Patents

Literature

51results about How to "Hardness does not decrease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tire apex composition for improving bond system and its preparation method and application

The invention relates to the tire manufacture field, especially to a tire apex composition for improving a bond system and its preparation method and application. The tire apex composition for improving the bond system is formed by the mixing of the following ingredients of: by weight, 70-100 parts of natural rubber, 0-30 parts of styrene-butadiene rubber, 55-75 parts of carbon black, 1.0-4.0 parts of resorcinol, 0.2-3.0 parts of cobalt decanoate, 3-8 parts of a methylene donator adhesive, 0-20 parts of white carbon black, 3-8 parts of a vulcanizing agent and a sulfuration promoter and other processing auxiliary agents. The tire apex composition for improving a bond system obviously raises modulus and binding property, decreases heat generation, minimizes modulus loss at high temperature,and simultaneously reduces formula cost. By employing BTR tires under the precondition of unchanged structure, the hard apex strength and hardness can be guaranteed not to be decreased, the modulus is substantially increased, the bond performance between the apex and steel wires / steel wire cords is remarkably improved, and the anti-destroy performance of tire bead positions is raised.

Owner:ZHONGCE RUBBER GRP CO LTD

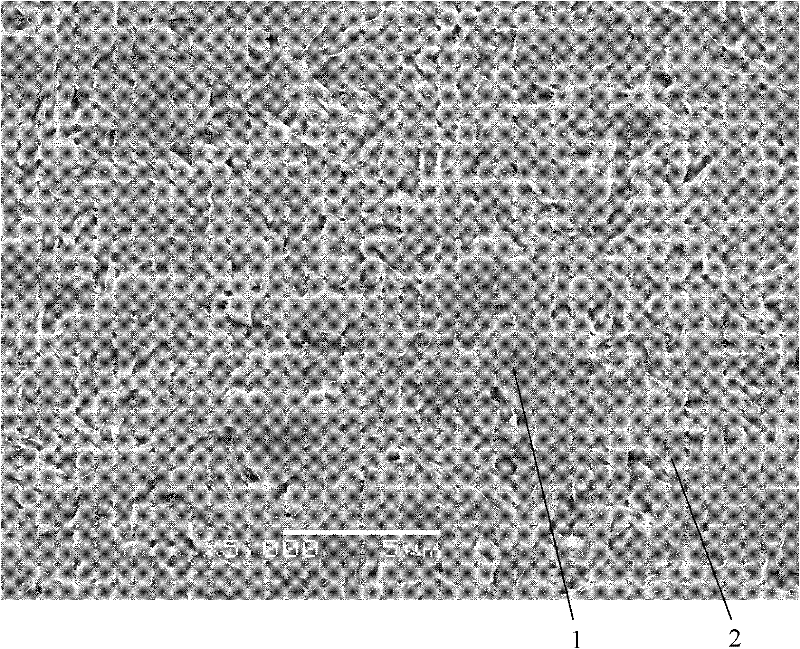

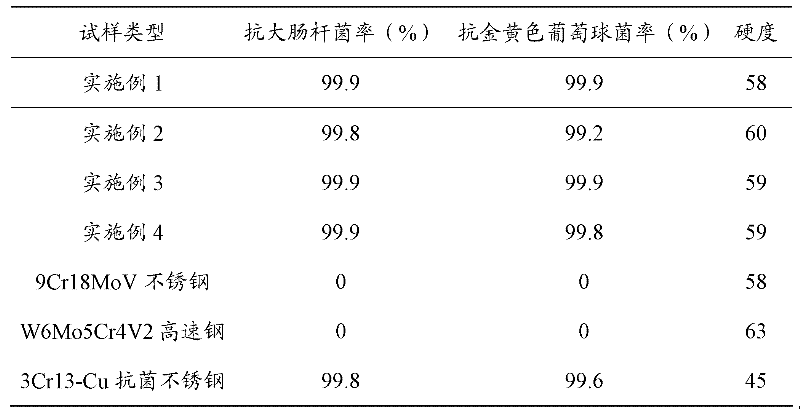

Super-hard copper-containing martensite antibiotic stainless steel

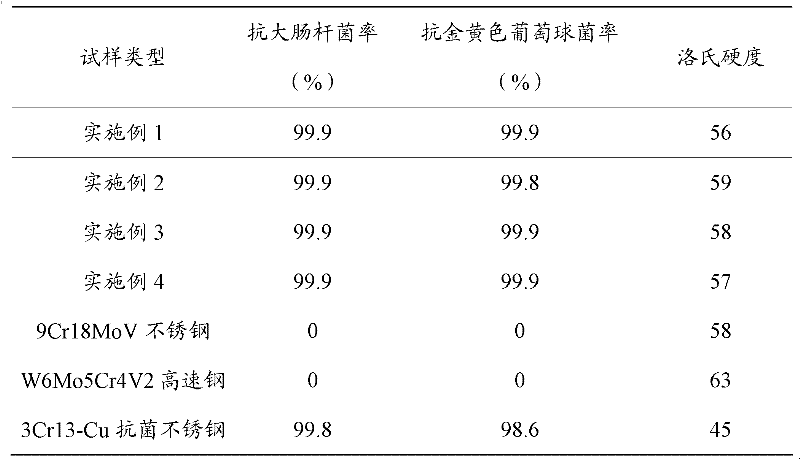

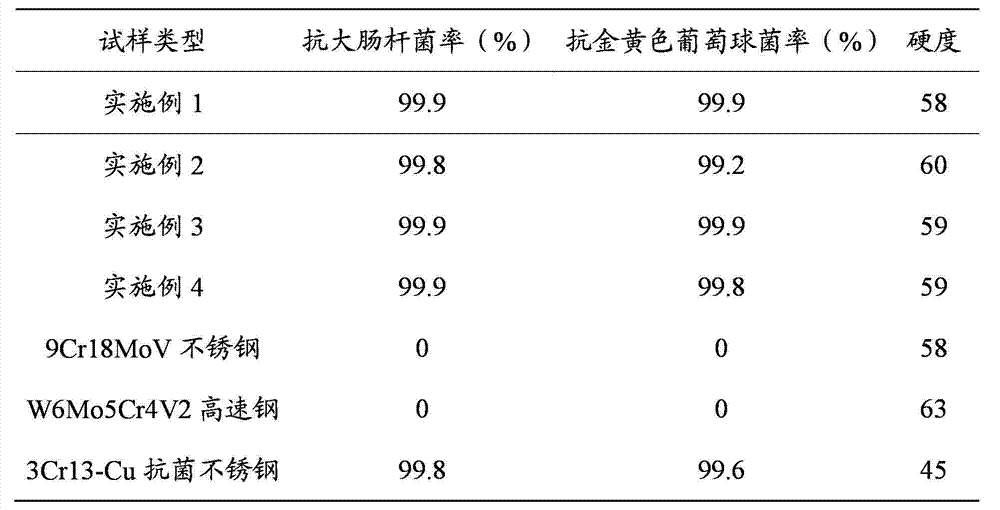

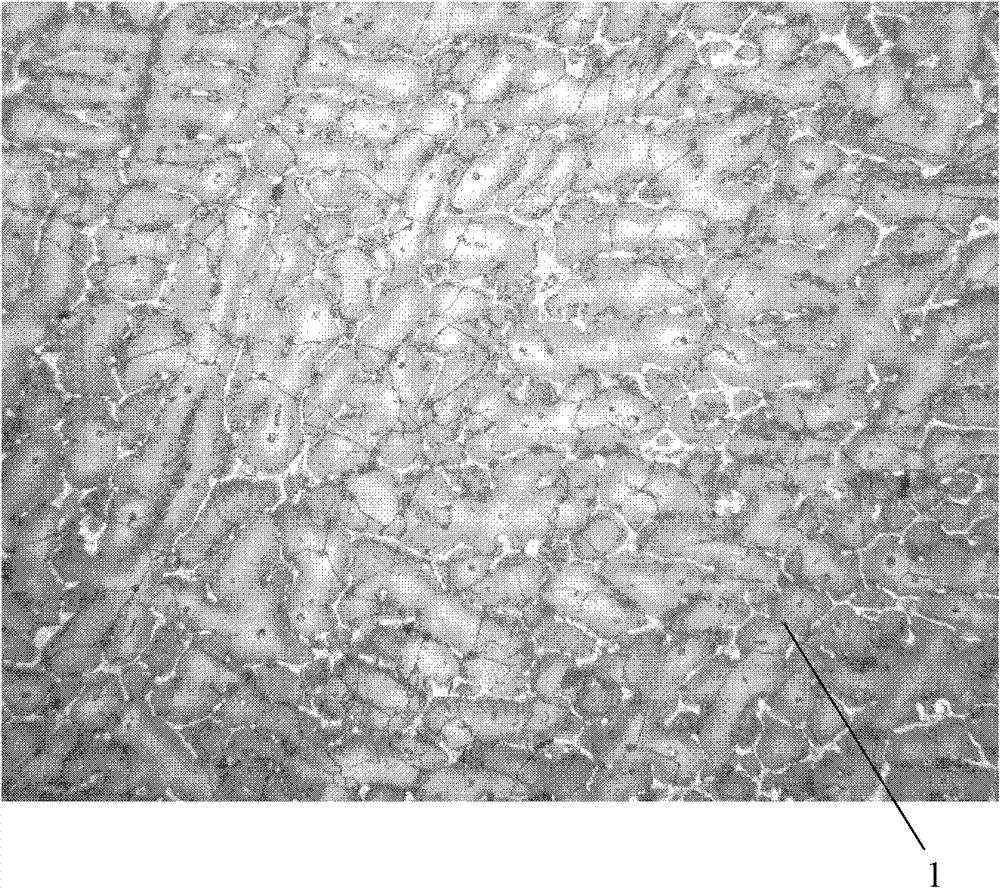

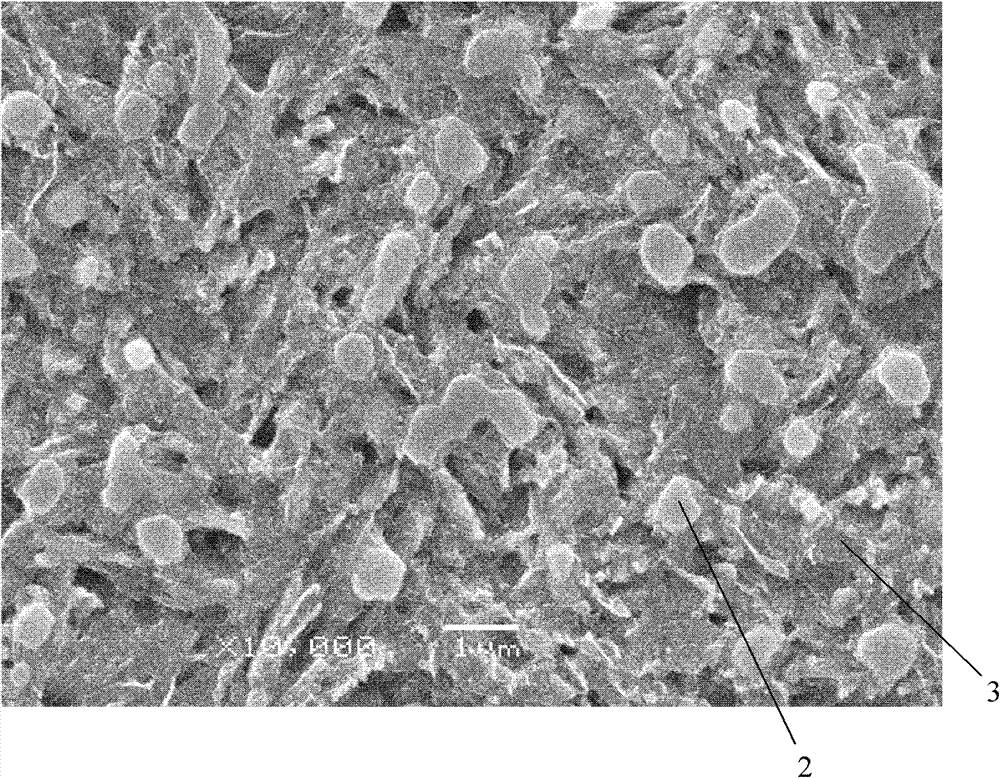

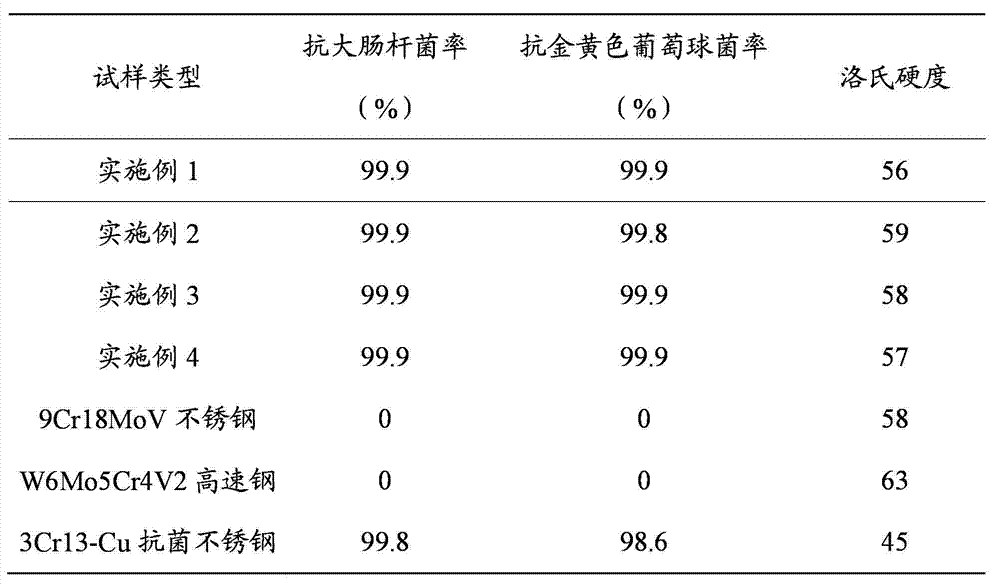

The invention relates to super-hard copper-containing martensite antibiotic stainless steel. The stainless steel comprises the following chemical components by weight percent: 0.8-1.2% of C, 16-18% of Cr, 1.0-3.0% of Mo, 0.1-1.0% of V, 1.0-3.0% of W, 0.5-3.0% of Ni, 2.5-3.5% of Cu, 0.1-1.0% of Re, less than or equal to 0.035% of S, less than or equal to 0.03% of P, less than or equal to 2.0% of other impurities and the balance of Fe. The copper-containing martensite antibiotic stainless steel has good antibiotic property, and the hardness and wear resistance of the stainless steel are greatlyimproved, thereby meeting the requirement of cutters manufactured in industries such as family, medical treatment and the like on the hardness and antibiotic property of the stainless steel.

Owner:SHANDONG JIANZHU UNIV

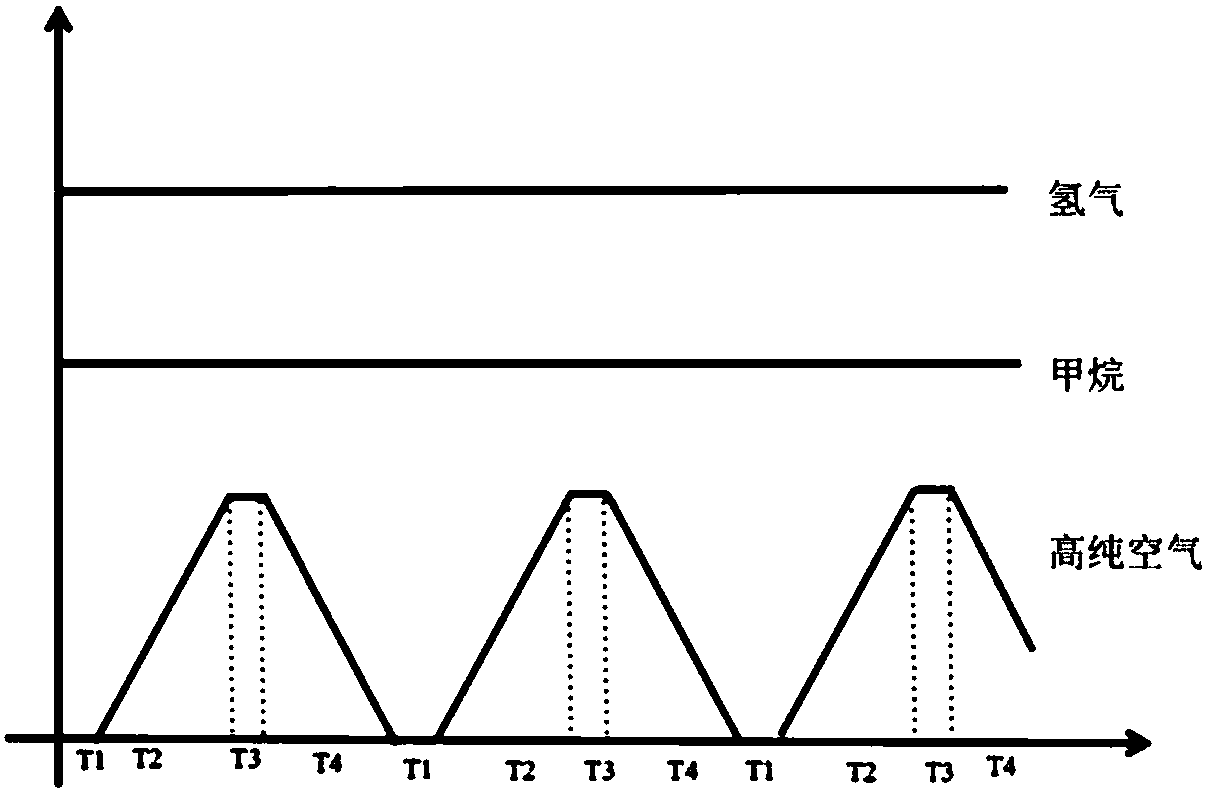

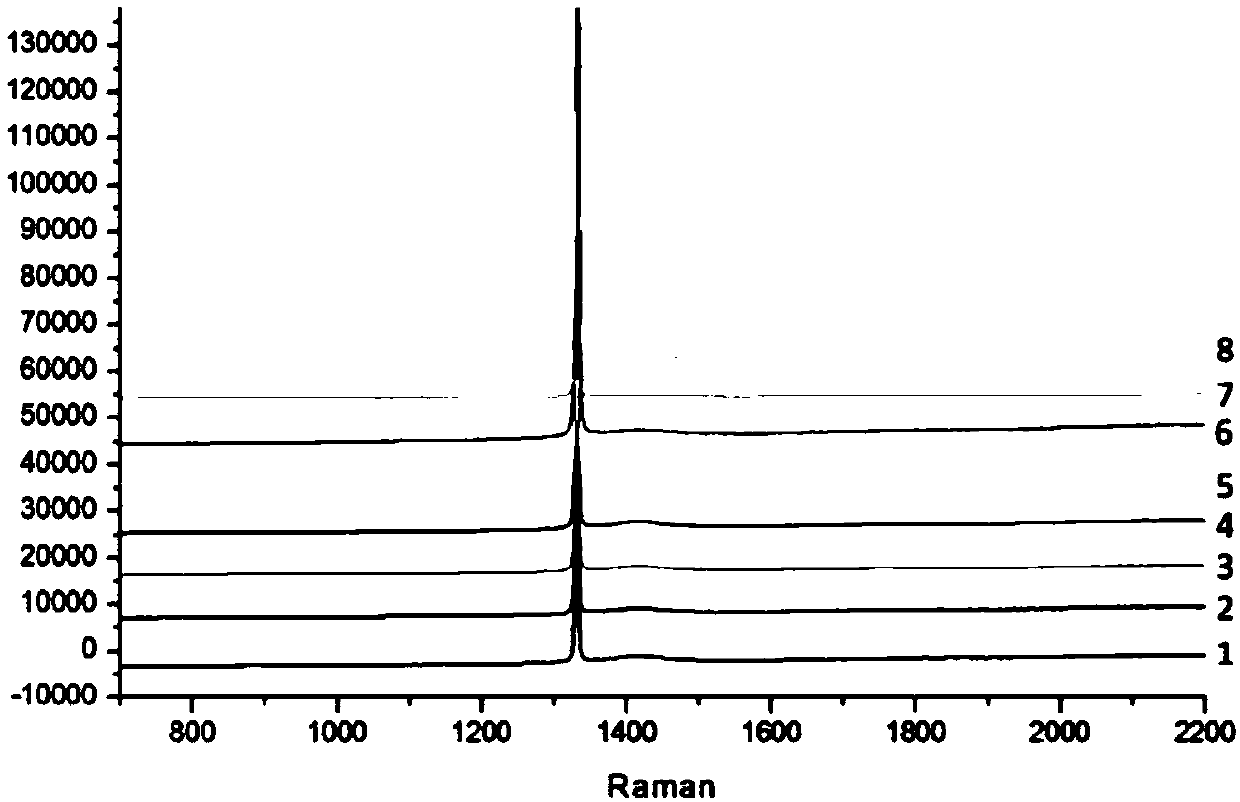

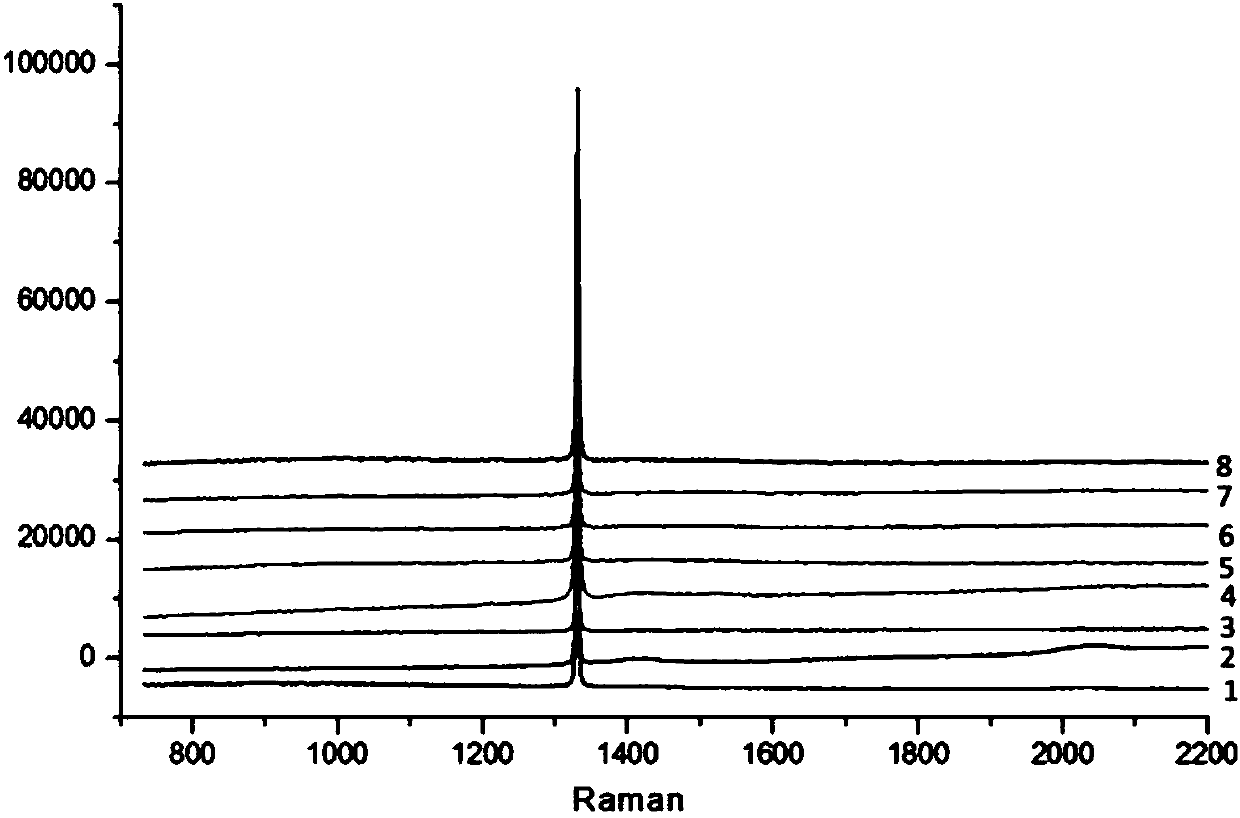

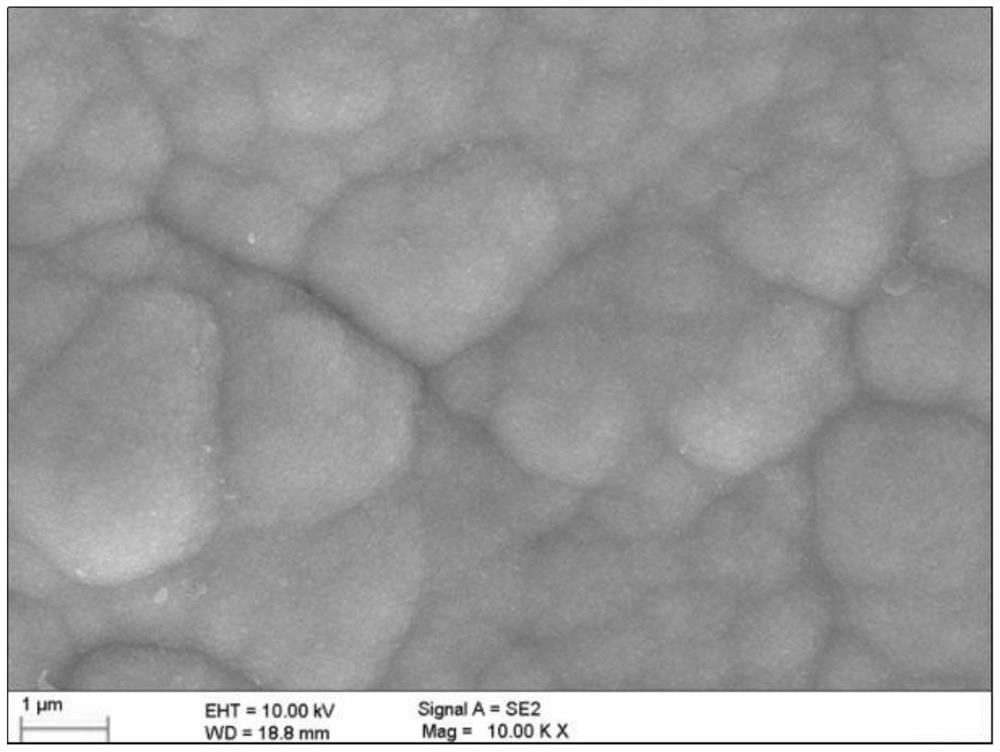

Gradient monocrystalline diamond and preparation method thereof

ActiveCN107740184AFast growthHigh hardnessPolycrystalline material growthFrom chemically reactive gasesHydrogenNitrogen

The invention relates to the field of growth of monocrystalline diamonds through a microwave plasma chemical vapor deposition method and in particular relates to a gradient monocrystalline diamond anda preparation method thereof. Microwave plasma chemical vapor deposition equipment is adopted and high-purity air is introduced in a hydrogen and methane mixed gas source according to a continuous gradient concentration, so as to realize alternating deposition of a high-quality monocrystalline diamond layer without nitrogen and a nitrogen-containing diamond layer; then the gradient monocrystalline diamond with high quality, high strength and good toughness is prepared.

Owner:湖北碳六科技有限公司

Multiple-wire submerged-arc welding technology for guaranteeing subsea pipeline steel pipe connector comprehensive performance

ActiveCN103433604AImprove performanceHigh tensile strengthArc welding apparatusWorkpiece edge portionsUltrasound attenuationLine tubing

The invention discloses a multiple-wire submerged-arc welding technology for guaranteeing subsea pipeline steel pipe connector comprehensive performance, and belongs to the technical field of pipeline steel welding. The multiple-wire submerged-arc welding technology solves the problem that impact energy of 28.8mmX65MS pipeline steel pipe weld metal and fusion lines and connector rigidity cannot meet the engineering requirements. Welding of an inner weld joint and welding of an outer weld joint are completed by the adoption of automatic three-wire submerged-arc welding, a first wire of the inner weld joint, a second wire of the inner weld joint and a weld wire of the outer weld joint are H08C weld wires, and a third wire of the inner weld joint is an H08E weld wire; the diameter of the first wire and the diameter of the second wire are respectively 4.0mm, and the diameter of the third wire is 3.2mm. The bevel angle of a connector should be as small as possible, the base metal fusion ratio is improved, the comprehensive performance of the connector is guaranteed through weld joint attenuation by base metal, the bevel angle is chosen to be 60 degrees to 70 degrees, and a truncated edge of 8-10mm is reserved. According to the multiple-wire submerged-arc welding technology, through optimization of the bevel angle and different matching of weld materials, the harsh requirements for the comprehensive performance of the steel pipe welding connector of a subsea pipeline with the ratio of thickness to radial dimension being 0.0354 are met, and the technology is economical, simple and convenient to apply, easy to implement and beneficial to popularization.

Owner:SHOUGANG CORPORATION

Plasma electrode and manufacturing method thereof

ActiveCN105252160ASmall impact on structureShorten brazing timePlasma welding apparatusWelding/cutting media/materialsOptoelectronicsTransmitter

The invention discloses a plasma electrode and a manufacturing method of the plasma electrode. The plasma electrode comprises an electrode body and a brazing type inner core. A cooling hole is formed in the electrode body. An inner core hole communicated with the cooling hole is formed in the head of the electrode body. The brazing type inner core is welded in the inner core hole of the electrode body. The brazing type inner core comprises an electrode body inner core and an electrode transmitter. A brazing hole is formed in the electrode body inner core. The electrode transmitter is welded in the brazing hole in the electrode body inner core. The plasma electrode and the brazing type inner core of the plasma electrode are of split structures, and the electrode body inner core is connected with the transmitter in a brazing manner and is then assembled with the electrode body. The influences of the high temperature on the overall structure of the electrode are small during welding, even if the electrode body inner core deforms due to the high temperature in the brazing process, no influence is caused on the overall shape of the product, and the overall product quality cannot be influenced.

Owner:常州特尔玛科技股份有限公司

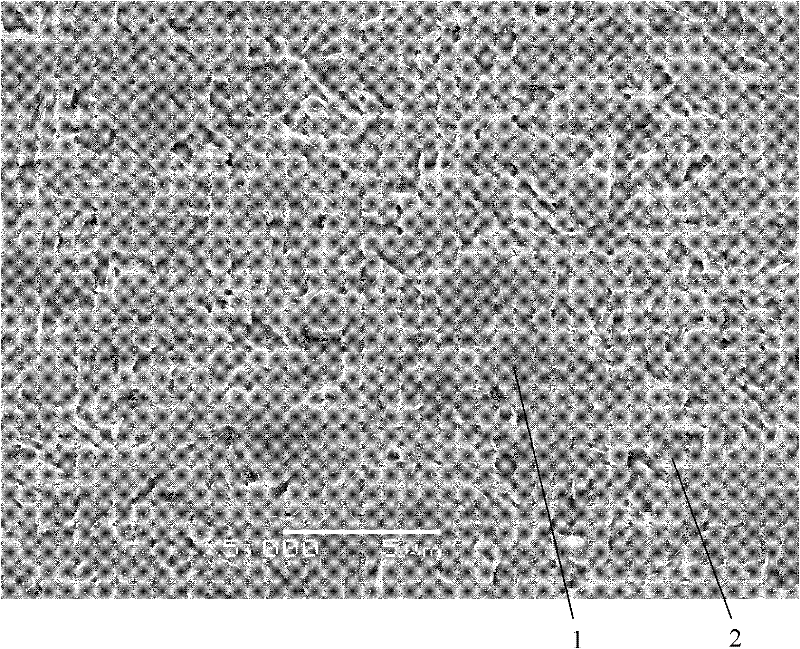

High-hardness silver-bearing martensite antibacterial stainless steel

The invention relates to high-hardness silver-containing martensite antibacterial stainless steel. The stainless steel comprises the following chemical components in percentage by weight: 0.8-1.2% of C, 16-18% of Cr, 1.0-3.0% of Mo, 0.1-1.0% of V, 1.0-3.0% of W, 0.7-1.2% of Al, 0.1-0.2% of Ag, 0.1-1.0% of Re, not more than 0.035% of S, not more than 0.03% of P, not more than 2.0% of other impurities and the balance of Fe. The silver-containing martensite antibacterial stainless steel disclosed by the invention has the advantages of excellent antibacterial property larger than 99.0%, largely improved hardness and wear resistance and not less than HRC57 of hardness, and meets the requirements of cutter manufacturing of household, medical and the like industries on hardness and antibacterialproperty.

Owner:SHANDONG JIANZHU UNIV

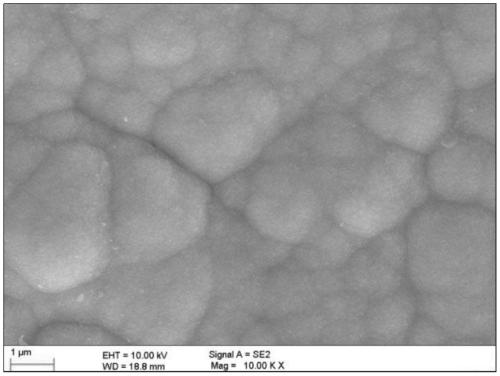

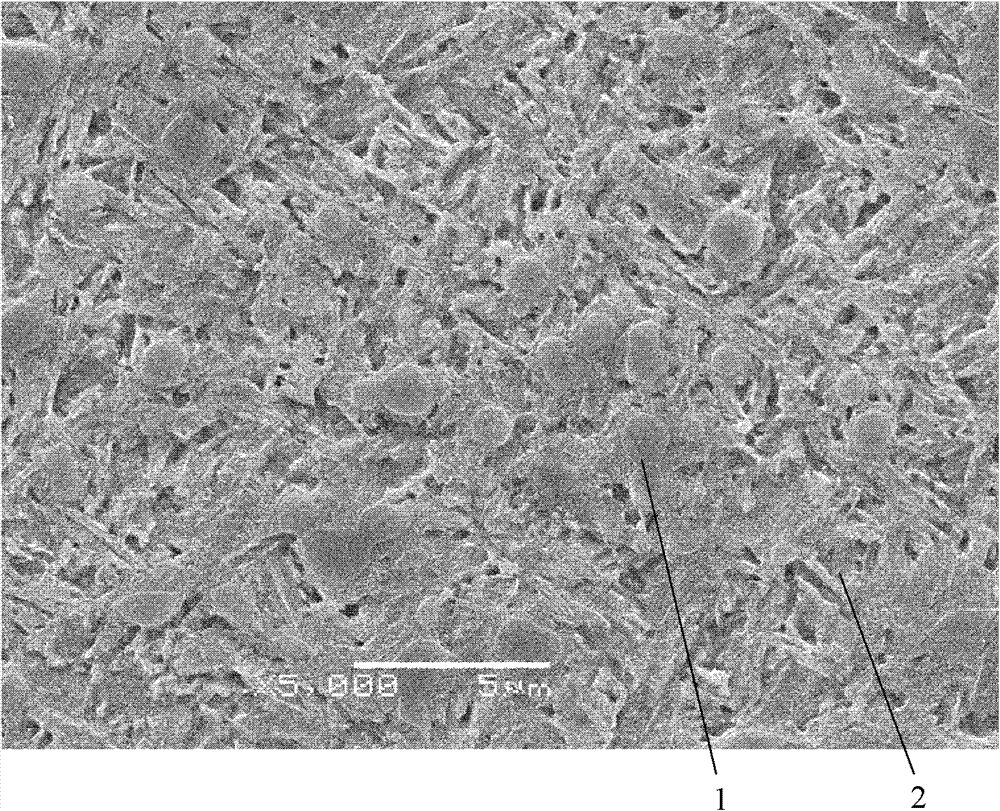

Three-phase structured cemented carbide and preparation method thereof

The invention provides three-phase structured cemented carbide and a preparation method thereof. The three-phase structured cemented carbide is characterized in that middle bonding phase cemented carbides are distributed on the surfaces of spherical particles of low bonding phase cemented carbides, and high bonding phase cemented carbides are distributed on the surfaces of particles of the middlebonding phase cemented carbides; the weight ratio of the low bonding phase cemented carbides is 62-85%, the weight ratio of the middle bonding phase cemented carbides is 5-18%, and the weight ratio ofthe high bonding phase cemented carbides is 10-20%; magnetic saturation of the low bonding phase cemented carbides is 145-160 emu / g, magnetic saturation of the middle bonding phase cemented carbidesis 140-155 emu / g, and magnetic saturation of the high bonding phase cemented carbides is 135-150 emu / g; drying mixing and granulating are conducted on power materials of the low bonding phase cementedcarbides and the middle bonding phase cemented carbides; then power materials of the high bonding phase cemented carbides are added for drying mixing and granulating; and the three-phase structured cemented carbide is obtained by low pressure sintering. The three-phase structured cemented carbide is used for oil cylindrical tooth alloy and is of a three-layer structure on a grain structure, and the abrasion resistance is high under the premise of continuous teeth.

Owner:武汉新锐合金工具有限公司 +1

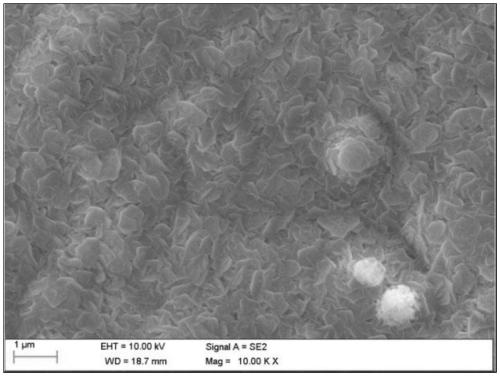

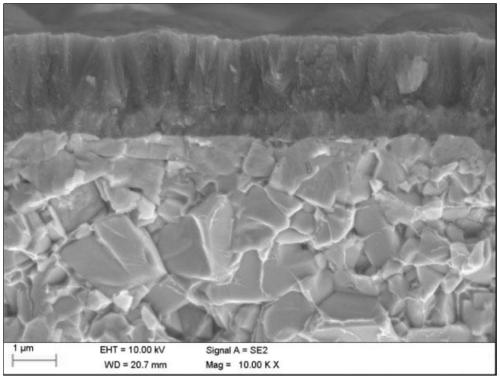

Method for preparing thermally sprayed ceramic coating of plunger of high-pressure cleaning machine

InactiveCN102212772AHigh hardnessHigh chemical inertnessMolten spray coatingTemperature resistanceCeramic coating

The invention discloses a method for preparing a thermally sprayed ceramic coating of a plunger of a high-pressure cleaning machine. A used plasma sprayed ceramic coating has the characteristics of high hardness, high chemical inertness and good high-temperature resistance. The hardness of the coating cannot be reduced below 540 degrees centigrade; due to low surface friction coefficient, the coating has a function of reducing friction of a friction pair; and due to good corrosion resistance, the coating can be applicable in various types of corrosive conditions and is especially applicable to being used in the plunger of the high-pressure cleaning machine.

Owner:德清县武康镇创智热喷涂厂(普通合伙)

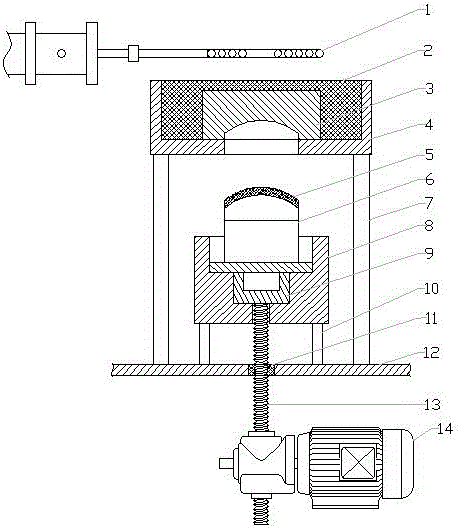

Method for preparing tungsten carbide wear-resistant coating needed for swing head of swing forging machine through induction heating

ActiveCN106180938AAchieve localized heatingReduce hardnessHeating appliancesSoldering auxillary devicesEpoxyWear resistant

A method for preparing a tungsten carbide wear-resistant coating needed for a swing head of a swing forging machine through induction heating includes the steps that a composite powder pasty prefabricated layer which is blended with epoxy resin and contains tungsten carbide powder and self-fluxing alloy powder is pasted on a metal matrix; then BNi2 solder is pasted on the upper surface of the tungsten carbide composite powder pasty prefabricated layer in the same way; and the metal fabricated part is placed in an argon gas protection induction device to be subjected to induction heating. According to the method, the adopted experiment measures are simple and feasible, the prepared tungsten carbide wear-resistant coating is low in cost, simple and feasible, the strength of the matrix is high, and because holes are formed for storing oil, the wear resistance of the coating is remarkably improved.

Owner:NANCHANG INST OF TECH

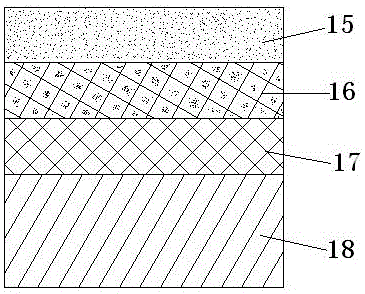

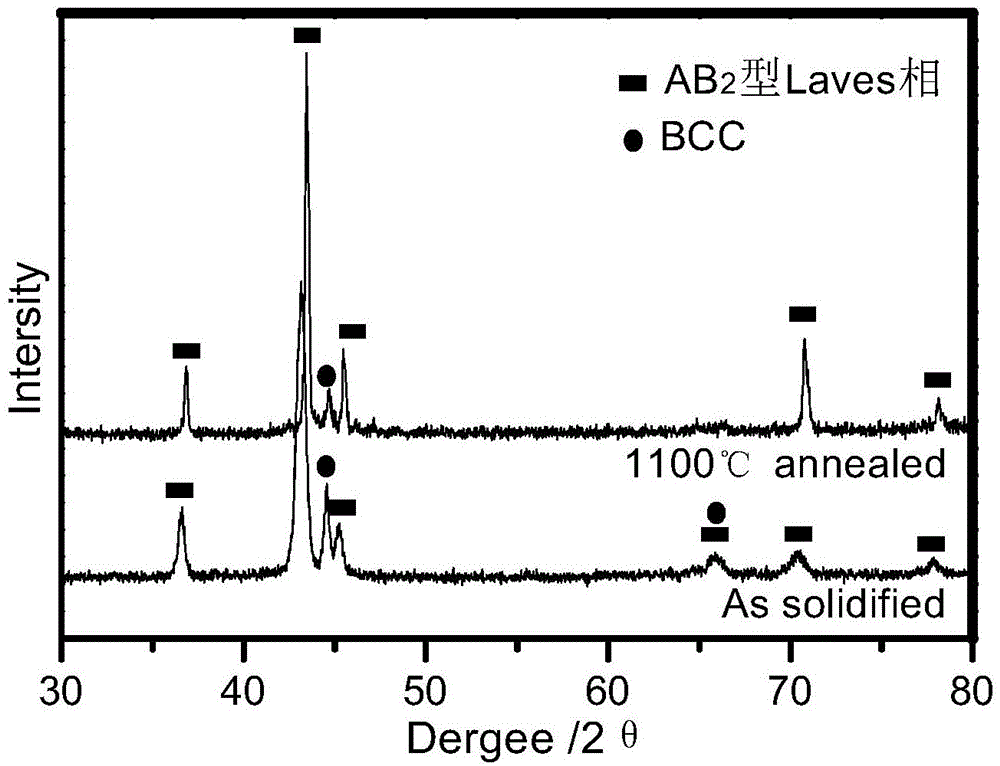

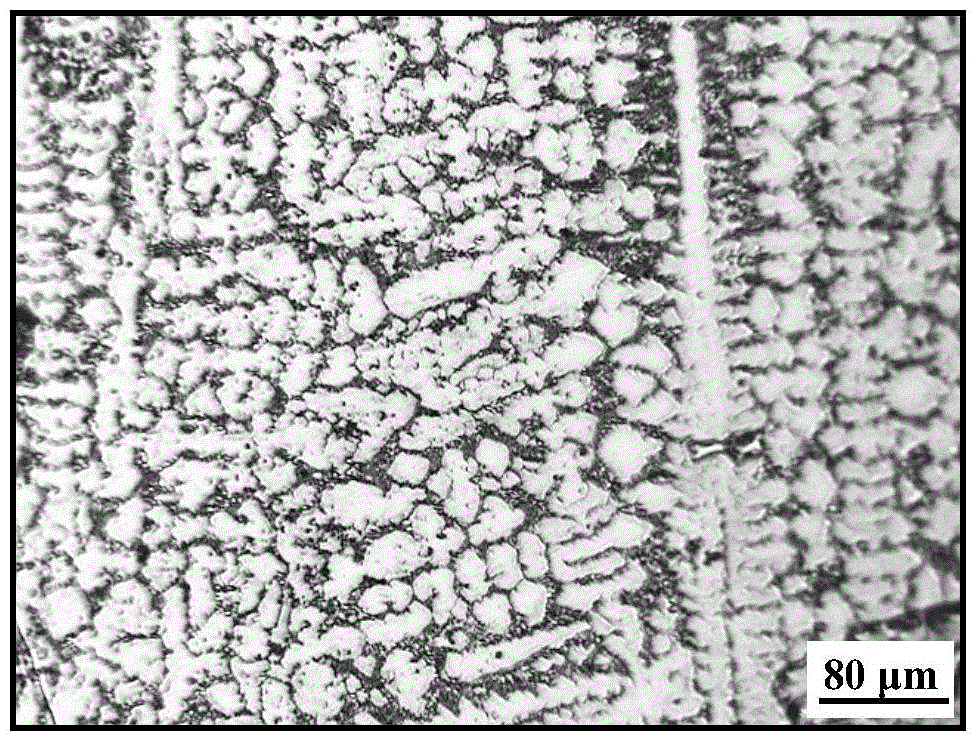

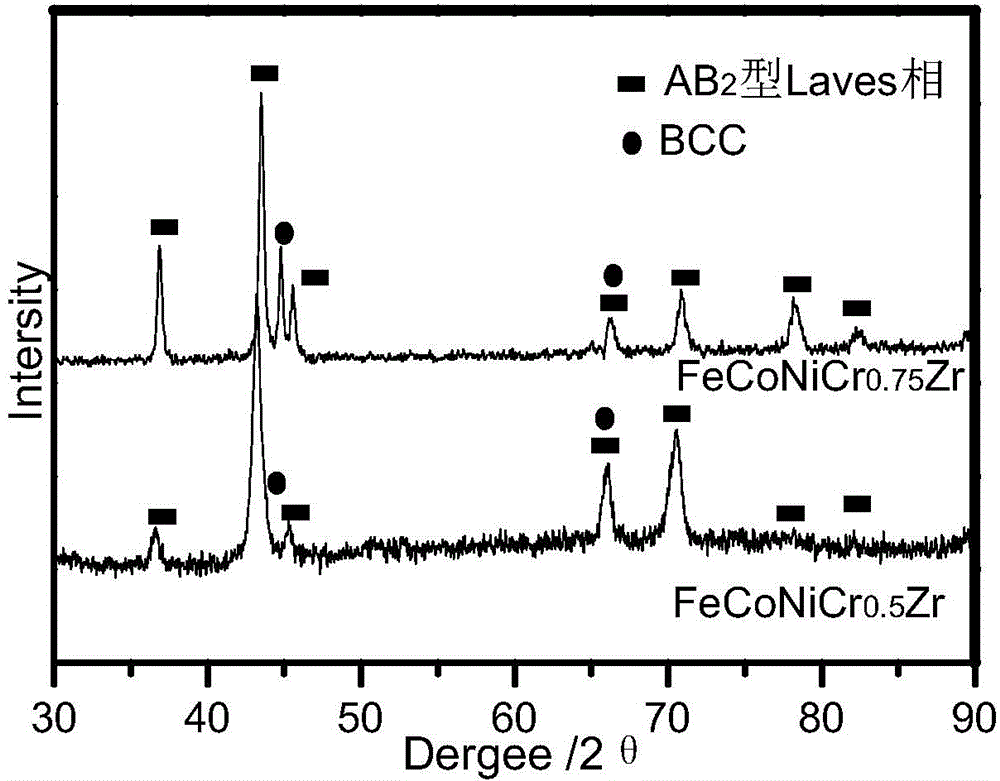

Multiple-principal-component Laves-base intermetallic compound and preparation method thereof

ActiveCN104818418AGood high temperature aging strengthening effectHigh hardnessMaterial DesignElectric arc furnace

The invention discloses a multiple-principal-component Laves-base intermetallic compound and a preparation method thereof, belonging to the field of alloy material design. The component element is FeCoNiCrxZr, wherein x is 0.5-1. The principal phase of the multiple-principal-component Laves-base intermetallic compound obtained by arc smelting and heat treatment is a Laves intermetallic compound, or the Laves phase base contains a small amount of bcc-structure solid solution. Due to the high entropic effect and topology structure features of the multiple-principal-component Laves phase, the multiple-principal-component Laves-base intermetallic compound has the advantages of superhigh hardness, superhigh structural stability, superhigh tempering softening resistance and favorable high-temperature aging reinforcement effect, and is applicable to the field of 1100-DEG C-below high-temperature structure materials in industry.

Owner:菏泽市金沃泰化工有限公司

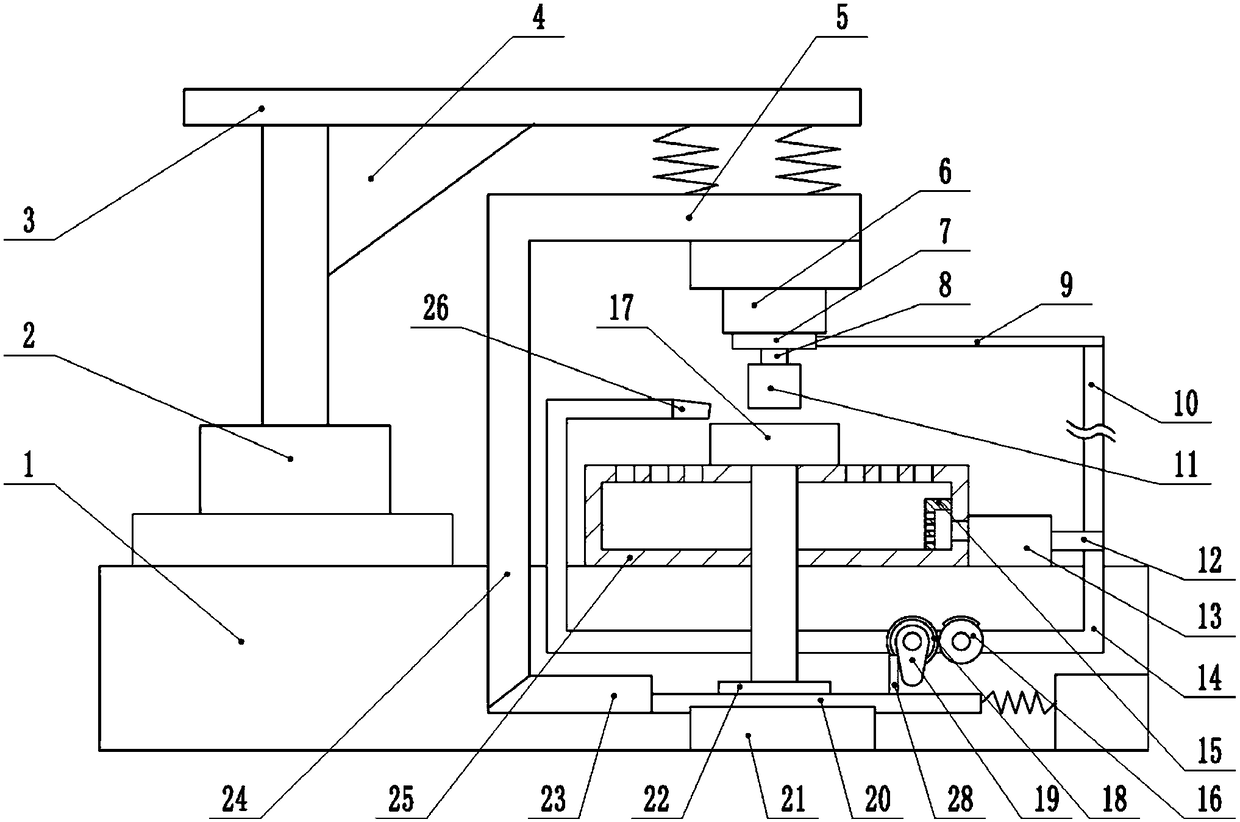

Grinding device for automobile accessories

ActiveCN108500770AReduce the difficulty of turningImprove grinding efficiencyEdge grinding machinesGrinding carriagesEngineeringHardness

The invention discloses a grinding device for automobile accessories. The grinding device comprises a frame. A support plate is arranged below a workbench. A circular ring tube is fixed on the supportplate. A rotating shaft is rotationally connected in the inner circle of the circular ring tube. A through hole is formed in the rotating shaft. An open hole is formed in the circular ring tube. A grinding head is fixed on the rotating shaft. Radiating holes are formed in the grinding head. The through hole is communicated with the radiating holes. A connecting pipe is connected to the circular ring tube. A collecting box is fixed on the frame. Collecting holes are uniformly distributed in the collecting box. A rotating rod is rotationally connected to the collecting box. A fixing seat is fixed on the rotating rod. A negative-pressure pump is fixed on the frame. The negative-pressure pump is communicated with the collecting box. The negative-pressure pump is communicated with a gas outletpipe. A driving mechanism is arranged on the frame. Compared with the prior art, by the adoption of the scheme, the gas output by the negative-pressure pump can carry heat generated by the grinding accessories out of the grinding head, the hardness of the grinding head cannot be reduced, and therefore the grinding quality is ensured; and through the driving mechanism, the accessories rotate intermittently, and the grinding efficiency is greatly improved.

Owner:宁波隆锐机械制造有限公司

Cutting tool and manufacturing method thereof

ActiveCN110318039ASimple and intuitive visual judgment basisBeautiful appearance and colorChemical vapor deposition coatingSuperimposed coating processWear resistanceMaterials science

The invention discloses a cutting tool and a manufacturing method thereof. The cutting tool comprises a substrate and a single layer of coating or multiple layers of coatings, the single layer of coating or the multiple layers of coatings coat the substrate, the single layer of coating or the multiple layers of coatings internally at least comprises one layer of (AlxSiyTi1-x-y)N coating, wherein xis greater than or equal to 0.70, y is greater than 0 and less than or equal to 0.1. According to the cutting tool and the manufacturing method thereof, the (AlxSiyTi1-x-y)N coating coats the cuttingtool, high aluminum of the coating is ensured, meanwhile, an amorphous coated nanocrystalline structure is formed due to doping of Si elements, the coating structure is refined, the high-temperaturehardness of the coating is improved, the oxidation resistance of the coating is not reduced, and meanwhile, the wear resistance of the coating is improved.

Owner:GANZHOU ACHTECK TOOL TECH

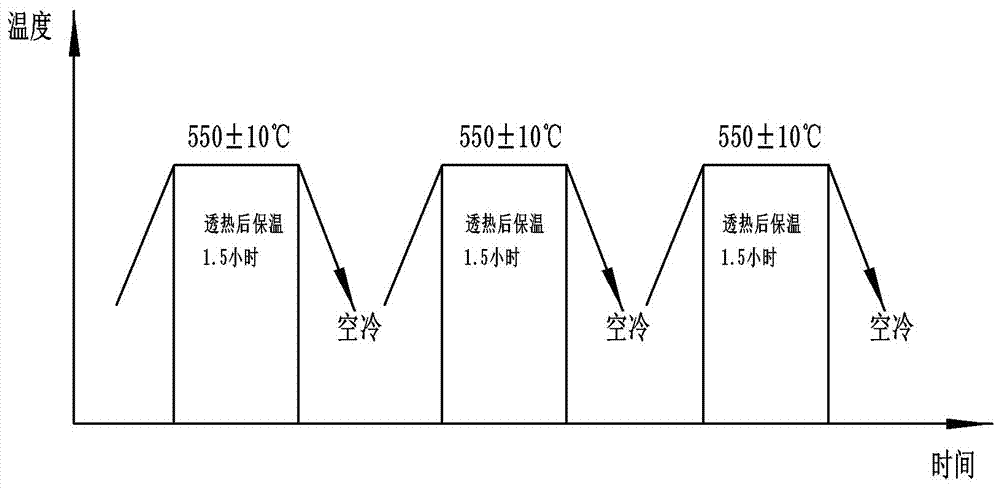

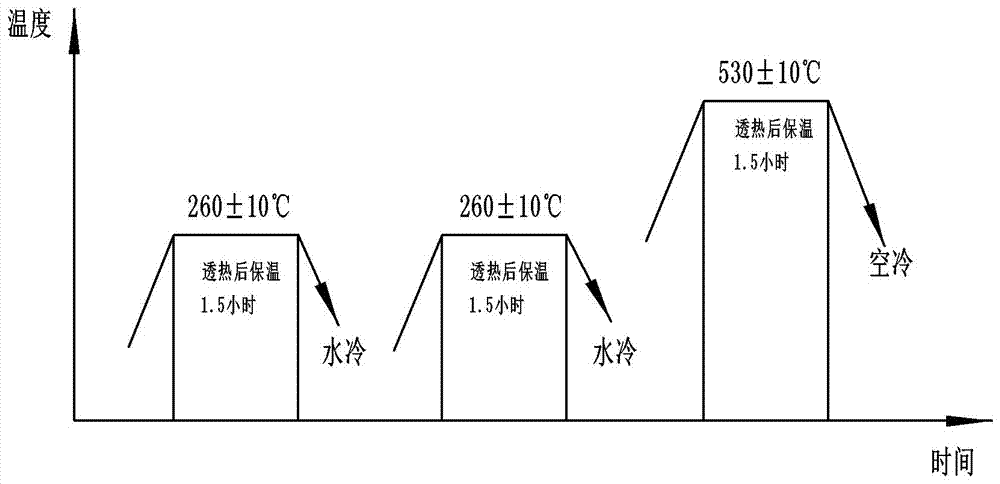

Novel tempering technology adopted after high-speed steel quenching

The invention belongs to the technical field of heat treatment of iron-base alloys and particularly relates to a novel tempering technology adopted after high-speed steel quenching. The novel tempering technology includes the following steps that firstly, M2 high-speed steel is heated to 1210 DEG C to 1230 DEG C, the product is subjected to austenitizing, heat preservation is conducted for 8 min to 12 min, and cooling is conducted to the temperature lower than the martensite start temperature by 5 DEG C to 80 DEG C; secondly, the first time of tempering is conducted, wherein after the first step is completed, the product is heated to 250 DEG C to 270 DEG C, heat preservation is conducted for 80 min to 100 min, and then hardening is conducted; thirdly, the second time of tempering is conducted, wherein after the first time of tempering, the product is heated to 250 DEG C to 270 DEG C again, heat preservation is conducted for 80 min to 100 min, and then hardening is conducted; and fourth, the third time of tempering is conducted, wherein after the second time of tempering is conducted, the product is heated to 520 DEG C to 540 DEG C, heat preservation is conducted for 80 min to 100 min, and then air cooling is conducted. The novel tempering technology is used for machining the product, the toughness of the product can be improved while the product hardness is not reduced, and the service life of the product can be prolonged by about 17% to 24%; and in addition, due to the fact that the tempering temperature is greatly reduced, energy consumption is reduced by about 40% to 46%, and the production cost of an enterprise is effectively reduced.

Owner:重庆派斯克刀具制造股份有限公司

Powder material for laser manufacturing of composite lining plate for rolling mill house and mill roll bearing block and manufacturing method of lining plate

ActiveCN109868469ALow costGood cladding performanceMetallic material coating processesMachiningHeat treated

The invention discloses a powder material for laser manufacturing of a composite lining plate for a rolling mill house and a mill roll bearing block and a manufacturing method of the lining plate. Thepowder material is prepared from the following components in percentage by mass: 0.1%-0.2% of C, 15%-23% of Cr, 0.2%-0.7% of Si, 0.5%-2% of Mo, 2%-3% of Ni, 0.2%-0.7% of B, 0.2%-1.0% of the Mn, 0.02%-0.2% of MnN, 0.1%-0.5% of Y, and the balance of Fe; and the powder material is fused on a substrate through a laser, and subsequent heat treatment and machining are conducted to complete manufacturing of the lining plate. According to the powder material for laser manufacturing of the composite lining plate for the rolling mill house and the mill roll bearing block and the manufacturing method ofthe lining plate, corrosion resistance of the prepared lining plate is outstanding, the service life of the lining plate is at least 2 times an original lining plate, and the production cost is lowered.

Owner:沈阳大陆激光工程技术有限公司

Preparation method of 7CrSiMnMoV diameter-expanding die sheet

The invention discloses a preparation method of a 7CrSiMnMoV diameter-expanding die sheet. The preparation method comprises the following steps: forging a 7CrSiMnMoV alloy steel billet subjected to electroslag remelting and refining; carrying out isothermal annealing on a 7CrSiMnMoV alloy steel forging; carrying out hole plugging on a 7CrSiMnMoV alloy steel diameter-expanding die sheet subjected to rough machining, and coating with a high-temperature-resistant anti-oxidation coating; putting the 7CrSiMnMoV alloy steel diameter-expanding die sheet into an atmosphere protection heating furnace; feeding nitrogen gas, ammonia gas and methanol, and heating; feeding nitrogen gas and methanol for protection, and austenitizing; quenching by using nitrate; and carrying out reshaped tempering. The 7CrSiMnMoV diameter-expanding die sheet prepared according to the invention does not have the defects such as quenching cracks, decarburization and the like, has excellent quenching depth, bending strength, compressive strength, impact toughness and hardness and the like, and can meet the needs of machining; and the 7CrSiMnMoV diameter-expanding die sheet is not deformed after being machined, therefore, the die sheet can meet the requirements of stably carrying out diameter expanding on 20000-30000 tubes.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of high-hardness and high-strength expanding pyramid of mechanical expanding mill

The invention discloses a preparation method of a high-hardness and high-strength expanding pyramid of a mechanical expanding mill. The preparation steps are as follows: (1) smelting, spheroidizing, inoculating and casting; (2) annealing; (3) plugging holes with refractory clay and asbestos, blocking grooves, sealing center holes so that the preparation works are completed; (4) charging the expanding pyramid of which the large end downwards faces into a tooling of which the bottom is a plane, placing the tooling inside a well-type heating furnace and drying the refractory clay so as to complete the charging operation; (5) by controlling the temperature-raising speed and the temperature-raising temperature, heating; (6) by controlling the temperature-raising speed, the temperature-raising temperature and the temperature-raising time, austenitizing; (7) by controlling the time and temperature, carrying out three-stage quenching; and (8) by controlling the time and temperature, tempering. The high-hardness and high-strength austenitic-bainitic nodular cast iron expanding pyramid subjected to above treatment steps has no defects such as quenching cracks, high quenching depth, good compressive strength, impact toughness and hardness, can meet the needs of machining and cannot be deformed after machining. The expanding pyramid is suitable for preparing steel tubes having steel grade of X60-X80 and wall thickness of 10-18 mm.

Owner:HUNAN UNIV OF SCI & TECH

Method for removing deposited carbon from aero-engine thrust augmentation fuel manifold

InactiveCN110961405AHardness does not decreaseNo damage to performanceCleaning using liquidsProcess engineeringCarbon deposit

The invention discloses a method for removing deposited carbon from an aero-engine thrust augmentation fuel manifold, and belongs to the technical field of aero-engines. According to the method basedon the oxidation-reduction effect of high-temperature alkali liquor, deposits as deposited carbon in the surface of a part is loosened by oxidation-reduction and thus peeled from the matrix surface, deposited carbon in the thrust augmentation fuel manifold is separated from the pipe wall by oscillation and taken away from an oil inlet pipe connecting nozzle through oil by means of an ultrasonic oscillation reverse suction force, and the deposited carbon is removed. Via the method, it is guaranteed that a chromium layer of the oil inlet pipe connecting nozzle is not damaged, deposited carbon ofthe novel engine thrust augmentation fuel manifold can be efficiently removed in a quality-guaranteeing mode, and the qualified rate of deposited carbon removal of the thrust augmentation fuel manifold reaches 95%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

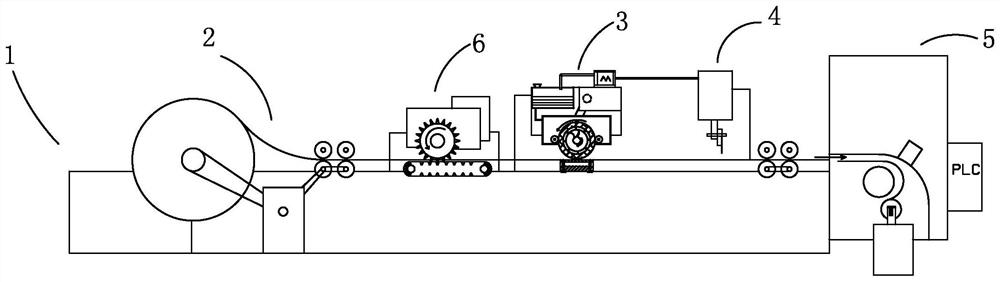

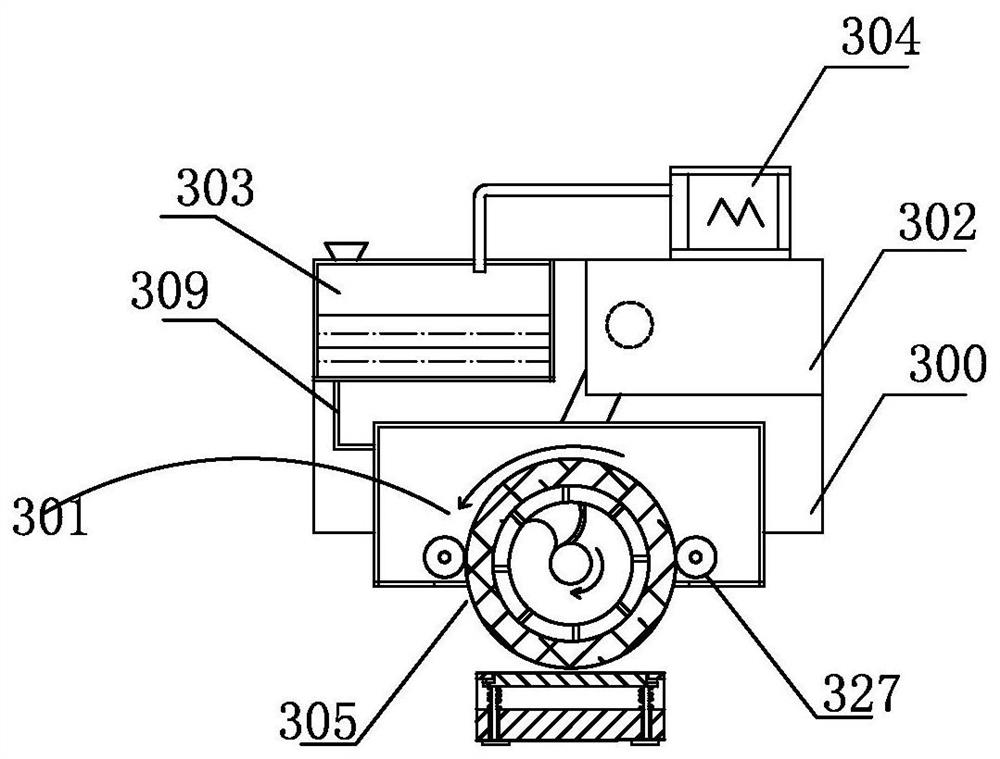

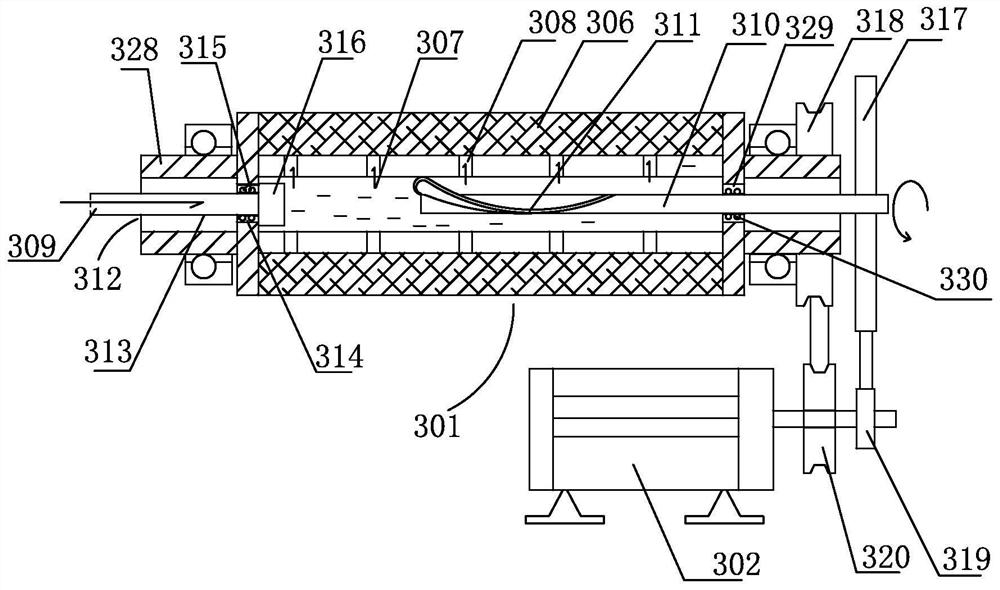

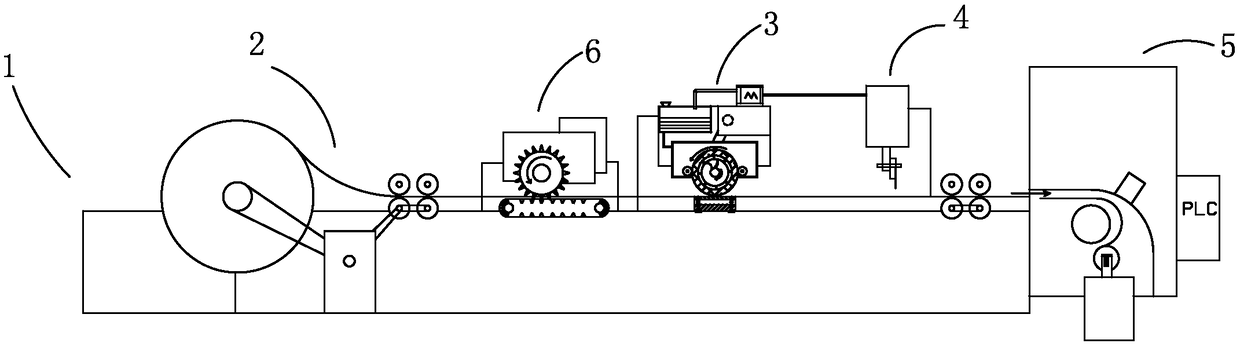

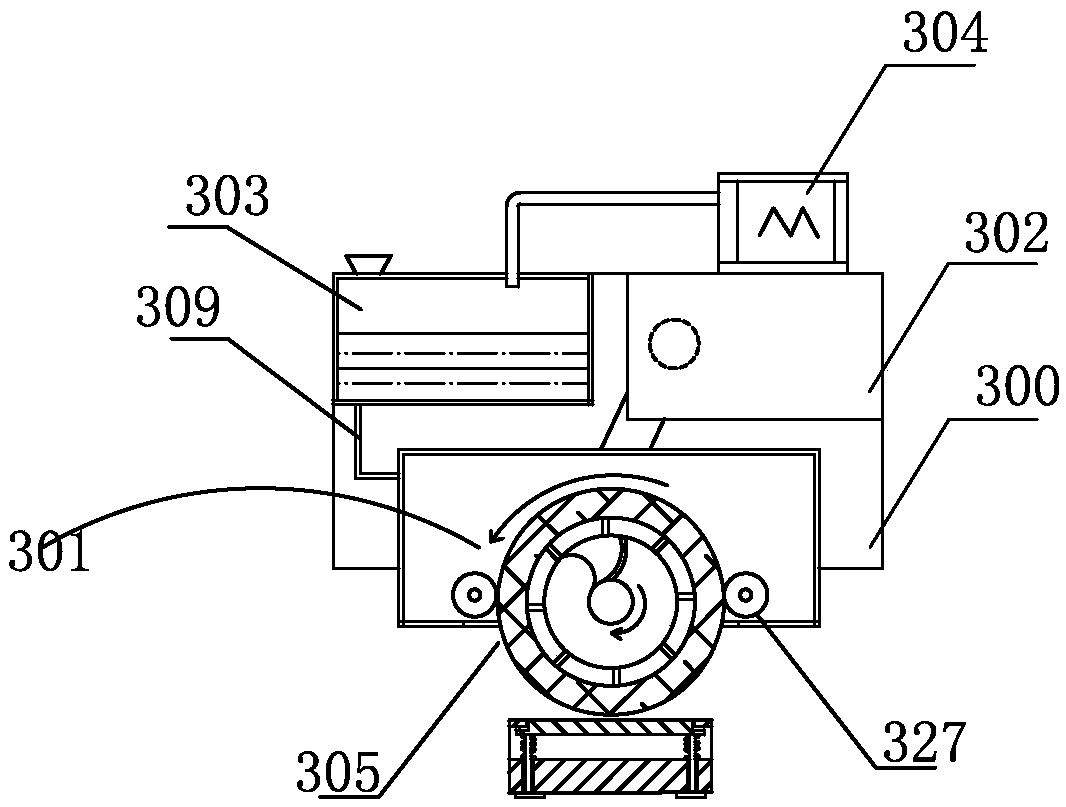

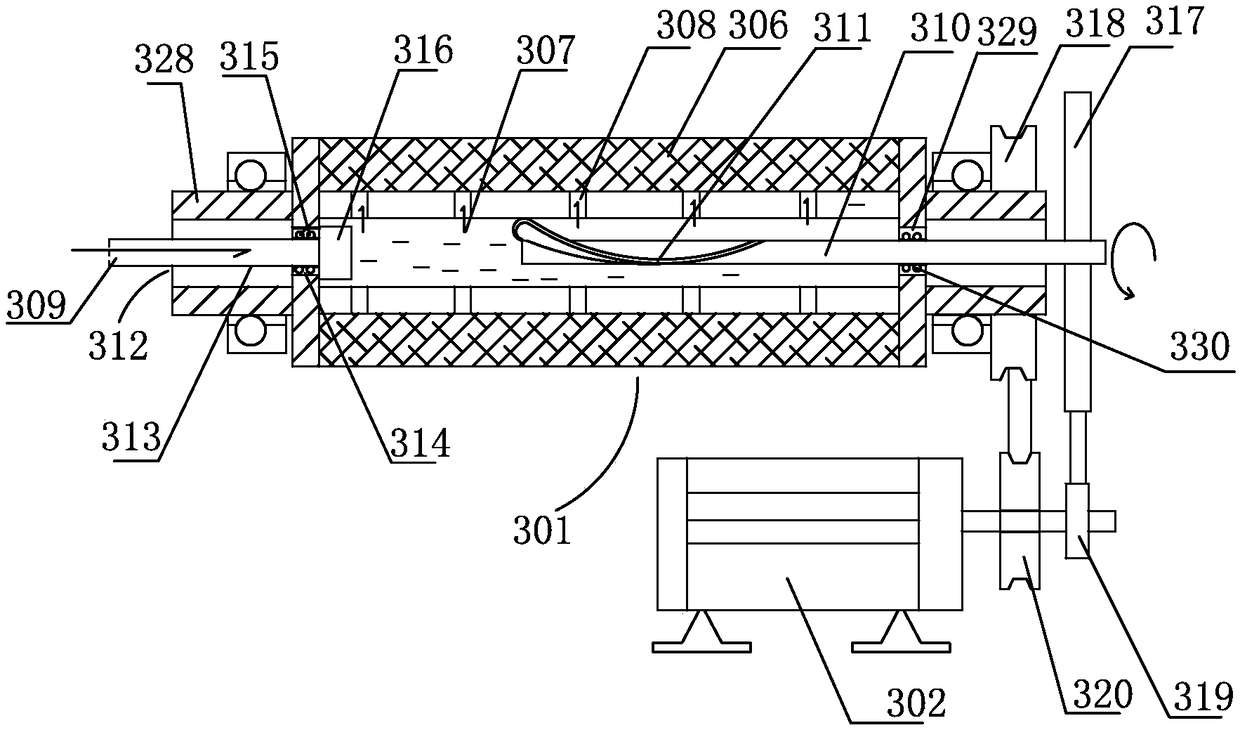

A roll device for making fireworks paper rolls

The invention provides a winding drum device for manufacturing firework and firecrackers paper drums. The device comprises a rack, the paper feeding mechanism arranged on the rack, an impression mechanism, a glue coating mechanism, a cutting mechanism and a winch mechanism, wherein the impression mechanism is used for impressing the roll paper into a corrugated shape, so that the amount of rolledpaper is reduced, and meanwhile, enough hardness of the rolled paper drums can be guaranteed; the glue coating mechanism comprises a hollow coating roller body and a brush layer which is arranged on the outer side wall of the coating roller body and is made of a flexible material and provided with a plurality of gaps; glue is fed into an inner cavity of the coating roller body through a glue conveying pipe, and the glue is uniformly smeared on the brush layer through a glue channel; finally, the brush layer is in contact with the roll paper, the glue coats the surface of the roll paper. The use amount of watering can be saved, and the glue can uniformly coat the roll paper as well, the rolled paper drums can be package from being adhered to one another, and the paper drums are easier to dry.

Owner:上栗县梦幻烟花制造有限公司

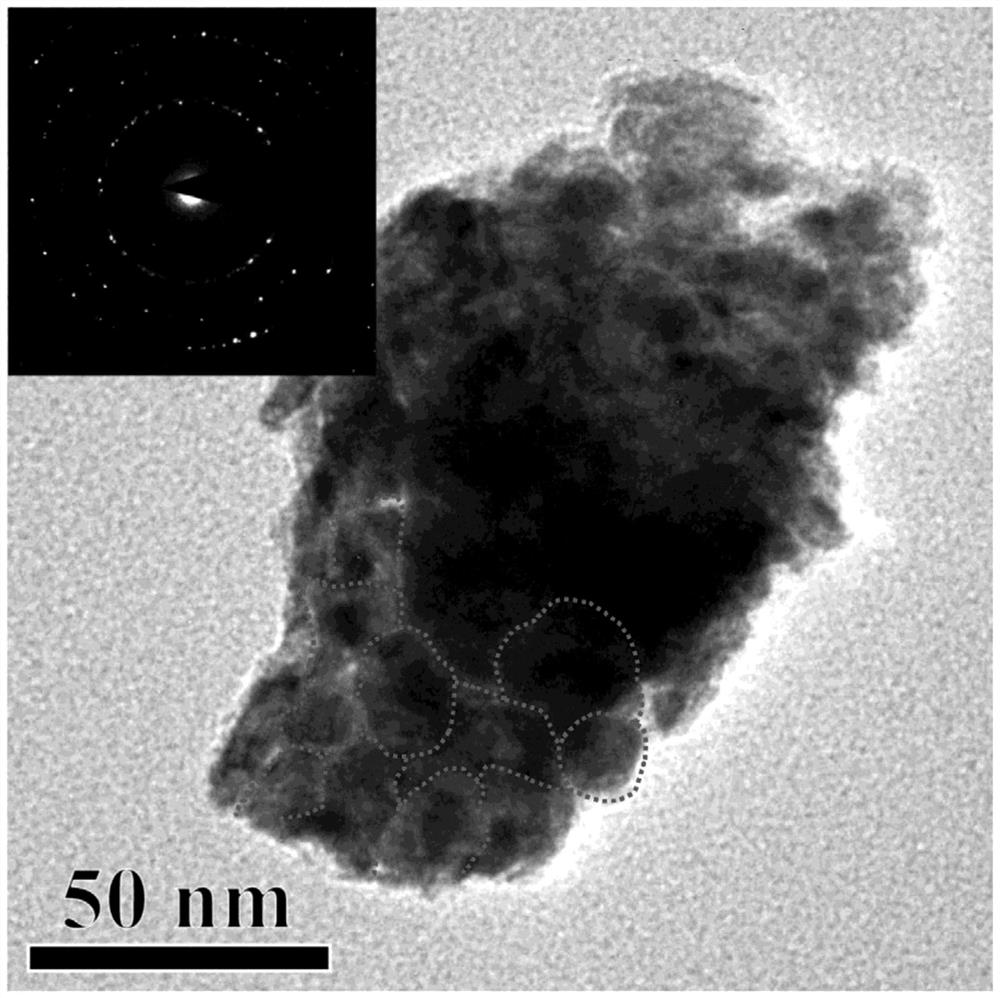

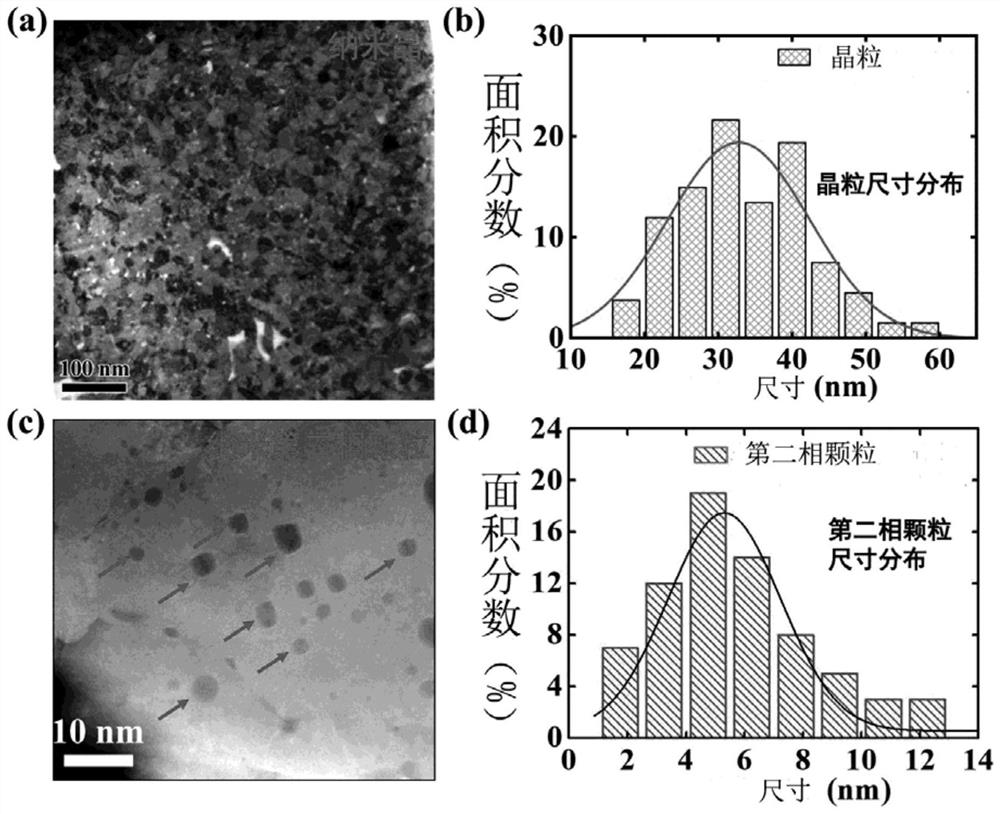

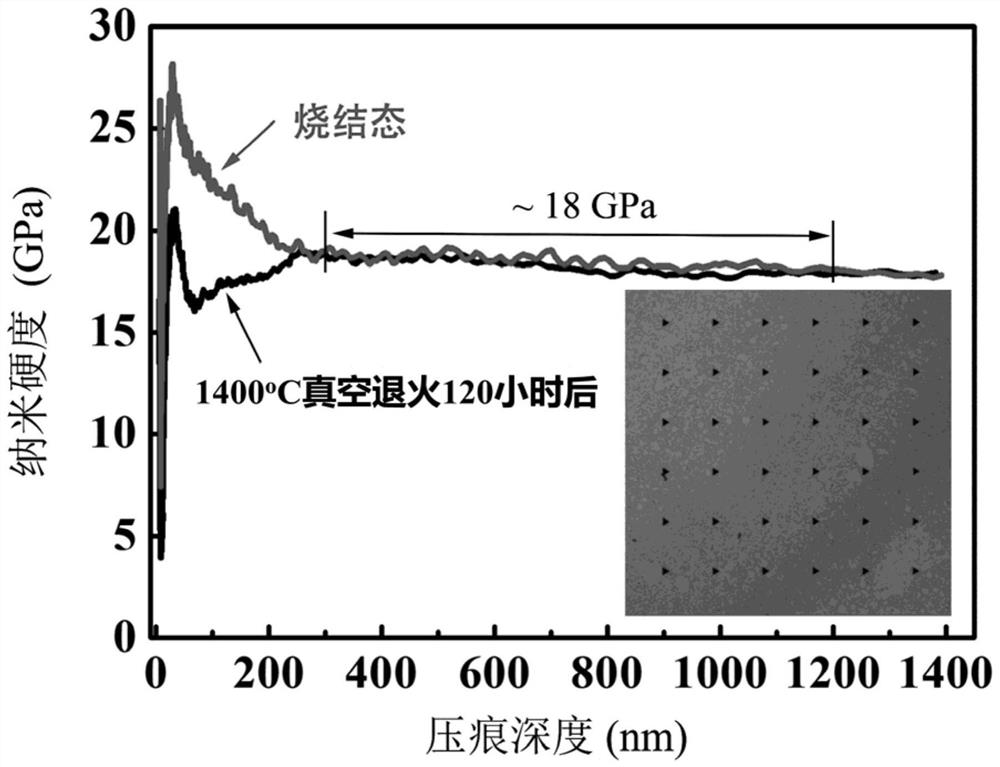

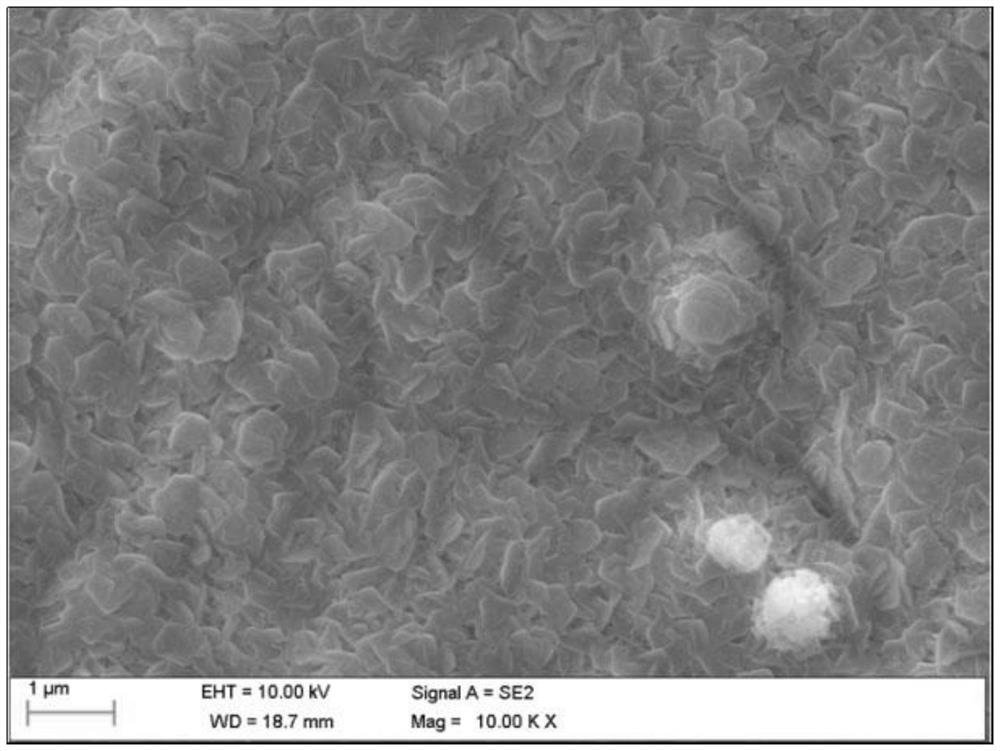

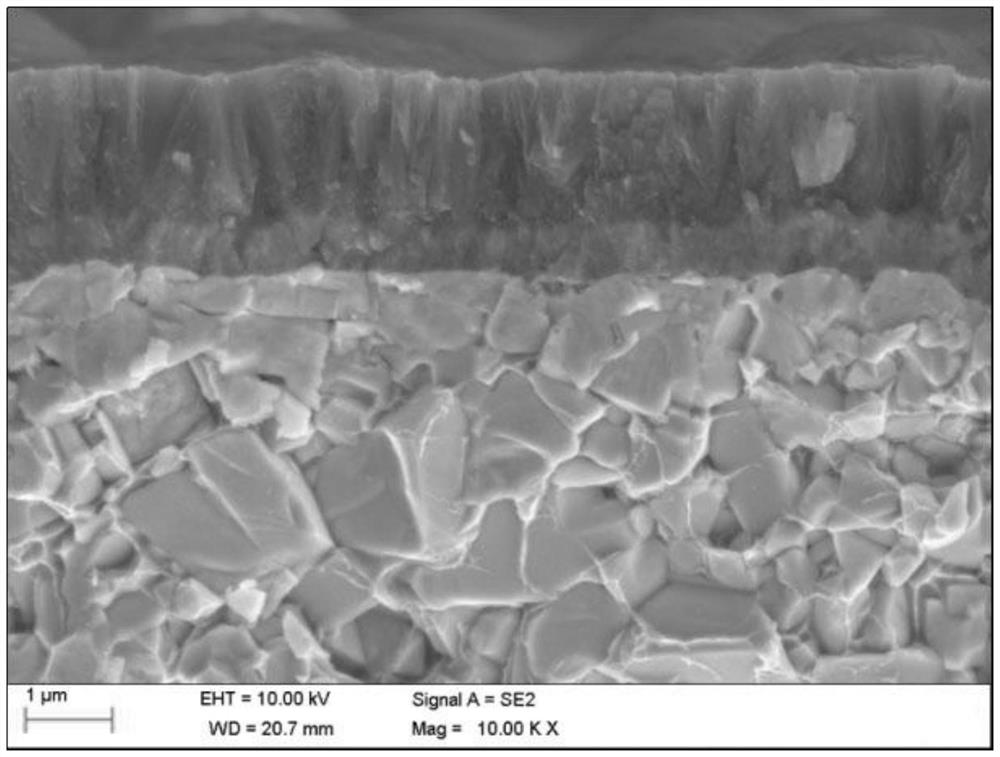

Double-nanostructure tungsten alloy with good high-temperature stability and preparation method and application thereof

The invention belongs to the technical field of material science, and discloses a double-nanostructure tungsten alloy with good high-temperature stability and a preparation method and application thereof. The double-nanostructure tungsten alloy comprises the following raw material components: tungsten, titanium and zirconium carbide. The preparation method of the double-nanostructure tungsten alloy comprises the following steps of: (1) raw material mixing: weighing the components according to the formula ratio, and performing ball milling in a protective atmosphere to realize alloying and nanocrystallization to obtain nanocrystalline alloy powder; and (2) sintering and forming: putting the nanocrystalline alloy powder obtained in the step (1) into a mold, and performing pressure sinteringto prepare the double-nanostructure tungsten alloy. The sizes of tungsten crystal grains and second phase dispersed particles in the double-nanostructure tungsten alloy are both nanoscale, and the double-nanostructure tungsten alloy has good hardness and high-temperature stability.

Owner:GUANGZHOU UNIVERSITY

Cutting tool and method of making the same

ActiveCN110318039BImprove antioxidant capacityRaise room temperatureChemical vapor deposition coatingSuperimposed coating processWear resistanceMaterials science

The present invention discloses a cutting tool and its manufacturing method, including a single layer or multi -layer coating on the base and coating on the base. x SI y TI 1‑x‑y ) N coating, wheren, x ≥ 0.70, 0 <y ≤0.1.The invention cutting tool is coated (AL x SI y TI 1‑x‑y ) N coating, while ensuring the high aluminum of coating, due to the incident of SI elements, the amorphous parcel nanocrystalline structure is formed, the coating tissue is refined, the high temperature hardness of the coating is improved, and the coating antioxidant is not reduced.At the same time, the wear resistance of the coating is improved.

Owner:GANZHOU ACHTECK TOOL TECH

Winding drum device for manufacturing firework and firecrackers paper drums

The invention provides a winding drum device for manufacturing firework and firecrackers paper drums. The device comprises a rack, the paper feeding mechanism arranged on the rack, an impression mechanism, a glue coating mechanism, a cutting mechanism and a winch mechanism, wherein the impression mechanism is used for impressing the roll paper into a corrugated shape, so that the amount of rolledpaper is reduced, and meanwhile, enough hardness of the rolled paper drums can be guaranteed; the glue coating mechanism comprises a hollow coating roller body and a brush layer which is arranged on the outer side wall of the coating roller body and is made of a flexible material and provided with a plurality of gaps; glue is fed into an inner cavity of the coating roller body through a glue conveying pipe, and the glue is uniformly smeared on the brush layer through a glue channel; finally, the brush layer is in contact with the roll paper, the glue coats the surface of the roll paper. The use amount of watering can be saved, and the glue can uniformly coat the roll paper as well, the rolled paper drums can be package from being adhered to one another, and the paper drums are easier to dry.

Owner:上栗县梦幻烟花制造有限公司

Treatment process for shortening planetary extruder screw length

ActiveCN102312058AHigh hardnessHardness does not decreaseFurnace typesHeat treatment furnacesFree coolingRoom temperature

The invention discloses a treatment process for shortening planetary extruder screw length. The treatment process comprises the following steps of 1, a rapid cooling step comprising heating a workpiece to a temperature of 1000 to 1050 DEG C during vacuum quenching, carrying out heat preservation for a period of time, and cooling rapidly the heated workpiece by low-temperature ammonia gas to a temperature less than or equal to 470 DEG C, 2, a tempering step comprising heating the workpiece treated by the step 1 to a temperature great than or equal to 485 DEG C, maintaining the reheated workpiece at the temperature for at least 3 hours, and cooling the reheated workpiece to a temperature less than or equal to 300 DEG C, and 3, a cooling step comprising transferring the workpiece treated by the step 2 out from a furnace form the furnace and cooling at room temperature. After a planetary extruder screw is treated by the treatment process, tempered martensite remaining in the planetary extruder screwan during the vacuum quenching is transformed into sorbite and thus crystal particles become small; an extended workpiece contracts to the length before heat treatment; and hardness of the workpiece is not reduced. Therefore, a workpiece which will be scrapped can be assembled normally; wear of a planetary extruder screw is reduced; and a part service life is prolonged.

Owner:北京华腾佳和科技有限公司

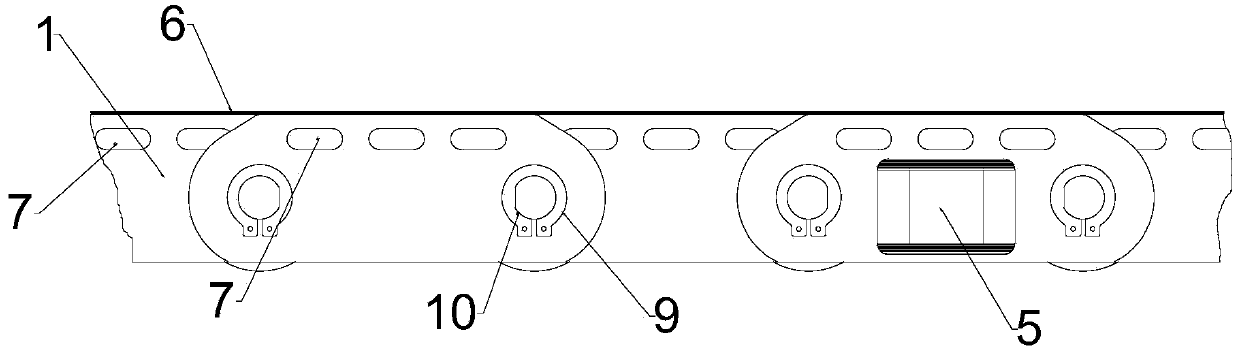

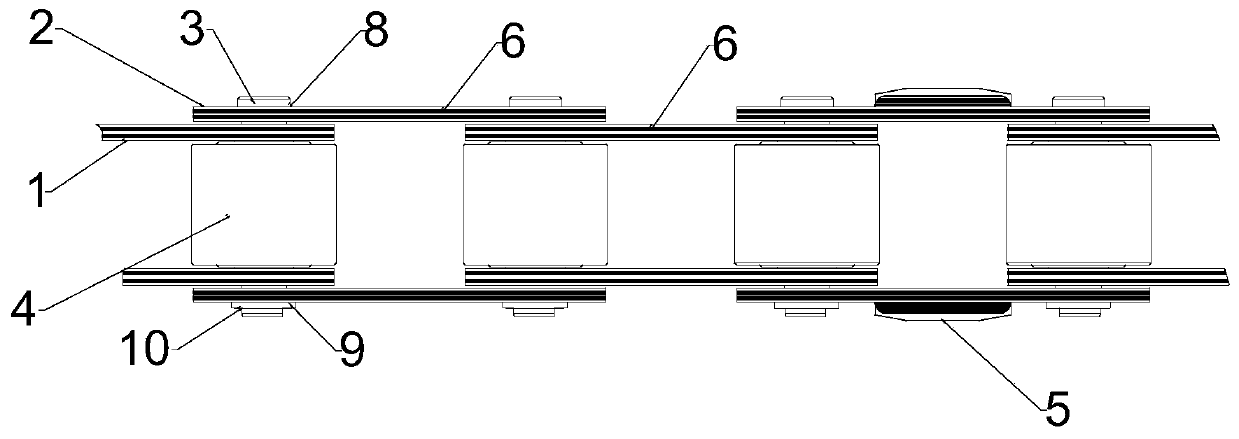

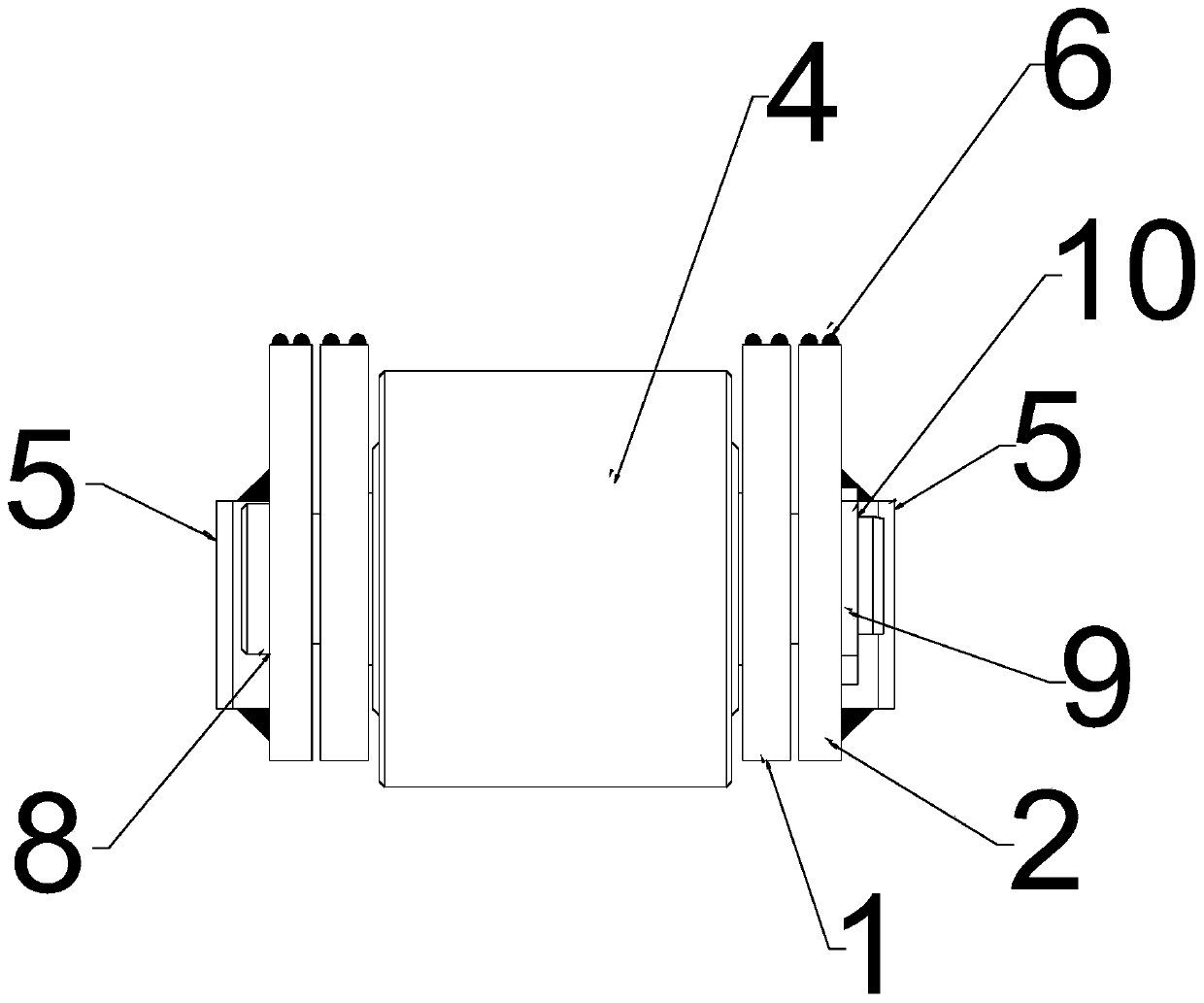

Conveying chain

PendingCN111306254AGuaranteed StrengthSmall temperature changeChain linksDriving chainsPhysicsEngineering

The invention relates to the technical field of mechanical transmission, and specifically relates to a conveying chain. The conveying chain comprises inner chain plates, outer chain plates, a pin shaft and a sleeve, wherein the pin shaft sequentially penetrates through the outer chain plate at a rear side, the inner chain plate at the rear side, the sleeve, the inner chain plate at a front side and the outer chain plate at the front side from the rear to the front; a high-hardness guide plate is welded and fixed to a side end surface away from the corresponding inner chain plate, of each outerchain plate; and welding layers are welded to the upper edges of each inner chain plate and the corresponding outer chain plate, heat dissipation windows are formed in each inner chain plate and thecorresponding outer chain plate, a step surface is machined at a rear end of the pin shaft, a retainer ring groove is machined in a front end of the pin shaft, and a locking retainer ring is installedin the retainer ring groove in a clamping manner. According to the conveying chain, the wear and the deformation of the chain plates is greatly reduced, and meanwhile, the service lives of the guideplate and the chain are effectively prolonged; and the conveying chain is worthy of being popularized and used.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

Thermal treatment method of 7CrSiMnMoV diameter expanding cone

ActiveCN104451095AReduce hardnessMeet the needs of machiningFurnace typesHeat treatment furnacesQuenchingDecarburization

The invention discloses a thermal treatment method of a 7CrSiMnMoV diameter expanding cone. The thermal treatment method comprises the following steps: (1) completing preparation operation, namely, plugging holes and grooves, and coating a high-temperature resisting anti-oxidation coating; (2) feeding the 7CrSiMnMoV diameter expanding cone into a tool of which the bottom is a plane in a manner that the large end of the 7CrSiMnMoV diameter expanding cone faces downwards, putting the tool into an atmosphere protection heating furnace, introducing nitrogen to expel air, and completing the furnace feeding operation; (3) controlling the heating speed and the temperature, introducing nitrogen, ammonia gas and methanol, and heating; (4) controlling the heating time, the temperature and the time, introducing nitrogen and methanol for protection, and austenitizing; (5) controlling the time and the temperature, and performing nitrate quenching; and (6) controlling the time and the temperature, and annealing. The 7CrSiMnMoV diameter expanding cone treated by using the thermal treatment method is free of defect such as quenching cracks and decarburization, parameters such as the quenching depth, the bending resistance, the pressure resistance, the impact toughness and the hardness, of the material of the cone, are remarkably improved, the requirements on mechanical processing are met, and no deformation is caused after mechanical processing.

Owner:HUNAN UNIV OF SCI & TECH

Treatment process for shortening planetary extruder screw length

ActiveCN102312058BHigh hardnessModerate hardnessFurnace typesHeat treatment furnacesTemperingHeat conservation

The invention discloses a treatment process for shortening planetary extruder screw length. The treatment process comprises the following steps of 1, a rapid cooling step comprising heating a workpiece to a temperature of 1000 to 1050 DEG C during vacuum quenching, carrying out heat preservation for a period of time, and cooling rapidly the heated workpiece by low-temperature ammonia gas to a temperature less than or equal to 470 DEG C, 2, a tempering step comprising heating the workpiece treated by the step 1 to a temperature great than or equal to 485 DEG C, maintaining the reheated workpiece at the temperature for at least 3 hours, and cooling the reheated workpiece to a temperature less than or equal to 300 DEG C, and 3, a cooling step comprising transferring the workpiece treated by the step 2 out from a furnace form the furnace and cooling at room temperature. After a planetary extruder screw is treated by the treatment process, tempered martensite remaining in the planetary extruder screwan during the vacuum quenching is transformed into sorbite and thus crystal particles become small; an extended workpiece contracts to the length before heat treatment; and hardness of the workpiece is not reduced. Therefore, a workpiece which will be scrapped can be assembled normally; wear of a planetary extruder screw is reduced; and a part service life is prolonged.

Owner:北京华腾佳和科技有限公司

Die material with high-temperature stability and high resistance to cold and hot fatigue

InactiveCN103495719AHigh resistance to cold and heat fatigueDecreased hardnessHigh resistanceHardness

The invention discloses a die material with high-temperature stability and high resistance to cold and hot fatigue. The die material is formed by combining a material with high resistance to cold and hot fatigue and a material with high-temperature stability, the material with the high resistance to the cold and hot fatigue is composed of high-speed steel rollers, the material with the high-temperature stability is composed of hot-working die steel which is formed by combining 4CrW2Si and 3Cr2W8V, and the high-speed steel rollers and the hot-working die steel are combined in a high-temperature fusing mode. By the mode, the die material can have the very high resistance to the cold and hot fatigue, and meanwhile at a high temperature, the stability of the die material can be kept, and hardness and strength of the die material will not decline.

Owner:SUZHOU YIQUN MOLD

High-hardness silver-bearing martensite antibacterial stainless steel

InactiveCN102242313BHardness does not decreaseImprove antibacterial propertiesChemical compositionHardness

The invention relates to high-hardness silver-containing martensite antibacterial stainless steel. The stainless steel comprises the following chemical components in percentage by weight: 0.8-1.2% of C, 16-18% of Cr, 1.0-3.0% of Mo, 0.1-1.0% of V, 1.0-3.0% of W, 0.7-1.2% of Al, 0.1-0.2% of Ag, 0.1-1.0% of Re, not more than 0.035% of S, not more than 0.03% of P, not more than 2.0% of other impurities and the balance of Fe. The silver-containing martensite antibacterial stainless steel disclosed by the invention has the advantages of excellent antibacterial property larger than 99.0%, largely improved hardness and wear resistance and not less than HRC57 of hardness, and meets the requirements of cutter manufacturing of household, medical and the like industries on hardness and antibacterial property.

Owner:SHANDONG JIANZHU UNIV

Super-hard copper-containing martensite antibiotic stainless steel

The invention relates to super-hard copper-containing martensite antibiotic stainless steel. The stainless steel comprises the following chemical components by weight percent: 0.8-1.2% of C, 16-18% of Cr, 1.0-3.0% of Mo, 0.1-1.0% of V, 1.0-3.0% of W, 0.5-3.0% of Ni, 2.5-3.5% of Cu, 0.1-1.0% of Re, less than or equal to 0.035% of S, less than or equal to 0.03% of P, less than or equal to 2.0% of other impurities and the balance of Fe. The copper-containing martensite antibiotic stainless steel has good antibiotic property, and the hardness and wear resistance of the stainless steel are greatlyimproved, thereby meeting the requirement of cutters manufactured in industries such as family, medical treatment and the like on the hardness and antibiotic property of the stainless steel.

Owner:SHANDONG JIANZHU UNIV

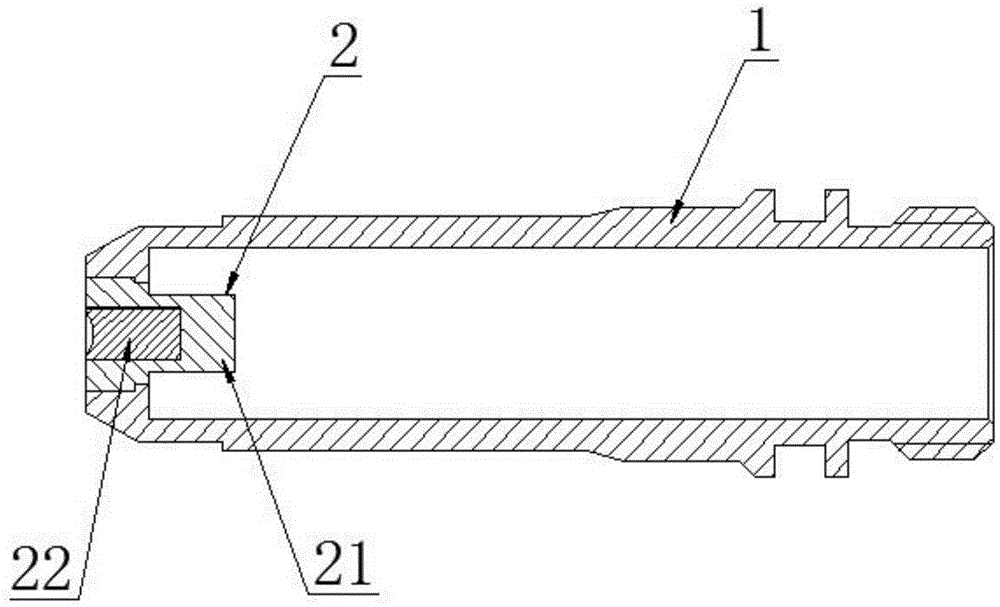

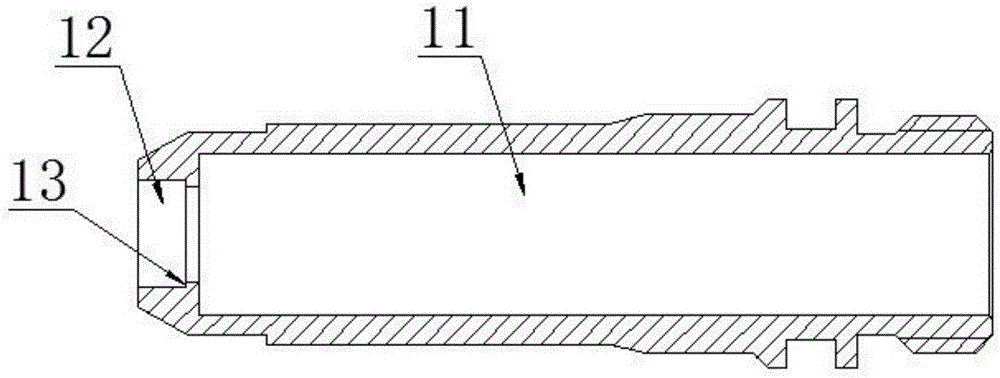

Drying structure, drying tool and drying method

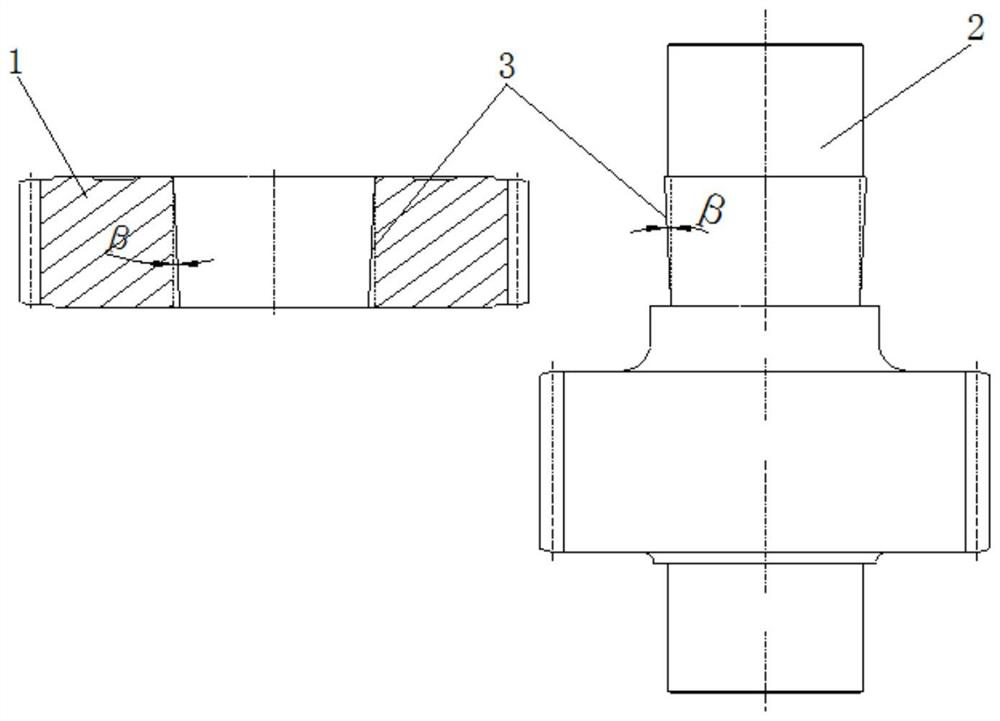

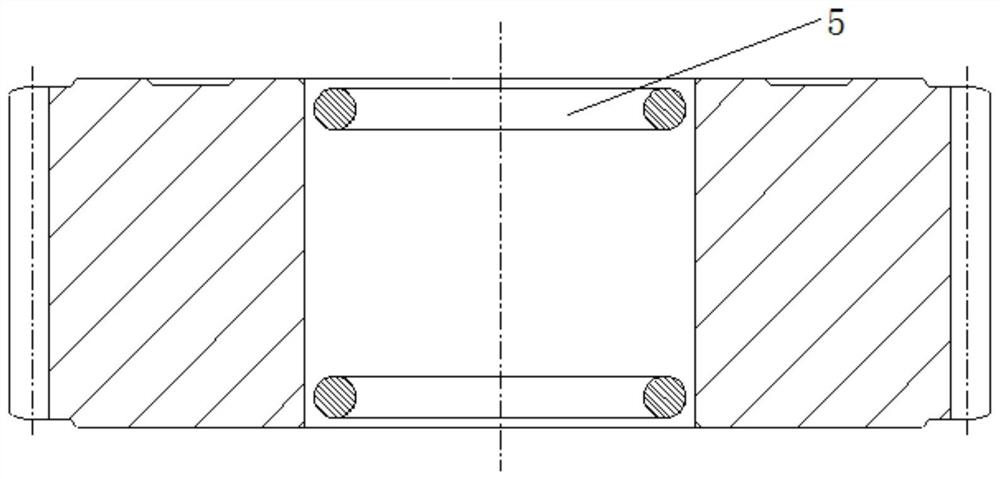

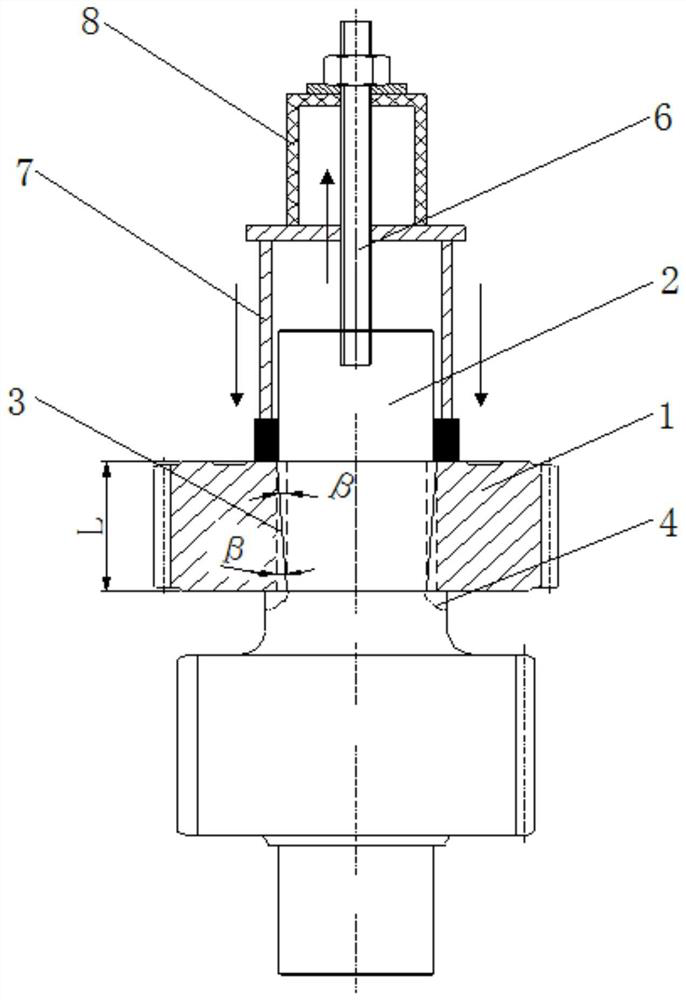

PendingCN113305539AAchieve fitHardness does not decreaseMetal working apparatusInterference fitEngineering

The invention belongs to the technical field of drying, and particularly relates to a drying structure, a drying tool and a drying method. The drying structure comprises a containing body and a contained body which are in interference fit, wherein a taper directional sliding structure is arranged between the containing body and the contained body, a gas escape structure communicating with an interlayer between the containing body and the contained body is arranged on a shaft shoulder of the contained body, the taper directional sliding structure comprises inclined conical surfaces which are arranged on an inner hole of the containing body and the outer circle of the contained body correspondingly and are matched with each other, the inclined conical surfaces are arranged in an inclined mode from top to bottom, the gas escape structure comprises a plurality of exhaust grooves which are uniformly distributed in the circumferential direction of the shaft shoulder of the contained body, one ends of the exhaust grooves are located on the inner side of the minimum diameter end of the inner hole of the containing body, and the other ends of the exhaust grooves communicate with the outside of the shaft shoulder of the contained body. According to the drying structure, the drying tool and the drying method, through the design of the taper directional sliding structure, the gas escape structure, a double-side induction coil and a three-point uniform pressure structure, the drying gap can be less than or equal to 0.03mm, and even complete fit without gaps can be realized.

Owner:CHANGZHOU TIANSHAN HEAVY IND MACHINERY

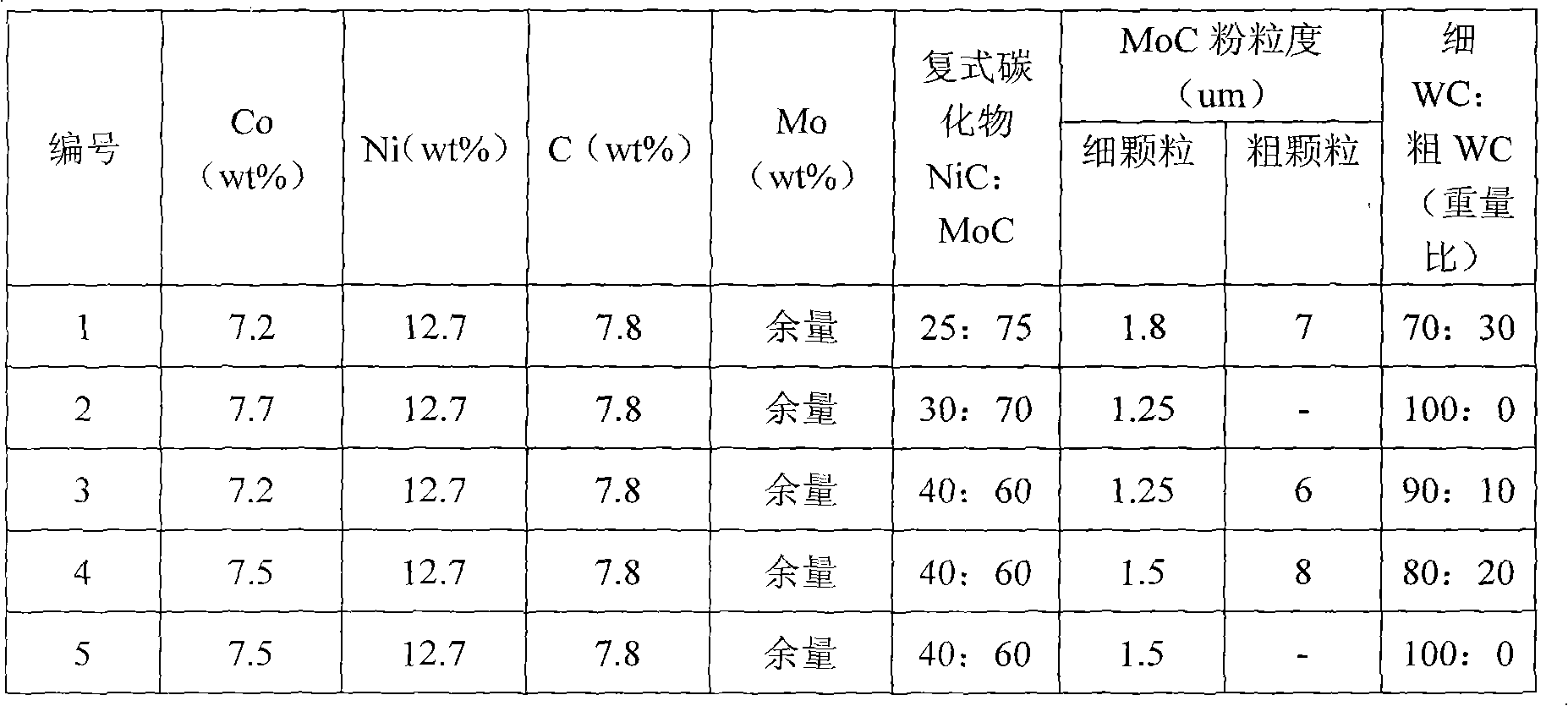

Preparation method of molybdenum-cobalt-nickel high-hardness high-strength alloy

The invention relates to a preparation method of a molybdenum-cobalt-nickel high-hardness high-strength alloy, which comprises the following steps: proportioning MoC-NiC compound carbide, MoC powder and Co powder, carrying out ball milling, drying, doping with a forming agent, carrying out pressure forming, sintering and the like. The weight ratio of NiC to MoC in the compound carbide is 30:70-40:60; and in the proportioning process, the content of Co is controlled at (7.2-7.7) wt%, and the MoC powder of (1.2-1.8) um is adopted. The preparation method of the molybdenum-cobalt-nickel high-hardness high-strength alloy can enhance the bending strength, thereby solving the problem of high tendency to cracking of the alloy cutter blade during welding and sharpening, the problem of high tendency to breaking when the alloy cutter blade is used for cutting, and the like.

Owner:赵宏伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com