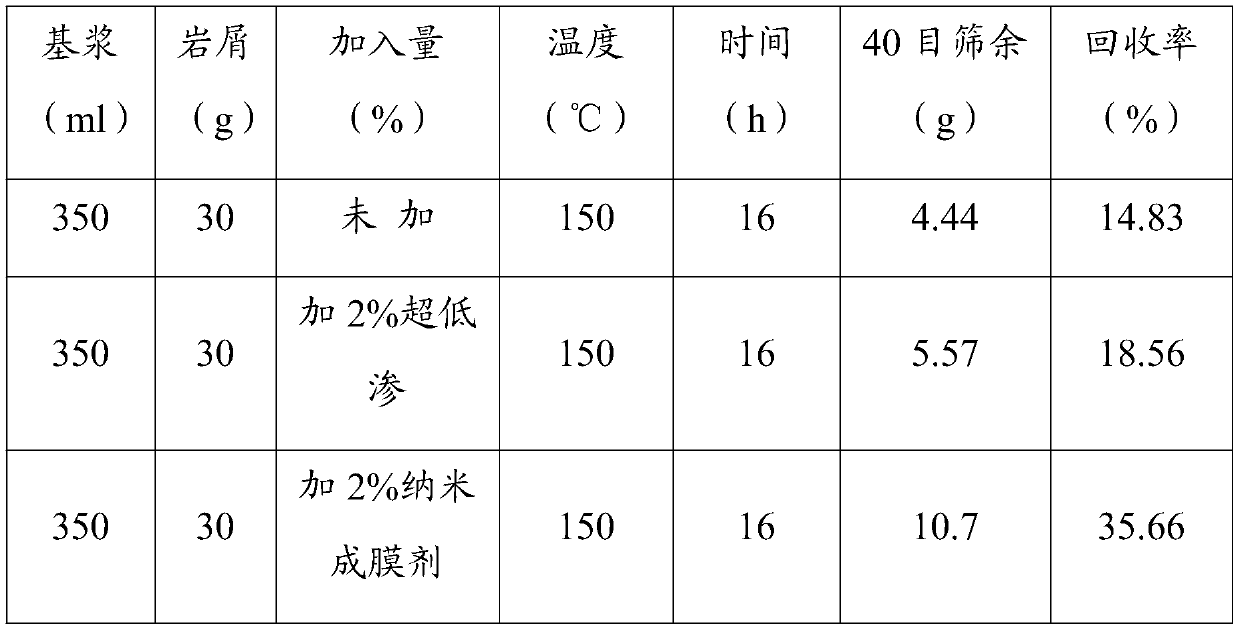

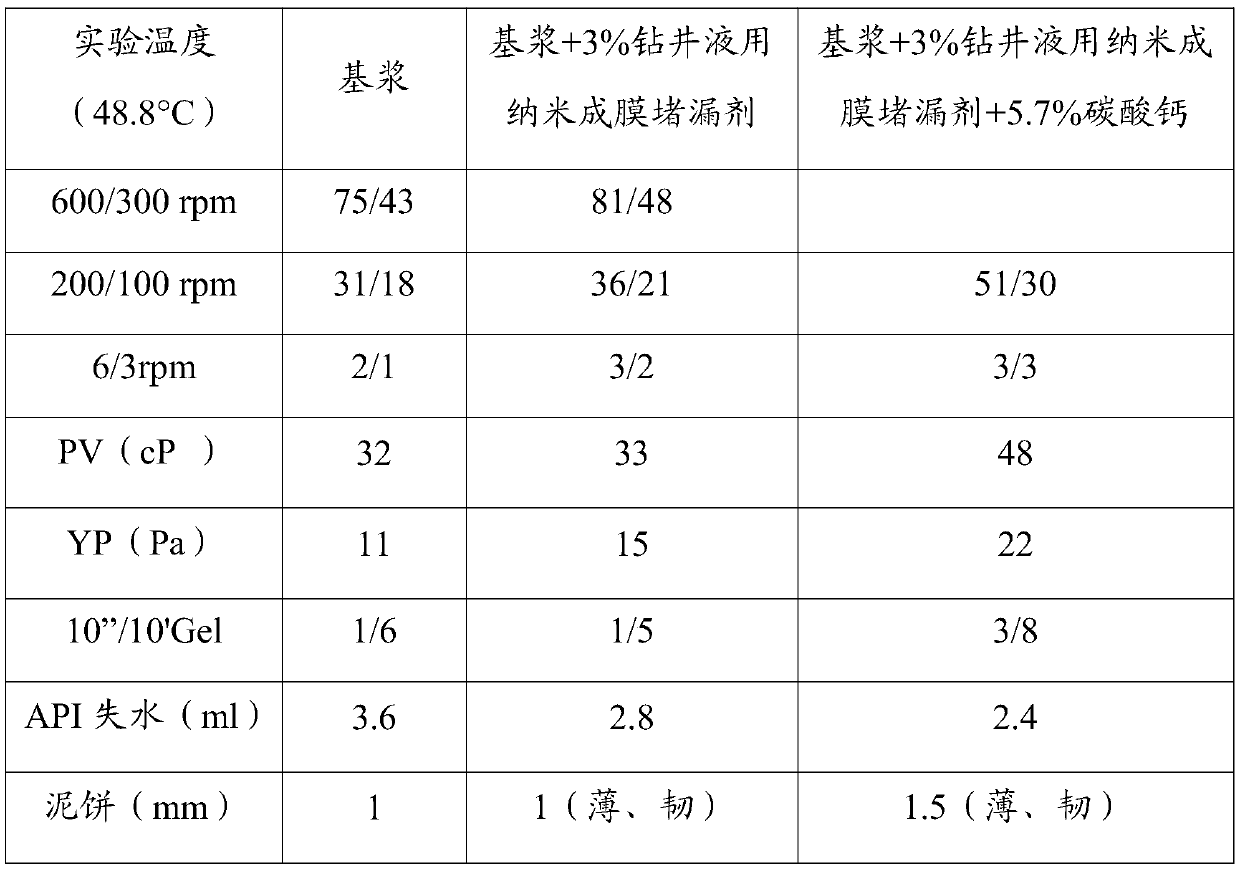

Nano filming plugging agent for drilling fluid and preparation method and application of nano filming plugging agent

InactiveCN110157397AImprove the blocking effectReduce high temperature and high pressure filtration lossDrilling compositionPolymer scienceEngineering

The invention provides a nano filming plugging agent for a drilling fluid. The nano filming plugging agent comprises the following components: silicon oxide, polyurethane granules, a dispersant and analcohol. By controlling proportions and preparation processes of raw materials, the prepared nano filming plugging agent for the drilling fluid is an odorless white liquid, the density is 1.05g / cm<3>, the granularity of solid particles is 50-400nm, the nano filming plugging agent for the drilling fluid is compressed in the surface of a wall well or microcracks of mud shale to form a semi-permeable isolation film, that is, a complete protection layer is formed on the wall well, fluids can be prevented from entering a stratum, effective pressure can be increased, ineffective pressure can be reduced, a wall well stabilizing function can be effectively brought into play, the drilling fluid blocking capability can be improved, the filter loss of the drilling fluid can be reduced, the quality and plugging performance of mud cakes can be improved, the inhibition of the drilling fluid can be improved, a liquid in a shaft can be prevented from entering stratum pores and cracks, the probabilityof differential pressure adhesion and tool jamming can be reduced, and in addition, the nano filming plugging agent is simple, convenient and easy in control of preparation processes, convenient andrapid to use, and high in popularization and application value.

Owner:XINJIANG GRAND OILFIELD TECH

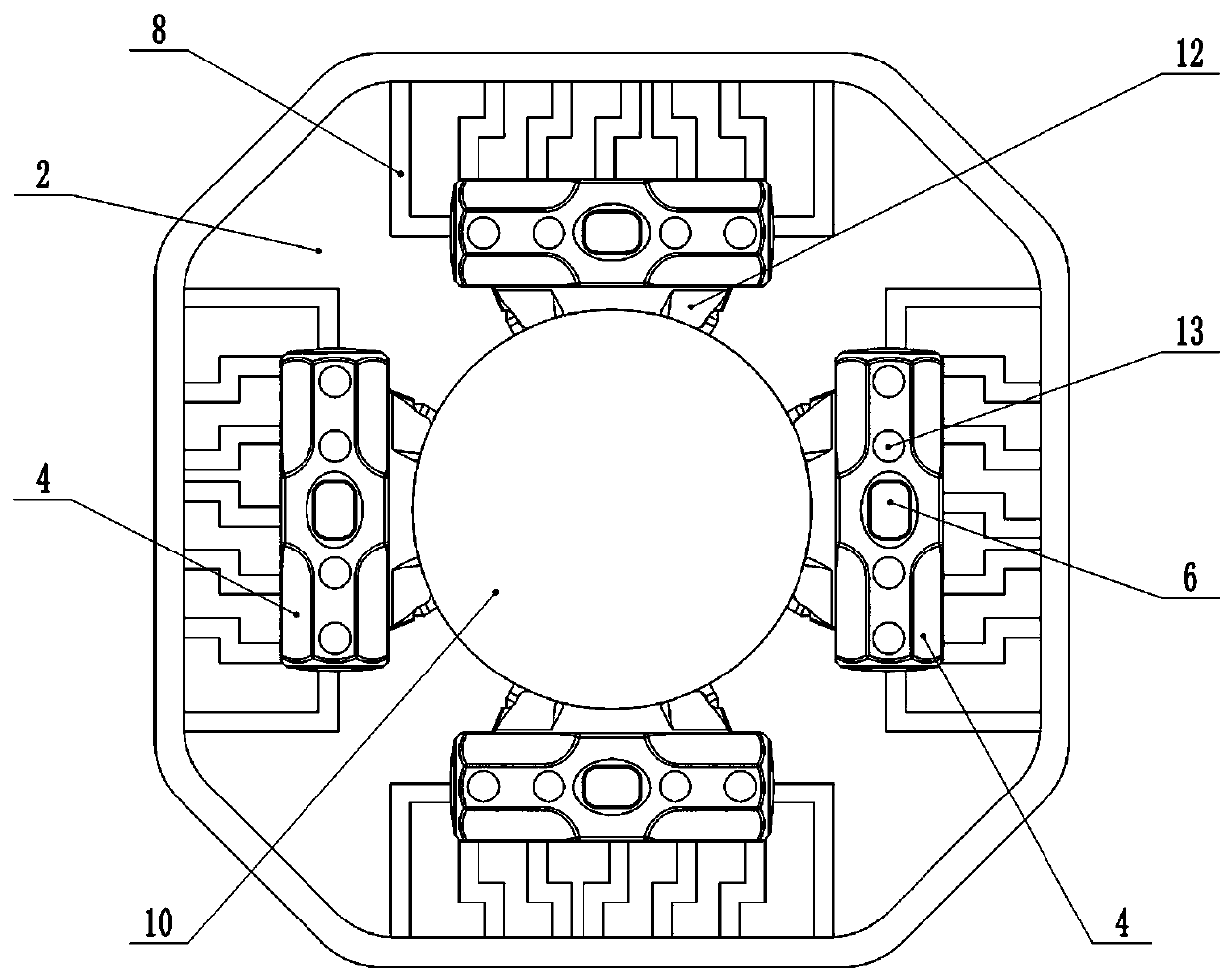

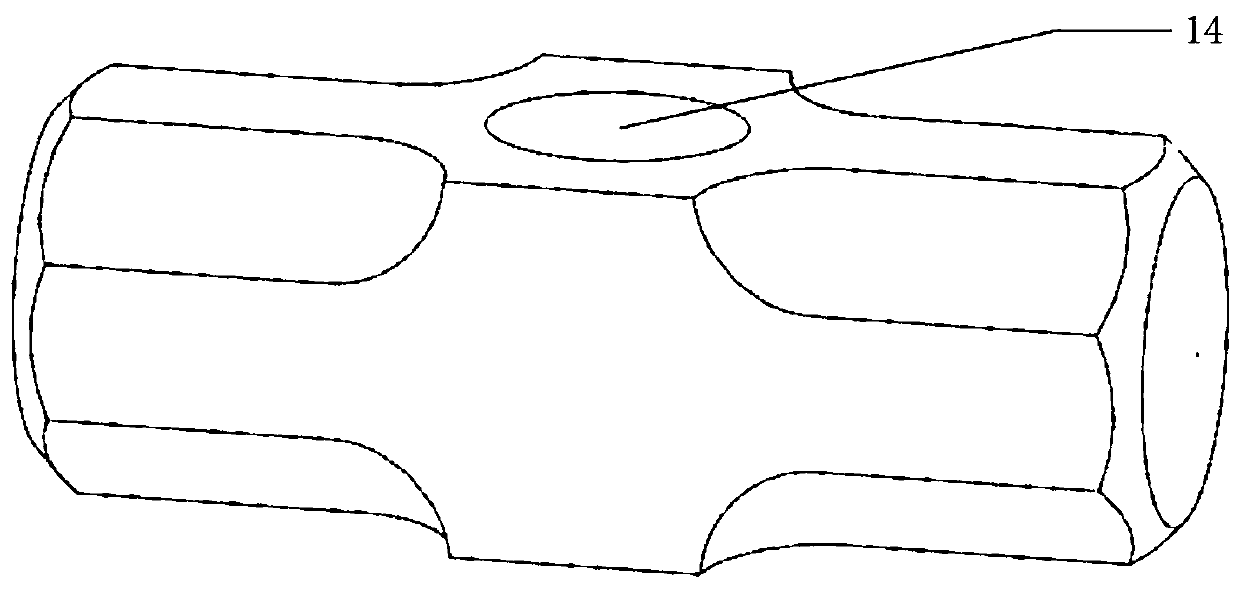

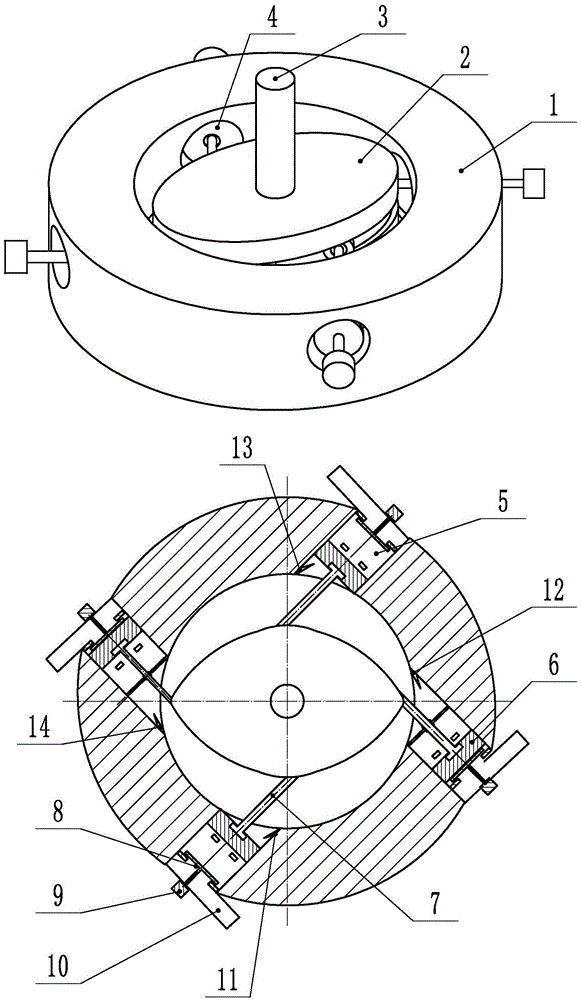

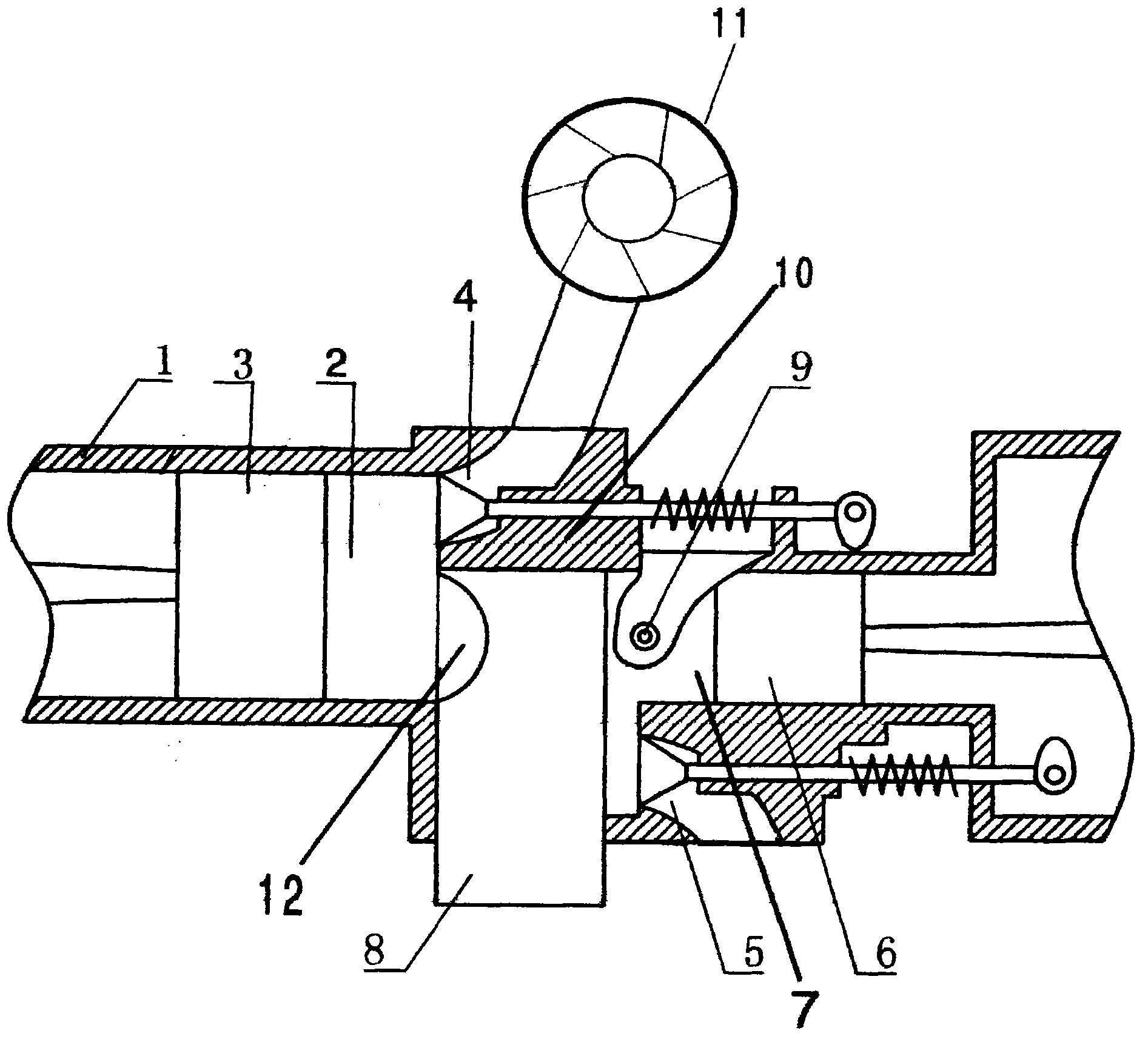

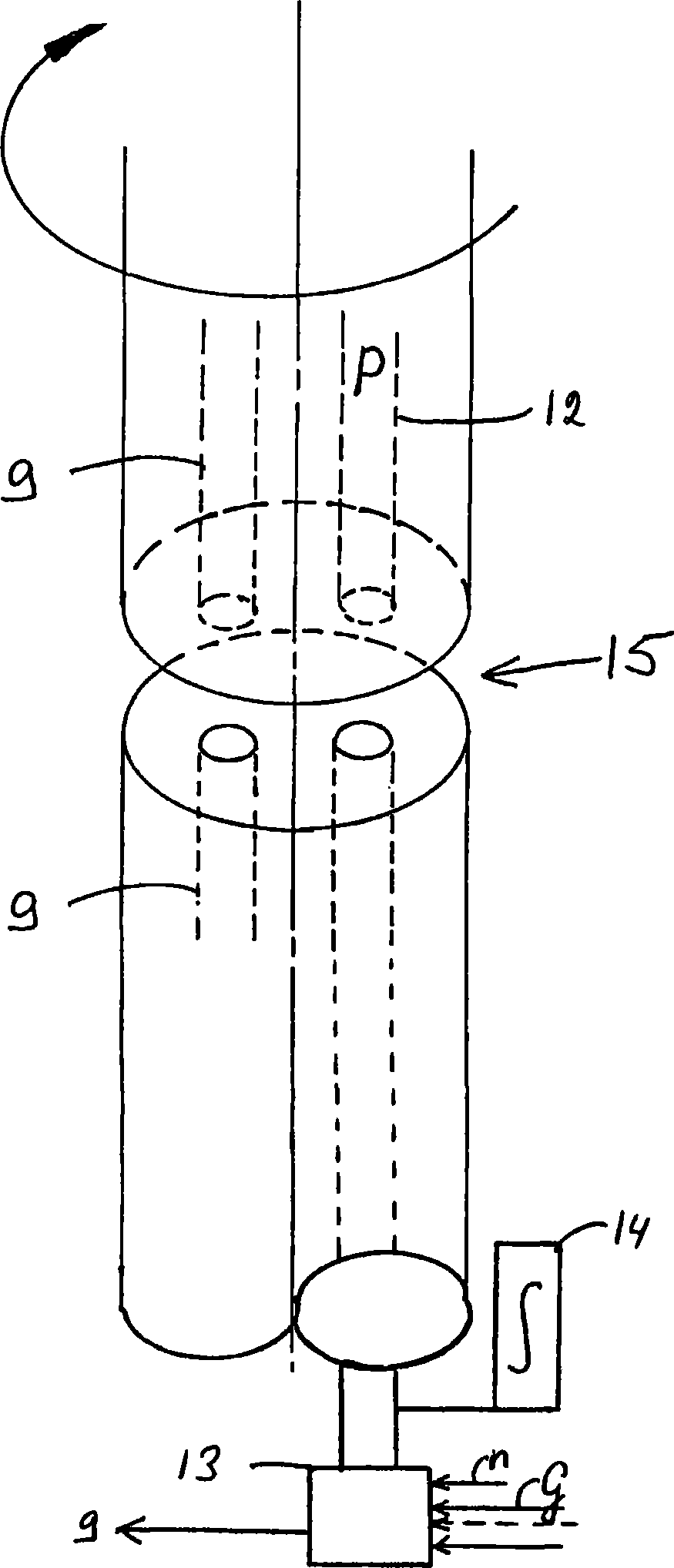

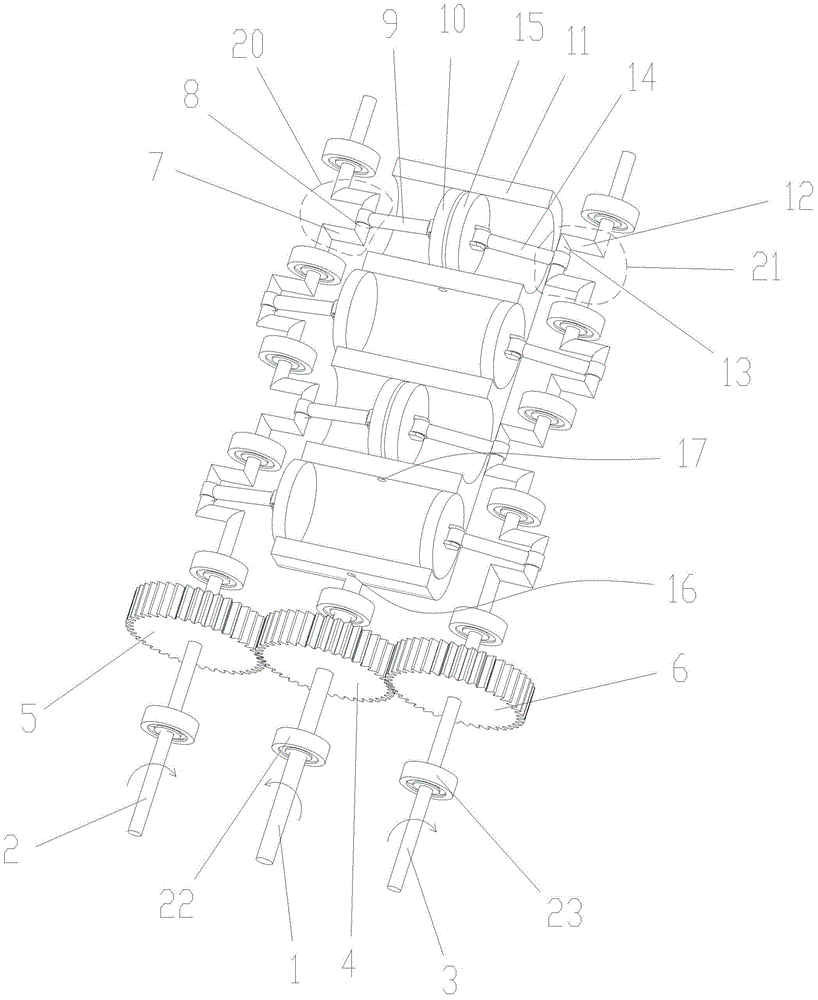

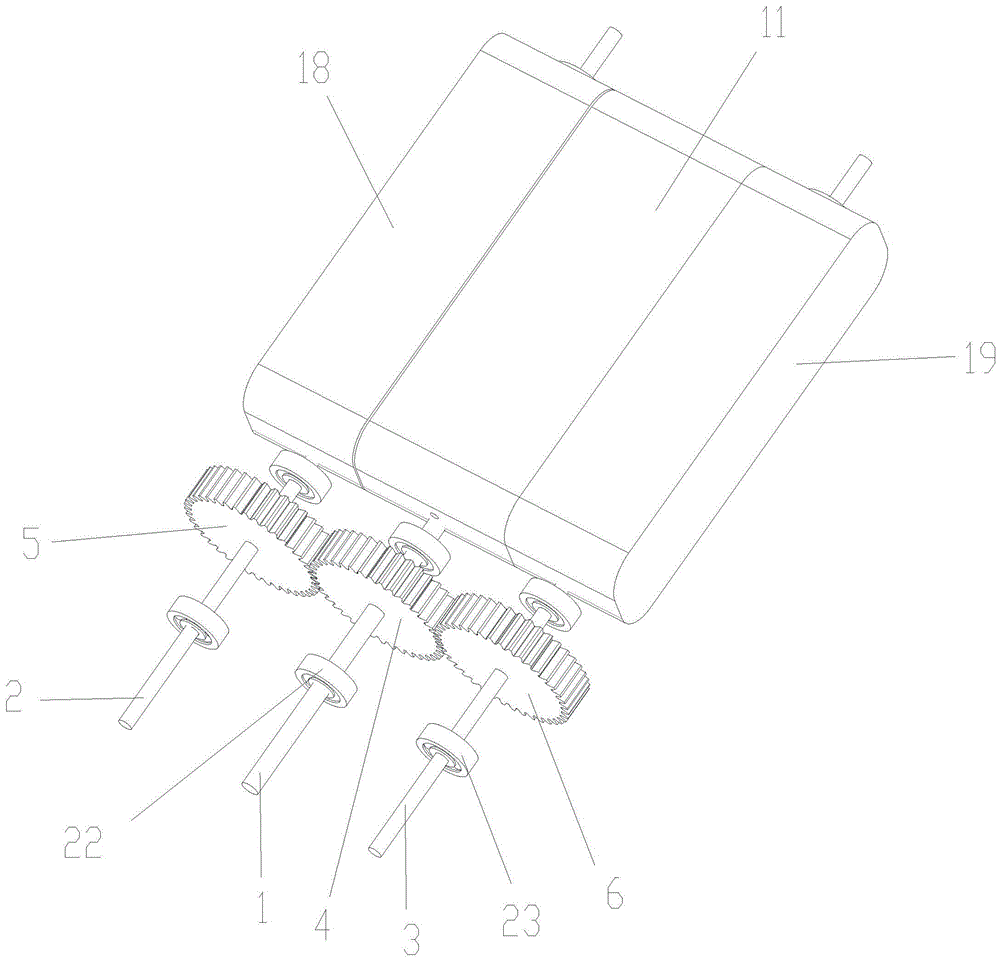

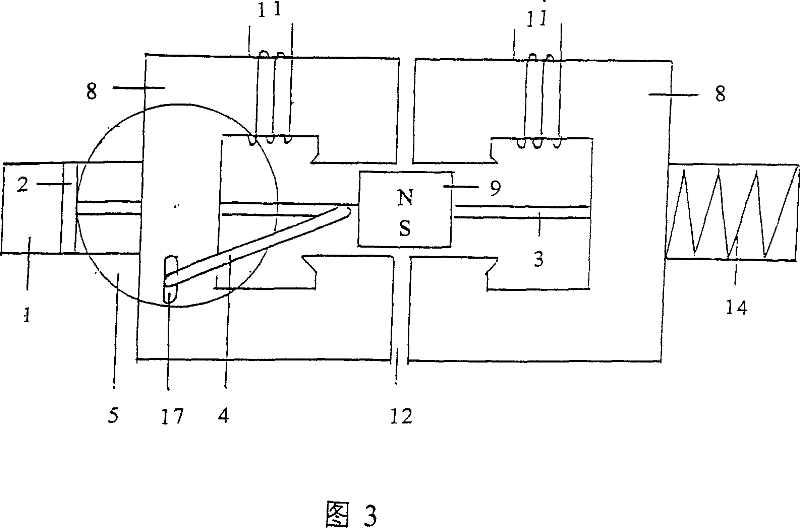

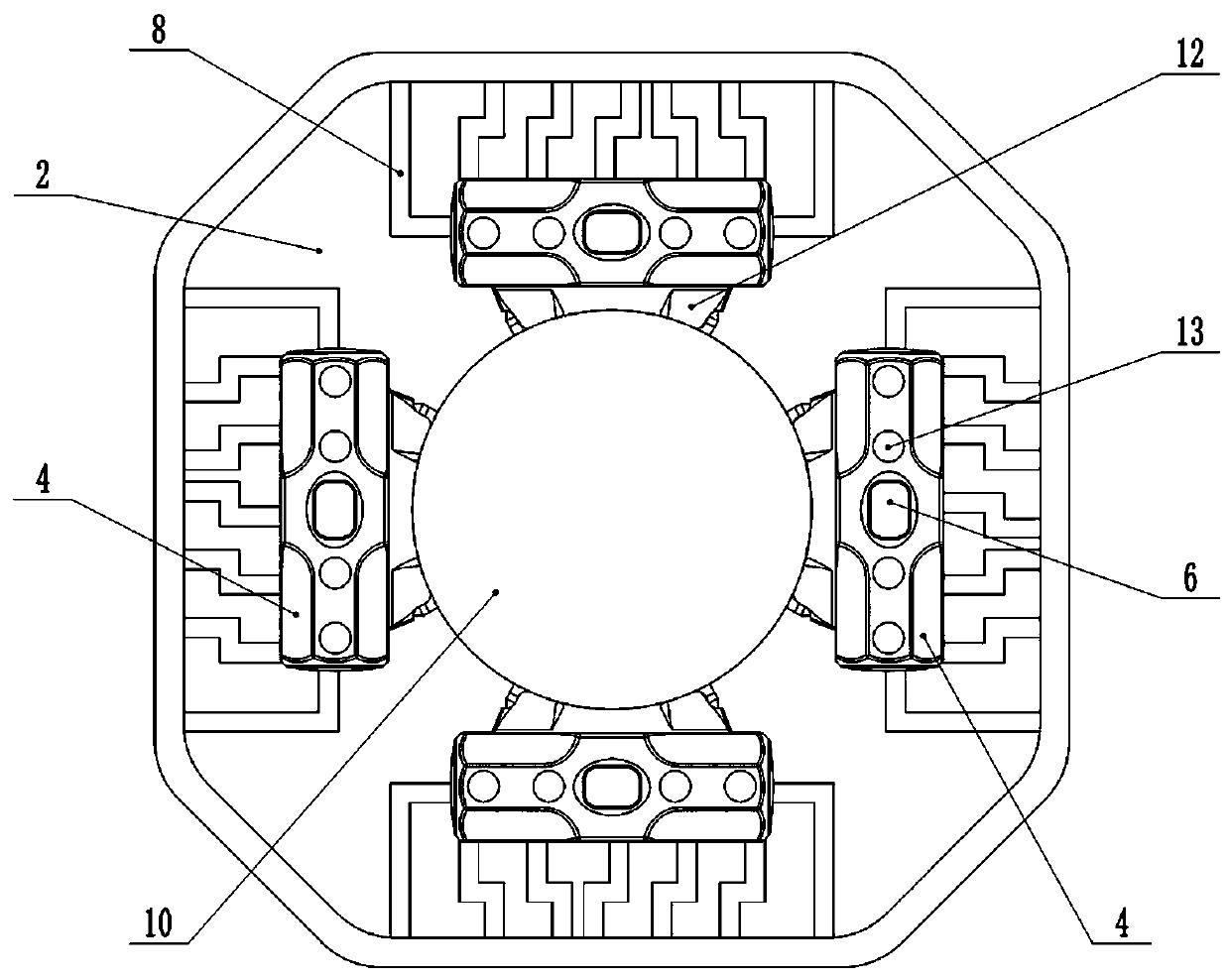

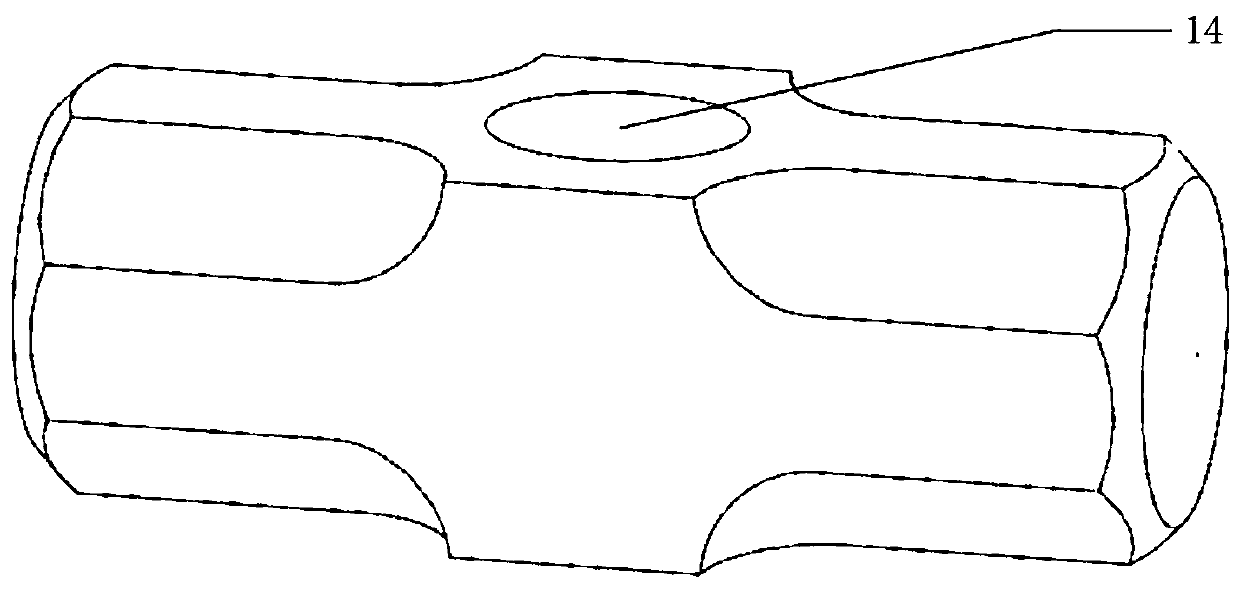

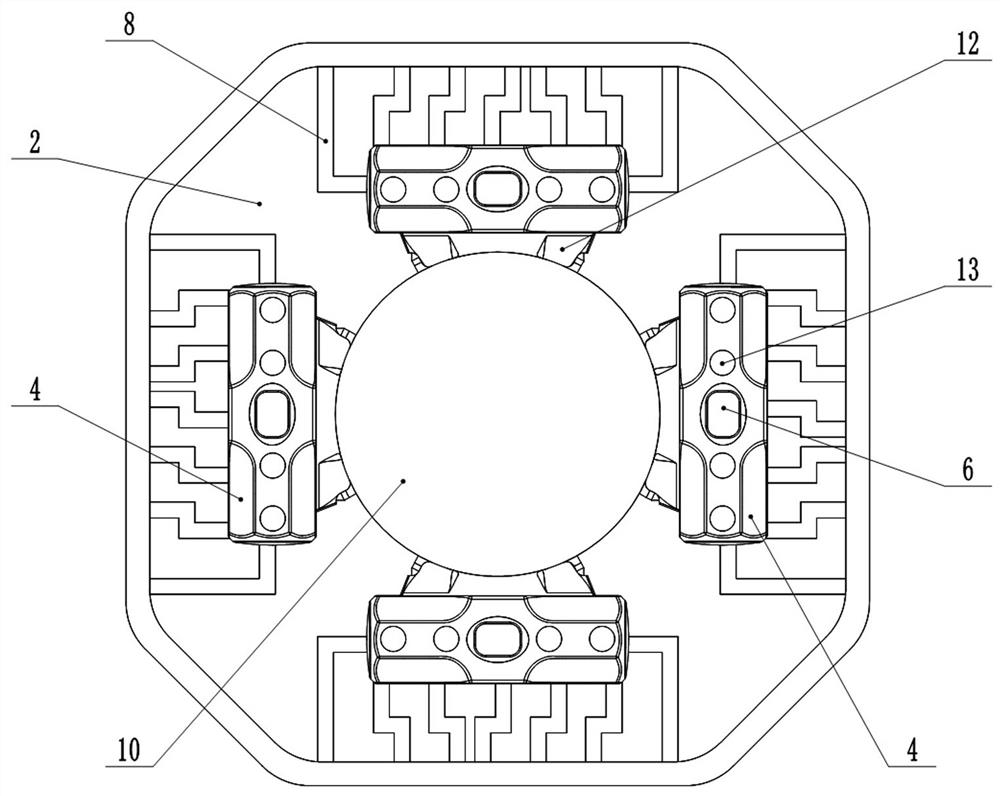

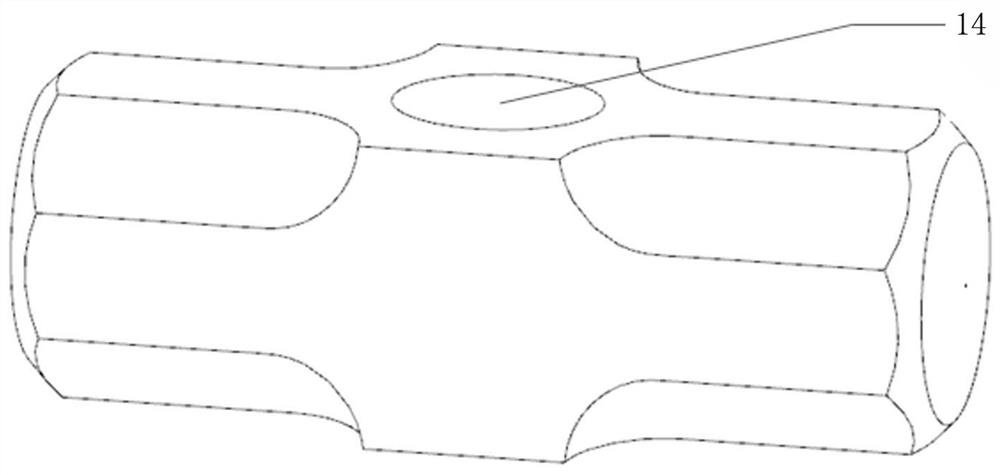

Contraposition double-eccentric-wheel sliding groove push-pull reciprocating compressed air pressurizing homogeneity compression ignition internal combustion engine

InactiveCN105156207AIncreased effective work pressureIncrease effective pressureMachines/enginesPush and pullPush pull

The invention provides a contraposition double-eccentric-wheel sliding groove push-pull reciprocating compressed air pressurizing homogeneity compression ignition internal combustion engine. The eccentric distance of a rotating double-eccentric-wheel serves as a reciprocating stroke to drive pistons to complete air suction, compression, acting pressure gas discharging, pressurized air is supplied to a coaxial double-eccentric-wheel sliding groove type power output internal combustion engine, and the pressurized air flows quickly into all air cylinders of the internal combustion engine through an air intake branch; the air flowing into the air cylinder is the pressurized air 2-5 times larger than the atmospheric pressure, the air exchange efficiency, air inlet density, air inflation and effective internal combustion engine pressure are greatly improved, and the internal combustion engine is a real pressurizing homogeneity compression ignition two-stroke internal combustion engine; even numbers of air cylinders are correspondingly arranged in pairs and evenly embedded into the periphery of the same circular-ring-shaped cylinder body; the inner circle center is the rotating double-eccentric-wheel sliding groove provided with an integrated power shaft and precisely assembled to and connected with a T-shaped sliding mechanism at a big end of connection rod in a sliding mode to transfer power, the rotating double-eccentric-wheel sliding groove provided with the integrated power shaft rotates by a circle, the big end of the connection rod slides in a limiting sliding groove with the eccentric distance as the stroke, and all the air cylinder pistons are pushed and pulled by two reciprocating strokes, in other words, the pistons act twice when the power shaft rotates by a circle.

Owner:高阳

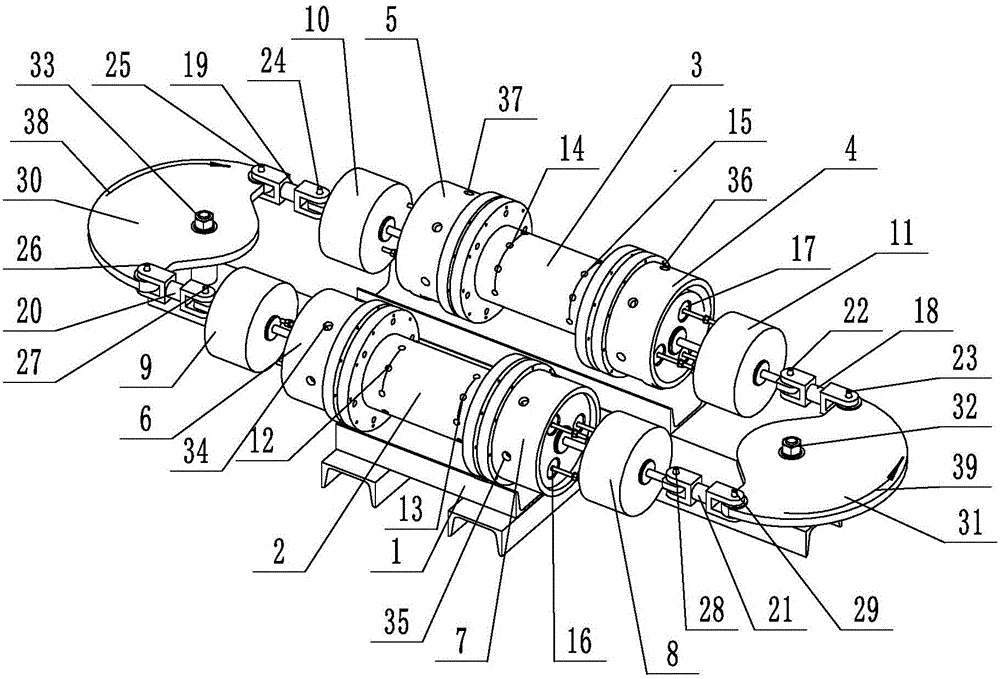

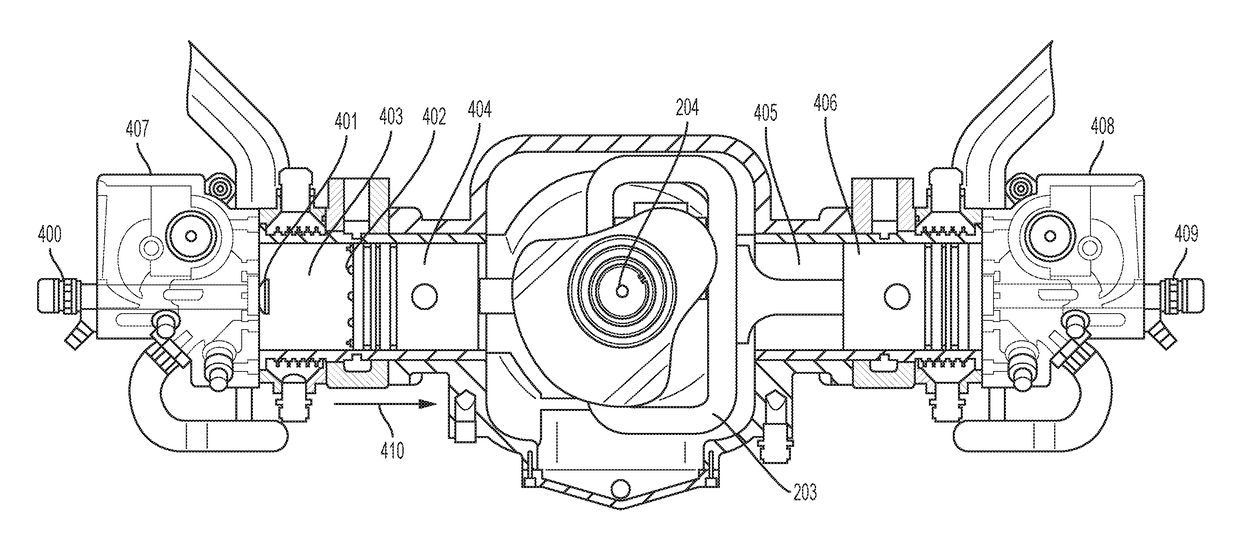

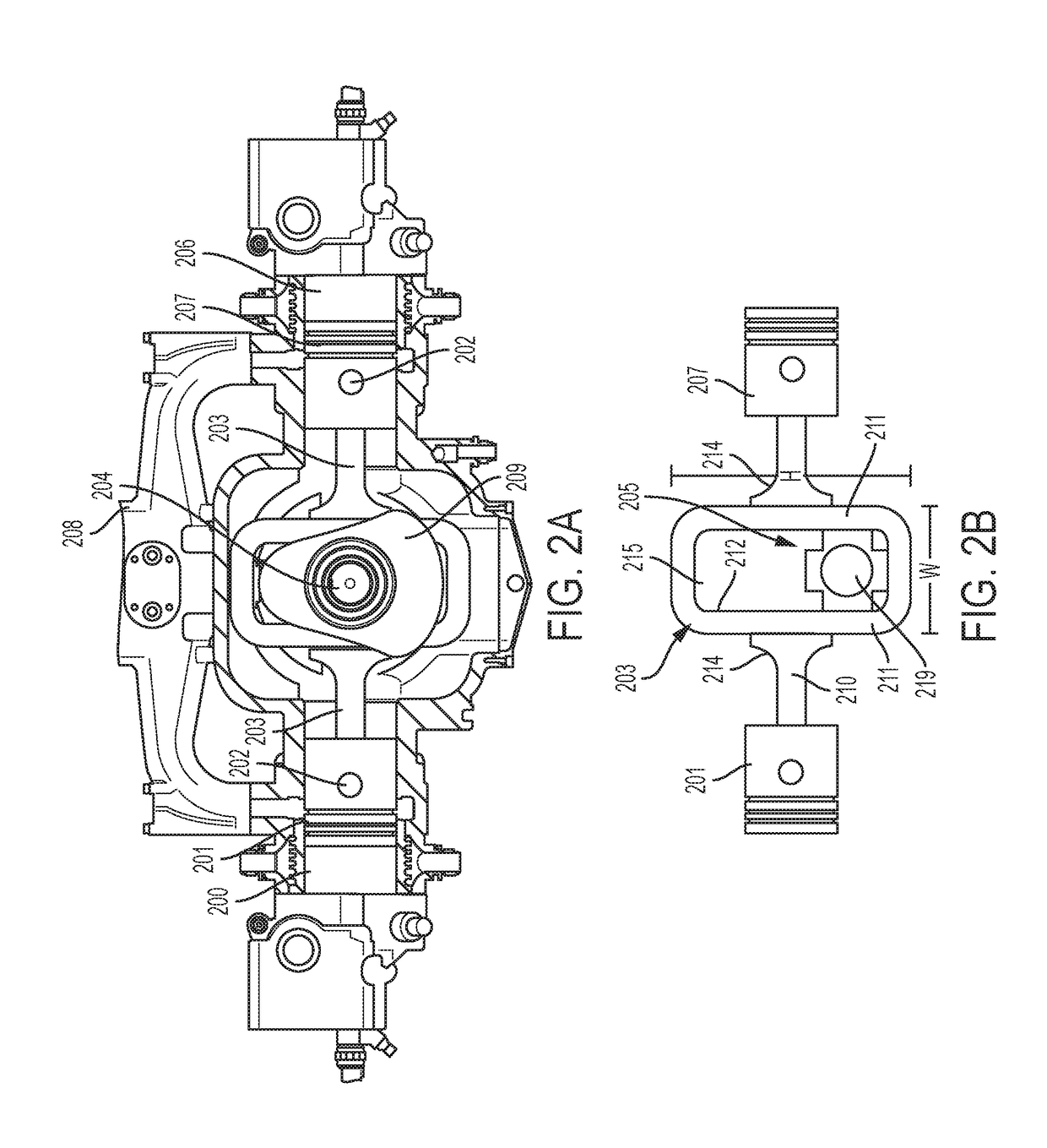

Horizontally-opposed-cylinder, horizontally-opposed-piston and two-stroke homogeneous compression-ignition engine and generators

ActiveCN106285934ACompact structureHigh failure rateMachines/enginesElectricityHomogeneous charge compression ignition

The invention discloses a horizontally-opposed-cylinder, opposed-piston and two-stroke homogeneous compression-ignition reciprocating engine and linear generators. Two pistons are arranged inside each of two parallel cylinders for doing work oppositely; four blast pump pistons, of which the effective area is 2-3 times greater than that of the work-doing pistons, are arranged behind the four pistons, and are used for supplying pressurized mixed fuel gas to the cylinders; four coaxial linear generators are arranged behind four blast pumps; shaft heads behind the four generators are connected with two interconnecting fulcrums of two semicircular rocker mechanisms fixed to central vertical shafts at the two ends of the two cylinders; when the two pistons in one cylinder move towards a combustion chamber, which is shared by the two pistons, in the center of the cylinder, the two pistons in the other cylinder move oppositely to the two ends of the cylinder; when the two pistons in one cylinder move up to 5-10 degrees in front of an upper stopping point, mixed fuel catches fire and bursts out through compression ignition to force the two pistons to rapidly move towards a lower stopping point, push the coaxial blast pumps to blast air, push the generators to generate electricity and push the two semicircular rocker mechanisms to rotate in the reverse direction so as to push the two pistons in the other cylinder to do compression work on the upper stopping point at the center of the cylinder.

Owner:高阳

Repeated pressure boosting internal combustion engine

InactiveCN103511062AImprove air tightnessIncrease the compression ratioInternal combustion piston enginesLow speedTurbocharger

The invention relates to an internal combustion engine and provides a repeated pressure boosting internal combustion engine which can separately complete an energy conversion process and is high in energy utilization efficiency, low in fuel consumption rate and high in speed, torque and power. According to the main principle of the repeated pressure boosting internal combustion engine, the suction process, the compression process, the acting process and the exhaust process are separately conducted in two air cylinders which are different in size, effective pressure in the air cylinders is increased at the time of acting through self structures, as a result, the combustion process is improved, and thermal efficiency is also improved; moreover, matched with a turbocharger, a compression air cylinder 2 can suck in more air in a high speed stage to support the combustion of fuel. The repeated pressure boosting internal combustion engine has the advantages of being simple in structure, high in thermal efficiency, wide in operation adjustable range, low in oil consumption, good in acceleration performance, sufficient in power at a low speed, and strong in power at a high speed; moreover, acting frequency is doubled, the rotating speed range is substantially expanded, and therefore vibrations are reduced; due to the supercharged effect after combustion, the combustion process is improved, the fuel can be combusted more sufficiently and thoroughly, and the emission performance is better.

Owner:赵强国

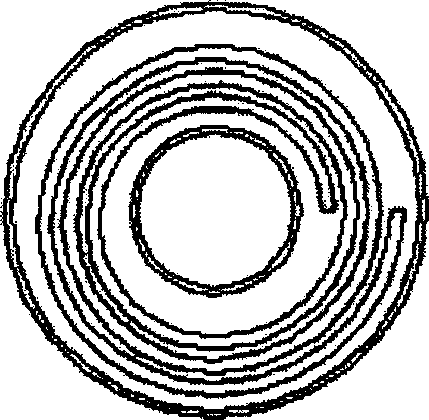

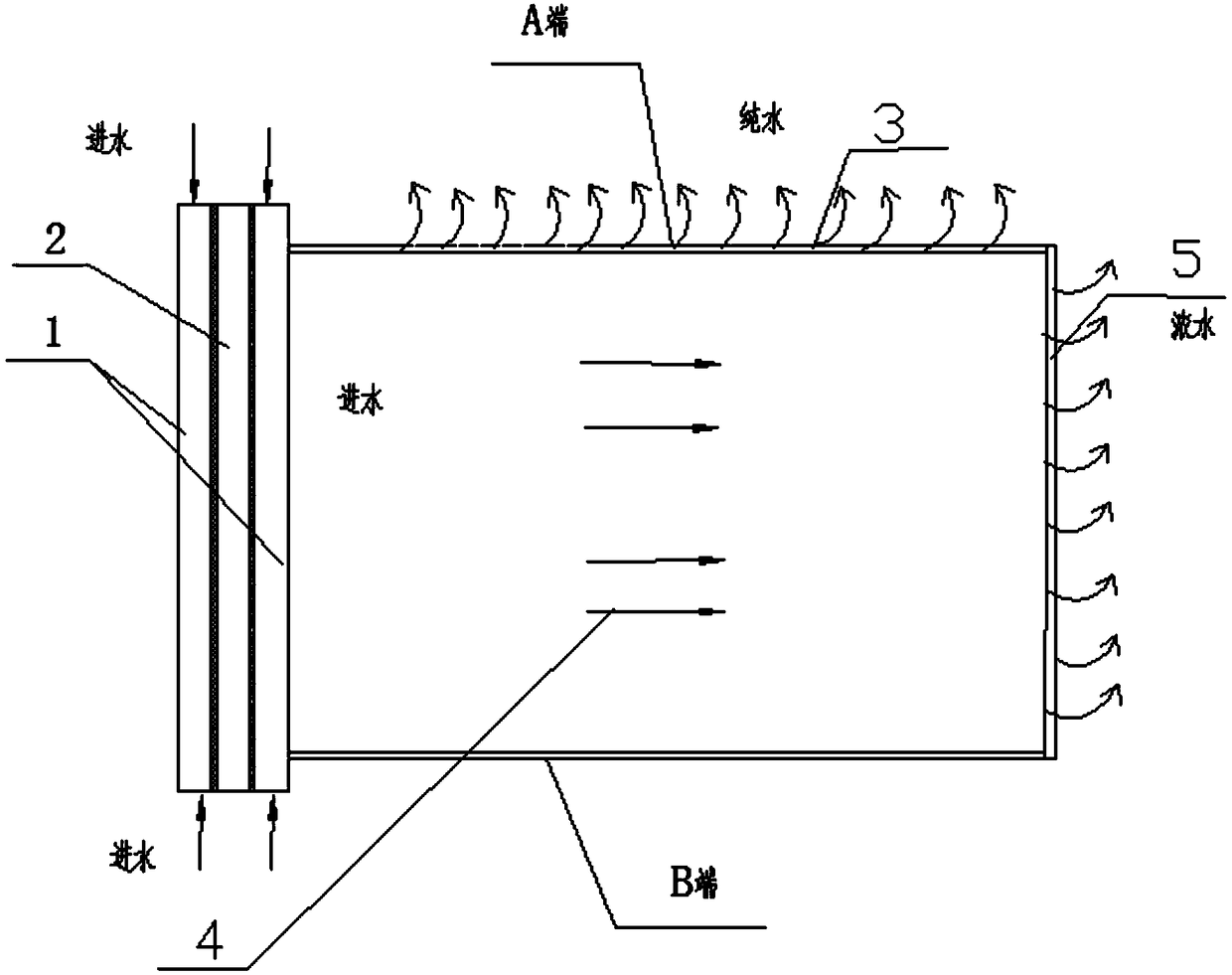

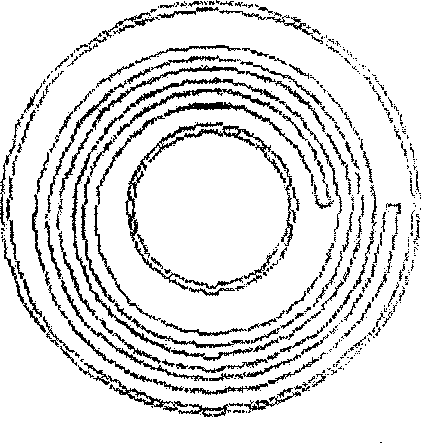

Reverse osmosis membrane filter element and water purifier

PendingCN108996614AFully filteredIncrease contact timeReverse osmosisWater/sewage treatment bu osmosis/dialysisReverse osmosisProduced water

The invention provides a reverse osmosis membrane filter element and a water purifier. The reverse osmosis membrane filter element comprises a central shaft; water inlet pipes, wherein the sidewall ofeach water inlet pipe is provided with at least one raw water outlet, at least one end of each water inlet pipe forms a raw water inlet, and a plurality of the water inlet pipes are arranged around the central shaft to form a central pipe group; and at least one reverse osmosis membrane module, wherein reverse osmosis membranes in the reverse osmosis membrane module are configured to pass throughspace between the central shaft and the water inlet pipes, and are rolled around the central pipe group to form a main filter element body having an inflow water passage and a produced water passage,the inflow water passage is in communication with the raw water outlets, a concentrated water out is formed in one side, away from the water inlet pipes, of the inflow water passage, and a pure wateroutlet is formed in at least one of the two sides, along the axis direction of the central pipe group, of the produced water passage. The reverse osmosis membrane filter element and the water purifier of the invention have high water making efficiency and good anti-pollution performance.

Owner:GREE ELECTRIC APPLIANCES INC

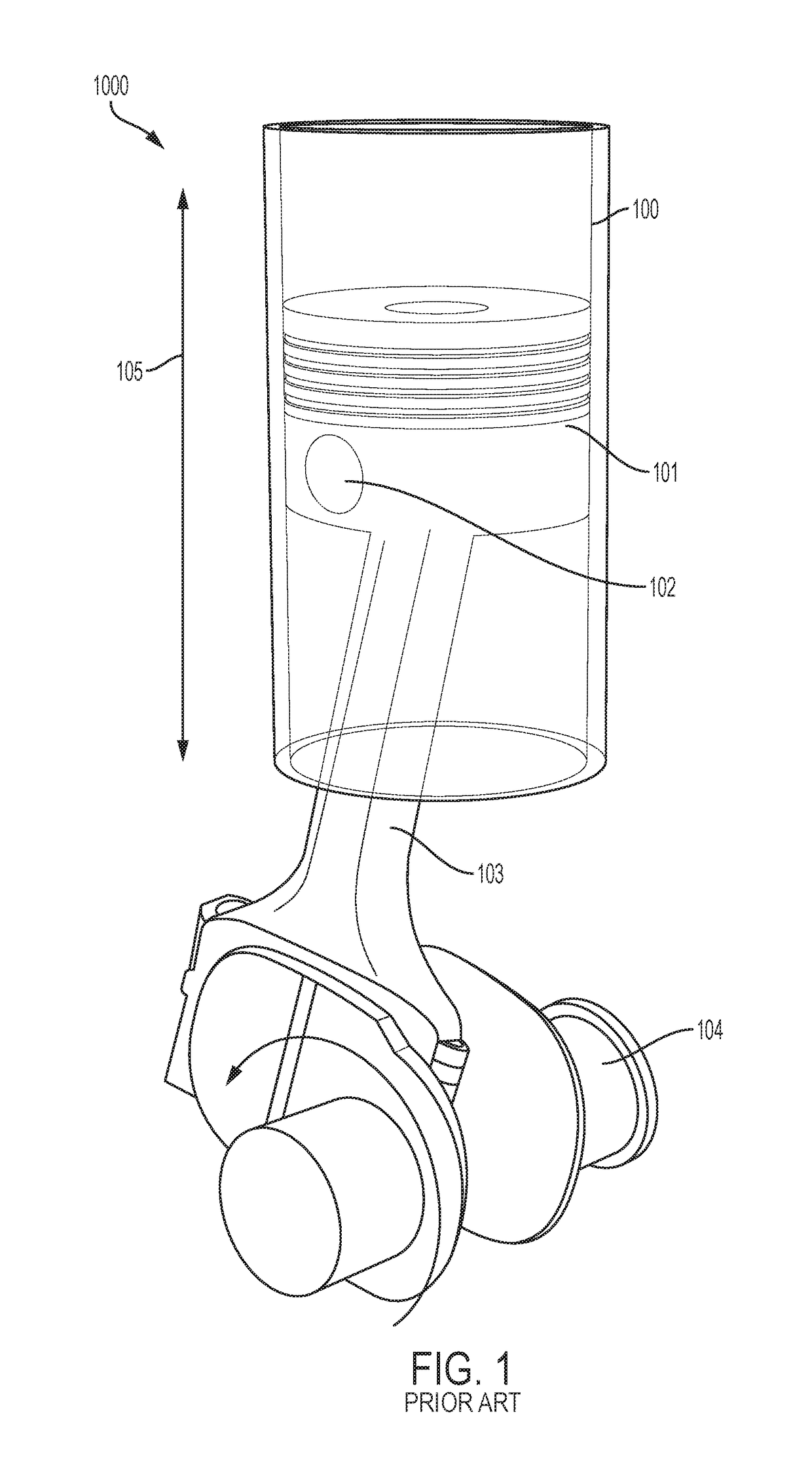

Sliding linear internal combustion engine

InactiveUS20180306108A1Improve thermal efficiencyIncrease effective pressureReciprocating piston enginesPistonEngineering

An internal combustion engine comprising a crankshaft rotatable about an axis, one or more pairs of cylinders opposed from each other on either side of the crankshaft, one or more pairs of pistons alternately moveable within the cylinders by combustion therein, and a common rod connecting the pair of pistons, the pistons and common rod being linearly slideable in a first direction. A linear bearing is disposed on the common rod between the pair of pistons and connects the common rod to the crankshaft, the linear bearing being slideable in a second direction normal to the first direction. As the pair of pistons alternately move within the cylinders, the crankshaft is driven by movement of the common rod and pair of pistons back and forth in the first direction and movement of the linear bearing back and forth in the second direction.

Owner:DAVIS GLOBAL ENGINES LLC

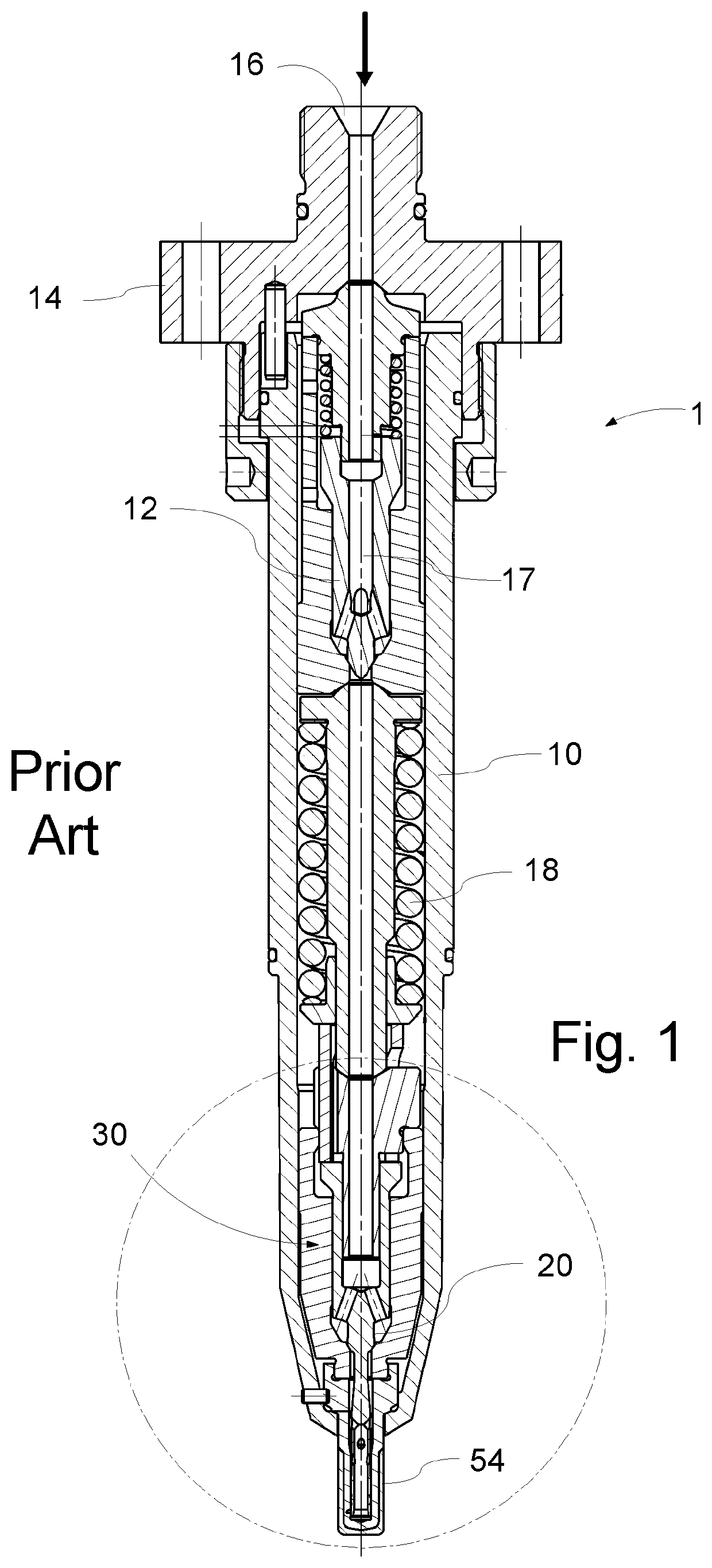

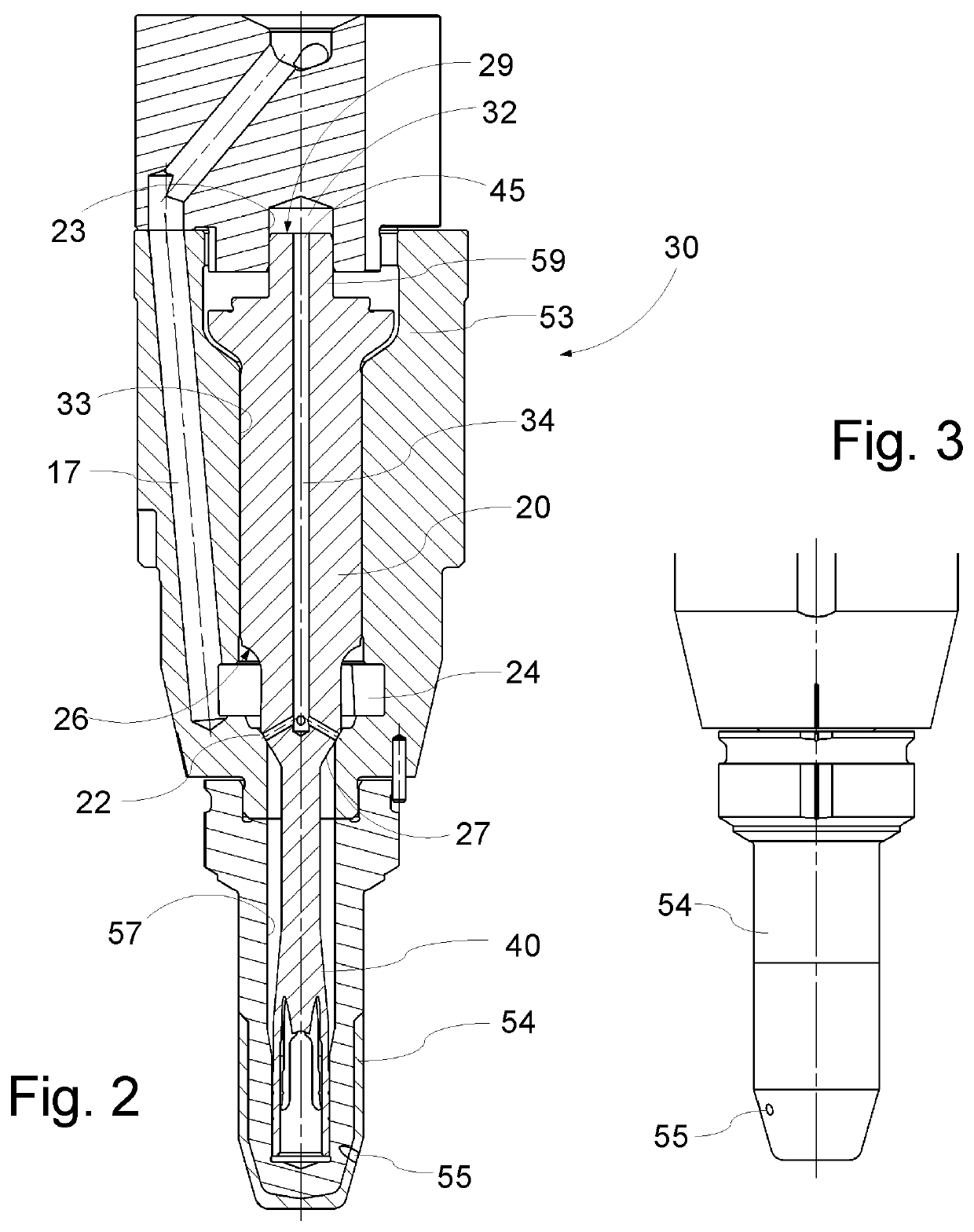

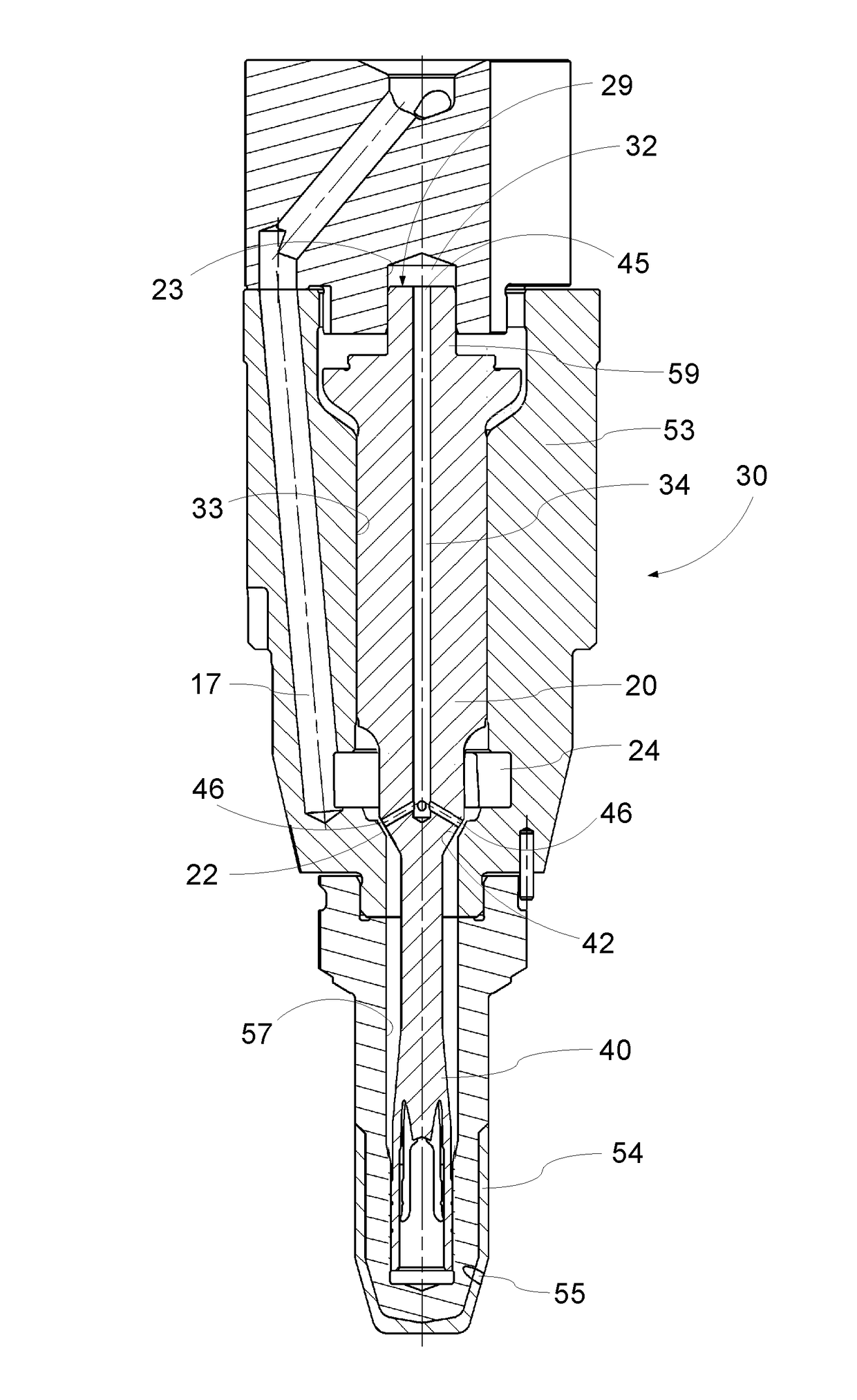

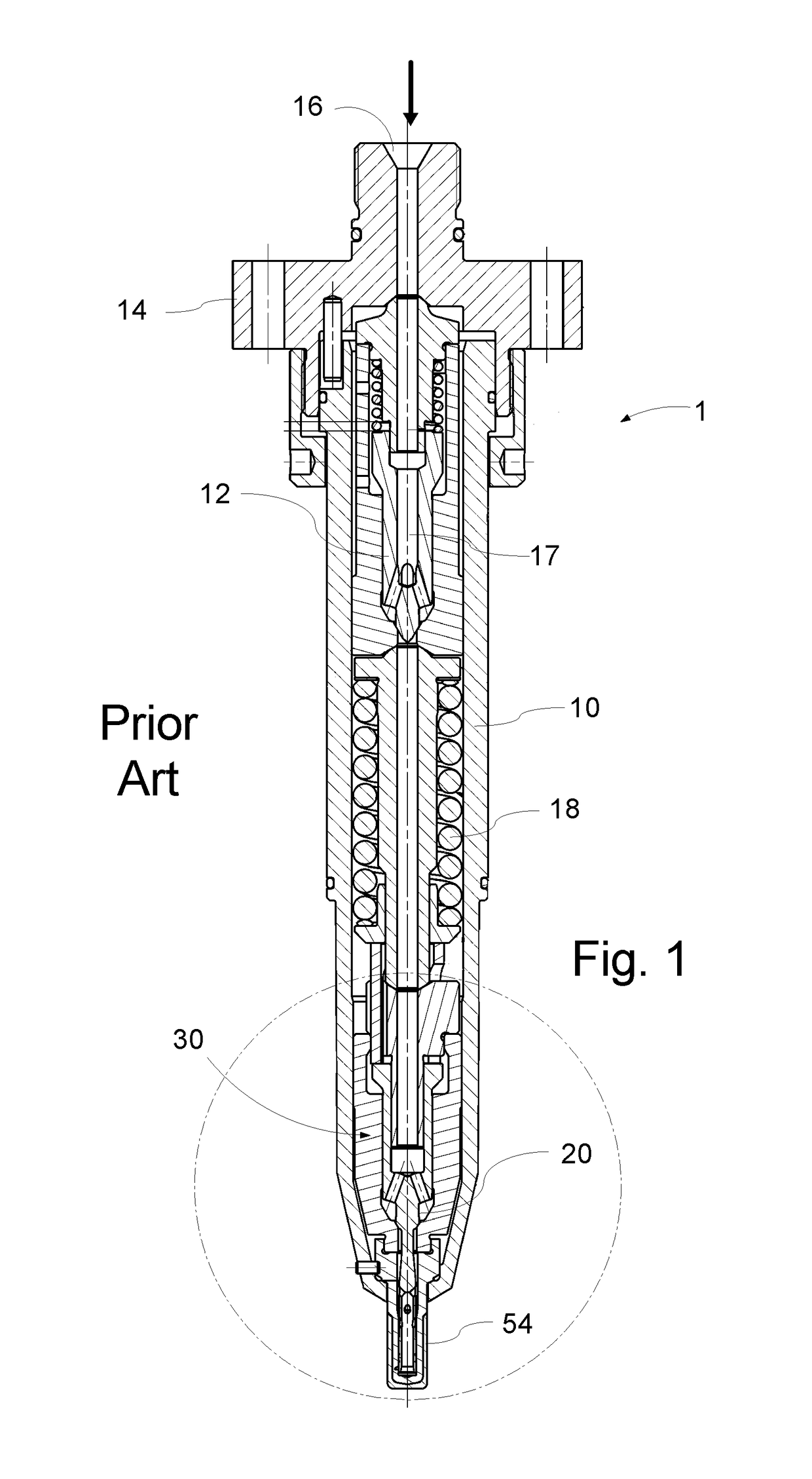

Fuel valve for a large two-stroke self-igniting internal combustion engine

ActiveUS10550811B2Avoid flowIncrease effective pressureFuel injection apparatusMachines/enginesCombustion chamberInternal combustion engine

A fuel valve for injecting fuel into the combustion chamber of a large two-stroke self-igniting internal engine combustion engine, with a valve needle that is resiliently biased towards a valve seat. The effective pressure surface that causes fuel pressure to urge the valve needle in the opening direction increases significantly when the valve needle has lift from the valve seat. A supplementary effective pressure surface is provided on the valve needle. The supplementary effective pressure surface creates a force urging the valve needle towards the valve seat when the supplementary effective pressure surface is exposed to fuel pressure.

Owner:MAN ENERGY SOLUTIONS FILIAL AF MAN ENERGY SOLUTIONS SE TYSKLAND

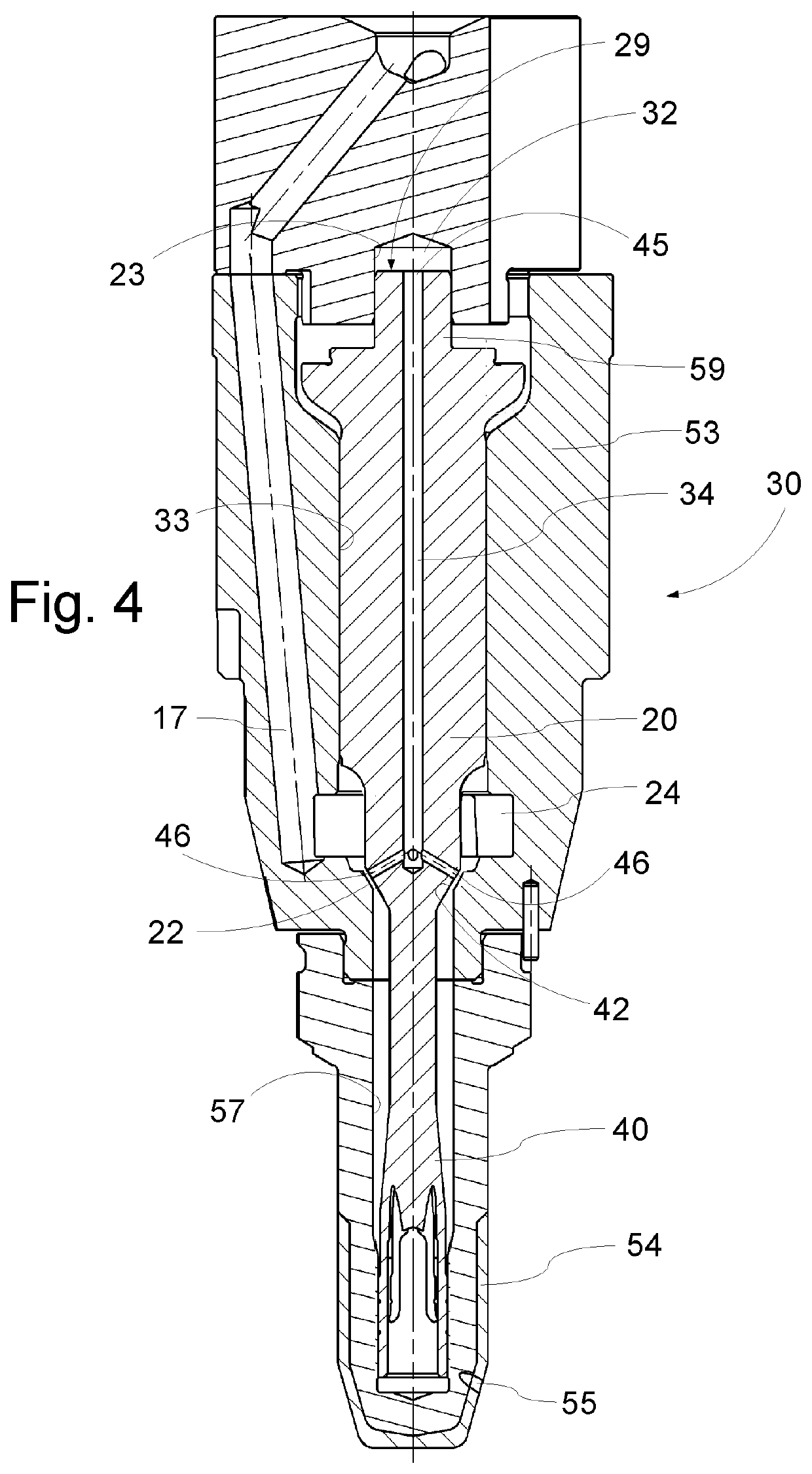

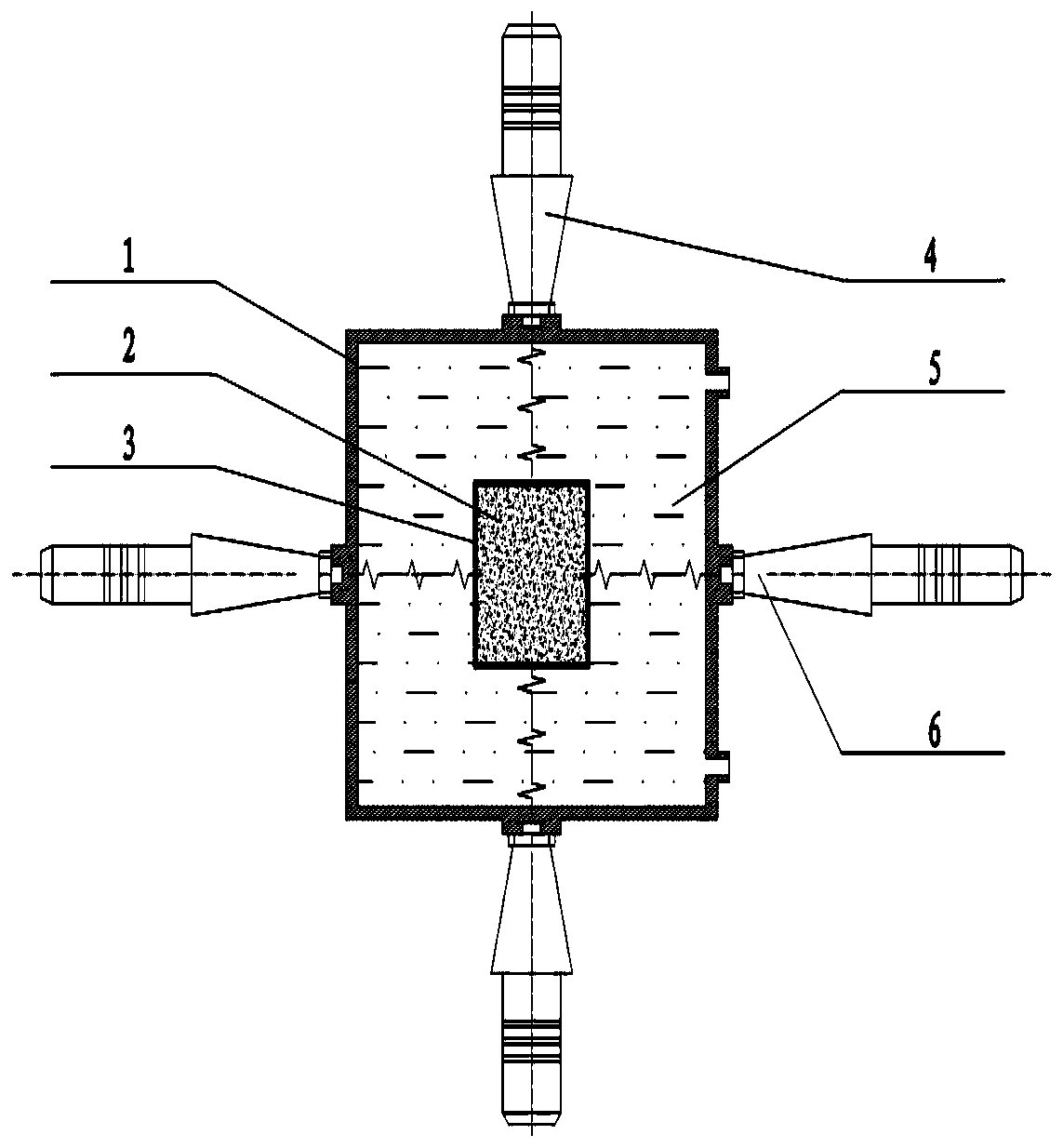

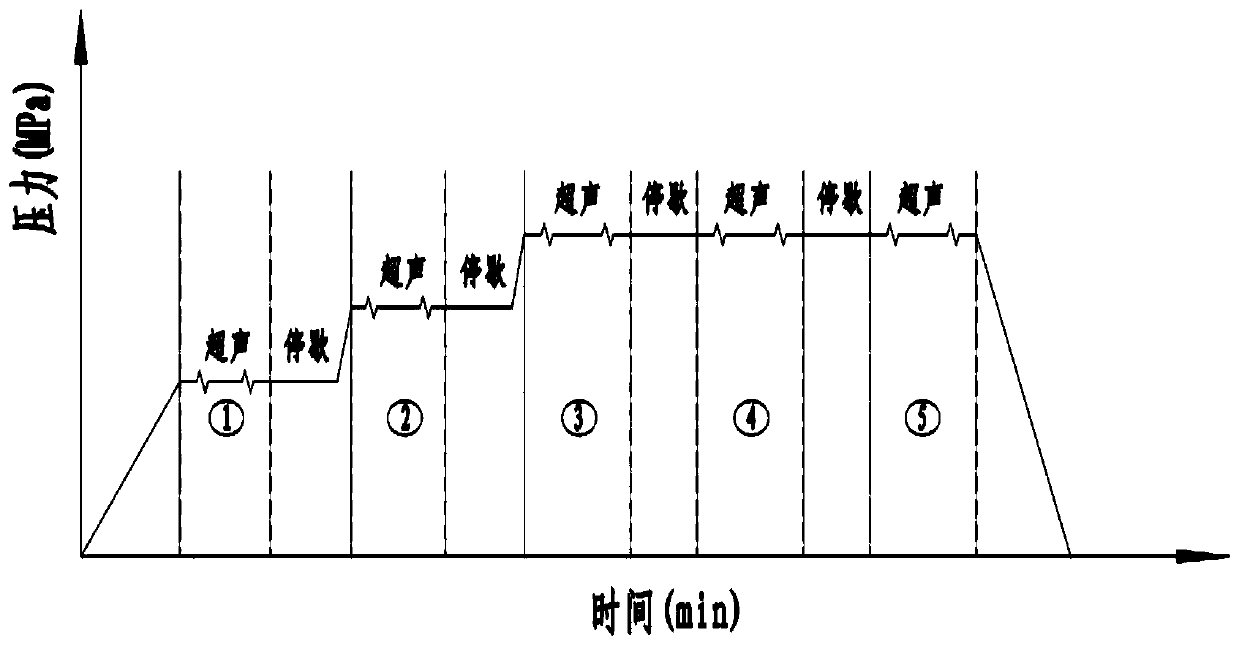

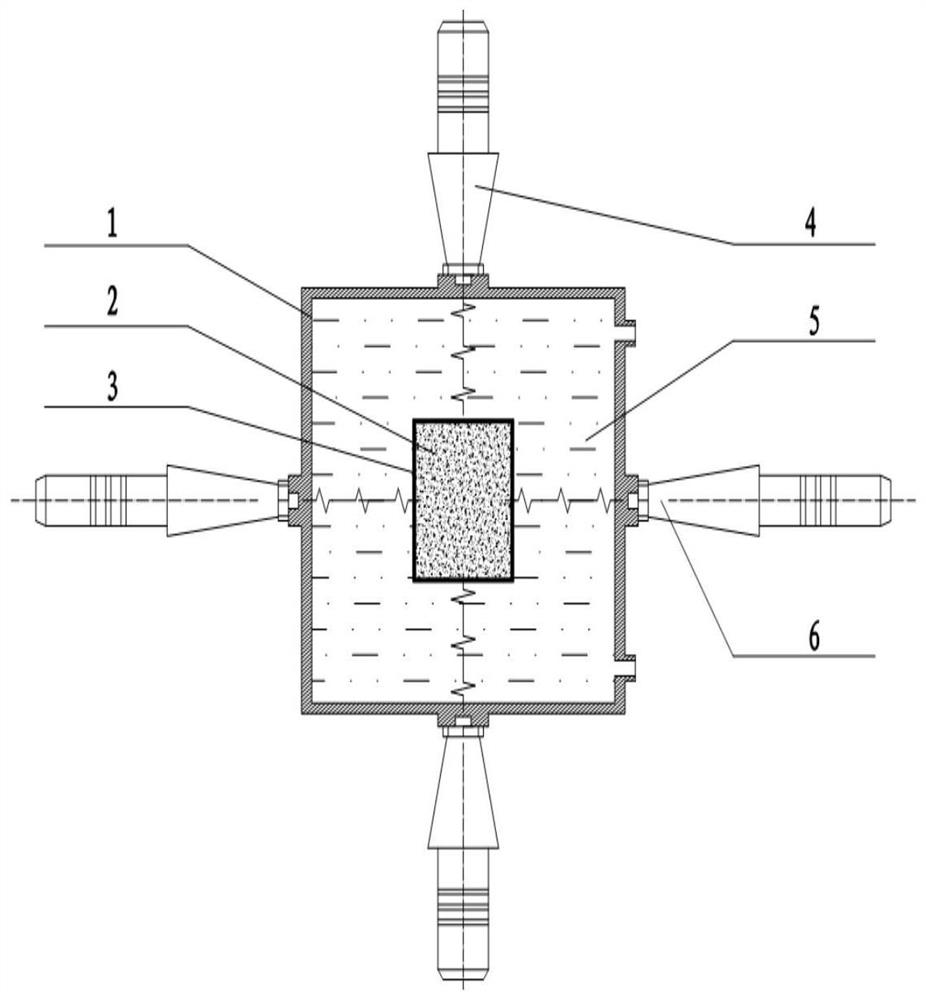

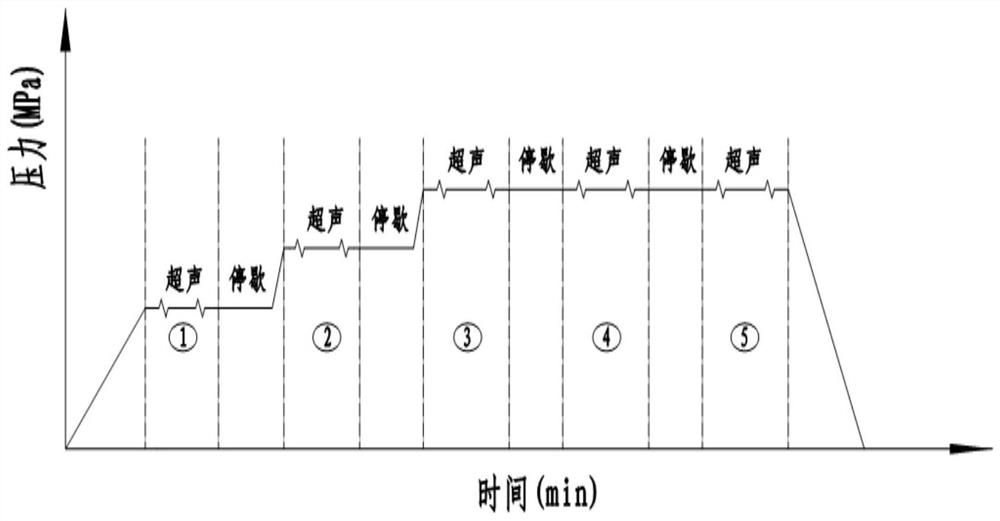

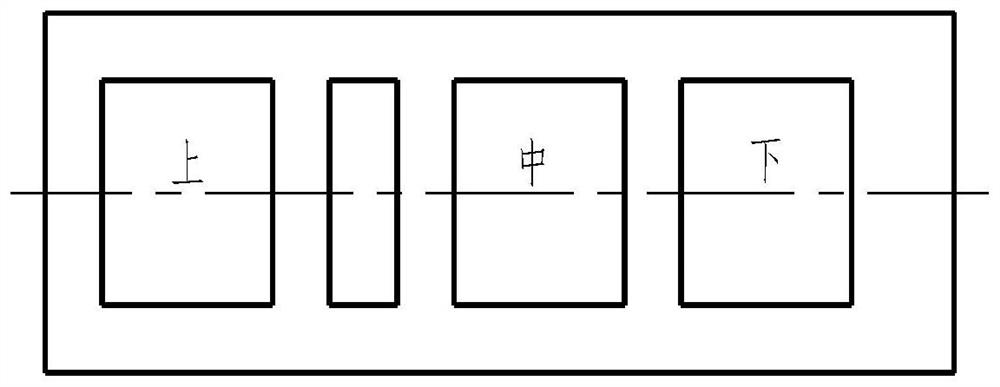

Ultrasonic auxiliary powder forming method in fluid environment

The invention discloses an ultrasonic auxiliary powder forming method in the fluid environment. Firstly, powder particles are formed under the action of hydrostatic pressure, the density of powder pressing blanks reaches about 80% of the theoretical density of the powder pressing blanks, application of the hydrostatic pressure is kept, power ultrasounds are introduced, and the powder pressing blanks are further densified and are uniform in stress under the ultrasonic vibration action. According to the ultrasonic auxiliary powder forming method in the fluid environment, the power ultrasounds are introduced in the powder particle hydrostatic pressure forming process, mobility and filling performance of the powder particles are improved, and the pressure needed for densification is reduced; and meanwhile, the density distribution uniformity of the formed pressing blanks can be improved, accordingly, residual stress of the powder pressing blanks is reduced, and the mechanical performance of the powder pressing blanks is improved. Meanwhile, the mechanical vibration action generated during spreading of ultrasonic waves in an oil medium, the ultrasonic cavitation effect, the heat actiongenerated due to sound wave absorption through the medium and the like are utilized, viscosity of the fluid medium can be obviously reduced, and the purpose of improving mobility of the fluid medium is achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Mechanical air fuel ratio regulating carburettor with fuel pressure regulation

InactiveCN101087943BImprove combustion efficiencyIncrease effective pressureMachines/enginesCarburettorsCarburetorEngineering

The present invention describes a carburetor (8) which comprises an air inlet (2) including a mechanically adjustable air valve (3), a mechanically adjustable sprayer that connects the air inlets, and a mechanically measuring device that is connected to the air valve and the sprayer and sustains the stoichiometric ratio between the amount of the air and the fuel. Besides, the vaporizer comprises a fuel pressure adjusting device (13) which affects the fuel pressure according to one or more than one power engine load parameter, and under the fuel pressure the vacuum suction feeding pipe (12) communicating the air inlets (2) obtains the vacuum signal in the air inlet. The fuel pressure is adjusted according to the measured vacuum signal and the discharging of unburnt fuel is reduced under certain dynamic conditions of the internal combustion engine.

Owner:安东尼 约翰 威廉姆斯

Manufacture method and die for powder metallurgy inside spin ratchet wheel

The invention relates to a method for producing powder smelt screw ratchet, which comprises: mixing the materials, compressing molding, sintering, compressing and shaping, to obtain the ratchet. The invention also discloses a relative mould, which is formed by a compressing upper punch, compressing middle mould, compressing lower punch; the upper part of lower punch has the inner screw tooth matched with the outer screw tooth; the upper punch is sliding matched with the middle mould; the middle mould is sliding matched with the lower mould; the compressing core rod has compressing core rod, friction plate, and rotation element; the upper part of compressing core rod has outer screw tooth; the lower end of core rod and the upper end of rotating element have friction plate between them, while their contact surface has lubricant. The invention, via the rotation of core rod, realizes the one-time molding and demoulding of inner screw ratchet, to improve the yield and reduce the cost.

Owner:南通市海门常乐粉末冶金厂

Metal casting mold and method for manufacturing aluminum bronze explosion-proof hammer

The invention relates to a metal mold for manufacturing an aluminum bronze explosion-proof hammer, which includes a horizontally divided upper half mold and a lower half mold; A lower mold half-cavity corresponding to the upper mold half-cavity is provided, an upper half-core is arranged in the center of the top surface of the upper mold half-cavity, and a lower half-core is arranged in the center of the bottom surface of the lower mold half-cavity; The outside of the explosion-proof hammer head cavity is located on the parting surface of the upper half and the lower half, and an exhaust channel is provided; the upper half is provided with an upper pressure head; the center of the lower half is provided with a material storage cavity, the bottom of the storage cavity is provided with a lower pressure head; a flow channel is provided between the storage cavity and the lower mold half cavity. The present invention also relates to a method for manufacturing an aluminum bronze explosion-proof hammer by using the above-mentioned metal casting mold, so as to solve the problems of low density, coarse structure and easy jumping during use of the aluminum bronze explosion-proof hammer produced by the existing casting technology.

Owner:HEBEI BOTOU SAFETY TOOLS CO LTD +1

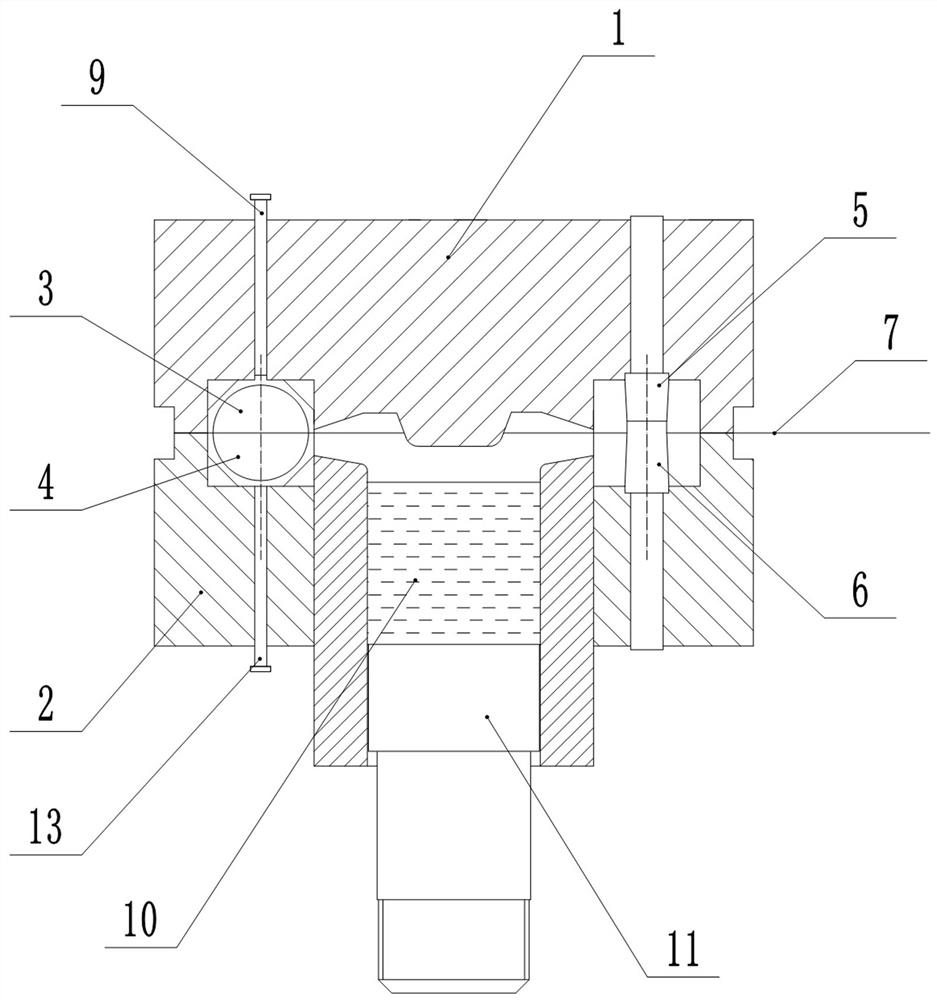

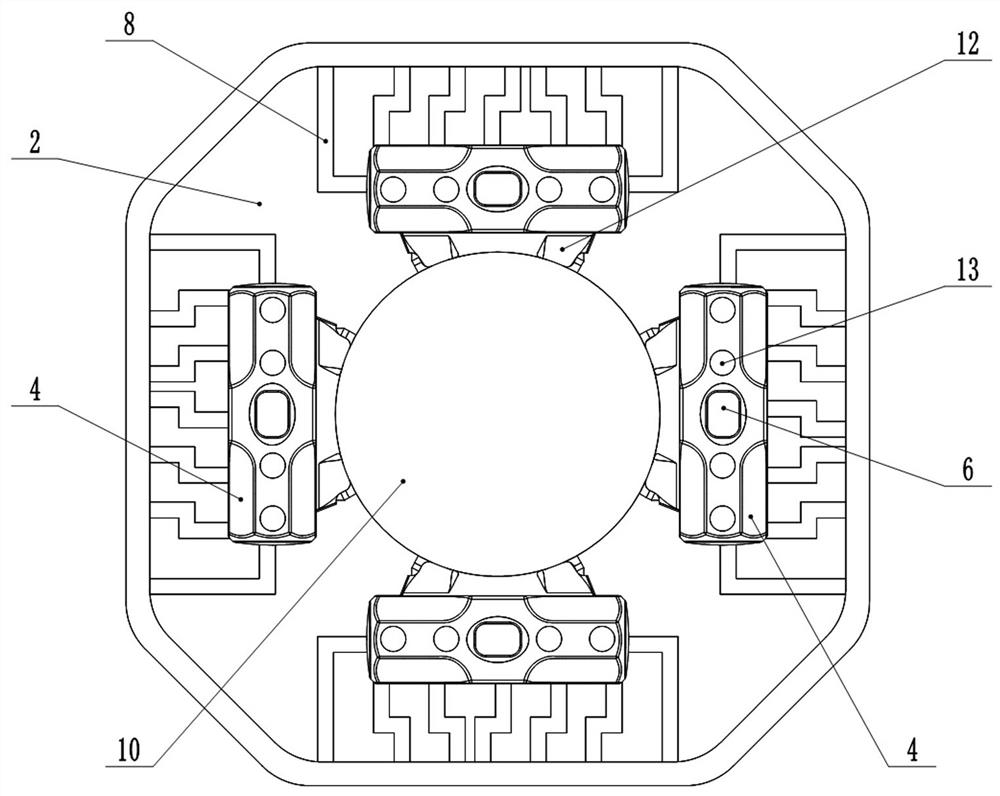

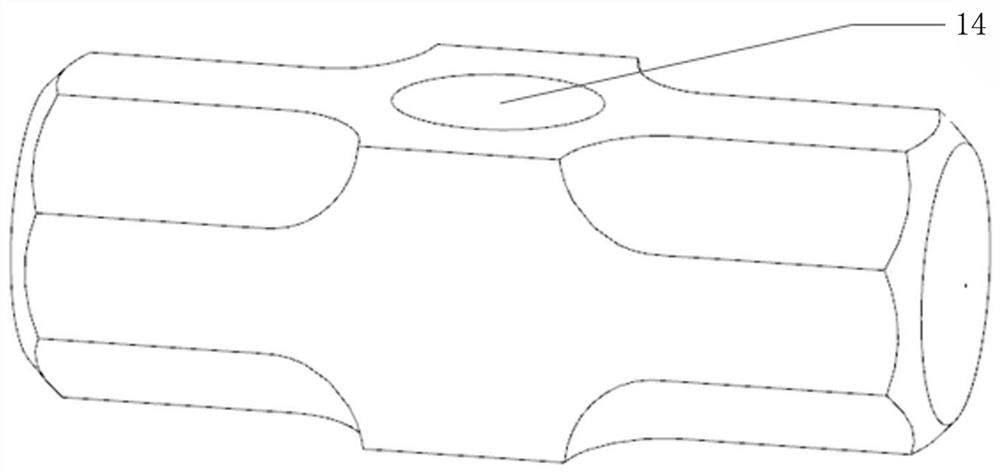

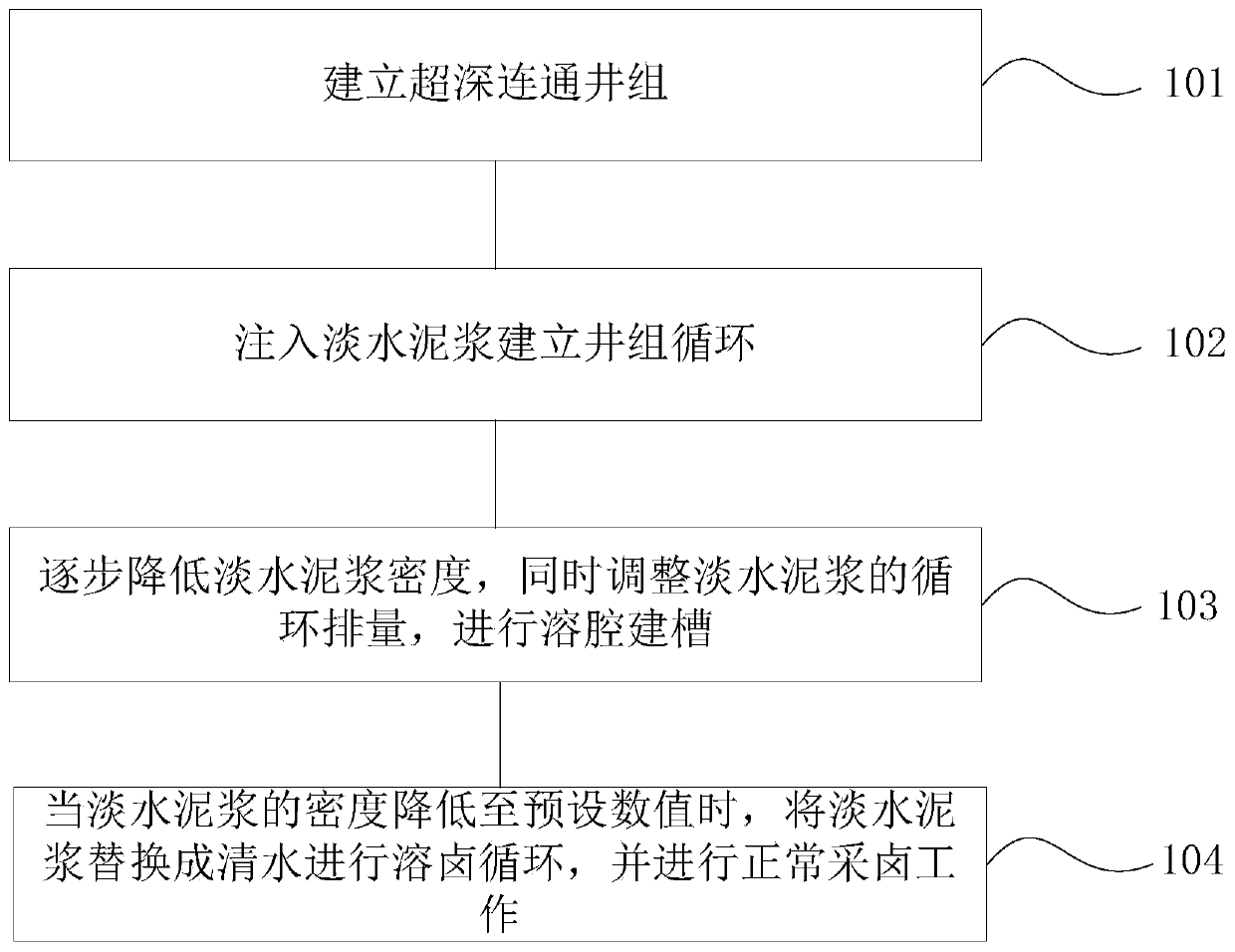

Dissolving cavity groove-construction method for tertiary-system stratum ultra-deep connection brine mining well

InactiveCN111287725ARealize normal brine miningIncrease effective pressureFluid removalFlushingBrine miningFresh water

The invention relates to the technical field of bittern production, in particular to a dissolving cavity groove-construction method for a tertiary-system stratum ultra-deep connection brine mining well. The dissolving cavity groove-construction method for the tertiary-system stratum ultra-deep connection brine mining well comprises the following steps of: establishing an ultra-deep connection wellgroup; injecting fresh water mud, and establishing well group circulation; gradually lowering the concentration of the fresh water mud, meanwhile, regulating a circulation displacement of the fresh water mud, and carrying out dissolving cavity groove construction; and when the concentration of the fresh water mud is lowered to a preset numerical value, replacing the fresh water mud with clear water, and carrying out dissolved brine circulation, and carrying out normal brine mining work. When the method provided by the embodiment of the invention is adopted, well bottom effective pressure canbe improved, and stratum stress is gradually released to avoid a situation that a stratum suddenly loses stability and collapses on a large area to block a channel. Meanwhile, salt bed creepage and hole shrinkage can be alleviated so as to gradually enlarge a horizontal channel, transition from mud to clear water is successfully finished during a groove-construction period of the ultra-deep connection well group, and therefore, the normal brine mining of the ultra-deep connection well group is successfully realized.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Ultrasonic-assisted powder forming method in a fluid environment

The invention discloses an ultrasonic-assisted powder forming method in a fluid environment. Firstly, the powder particles are formed under the action of hydrostatic pressure, so that the density of the powder compact reaches about 80% of its theoretical density, and the hydrostatic pressure is kept applied and introduced Ultrasonic power makes the powder compact further compacted and stress homogenized under the action of ultrasonic vibration. The present invention improves the fluidity and filling performance of powder particles by introducing power ultrasound into the hydrostatic pressure forming process of powder particles, reduces the pressure required for compaction, and can improve the density distribution uniformity of the formed compact at the same time, thereby reducing the powder density. The residual stress of the body compact increases its mechanical properties. At the same time, the viscosity of the fluid medium can be significantly reduced and the fluidity of the fluid medium can be improved by using the mechanical vibration generated when the ultrasonic wave propagates in the oil medium, the ultrasonic cavitation effect, and the thermal effect generated by the medium absorbing the sound wave.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

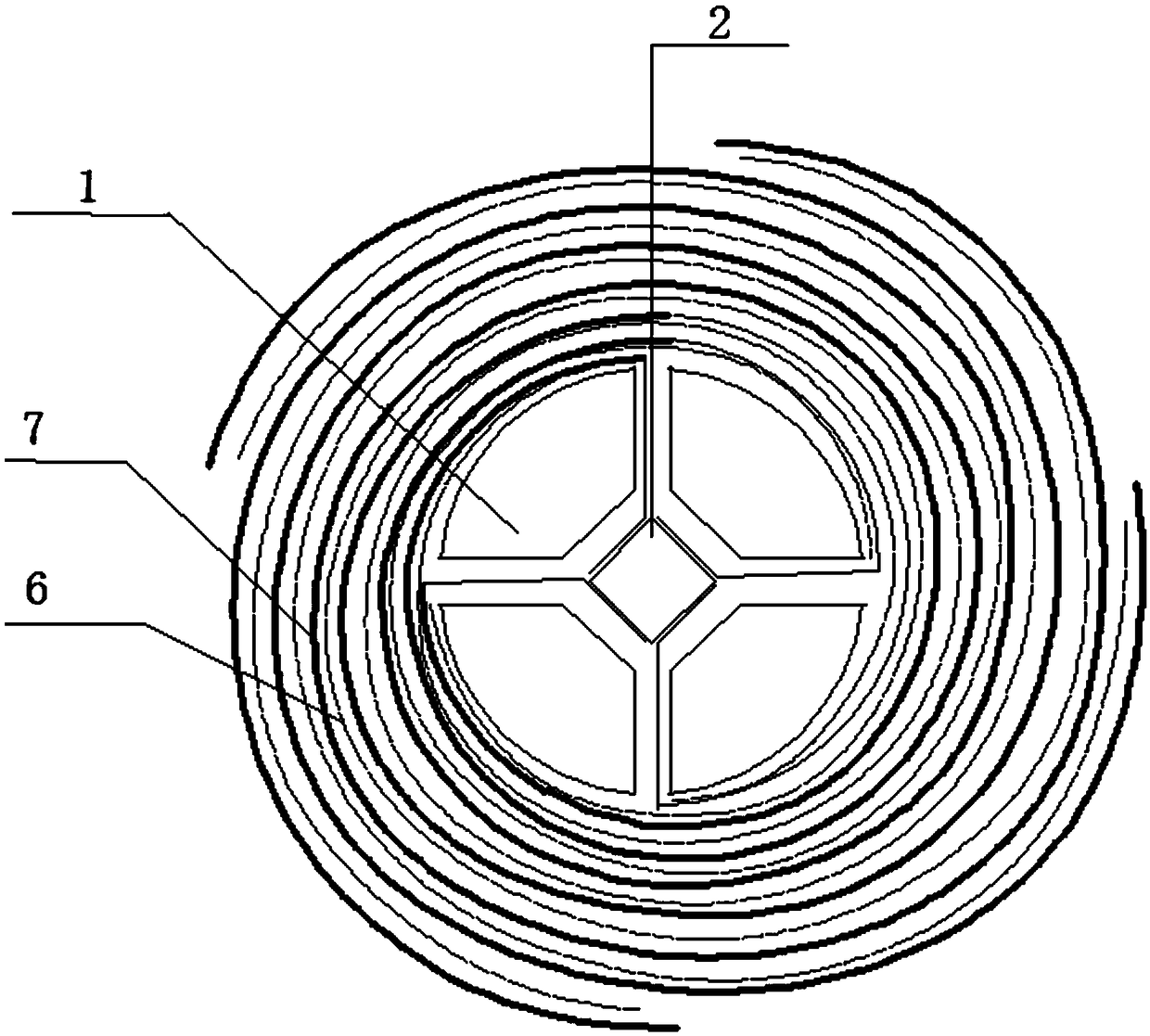

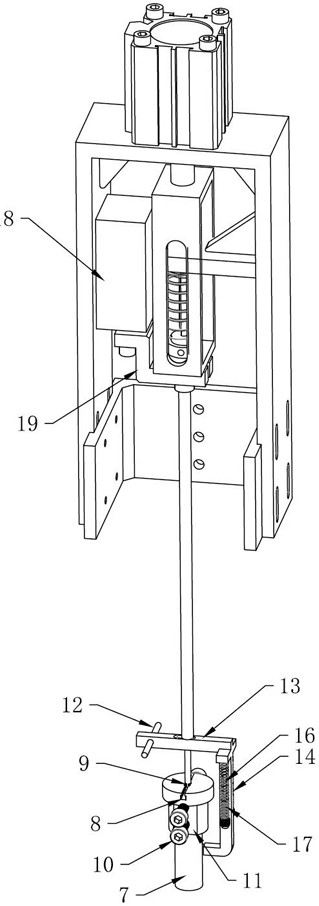

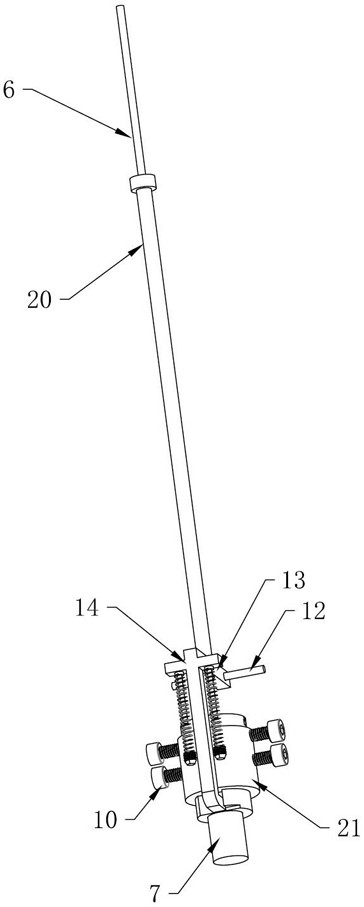

Hollow coil winding clamp and winding method

ActiveCN113963937ASimple actionFast and efficient windingCoils manufactureClassical mechanicsSpring force

The invention relates to a hollow coil winding clamp, a cross clamp of the hollow coil winding clamp can achieve power of wire clamping action and clamp loosening action under the action of a clamp pressing air cylinder, the action is simple, and wire clamping is rapid and efficient. The power of the wire clamping action of the cross clamp directly comes from the extension of an air cylinder, an ejector sleeve is a long-strip-shaped cylindrical object, and the arm length can be increased, so that the moment generated under the condition that the spring force is reduced is enough to open the clamp. The hollow coil winding clamp has the advantages of small resistance generated by extension of the pressing and clamping cylinder, large force of the clamp pressing on the enameled wire, good wire clamping effect and the like.

Owner:GUANGDONG DECE TECH LTD

Multipurpose reciprocating internal combustion engine

InactiveCN100337016CIncrease effective pressureReduce wearMachines/enginesExternal combustion engineFuel oil

The invention discloses a multipurpose internal combustion reciprocating engine, wherein the power piston is directly connected with the dynamo-electric generator rotor or the compression piston of a compressor and hydrostatic machine plunger piston, forming an integration. The engine distribution wheel has an electromagnetic driven compression ratio regulating device. A synchronous device consisting two pairs of bevel gears and a steel tube is used balance the mass of alternative motion and eliminate vibration. Because of the simple engine structure, no cylinder lateral pressure and adjustable compression ratio, the engine is easy to start.

Owner:邹立田

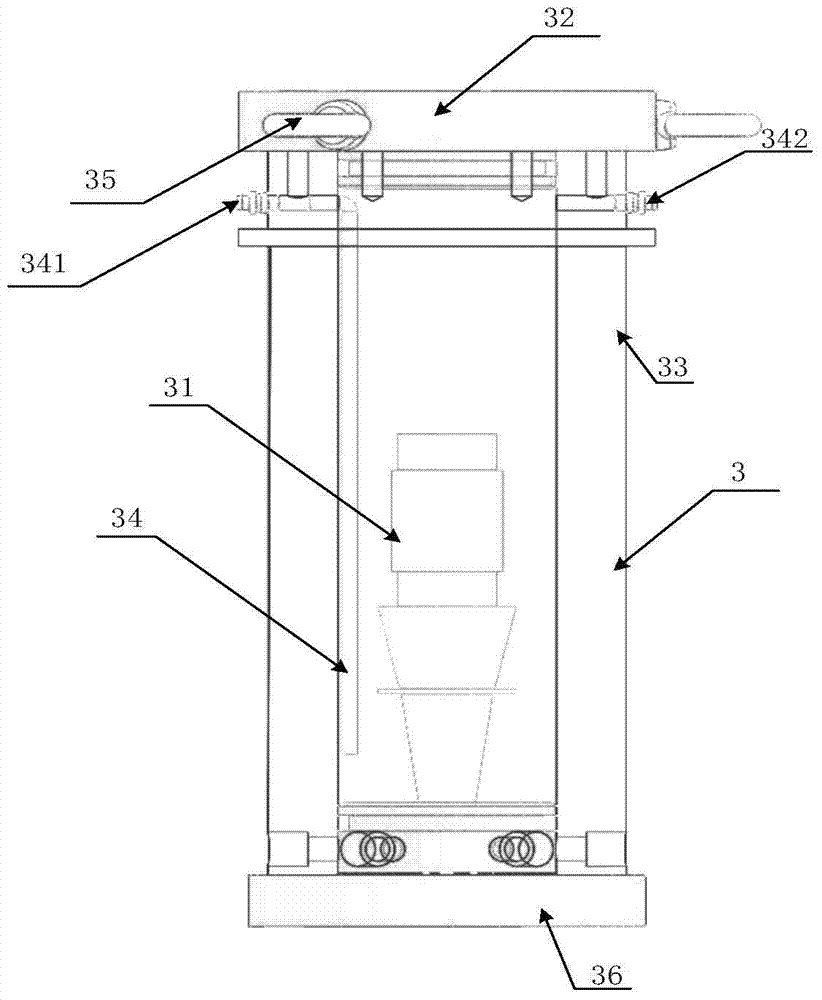

Powder material compression molding method assisted by ultrasonic vibration

ActiveCN105619867BReduce internal frictionReduce external frictionShaping pressMetallurgyVolumetric Mass Density

The invention relates to the technical field of pressing formation on powder materials, and provides a method for performing pressing formation on a powder material under assistance of ultrasonic vibration. The method comprises the following steps that safety equipment for performing the pressing formation on the powder material is established; a to-be-pressed powder material is put in an ultrasonic die sleeve; a hydraulic machine is started, an ultrasonic punch does a relative movement under action of the hydraulic machine, and the powder material is driven to do a downward movement so as to be pressed; and a finished product obtained after the powder material in the ultrasonic die sleeve is pressed is taken out. According to the technical solution provided by the invention, internal friction among particles of the powder material and external friction between the particles and a die wall of the ultrasonic die sleeve are reduced, effective pressure of grains on different layers is increased, internal density uniformity is improved, and internal stress is reduced, therefore high-quality formation preparation of the grains is realized.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Metal casting mold for manufacturing aluminum bronze explosion-proof hammer and method thereof

The invention relates to a metal casting mold for manufacturing an aluminum bronze explosion-proof hammer. The metal casting mold comprises an upper half mold and a lower half mold which are horizontally parted, wherein an upper casting mold half cavity is formed in the upper half mold; a lower casting mold half cavity corresponding to the upper casting mold half cavity is correspondingly formed in the lower half mold; an upper half core is arranged in the center of the top surface of the upper casting mold half cavity; a lower half core is arranged in the center of the bottom surface of the lower casting mold half cavity; an exhaust passage is formed in the parting surface of the upper half mold and the lower half mold on the outer side of an explosion-proof hammer head cavity; an upper pressure head is arranged on the upper half mold; a storage cavity is formed in the center of the lower half mold; a lower pressure head is arranged at the bottom of the storage cavity; and a runner isarranged between the storage cavity and the lower casting mold half cavity. The invention further relates to a method for manufacturing the aluminum bronze explosion-proof hammer by using the metal casting mold, so that the problems of low density, thick and large structure and being prone to block jumping in use in the production of the aluminum bronze explosion-proof hammer head in the prior art of casting are solved.

Owner:HEBEI BOTOU SAFETY TOOLS CO LTD +1

A fuel valve for a large two-stroke self-igniting internal combustion engine

ActiveUS20180298859A1Low closing pressureIncrease effective pressureFuel injection apparatusMachines/enginesExternal combustion engineEngineering

A fuel valve for injecting fuel into the combustion chamber of a large two-stroke self-igniting internal engine combustion engine, with a valve needle that is resiliently biased towards a valve seat. The effective pressure surface that causes fuel pressure to urge the valve needle in the opening direction increases significantly when the valve needle has lift from the valve seat. A supplementary effective pressure surface is provided on the valve needle. The supplementary effective pressure surface creates a force urging the valve needle towards the valve seat when the supplementary effective pressure surface is exposed to fuel pressure.

Owner:MAN ENERGY SOLUTIONS FILIAL AF MAN ENERGY SOLUTIONS SE TYSKLAND

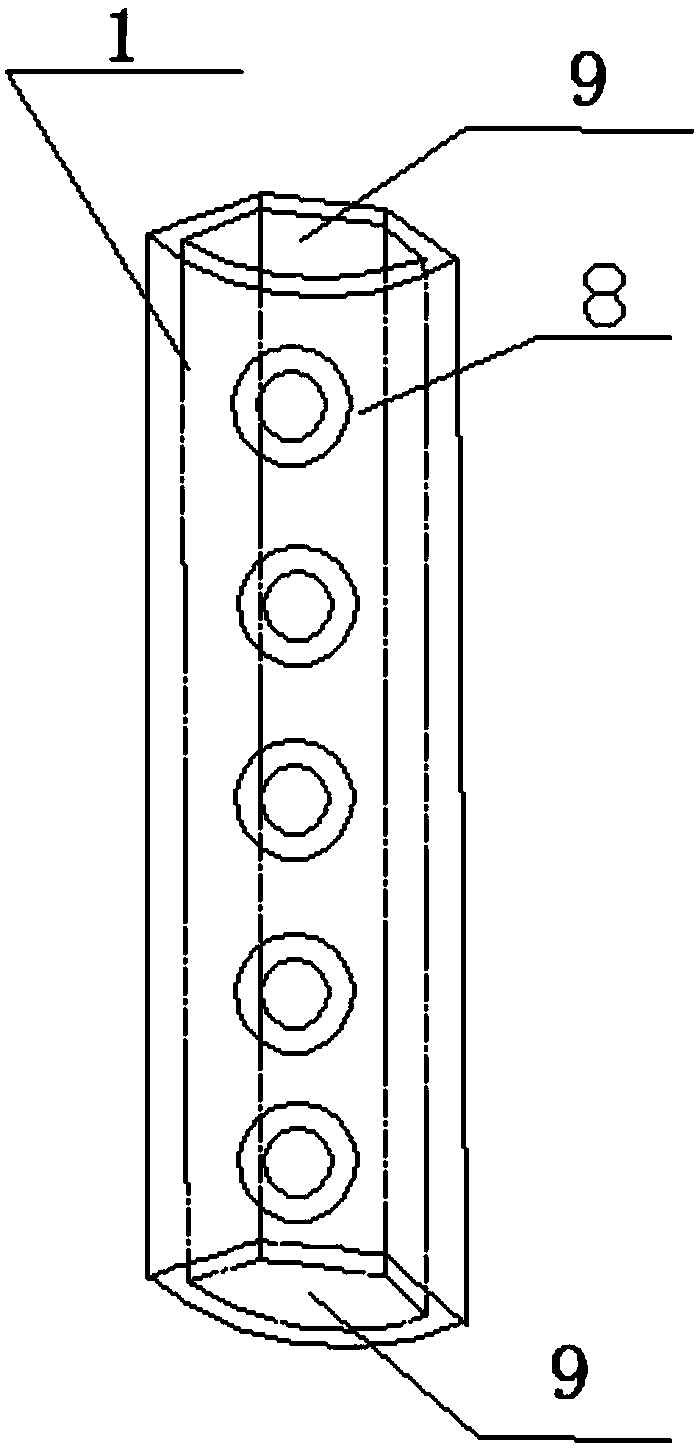

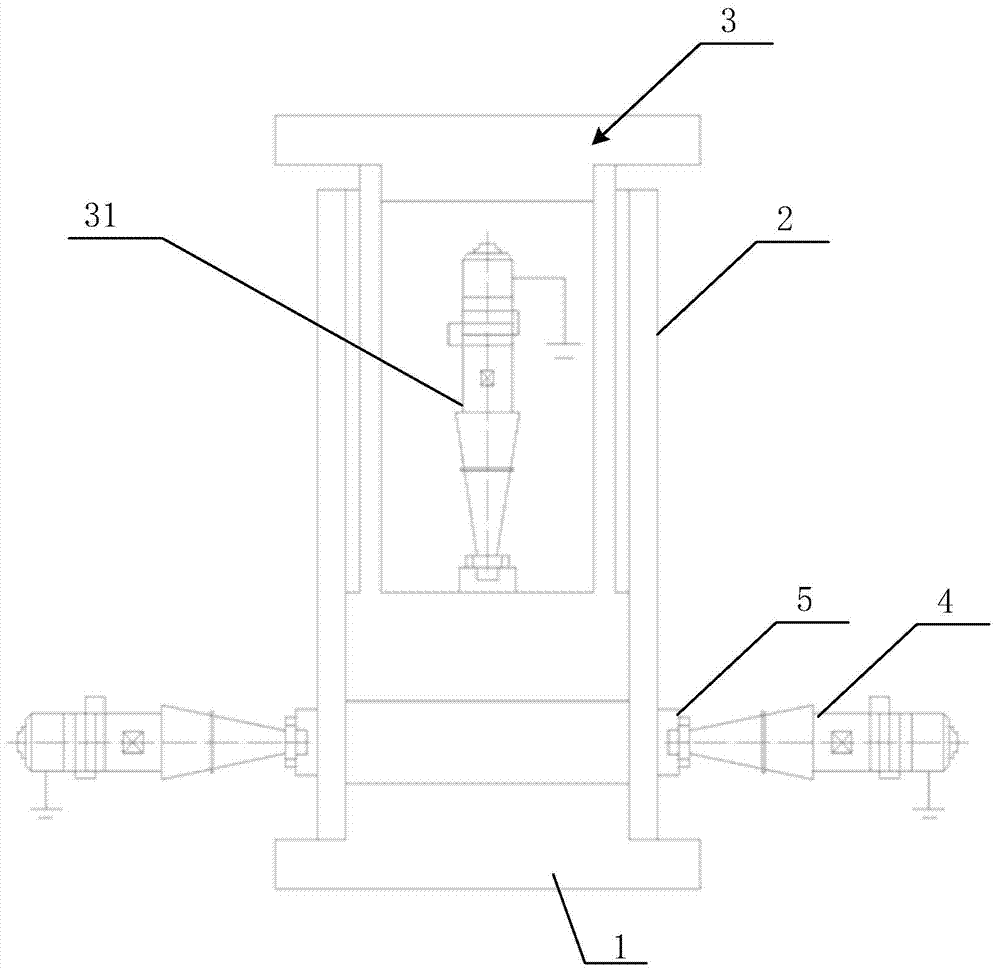

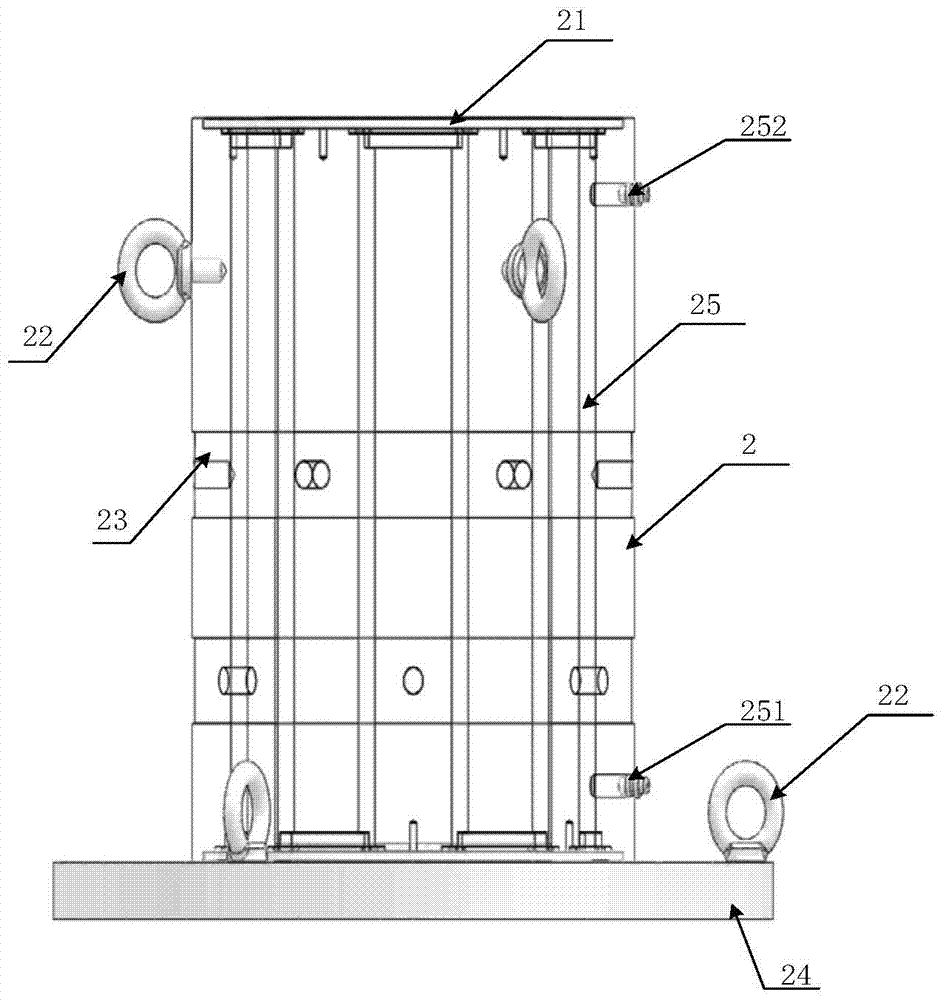

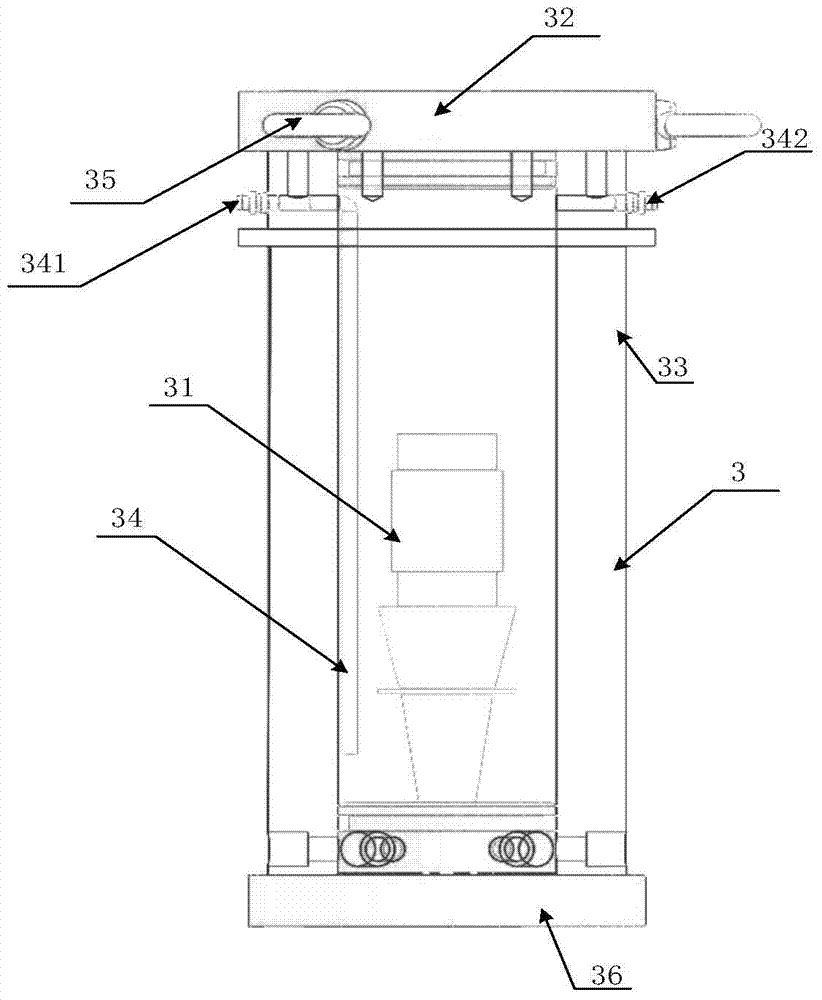

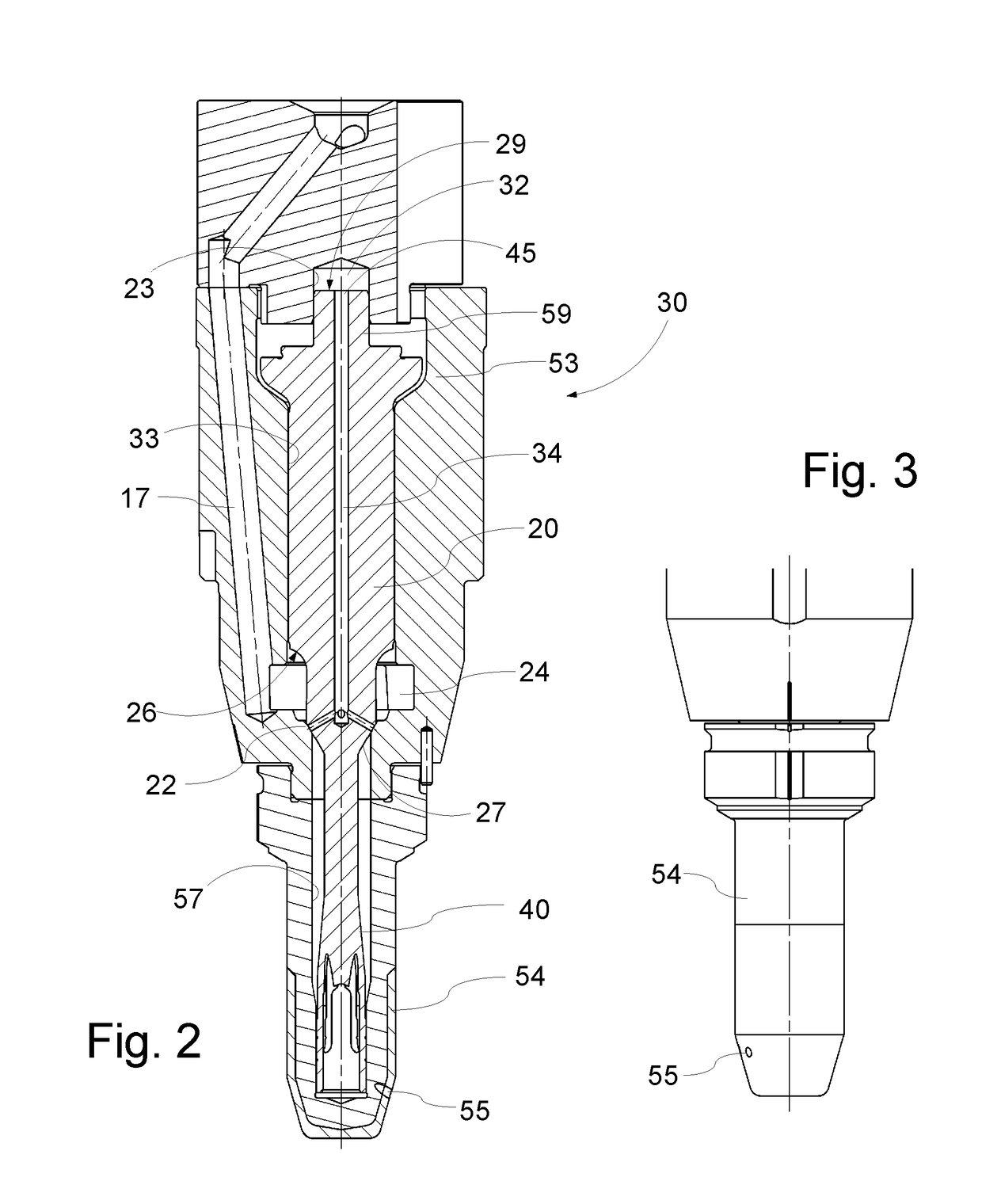

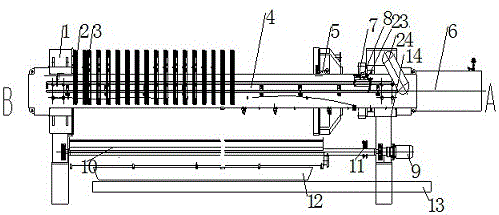

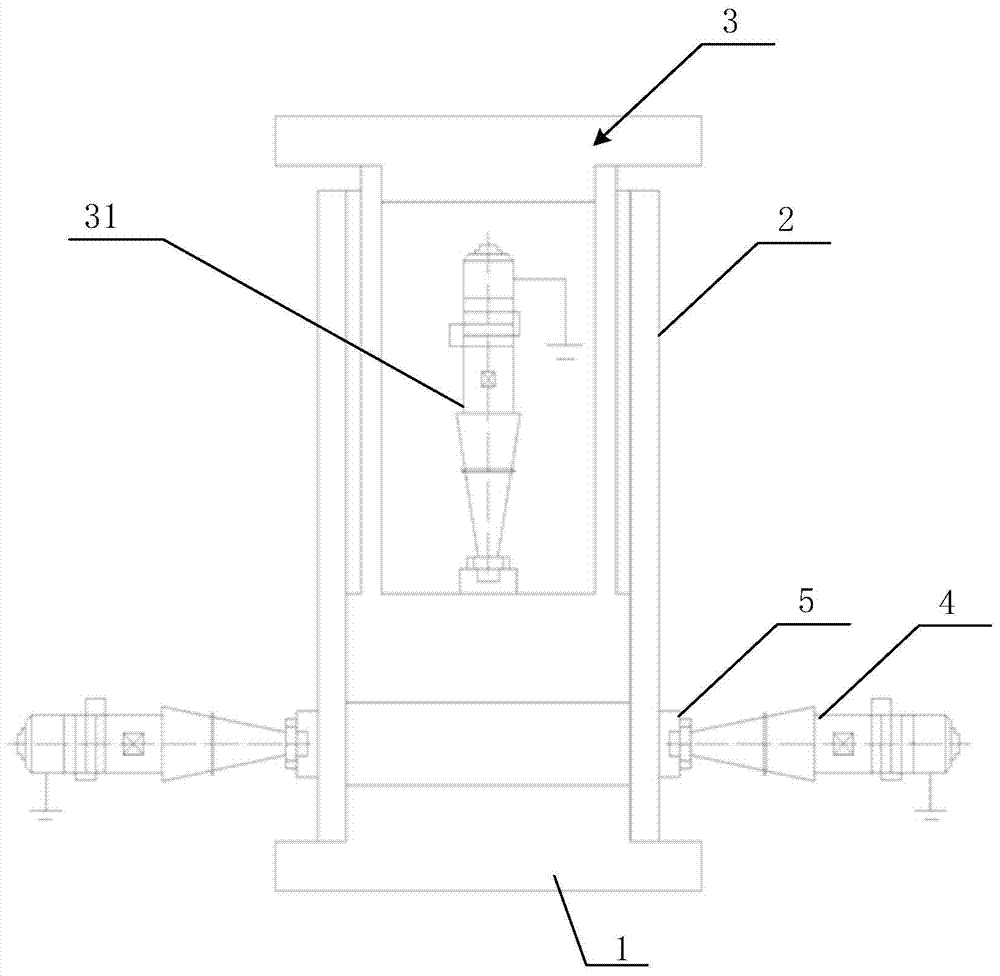

A high-efficiency filter press

The invention discloses a high-efficiency filter press which comprises a frame, wherein a thrust plate is fixedly arranged at one end of the frame while a movable plate is arranged at the other end of the frame; the movable plate is driven by a main oil cylinder and is moveably arranged on the frame; a plurality of filter plates which can move horizontally are arranged between the thrust plate and the movable plate on the frame; a mud inlet is formed each filter plate; a feeding variable cavity small oil cylinder is arranged between two adjacent filter plates and a filter cavity is formed therebetween; filter cloth is arranged in the filter cavity; a pulling plate mechanism for separating the filter plates is arranged on the frame. The high-efficiency filter press disclosed by the invention has the characteristics of being great in compression ratio, large in effective squeezing volume, great in squeezing pressure, low in water content of squeezed substances, high in work efficiency and long in service life of the filter plates.

Owner:陈建芬 +1

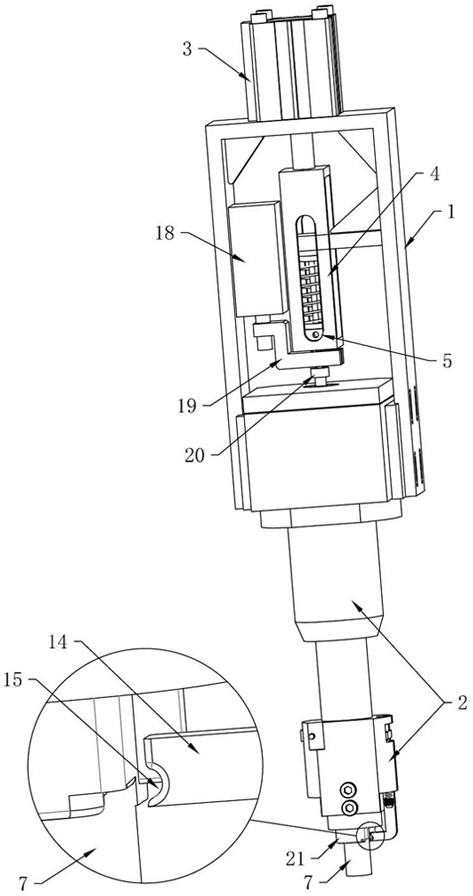

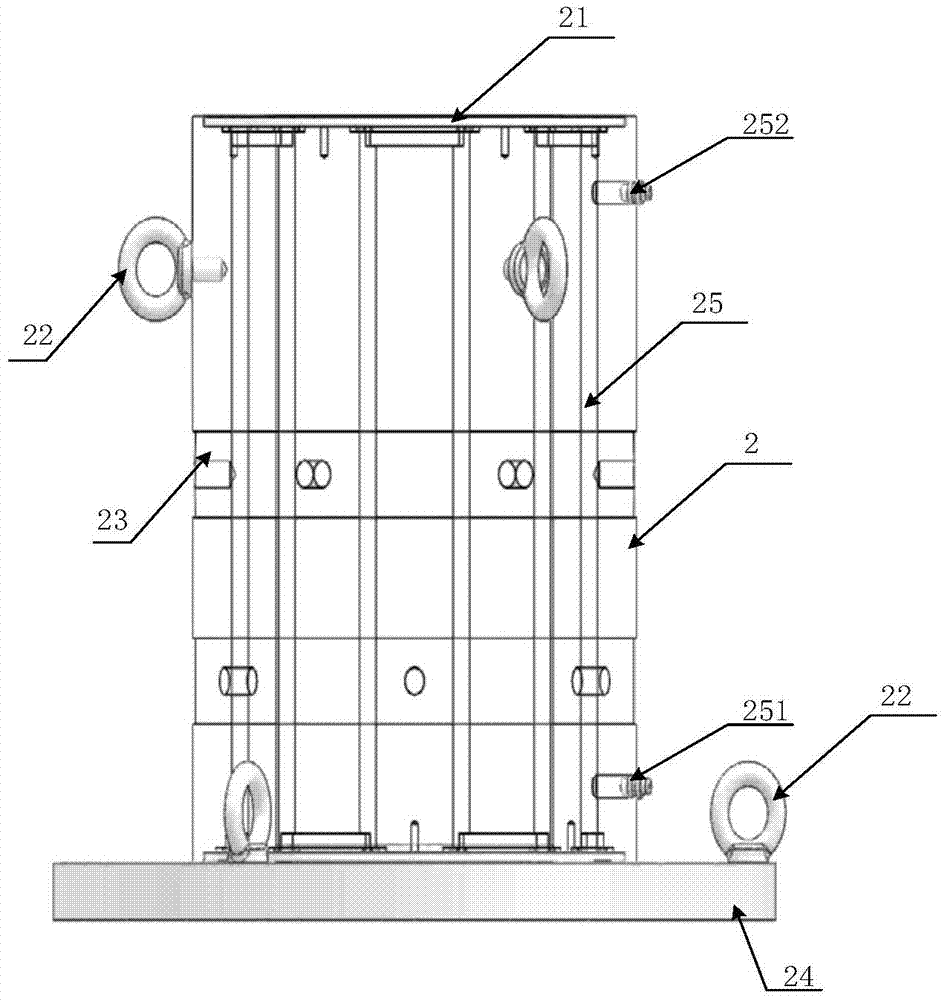

Powder material compression molding safety equipment assisted by ultrasonic vibration

ActiveCN105643975BReduce internal frictionReduce external frictionShaping pressTransducerUltrasonic vibration

The invention relates to the technical field of powder material pressing molding and provides a powder material pressing molding safety device under the assistance of ultrasonic vibration. The device comprises an ultrasonic base, an ultrasonic die sleeve installed on the ultrasonic base, an ultrasonic punch used in cooperation with the ultrasonic die sleeve, a hydraulic machine driving the ultrasonic punch, a first ultrasonic transducer and a transducer connecting part. By means of the technical scheme, inner friction among powder material particles and outer friction between the particles and the side wall of the ultrasonic die sleeve are lowered, the effective pressure of different layers of grains is improved, densification of powder material parts is effectively improved under existing moderate molding conditions, internal density uniformity is improved, internal stress is reduced, and therefore the grains can be molded and manufactured with high quality.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Vacuum secondary hot pressing manufacturing process of a high-strength polycrystalline diamond wire drawing die

The invention discloses a manufacturing process of a high-strength polycrystalline diamond wire drawing die by vacuum secondary hot pressing. The insert is obtained by vacuum secondary hot pressing of metal powder: The pressure is 20-45MPa, the temperature is raised to 500-550°C at a rate of 20-30°C / min, the temperature is kept for 10-20min, the temperature is raised to 600-650°C at a rate of 10-15°C / min, and the heat is kept for 10-15min , hold the pressure for 15-20 minutes and cool to obtain a wire drawing die. The invention adopts the method of vacuum secondary hot pressing to improve the density of the material; it can eliminate the elastic strain in the cold pressing process and reduce the adverse effect of size increase after demoulding; the vacuum sintering is neutral sintering without oxygen and reducing gas , so that the obtained wire drawing die insert fits closely with the die core and the steel sleeve; the secondary hot pressing makes the particles fully fill in the gap of the sintered body, improving the utilization rate of the die.

Owner:天长市天屹模具科技发展有限公司

A method of manufacturing beryllium bronze explosion-proof hammer

The invention relates to a method for manufacturing a beryllium bronze explosion-proof hammer, which is formed by a metal mold, and the metal column includes an upper half mold and a lower half mold that are horizontally split; the upper mold half is provided with an upper mold half cavity, the lower mold half cavity is correspondingly provided with a lower mold half cavity corresponding to the upper mold half cavity, and an upper half core is arranged in the center of the top surface of the upper mold half cavity, and the lower mold half cavity The center of the bottom surface is provided with a lower half core; the outside of the explosion-proof hammer head cavity is provided with an exhaust channel on the parting surface of the upper half type and the lower half type; the upper half type is provided with an upper pressure head; the The center of the lower half mold is provided with a material storage cavity, and the bottom of the material storage cavity is provided with a lower pressure head; a flow channel is provided between the material storage cavity and the lower mold half cavity. The invention also relates to a method for manufacturing a beryllium bronze explosion-proof hammer by using the above-mentioned metal casting mold, so as to solve the problems of low density, coarse structure and easy jumping during use of the beryllium bronze explosion-proof hammer produced by the existing casting technology.

Owner:HEBEI BOTOU SAFETY TOOLS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com