Method for preparing tungsten carbide wear-resistant coating needed for swing head of swing forging machine through induction heating

A technology of induction heating and wear-resistant coating, which is applied in the field of wear-resistant coating preparation in material processing engineering, can solve the problems such as the decrease of the hardness of the brazing substrate, and achieve a large coating thickness, easy realization, and improved wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

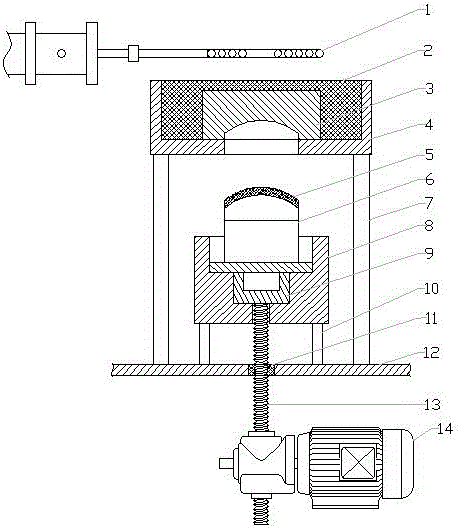

[0047] The method for preparing the tungsten carbide wear-resistant coating required for the swing head of the pendulum mill according to the argon protection induction heating described in this embodiment includes the following steps:

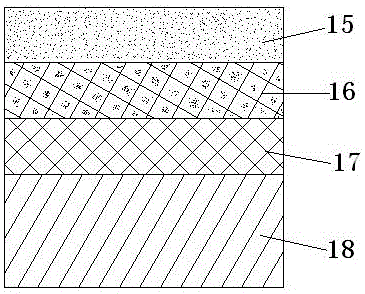

[0048] (1) Stick the paste prefabricated layer containing tungsten carbide WC or tungsten carbide-cobalt WC-Co, self-fluxing alloy powder on the metal substrate with epoxy resin adhesive; the paste prefabricated layer can be two layers Above, the content of tungsten carbide WC or tungsten carbide-cobalt WC-Co in different layers is different, from the surface layer to the paste precoat close to the steel substrate, the content of tungsten carbide WC or tungsten carbide-cobalt WC-Co gradually Reduced to form a tungsten carbide-cobalt content gradient to reduce welding stress;

[0049] The formula of described pasty prefabricated layer is:

[0050] (A) Tungsten carbide WC or tungsten carbide-cobalt WC-Co, and mechanically alloyed self-fluxing a...

Embodiment 2

[0062] The method for preparing the tungsten carbide wear-resistant coating required for the swing head of the pendulum mill according to the argon protection induction heating described in this embodiment includes the following steps:

[0063] (1) Stick the paste prefabricated layer containing tungsten carbide WC or tungsten carbide-cobalt WC-Co, self-fluxing alloy powder on the metal substrate with epoxy resin adhesive; the paste prefabricated layer can be two layers Above, the content of tungsten carbide WC or tungsten carbide-cobalt WC-Co in different layers is different, from the surface layer to the paste precoat close to the steel substrate, the content of tungsten carbide WC or tungsten carbide-cobalt WC-Co gradually Reduced to form a tungsten carbide-cobalt content gradient to reduce welding stress;

[0064] The formula of described pasty prefabricated layer is:

[0065] (A) Tungsten carbide WC or tungsten carbide-cobalt WC-Co, and mechanically alloyed self-fluxing a...

Embodiment 3

[0077] The method for preparing the tungsten carbide wear-resistant coating required for the swing head of the pendulum mill according to the argon protection induction heating described in this embodiment includes the following steps:

[0078] (1) Stick the paste prefabricated layer containing tungsten carbide WC or tungsten carbide-cobalt WC-Co, self-fluxing alloy powder on the metal substrate with epoxy resin adhesive; the paste prefabricated layer can be two layers Above, the content of tungsten carbide WC or tungsten carbide-cobalt WC-Co in different layers is different, from the surface layer to the paste precoat close to the steel substrate, the content of tungsten carbide WC or tungsten carbide-cobalt WC-Co gradually Reduced to form a tungsten carbide-cobalt content gradient to reduce welding stress;

[0079] The formula of described pasty prefabricated layer is:

[0080] (A) Tungsten carbide WC or tungsten carbide-cobalt WC-Co, and mechanically alloyed self-fluxing all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com