Semi-closed underground brine mining system and construction method thereof

An underground brine, semi-closed technology, applied in the fields of fluid extraction, earthwork drilling, sealing/isolation, etc., can solve the problems of small brine extraction, insufficient extraction, slow flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

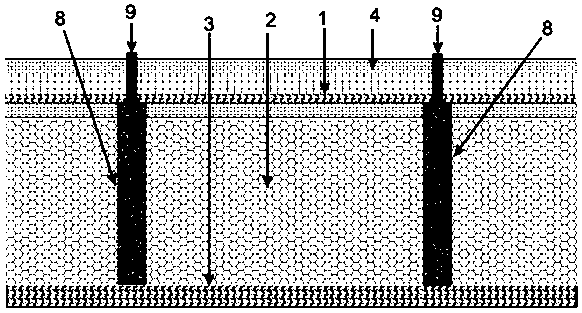

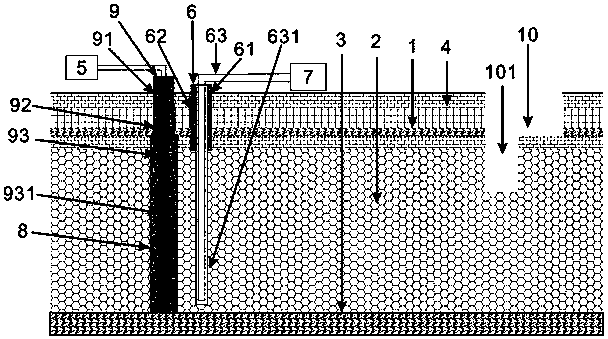

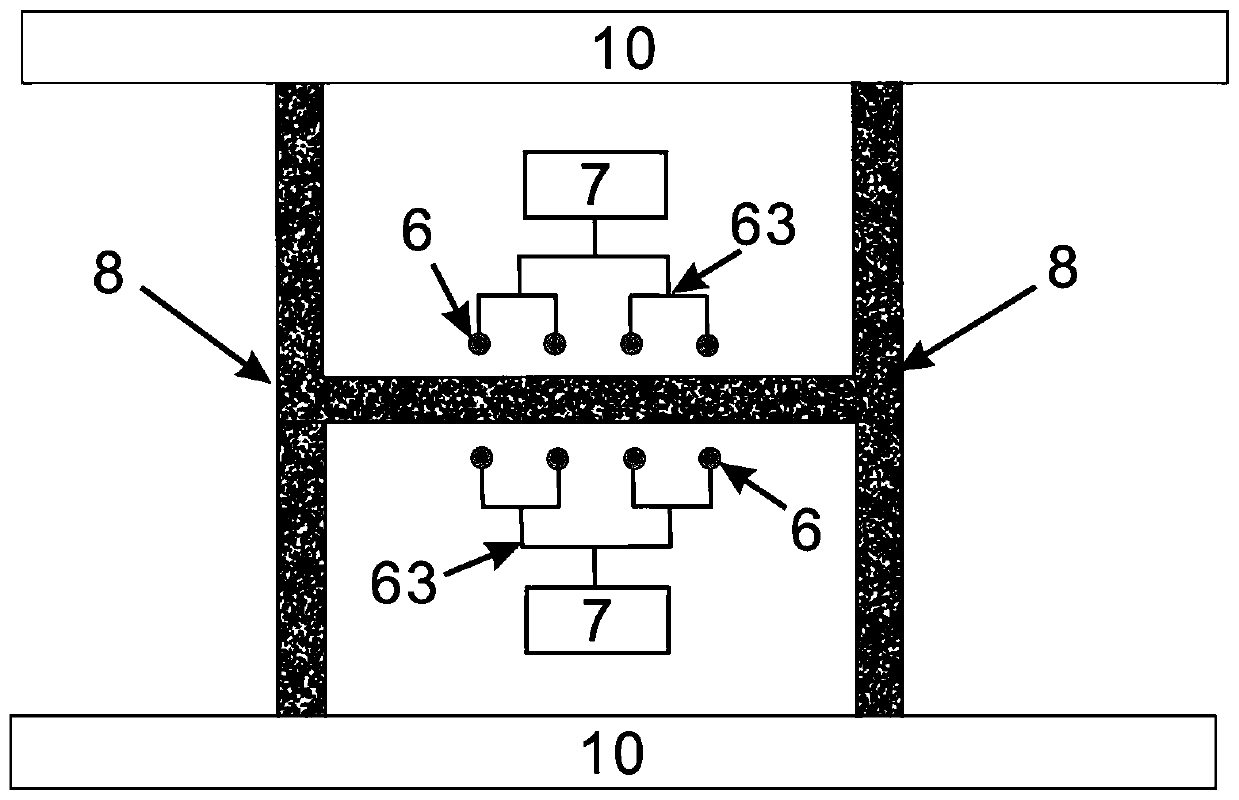

[0029]The overall structure of the semi-closed underground brine mining system of the embodiment of the application, please refer to Figure 1 to Figure 5 shown.

[0030] figure 1 It is the first cross-sectional schematic diagram of the semi-closed underground brine mining system of the embodiment of the present application. refer to figure 1 , the semi-enclosed underground brine mining system of the present application, comprising an air compressor, a first water-resisting layer 1, a second water-resisting layer 3, located between the first water-resisting layer 1 and the second water-resisting layer 3 The brine storage layer 2, the partition wall 8 and the brine collecting channel 10. Firstly, a partition wall 8 is formed for the brine storage layer 2 located between two or more natural deposition water-resisting layers. The partition wall 8 is a continuous curtain wall formed by drilling and grouting, including a plurality of columns arranged side by side and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com