Efficient well lid dismantling device

A manhole cover and high-efficiency technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of inconvenient disassembly, unfavorable replacement and maintenance of plastic pipes, and increase the difficulty of disassembly of sewer manhole covers. The effect of taking the difficulty and reducing the difficulty of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

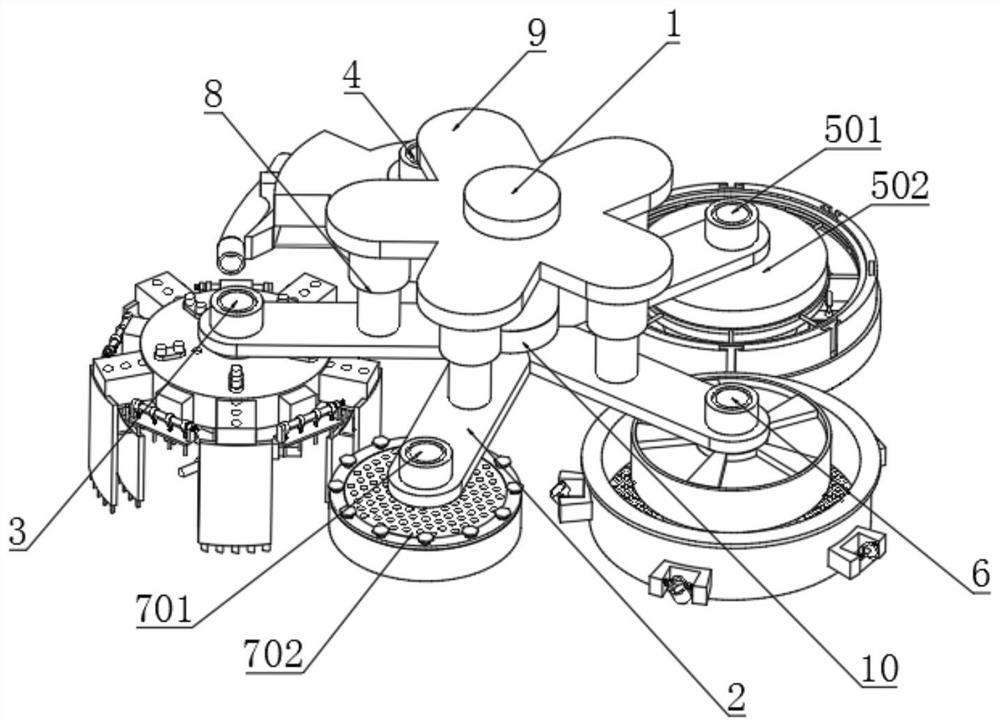

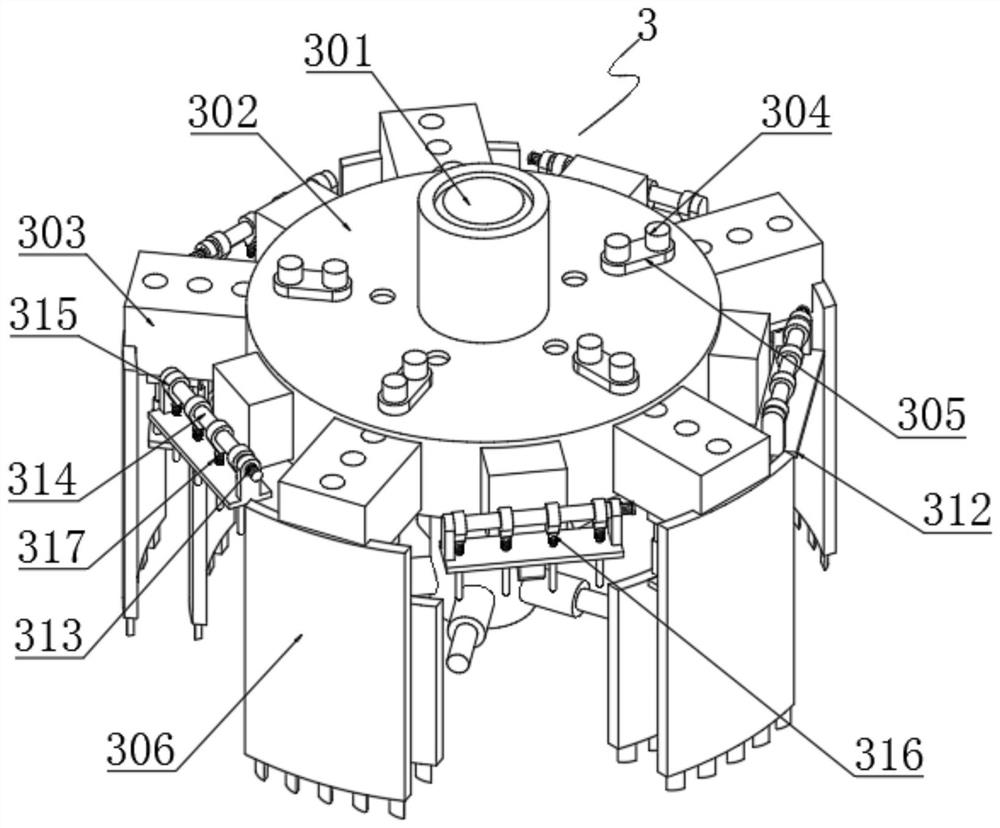

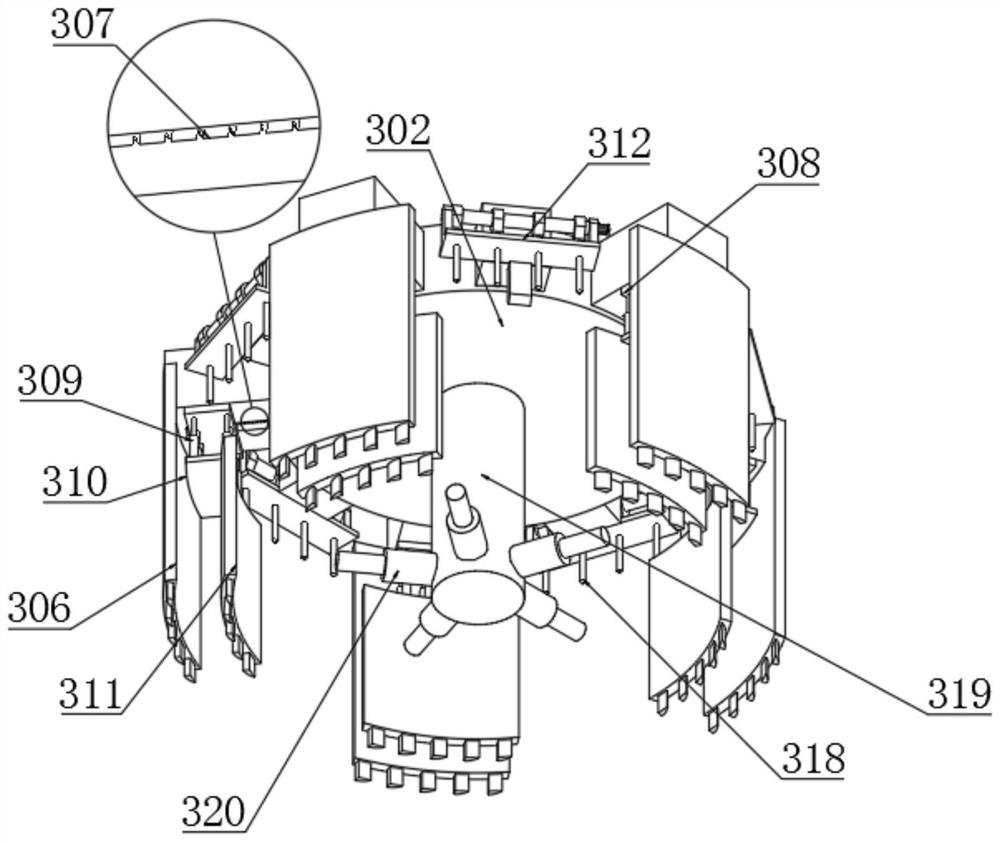

[0034] Example: such as Figure 1-8 As shown, the present invention provides a technical solution for a high-efficiency manhole cover removal device, a high-efficiency manhole cover removal device, including a column 1, and the bottom end of the column 1 rotates in the middle and is rotatably connected to a rotating column 10, and the outer surface of the rotating column 10 slides equidistantly from the bottom end and middle Connected, the number of rotating plates 2 is set to five, five rotating plates 2 are welded with electric telescopic columns 8 in the middle of the top, and the top of the electric telescopic columns 8 is welded with pentagonal strips 9, and the middle part of the inner wall of one rotating plate 2 is equipped with a cutting and crushing device. Take the mechanism 3, a dust suction mechanism 4 is installed in the middle of the inner wall of the second rotating plate 2, a limited vibration smoothing mechanism 5 is installed in the middle of the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com