Patents

Literature

36 results about "Brine mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brine mining is the extraction of useful materials (elements or compounds) which are naturally dissolved in brine. The brine may be seawater, other surface water, or groundwater. It differs from solution mining or in-situ leaching in that those methods inject water or chemicals to dissolve materials which are in a solid state; in brine mining, the materials are already dissolved.

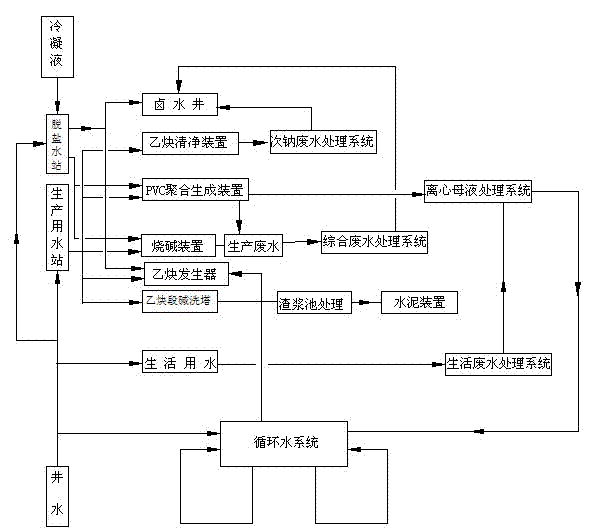

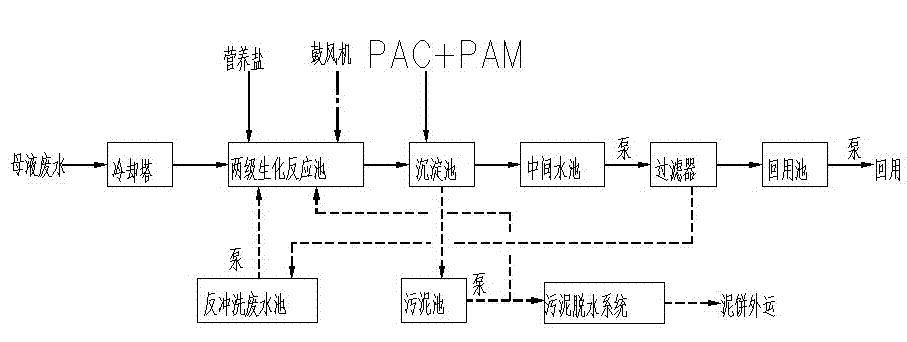

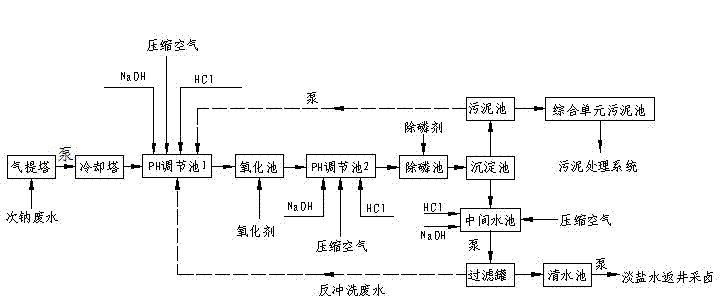

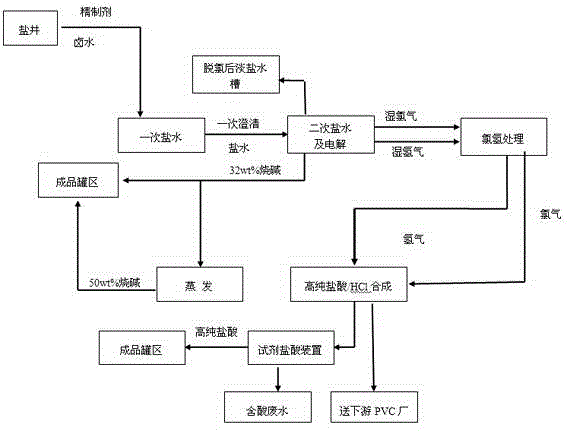

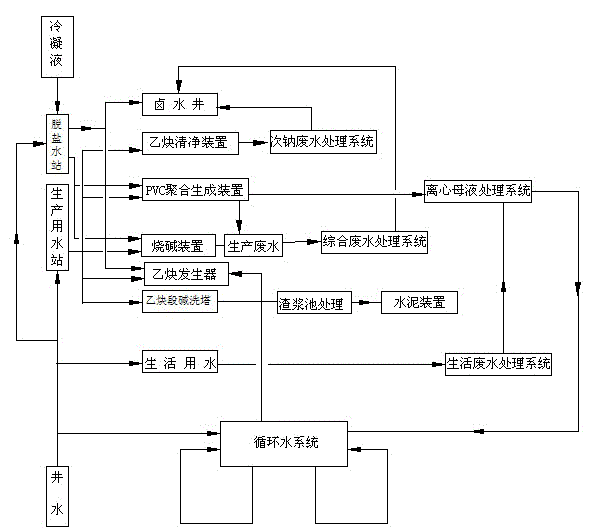

Wastewater zero discharge system of chlorine-alkali industry

ActiveCN102964024ALow costEnable recyclingMultistage water/sewage treatmentWater desalinationSaline water

The invention discloses a wastewater zero discharge system of chlorine-alkali industry. The system includes a sodium hypochlorite wastewater treatment system, a centrifugal mother liquor treatment system, a comprehensive wastewater treatment system, a domestic sewage treatment system and a circulating water system. Well water is treated by a water desalination plant, and the generated desalinated water is transported to a caustic soda device and a PVC polymerization device to be used in production. One part of the concentrated saline water generated by the water desalination plant is used for an acetylene generator, and the other part is delivered into a dilute saline water trough and returned to a brine well so as to be used in brine mining. A production water station is mainly used for an acetylene purification device, the PVC polymerization generation device, the caustic soda device and an acetylene section alkali washing tower. The sodium hypochlorite wastewater discharged from the acetylene purification device is treated by the sodium hypochlorite wastewater treatment system to reach the standard, and is then returned to the saline well to be used for saline mining. The centrifugal mother liquor from the PVC polymerization generation device is treated by the centrifugal mother liquor treatment system to reach the standard, and is then returned to the circulating water system. The production wastewater from the PVC polymerization generation device and the production wastewater from the caustic soda device are treated by the comprehensive wastewater treatment system to reach the standard, and are then returned to the saline well to be used for dilute saline water saline mining.

Owner:HENAN YONGYIN CHEM IND CO LTD

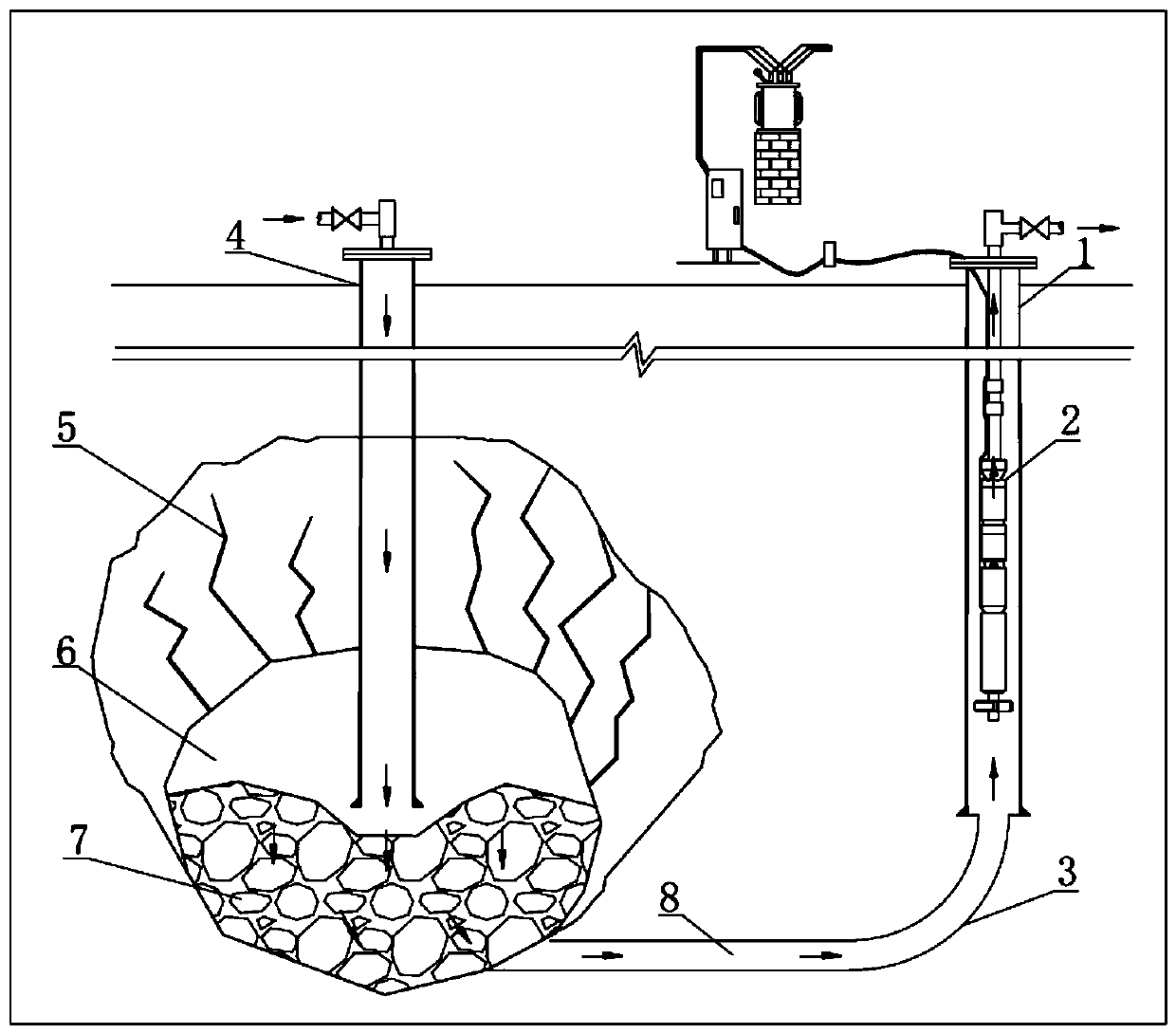

Method for extraction of deep-seated intercrystalline bittern of salt lake mining area

ActiveCN102659139AIncrease collection rateMaintain dynamic balanceAlkali metal chloridesSalt lakeMining engineering

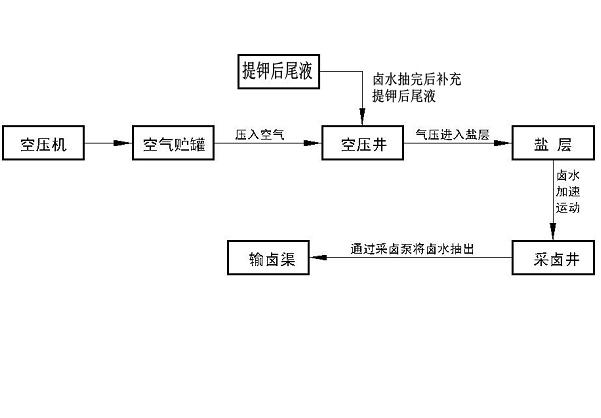

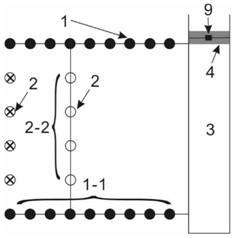

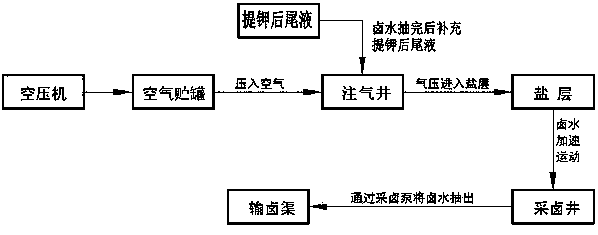

The invention relates to a method for extraction of deep-seated intercrystalline bittern of a salt lake mining area. The method comprises the following steps of 1, excavating a gas-injection well, brine mining wells and a brine transportation channel on a salt lake ore bed, arranging an air compressor on the salt lake ore bed, arranging a brine tail liquid injection pipe in the gas-injection well around which the brine mining wells each provided with a brine transportation pipe in the interior are uniformly arranged; and arranging a brine mining pump in each one of the brine mining wells, wherein the brine mining pump is connected to one end of the brine transportation pipe of which the other end is connected to the brine transportation channel, 2, continuously pumping compressed air into the salt lake ore bed by the air compressor so that deep-seated intercrystalline bittern gushes out, 3, pumping out the deep-seated intercrystalline bittern from underground by the brine mining pumps and outputting the deep-seated intercrystalline bittern to the brine transportation channel, 4, injecting a brine tail liquid subjected to potassium extraction into the salt lake ore bed in the gas-injection well so that the brine tail liquid reaches a salt bed and forms novel potassium-containing brine, and 5, repeating the steps of 2-4 so that a cycle is finished. The method utilizes compressed air to realize extrusion of intercrystalline bittern and deep-seated bittern so that resources are fully utilized.

Owner:MANGYA XINGYUAN POTASH FERTILIZER +2

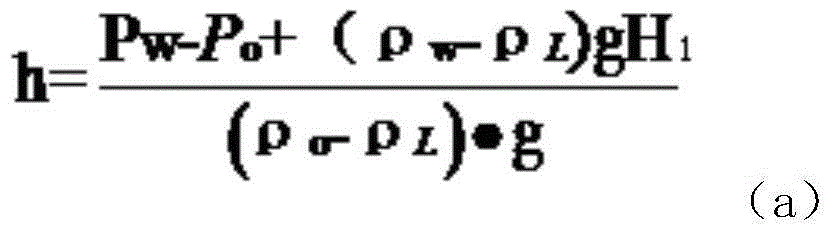

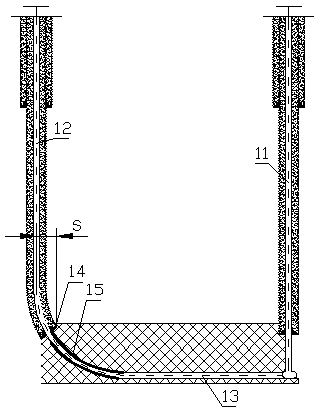

Salt cavern type gas storage cavity construction process oil-water interface detection method

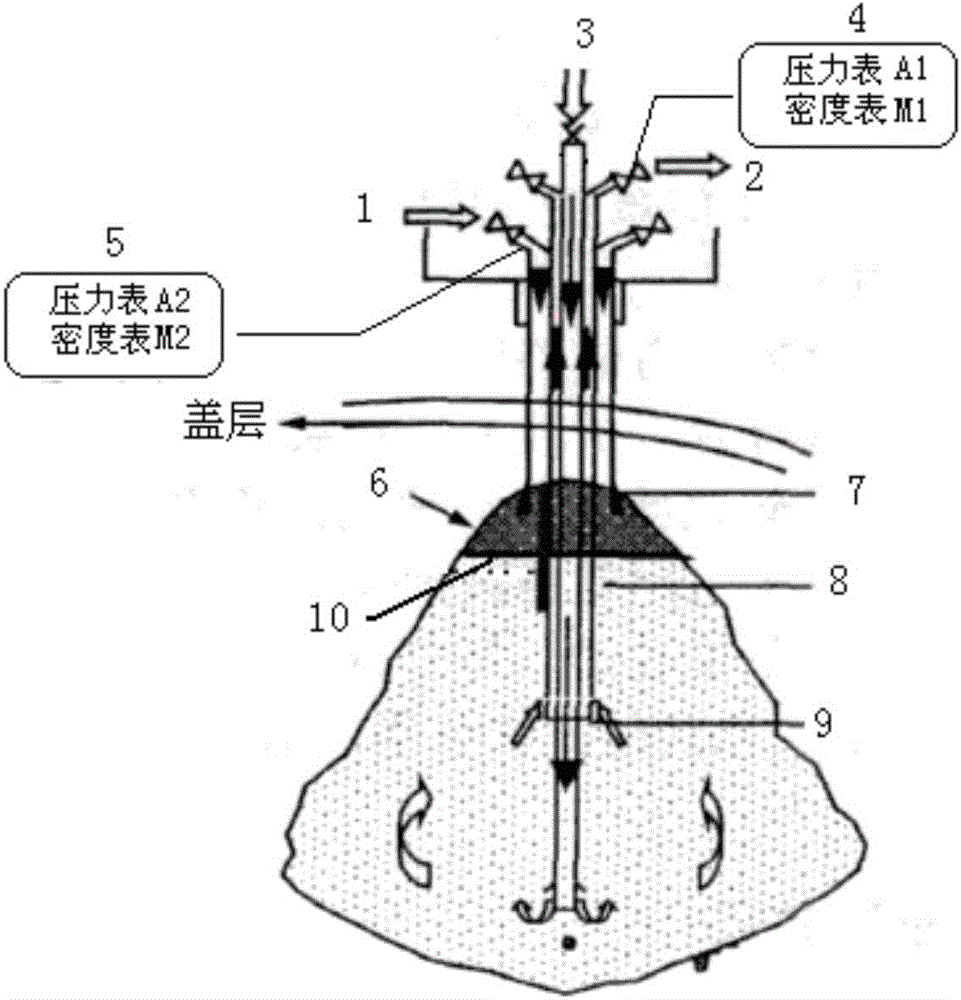

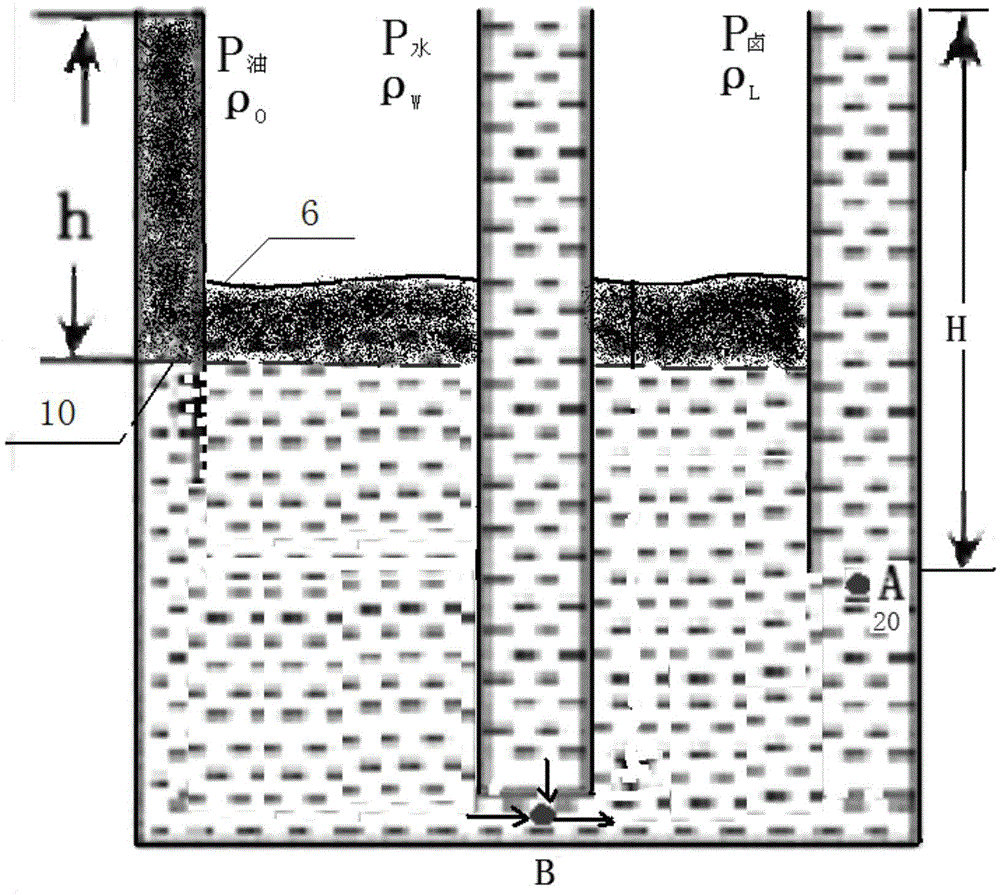

ActiveCN104568052AAvoid construction risksAvoid cumbersome processLevel indicators by pressure measurementLiquid densityOil water

The invention discloses a salt cavern type gas storage cavity construction process oil-water interface detection method which includes the steps: mounting a high-precision pressure meter and a density meter on a wellhead; respectively measuring the wellhead pressure and the liquid density of a brine mining pipe and an oil filling pipe; substituting measured data into a calculation formula derived according to equivalent 'U'-shaped pipe model construction, and performing oil-water interface calculation to obtain the real depth of an oil-water interface. By the detection method, a downhole tripped detection instrument is omitted, construction risks caused by cable damage or instrument damage in the tripping process are avoided, measure process is simplified, and the complicated technological process of tripping a string again in change of the design depth of the oil-water interface is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

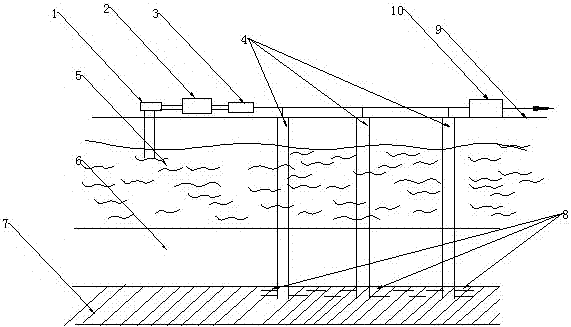

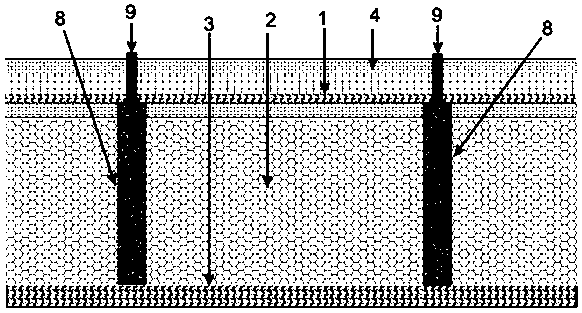

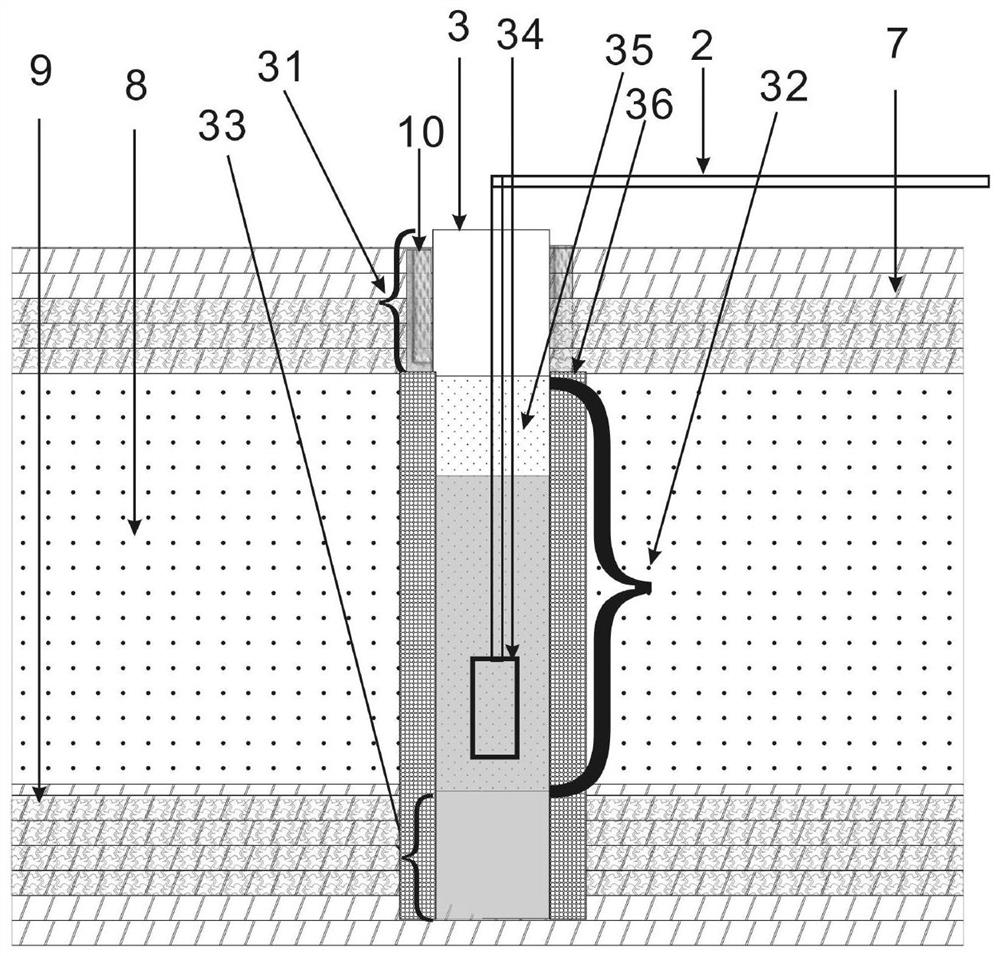

Closed underground brine mining system and construction method thereof

ActiveCN111287703AIncrease flow rateHigh trafficFluid removalSealing/packingBrine miningPetroleum engineering

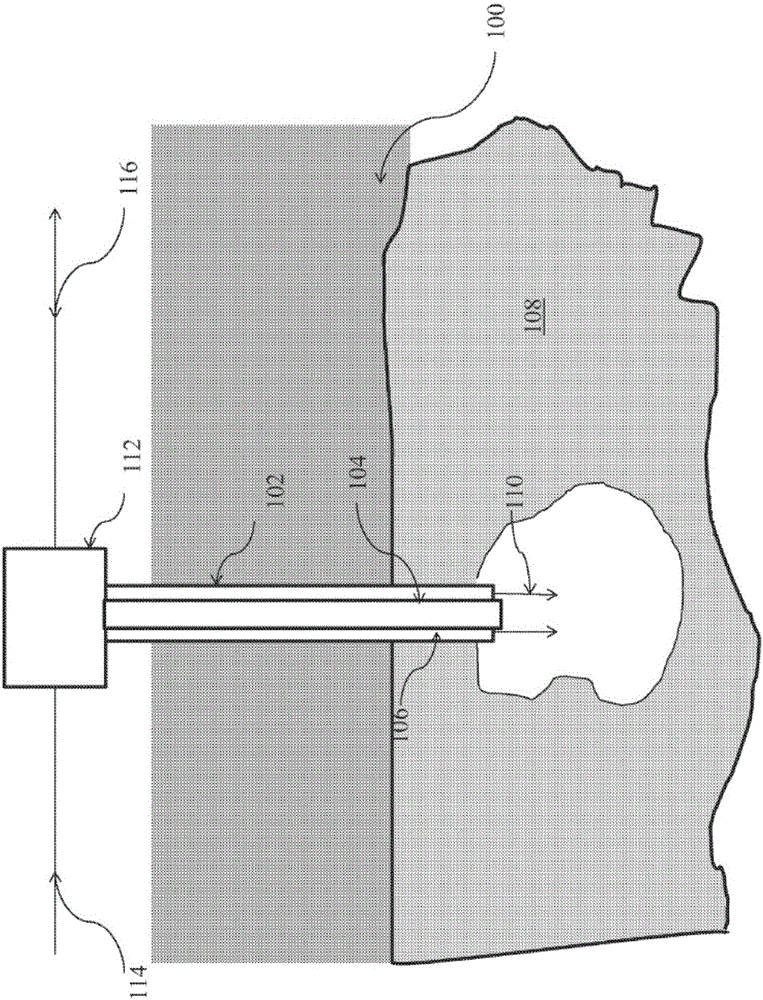

The invention relates to the technical field of underground brine mining, and specifically provides a closed underground brine mining system and a construction method thereof. The closed underground brine mining system includes a gas compression device, a first water isolation layer, a second water isolation layer, a brine storage layer, partition walls, brine drainage wells and water isolation dams, wherein the brine storage layer, the partition walls, the brine drainage wells and the water isolation dams are located between the first water isolation layer and the second water isolation layer. The upper ends of the partition walls extend to the first water isolation layer, the lower ends of the partition walls extend to the second water isolation layer, and the partition walls, the firstwater isolation layer, the second water isolation layer and the water isolation dams divide the brine storage layer into a plurality of enclosed spaces. Each enclosed space is a brine mining block. Agas compression well is arranged at the position, near the center of a lake, in each brine mining block, the brine drainage wells are arranged at the positions, near the edge of the lake, in the brinemining blocks, the brine drainage wells are provided with brine drainage pipes, and brine can be drained through the brine drainage pipes and then directly transported to salt pans or grit chambers.The closed underground brine mining system can reduce the cost of brine mining, greatly increases the mining amount of the brine, and improves the mining efficiency and increases the recovery rate.

Owner:青海凹口凸钾镁盐技术有限公司

Method for exploiting natural gas hydrates by injecting saturated hot brine

InactiveCN106930740AMining continues to be stableSlow down decompositionConstructionsFluid removalThermal energyDecomposition

The invention relates to a method for exploiting natural gas hydrates by injecting saturated hot brine. The method is characterized in that the saturated hot brine is injected into a horizontal seam net which is cracked at the top of a natural gas hydrate reservoir stratum in advance, the natural gas hydrates are rapidly decomposed by virtue of the high salinity and the temperature of the hot brine, and moreover under the action of gravity differences, on one hand, a natural gas is extracted from the upper part of the reservoir stratum, and on the other hand, the hot brine is mixed with decomposed water to continuously decompose the natural gas hydrates. By adopting the method, the injection quantity is greatly reduced, thermal energy input is reduced, decomposition of the natural gas hydrates can be accelerated because of pressure drop formed by reservoir stratum volume voidage, in addition, production wastewater does not need to be fed back, and the natural gas hydrates can be economically and continuously exploited.

Owner:SOUTHWEST PETROLEUM UNIV

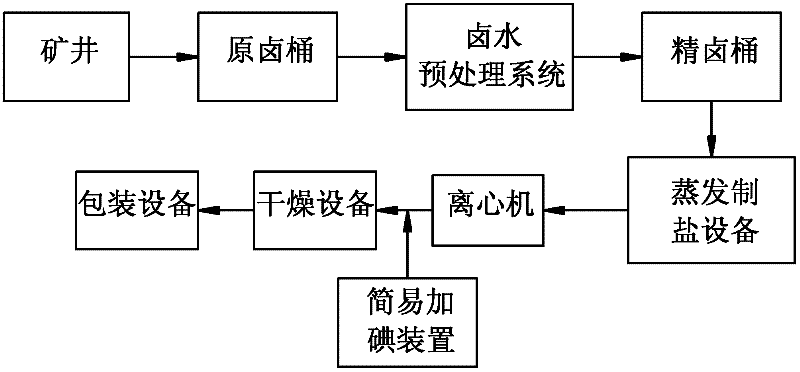

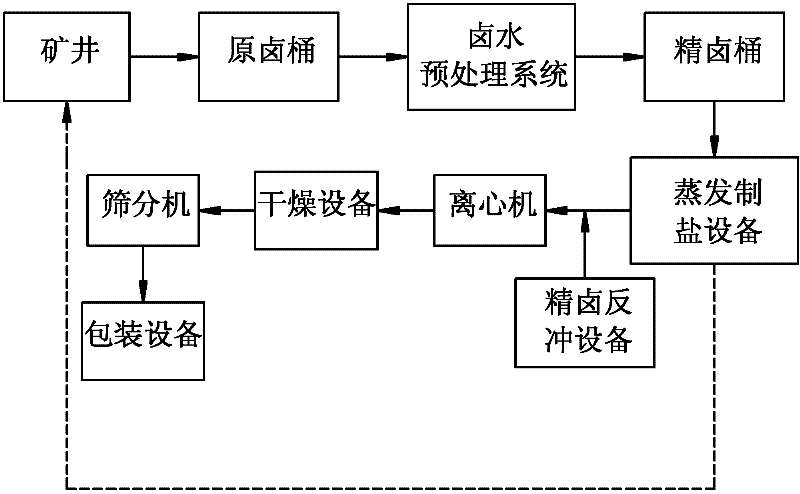

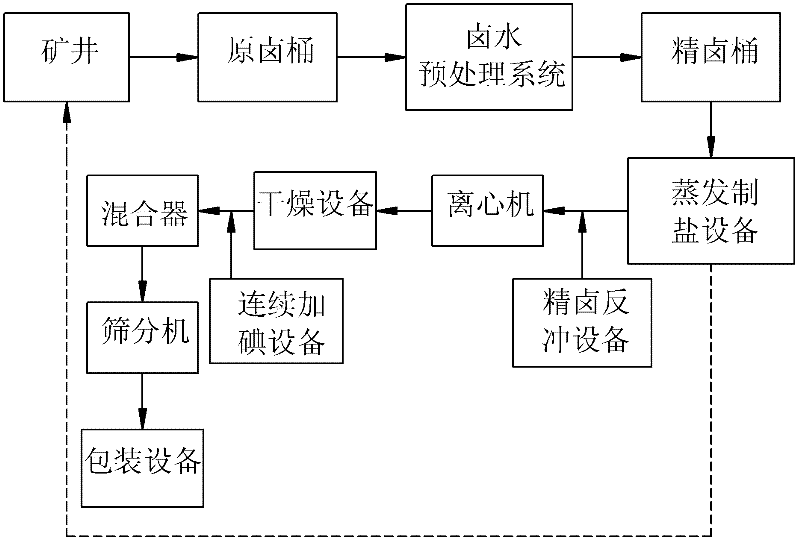

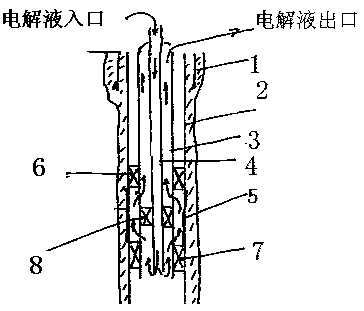

Preparation process and special device for salt with green food label

InactiveCN102502711AQuality improvementEvenly distributedAlkali metal chloridesAnticaking agentIodide

The invention relates to a preparation process and a special device for salt with green food label. The device comprises mine brine mining equipment, an original brine barrel, a brine pretreatment system, a refined brine barrel and evaporation salt-making equipment, which are sequentially arranged. A salt slurry outlet of the evaporation salt-making equipment is sequentially provided with a centrifugal machine and a drying device, while a condensed water outlet of the evaporation salt-making equipment is communicated with the mine brine mining equipment; a refined brine countercurrent device for refined brine countercurrent backwashing salt slurry is arranged between the evaporation salt-making equipment and the centrifugal machine; and an outlet of the drying device is provided with a sieving machine, and a sieving machine outlet is provided with packaging equipment. The salt is prevented from caking by physical molecular structure of sodium chloride through improving production process and production equipment, optimizing process indexes and obviating potassium ferrocyanide and other anticaking agent. Qualification rate of iodized salt manufactured with the invention is 100%, the utilization rate of potassium iodate is 95%, the iodide content of finished product salt is steady and reliable; and the fluctuation range is within 5 mg / L.

Owner:CHINASALT JINTAN

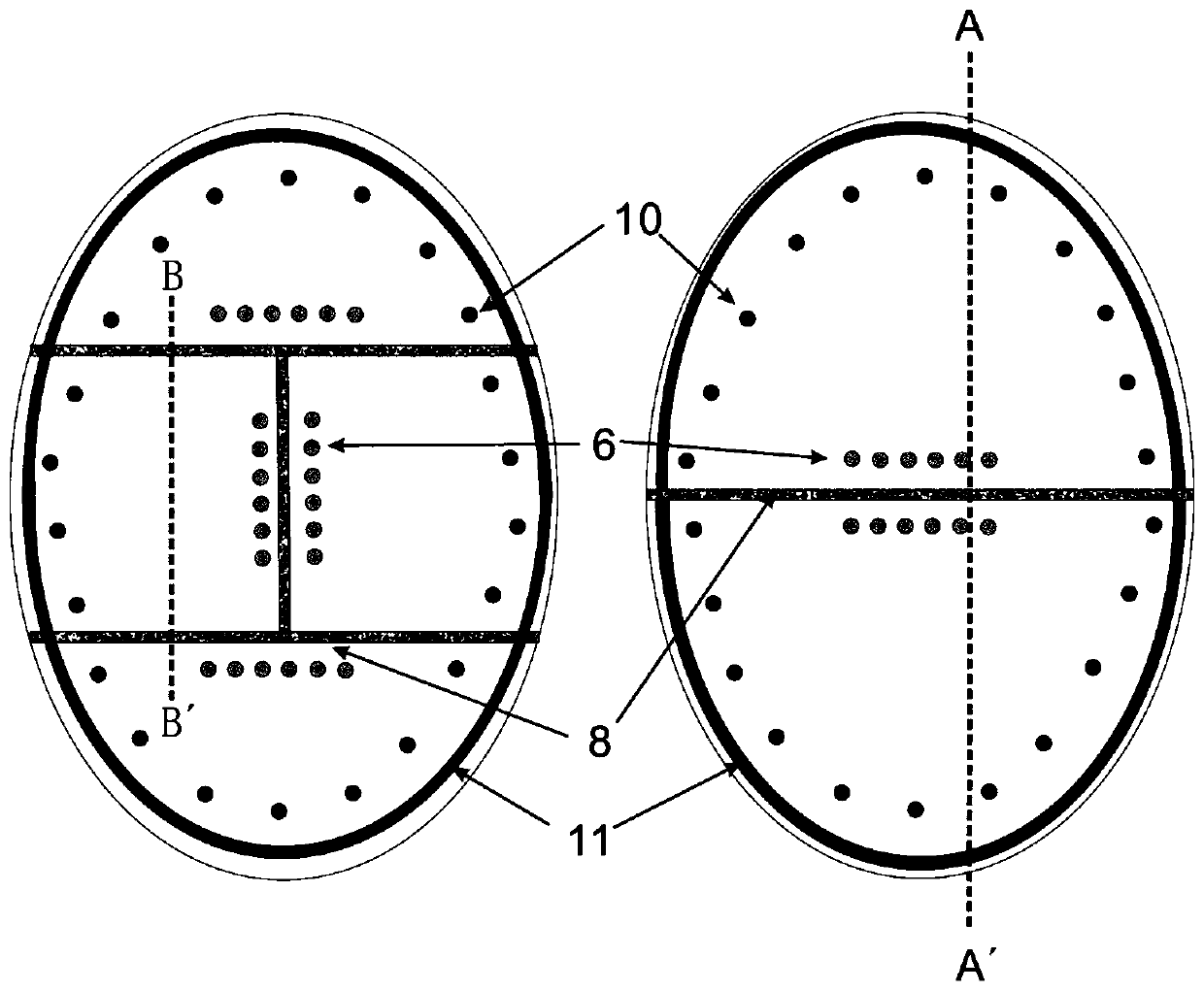

Semi-closed underground brine mining system and construction method thereof

ActiveCN111287704AIncrease flow rateHigh trafficFluid removalSealing/packingMining engineeringBrine mining

The invention relates to a semi-closed underground brine mining system and a construction method thereof. The semi-closed underground brine mining system comprises a gas pressing device, a first waterresisting layer, a second water resisting layer, a brine storage layer positioned between the first water resisting layer and the second water resisting layer, a partition wall and brine collecting channels. The upper end of the partition wall extends to the first water resisting layer, and the lower end extends to the second water resisting layer; and the brine storage layer is divided into multiple closed spaces by the partition wall, the first water resisting layer and the second water resisting layer. The brine collecting channels and brine outlets are excavated in a top salt rock layersof the closed spaces; the closed spaces are horizontally penetrated by the brine collecting channels to form semi-closed spaces; and the semi-closed spaces are brine collecting blocks. A gas pressingwell is arranged in each brine collecting block; brine outlets are excavated in the opening sides of the brine collecting blocks; and the brine outlets penetrate to the brine storage layer, and communicate the brine storage layer with the brine collecting channels. The semi-closed underground brine mining system can reduce the brine collecting cost, greatly improves the brine collecting amount, improves the mining efficiency, and improves the recovery rate.

Owner:青海凹口凸钾镁盐技术有限公司

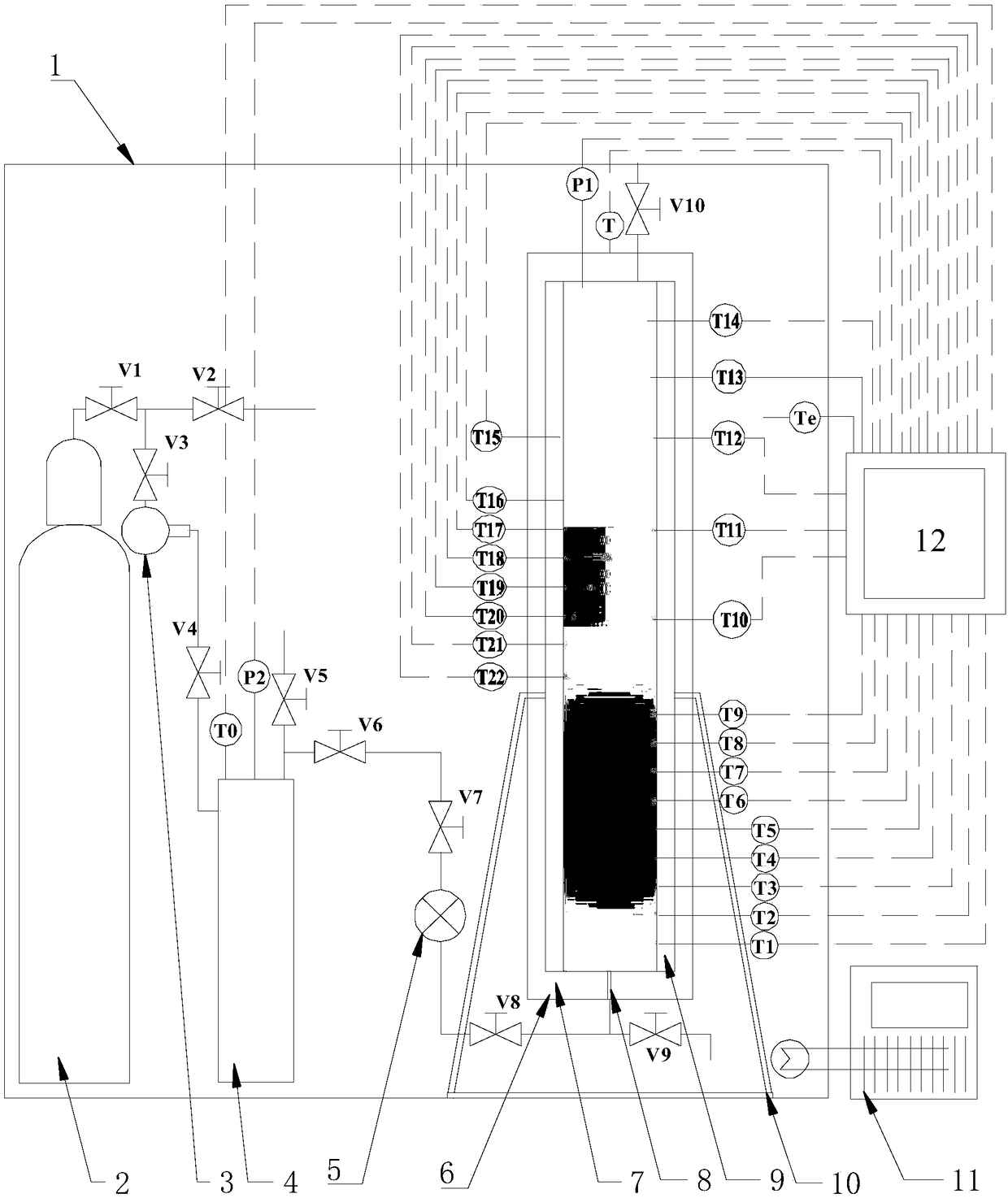

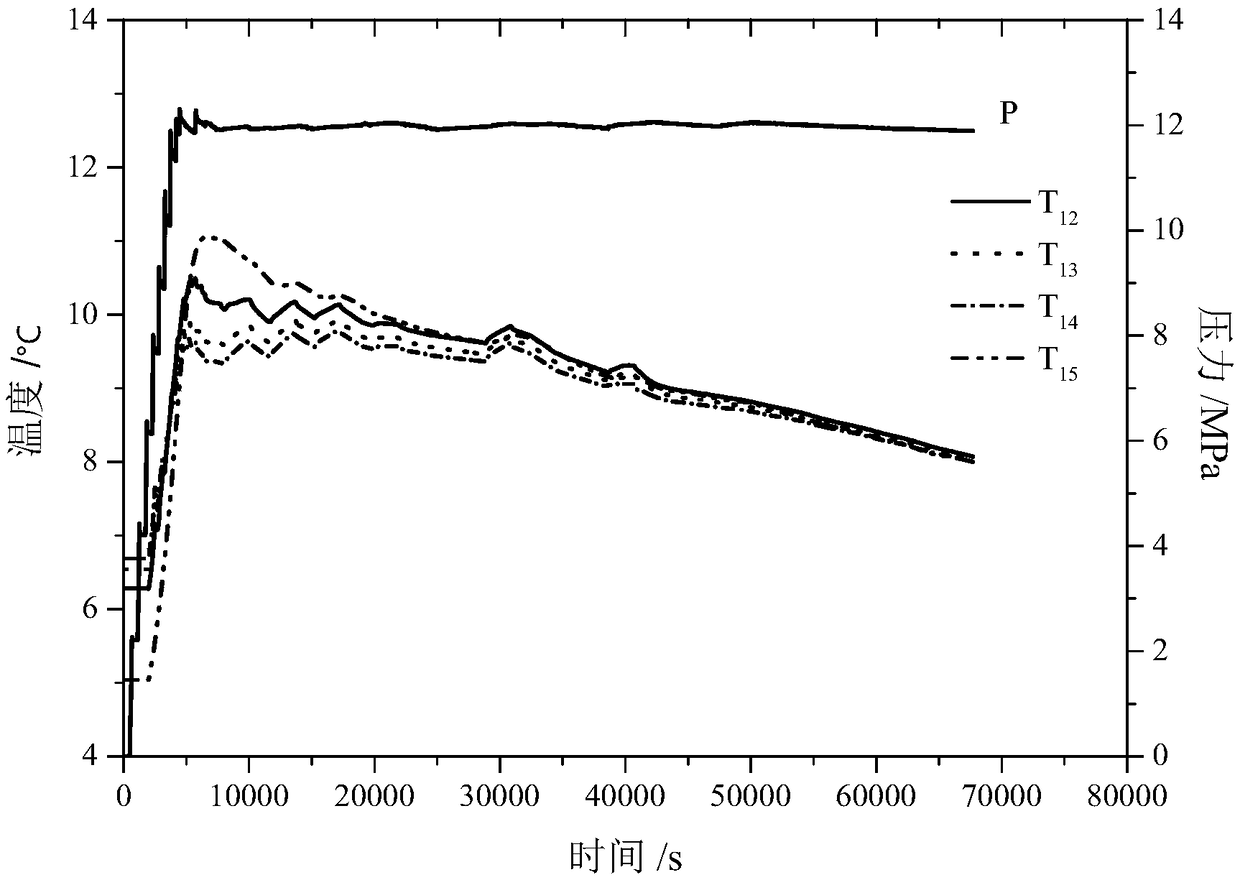

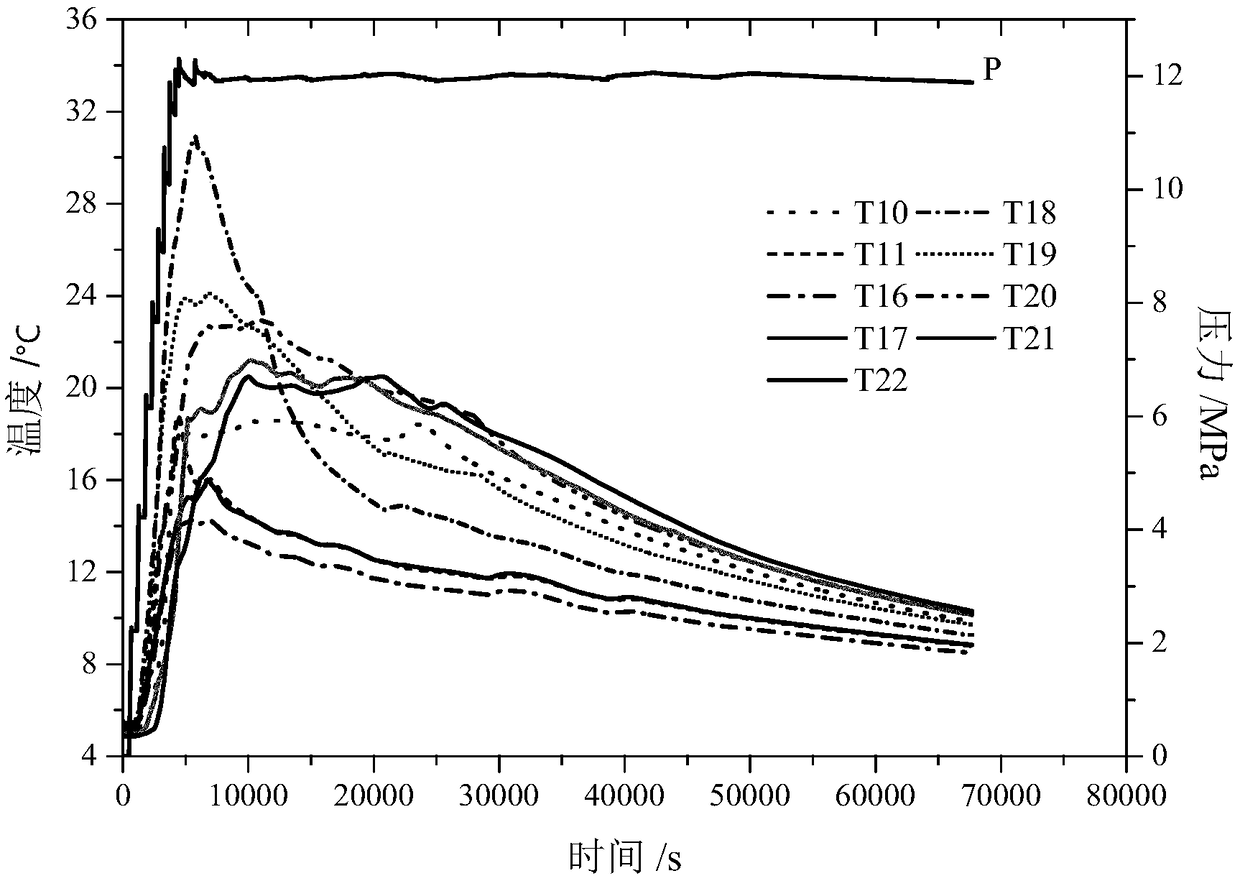

Experimental facility for temperature characteristic study in hydrate formation process

InactiveCN109142436ARealize simulationAvoid getting lostMaterial heat developmentCeiling temperatureEngineering

The invention discloses an experimental facility for temperature characteristic study in a hydrate formation process. The experimental facility comprises a low-temperature chamber, a gas supply unit,a liquid supply unit, a heat insulating reaction kettle and a data collecting and recording unit, wherein the low-temperature chamber is used for simulating a low-temperature seabed environment and precooling gas and a liquid introduced into the heat insulating reaction kettle; the gas supply unit is used for supplying experimental gas to the heat insulating reaction kettle; the liquid supply unitis used for supplying an experimental liquid to the heat insulating reaction kettle; the data collecting and recording unit is used for collecting and recording experimental data in the hydrate formation process in real time. The experimental facility is not only applicable to the temperature characteristic study of the hydrate formation process in different systems, but also is suitable for determining ceiling temperature of the systems of an in-situ hot brine mining method under different experimental conditions, and hot fluid at specific temperature for implementation of the in-situ hot brine mining method is prepared through change of the experimental conditions and replacement of solution systems.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

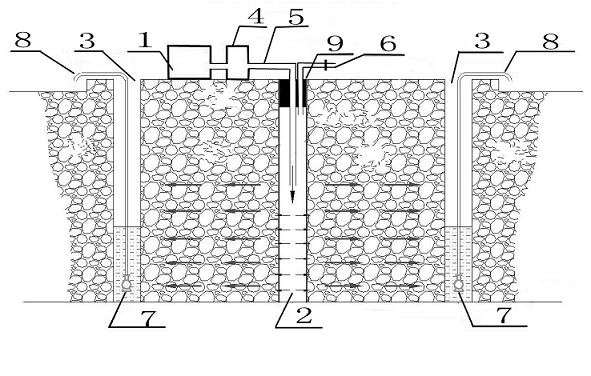

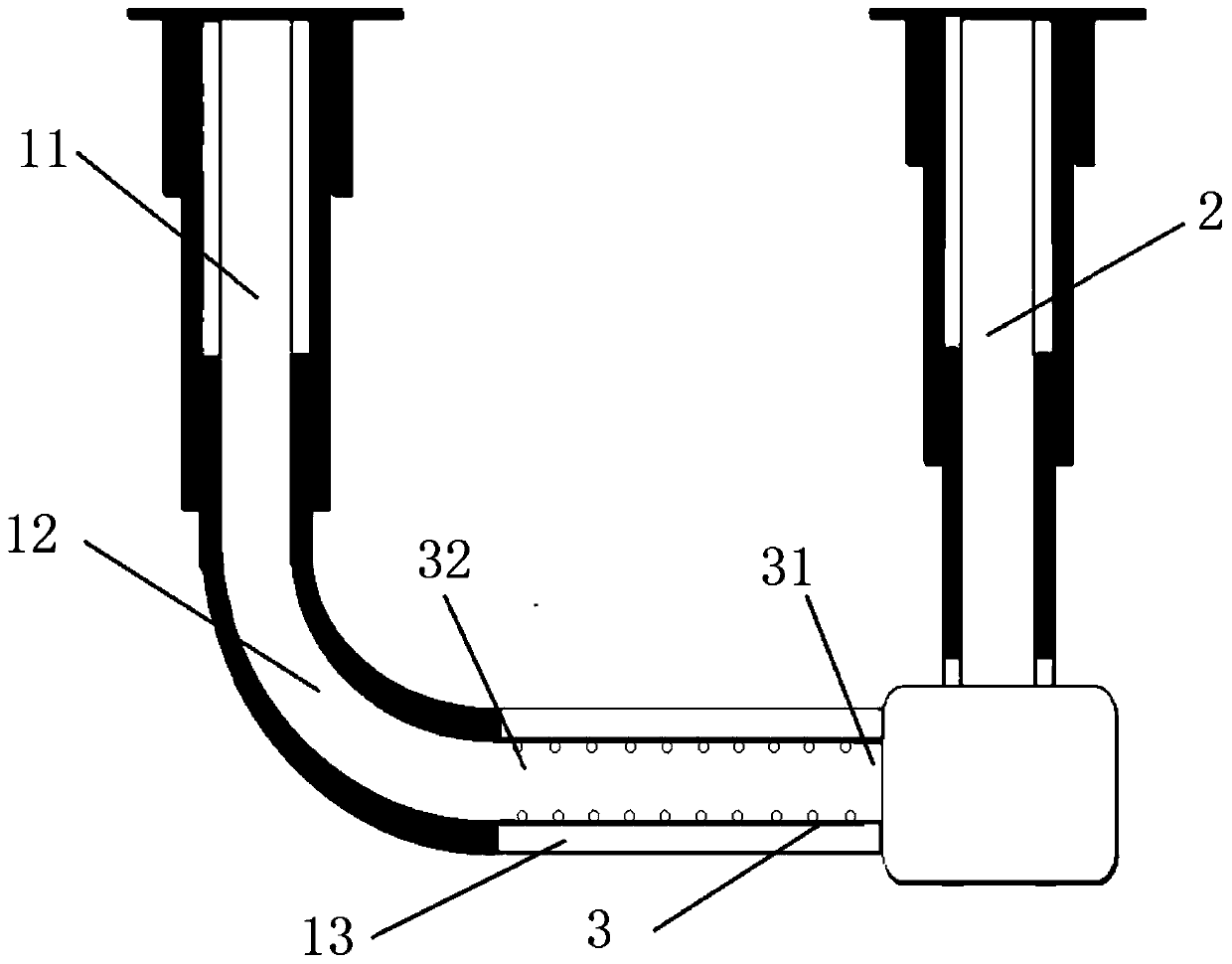

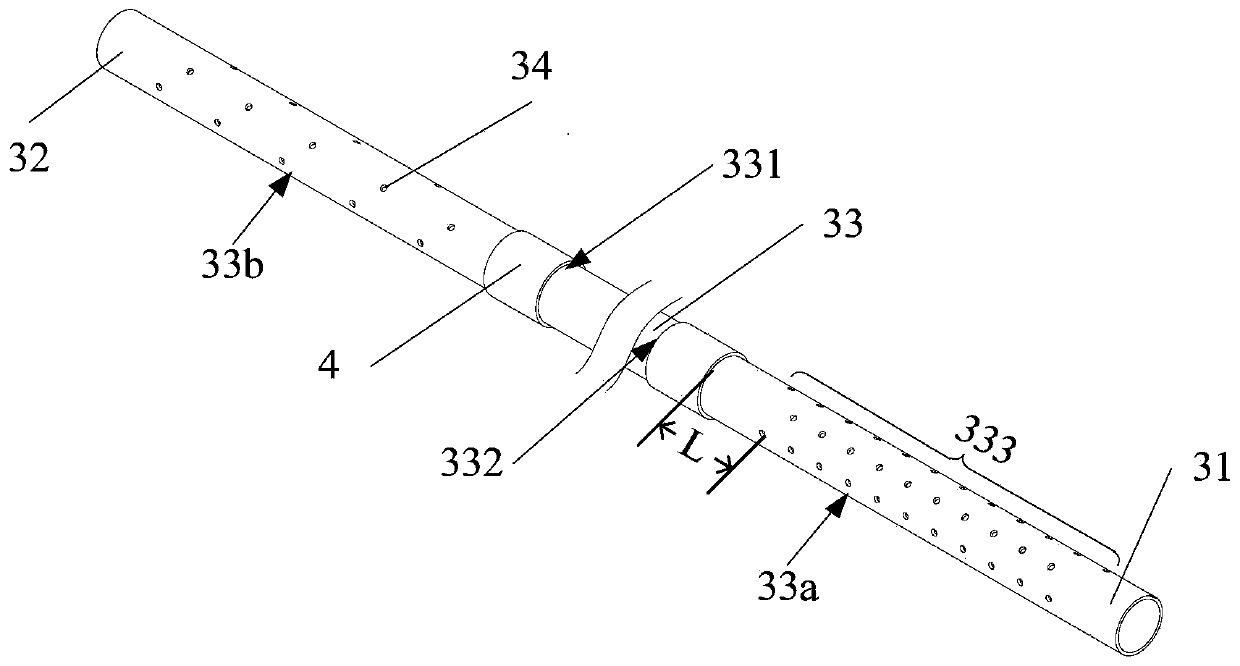

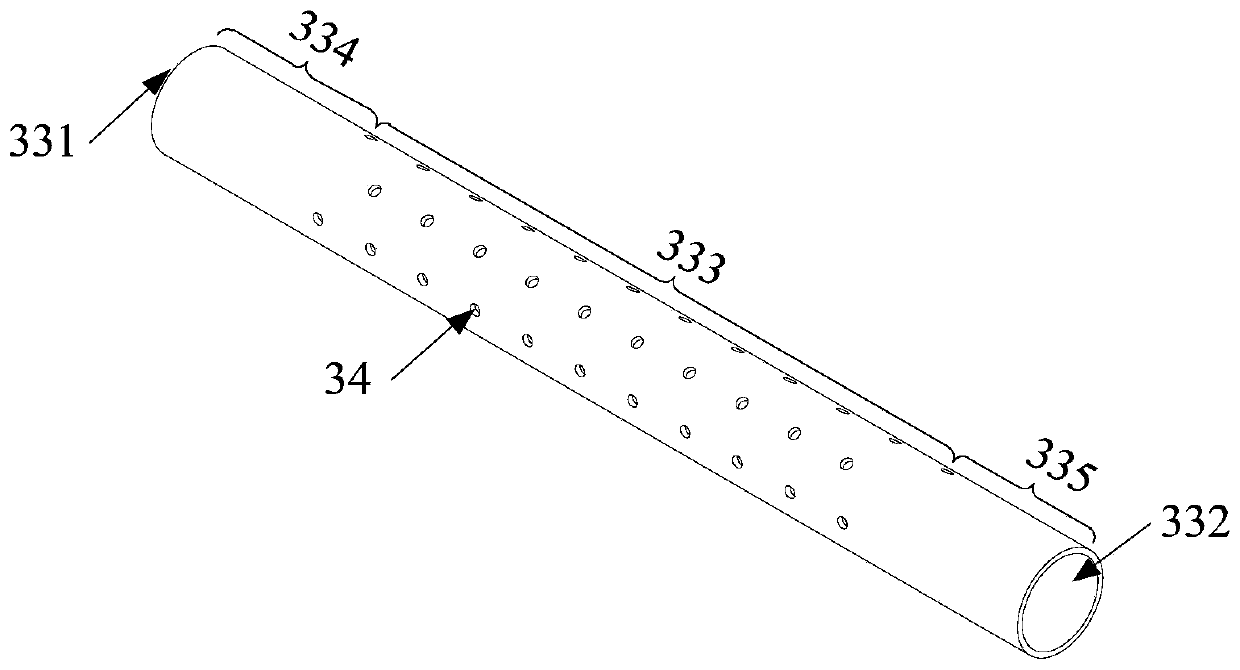

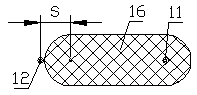

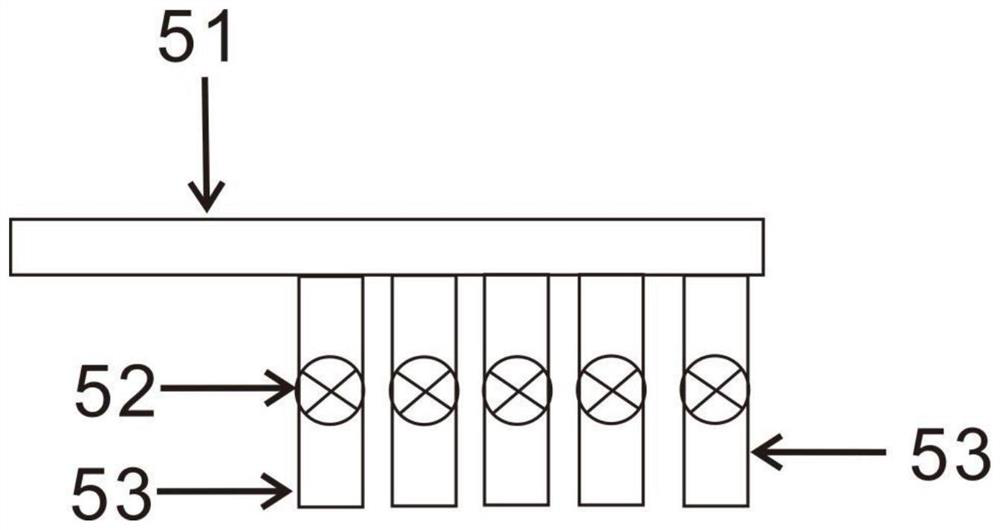

Brine mining well casing pipe and brine mining well structure

The invention discloses a brine mining well casing pipe and a brine mining well structure, relates to the technical field of mineral salt mining, and solves the problem that a brine mining well is likely to be blocked. The invention has the main technical scheme that the brine mining well casing pipe comprises a pipe wall and a flowing channel surrounded by the pipe wall, wherein a plurality of through holes which communicate with the flowing channel are formed on the pipe wall, the brine mining well casing pipe is used for being arranged on the horizontal section of a water injection well, and the flowing channel is used for forming a communication channel on the horizontal section. The invention is mainly used for manufacturing the brine mining well casing pipe.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

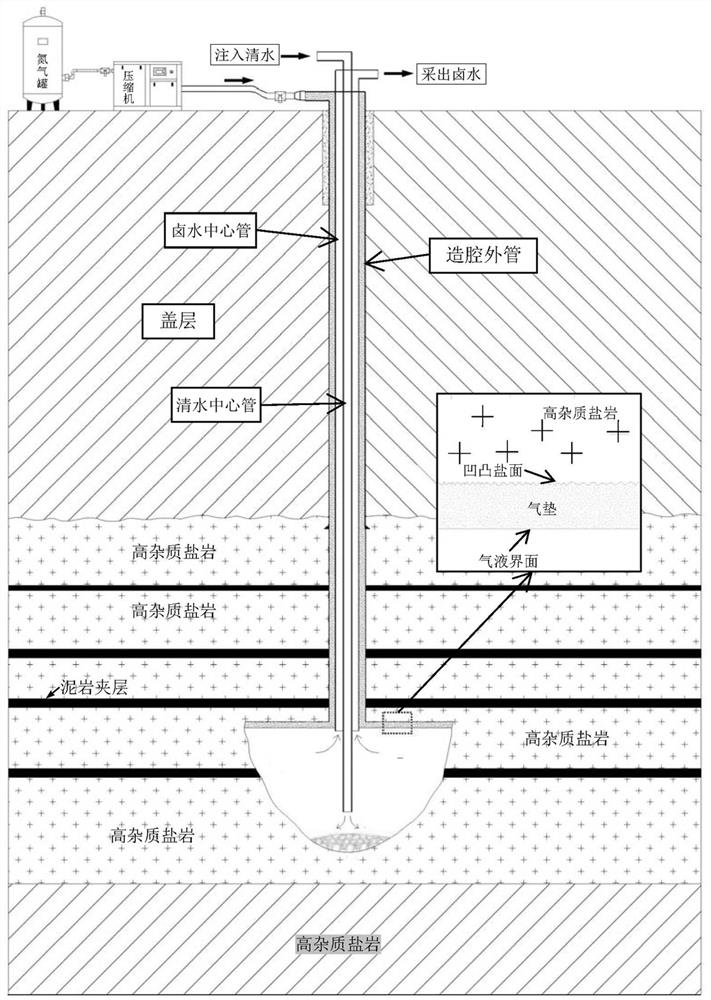

Air cushion type brine mining method for salt rock stratum containing high-impurity salt rock and mudstone interlayer

ActiveCN112502686AImprove solubilitySufficient size to collapseFluid removalAir liquid interfacePhysical chemistry

The invention discloses an air cushion type brine mining method for a salt rock stratum containing a high-impurity salt rock and a mudstone interlayer. The air cushion type brine mining method comprises the following steps that (1), a dissolving cavity is formed; (2), high-pressure gas is injected through a gas injection channel between a cavity making outer pipe and a brine central pipe, and an air cushion is formed at the top of the cavity; (3), lateral dissolving is carried out, and after the transverse size of the cavity reaches the standard, and the gas-liquid interface is kept above a salt rock roof; (4), when upward dissolving is carried out for a period of time and corrosion is insufficient, the displacement of injected clear water is increased; (5), when the mudstone interlayer ismet during upward dissolving, the gas-liquid interface descends to form an air cushion below the mudstone interlayer, and after the transverse size of a cavity below the mudstone interlayer reaches the standard, the gas-liquid interface is lifted to enable the brine to make full contact with the mudstone interlayer so as to promote the brine to permeate, soften and collapse the mudstone interlayer; and (6), after the mudstone interlayer is completely collapsed, the cavity is mainly dissolved upwards, and step 3-6 are repeated. The problems of corrosion of the high-impurity salt rock stratum,interlayer collapse control and cavity form control are solved.

Owner:CHINA PETROCHEMICAL CORP +2

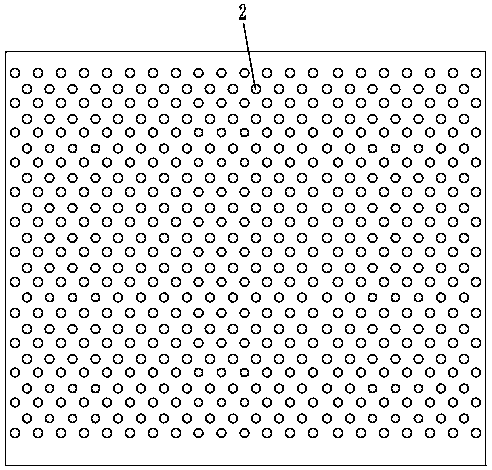

Screen pipe for salt well brine mining and using method thereof

The invention relates to the technical field of salt well mining, in particular to a screen pipe for salt well brine mining. The screen pipe comprises a center pipe arranged in a salt well intermediate casing. The lower end of the center pipe is connected with a guide cone. A plurality of long-strip-shaped kerfs are formed in the positions, close to the guide cone, of the lower portion of the center pipe. The total area of the kerfs is greater than the cross sectional area of the center pipe. The invention further comprises a using method of the screen pipe for salt well brine mining. The method comprises the following steps that (1) the screen pipe for salt well brine mining is inserted into gravel of a salt ledge of a salt cavern, water is injected when the screen pipe is inserted; and (2) water is injected into an annulus between the screen pipe for salt well brine mining and the intermediate casing, and then brine is extruded out of the screen pipe for salt well brine mining through pressure. By adopting the structure, the kerfs are adopted by the screen pipe for salt well brine mining for replacing small holes. In this way, the width of the kerfs is far smaller than the diameter of the small holes with the same displacement, and the effect of filtering gravel of the screen pipe is obviously improved. Besides, the screen pipe can be inserted more deeply so as to extract brine with the high salt mine grade.

Owner:CHINASALT JINTAN

Method for pouring calcium magnesium salt mud into brine well cavity

InactiveCN109437244ASolve pollutionGood benefitAlkali metal chloridesAlkali metal halide purificationLiquid ratioSlag

The invention provides a method for pouring calcium magnesium salt mud into a brine well cavity. The method for pouring the calcium magnesium salt mud into the brine well cavity, provided by the invention, comprises the following steps: (1) adding the calcium magnesium salt mud into a stirring barrel to be diluted and stirred; (2) pumping the diluted calcium magnesium salt mud into a neutralizingbarrel, adding condensate water and acid liquid, and adjusting the solid-to-liquid ratio to be not higher than 5%, and the pH value to be within 8.2-8.8; (3), pumping a product obtained in the step (2) into a slag storage barrel, and supplementing with clear water; (4) pouring the product in the slag storage barrel into the brine well cavity for brine mining. According to the invention, the problem of the environment and groundwater pollution during airing, transportation and burying processes of the calcium magnesium salt mud is avoided, so that excellent environmental and social and economicbenefits are obtained.

Owner:HWASU

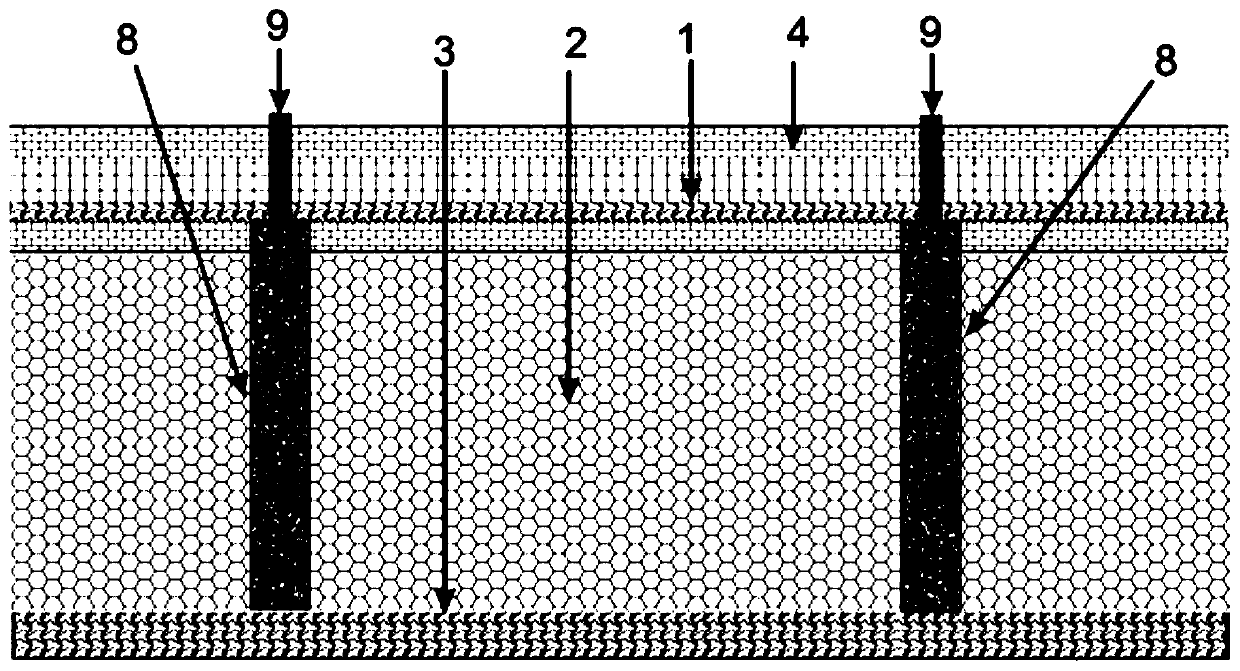

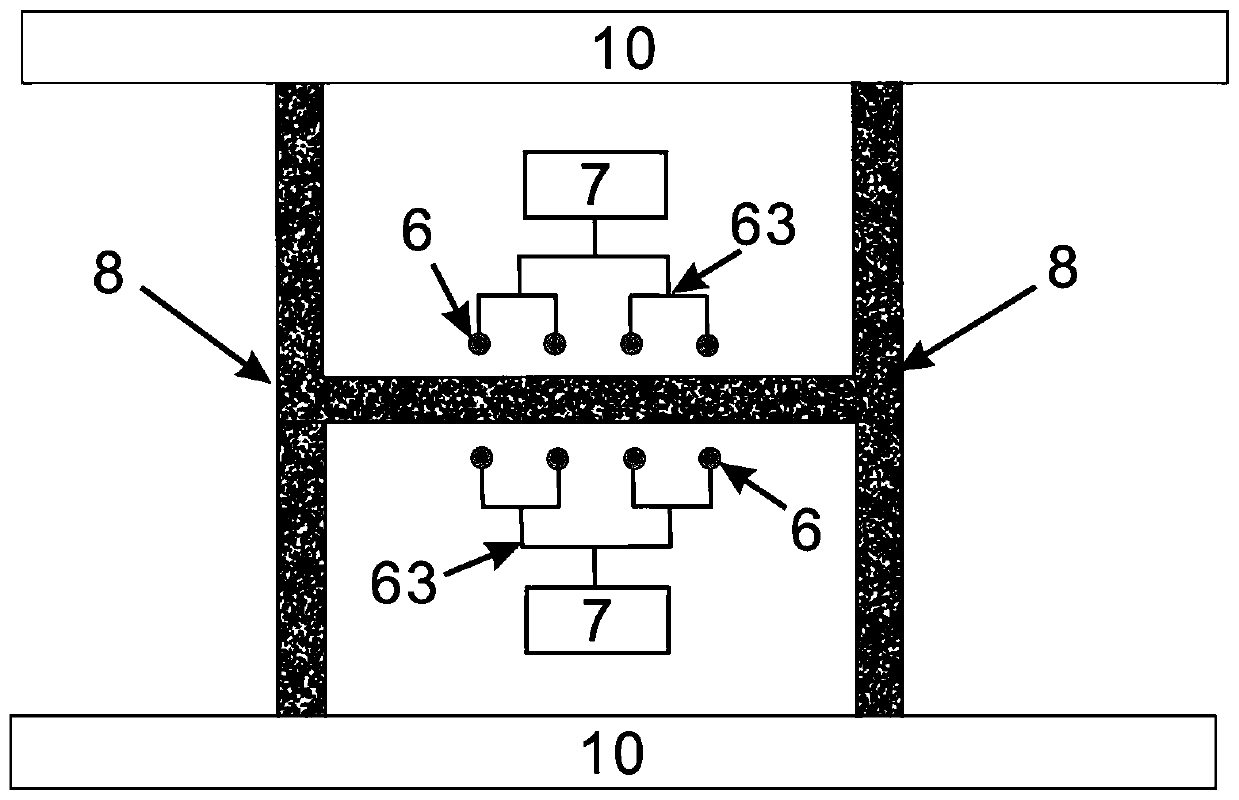

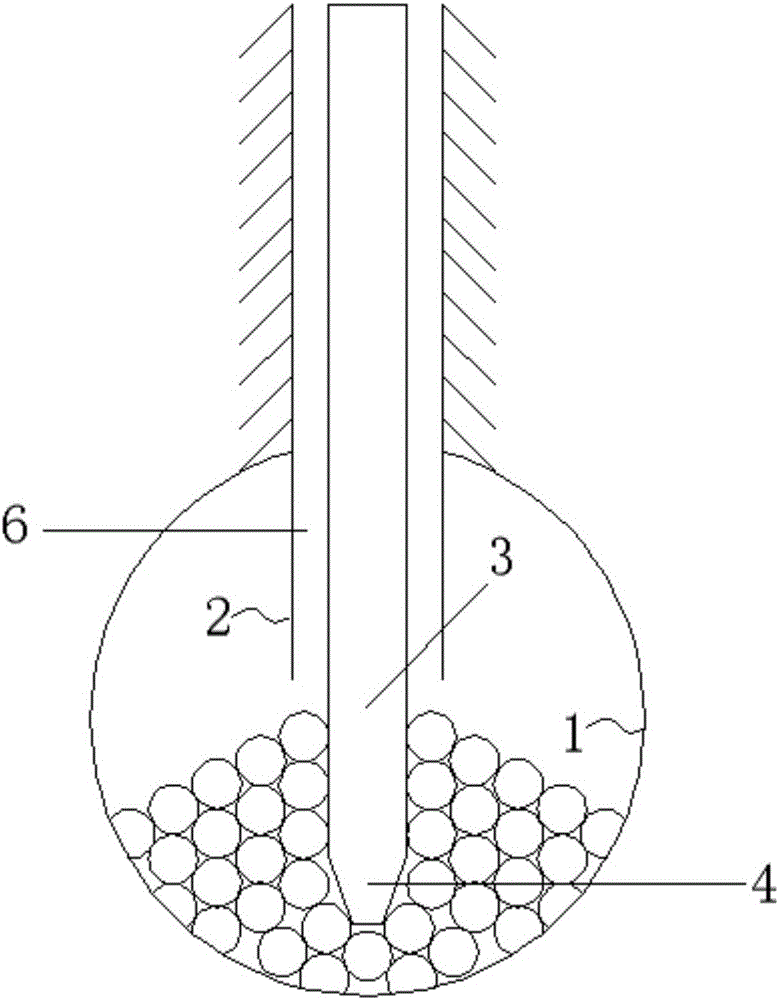

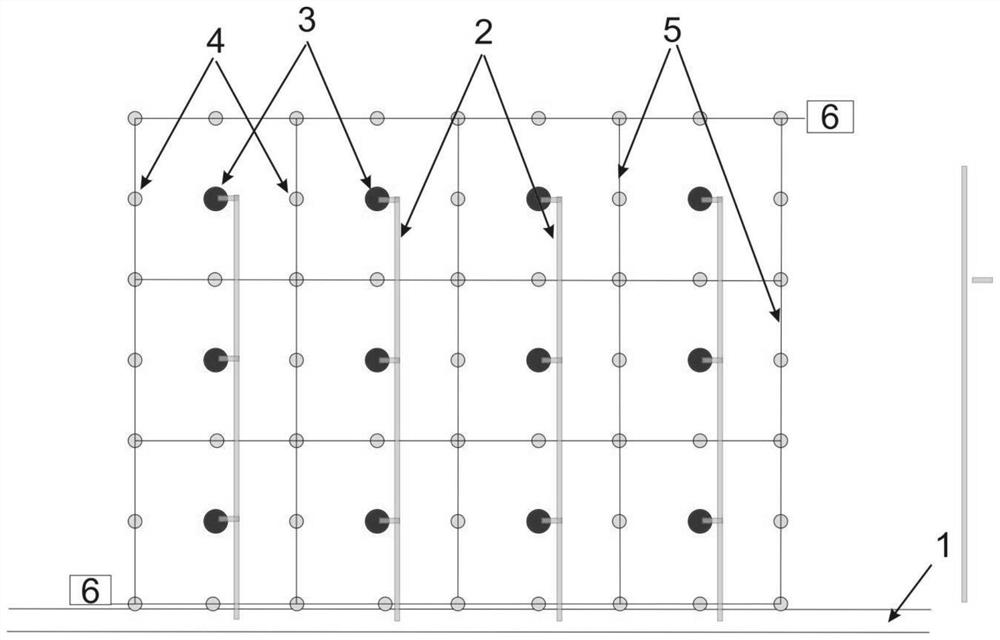

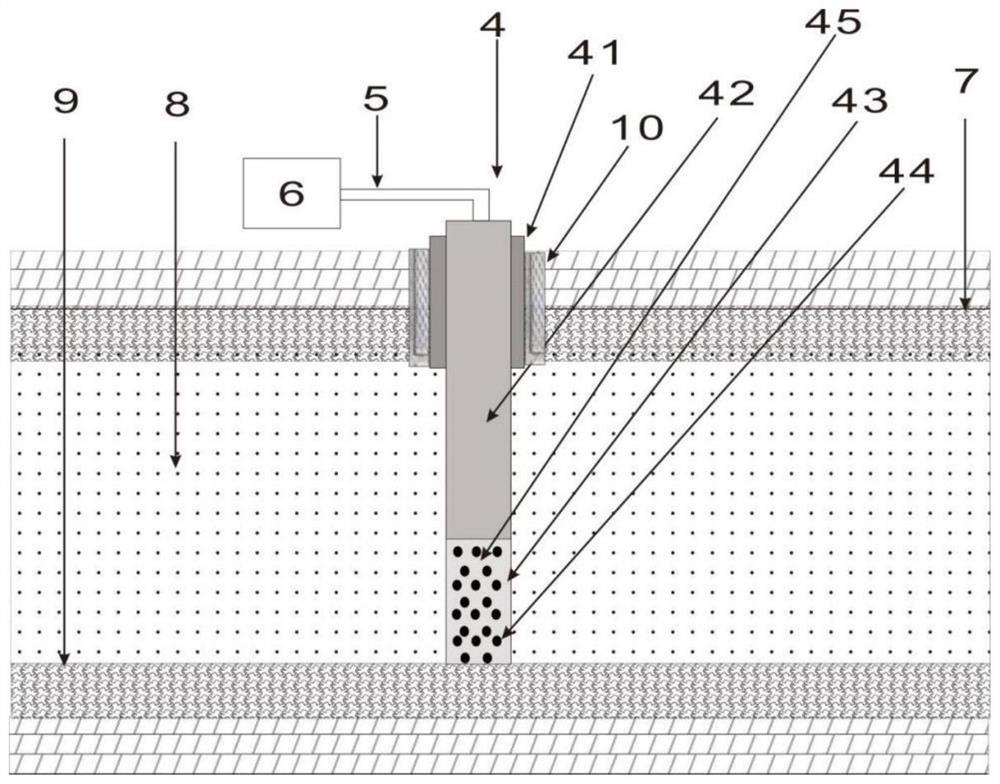

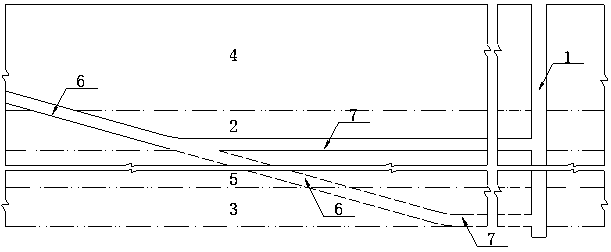

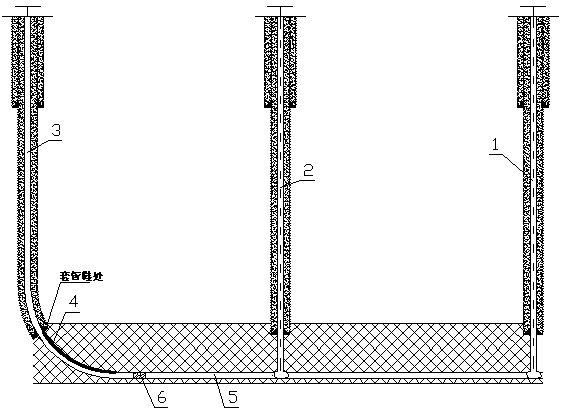

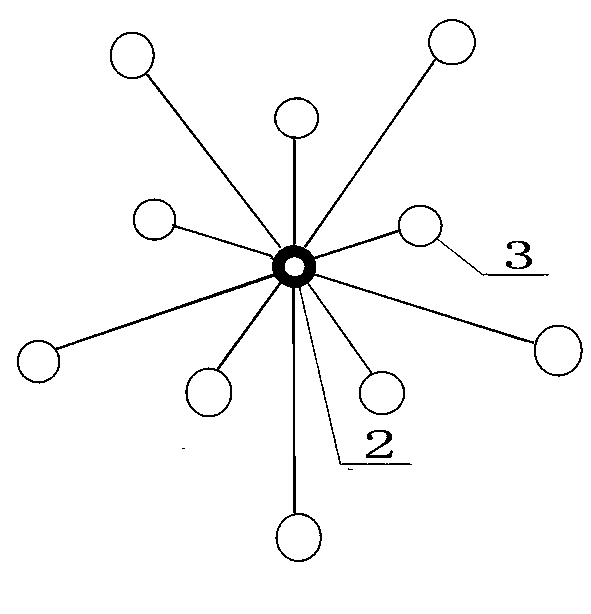

Mining method of brine ore with low porosity, low water yield and low permeability

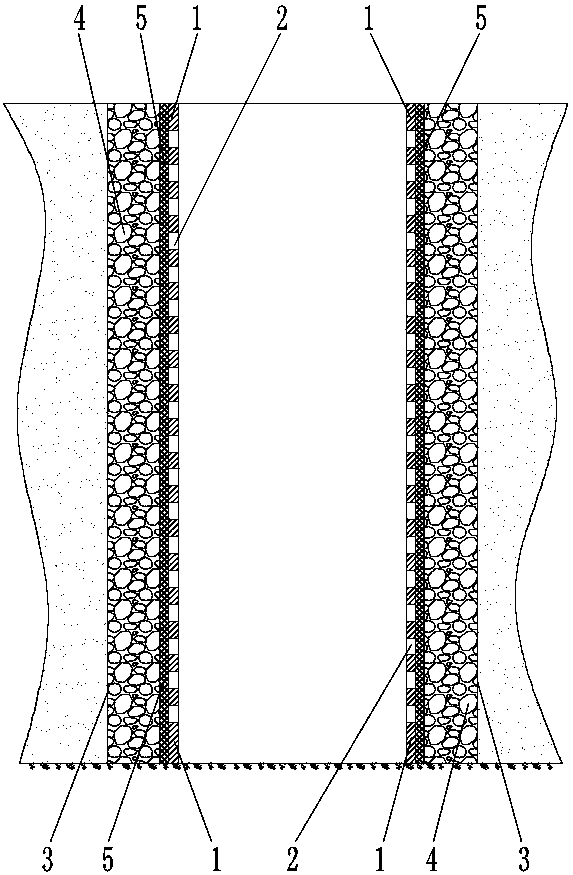

ActiveCN112647907AReduce the cost of brine miningIncrease the amount of brineConstructionsFluid removalMining engineeringBrine mining

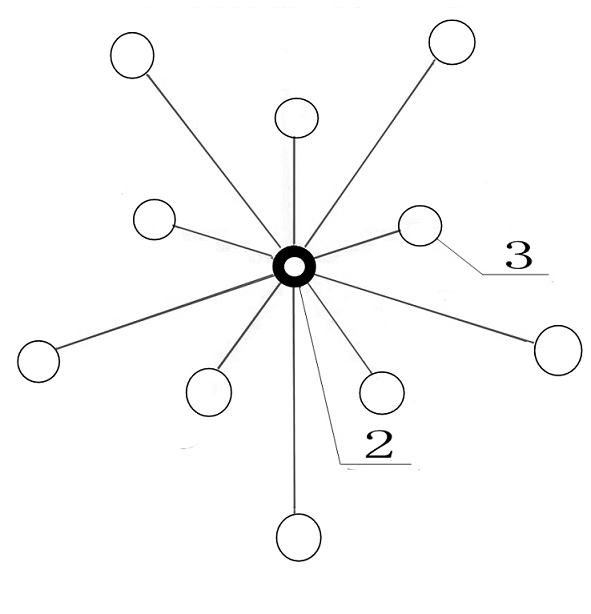

The invention relates to the technical field of underground brine exploitation. The invention provides a mining method of a brine ore with low porosity, low water yield and low permeability. The mining method is applied to an air-driven brine mining system, the system comprises a brine conveying channel (1), a plurality of parallel brine conveying pipes (2) connected to the brine conveying channel (1), a plurality of brine mining wells (3) connected to each brine conveying pipe (2), a plurality of gas injection holes (4) uniformly distributed in a brine mining area, a plurality of gas conveying pipes (5) for connecting the gas injection holes (4) in series, and an air compressor unit (6). According to the method, the brine mining cost can be reduced, the brine mining amount can be greatly increased, the mining efficiency can be improved, and the recovery rate can be increased when the brine ore of the fine-debris aquifer with low porosity, low specific yield and low permeability is mined.

Owner:MINMETALS SALT LAKE CO LTD +1

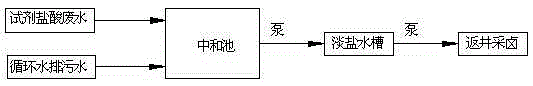

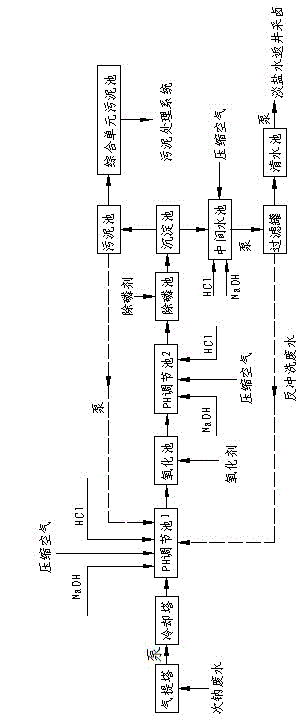

Chlor alkali production waste acid recycling method

InactiveCN105417669AReduce processing costsIncrease profitWater/sewage treatment by neutralisationAcid waterWastewater

A chlor alkali production waste acid recycling method comprises the following steps: waste acid water generated by a chlor alkali production reagent hydrochloric acid apparatus is mixed with alkaline circulating water system blow-off sewage, obtained wastewater is neutralized, and neutralized wastewater is conveyed to a salt well to carry out brine mining. The waste acid water is neutralized by using circulating water blow-off sewage, so the use amount of caustic soda is saved, the treatment cost of the waste acid water is reduced, and the comprehensive utilization rate of the waste acid water is improved.

Owner:HENAN YONGYIN CHEM IND CO LTD

Method for increasing brine output from brine mining well in salt lake mining area

InactiveCN109469471AExpand the brine areaIncrease the amount of brineFluid removalSalt lakeDirectional well

A method for increasing the brine output from a brine mining well in a salt lake mining area includes the following steps that 1, vertical deep well is built, wherein the designed depth of the vertical deep well is determined according to the occurrence conditions of the brine-containing ore deposit, and the shaft bottom needs to be located 5-8 cm away from a bottom plate of the brine-containing ore deposit at the lowermost portion in mining; 2, a directional horizontal well is built, wherein mining of a confined brine strata proceeds from top to bottom, horizontal sections are constructed along a bottom plate of the pressure-bearing brine-containing ore deposit I after the directional well traverses the overlying strata, and the directional well is communicated with the vertical deep well; 3, replacement mining is performed, wherein when the brine output of the upper portion of the pressure-bearing brine-containing ore deposit I is reduced and cna not reach the production scale requirement, the stable inclined section of the directional well continues to deepen downward, the horizontal sections are constructed along a bottom plate of the pressure-bearing brine-containing ore deposit II so that the directional well is communicated with the vertical deep well. According to the steps, the lower portion of the pressure-bearing brine-containing ore deposit continues to be mined. The method can increase the brine output area of the deep confined brine strata, improves the brine output of the vertical deep well, has remarkable economic benefits, and makes full use of the salt lake brine resources.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Method for jointly mining salt through directional well and submergence electric pump

ActiveCN107605485AReduce corrosion damageStable productionUnderground miningSurface miningDirectional wellBrine mining

The invention discloses a method for jointly mining salt through a directional well and a submergence electric pump. The method comprises the following steps that (1) water injection is conducted on asalt cavity of a brine well of a communicating and to-be-mined salt bed; (2) the stability area nearby the salt cavity of the brine well is determined; (3) the directional well is drilled on the stability area, and the directional well communicates with the salt cavity; and (4) the electric submergence pump is down into the directional well, and brine in the salt cavity is extracted. According tothe method for jointly mining the salt through the directional well and the submergence electric pump, the pressure in the salt cavity is obviously lower than that of a water-lift brine mining technology, etching and damage of injected water to surrounding rock are slowed down, meanwhile, the directional well and brine extracting equipment are located in the stability area, production is stable,and the brine quality is good; and the method is safe, the production period is long, salt mine falling off from the interior of the salt cavity can be dissolved and recovered, the method can be usedin a well group which loses the airtight condition, and the recovery ratio of the salt mine is effectively increased.

Owner:中盐勘察设计院有限公司

Method for determining air-driven distance in air-driven brine mining method

The invention discloses a method for determining an air-driven distance in an air-driven brine mining method. The method comprises the following steps that S1, a brine collecting channel is excavated;S2, two grouting drill hole sets with a certain interval are arranged on the same side perpendicular to the brine collecting channel in parallel, each grouting drill hole set is composed of a plurality of grouting drill holes with a certain interval, a cementing material is injected into a brine storage layer through the grouting drill holes by means of a grouting pump, pores of part of the brinestorage layer are filled with the cementing material, and thus a waterproof columnar body is formed; S3, a continuously closed curtain wall is formed; S4, a gas injection drilling set is constructedat the end, away from the brine collecting channel, of the curtain wall perpendicular to the curtain wall formed by the two grouting drill hole sets, and air is injected into the brine storage layer through a gas injection device; and S5, the brine amount of the brine collecting channel is monitored in real time, and the length of the grouting drill hole sets and the distance between the gas injection drill holes and the brine collecting channel are adjusted. The step 5 is repeated until the most suitable air-driven distance of the brine storage layer is determined. The method can greatly improve the collection efficiency.

Owner:MINMETALS SALT LAKE CO LTD +1

Brine mining well structure for slattern geology containing multiple drift sand layers

PendingCN108222896AEffective filteringSimple structureUnderground miningFluid removalStructure of the EarthBrine mining

The invention relates to the technical field of brine mining in salterns and discloses a brine mining well structure for slattern geology containing multiple drift sand layers. The brine mining well structure comprises a well body. A filter steel cylinder is arranged in the well body, and the height of the filter steel cylinder is the same as the depth of the well body; the bottom of the well bodysupports the filter steel cylinder; and filter holes are formed in the cylinder wall of the filter steel cylinder. The structure is simple and reasonable, the construction problems such as well collapse and pump burying can be prevented effectively, drift sand of the drift sand layers is filtered effectively, the well washing efficiency is promoted, and thus the well-forming process is rapid andsmooth.

Owner:CHINA MCC5 GROUP CORP

Rock salt mine mining method

PendingCN110566176AEliminate solubilityEliminates melting point shiftsFluid removalBrine miningMineralogy

The invention discloses a rock salt mine mining method. The rock salt mine mining method comprises the following steps that (A) a vertical well A is constructed, and a salt trough is built; the miningmethod is characterized in that the mining method further comprises that (B) a vertical well B is constructed, and a salt trough is built; (C) a horizontal well is constructed, the horizontal well comprises a vertical well section, an inclining increasing section and a horizontal section, and the horizontal section communicates with the salt troughs of the vertical well A and the vertical well B;(D) cement is injected into the horizontal section of the horizontal well for plugging, the horizontal well is separated from the adjacent vertical well, and the vertical well A still communicates with the vertical well B; and (E) horizontal abutting joint is conducted through the vertical well A and the vertical well B for communicating with brine mining. According to the rock salt mine mining method, the problems that rock salt is insoluble and a melting start point is offset from the casing shoe position to the inclining increasing section are eliminated, and the recovery ratio of rock salt resources can be increased.

Owner:四川盐业地质钻井大队

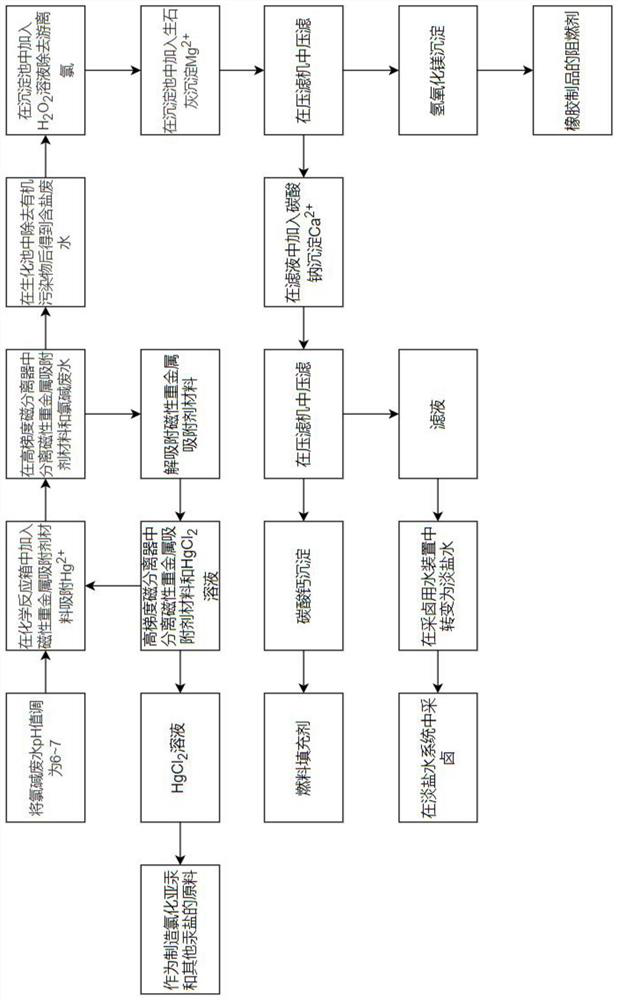

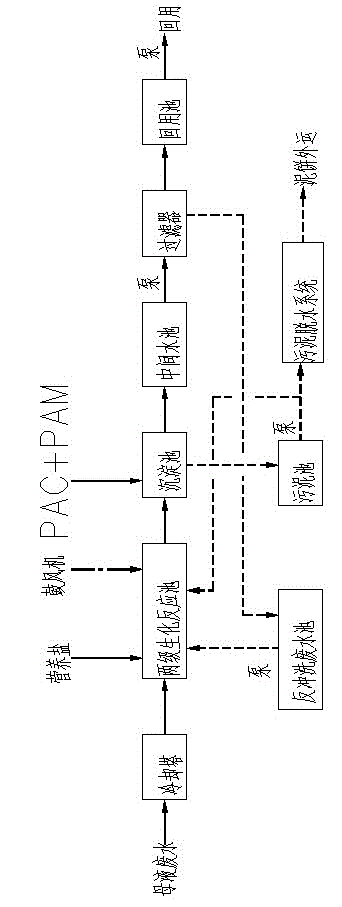

Resource recycling method of chlor-alkali wastewater

PendingCN114409156ATake advantage ofReduce processing costsCalcium/strontium/barium carbonatesOther chemical processesMagnesium saltSorbent

The invention provides a resource recycling method of chlor-alkali wastewater, and belongs to the technical field of wastewater treatment. The method comprises the following steps: adjusting the pH value of the chlor-alkali wastewater to 6-7, and then mixing the chlor-alkali wastewater with a magnetic mercury adsorbent for adsorption to obtain mercury-removed wastewater and a mercury-magnetic mercury adsorbent; carrying out desorption adsorption on the mercury-magnetic mercury adsorbent to obtain a recovered magnetic mercury adsorbent and a mercury ion solution; sequentially carrying out organic pollutant removal treatment, free chlorine removal and magnesium precipitation reaction on the mercury-removed wastewater to obtain magnesium hydroxide and magnesium-removed wastewater; carrying out calcium precipitation reaction on the magnesium-removed wastewater to obtain calcium carbonate and calcium-removed wastewater; and collecting brine from the calcium-removed wastewater to obtain light salt brine. The mercury ion solution (used for preparing mercury salt), magnesium hydroxide (used as a flame retardant, a neutralizer and a flue gas desulfurizer and used for preparing calcium carbonate and magnesium salt), calcium carbonate (used as a pigment filler, a raw material of optical neodymium glass and flux limestone in metallurgical industry) and light salt brine (used for brine mining) obtained by the method can realize full utilization of resources in chlor-alkali wastewater.

Owner:YUNNAN UNIV

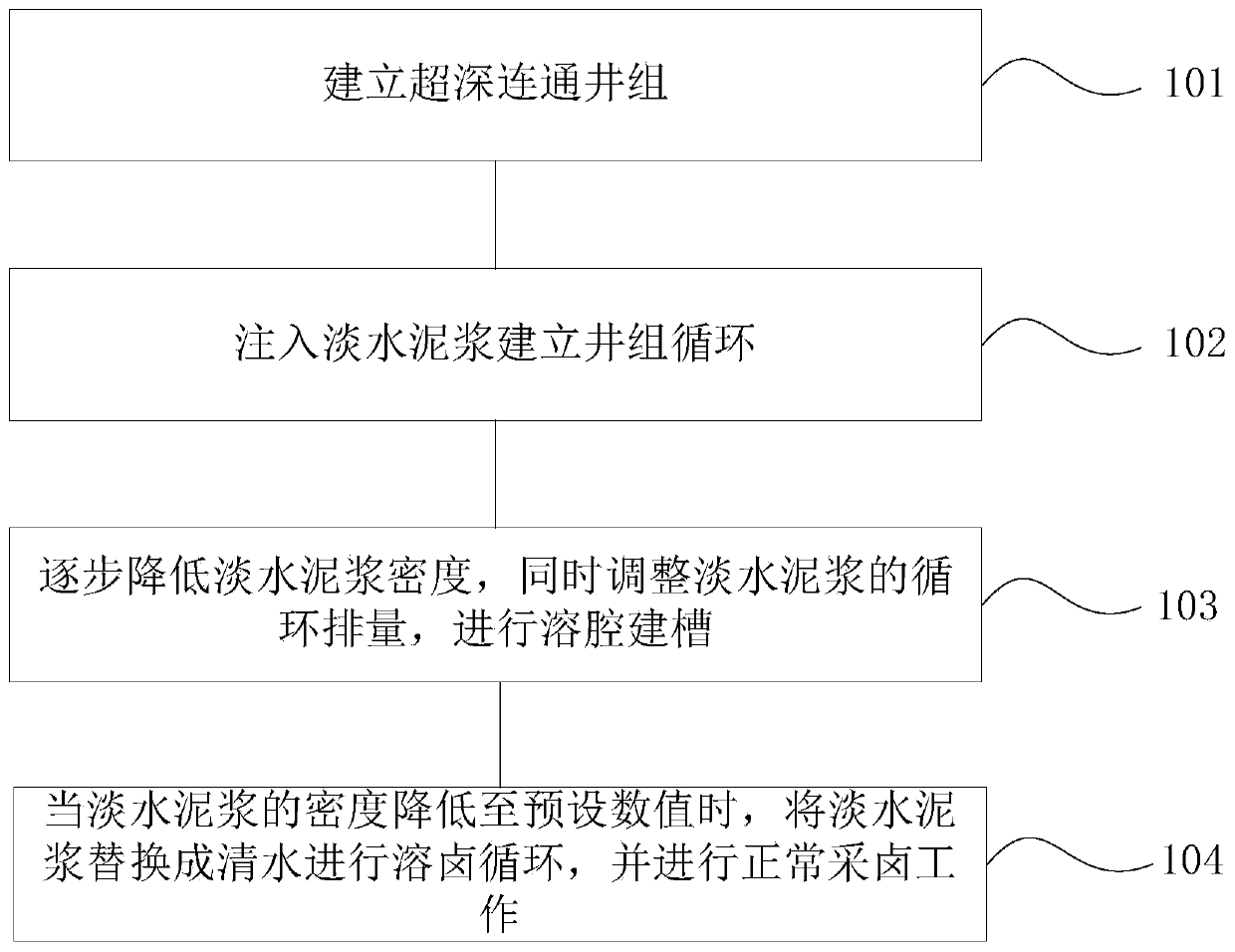

Dissolving cavity groove-construction method for tertiary-system stratum ultra-deep connection brine mining well

InactiveCN111287725ARealize normal brine miningIncrease effective pressureFluid removalFlushingBrine miningFresh water

The invention relates to the technical field of bittern production, in particular to a dissolving cavity groove-construction method for a tertiary-system stratum ultra-deep connection brine mining well. The dissolving cavity groove-construction method for the tertiary-system stratum ultra-deep connection brine mining well comprises the following steps of: establishing an ultra-deep connection wellgroup; injecting fresh water mud, and establishing well group circulation; gradually lowering the concentration of the fresh water mud, meanwhile, regulating a circulation displacement of the fresh water mud, and carrying out dissolving cavity groove construction; and when the concentration of the fresh water mud is lowered to a preset numerical value, replacing the fresh water mud with clear water, and carrying out dissolved brine circulation, and carrying out normal brine mining work. When the method provided by the embodiment of the invention is adopted, well bottom effective pressure canbe improved, and stratum stress is gradually released to avoid a situation that a stratum suddenly loses stability and collapses on a large area to block a channel. Meanwhile, salt bed creepage and hole shrinkage can be alleviated so as to gradually enlarge a horizontal channel, transition from mud to clear water is successfully finished during a groove-construction period of the ultra-deep connection well group, and therefore, the normal brine mining of the ultra-deep connection well group is successfully realized.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

A kind of brine mining well casing maintenance device and method

InactiveCN106150400BExtended service lifeGuaranteed connectivityDrilling rodsSealing/packingBrine miningSucker rod

The invention provides a brine well casing pipe maintenance device, comprising a borehole, a casing pipe, an oil pipe and a casing pipe corrosion section, wherein the casing pipe is fixed in the borehole, and an upper packer and a lower packer are respectively arranged at the upper end and the lower end of the casing pipe corrosion section of the casing pipe; the oil pipe is positioned in the casing pipe, a hollow sucker rod is arranged in the oil pipe, an internal packer is arranged between the hollow sucker rod and the oil pipe, and the internal packer is positioned between the upper packer and the lower packer; annular spaces are respectively formed at the positions, where the oil pipe and the casing pipe corrosion section are arranged, of the casing pipe; a plurality of through holes are formed in the oil pipe at the casing pipe corrosion section. The brine well casing pipe maintenance device has the characteristics that the original size of the original borehole is ensured, so that the cyclic discharge capacity of the maintained casing pipe is constant, the casing pipe corrosion speed of a brine well is slowed down, the hidden danger caused by the reduction of borehole size is eliminated, and the aim of prolonging the production cycle of the brine well under the circumstances of conventional cyclic discharge capacity is achieved.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Wastewater zero discharge system of chlorine-alkali industry

ActiveCN102964024BEnable recyclingReduce processing loadMultistage water/sewage treatmentWater desalinationSaline water

The invention discloses a wastewater zero discharge system of chlorine-alkali industry. The system includes a sodium hypochlorite wastewater treatment system, a centrifugal mother liquor treatment system, a comprehensive wastewater treatment system, a domestic sewage treatment system and a circulating water system. Well water is treated by a water desalination plant, and the generated desalinated water is transported to a caustic soda device and a PVC polymerization device to be used in production. One part of the concentrated saline water generated by the water desalination plant is used for an acetylene generator, and the other part is delivered into a dilute saline water trough and returned to a brine well so as to be used in brine mining. A production water station is mainly used for an acetylene purification device, the PVC polymerization generation device, the caustic soda device and an acetylene section alkali washing tower. The sodium hypochlorite wastewater discharged from the acetylene purification device is treated by the sodium hypochlorite wastewater treatment system to reach the standard, and is then returned to the saline well to be used for saline mining. The centrifugal mother liquor from the PVC polymerization generation device is treated by the centrifugal mother liquor treatment system to reach the standard, and is then returned to the circulating water system. The production wastewater from the PVC polymerization generation device and the production wastewater from the caustic soda device are treated by the comprehensive wastewater treatment system to reach the standard, and are then returned to the saline well to be used for dilute saline water saline mining.

Owner:HENAN YONGYIN CHEM IND CO LTD

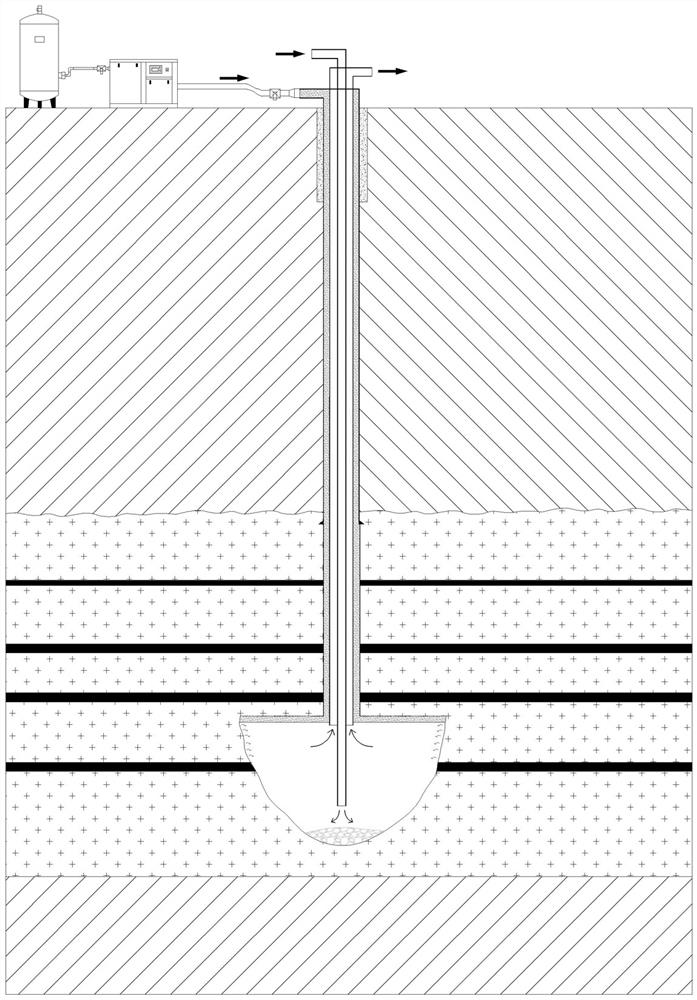

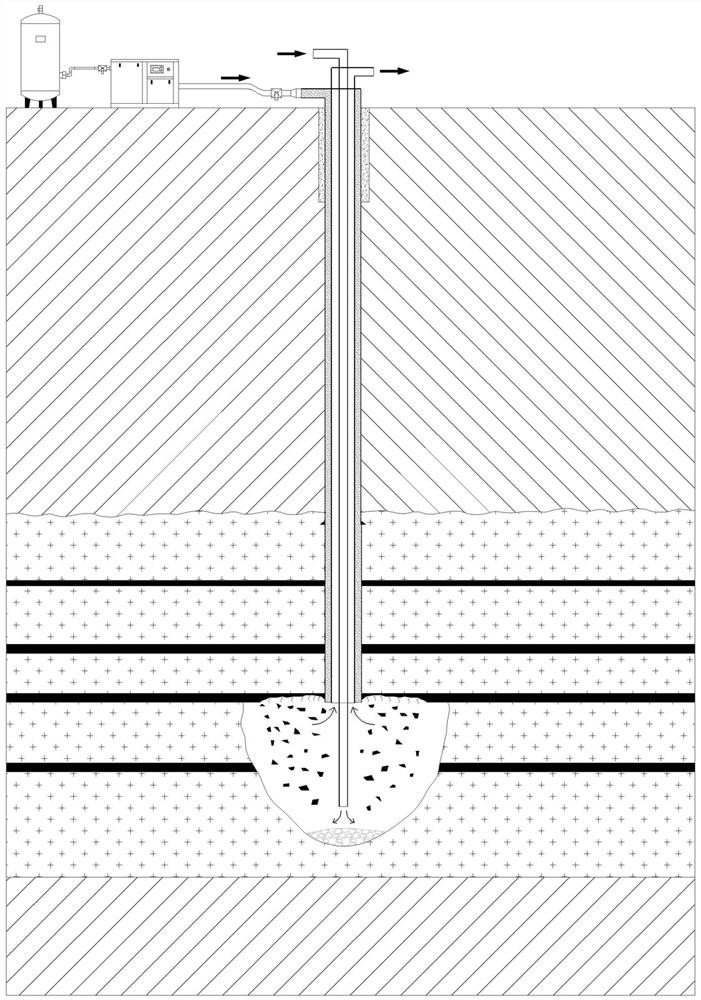

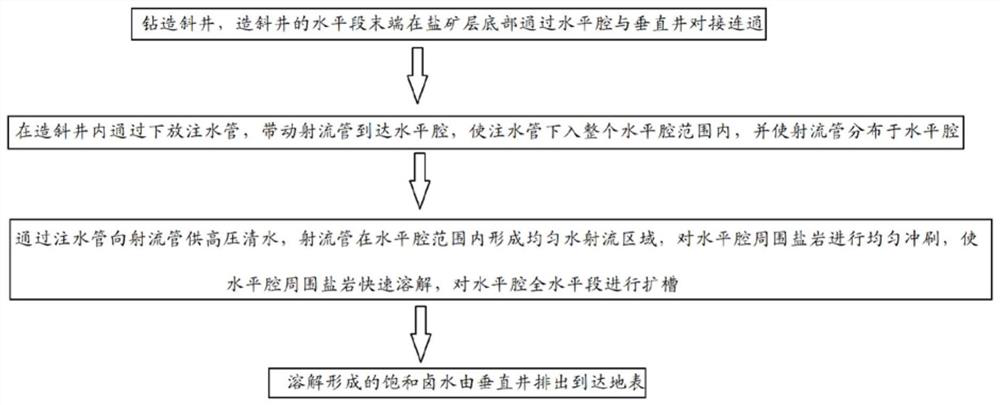

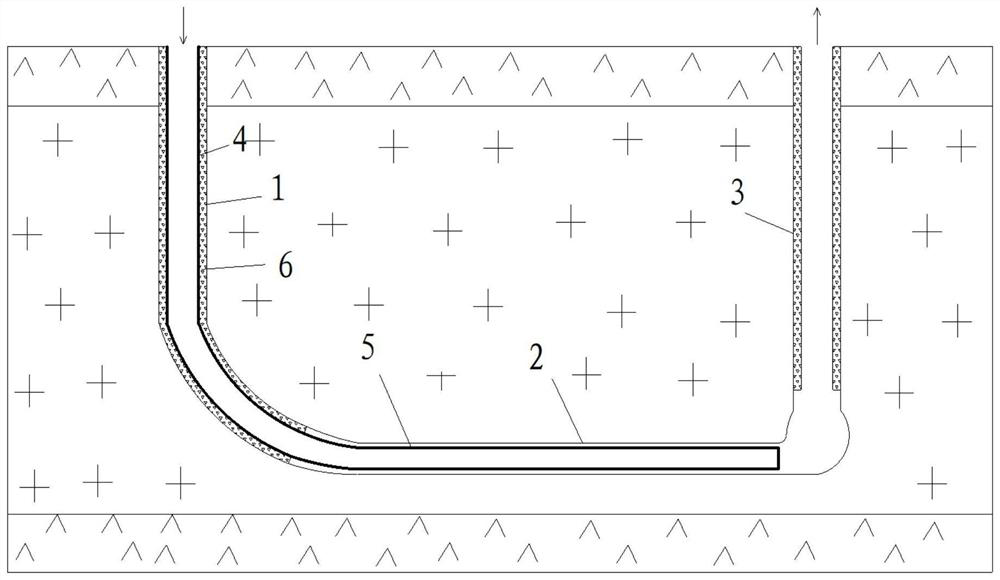

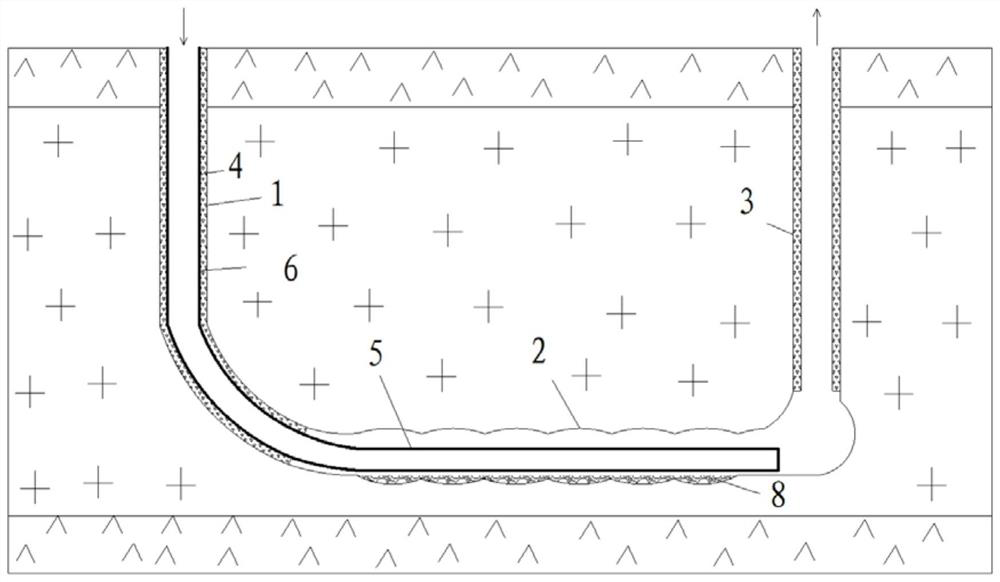

Groove expansion method in full horizontal section of butt joint shaft in ultra-deep salt mine

ActiveCN112227985BRapid slot expansionFast and timely slot expansionUnderground miningDirectional drillingBrine miningOil and natural gas

The invention discloses a full-horizontal groove expansion method for butt mining brine in a salt mine, which belongs to the technical field of underground storage of oil and natural gas. The method for expanding slots in the full horizontal section of brine butt mining in salt mines includes the following steps: in the deflection shaft, the water injection pipe is lowered to drive the jet pipe to reach the horizontal chamber, so that the water injection pipe is lowered into the entire horizontal chamber, and the jet pipe is distributed in the horizontal chamber. cavity; through the water injection pipe to supply high-pressure clean water to the jet tube, the jet tube forms a uniform water jet area within the range of the horizontal cavity, and evenly scours the salt rock around the horizontal cavity, so that the salt rock around the horizontal cavity is quickly dissolved, and the entire horizontal section of the horizontal cavity Carry out slot expansion. The groove expansion method of the full horizontal section of the salt mine butt mining brine of the present invention can promptly and rapidly expand the size of the horizontal cavity, and quickly expand the horizontal cavity before the horizontal cavity creeps and shrinks and blocks, ensuring the connectivity of the horizontal gas storage and expanding the storage capacity. The volume of the horizontal cavity of the gas storage.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

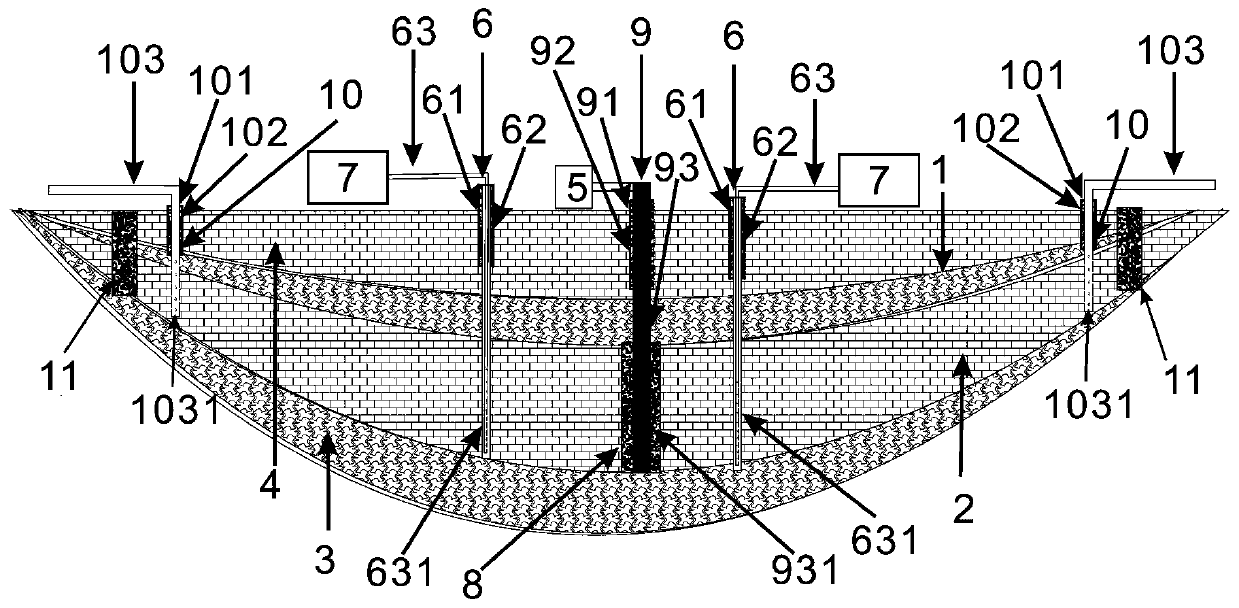

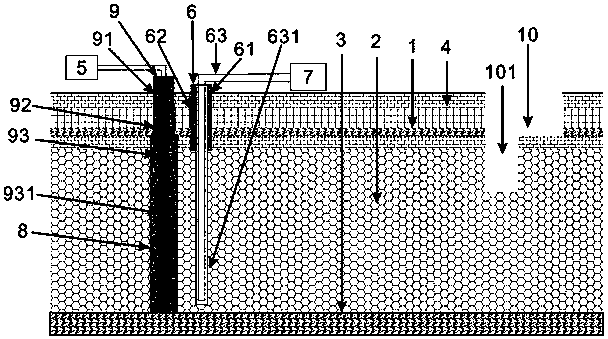

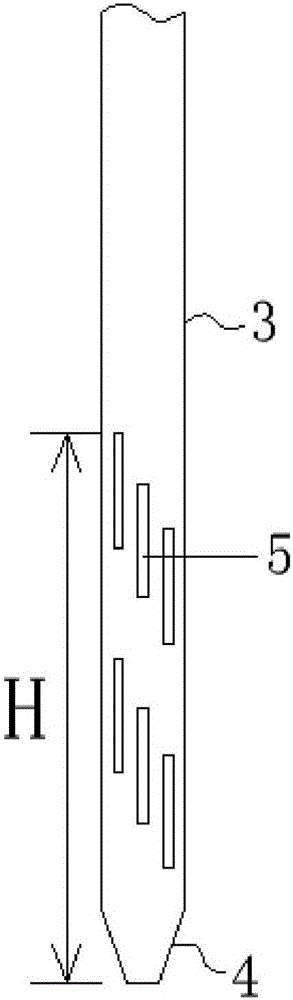

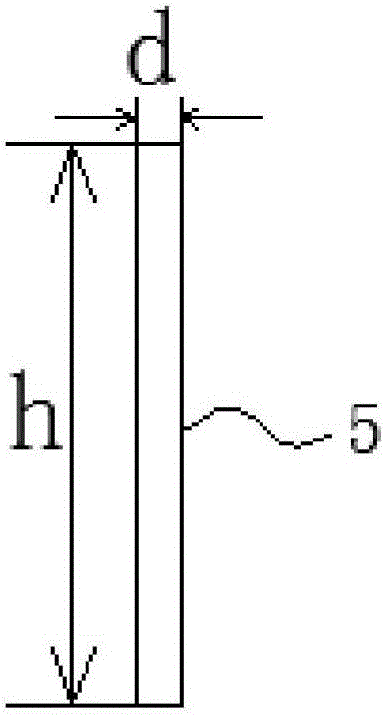

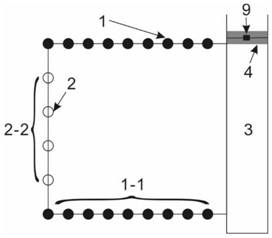

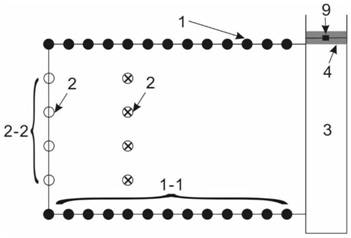

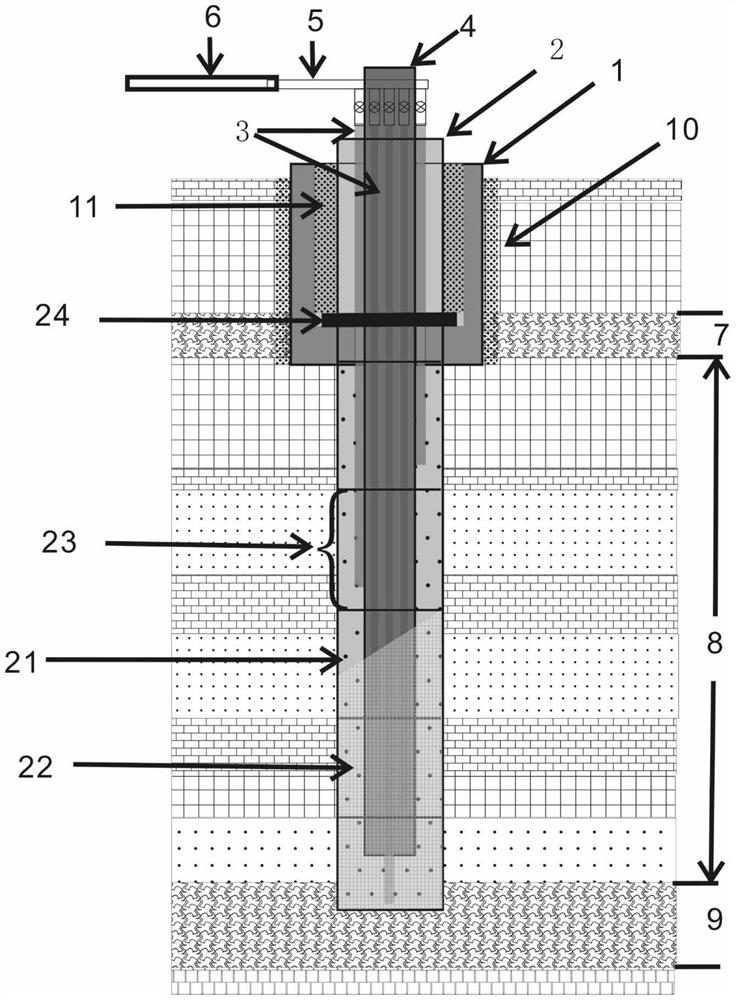

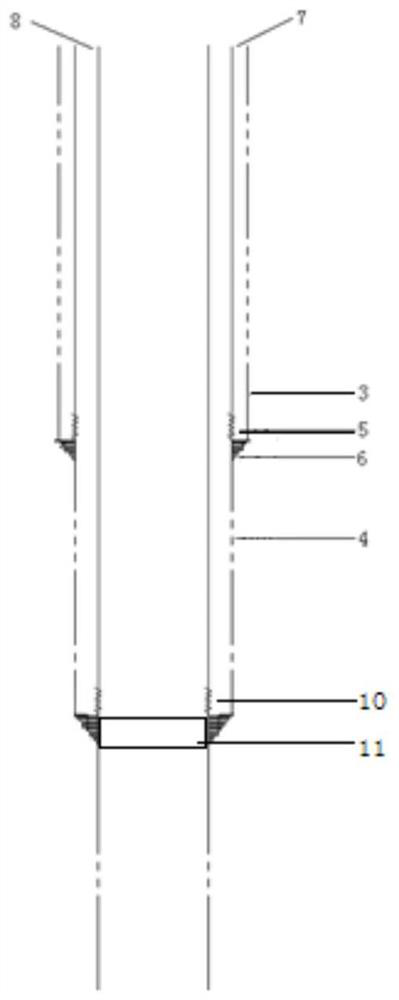

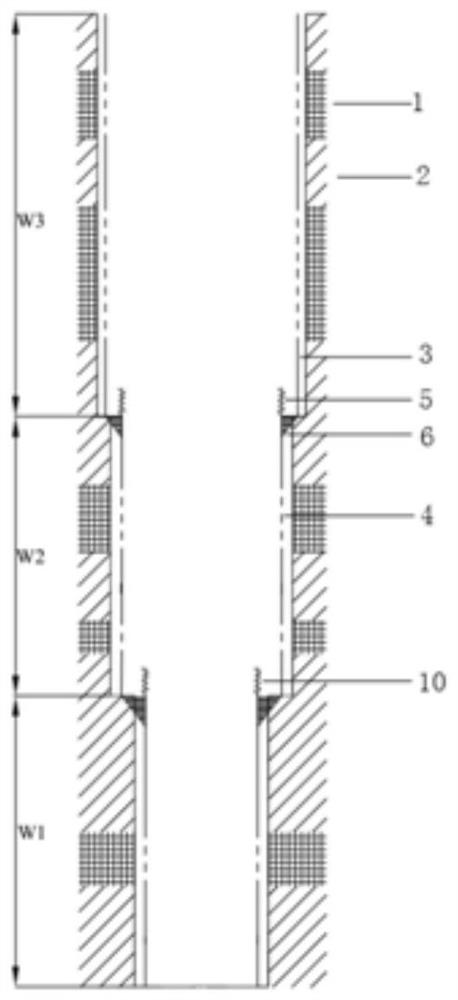

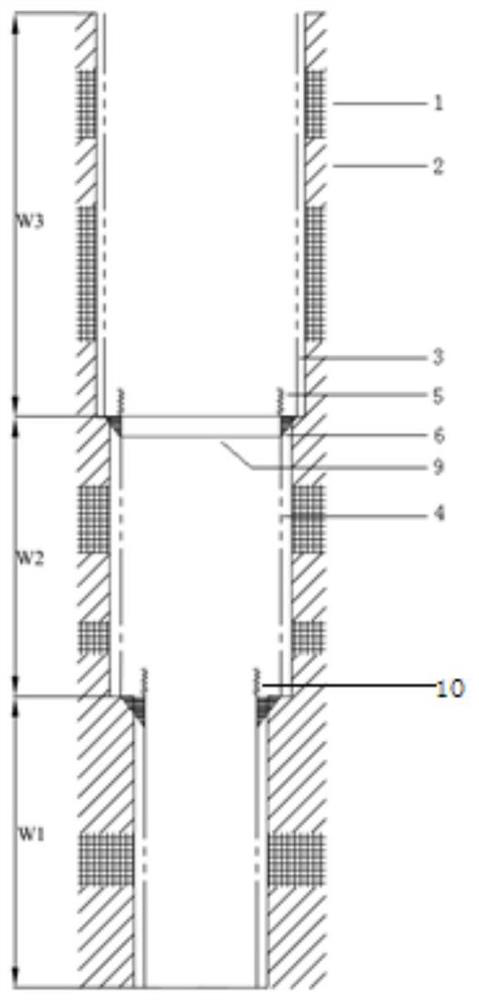

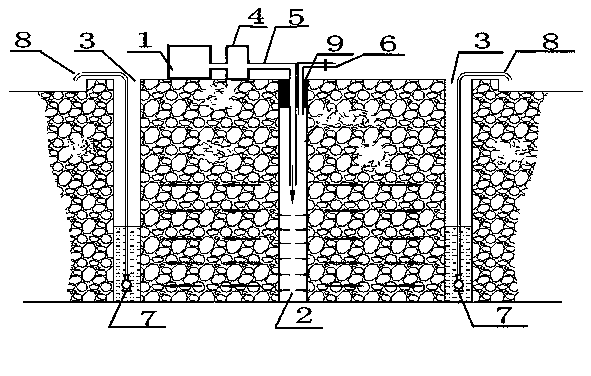

Construction method of gas injection hole

ActiveCN112302533AIncreased water supplyBrine mining costs increaseFluid removalSealing/packingThermodynamicsWell cementing

The invention provides a construction method of a gas injection hole. The construction method comprises the following steps that an upper water-resisting layer (7) is penetrated by using a phi 150mm drill bit, then a phi 150mm well cementation sleeve (1) is lowered, and the outer side of the well cementation sleeve (1) is fixed by using a magnesium-based cementing material in an out-of-wall grouting mode to form an out-of-pipe cement body (10); a fine debris water-containing layer (8) is drilled in the well cementation sleeve (1) by using a phi 110mm drill bit, and a lower water-resisting layer (9) is drilled; a drill bit with the diameter phi of 127 mm is drilled into the upper water-resisting layer (7) by the depth of 0.2-1 m in the well cementation sleeve (1), so that a closed steel ring (24) of a gas injection screen pipe (2) is embedded into the upper water-resisting layer (7); and the processed gas injection screen pipe (2) is put into the well cementation sleeve (1), and then amagnesium-based cementing material is poured to form an in-of-pipe cement body and enable the in-of-pipe cement body (11) to be cemented and fixed with the well cementation sleeve (1). According to the construction method of the gas injection hole, air with certain pressure can be injected into the water-containing layer, so that pore brine of the water-containing layer is rapidly discharged, thebrine mining cost can be reduced, the brine mining amount is greatly increased, and the mining efficiency and the recovery ratio are improved.

Owner:青海凹口凸钾镁盐技术有限公司

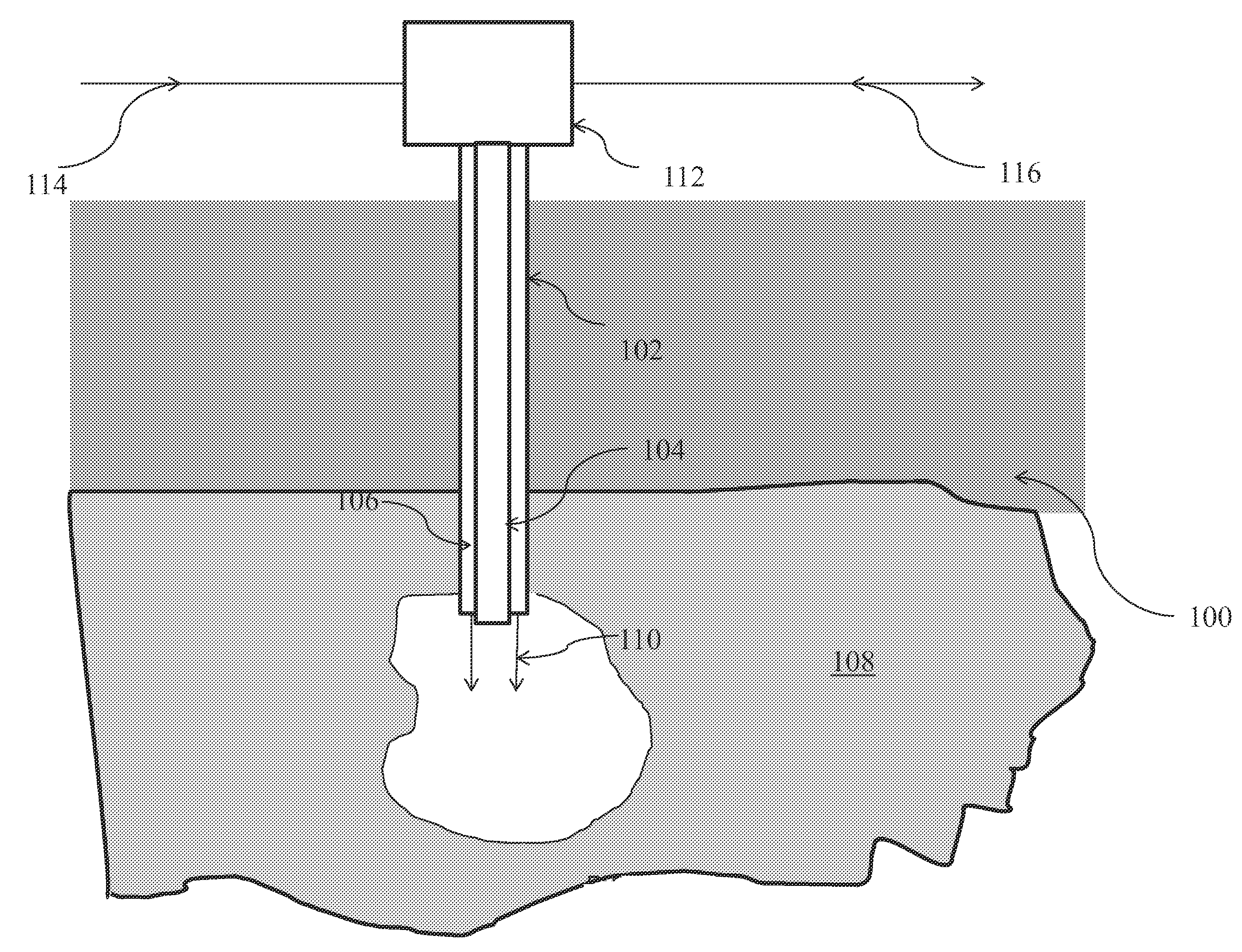

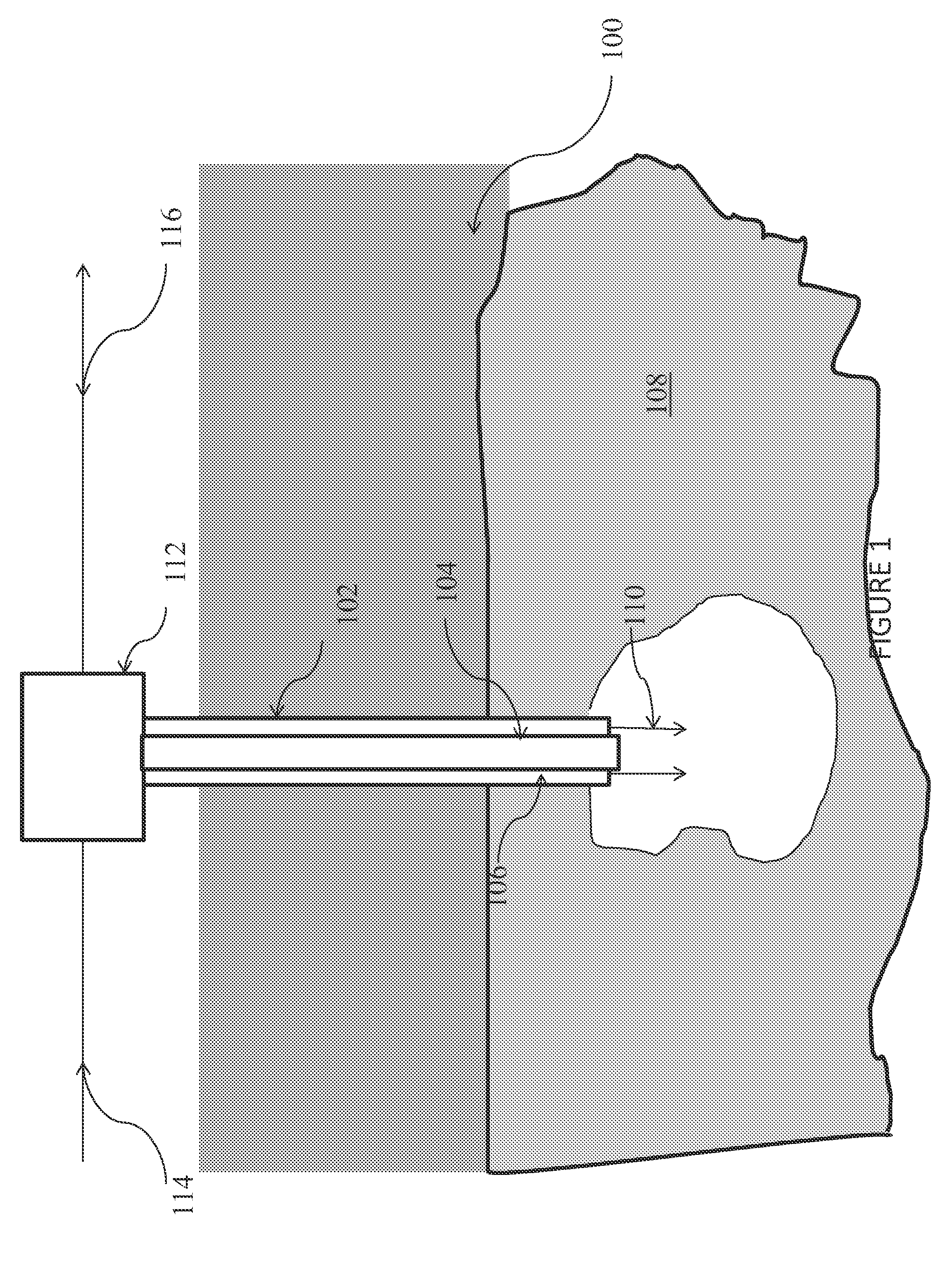

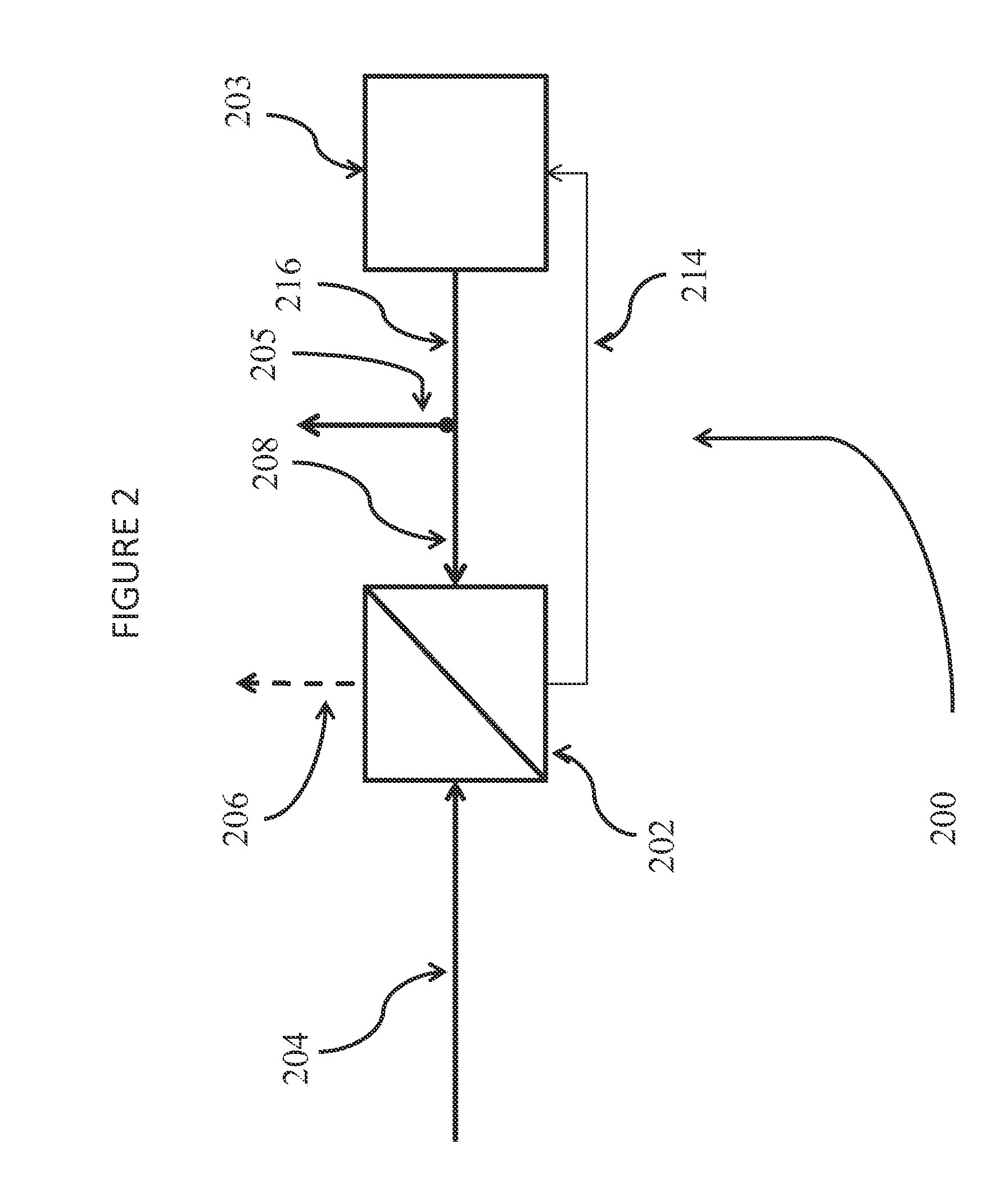

Brine mining process

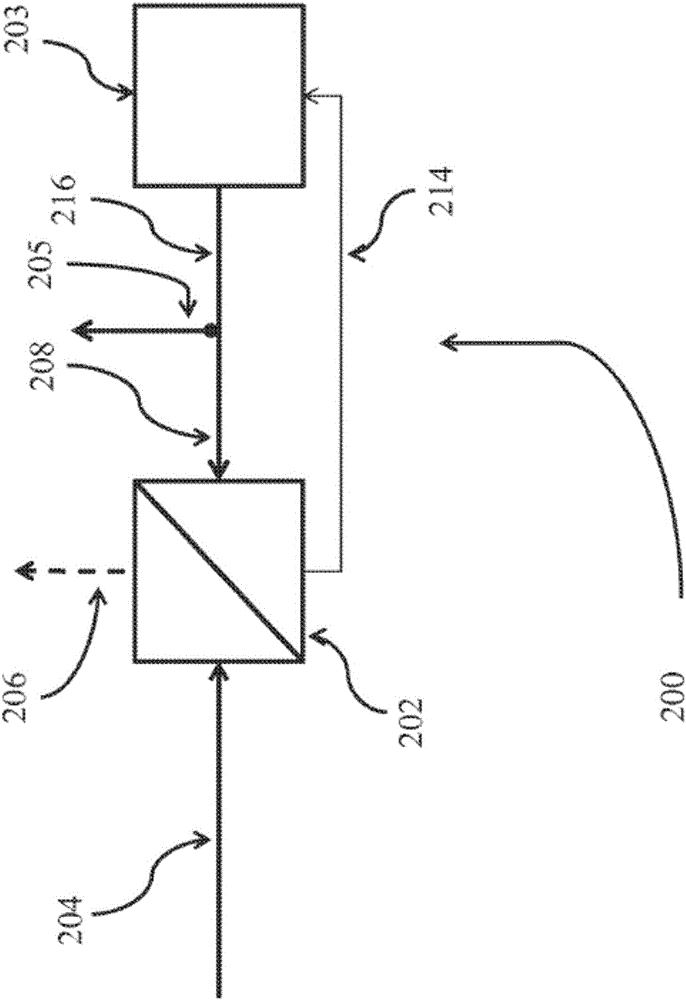

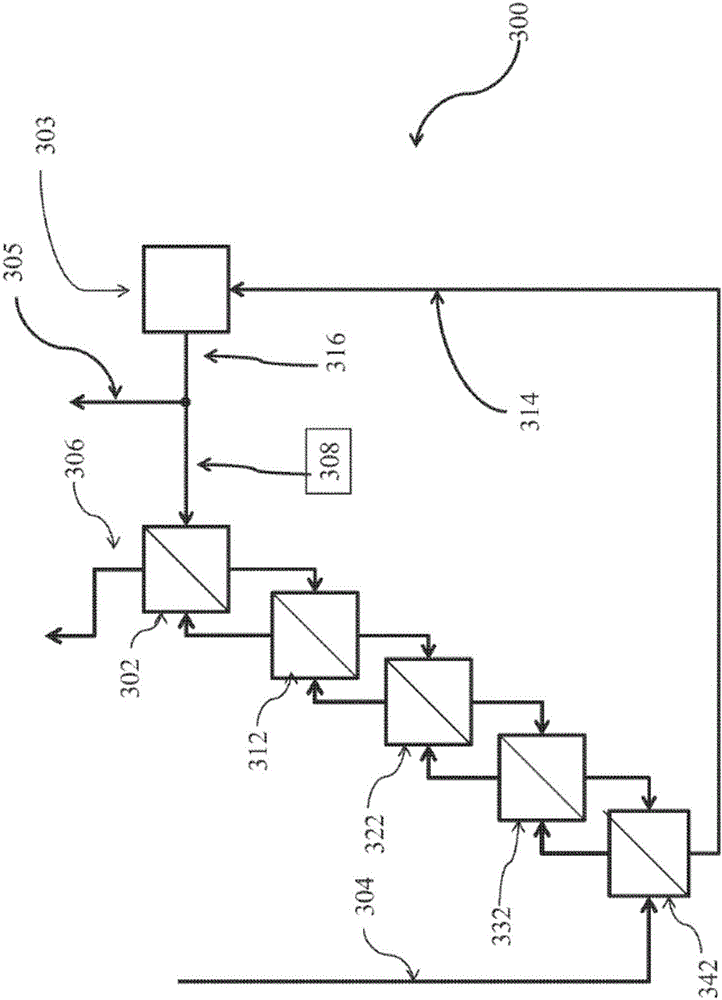

InactiveUS20160272513A1Reduce spendingReduced resourceWaste water treatment from quariesCalcium/strontium/barium carbonatesProcess equipmentBrine mining

The present invention relates to a brine mining process. The process incorporates a forward osmosis step wherein at least a portion of at least one process stream is provided to at least one forward osmosis unit. The process thus allows for the use of multiple sources, and qualities, of water, which, in turn, can reduce the reliance on natural water sources. Longevity of the mining, and any downstream, process equipment may be enhanced. At least a portion of the production stream may also be fed to a downstream process, such as a chlor-alkali process.

Owner:BLUE CUBE IP

Brine mining process

InactiveCN105745358AReduce dependenceCalcium/strontium/barium carbonatesWaste water treatment from quariesProcess equipmentWater resources

The present invention relates to a brine mining process. The process incorporates a forward osmosis step wherein at least a portion of at least one process stream is provided to at least one forward osmosis unit. The process thus allows for the use of multiple sources, and qualities, of water, which, in turn, can reduce the reliance on natural water sources. Longevity of the mining, and any downstream, process equipment may be enhanced. At least a portion of the production stream may also be fed to a downstream process, such as a chlor-alkali process.

Owner:BLUE CUBE IP +1

Method for producing potassium chloride, sodium chloride and magnesium sheet from bittern extracted from carnallite mine

ActiveCN102491373BReduce consumptionReduce dosageMagnesium chloridesAlkali metal chloridesSolubilityEvaporation

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

A layered water-stopping device and layered water-stopping process for deep holes

The invention discloses a layered water-stopping device for deep holes and a water-stopping process using the same. The diameter-reducing part of the sealing connection, the upward annular flange of the upper end of the lower sleeve arranged in the two adjacent sleeves, the water stop pipe detachably connected to the annular flange in a sealing manner, and the sealing pipe used for blocking the adjacent two sleeves Removable bridge plugs for ports on the lower casing in After using the device to stop water by the process of the present invention, the water-stopping effect is improved and it is suitable for deep brine wells, and at the same time, the drilling wells can be directly transformed into brine mining wells to avoid waste of resources.

Owner:江苏长江地质勘查院

Method for extraction of deep-seated intercrystalline bittern of salt lake mining area

ActiveCN102659139BIncrease collection rateMaintain dynamic balanceAlkali metal chloridesSalt lakeMining engineering

Owner:MANGYA XINGYUAN POTASH FERTILIZER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com