Patents

Literature

34results about How to "Reduce mining difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

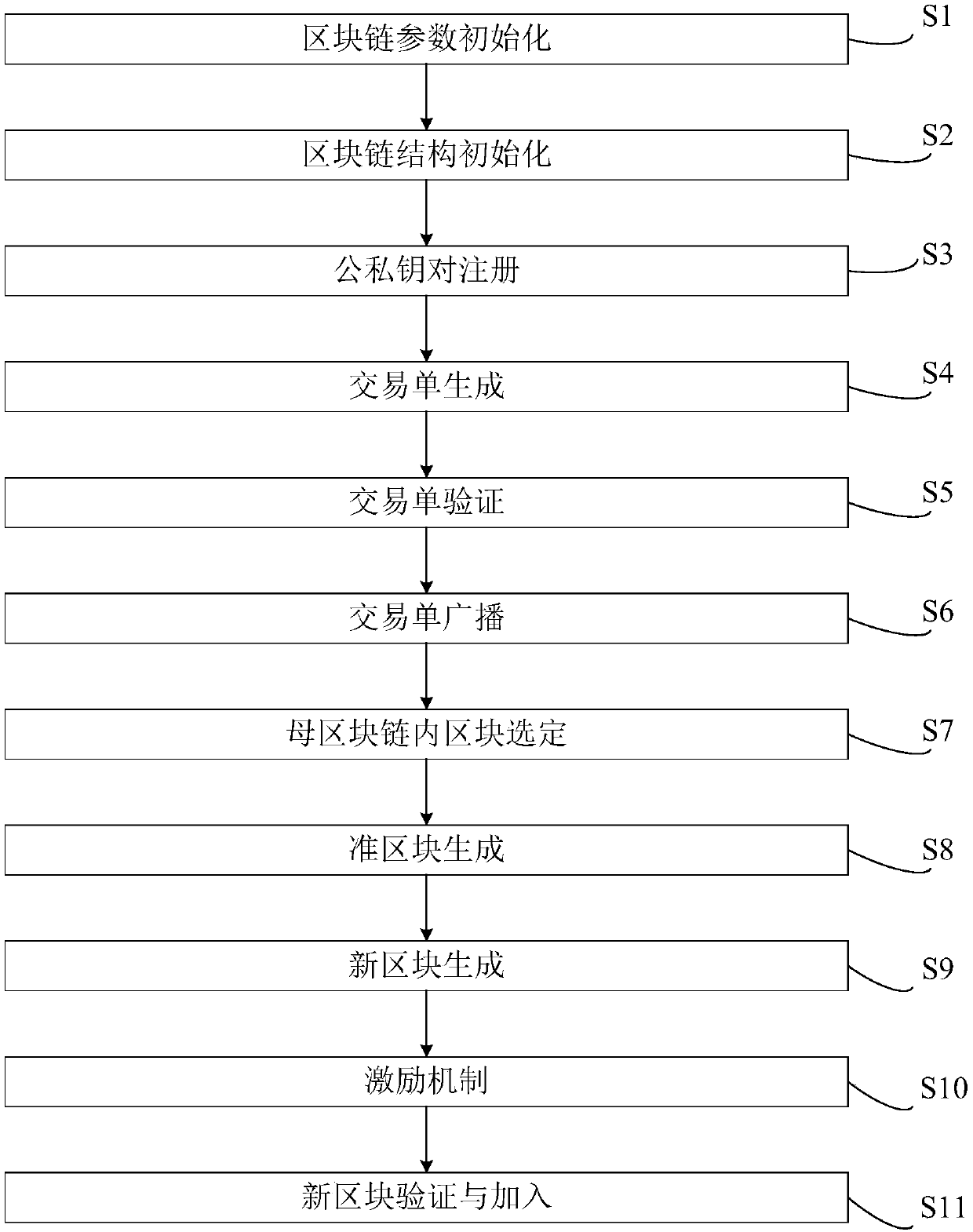

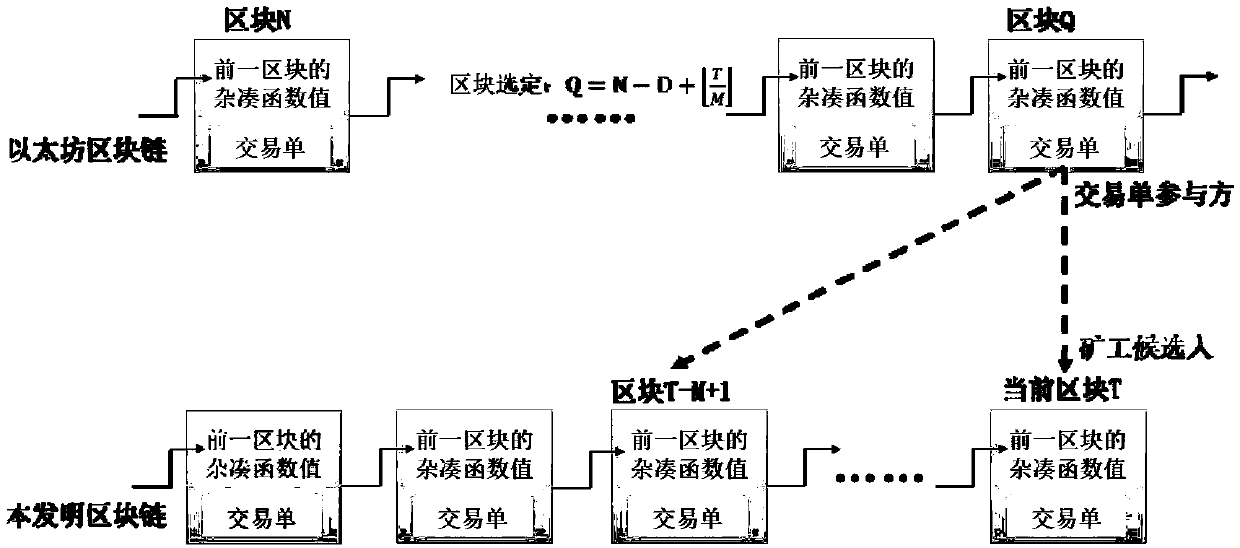

Safe, high-speed and lightweight blockchain system and method

ActiveCN109639430AIncrease spawn rateImprove verification efficiencyFinanceUser identity/authority verificationSteady statePoint to point network

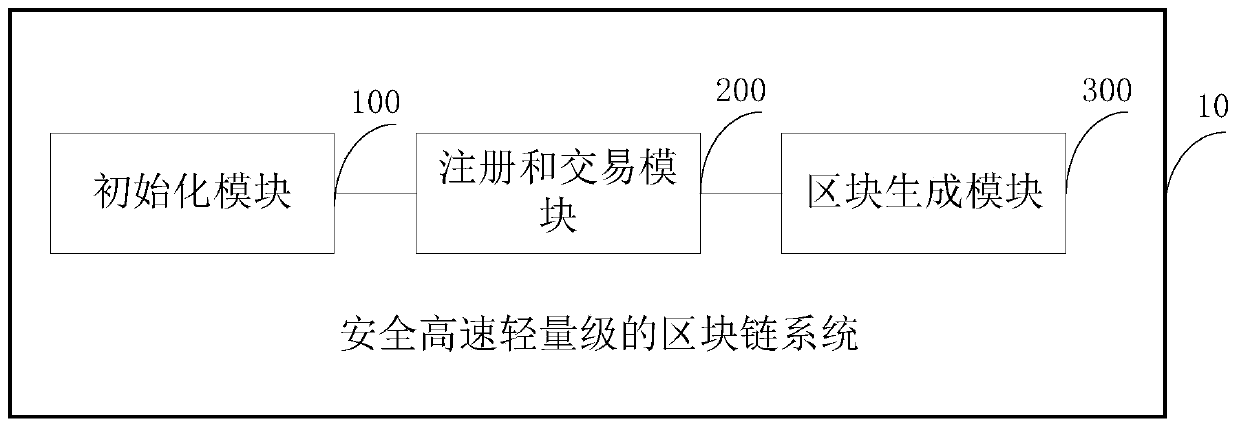

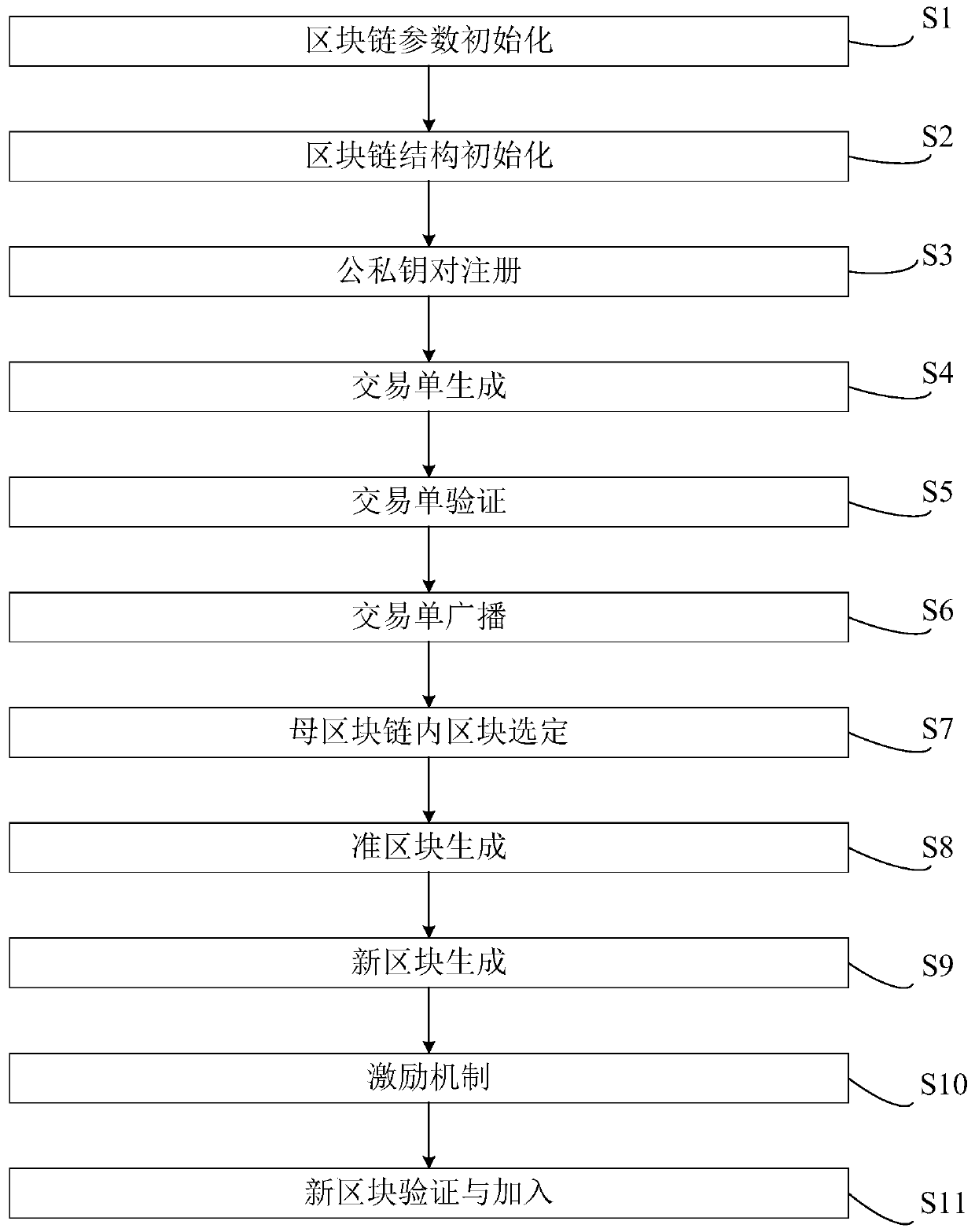

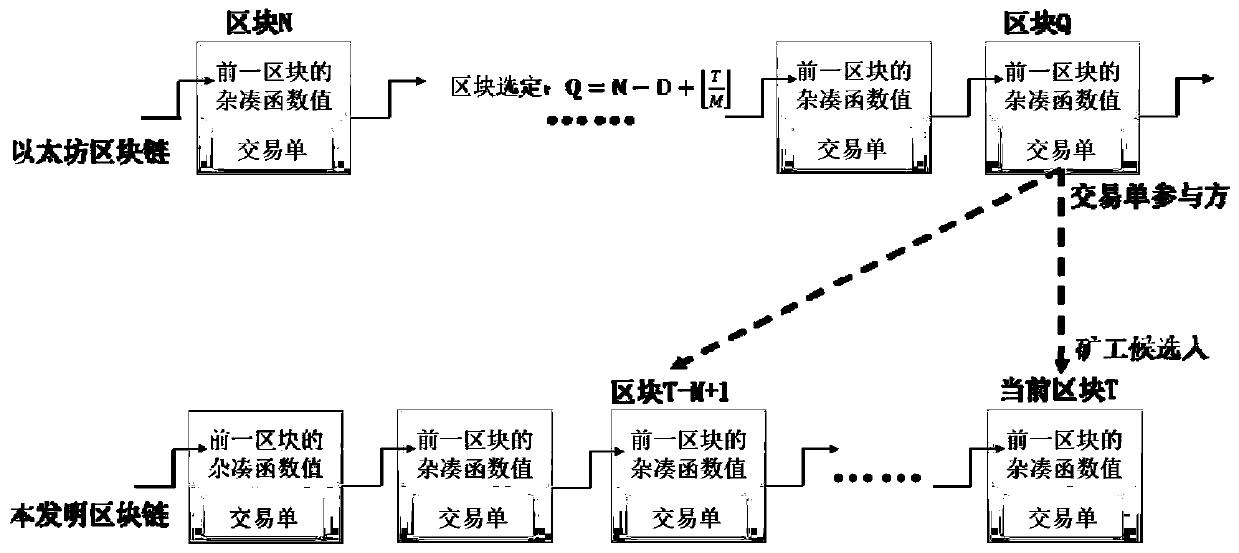

The invention discloses a safe, high-speed and lightweight blockchain system and method, wherein the system comprises an initialization module, a registration and transaction module and a block generation module; the initialization module runs when the system is initialized, and is used for setting relative parameters of the blockchain system and deploying a point-to-point network, so that the system function is initialized and reaches a steady state through block generation in an initial stage; the registration and transaction module is used for calling a user registration function when a user joins in the system, generating a public / private key pair of the user, sending a trading card into a blockchain network, verifying the validity of the trading card through a network node, and continuously broadcasting legal transaction to the whole network; the block generation module is used for determining a miner candidate set of a current block according to the trading participant address ina specific block in a target blockchain system appointed by the system; and a candidate in the miner candidate set generates a new block by competition by utilization of a consensus mechanism. By means of the system, the problem of low verification efficiency ubiquitous in the blockchain system can be effectively solved.

Owner:BEIHANG UNIV

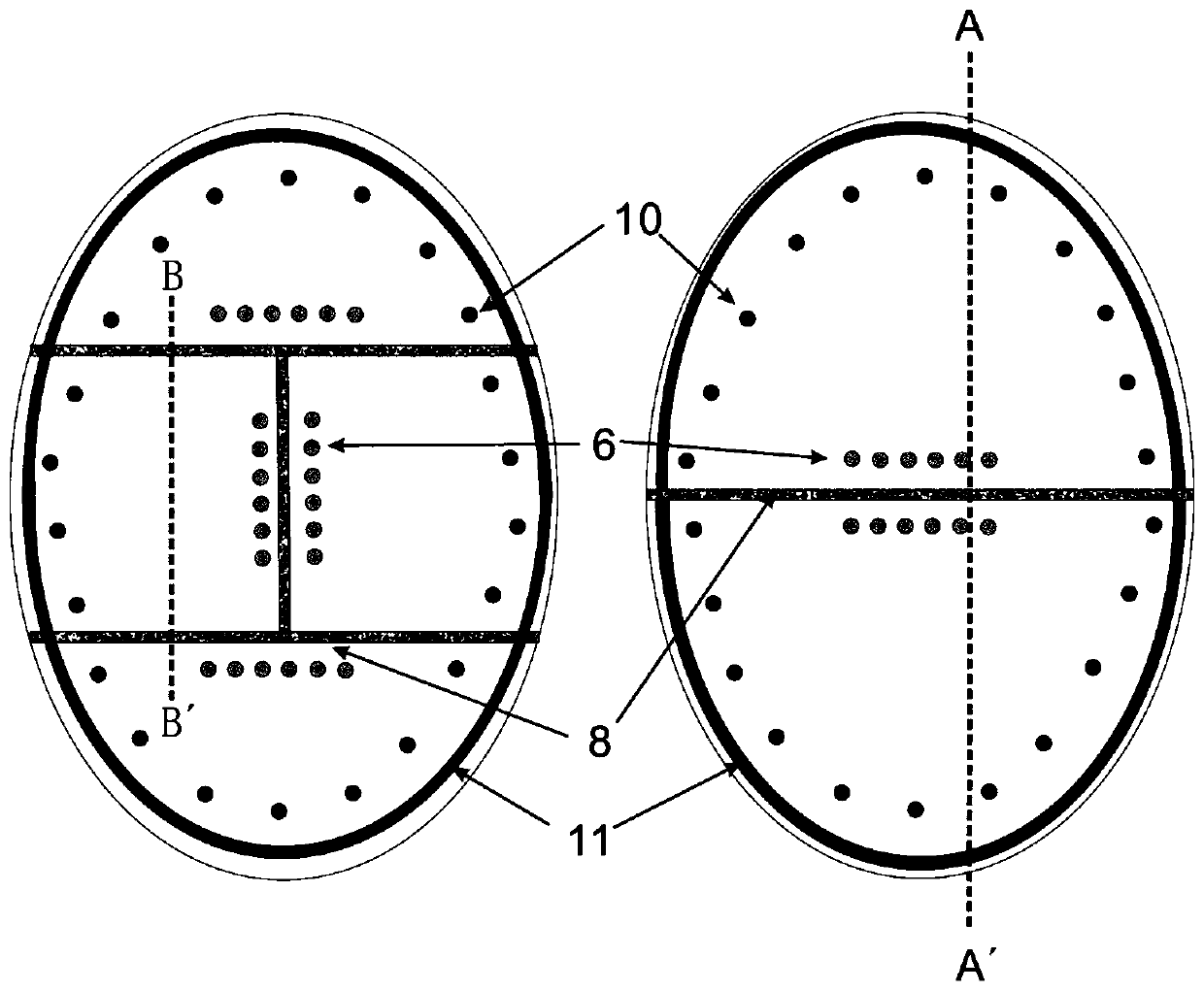

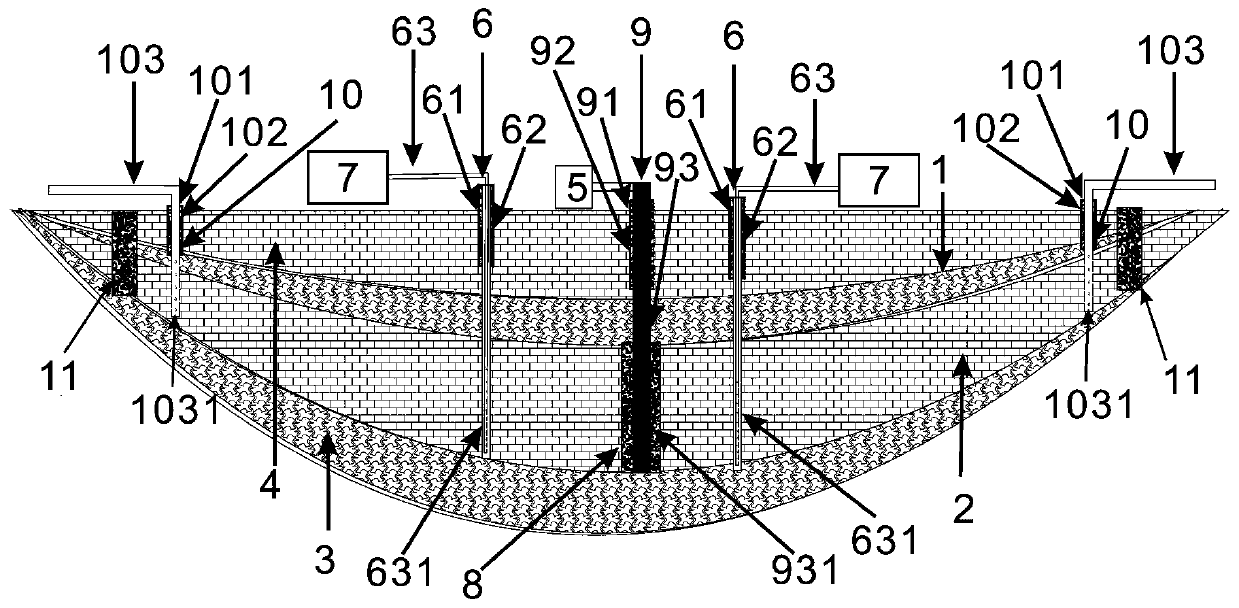

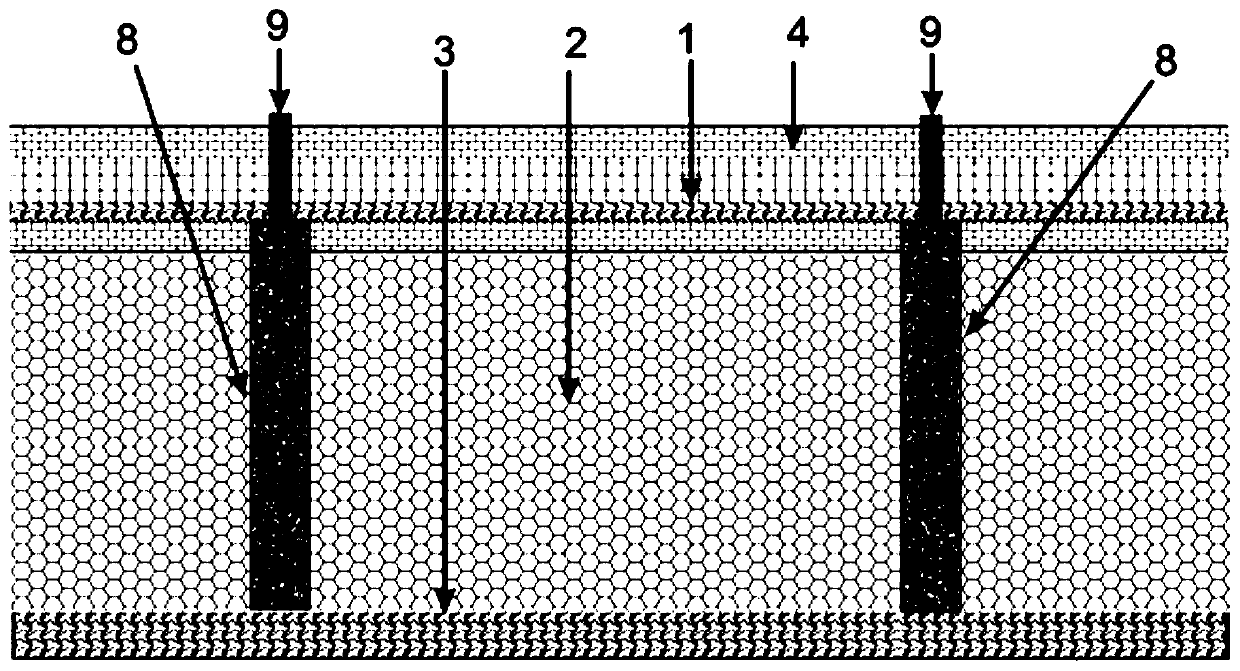

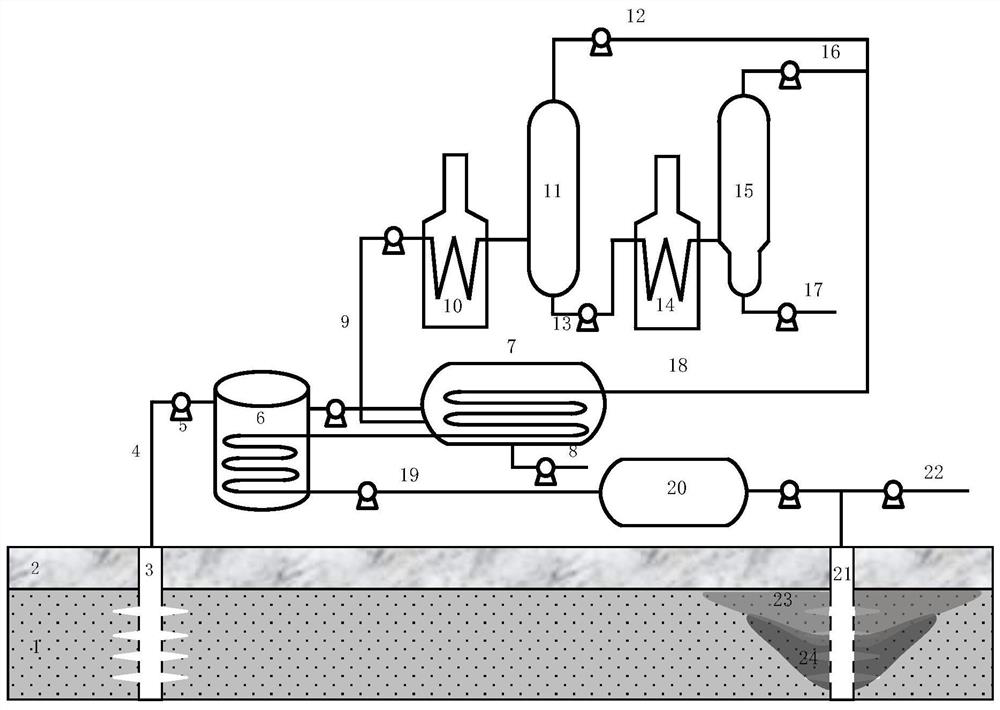

Closed underground brine mining system and construction method thereof

ActiveCN111287703AIncrease flow rateHigh trafficFluid removalSealing/packingBrine miningPetroleum engineering

The invention relates to the technical field of underground brine mining, and specifically provides a closed underground brine mining system and a construction method thereof. The closed underground brine mining system includes a gas compression device, a first water isolation layer, a second water isolation layer, a brine storage layer, partition walls, brine drainage wells and water isolation dams, wherein the brine storage layer, the partition walls, the brine drainage wells and the water isolation dams are located between the first water isolation layer and the second water isolation layer. The upper ends of the partition walls extend to the first water isolation layer, the lower ends of the partition walls extend to the second water isolation layer, and the partition walls, the firstwater isolation layer, the second water isolation layer and the water isolation dams divide the brine storage layer into a plurality of enclosed spaces. Each enclosed space is a brine mining block. Agas compression well is arranged at the position, near the center of a lake, in each brine mining block, the brine drainage wells are arranged at the positions, near the edge of the lake, in the brinemining blocks, the brine drainage wells are provided with brine drainage pipes, and brine can be drained through the brine drainage pipes and then directly transported to salt pans or grit chambers.The closed underground brine mining system can reduce the cost of brine mining, greatly increases the mining amount of the brine, and improves the mining efficiency and increases the recovery rate.

Owner:青海凹口凸钾镁盐技术有限公司

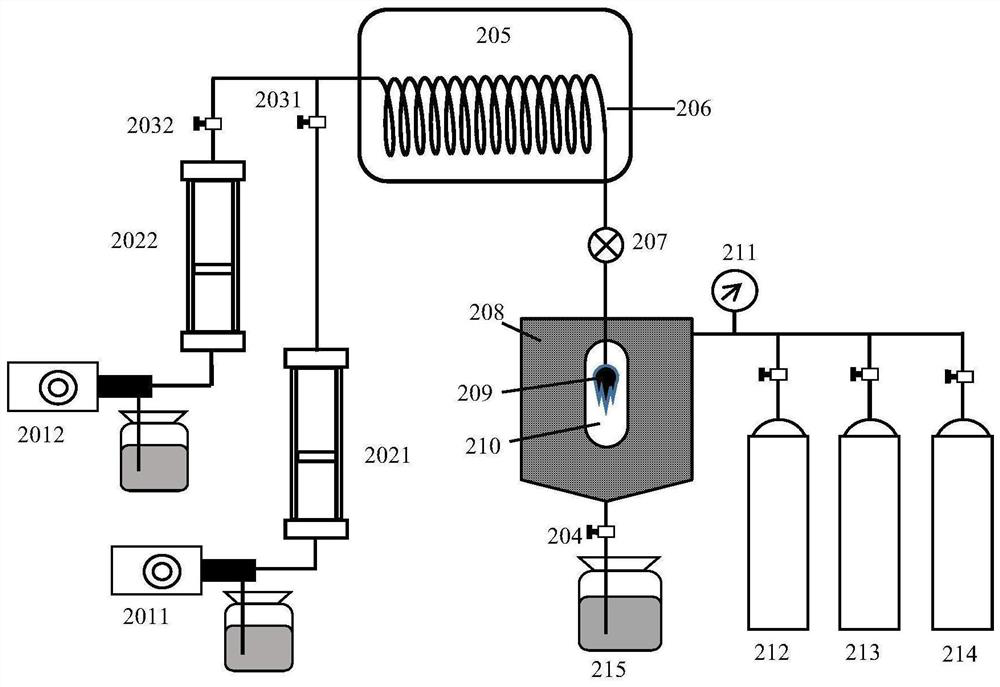

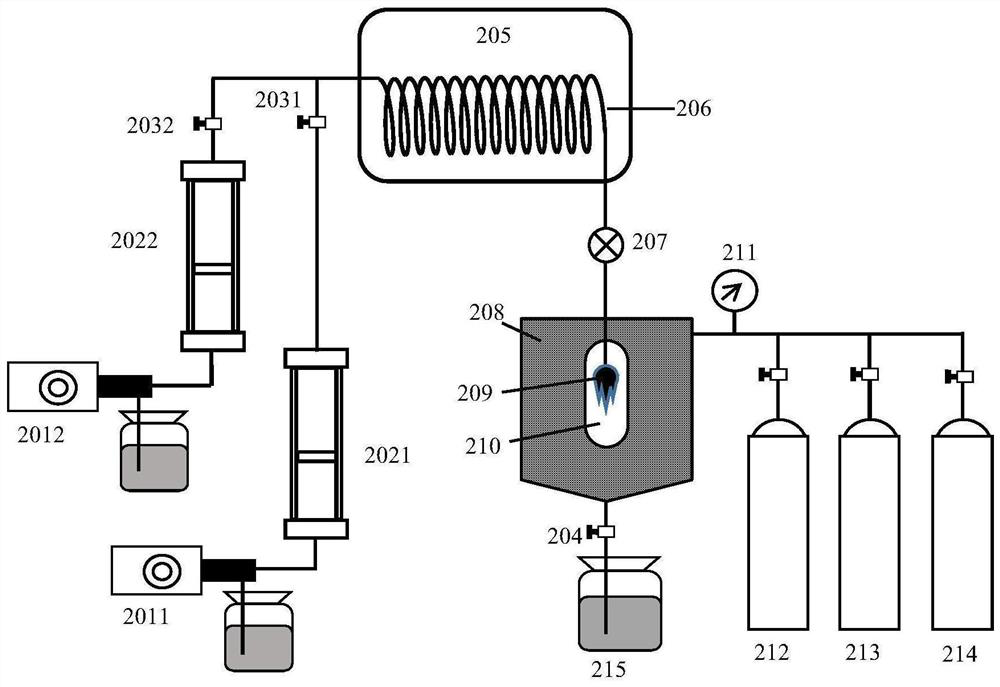

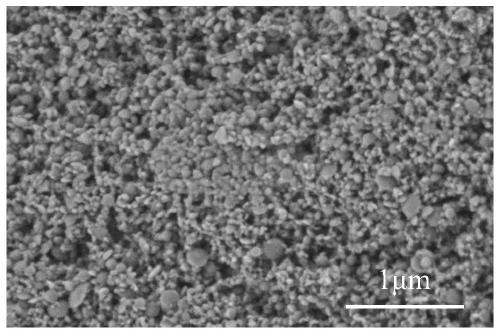

Preparation method and application of catalyst for visbreaking behavior of heavy oil by aquathermolysis

InactiveCN109675561AReduce gelatinLow asphaltene contentCatalytic crackingDrilling compositionReaction temperatureSolvent

The invention belongs to the field of catalyst synthesis, and particularly relates to a preparation method and an application of a catalyst for visbreaking behavior of heavy oil by aquathermolysis. The method comprises specific steps as follows: ferric chloride is weighed and added to a three-neck beaker, ethanol, water, n-hexane and oleic acid are added to the three-neck beaker in sequence, magnetic stirring is performed, NaOH is added, heating and reflux condensation are performed, after a ferric oleate compound and an oleic acid mixture are synthesized and added to sodium alkylbenzene sulfonate, a mixture is dissolved in octyl ether, 1-octadecene or 1-eicosylene, a mixed solution is subjected to temperature programming and then cooled to the room temperature, ethanol is added to the solution, centrifugal separation is performed, and the target product, namely, the catalyst for visbreaking behavior of the heavy oil by aquathermolysis is obtained. The target product is cheap and easily available and has low energy consumption and excellent visbreaking effect, and physical properties and nanoscale can be set by selecting correct reaction temperature, reaction solvent or reaction time.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

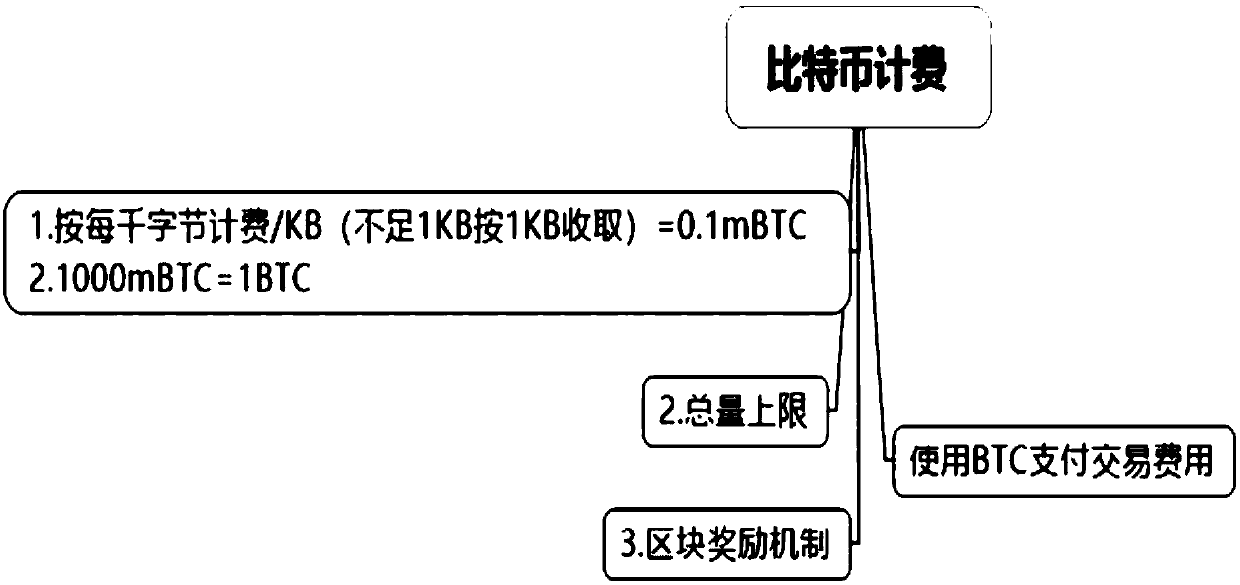

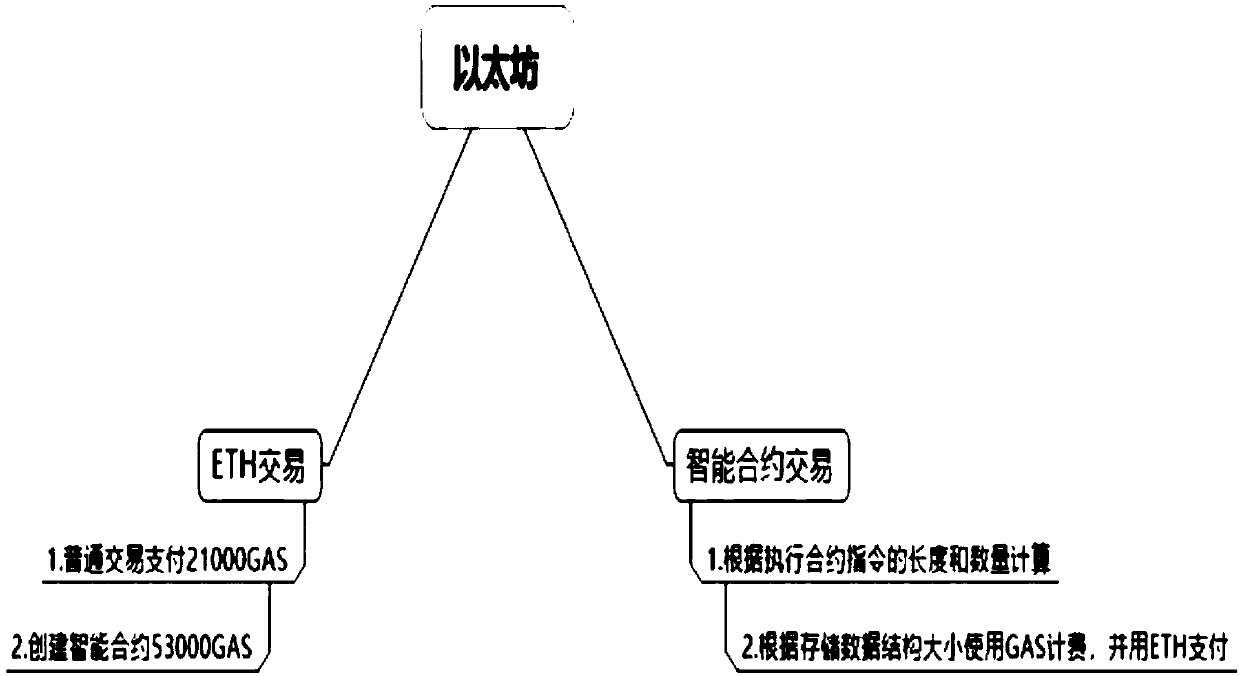

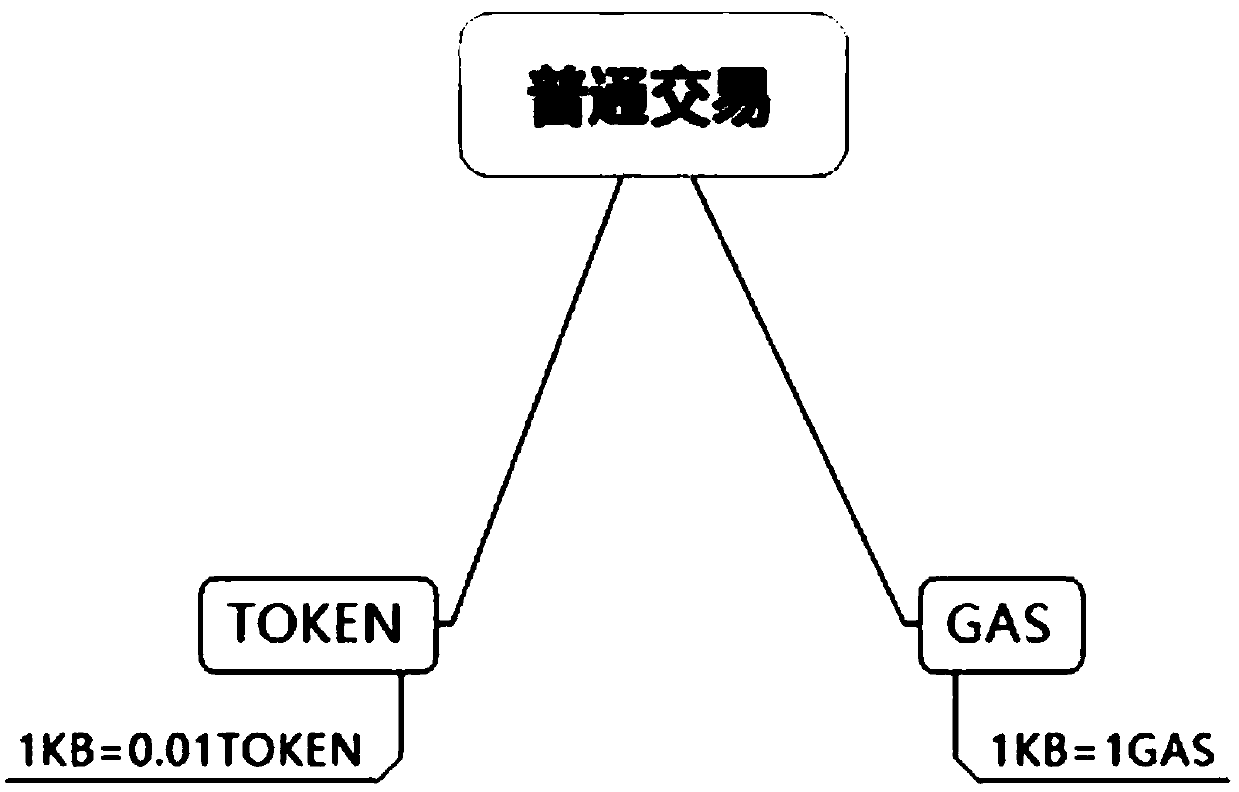

Blockchain-based multi-currency transaction fee collection method

InactiveCN108681891AFlexible configurationReduce participationFinancePayment circuitsPaymentCollection methods

The invention discloses a blockchain-based multi-currency transaction fee collection method. The method comprises the following steps of calculating a commission according to a transaction size, preferentially using gas billing and directly switching the token billing if a gas payment fee is insufficient, and completely transferring normal transaction gas and using token billing if a transaction currency is token. According to the method, the transaction cost is reduced by optimizing a transaction fee, the billing token is distinguished to be in a relatively stable range, and the price fluctuation is small. The participation of the mining machine is reduced, resources are saved, the difficulty of mining is reduced, a mining reward mechanism is canceled, the time of block out is improved, speculative behaviors are reduced, the transaction cost can be flexibly set, and the method is suitable for different business needs.

Owner:WEALEDGER NETWORK TECH CO LTD

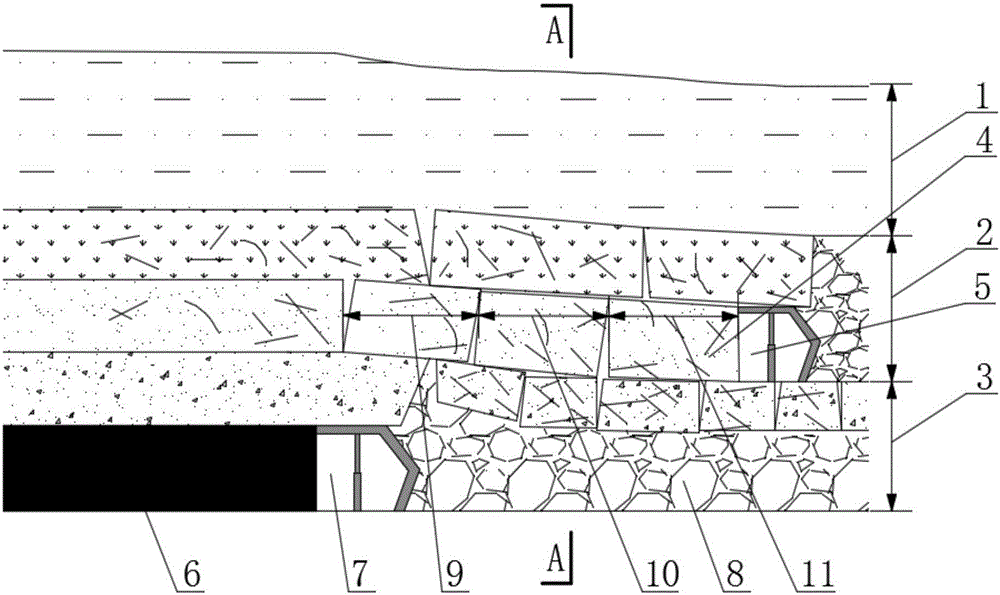

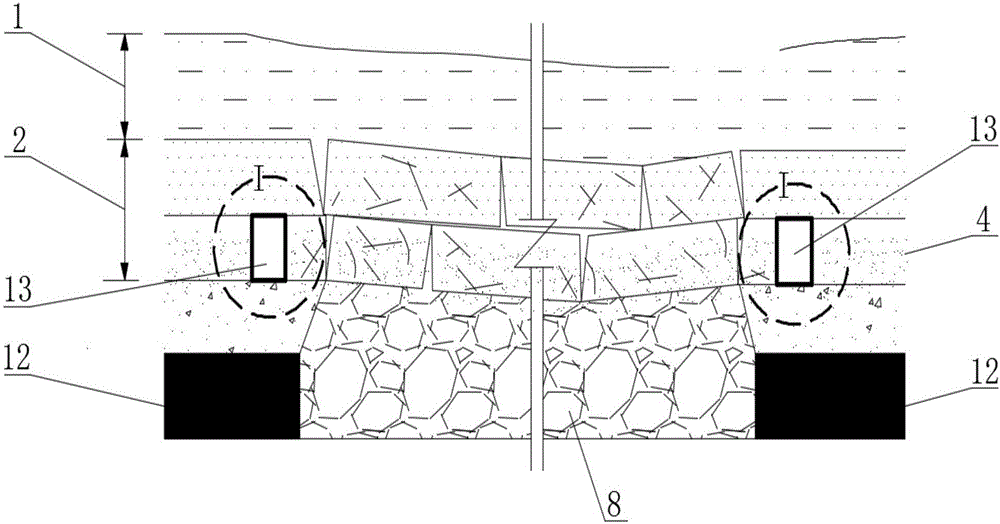

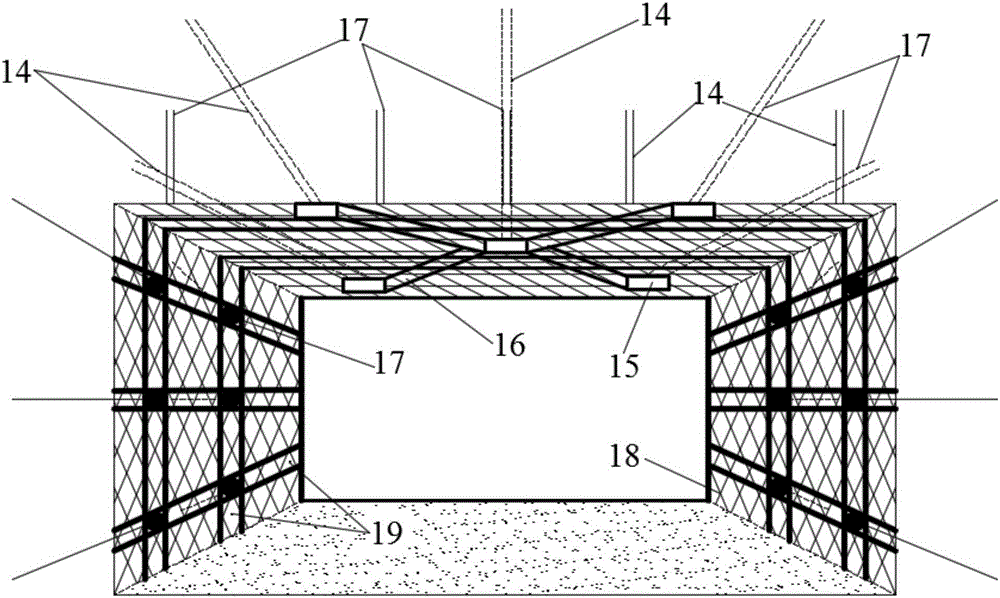

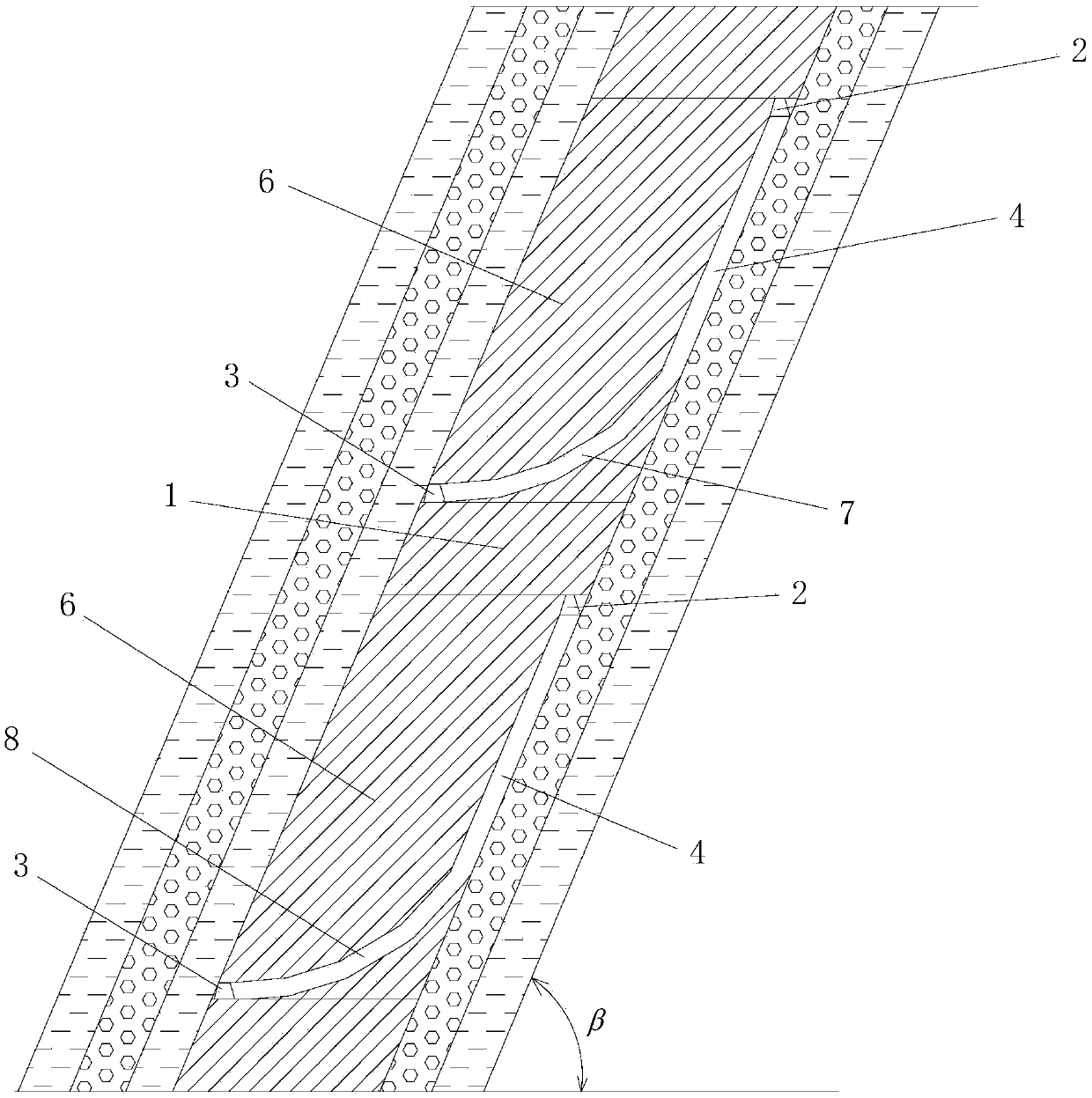

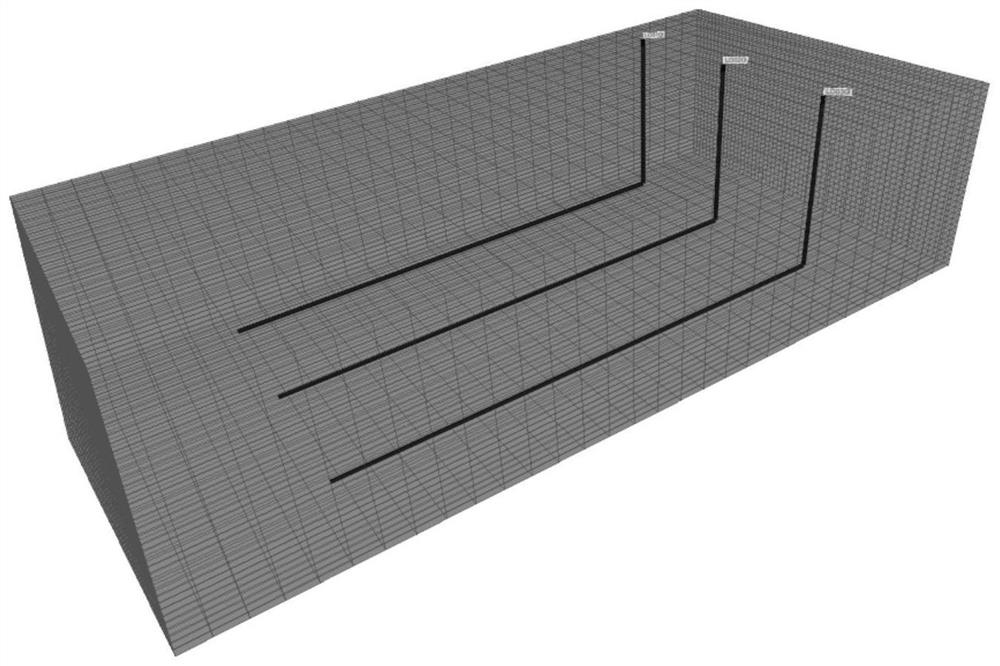

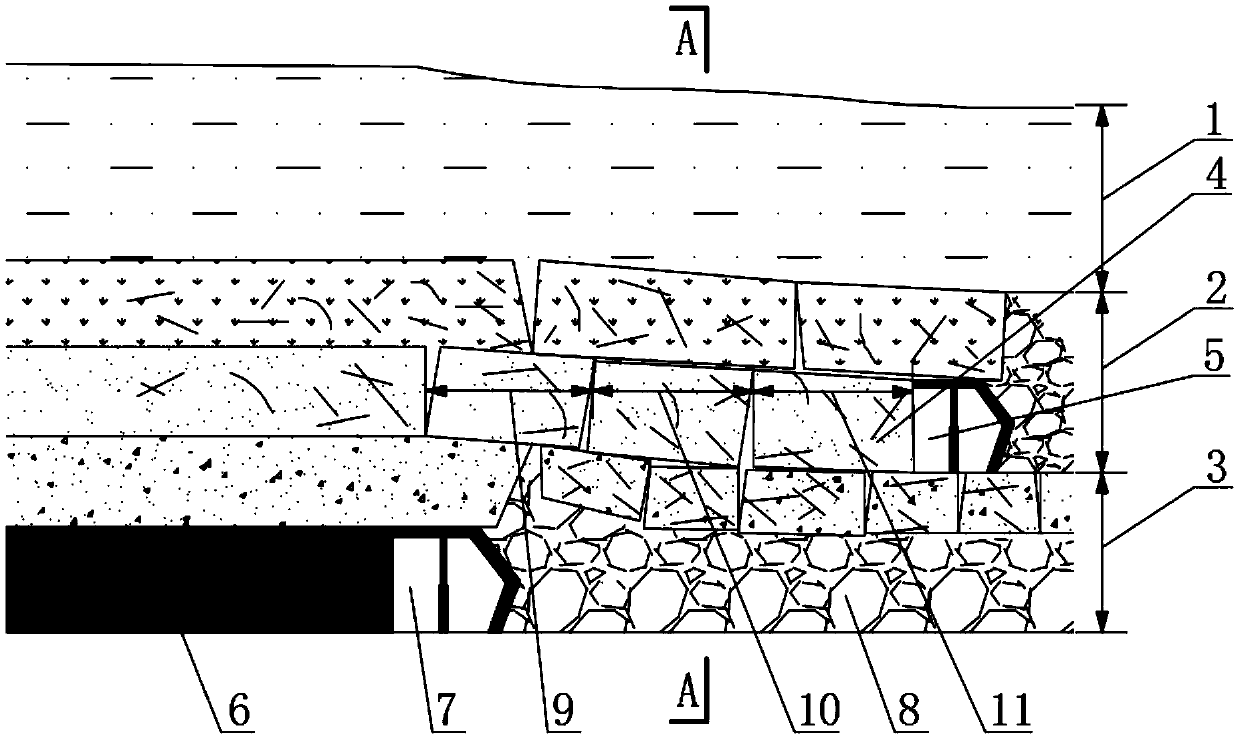

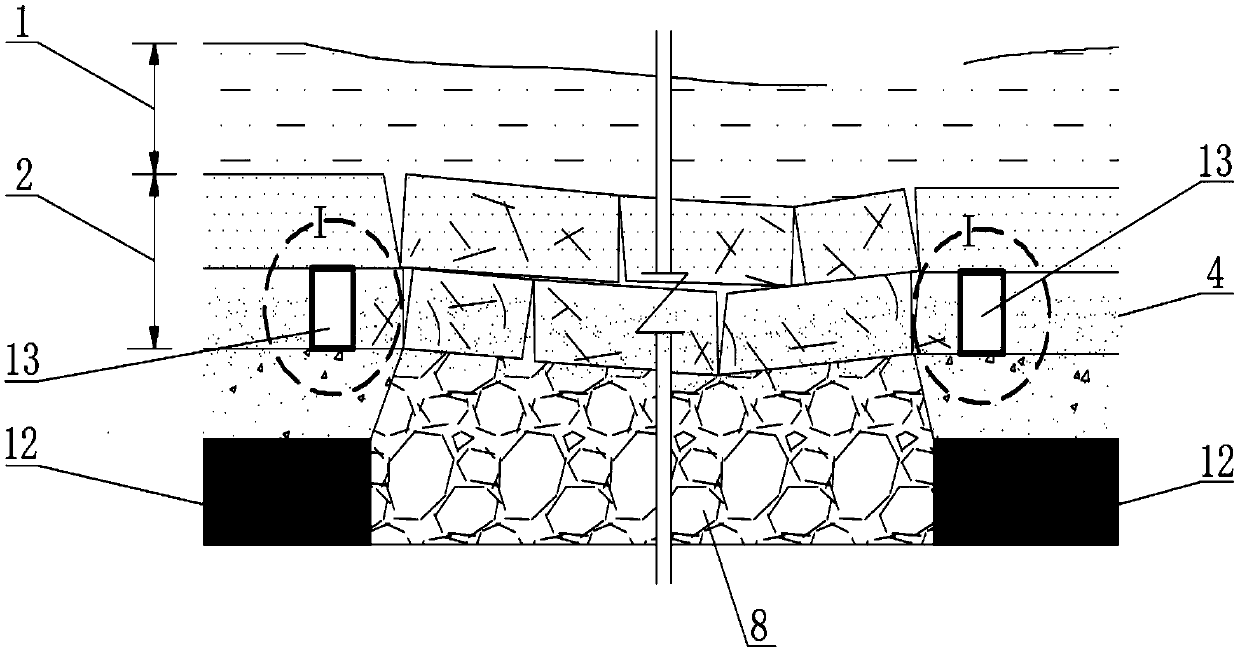

Method for combined exploitation of coal and its associated oil shales

ActiveCN106337685AReduce mining difficultyEnsure rock breaking efficiencyUnderground miningSurface miningResource utilizationOil shale gas

The invention provides a method for combined exploitation of coal and its associated oil shales. The method comprises the construction steps that when the coal and its associated oil shales are located in a reasonable exploitation bed separation distance range, coal resources located at the lower portion are firstly exploited, a mine bearing pressure is fully utilized to destroy associated oil shales located in an overlying rock layer and reduce the strength; then, the associated oil shales at the upper portion are exploited later to achieve combined exploitation of coal and its associated oil shales. Therefore, the shortcoming that when oil shales are independently exploited, the oil shale strength is higher and accordingly a coal cutter difficultly break rocks can be overcome. According to the exploitation method, existing infrastructures and sinking and driving engineering can be fully utilized, the roadway tunneling amount can be decreased, investment can be reduced, the costs are low, the phenomenon that the oil shales associated with coal are severely abandoned can be effectively completely eradicated or decreased, the resource utilization rate can be improved, an economic value is huge, and the method has the important practical significance on relieving of conventional energy source supply and demand pressure, energy structure adjustment and energy guaranteeing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

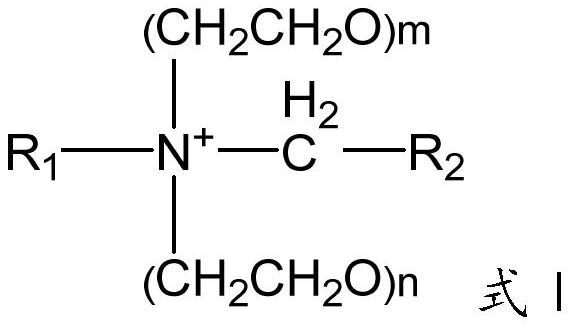

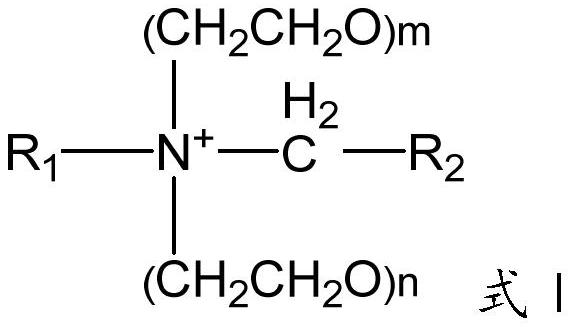

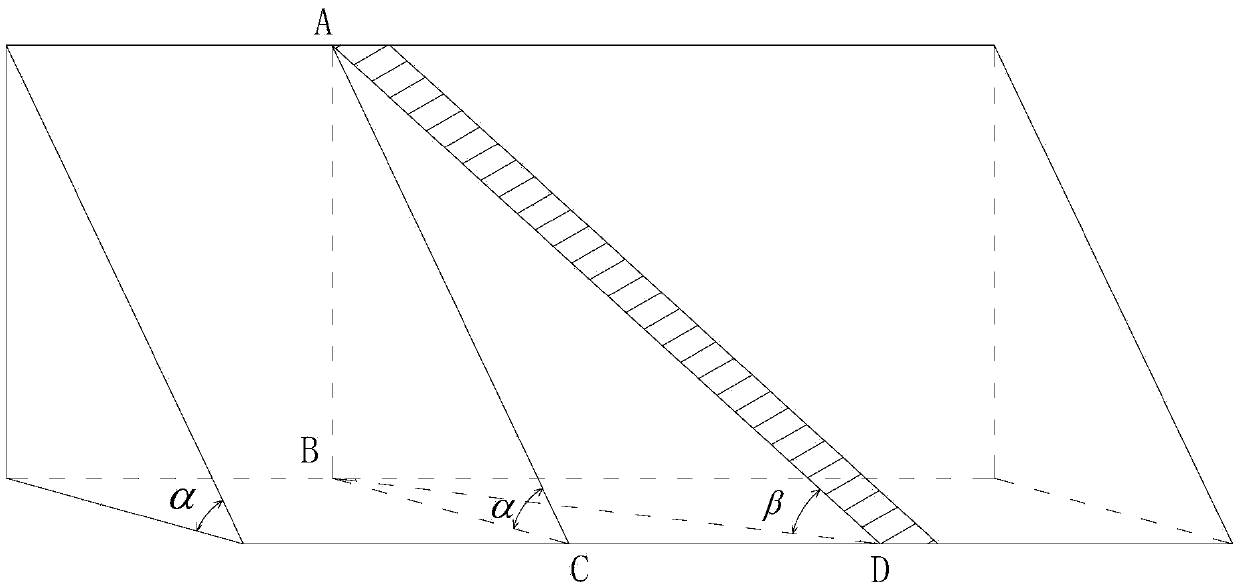

Oil displacement surfactant for high-temperature and high-salt oil reservoir as well as preparation method and application of oil displacement surfactant

ActiveCN112251208AImprove salt toleranceIncrease lossDrilling compositionBetaine compoundActive agent

The invention discloses an oil displacement surfactant for a high-temperature and high-salt oil reservoir as well as a preparation method and application of the oil displacement surfactant. The oil displacement surfactant comprises the following components in parts by weight: 1-35 parts of fatty acid alkanolamide or esterification derivatives thereof, 1-35 parts of betaine compounds, 1-30 parts ofalkylbenzene sulfonate and 1-30 parts of low-molecular alcohol. Through compounding of the anionic surfactant alkylbenzene sulfonate, the nonionic surfactant fatty acid alkanolamide and the zwitterionic surfactant betaine, the salt resistance and the divalent cation resistance of the surfactant are greatly improved through the synergistic effect of multiple groups, and the surfactant can be usedfor oil displacement of an oil layer with high mineralization degree; and the oil displacement surfactant can remarkably reduce oil-water interfacial tension, is high in stability, small in dosage andhigh in efficiency, can be used as an oil displacement surfactant of a high-temperature and high-salt oil reservoir, can also be suitable for a low-temperature and low-salt oil reservoir, and is widein application range.

Owner:DESHI ENERGY TECH GRP CO LTD +1

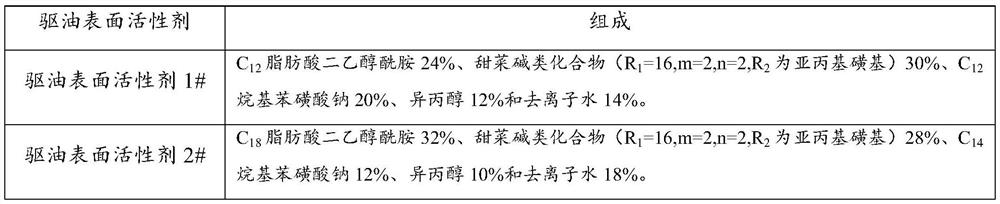

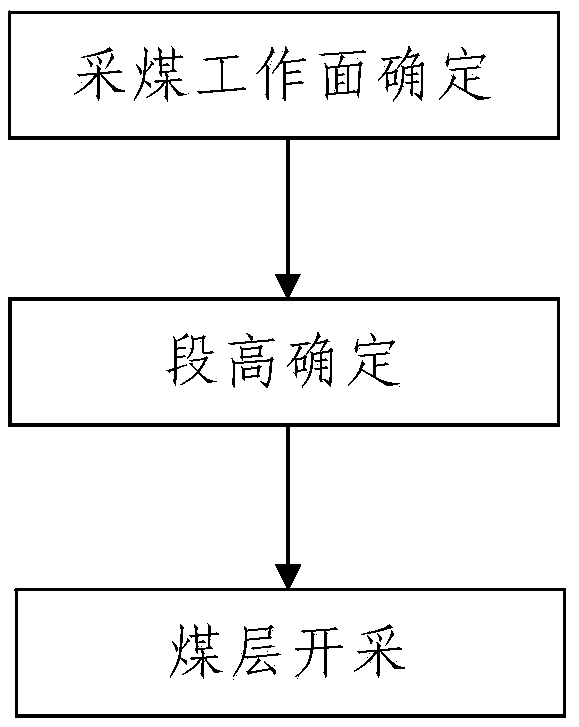

High section trend wall-type fully mechanized caving mining method for large inclined super high seam

ActiveCN105370282AThe method steps are simpleReasonable designUnderground miningSurface miningCoalMineralogy

The invention discloses a high section trend wall-type fully mechanized caving mining method for a large inclined super high seam. The method conducts respective mining on a plurality of mining sections in the same section from top to bottom, and the mining process is as follows: first, determination of a coal face: the coal face of a mining section in the current mining section is determined; the coal face is a high section trend wall-type inclined coal face and is the actual mining face; the coal face is divided into a lower section coal face and an upper section coal face above the lower section coal face; and the lower section coal face is a polyline section coal face, and the upper section coal face is a linear section coal face; 2, determination of the height of the section; and 3, coal seam mining: a plurality of coal seam sections are mined respectively. The method of the invention has the advantages of simpleness, reasonable design, simple construction and high-efficiency safe and reliable mining process, and can effectively solve the problems of severe mining difficulty, low safety factor and incapability of efficient mining in the mining process of large inclined super high seam.

Owner:XIAN UNIV OF SCI & TECH

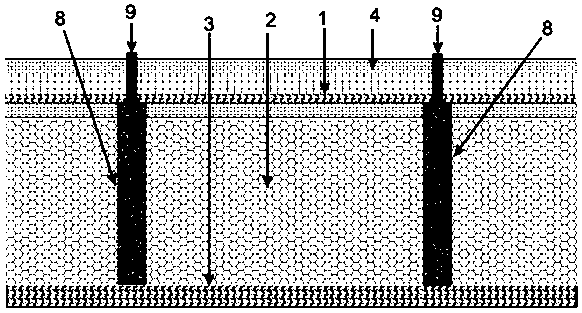

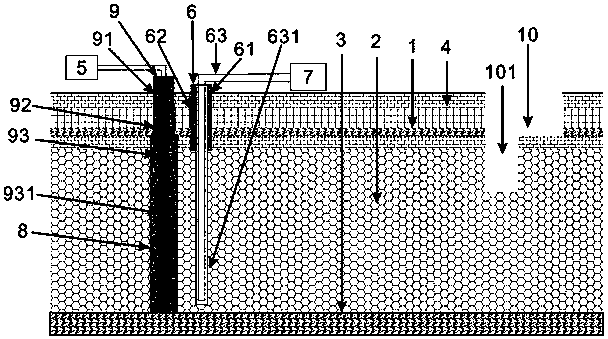

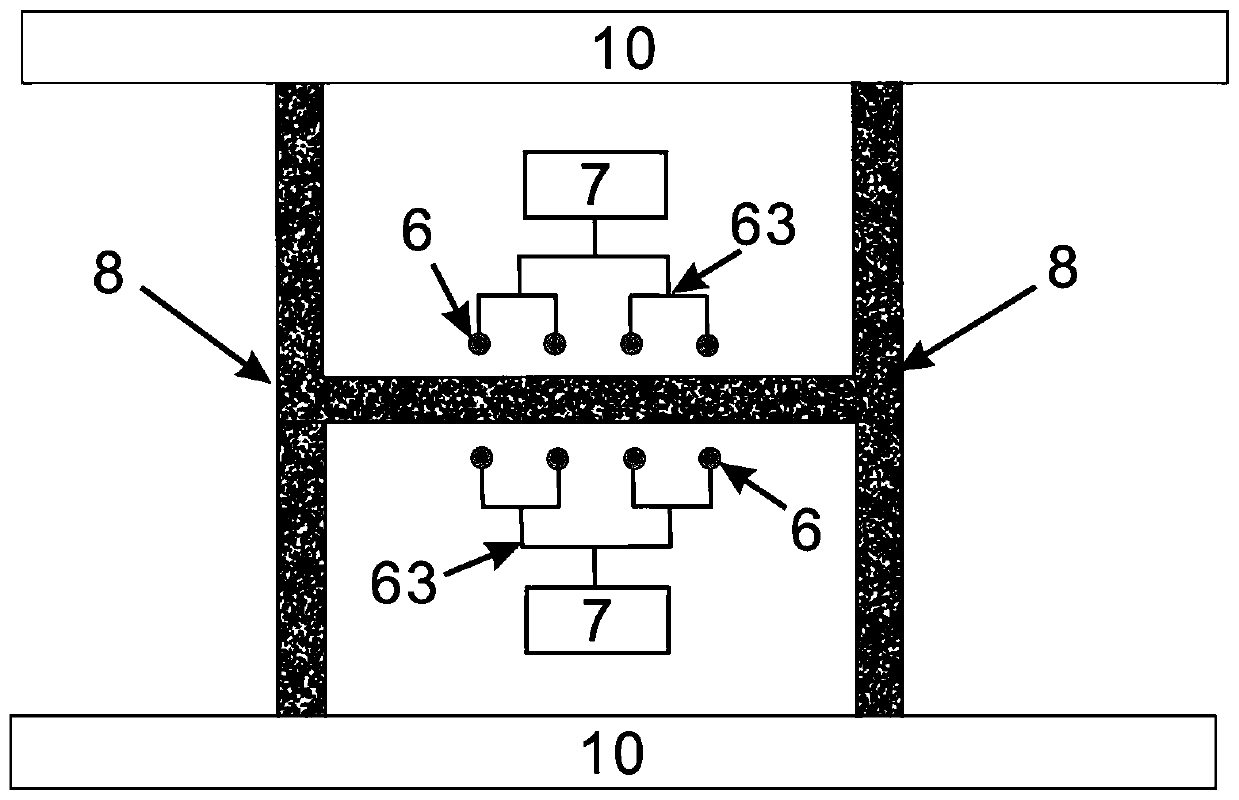

Semi-closed underground brine mining system and construction method thereof

ActiveCN111287704AIncrease flow rateHigh trafficFluid removalSealing/packingMining engineeringBrine mining

The invention relates to a semi-closed underground brine mining system and a construction method thereof. The semi-closed underground brine mining system comprises a gas pressing device, a first waterresisting layer, a second water resisting layer, a brine storage layer positioned between the first water resisting layer and the second water resisting layer, a partition wall and brine collecting channels. The upper end of the partition wall extends to the first water resisting layer, and the lower end extends to the second water resisting layer; and the brine storage layer is divided into multiple closed spaces by the partition wall, the first water resisting layer and the second water resisting layer. The brine collecting channels and brine outlets are excavated in a top salt rock layersof the closed spaces; the closed spaces are horizontally penetrated by the brine collecting channels to form semi-closed spaces; and the semi-closed spaces are brine collecting blocks. A gas pressingwell is arranged in each brine collecting block; brine outlets are excavated in the opening sides of the brine collecting blocks; and the brine outlets penetrate to the brine storage layer, and communicate the brine storage layer with the brine collecting channels. The semi-closed underground brine mining system can reduce the brine collecting cost, greatly improves the brine collecting amount, improves the mining efficiency, and improves the recovery rate.

Owner:青海凹口凸钾镁盐技术有限公司

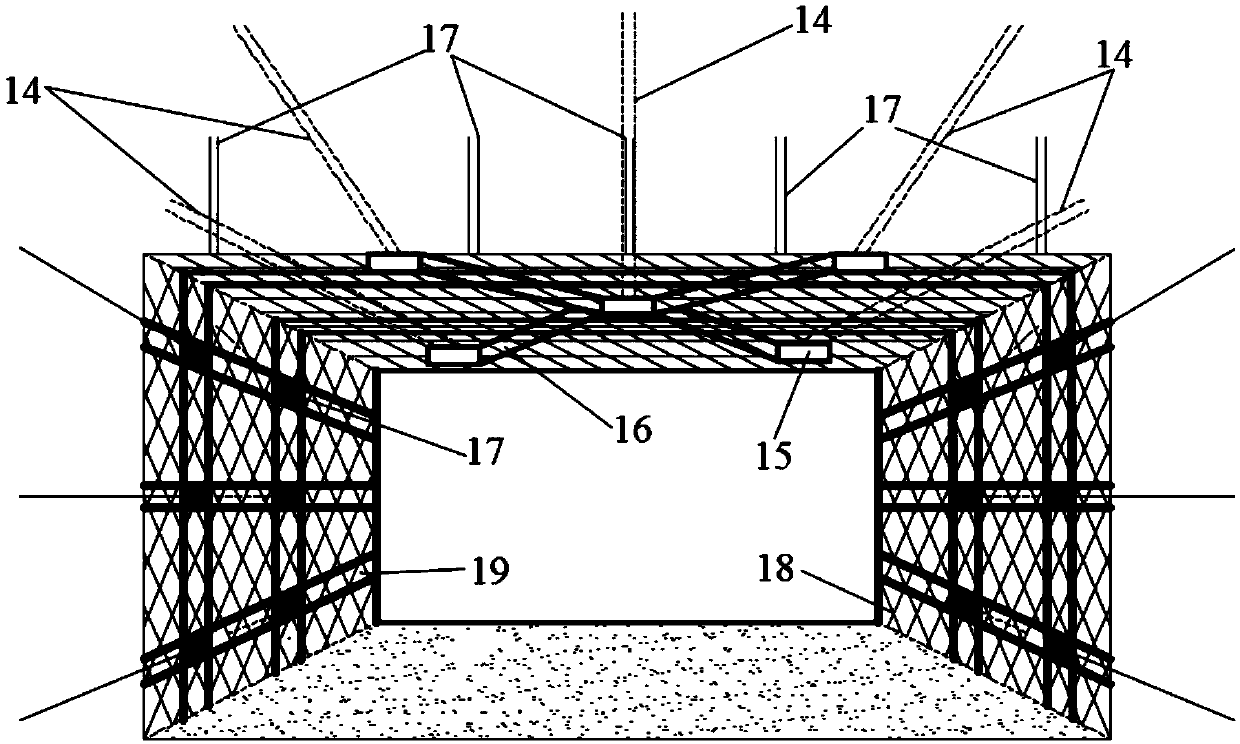

FRP pipe composite bar sea sand concrete column and preparation method thereof

PendingCN109098354AImprove bearing capacityLose weightArched girdersPortal framesAxial pressureRebar

The invention provides an FRP pipe composite bar sea sand concrete column and a preparation method thereof. The concrete column includes an FRP-steel composite bar cage, an FRP pipe and concrete. TheFRP steel-composite bar cage is formed by an FRP-steel composite bar and a spiral stirrup wound around the outside of the FRP-steel composite bar. The FRP steel-composite bar includes a steel bar andan FRP fiber layer coated on the outer surface of the steel bar. When the concrete column is subjected to axial pressure, the steel bar in the FRP-steel composite bar exerts the compression resistance. When the column is biased, the FRP-steel composite bar placed on the tension side can not only exert high tensile strength of an FRP material but also take advantages of the high tensile strength and good ductility of the steel. Correspondingly, the steel bar in the FRP-steel composite bar on the pressure side exerts the compression resistance, high modulus of elasticity, good ductility and outstanding anti-corrosion performance can be achieved, and seawater and sea sand not desalinated can be used directly.

Owner:GUANGDONG UNIV OF TECH

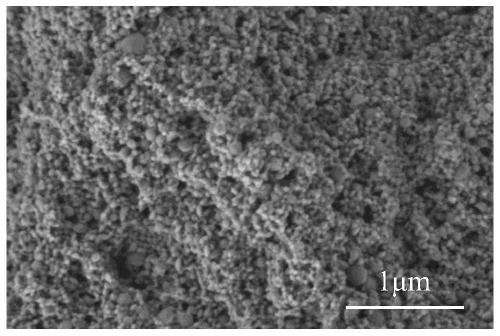

Preparation method of low-temperature thickened oil hydrothermal cracking viscosity-reduction catalyst

InactiveCN108212213AReduce mining difficultyImprove catalytic performanceCatalytic crackingOrganic-compounds/hydrides/coordination-complexes catalystsSaline waterHydroxamic acid

The invention relates to a preparation method of a low-temperature thickened oil hydrothermal cracking viscosity-reduction catalyst. At normal temperature, transition metal salt is dissolved in waterin a reaction container, while stirring, a hydroxamic acid compound is added in the reaction container, and then uniformly stirred, the solution in the reaction container is heat to the temperature of30-100 DEG C, then is stirred for 1-4 hours and cooled to room temperature, and water is steamed; a cocatalyst is added in residue in the reaction container, and the thickened oil hydrothermal cracking catalyst is obtained, the prepared catalyst has good catalysis effect under low temperature, the catalytic reaction at the temperature being more than 180 DEG C can reduce viscosity of the thickened oil can reach more than 70%, the catalyst is not dissolved in crude oil, processing difficulty during a crude oil processing process cannot be increased due to increase of the metal ion content in the crude oil, the catalyst has obvious advantage of protecting quality of the crude oil, operation is simple, thickened oil recovery difficulty is obviously reduced, and the catalyst is benefit for on-site popularization.

Owner:XI'AN PETROLEUM UNIVERSITY

Preparation and application of thermal cracking catalytic system of thickened oil

ActiveCN103849368AReduce mining difficultyIncreased processing difficultyFluid removalDrilling compositionIon contentRoom temperature

The invention relates to preparation and application of a thermal cracking catalytic system of thickened oil. The preparation comprises the following steps: under stirring, adding a substituted phenolic compound, a formaldehyde containing compound or liquor, secondary amine and water into a reaction kettle; dropwise adding transitional metal salt aqueous liquor into the reaction kettle; tightening the reaction kettle and placing in a constant temperature oven; after reaction, cooling to room temperature; adding methanol and urea into the liquor to obtain the thermal cracking catalytic system of thickened oil. The application comprises the following steps: pre-diluting the catalytic system by reinjection water by adopting a high pressure pump; pre-injecting an oil reservoir; and then, injecting steam. The condensation point of the thickened oil can be reduced by over 10 DEG C, and the viscosity is reduced by over 70%. The application is simple in operational process, the exploring difficulty of the thickened oil is remarkably reduced, and thus site popularization is facilitated. The catalytic system is insoluble in crude oil and does not lead to increase of metal ion content in crude oil to aggravate the treatment difficulty in the crude oil processing process, so that the system has a remarkable effect of protecting the quality of crude oil.

Owner:XI'AN PETROLEUM UNIVERSITY

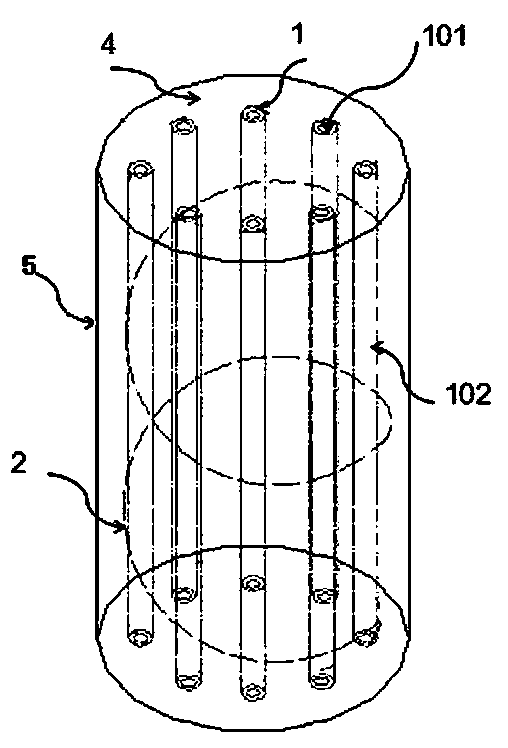

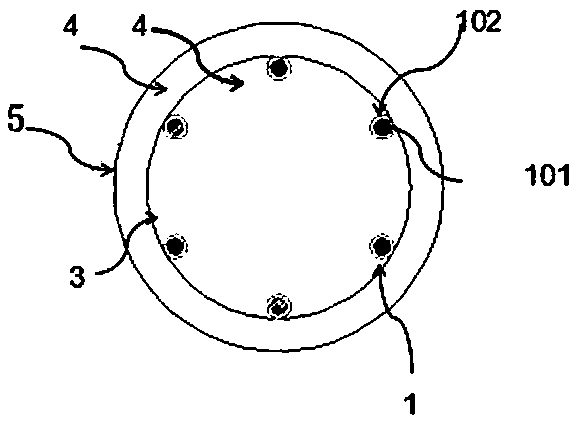

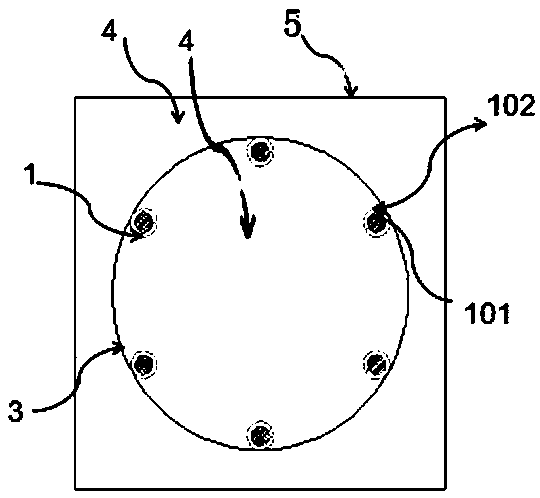

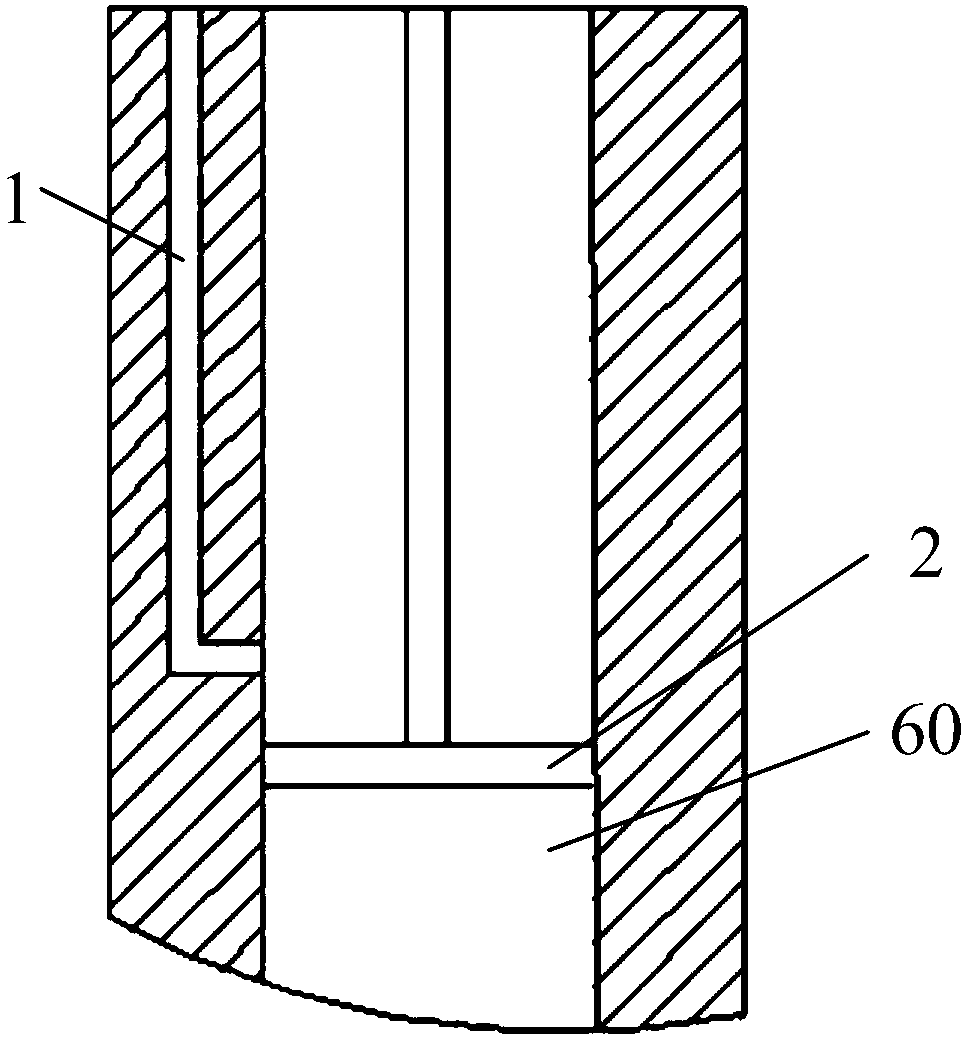

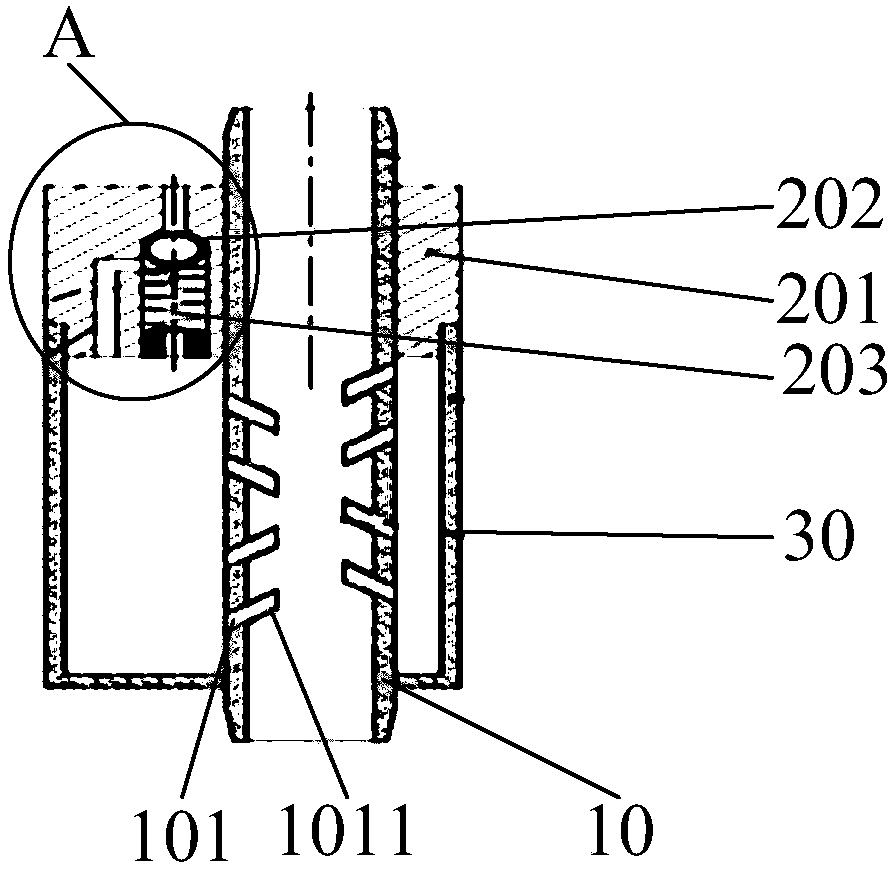

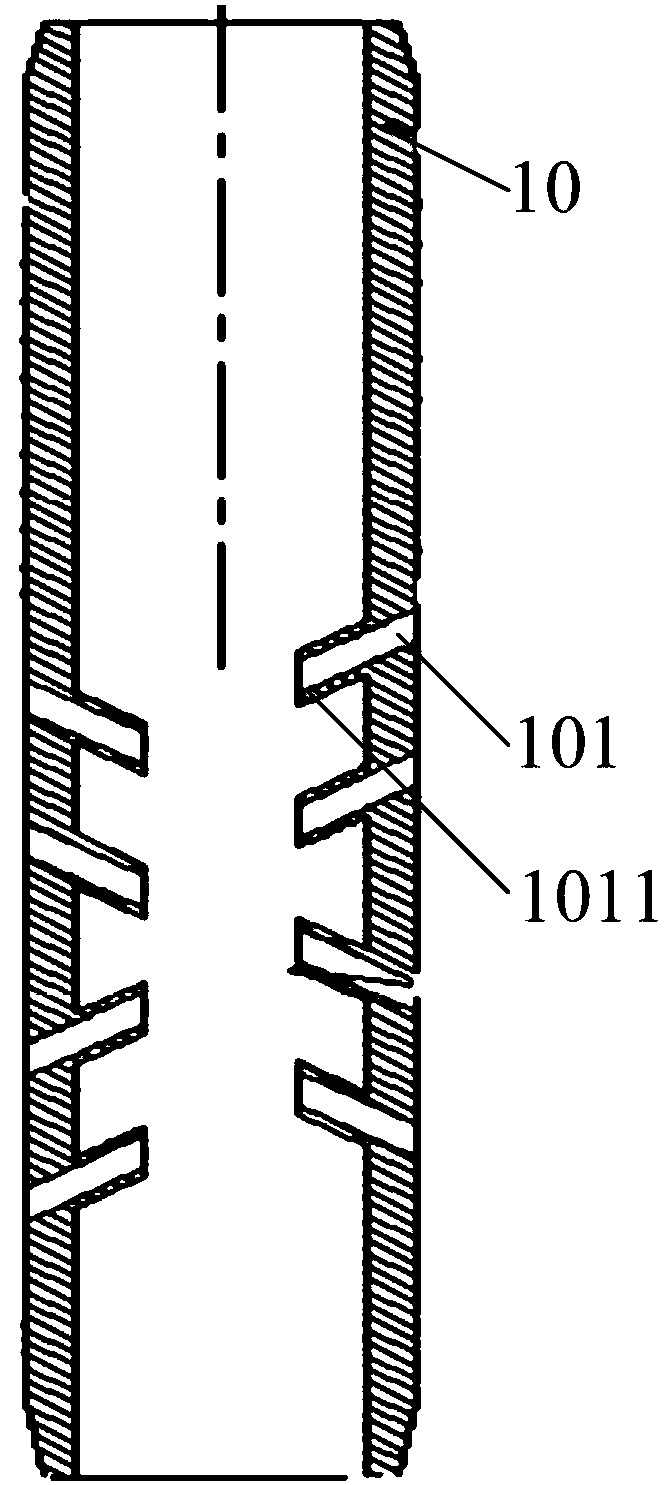

Thin oil mixing device and oil extraction pipe column

PendingCN110067538AGood dilution effectReduce mining difficultyDrilling rodsFluid removalCrude oilMixing effect

The invention provides a thin oil mixing device and an oil extraction pipe column. The thin oil mixing device comprises a mixing pipe and a uniflow device; the top end of the mixing pipe is used for communicating with an oil pipe, and a thin oil mixing hole is formed in the side wall of the mixing pipe; and the thin oil mixing hole is used for communicating with a thin oil mixing pipe through theuniflow device, and the uniflow device only allows thin oil to flow towards the thin oil mixing hole from the thin oil mixing pipe. The top end of the mixing pipe communicates with the oil pipe, the thin oil mixing hole is formed in the side wall of the mixing pipe and communicates with the thin oil mixing pipe through the uniflow device, the uniflow device only allows the thin oil to flow towardsthe thin oil mixing hole from the thin oil mixing pipe, thus when the pressure of crude oil in the oil pipe is increased, the uniflow device can prevent the crude oil from entering the thin oil mixing pipe, when the pressure of the oil pipe is decreased, the thin oil continues entering the oil pipe, the thin oil mixing effect is good, and the crude oil extraction difficulty is lowered.

Owner:PETROCHINA CO LTD

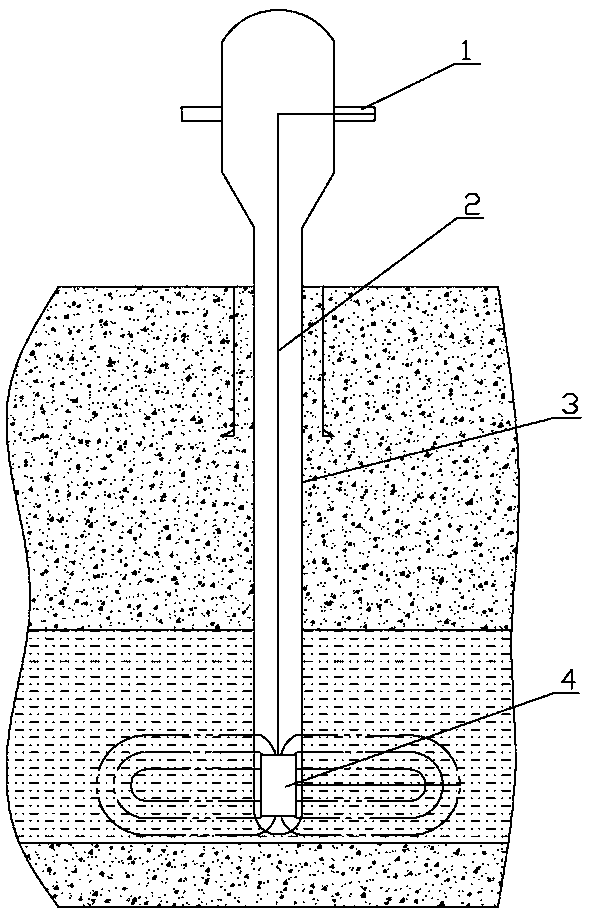

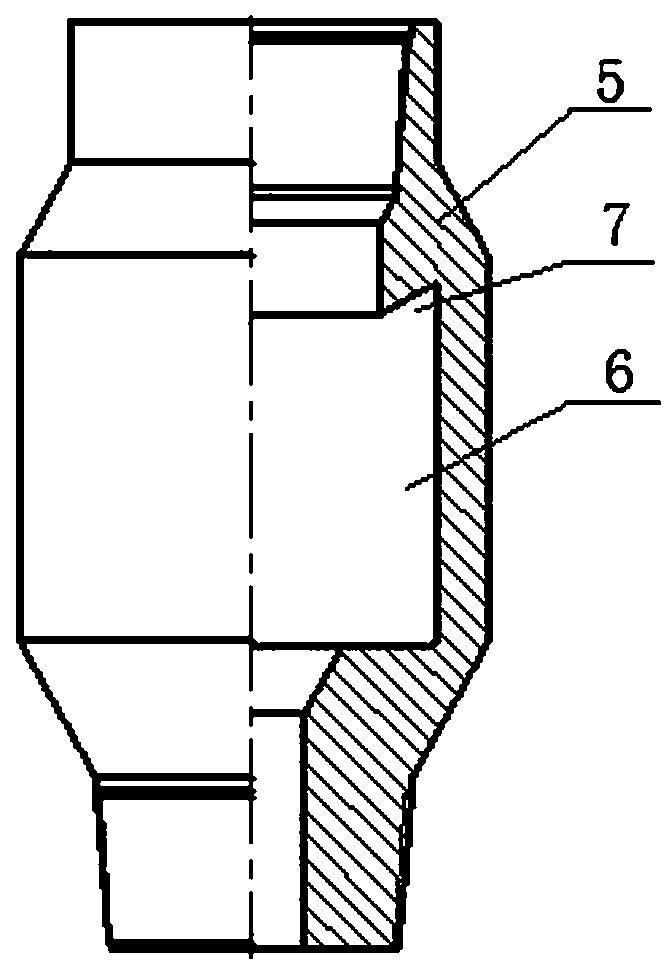

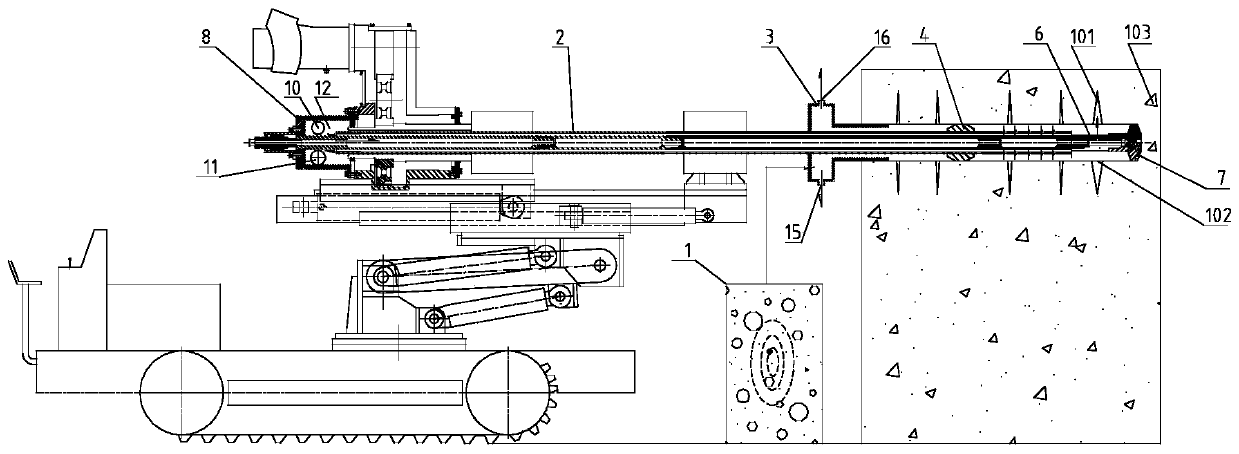

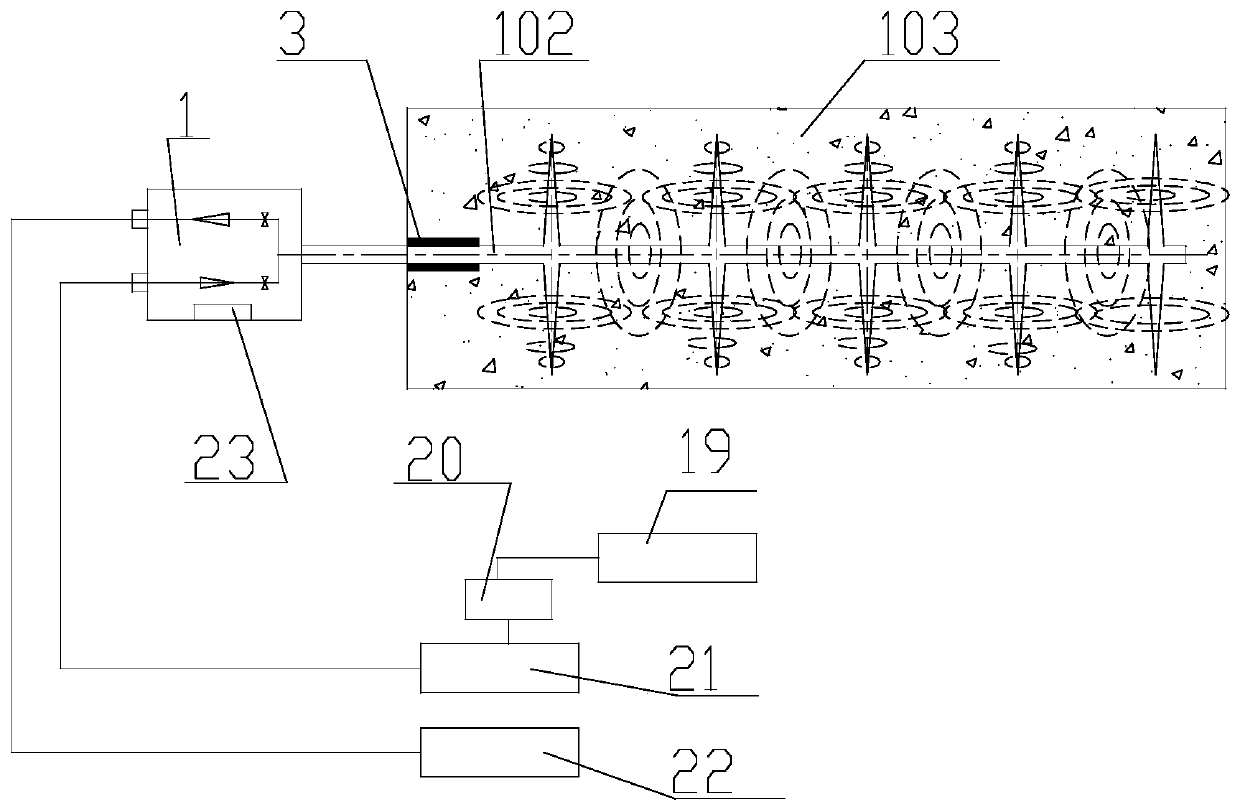

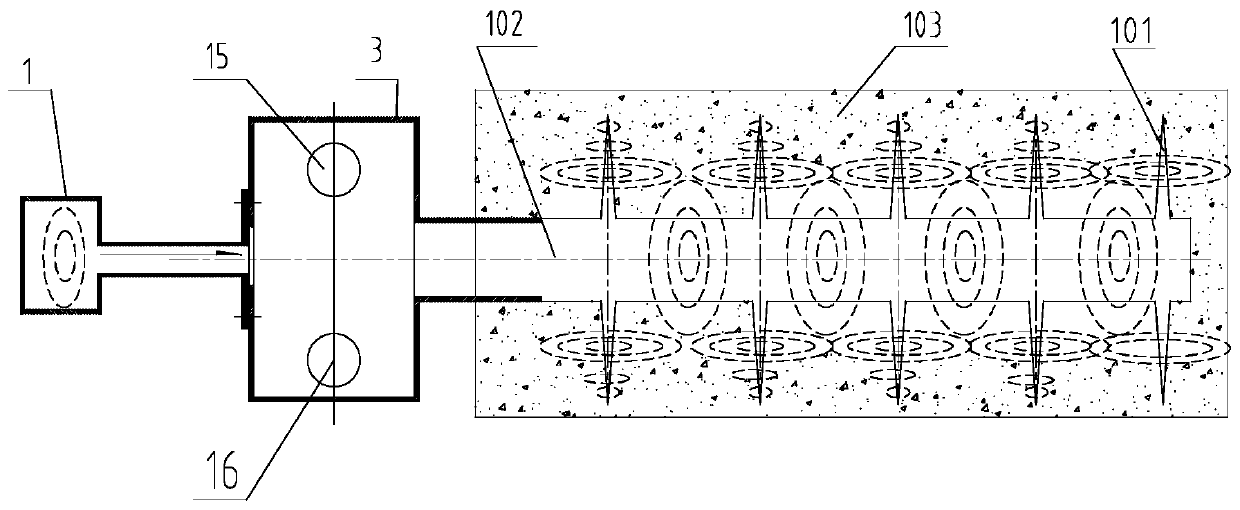

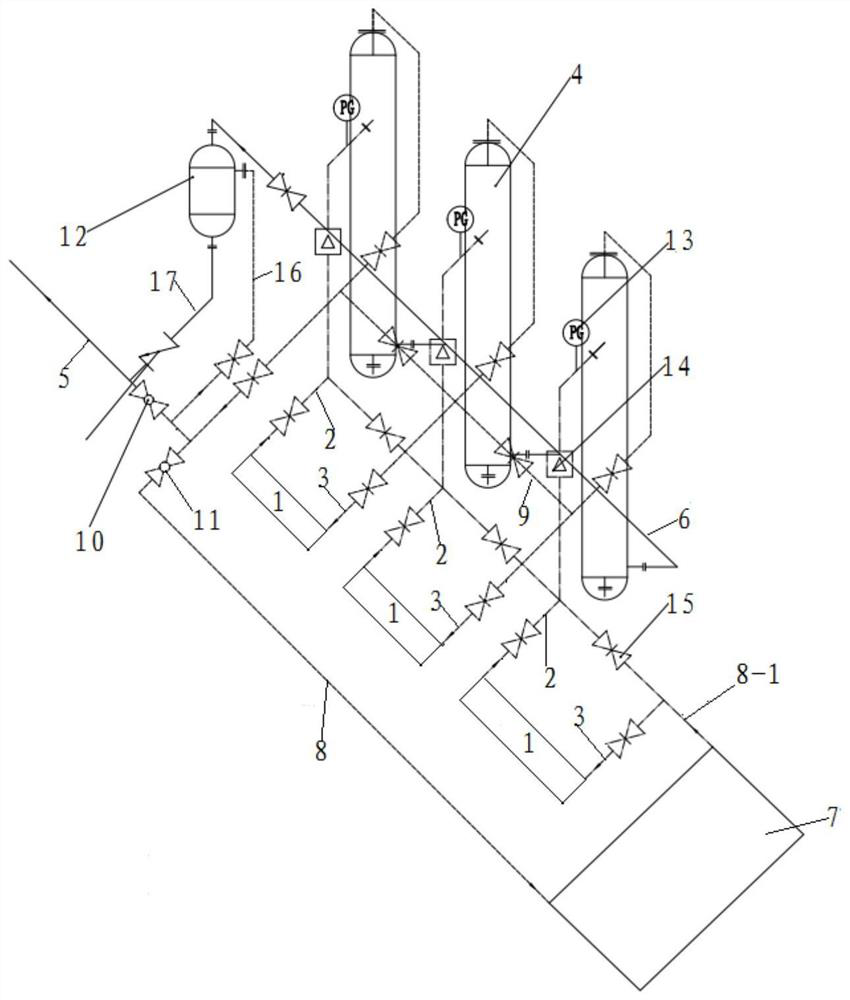

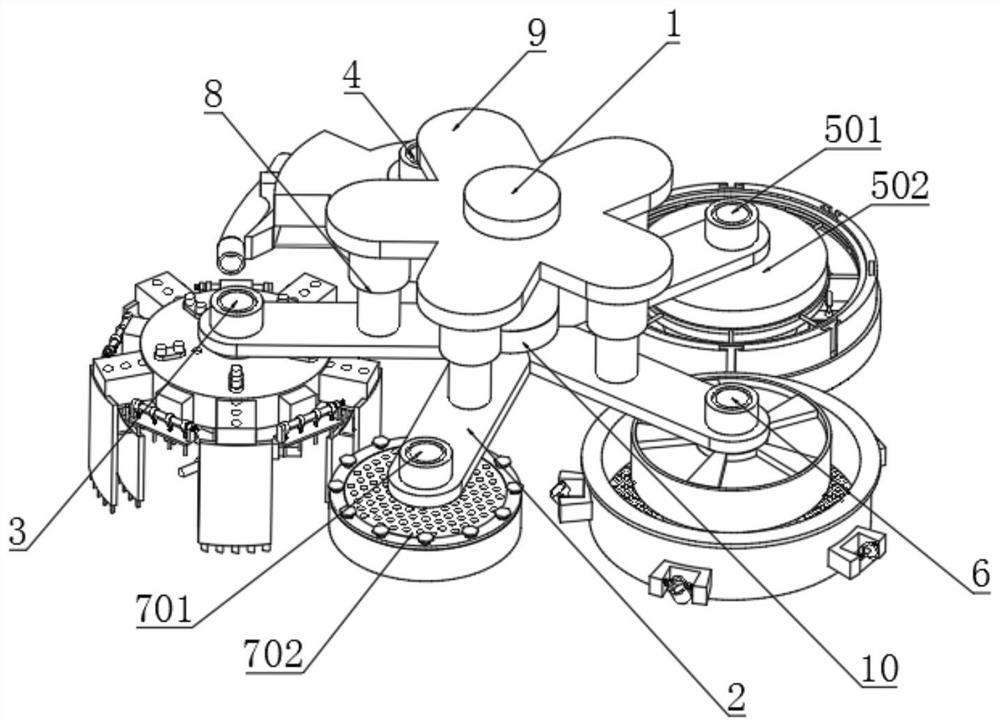

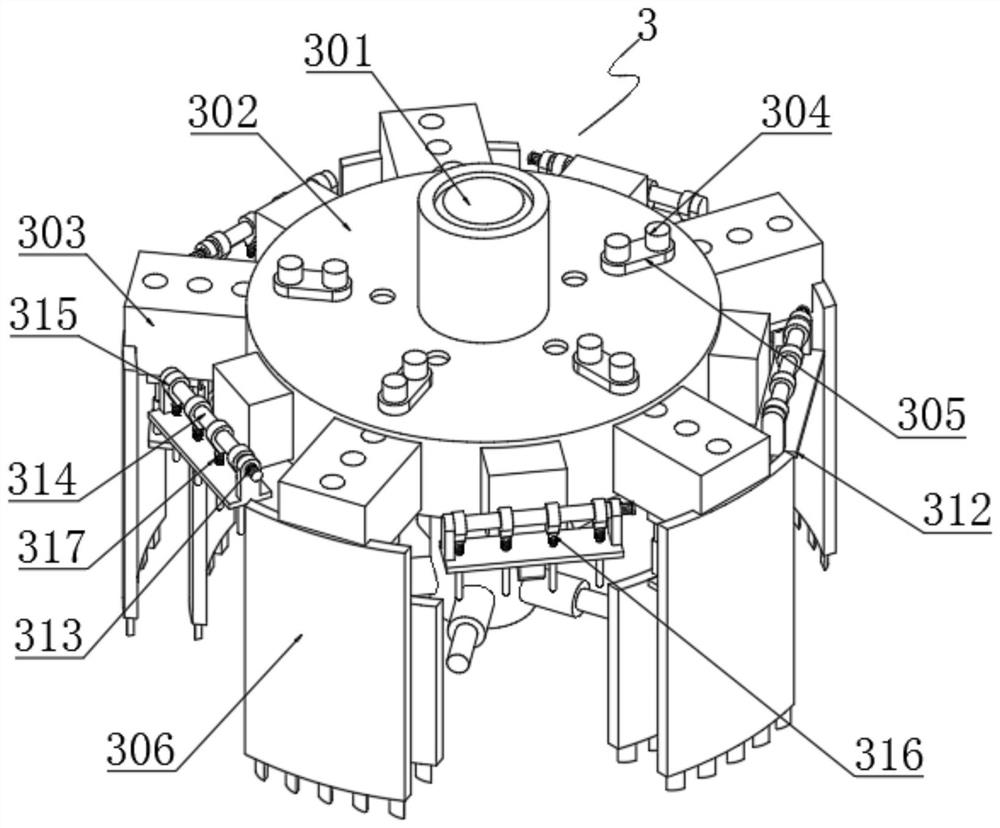

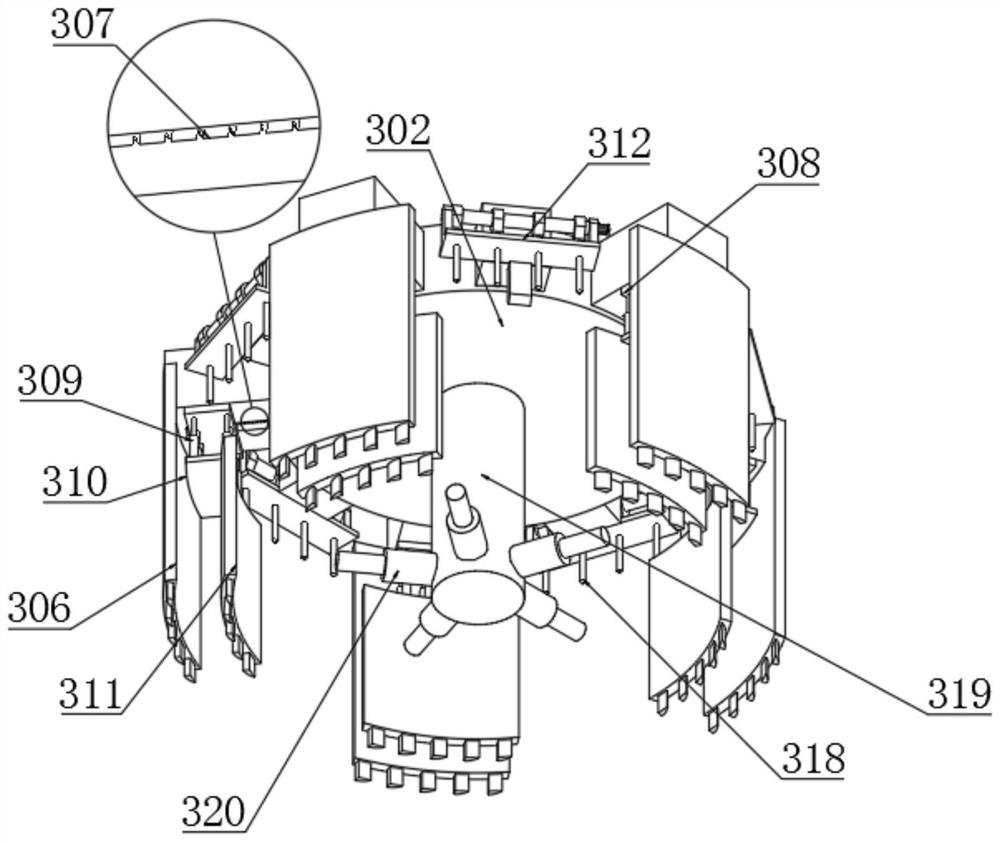

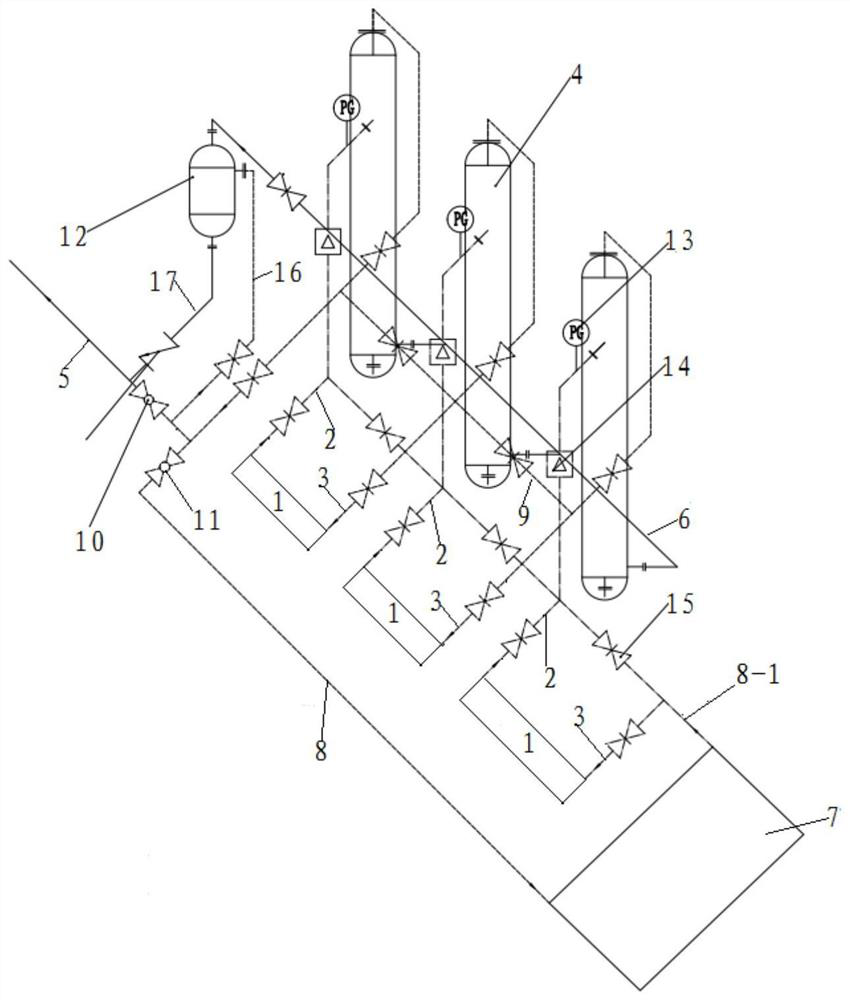

Pulse thickened-oil exploiting device and method for exploiting thickened oil by pulses

The invention relates to the technical field of thickened-oil exploitation, relating to a pulse thickened-oil exploiting device and a method for exploiting thickened oil by pulses. The pulse thickened-oil exploiting device and the method for exploiting thickened oil by pulses are suitable for thickened-oil exploitation projects with oil field high viscosity and poor mobility. The device comprisesa well mouth device, a transmission device, an oil layer pipe string and a convertor device. The outside of the well mouth is equipped with a well moth device capable of providing a high frequency pulse fluid. The device and the method are primarily used for the thickened-oil exploitation projects with oil field high viscosity and poor mobility. The traditional thickened oil exploitation idea is changed. The oil well exploitation structure is simplified. Miniature cracks are formed in a stratum by pulses. Therefore, seepage rate of rocks in the stratum is increased. Rocking dissolving is avoided due to impact of pulses upon thicken oil. The fluid property is greatly improved. Meanwhile, combined with biological and chemical flooding, density and viscosity are reduced. The recovery difficulty is lowered. Pulses form miniature cracks in the stratum, which further increases seepage rate of rocks in the stratum. Fluidity of thickened oil is effectively changed so that oil well recovery efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Gas pulsation quantum energy implantable presplitting anti-reflection gas extraction method and device

ActiveCN109723487ASolve the explosionSolve the problem of weakened transparencyFluid removalGas removalLiquid carbonGas explosion

The invention provides a gas pulsation quantum energy implantable presplitting anti-reflection gas extraction method and device. According to the invention, pulsating gas is used for pressurizing andpresplitting a coal seam, so that the problem of gas explosion caused by uncontrollable phase change expansion blasting of liquid carbon dioxide in the mining process is solved, and the gas mining safety is improved. Moreover, the problems of weakening permeability of the soft coal seam and high water pressure sealing of cracks and holes of the coal seam are solved, and the mining difficulty is reduced. Furthermore, the gas more easily breaks away from the coal seam through quantum energy implantation, so that the extraction efficiency is improved.

Owner:贵州天地聚能采矿工程技术有限公司

Method for exploiting high-viscosity oil

ActiveCN112593905AComponent cutting accuracy requirements are lowReduce equipment costsMaterial heat developmentFluid removalDesalinationViscosity

The invention provides a method for exploiting high-viscosity oil. According to the method, high-temperature low-viscosity oil or a combination of the high-temperature low-viscosity oil and gas is injected into a high-viscosity oil reservoir for huff-puff exploitation; the high-temperature low-viscosity oil or the combination of the high-temperature low-viscosity oil and the gas is used for reducing the viscosity of the high-viscosity oil in the stratum by dissolving and heating, and increasing the stratum pressure; the high-temperature low-viscosity oil comprises one or a combination of morethan two of a light fraction and a middle fraction obtained by on-site distillation of the high-viscosity oil; the light fraction is obtained by carrying out atmospheric distillation on high-viscosityoil subjected to dehydration and desalination treatment; and the middle fraction is obtained by performing reduced pressure distillation on a heavy fraction obtained by performing normal pressure distillation on high-viscosity oil subjected to dehydration and desalination treatment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation and application of heavy oil pyrolysis catalytic system

ActiveCN103849368BReduce mining difficultyIncreased processing difficultyFluid removalDrilling compositionRoom temperatureHigh pressure

The invention relates to preparation and application of a thermal cracking catalytic system of thickened oil. The preparation comprises the following steps: under stirring, adding a substituted phenolic compound, a formaldehyde containing compound or liquor, secondary amine and water into a reaction kettle; dropwise adding transitional metal salt aqueous liquor into the reaction kettle; tightening the reaction kettle and placing in a constant temperature oven; after reaction, cooling to room temperature; adding methanol and urea into the liquor to obtain the thermal cracking catalytic system of thickened oil. The application comprises the following steps: pre-diluting the catalytic system by reinjection water by adopting a high pressure pump; pre-injecting an oil reservoir; and then, injecting steam. The condensation point of the thickened oil can be reduced by over 10 DEG C, and the viscosity is reduced by over 70%. The application is simple in operational process, the exploring difficulty of the thickened oil is remarkably reduced, and thus site popularization is facilitated. The catalytic system is insoluble in crude oil and does not lead to increase of metal ion content in crude oil to aggravate the treatment difficulty in the crude oil processing process, so that the system has a remarkable effect of protecting the quality of crude oil.

Owner:XI'AN PETROLEUM UNIVERSITY

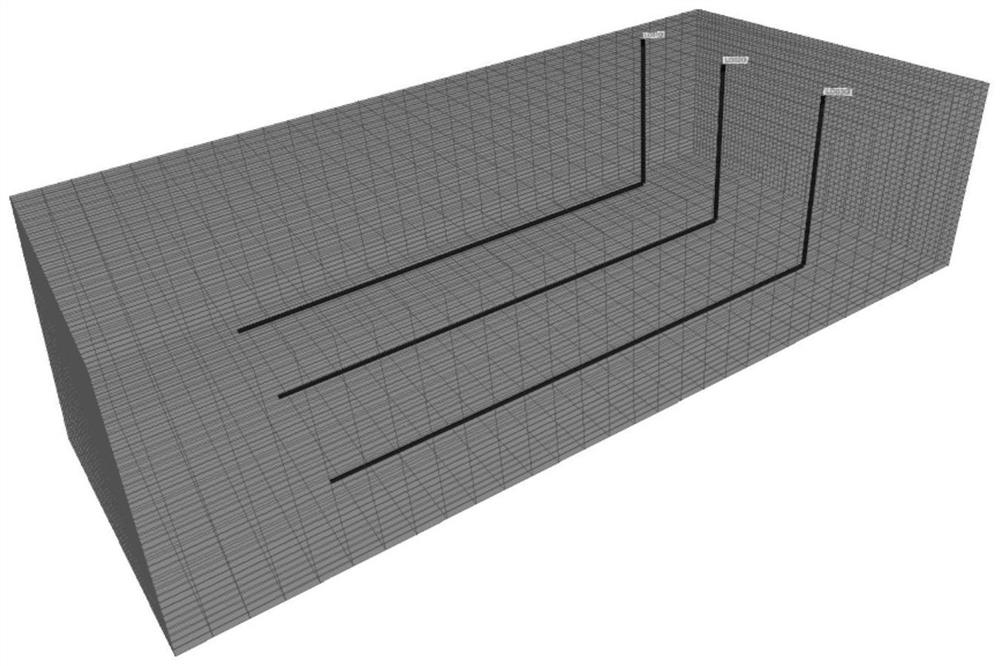

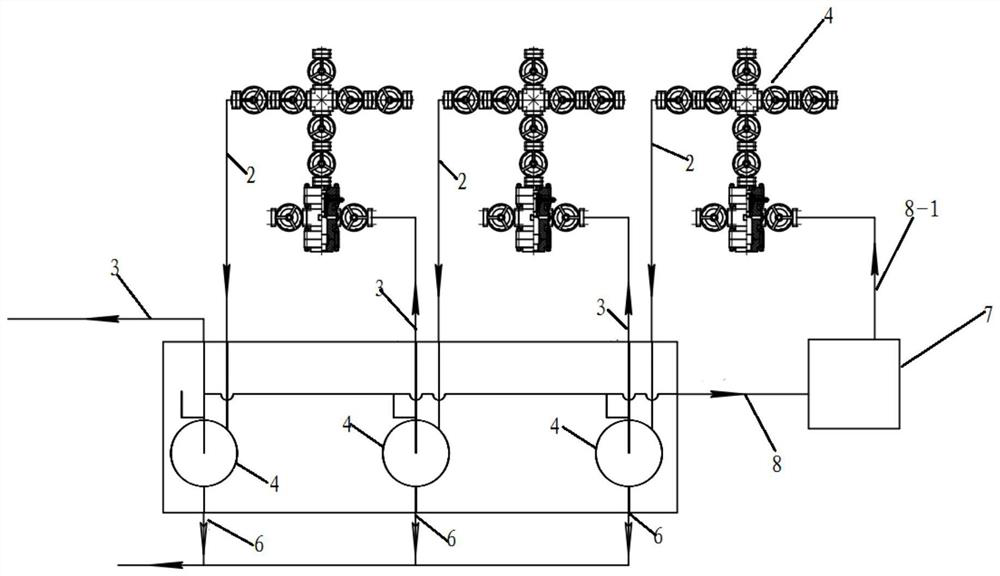

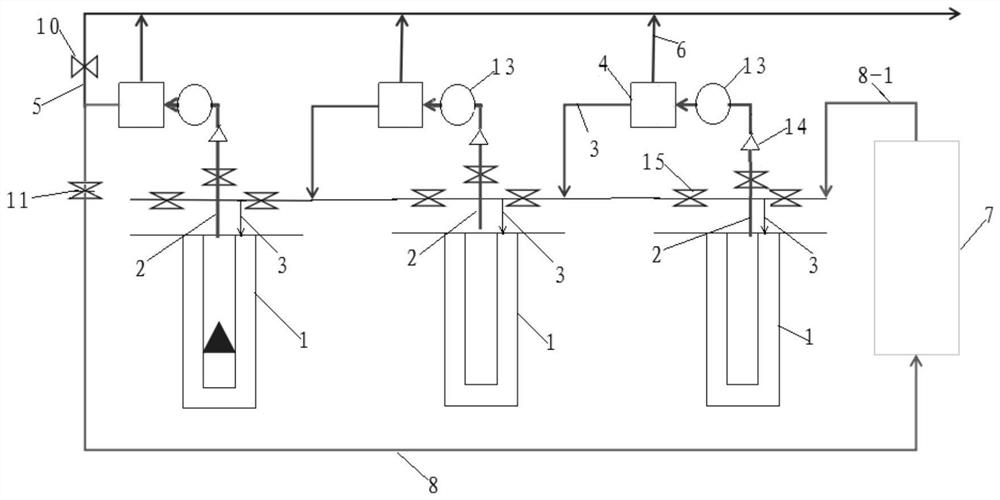

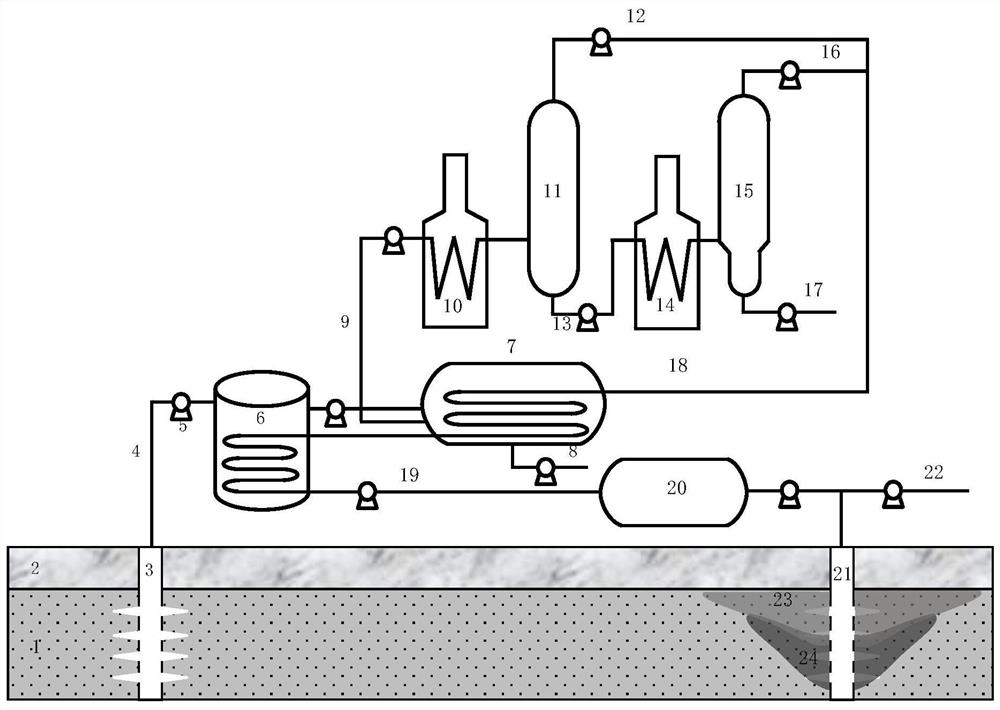

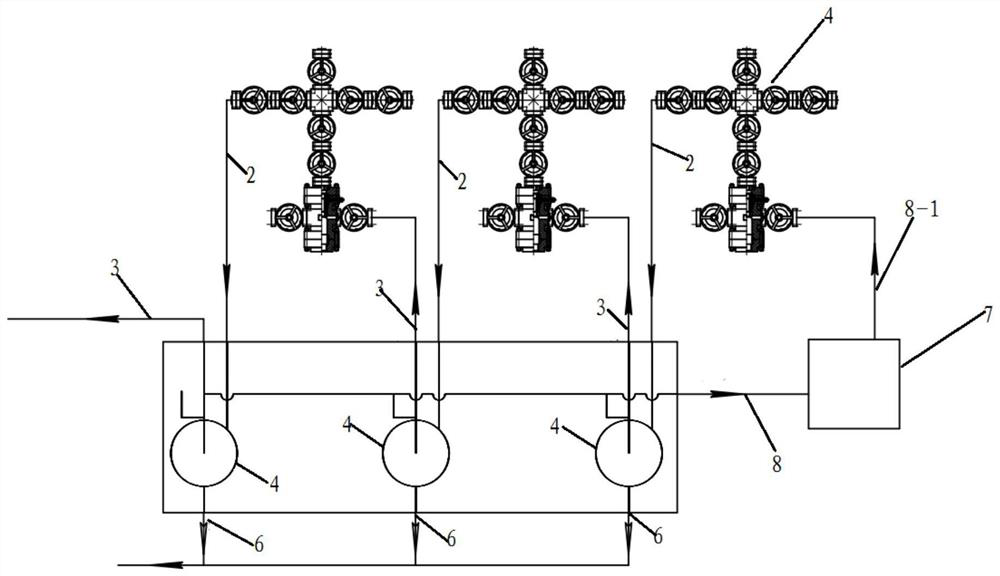

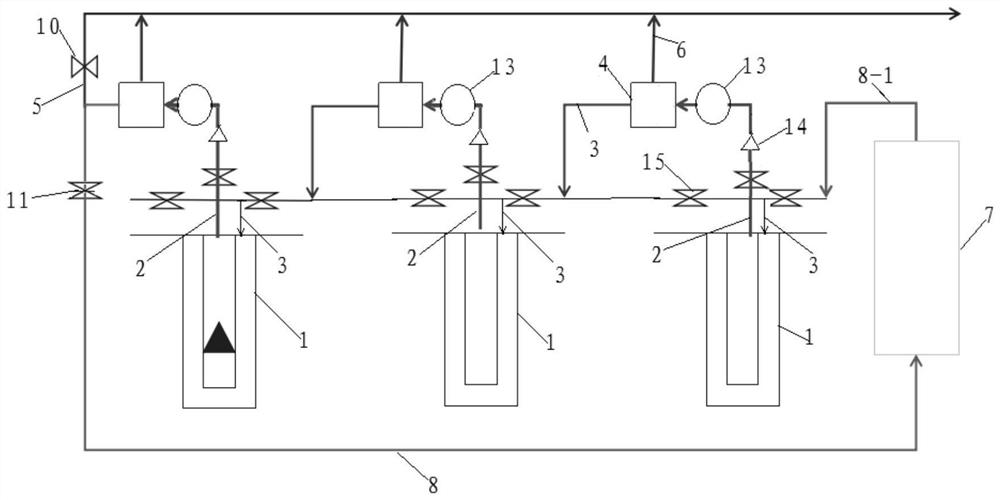

Drainage gas production system and method for prolonging life periods of gas fields and gas wells

The invention provides a drainage gas production system for prolonging life periods of gas fields and gas wells. The system comprises a plurality of gas-liquid separators, a plurality of gas output pipes, a plurality of gas input pipes, an export pipeline, and an air compressor. The gas-liquid separators respectively correspond to a plurality of gas wells to be separated from gas and liquid. One end of each gas output pipe is located in each gas well, and the other end of each gas output pipe is connected with an inlet of each gas-liquid separator. One end of each gas input pipe is connected with a gas outlet of each gas-liquid separator, and the other end is located in the next gas well. The export pipeline is connected with a gas input pipe at the tail end to output the gas outward. Theexport pipeline is further provided with a flow valve. A gas inlet end of the air compressor is connected with the gas input pipe at the tail end through a first circulation pipe, and a gas outlet endof the air compressor is connected with each gas input pipe through a second circulation pipe. Both the first circulation pipe and the second circulation pipe are provided with first valves. The invention further provides a drainage gas production method. The system has simple process, low cost, convenient operation and strong practicability, and can improve the final recovery rate of the gas fields.

Owner:西安奕鼎石油科技有限公司

Gas pulsation quantum energy implanted pre-splitting anti-reflection gas drainage method and device

ActiveCN109723487BSolve the explosionSolve the problem of weakened transparencyFluid removalGas removalThermodynamicsEngineering

Owner:贵州天地聚能采矿工程技术有限公司

Preparation and Application of Clean Heavy Oil Degradation Catalytic System

ActiveCN104910888BReduce mining difficultyDifficulty of mining favorsFluid removalDrilling compositionHigh pressureOil quality

The preparation and application of the clean heavy oil degradation catalytic system is prepared as follows: under stirring, add substituted phenolic compounds, formaldehyde-containing compounds or solutions, iminodiacetate and water into the hydrothermal reaction kettle, and then react to the hydrothermal reaction Add a transition metal salt aqueous solution dropwise into the kettle, the transition metal salt is chemically pure or above, tighten the hydrothermal reaction kettle and place it in a constant temperature box, and cool to room temperature after the reaction; add methanol and urea to the above solution to obtain a thick Oil-water thermal cracking catalytic system; when applied, use a high-pressure pump to pre-dilute this type of catalytic system with reinjection water, pre-inject into the oil reservoir, and then inject steam, which can reduce the freezing point of heavy oil by more than 10°C and reduce the viscosity by more than 70%. The process is simple, which significantly reduces the difficulty of heavy oil production and is conducive to field promotion; this type of catalytic system is insoluble in crude oil, will not increase the content of metal ions in crude oil and increase the difficulty of crude oil processing, and can significantly protect the quality of crude oil.

Owner:XI'AN PETROLEUM UNIVERSITY

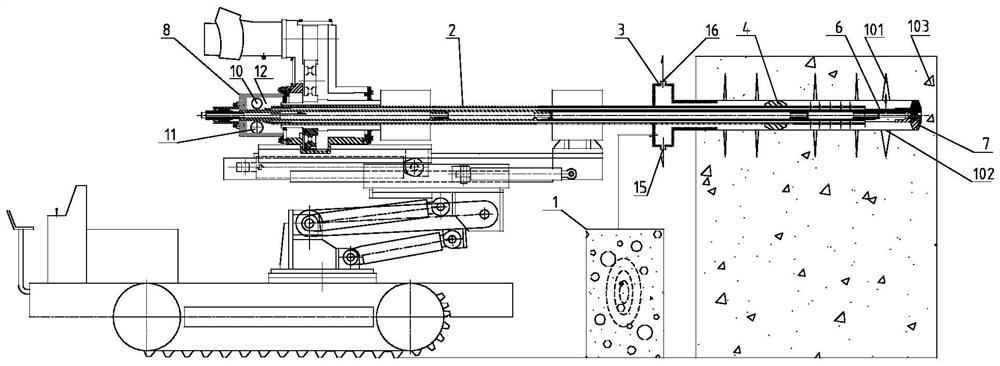

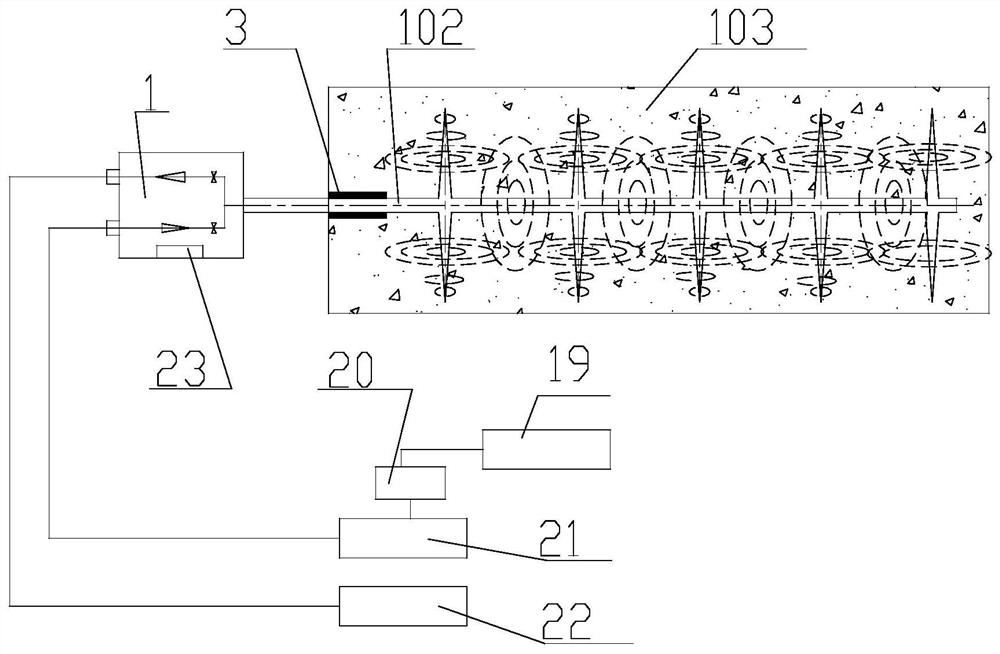

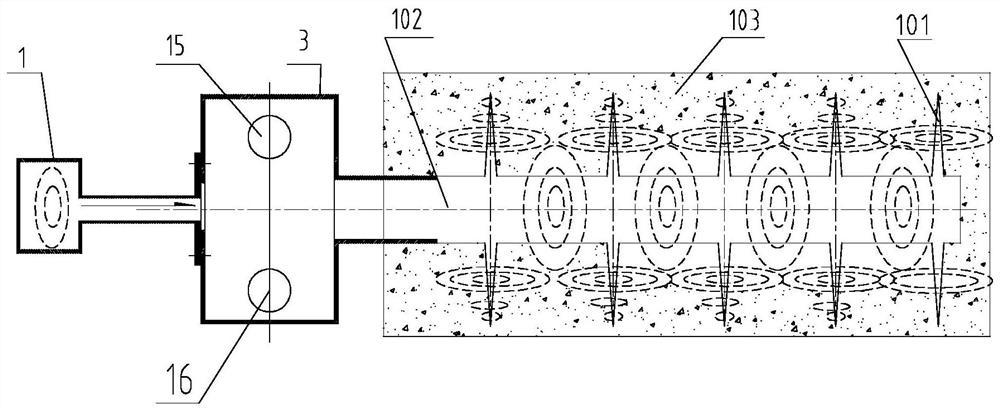

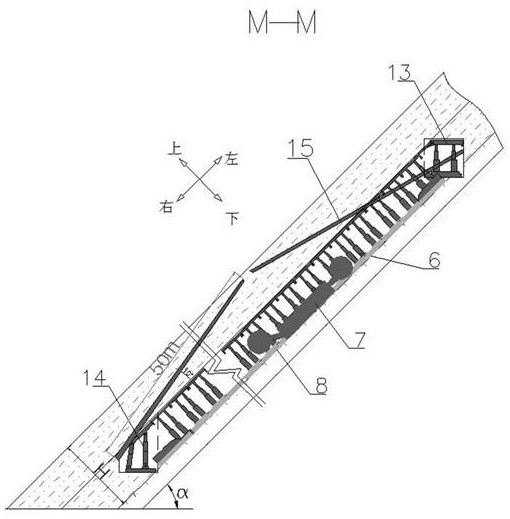

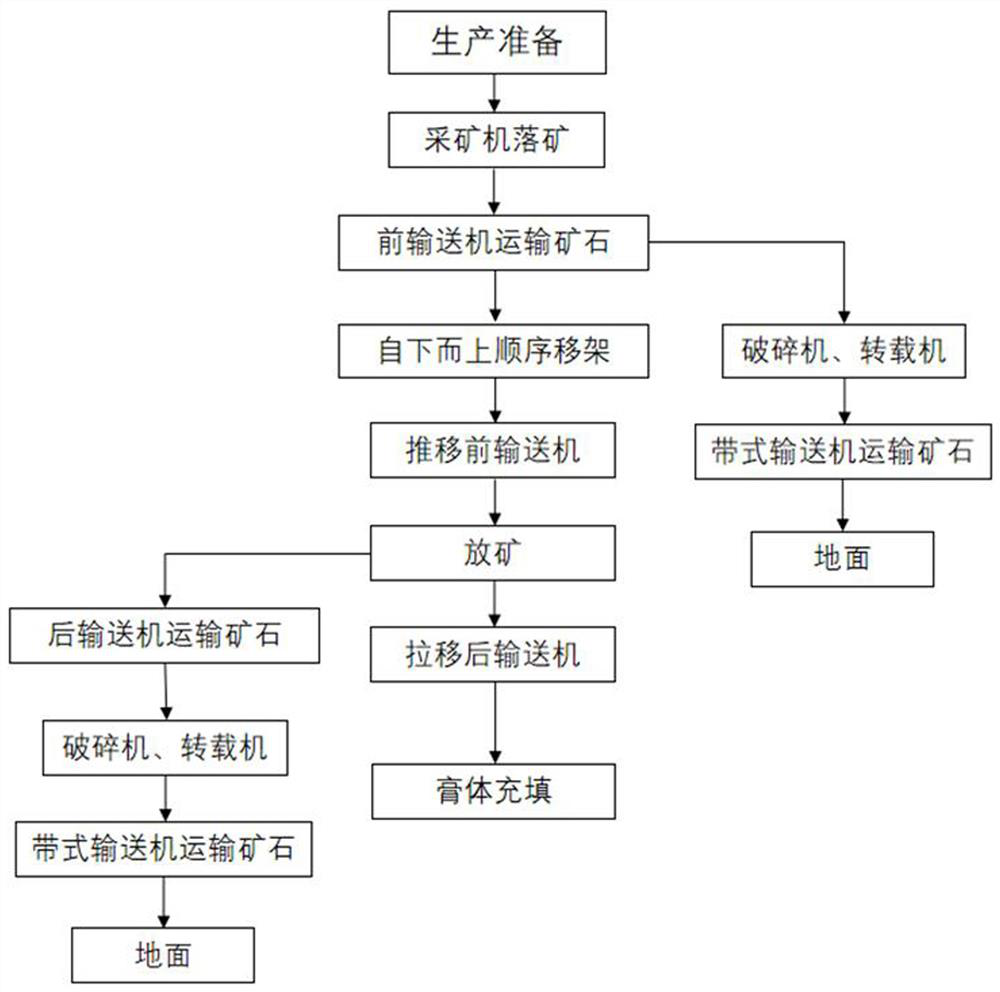

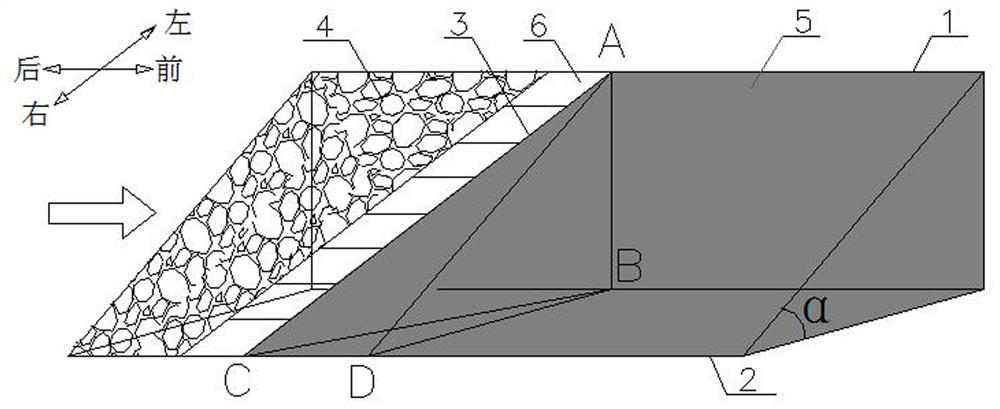

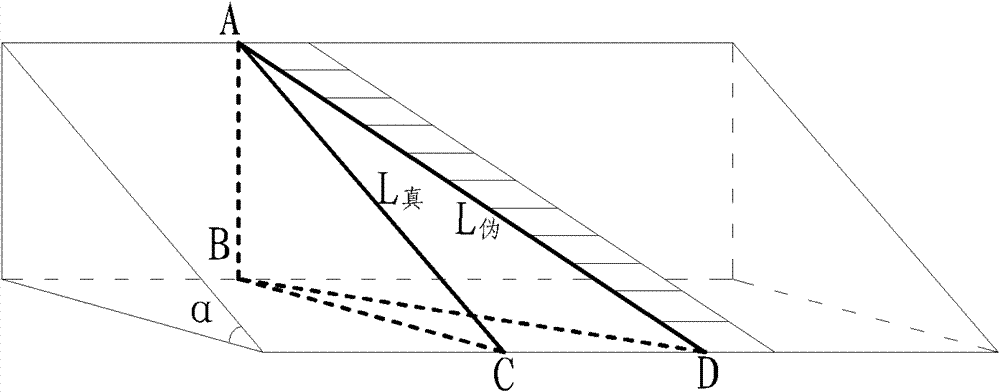

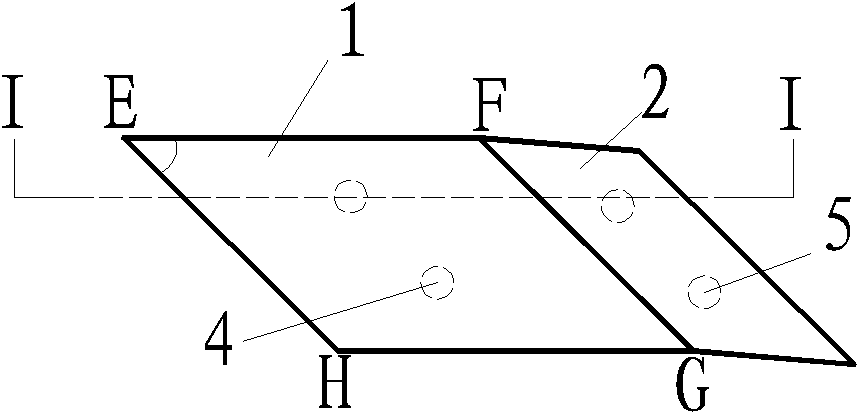

Ore drawing mining method for inclined layered solid ore deposit

PendingCN112983422AOptimize layoutReasonable designUnderground miningSurface miningMechanical engineeringMineralogy

The invention discloses an ore drawing mining method for an inclined layered solid ore deposit. The ore drawing mining method comprises the following steps of firstly arranging an air return roadway, a transportation roadway and a pseudo inclined working face, carrying out advanced presplitting blasting, then utilizing a mining machine to mine, propelling along the trend of an inclined ore body, carrying out ore falling and transporting to the ground, sequentially moving and supporting an ore drawing bracket after the mining is finished, then drawing and transporting the ore on a top layer ore body, and finally processing the goaf by using a filling method. The mining process can be propelled along the trend of an ore bed, the arrangement of the working face is simple, the false bevel angle of the working face is 20-30 degrees, the mining preparation engineering is simplified, the mining preparation cutting engineering amount is reduced, the mining efficiency is improved, the occurrence of roof accidents is reduced, and the problems of large mining preparation workload and low mining rate in an existing non-coal solid ore deposit mining technology are solved. The mining method is suitable for the non-coal solid ore deposit with the dip angle of 35-65 degrees and the thickness of 5-15 m.

Owner:XIAN UNIV OF SCI & TECH

Safe, high-speed and lightweight blockchain system and method

ActiveCN109639430BIncrease spawn rateImprove verification efficiencyFinanceUser identity/authority verificationFinancial transactionReliability engineering

The invention discloses a safe, high-speed and lightweight blockchain system and method, wherein the system comprises an initialization module, a registration and transaction module and a block generation module; the initialization module runs when the system is initialized, and is used for setting relative parameters of the blockchain system and deploying a point-to-point network, so that the system function is initialized and reaches a steady state through block generation in an initial stage; the registration and transaction module is used for calling a user registration function when a user joins in the system, generating a public / private key pair of the user, sending a trading card into a blockchain network, verifying the validity of the trading card through a network node, and continuously broadcasting legal transaction to the whole network; the block generation module is used for determining a miner candidate set of a current block according to the trading participant address ina specific block in a target blockchain system appointed by the system; and a candidate in the miner candidate set generates a new block by competition by utilization of a consensus mechanism. By means of the system, the problem of low verification efficiency ubiquitous in the blockchain system can be effectively solved.

Owner:BEIHANG UNIV

Efficient well lid dismantling device

PendingCN114319451AReduce the difficulty of turningReduce the difficulty of cuttingArtificial islandsUnderwater structuresStructural engineeringClassical mechanics

The efficient well lid dismantling device comprises a stand column, a rotating column is rotationally connected to the rotating middle of the bottom end of the stand column, five rotating plates are slidably connected to the middle of the bottom end of the outer surface of the rotating column at equal intervals, and an electric telescopic column is welded to the middle of the top end of each rotating plate; a pentagonal strip plate is welded to the top end of an electric telescopic column, a cutting, crushing and taking mechanism is installed in the middle of the inner wall of one rotating plate, a crushing rotating disc and an outer cutting disc can rotate conveniently through a crushing rotating motor in the cutting, crushing and taking mechanism, and the rotating difficulty of the outer cutting disc and an inner cutting disc is reduced; and meanwhile, through cooperation of an inner cutting disc, an outer cutting disc, a hydraulic rod, a threaded rod and a connecting piece, the asphalt pavement on the edge of the well lid can be conveniently cut, the cutting difficulty of the asphalt road side is lowered, the cutting difficulty of the edge of the asphalt pavement of the well lid in the prior art is lowered, and meanwhile the phenomenon that the cutting discs make contact with the well lid is prevented.

Owner:青岛卓航睿智信息科技有限公司

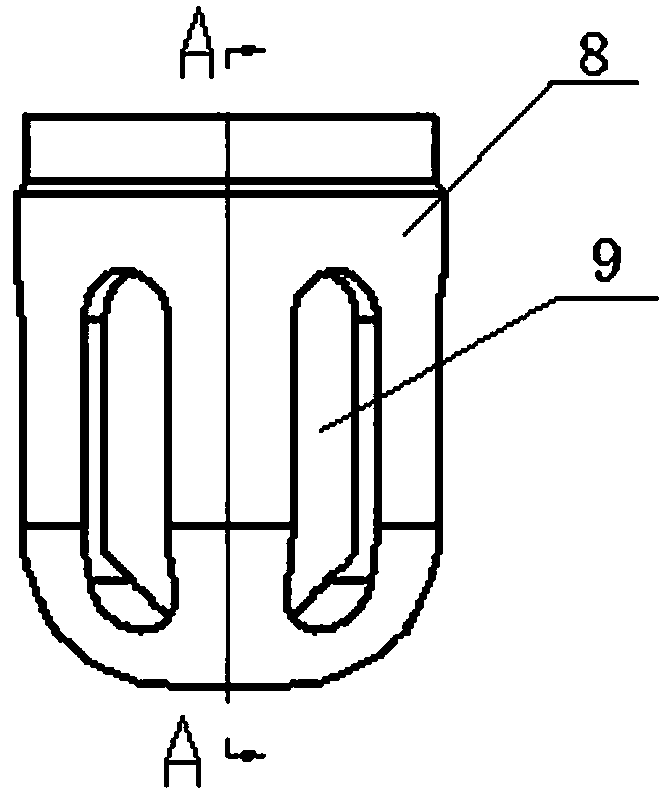

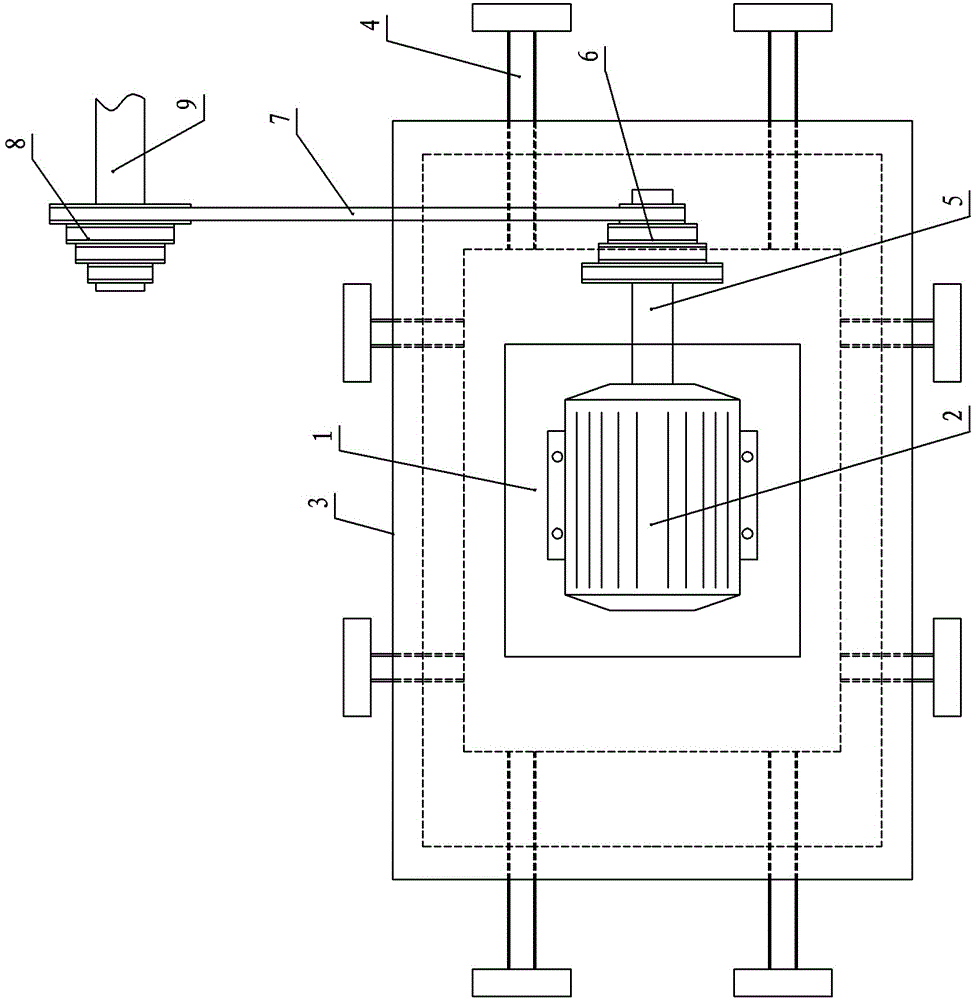

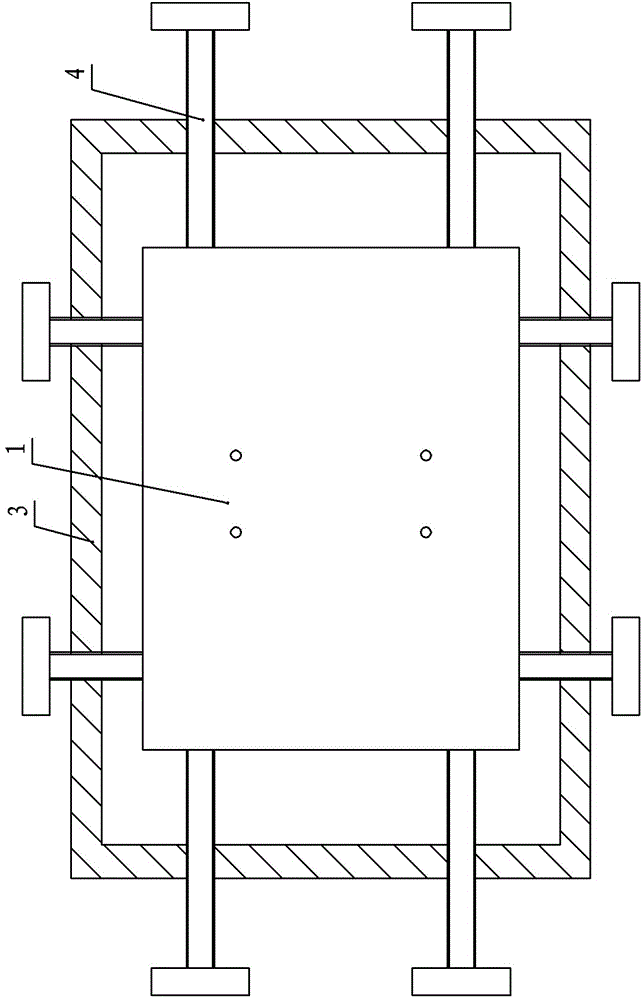

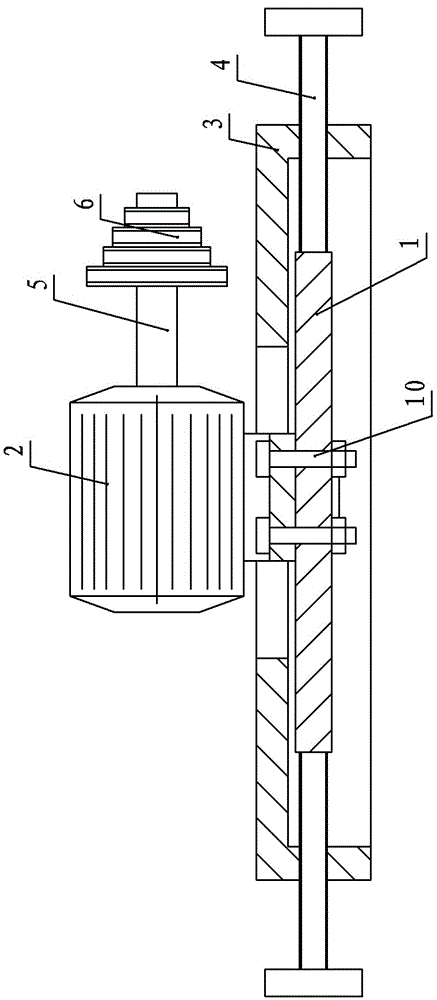

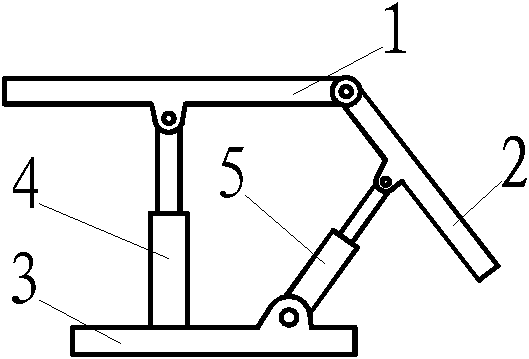

Variable-stroke-frequency device of beam pumping unit

ActiveCN102355083BFlexible adjustment of stroke timesAvoid shockFluid removalMechanical energy handlingJackscrewEngineering

The invention relates to a variable-stroke-frequency device of a beam pumping unit, which comprises a motor, a movable motor mounting mechanism and a twin-cone-pulley output mechanism, wherein the movable motor mounting mechanism comprises a square soleplate which is connected with the motor and a square framework plate which is installed on the upper part of the soleplate in a pressing way, the middle part of the framework plate is provided with a square opening, the length and the width of the square opening are smaller than the length and the width of the square soleplate, four edges of the square soleplate are respectively provided with a hem, each hem is provided with a jackscrew, the jackscrew passes through the hems to be contacted with the edges of the square soleplate, the motor is installed on the middle part of the square soleplate, and a motor shaft is connected with a transmission mechanism of the beam pumping unit through the twin-cone-pulley output mechanism. During theadjusting process of the stroke frequency, a belt is free from being replaced, and the adjusting process of the stroke frequency can be completed only by adjusting the jackscrews, so the labor intensity is low, and the work efficiency is high.

Owner:刘锋

A kind of mining method of high viscosity oil

ActiveCN112593905BComponent cutting accuracy requirements are lowReduce equipment costsMaterial heat developmentFluid removalAdhesiveDesalination

The invention provides a method for recovering high-viscosity oil. The method is a method of injecting high-temperature low-viscosity oil or a combination of high-temperature low-viscosity oil and gas into high-viscosity oil reservoirs for huff and puff production; The high-viscosity oil is reduced in viscosity through dissolution and heating, and the formation pressure is increased; the high-temperature low-viscosity oil includes one or more combinations of light distillate and middle distillate obtained from in-situ distillation of high-viscosity oil; the The light distillate is obtained by atmospheric distillation of the dehydrated and desalted high-viscosity oil; the middle distillate is obtained by vacuum distillation of the heavy fraction obtained by dehydrating and desalting the high-viscosity oil subjected to atmospheric distillation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A drainage gas production system and method for prolonging the life of gas wells in gas fields

The invention provides a drainage gas production system for prolonging the life of gas wells in a gas field. The system includes a plurality of gas-liquid separators, which are respectively in one-to-one correspondence with a plurality of gas wells to be separated from gas and liquid; a plurality of gas output pipes, each One end of the gas output pipe is located in each gas well, and the other end is connected with the air inlet of each gas-liquid separator; a plurality of gas input pipes, one end of each gas input pipe is connected with the gas outlet of each gas-liquid separator, and the other end is located in the next gas well; The external transmission pipeline is connected with the gas input pipe at the end for outputting the gas to the outside. The external pipeline is also provided with a flow valve; the air compressor, whose intake end passes through the first circulation pipe and the gas at the most terminal The input pipe is connected, and the gas outlet is connected to each gas input pipe through the second circulation pipe; the first circulation pipe and the second circulation pipe are both provided with a first valve; the invention also provides a drainage gas recovery method, and the process of the invention is simple , low cost, convenient operation, strong practicability, and can improve the ultimate recovery of gas fields.

Owner:西安奕鼎石油科技有限公司

A method for joint mining of coal and associated oil shale

ActiveCN106337685BReduce mining difficultyEnsure rock breaking efficiencyUnderground miningSurface miningResource utilizationUltimate tensile strength

The invention provides a method for combined exploitation of coal and its associated oil shales. The method comprises the construction steps that when the coal and its associated oil shales are located in a reasonable exploitation bed separation distance range, coal resources located at the lower portion are firstly exploited, a mine bearing pressure is fully utilized to destroy associated oil shales located in an overlying rock layer and reduce the strength; then, the associated oil shales at the upper portion are exploited later to achieve combined exploitation of coal and its associated oil shales. Therefore, the shortcoming that when oil shales are independently exploited, the oil shale strength is higher and accordingly a coal cutter difficultly break rocks can be overcome. According to the exploitation method, existing infrastructures and sinking and driving engineering can be fully utilized, the roadway tunneling amount can be decreased, investment can be reduced, the costs are low, the phenomenon that the oil shales associated with coal are severely abandoned can be effectively completely eradicated or decreased, the resource utilization rate can be improved, an economic value is huge, and the method has the important practical significance on relieving of conventional energy source supply and demand pressure, energy structure adjustment and energy guaranteeing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Dual phase change energy storage material and preparation method thereof

InactiveCN109796939AConsider performanceImprove utilization efficiencyHeat-exchange elementsHigher alkanesMass ratio

The invention relates to a dual phase change energy storage material and a preparation method thereof. The dual-phase change energy storage material comprises first nanocapsules, second nanocapsules and a building carrier material, wherein the mass of the building carrier material is 30-50% of the composite phase change energy storage material; the mass ratio of the first and second nanocapsule is40-60%:60-40%; both the first and second nanocapsules are made with a main material, a monomer, an initiator and an emulsifier; the first and second nanocapsules are differed in the composition of the main material, and the two main materials are different two of higher alkanes, such as cetane, heptadecane, octadecane and eicosane. Compared with traditional large-scale materials, the dual phase change energy storage material has the advantages that heat transfer area can be enlarged, better heat transfer advantage is gained, energy utilization efficiency is improved, and the leakage problem of the phase change material is partly solved.

Owner:HEBEI UNIV OF TECH

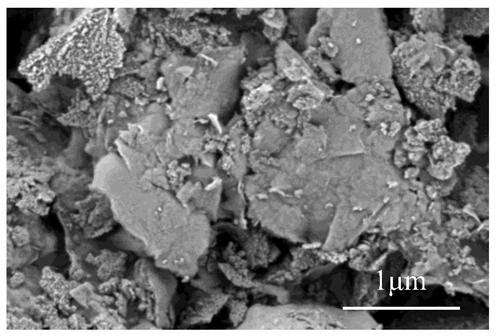

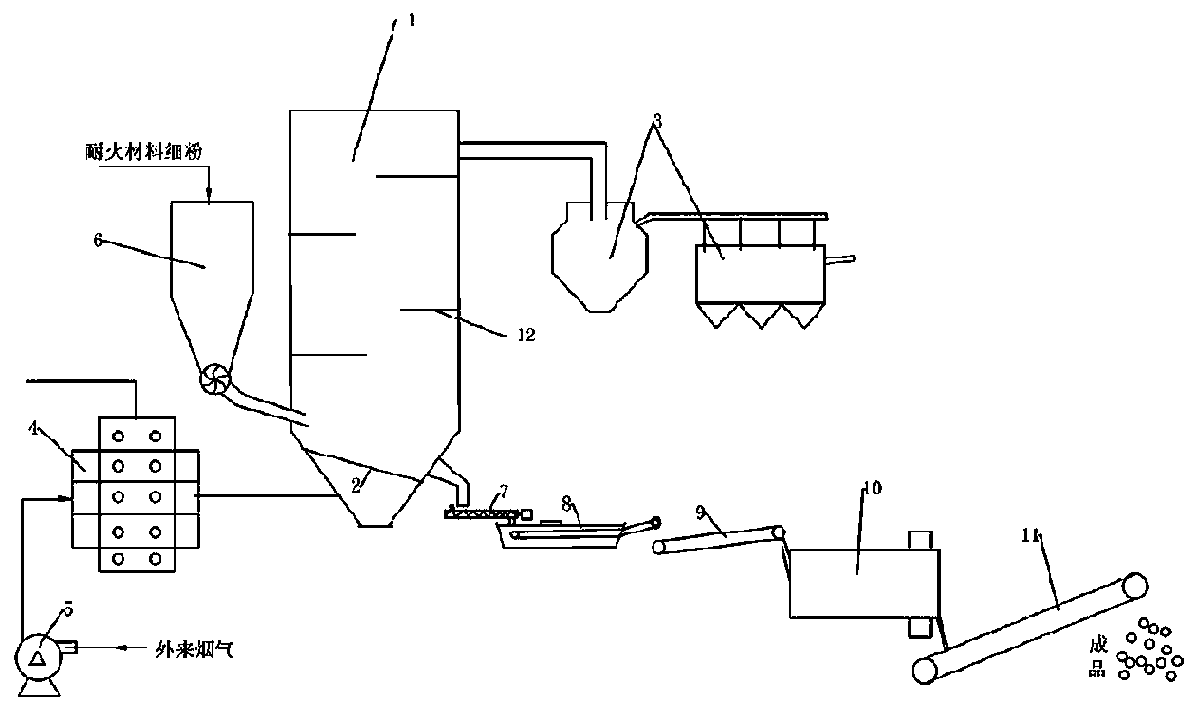

Iron removing device and technology for fine powder of refractory material

The invention discloses an iron removing device and technology for fine powder of a refractory material. The device comprises a fluidized bed furnace, the fluidized bed furnace is provided with, fromtop to bottom, a smoke vent for exhausting furnace gas, a feed port for receiving the fine powder of the refractory material and a discharge port for discharging reduced fine powder of the refractorymaterial, an air distribution plate is arranged in the fluidized bed furnace under the discharge port, a boiling cavity is enclosed by the air distribution plate and part thereover of the fluidized bed furnace, an air inlet cavity is enclosed by the air distribution plate and part thereunder of the fluidized bed furnace, and the air inlet cavity is provided with a flue gas inlet for conveying hotflue gas into the boiling cavity; and a first conveying mechanism, a cooling mechanism, a second conveying mechanism, a ball mill and an iron removing magnetic roller are arranged behind the dischargeport successively. The fine powder whose iron content is higher than 5% of the refractory material is placed in the fluidized bed furnace, and flue gas not lower than 750 DEG C is input into the fluidized bed furnace to form the reducing atmosphere, and thus, iron oxide in the fine powder of the refractory material can be reduced, in the reducing atmosphere, into elementary iron which can be removed by the magnetic roller.

Owner:山西惟泰安全环保工程技术有限公司

Down-dip mining method of shaped hydraulic bracket on long-wall working surface in direction of large dip angle coal bed

InactiveCN102061921BReasonable designMining method is simpleUnderground miningSurface miningStructure of the EarthInstability

Owner:XIAN UNIV OF SCI & TECH +1

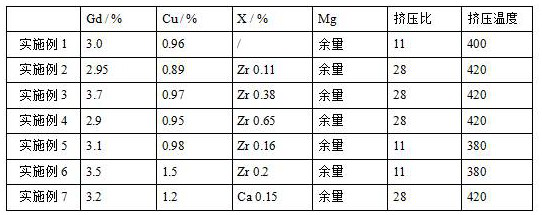

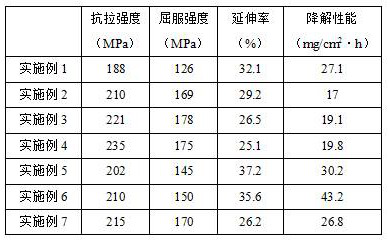

High-plasticity rapidly-degradable magnesium alloy and preparation method thereof

The invention discloses a high-plasticity rapidly-degradable magnesium alloy and a preparation method thereof. The high-plasticity rapid degradation magnesium alloy comprises the following components in percentage by weight: 1-6% of Gd; 0.05 to 2 percent of Cu; and the balance of Mg and inevitable impurities. The preparation method comprises the following steps: (1) burdening according to magnesium alloy components; (2) in the smelting process, CO2 and SF6 are adopted as protective gas, the temperature is increased to 720-750 DEG C, then heat preservation is conducted, after all the raw materials are smelted, the temperature is reduced to 700-720 DEG C, standing and heat preservation are conducted for 25-30 min, the raw materials are taken out, salt bath water cooling is conducted, and an alloy cast ingot is obtained; (3) the prepared alloy cast ingot is subjected to homogenization treatment for 4-12 h at the temperature of 400-440 DEG C; and (4) the cast ingot is preheated for 30 min at the temperature of 350-430 DEG C, and one-time extrusion forming is conducted according to the extrusion ratio of 11-28. The mechanical property and the degradation rate of the prepared magnesium alloy are obviously improved, the use requirements of fracturing tools are met, the magnesium alloy can be widely applied to the field of energy mining such as oil and gas mining, the mining difficulty is reduced, and the mining efficiency is improved.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com