Brine mining well casing pipe and brine mining well structure

A technology of well casing and well structure, applied in casing, wellbore/well components, drill pipe, etc., can solve the problems of the collapse of the communication channel, the inability of the brine well to be put into production, and the formation pressure is high, so as to avoid the communication channel being blocked. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] For further elaborating the technical means and effects that the present invention takes to reach the predetermined invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to its specific implementation mode, Structure, characteristic and effect thereof are as follows in detail.

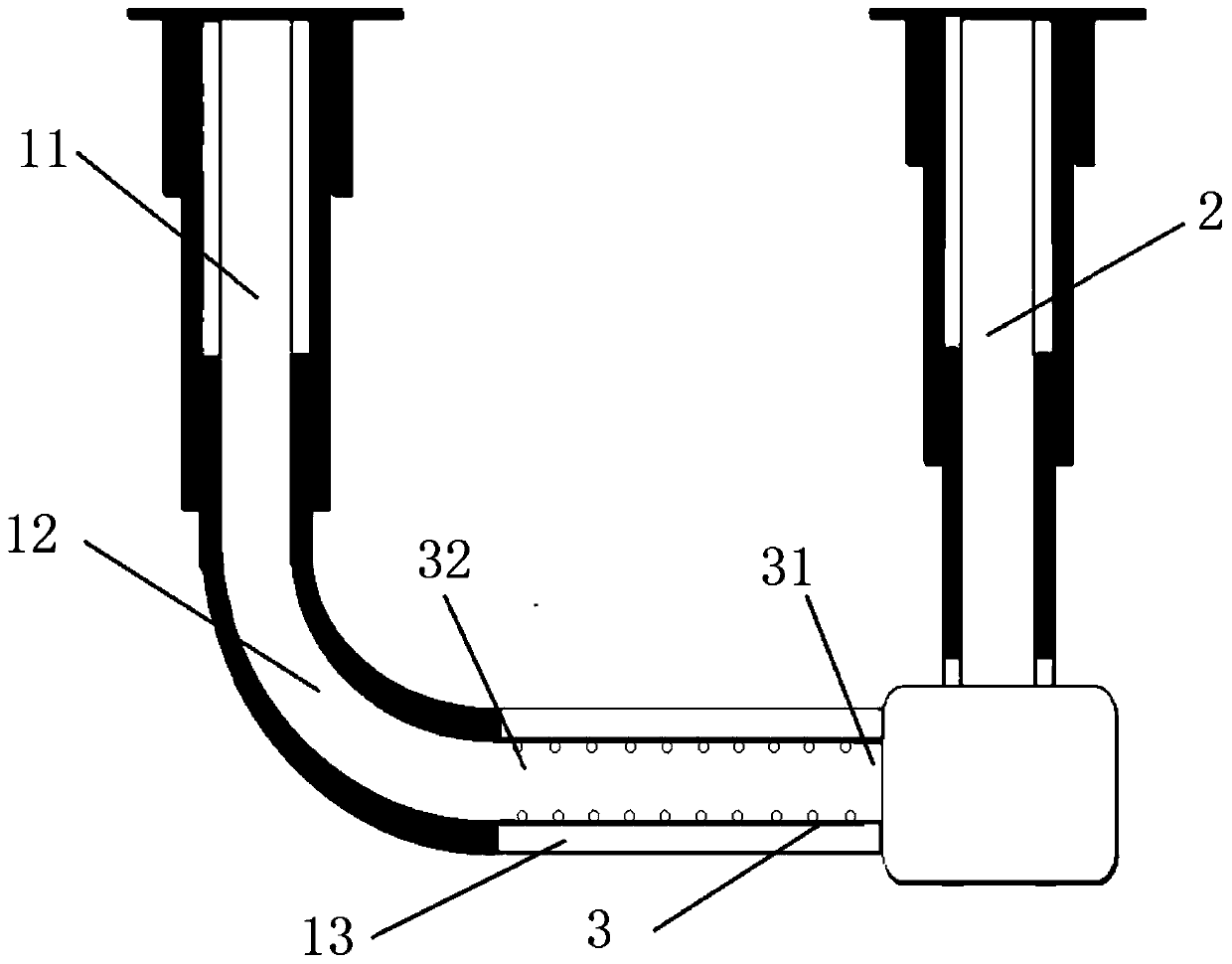

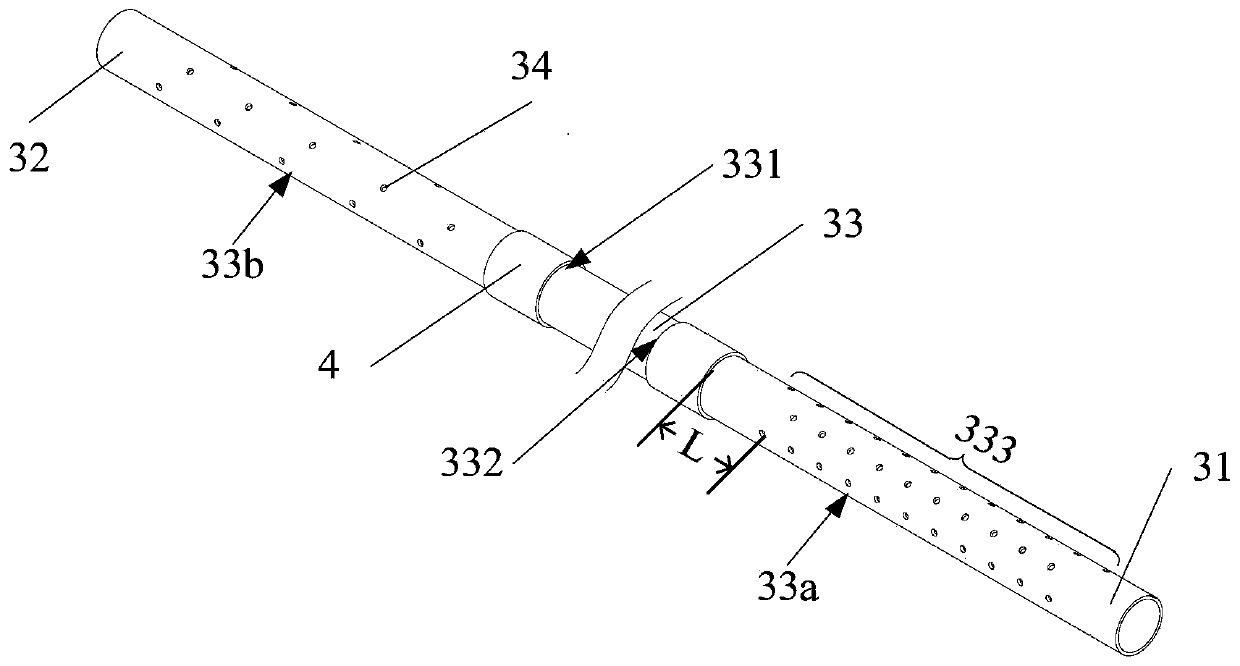

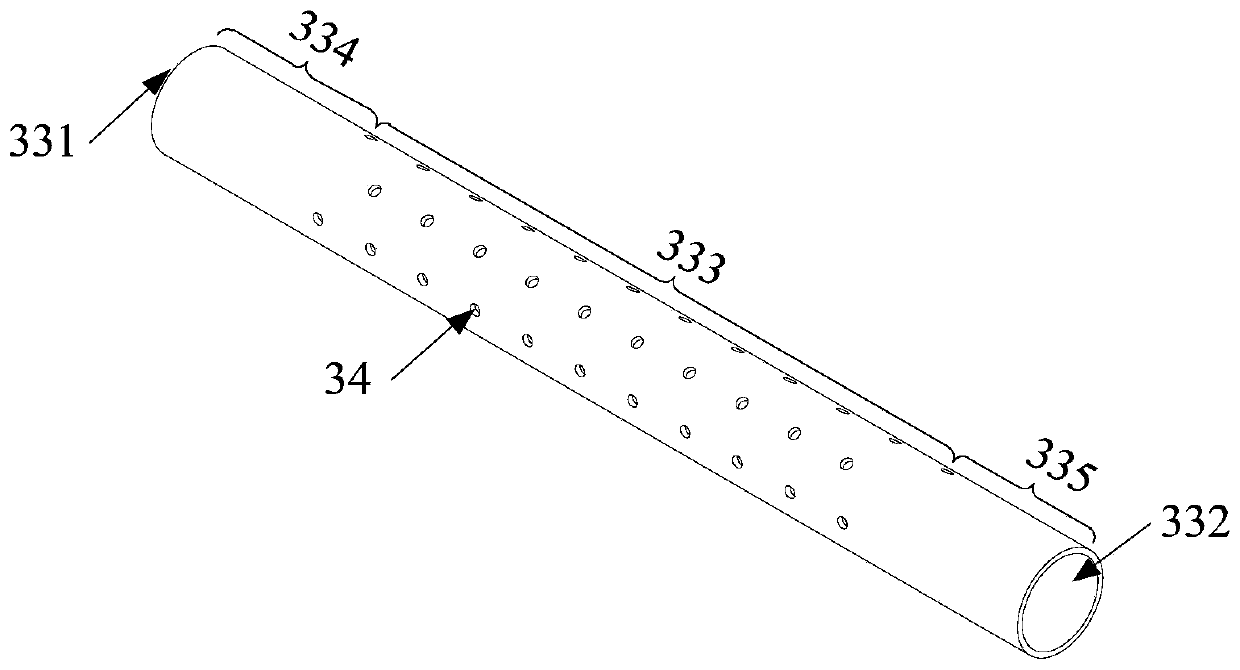

[0027] On the one hand, the embodiment of the present invention provides a brine production well casing 3, such as figure 1 As shown, it is used for the brine extraction well structure, and the brine extraction well structure includes: a water injection well, including: a vertical well section 11, a deflection section 12 and a horizontal section 13 connected in sequence; One end of the deflection end is connected; the casing 3 of the brine production well includes: the pipe wall and the flow passage surrounded by the pipe wall, and a plurality of passages communicating with the flow passage are formed on the pipe wall The hole 34 is used for setting the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com