Resource recycling method of chlor-alkali wastewater

A recycling and waste water technology, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of resource recycling and resource waste of difficult chlor-alkali wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] After obtaining the pH adjusted wastewater, the invention mixes the pH adjusted wastewater with the magnetic mercury adsorbent for solid-liquid separation after adsorption to obtain mercury removal wastewater and mercury magnetic mercury adsorbent. In the invention, the preparation method of the magnetic mercury adsorbent preferably comprises the following steps: filtering, distilling, deodorizing and decolorizing the kitchen waste oil in turn to obtain the refined kitchen waste oil; The refined kitchen waste oil, sulfur powder and Fe 3 O 4 @SiO 2 The magnetic mercury adsorbent was obtained by the mixed reaction of nanoparticles. In the invention, the sulfur powder, refined kitchen waste oil and Fe 3 O 4 @SiO 2 The mass ratio of nanoparticles is preferably 10 ~ 12:4 ~ 6:1, more preferably 10.5 ~ 11.5:4.5 ~ 5.5:1. In the invention, the magnetic mercury adsorbent is preferably prepared according to the method disclosed in Chinese patent cn111167424a, which will not be repeate...

Embodiment 1

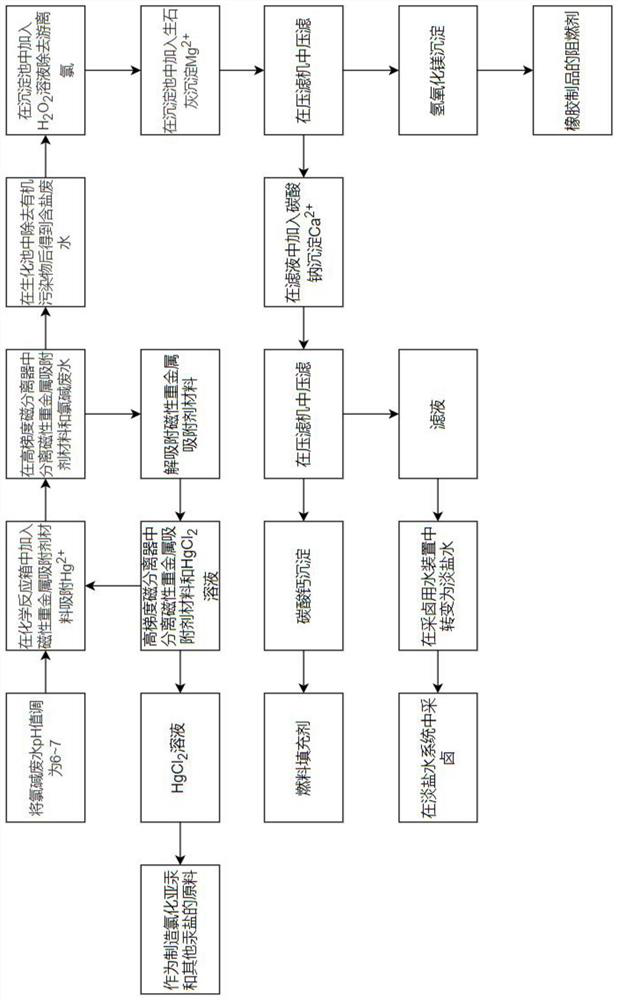

[0051] according to Figure 1 Chlor alkali wastewater treatment is carried out according to the flow chart shown in.

[0052] (1) Adjust pH

[0053] Taking a Chlor Alkali Company in Yunnan as an example, the pH value of chlor alkali wastewater is monitored in real time by pH analyzer, and 1m is taken 3 Chlor alkali wastewater (mass: 1.56 tons), under the condition of room temperature, adjust the pH value to 6.5 by adding quicklime to obtain pH adjusted wastewater; Among them, the amount of limestone is 550.0kg.

[0054] (2) Adsorption magnetic separation

[0055] The pH adjusted wastewater is introduced into the chemical reaction tank, 30.0kg magnetic mercury adsorbent is added, mixed evenly, adsorbed at room temperature for 24h, and passed through Hg 2+ Real time monitoring of Hg in solution by content analyzer 2+ Content, then flow into the high gradient magnetic separator at the flow rate of 1.3m / min, and separate by magnetic separation under the condition of 5kgs to obtain Hg a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com