Auto parts grinding device

A technology for auto parts and racks, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., which can solve the problems of non-replacement, reduced hardness of the grinding head, and long stay, so as to save time for changing positions , Guarantee the quality of grinding and reduce the difficulty of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

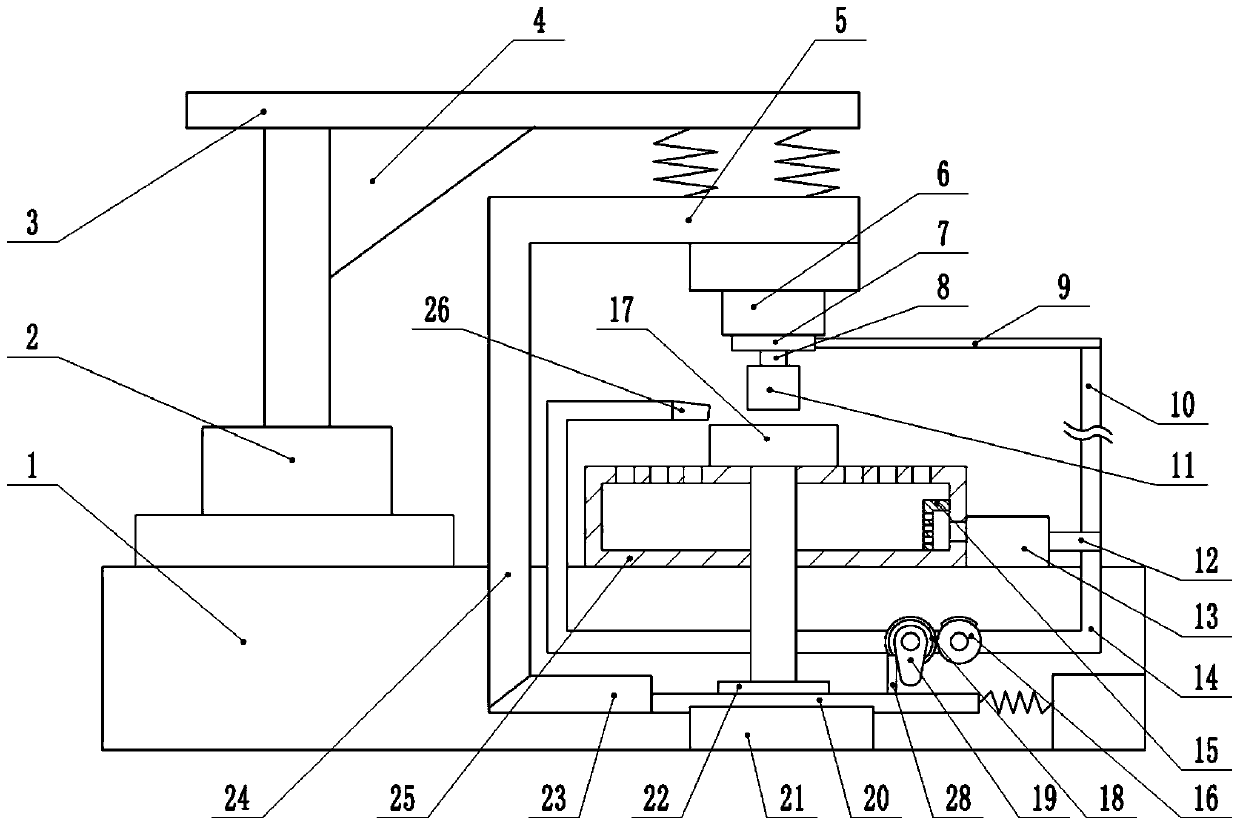

[0019] The reference signs in the drawings of the description include: frame 1, hydraulic cylinder 2, workbench 3, triangular plate 4, support plate 5, motor 6, ring pipe 7, rotating shaft 8, connecting pipe 9, hose 10, grinding head 11. Air outlet pipe 12, negative pressure pump 13, branch pipe 14, filter cover 15, fan gear 16, fixed seat 17, gear 18, cam 19, slide bar 20, chute 21, ratchet 22, second wedge bar 23, first A wedge bar 24, collection box 25, nozzle 26.

[0020] The embodiment is basically as attached figure 1 Shown: The auto parts grinding device includes a frame 1, on which a hydraulic cylinder 2 is threaded through bolts, and a workbench 3 is welded on the output shaft of the hydraulic cylinder 2, and the connection between the workbench 3 and the output shaft of the hydraulic cylinder 2 A triangular plate 4 is welded between them, a support plate 5 is arranged under the workbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com