Conveying chain

A technology for conveying chains and inner chain plates, applied in the field of mechanical transmission, can solve the problems of easy deformation of chain plates, grinding chain plates, chain failure, etc., and achieve the effects of ensuring strength, reducing thermal deformation, and small temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

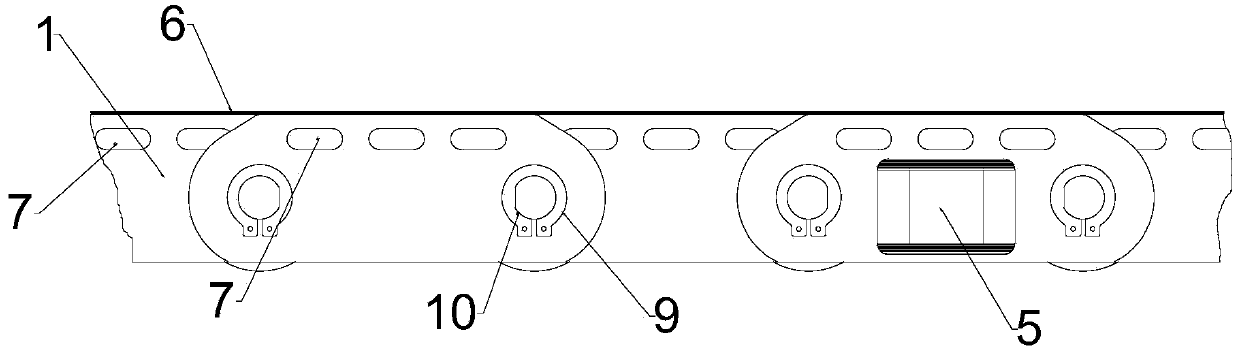

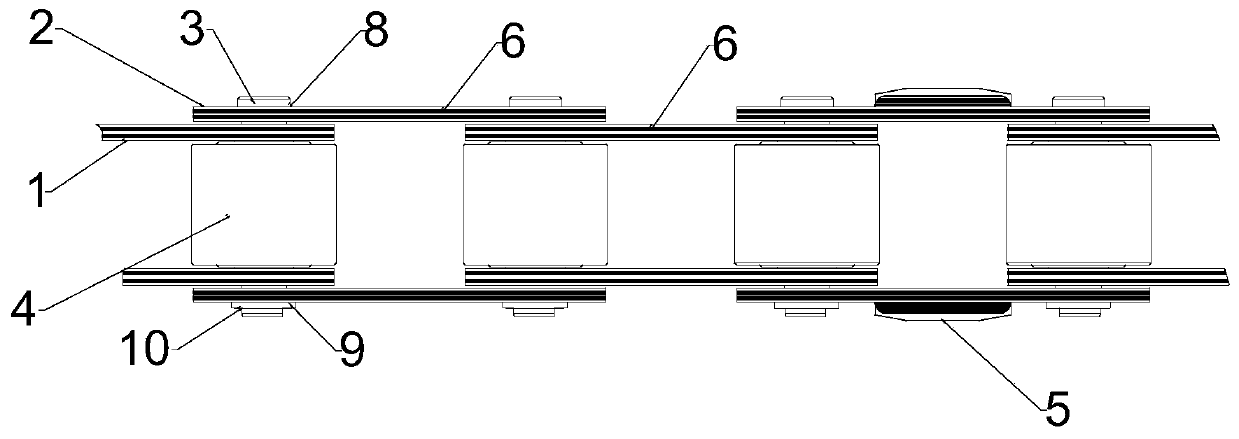

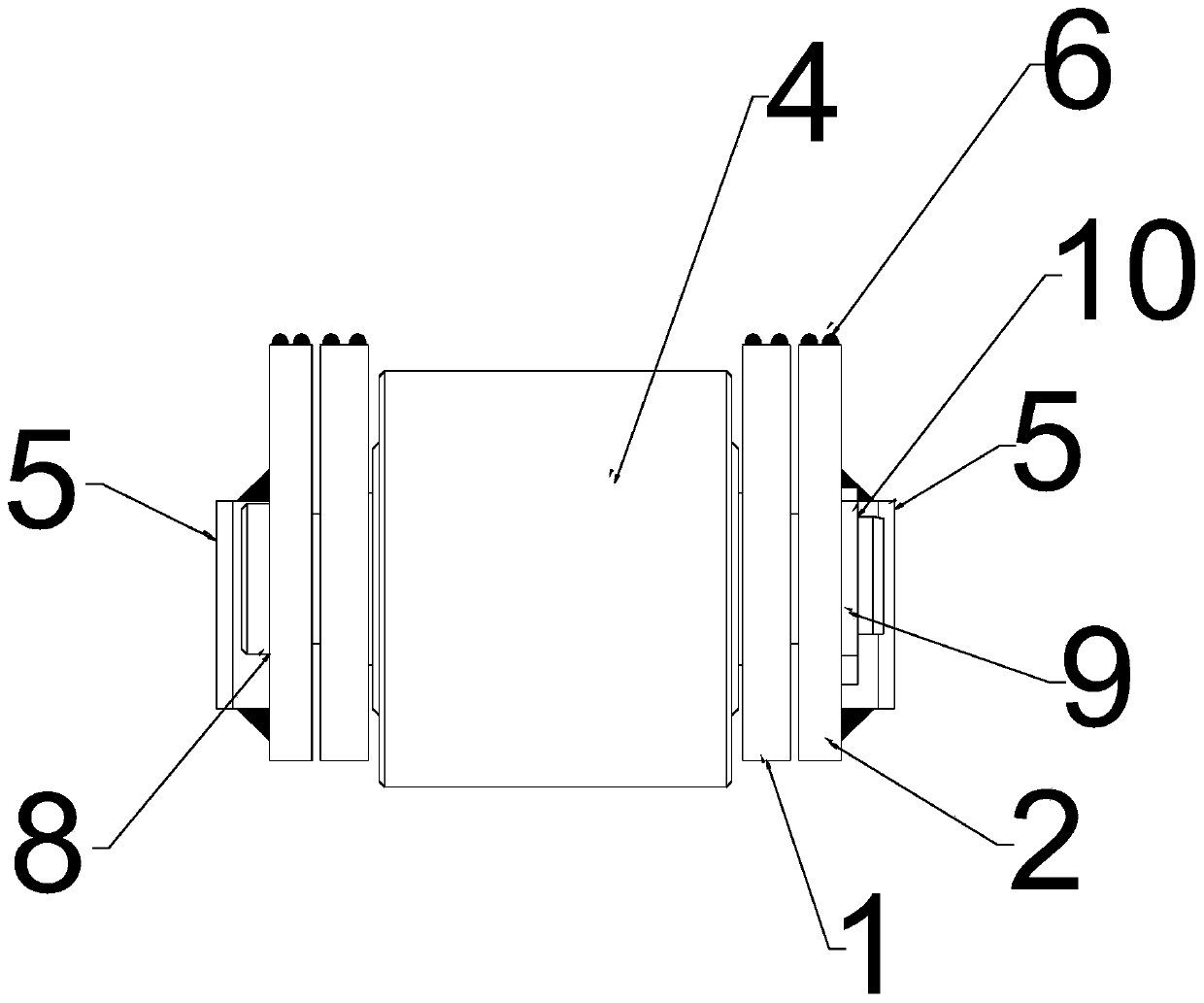

[0020] see Figure 1-Figure 4 , a conveyor chain, including an inner chain plate 1, an outer chain plate 2, a pin shaft 3 and a sleeve 4, and the pin shaft 3 passes through the outer chain plate 2 on the rear side and the inner chain plate on the rear side in sequence from back to front. The chain plate 1, the sleeve 4, the inner chain plate 1 on the front side and the outer chain plate 2 on the front side; the outer chain plate 2 is welded and fixed with the high The hardness guide plate 5; the upper edge of the inner chain plate 1 and the outer chain plate 2 is welded with a welding layer 6, which has the technical effect of high temperature resistance and wear resistance, and can reduce the heat transfer of high temperature section steel to the chain plate; The inner chain plate 1 and the outer chain plate 2 are provided with a heat dissipation window 7, and the heat dissipation window 7 is round, rectangular or waist-shaped; the heat dissipation window 7 is a through hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com