Test device for fire damage of steel cable structure and use method

A test device and wire rope technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of long interval between heating treatment and cooling, and achieve the effect of preventing uneven heating, rapid cooling treatment, and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose, technical solution and feasibility of the present invention more clear and detailed, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific examples described below are only used to explain the present invention, not to limit the present invention.

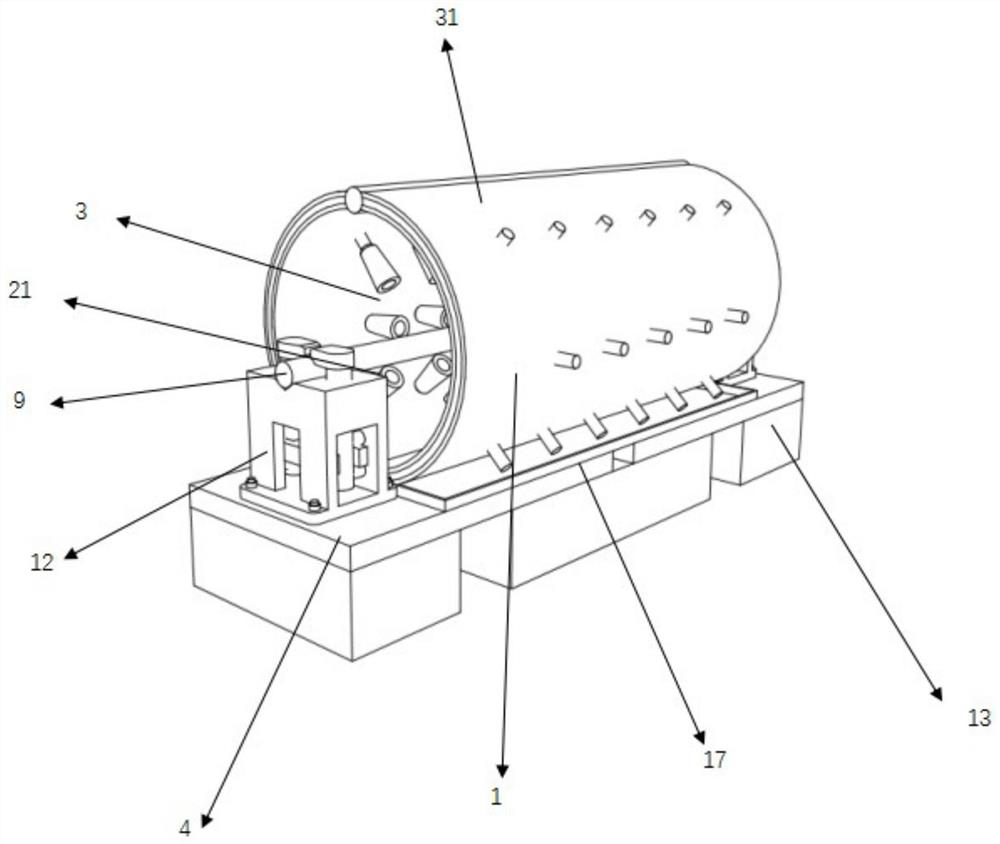

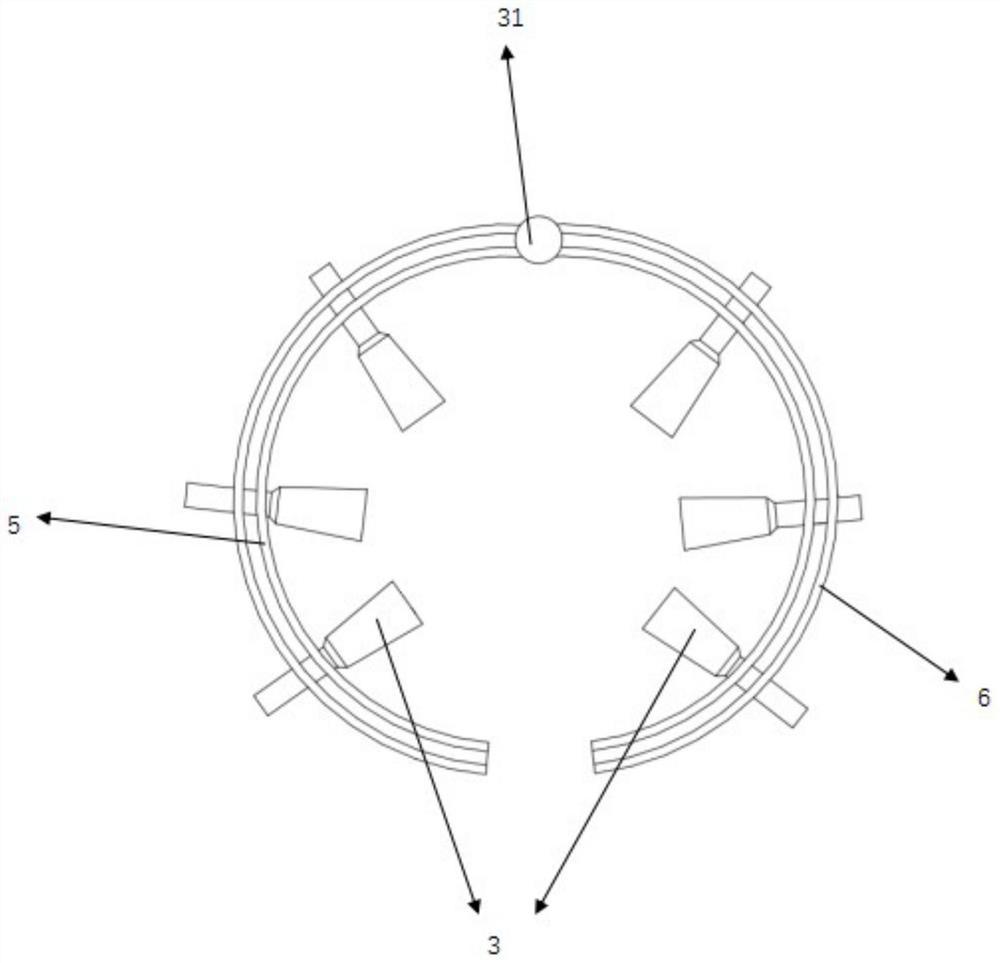

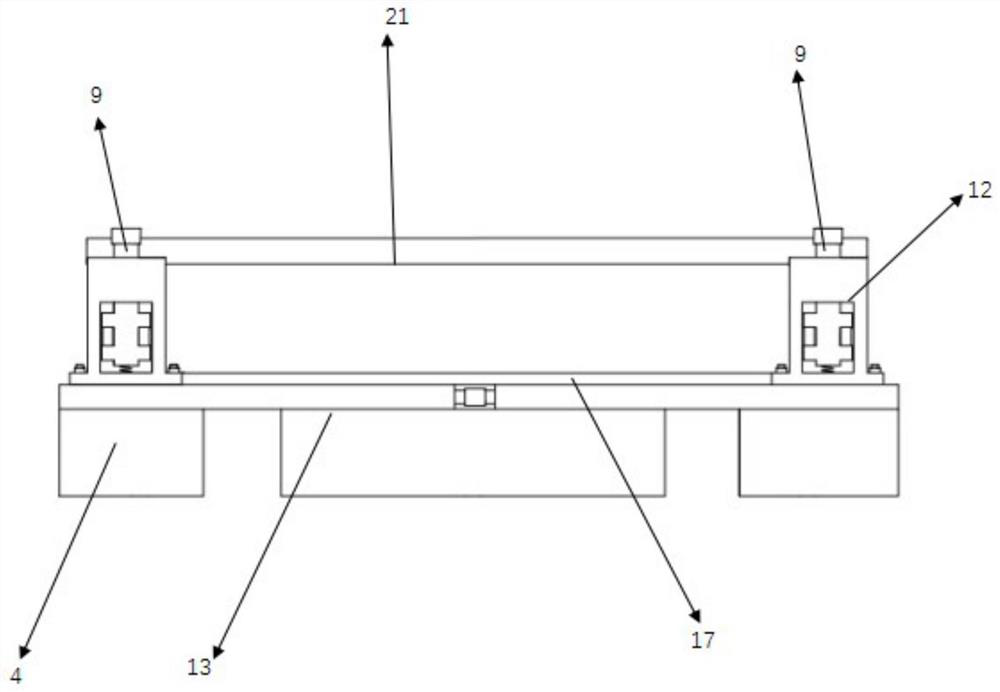

[0050] see Figure 1 to Figure 11 , a test device for fire damage and cooling treatment of steel cable structures, including a high-temperature calciner 1, a cooling device 2, a loading device 13, a sliding guide rail 14, a protective shell 18, an operation panel 23, and a sliding device-32 , sliding device two 33, control system, the operation panel 23 is fixed on the protective shell 18, to attach image 3 The up and down, left and right directions of the application define the up and down, left and right directions of the application, so as to describe the application, the clamping devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com