Patents

Literature

57results about How to "Achieve localized heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

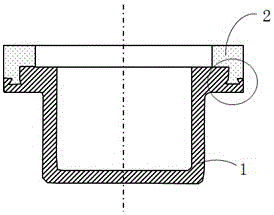

Method for connecting plastic and metal heterostructure

InactiveCN106393705AIncreased mechanical occlusionImprove the bonding strength of the interfaceLaser beam welding apparatusChemical LinkageTemperature control

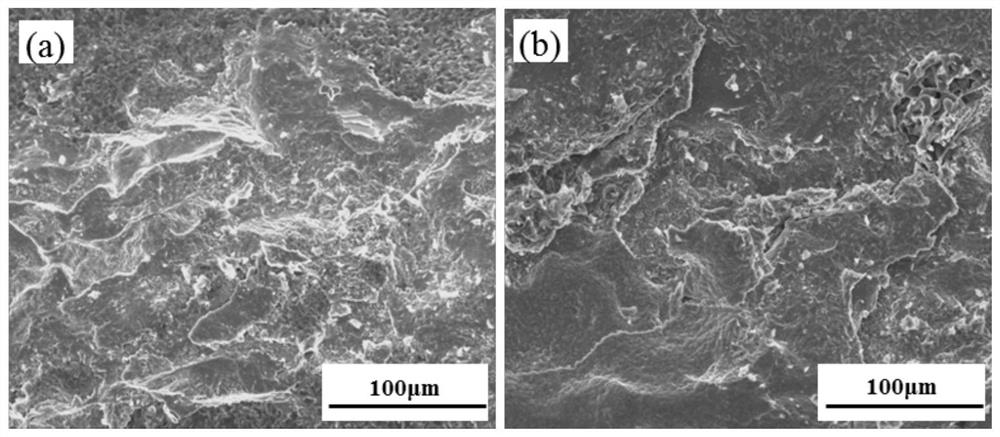

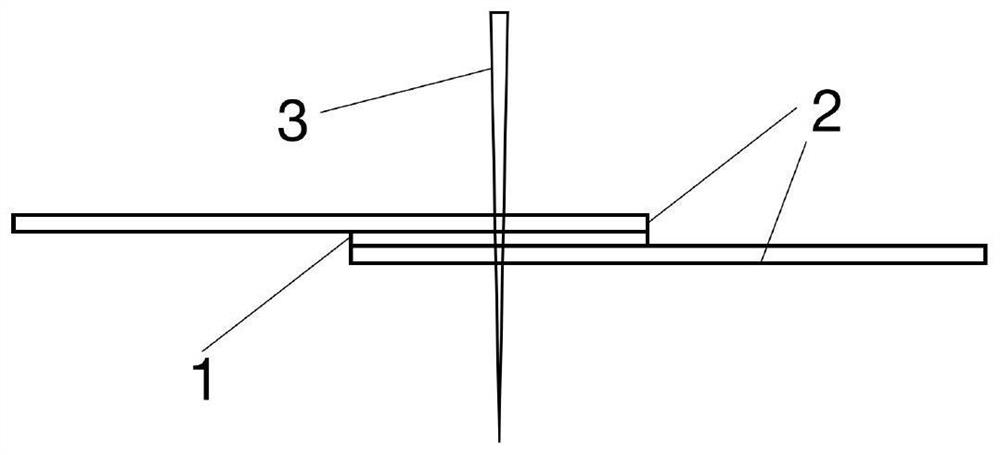

The invention provides a method for connecting plastic and a metal heterostructure. The method comprises the following steps that S1, laser roughening treatment is conducted on the surface of a to-be-connected metal part, and local protrusions and dents are generated on the surface of the metal part, so that a metallic oxide layer is formed; S2, the metal part subjected to laser roughening treatment and a to-be-connected plastic part are hot-pressed, so that the metal part and the plastic part are bonded together; and S3, out-of-focus laser beams are adopted to penetrate through the plastic part so as to reach the interface between the plastic part and the metal part, and the portion, at the interface, of the plastic part is partially melted. According to the method for connecting the plastic and the metal heterostructure, operation is easy, the mechanical engaging and chemical bonding degree of the plastic and metal is increased through the required local protrusions and dents formed on the surface of the metal part and partial heating and temperature control of the interface, tight bonding of the plastic and the metal at the interface is facilitated, and the interface bonding strength and airtightness of the plastic and the metal heterostructure are improved accordingly.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

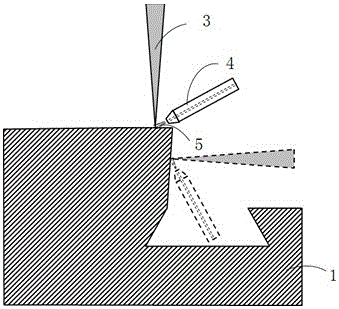

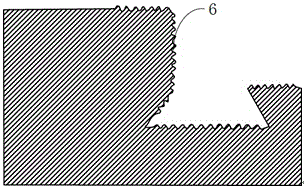

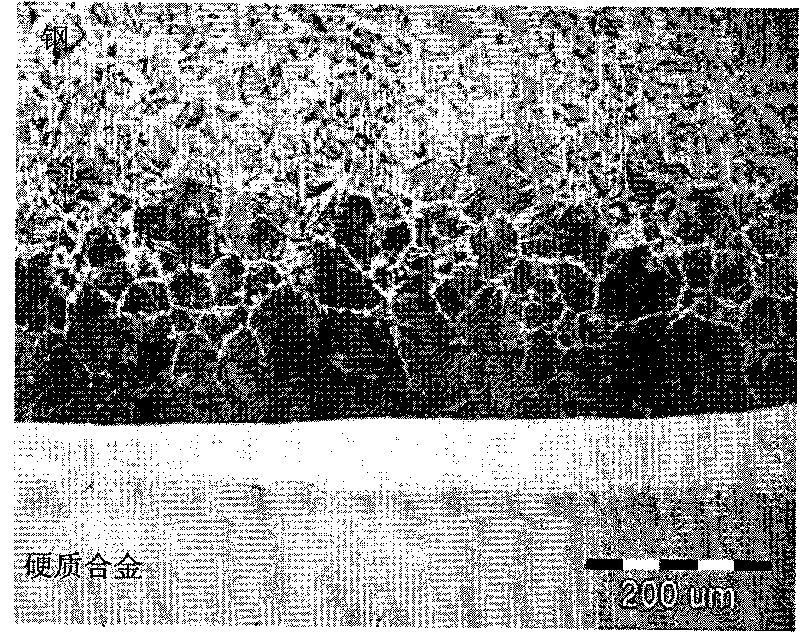

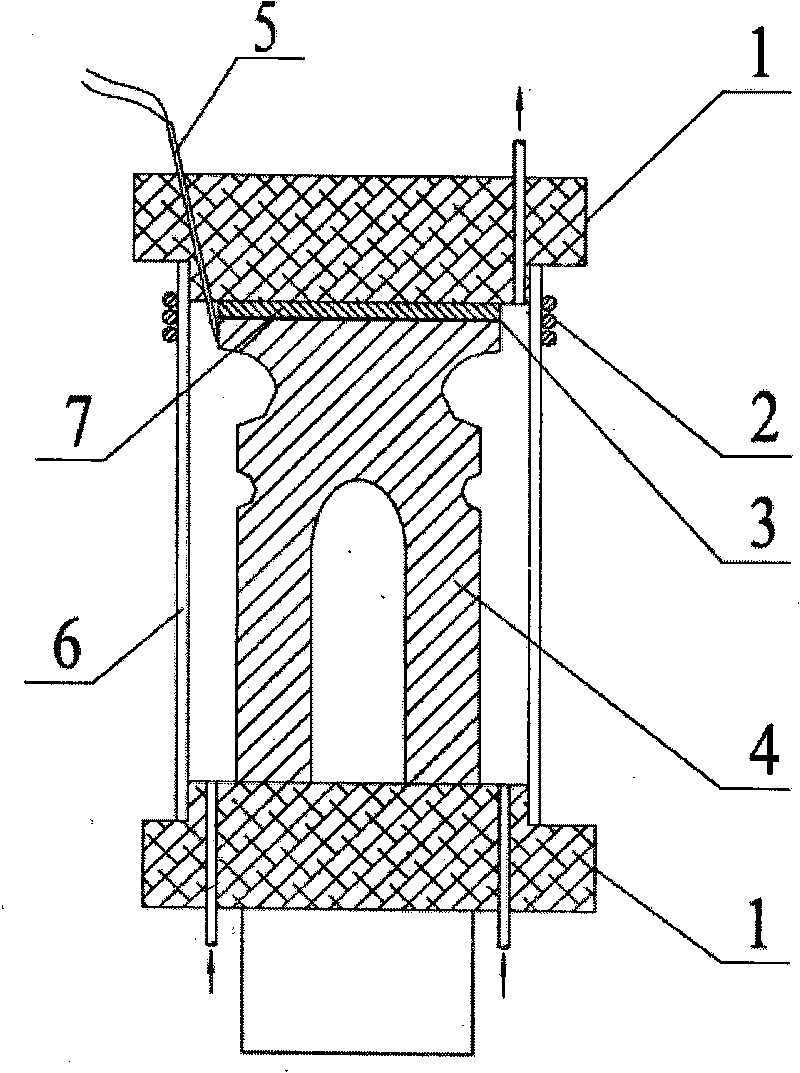

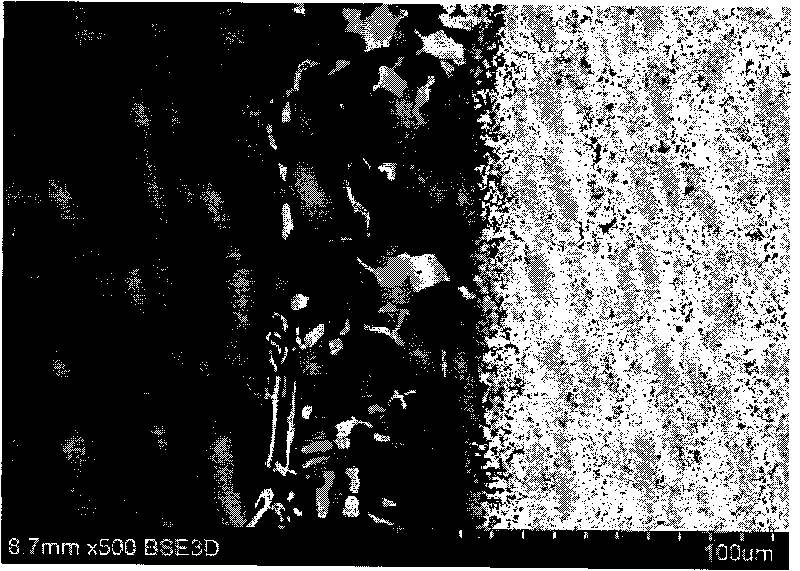

Method for soldering and welding hard alloy/steel compound tappet of engine by high-frequency induction

InactiveCN101704143AHeating fastShort liquefaction processSoldering apparatusWelding/soldering/cutting articlesPartial heatingTappet

The invention discloses a method for soldering and welding a hard alloy / steel compound tappet of an engine by high-frequency induction, relating to a method for welding a hard alloy / steel compound tappet of an engine. The invention solves the problems of high requirements of required production equipment and high production cost and the problem that an interface is easy to form harmful Eta phases to cause low anti-bending intensity of the combining part existing in the traditional method for welding the hard alloy / steel compound tappet. In the method of the invention, steel and hard alloy are soldered and welded into a whole in vacuum through high-frequency induction heating. The method of the invention realizes the partial heating on the joint of the hard alloy and the steel to prevent the growing of crystal particles due to the overheating of other wear-resistant parts of the tappet to result in performance degradation; the method combines the Eta phases in dispersive distribution to eliminate the interface embrittlement of joints caused by the Eta phases and simultaneously increases the mechanical properties of soldering seams, and the shearing intensity of the joints reaches 450 MPa; and the method has low cost and is suitable for mass production. The compound tappet prepared by using the method of the invention can be widely applied to the fields of automobiles, airplanes, and the like.

Owner:HARBIN INST OF TECH

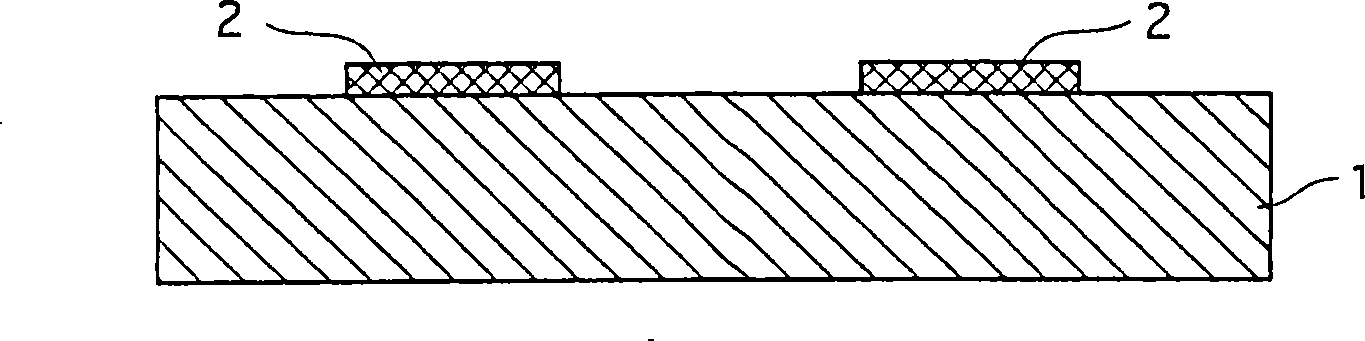

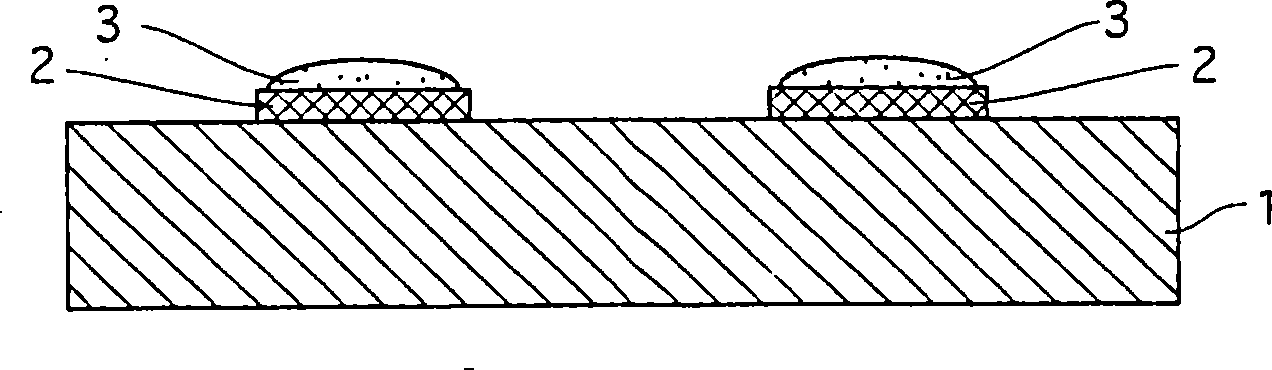

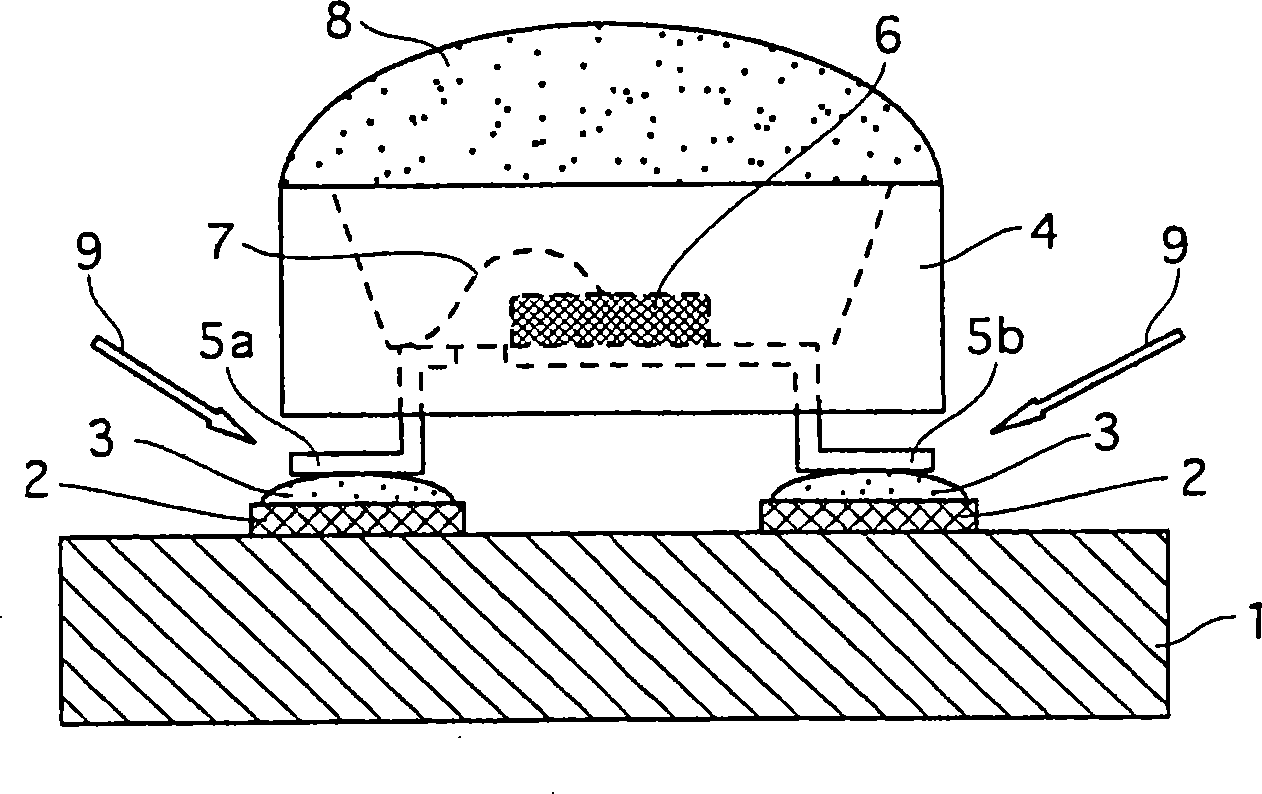

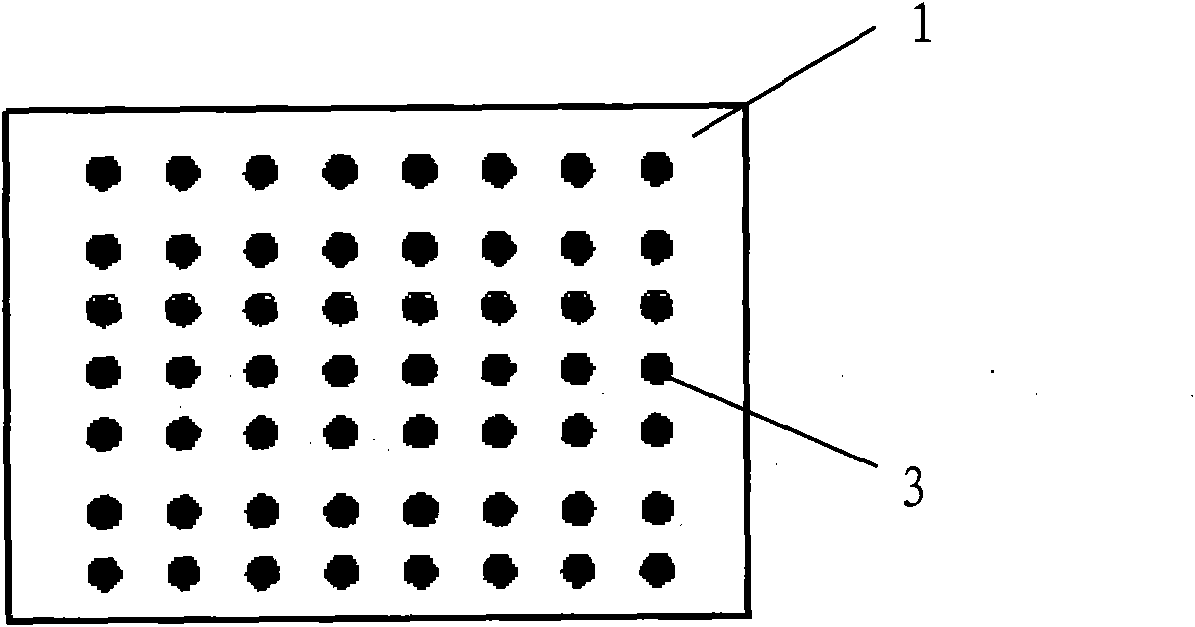

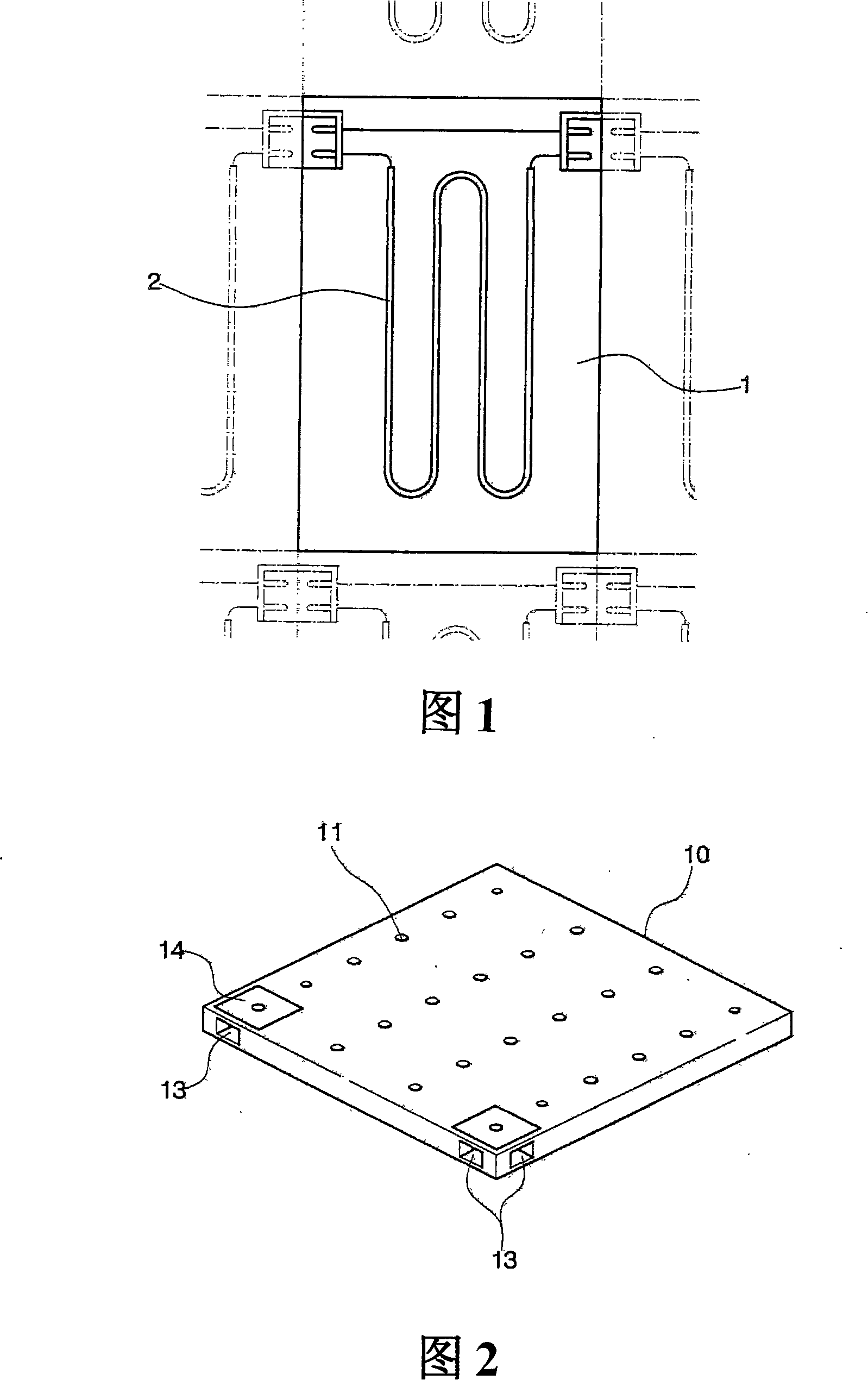

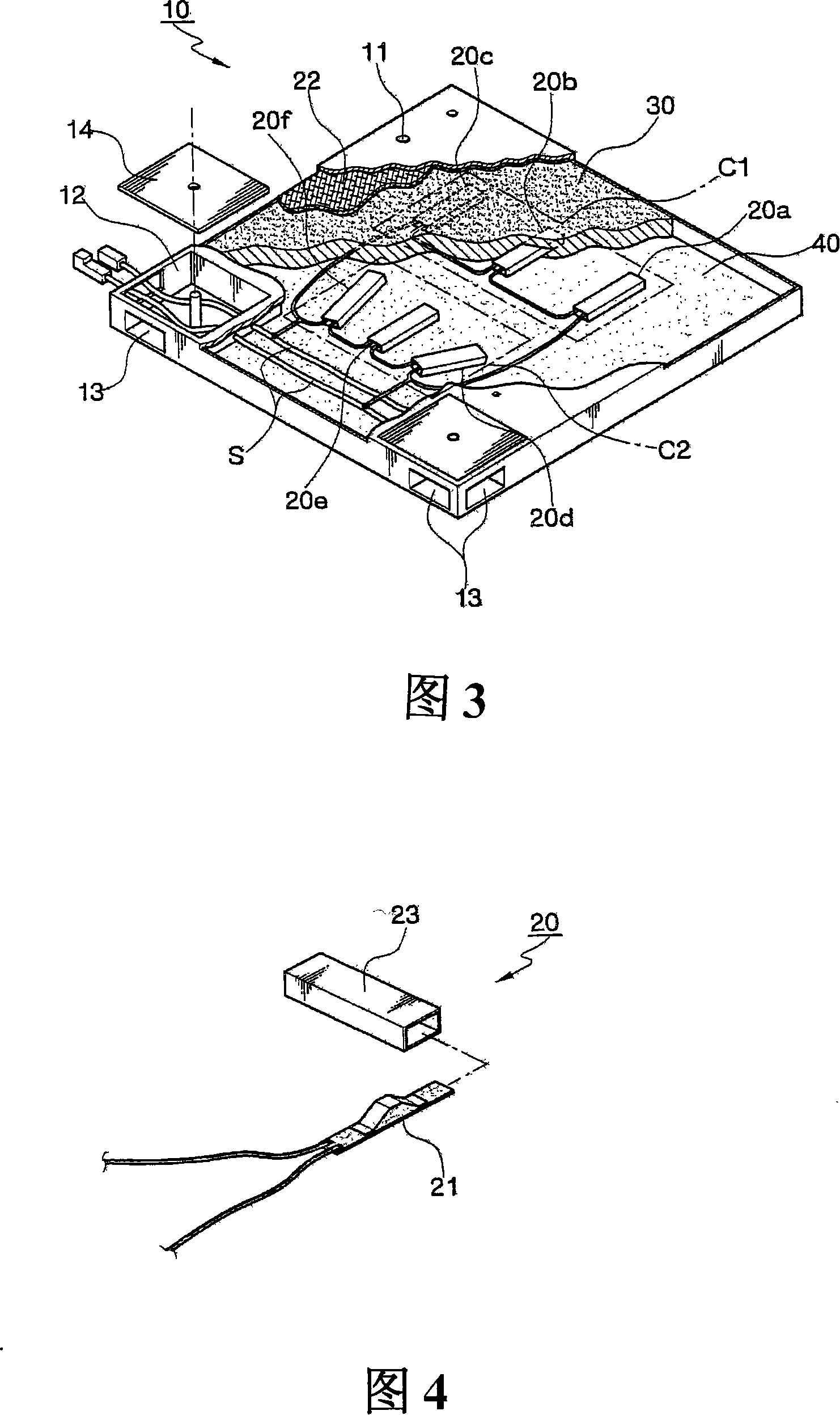

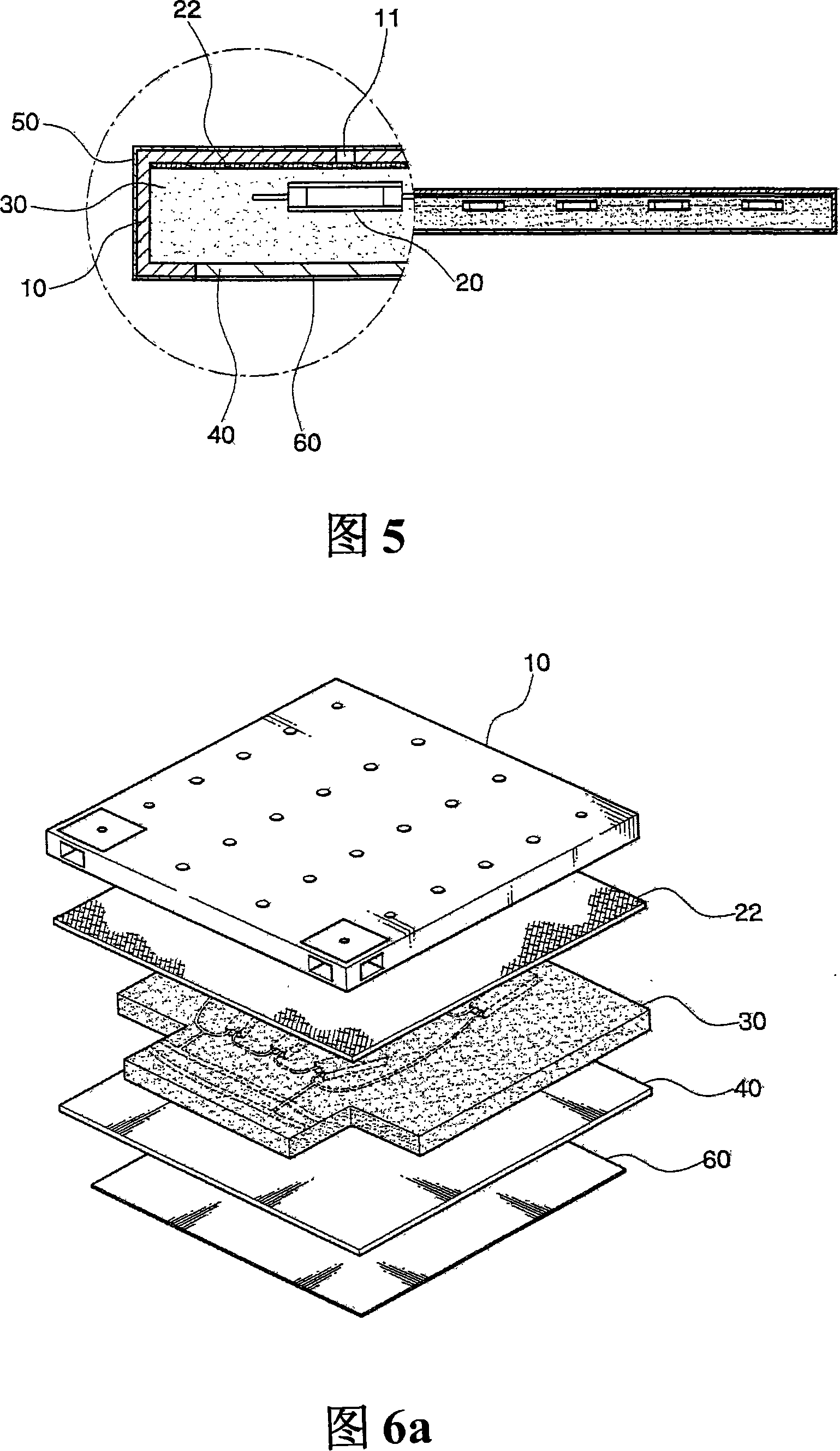

Surface mount circuit board, method for manufacturing surface mount circuit board, and method for mounting surface mount electronic devices

InactiveCN101252809AAchieve localized heatingPrinted circuit assemblingPrinted circuit non-printed electric components associationWire rodSurface mounting

A surface mount circuit board includes: an insulating substrate having through holes each extending from front to rear surfaces of the insulating substrate; high thermal conductive members each filing a different one of the though holes; lands each disposed to cover an end surface of a different one of the high thermal conductive members and also cover part of the front surface around the peripheral edge of the corresponding through hole; and heat receiving members each disposed to cover an end surface of a different one of the high thermal conductive members and also cover part of the rear surface around the peripheral edge of the corresponding through hole. Each land may be made of solder cream filled into and flashed out of the through hole. Alternatively to the high thermal conductive members, wire rods may be fitted into the respective through holes.

Owner:SHEEX

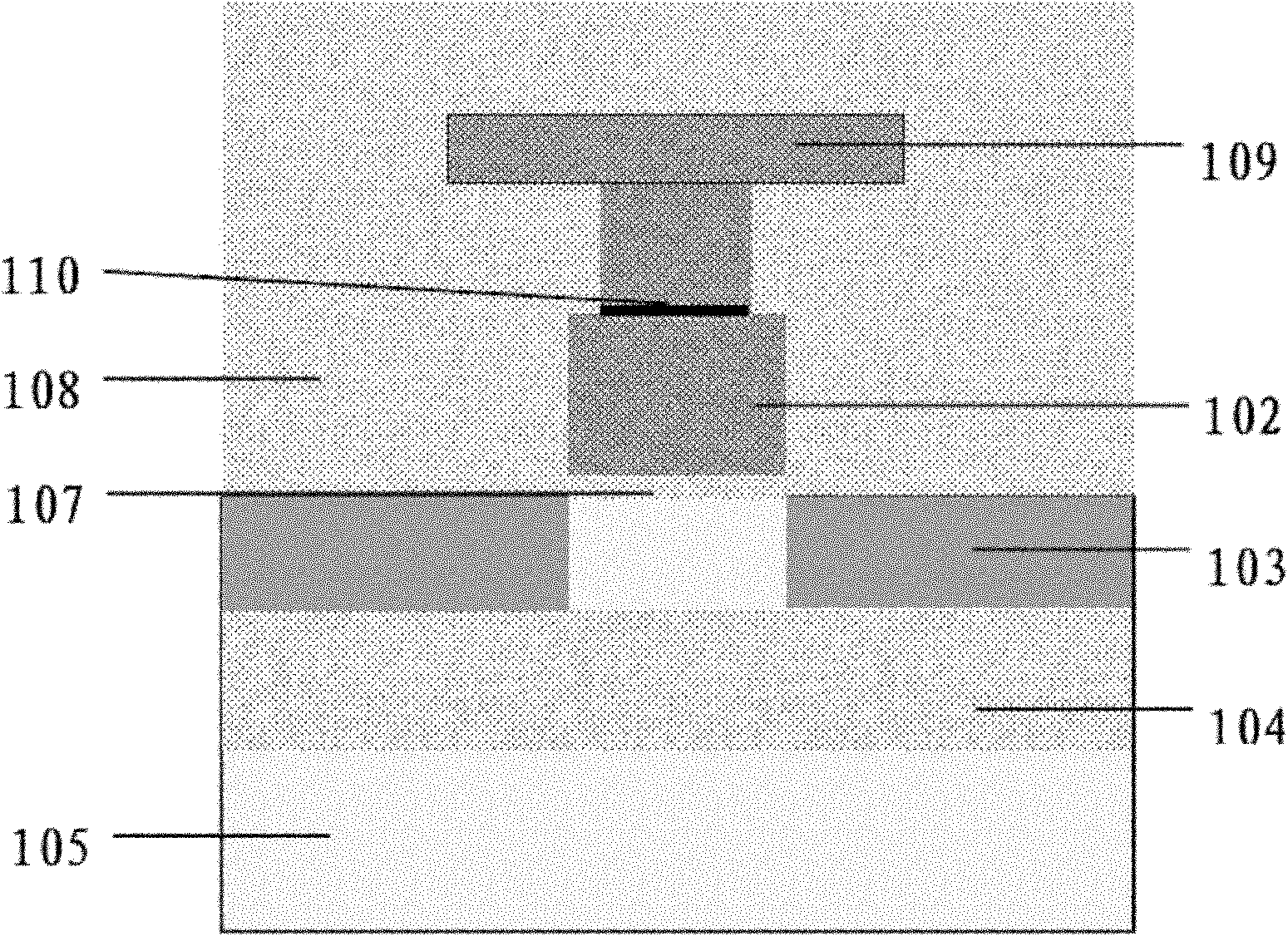

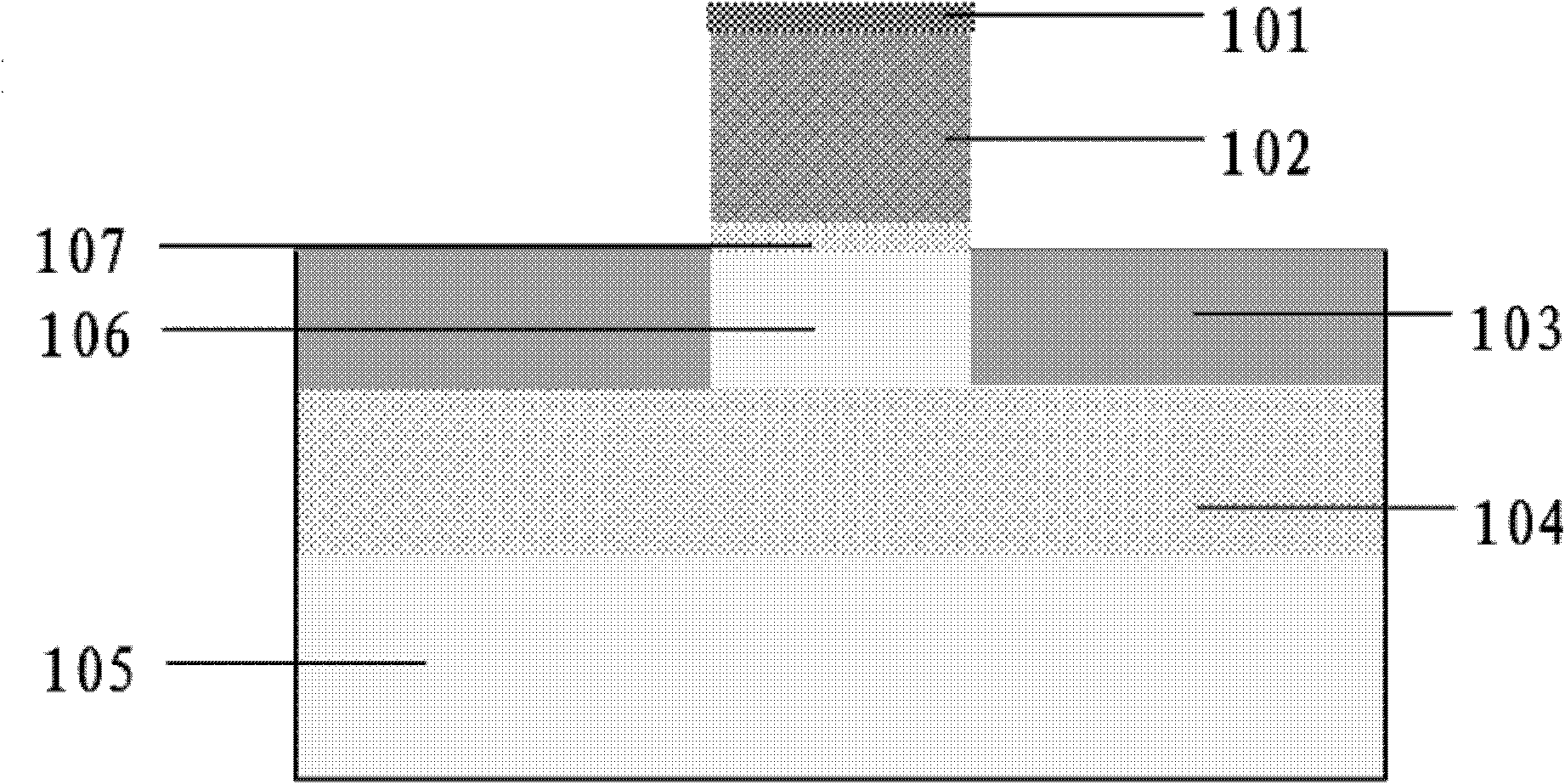

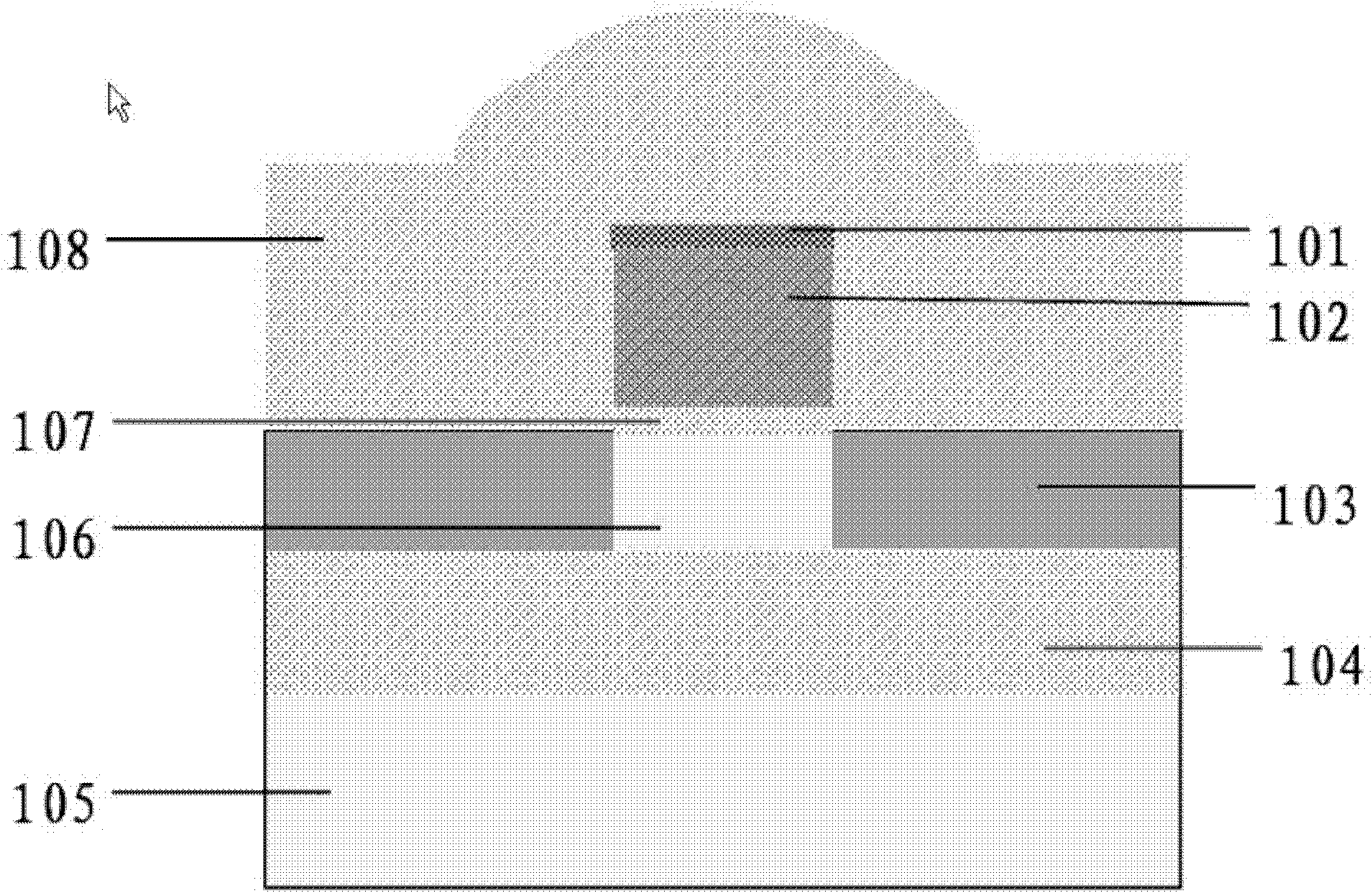

Heat characterization method and structure for monitoring temperature of transistor in real time

ActiveCN101915624ADoes not affect normal workEasy to operateThermometers using electric/magnetic elementsSolid-state devicesTransistor arrayAs element

The invention provides a heat characterization method and a heat characterization structure for monitoring the temperature of a transistor in real time, which belong to the field of monitoring techniques for characterizing the heat effect of the transistor. In the method, a material layer is arranged on a transistor gate to form a P-N junction with the transistor gate, and the temperature of the transistor element is measured according to the IV characteristic of the P-N junction. In the invention, a single element is combined with a high-sensitivity temperature control diode, the actual temperature of the element is approached more really because of the positioning of the PN junction on a polysilicon gate above a channel, the temperature of the element can be monitored in real time, and the operation is simple. In a large-scale transistor array, the structure is used for solving the problems such as real-time chip temperature monitoring and heat point distribution, heating the element locally and accordingly analyzing problems such as element reliability and circuit mismatch. Besides, the area of the structure corresponds to the size of the element, so the structure can be integrated on a chip.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Method for preparing tungsten carbide wear-resistant coating needed for swing head of swing forging machine through induction heating

ActiveCN106180938AAchieve localized heatingReduce hardnessHeating appliancesSoldering auxillary devicesEpoxyWear resistant

A method for preparing a tungsten carbide wear-resistant coating needed for a swing head of a swing forging machine through induction heating includes the steps that a composite powder pasty prefabricated layer which is blended with epoxy resin and contains tungsten carbide powder and self-fluxing alloy powder is pasted on a metal matrix; then BNi2 solder is pasted on the upper surface of the tungsten carbide composite powder pasty prefabricated layer in the same way; and the metal fabricated part is placed in an argon gas protection induction device to be subjected to induction heating. According to the method, the adopted experiment measures are simple and feasible, the prepared tungsten carbide wear-resistant coating is low in cost, simple and feasible, the strength of the matrix is high, and because holes are formed for storing oil, the wear resistance of the coating is remarkably improved.

Owner:NANCHANG INST OF TECH

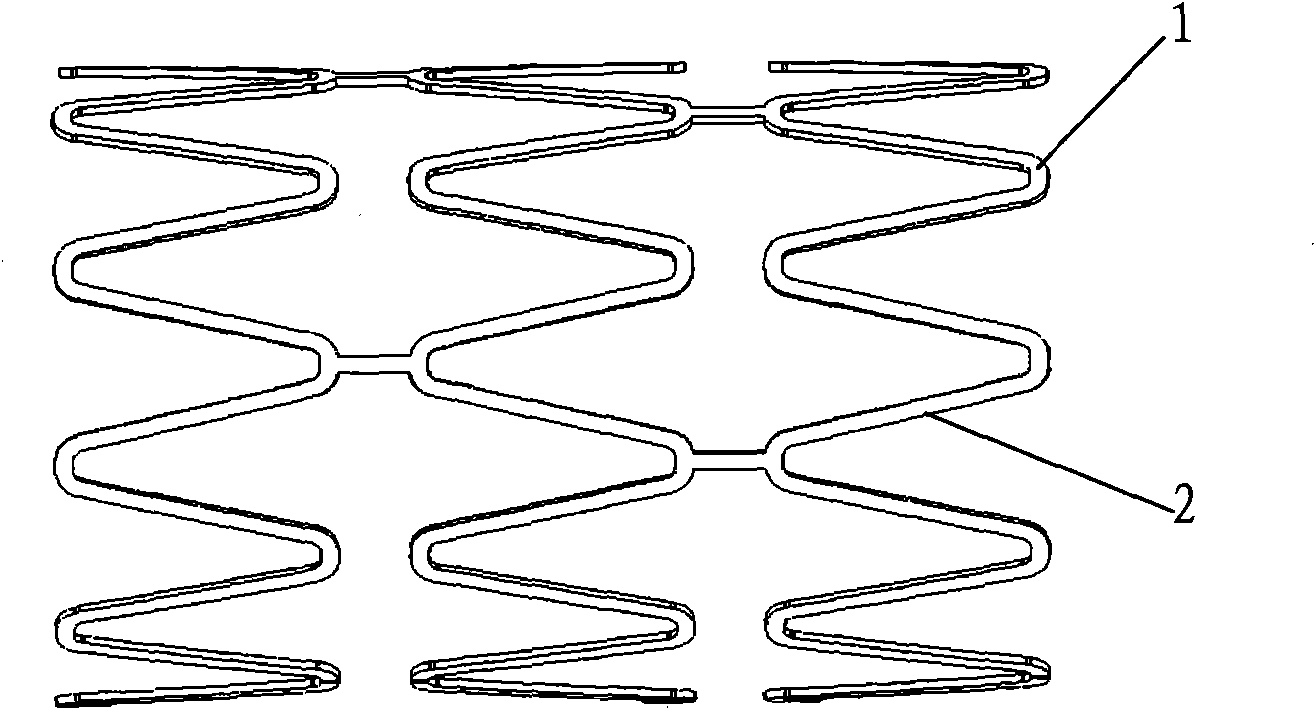

Biodegradable scaffold

ActiveCN102371006ACentralized heating pointControllable heating temperatureStentsSurgeryPercent Diameter StenosisBiomedical engineering

The invention discloses a biodegradable scaffold, which comprises a scaffold main body prepared by a biodegradable material. A lot of magnetic particles are distributed in the scaffold main body. According to the biodegradable scaffold, the magnetic nano-particles are added to the biodegradable polymer of the biodegradable scaffold; after expansion, the magnetic nano-particles inside the biodegradable scaffold are heated with the external alternating magnetic field to generate the heat energy, such that the local heating for the scaffold is achieved, the scaffold is subjected to thermoplastic deformation; the scaffold can be fixed and formed after the scaffold is cooled. The heating way by adopting the external alternating magnetic field has advantages of heating point centralizing, controllable heating temperature and less damage to the surrounding environment organizations, such that the retraction rate of the biodegradable scaffold of the present invention after the expansion can be effectively reduced, the problem of the restenosis generating inside the scaffold due to the scaffold collapsing and the scaffold shifting can be avoided, wherein the high retraction rate of the biodegradable scaffold in the prior art can cause the scaffold collapsing and the scaffold shifting.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

Technology for plating carbon film on surface of capillary glass tube

ActiveCN104947066AReduce energy lossAchieve localized heatingChemical vapor deposition coatingFiberCarbon film

The invention provides a device and a technology for plating the surface of a glass capillary tube with a carbon film. The device comprises a carbon dioxide laser printer fixed on a base and a prism matched with the carbon dioxide laser printer and further comprises a hollow casing, wherein a light transmitting window corresponding to the prism is formed in one side surface of the casing, a first gas hole and a second gas hole are formed in the other side surface of the casing, the first gas hole is communicated with a vacuum pump, and the second gas hole is communicated with an acetylene and nitrogen gas tank; an optical fiber clamp is arranged on the casing, and the inner part of the casing is hermetically sealed with the outer part of the casing. The carbon film plating device is suitable for carrying out carbon film deposition on the surface of the glass capillary tube in a chemical vapor deposition method. The glass capillary tube needing to plated with the film is inserted in a collimated glass tube, a tail fiber on the tail is tightened and sealed through a rubber pad, the optical fiber clamp, an optical fiber fixing clamp and a nut, and two turriform joint devices are respectively connected with the vacuum pump and the gas tank. The glass capillary tube coated with the carbon film can effectively prevent the corrosion of hydrogen ions in an external environment. The service life of the glass capillary tube is prolonged.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

Heat exchanger, and especially manufacturing method of adsorption type heat exchanger

InactiveCN104588895AReliable closureAvoid erosionHeat pumpsBoiler absorbersEngineeringLow melting point

The invention relates to a heat exchanger, and especially a manufacturing method of an adsorption type heat exchanger. A plurality of composition parts of the heat exchanger are composed of iron-based material, such as pipes, a housing part enclosing the bottoms of the pipes and surrounding the bottoms and the pipes are assembled and then brazing is subsequently performed. The method can reliably braze joint welding lines in different widths. When the composition parts, made of steel or stainless steel, of the heat exchanger are assembled, welding films are disposed between the joint welding lines of the composition parts of the heat exchanger, the joint welding lines are then filled with low-melting-point welding materials, and the brazing without a welding flux is then performed.

Owner:MAHLE BEHR GMBH & CO

Low-temperature sintered nano silver paste and sealing method of sealing device

InactiveCN110429065AGuaranteed Intrinsic PropertiesGuaranteed connection strengthSemiconductor/solid-state device detailsSolid-state devicesSilver pasteOrganic solvent

The invention provides a low-temperature sintered nano silver paste and a sealing method of a sealing device. The components of the low-temperature sintered nano silver paste comprise a glass powder,a silver powder and an organic solvent. The glass powder comprises, in mol percentages, 25% to 50% of Bi2O3, 40% to 60% of H3BO3, and 10% to 30% of ZnO. The low-temperature sintered nano silver pastesatisfies a low-temperature sintering requirement, is friendly to environment, and guarantees the intrinsic characteristics of a material at a sealing part, and the connection strength and the air impermeability of the sealing part. The nano silver paste is printed on the surface of cleaned glass, ceramic and kovar alloy by steel screen or silk screen, and can form a silver film with high bondingforce and a shear strength more than 40MPa on the surface of the cleaned glass, ceramic and kovar alloy after a binder discharging and low-temperature sintering treatment.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

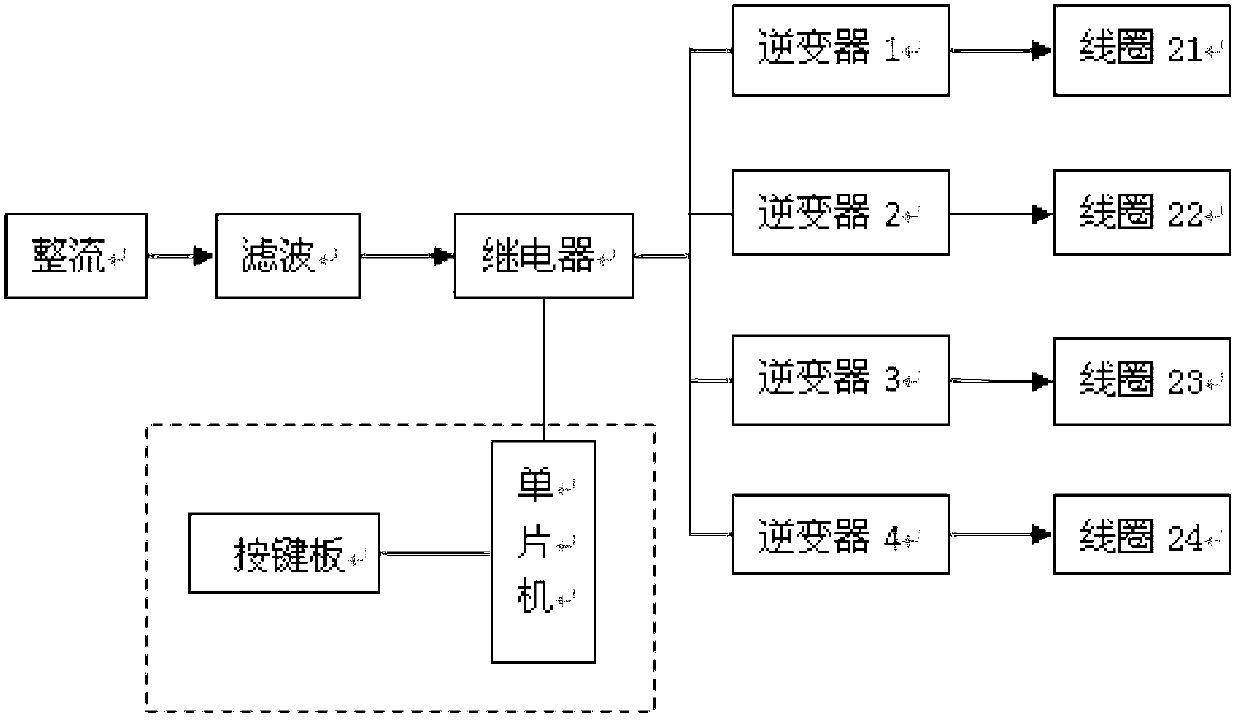

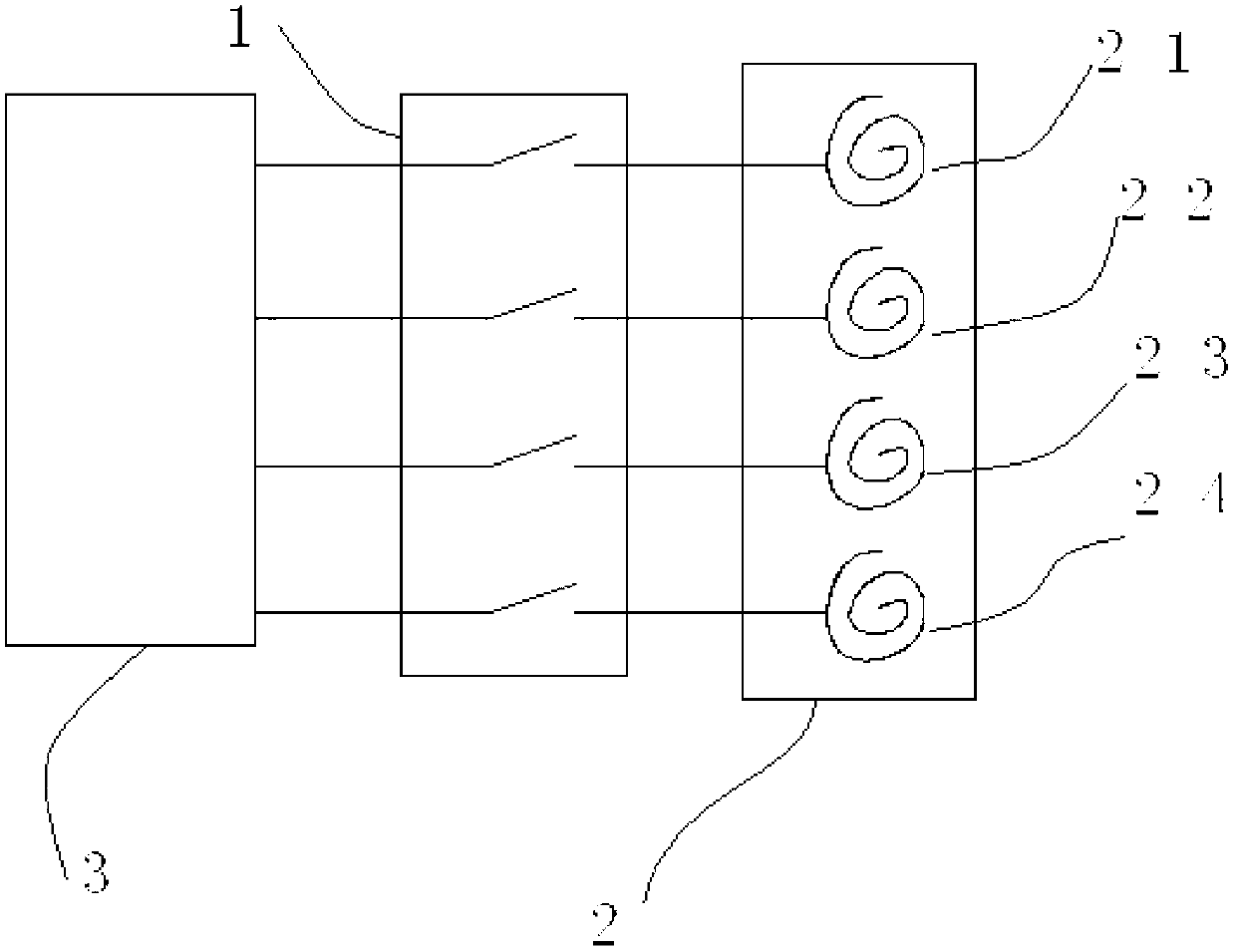

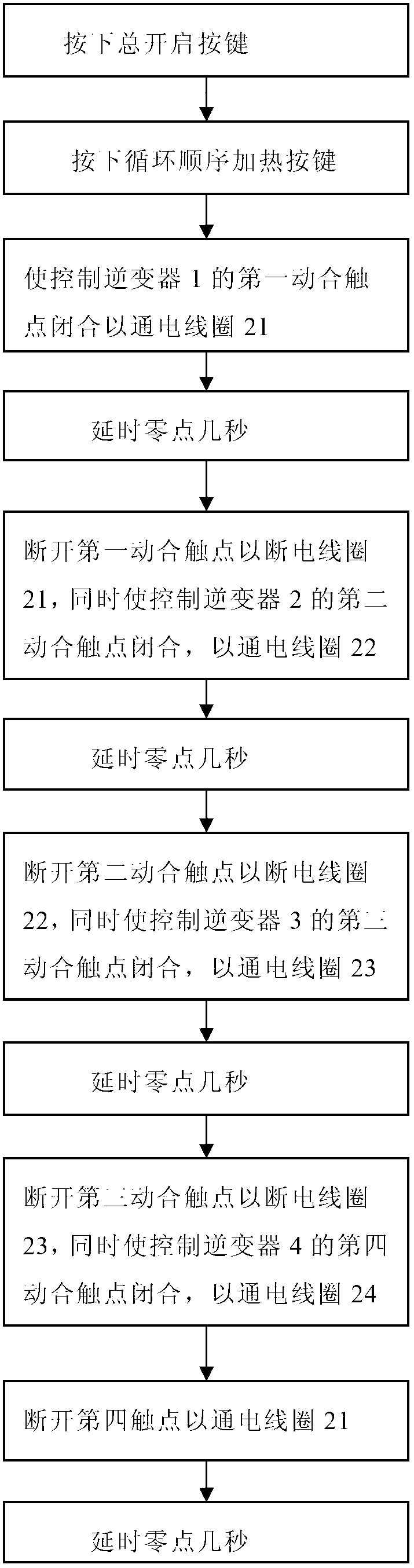

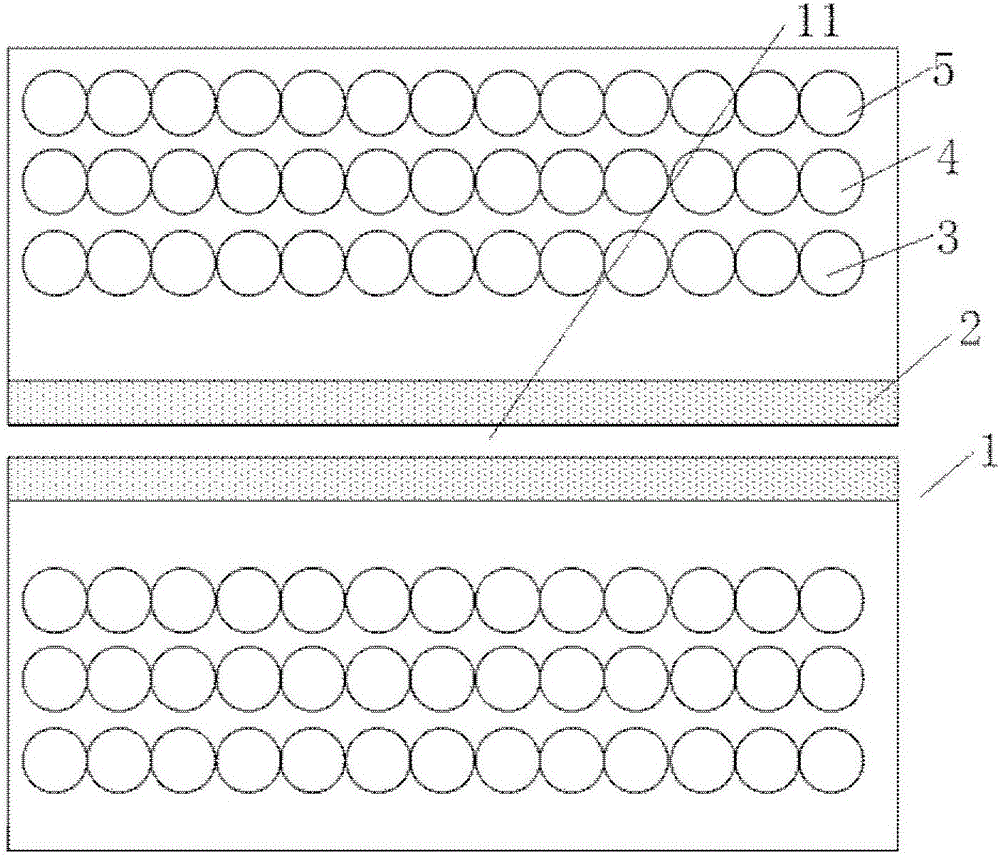

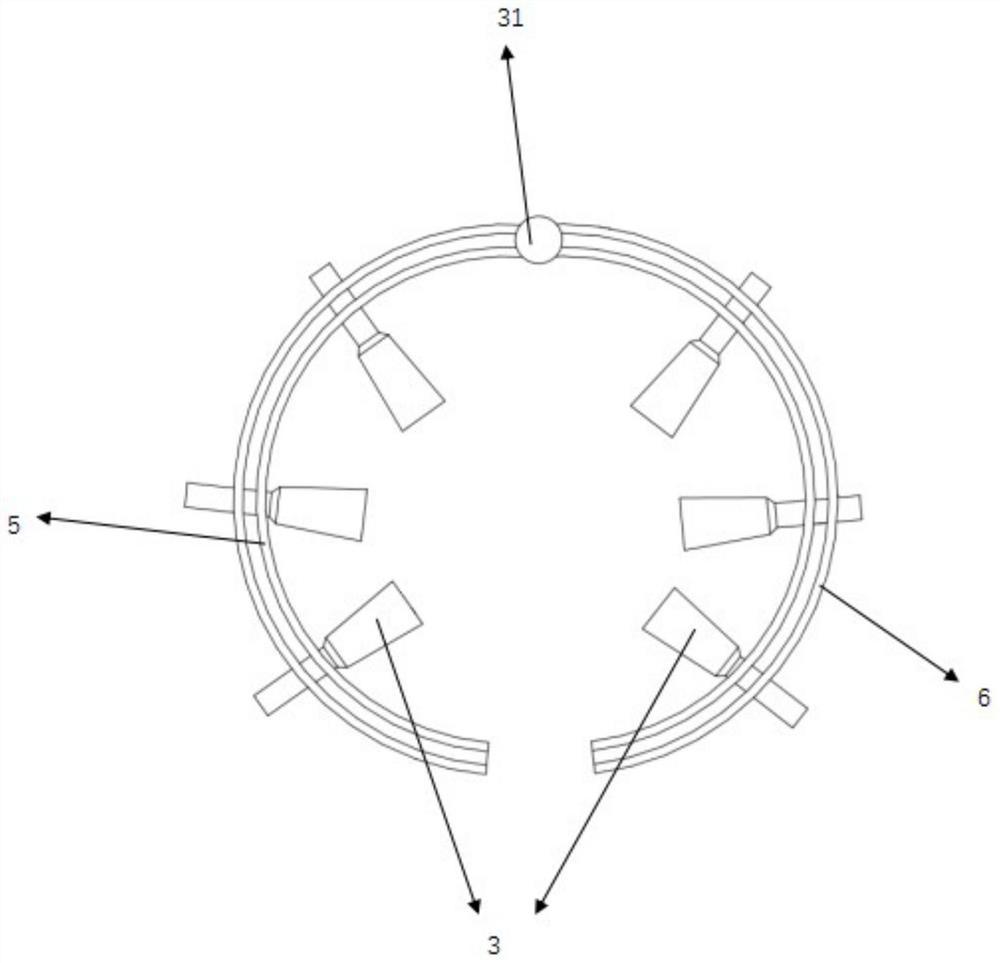

Induction heating system with external combined induction heating coil phased arrays and application for induction heating system

ActiveCN102740520AEliminate interactionAchieve localized heatingInduction heating controlMicrocontrollerCompression molding

The invention discloses an induction heating system which is provided with external combined induction heating coil phased arrays and used for an injection molding process and an application for the induction heating system, and belongs to the field of methods for manufacturing injection molding products. According to the technical scheme, a singlechip, a relay, inverters, coils and a keyboard are provided, wherein a program for controlling each heating mode states is pre-set in the singlechip; and switching among the heating mode states is realized by the keyboard; induction coils is powered on or powered off according to the preset program sequence or other ways, so that mutual influence of magnetic fields among the coils is eliminated, and the heating efficiency is improved; and meanwhile, the coils also can be separately or synchronously powered on or powered off according to the specific sequence, so that local temperature of a mould cavity can be controlled, and the heating flexibility is increased; and therefore, the system is particularly suitable for performing injection molding on parts which are made of thermoplastic or thermosetting composite materials or heating complicated mould cavities of injection moulds and locally heating the mould cavities of the injection moulds during compression molding production.

Owner:芜湖精益达模塑股份有限公司

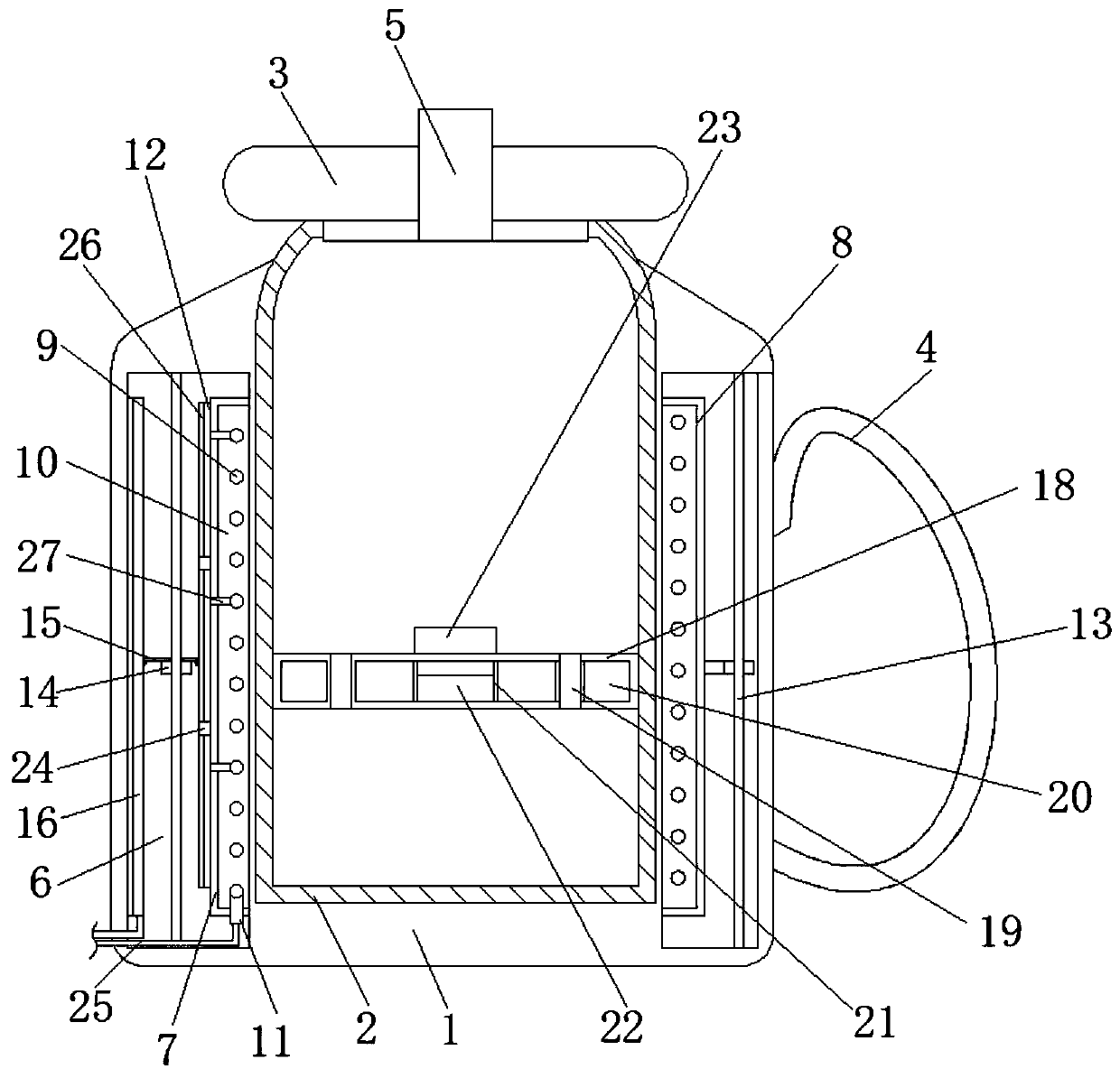

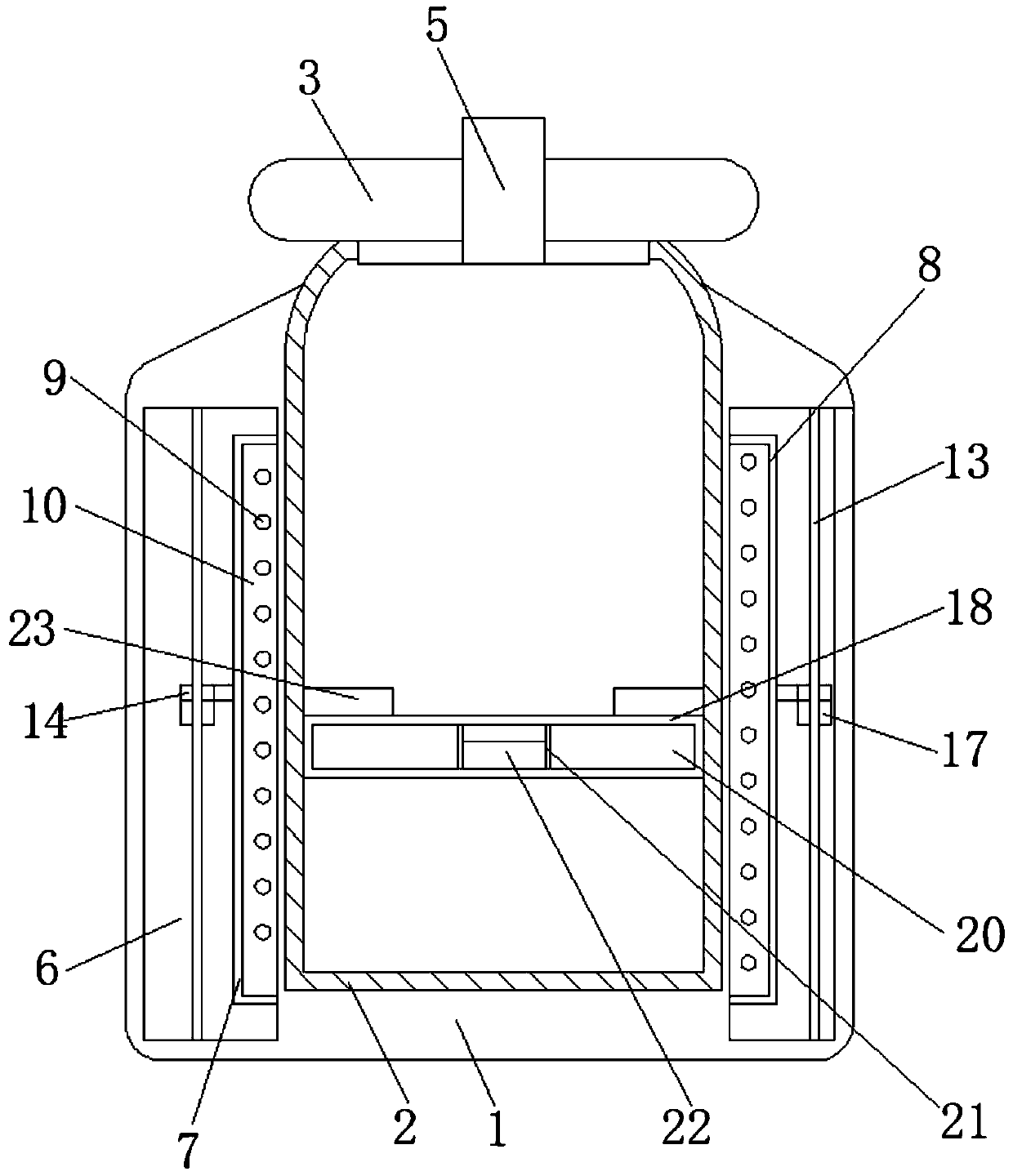

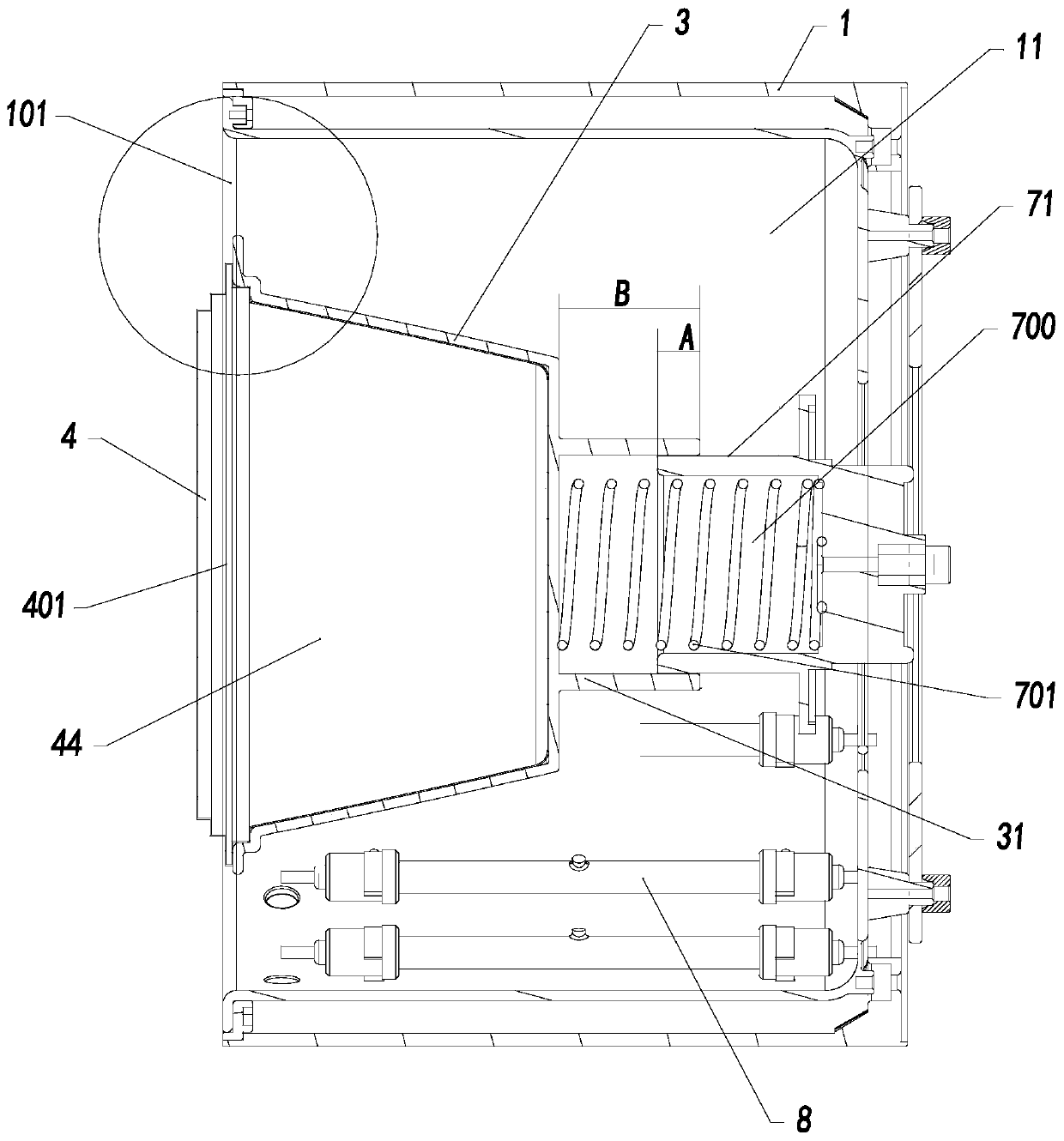

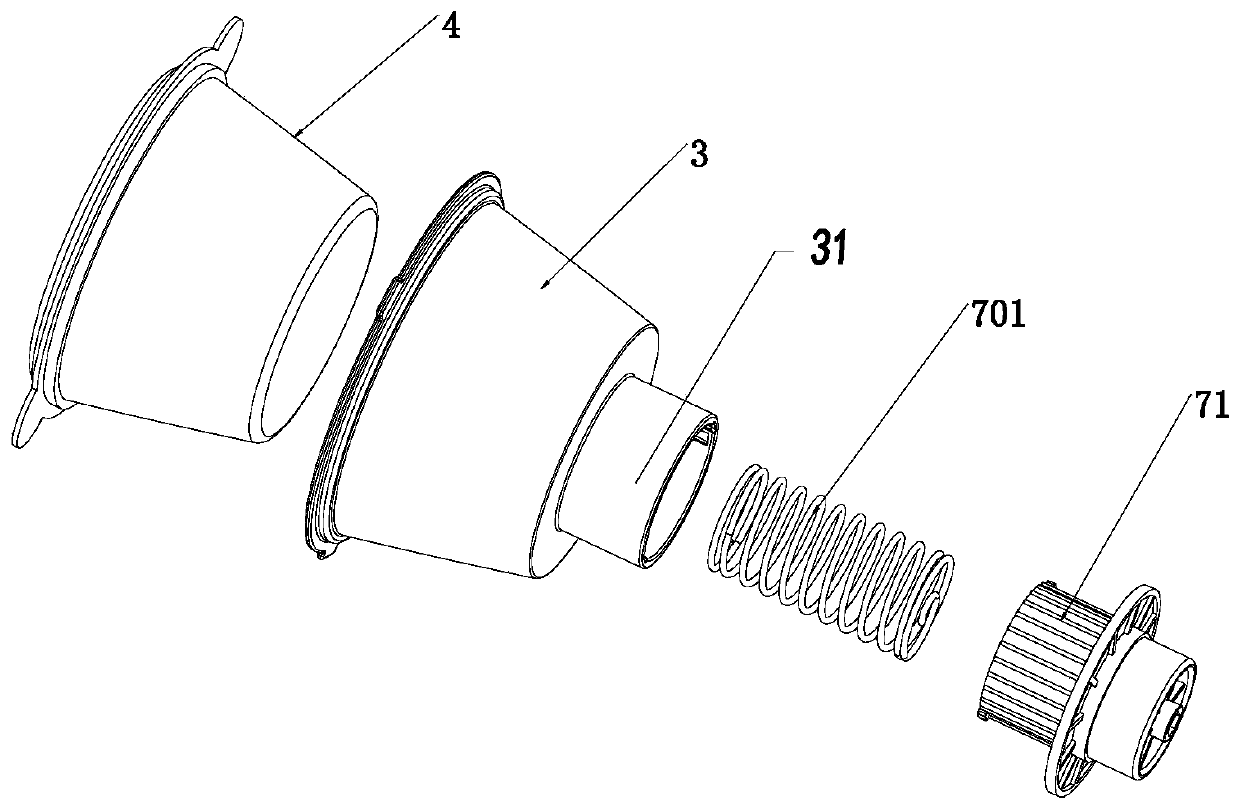

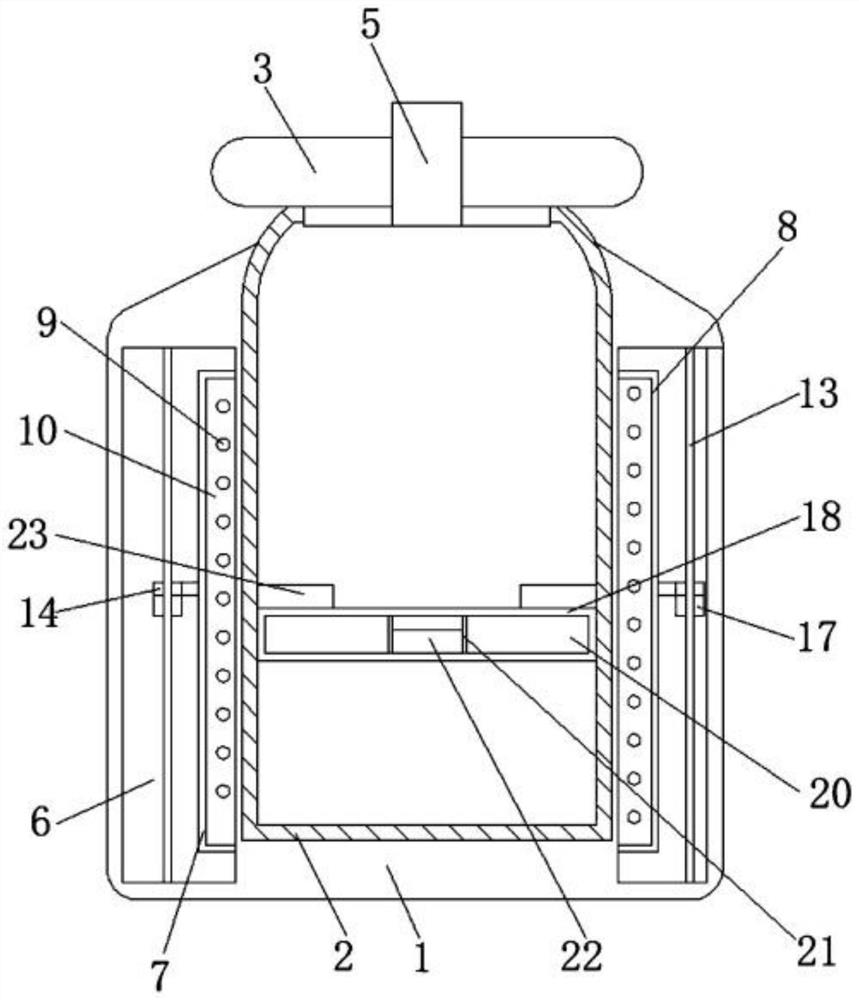

Lifting-type self-adaptive local-heating electric kettle

The invention belongs to the technical field of household appliances and discloses a lifting-type self-adaptive local-heating electric kettle which comprises an outer shell, an inner container, a kettle cover, a handle and an air release valve. The inner container is fixedly socketed in the outer shell, the kettle cover is connected at an opening of the inner container in an inserted manner, the air release valve is mounted in a hole in the middle of the kettle cover, the handle is welded on the right side face of the shell, an annular cavity is formed inside the outer shell, a heating shell is welded on the side wall, close to the inner container, of the annular cavity, and an electric heating wire is arranged in an annular notch formed in one side wall, close to the inner container, of the heating shell. Through sectional design of the electric heating wire, a contact piece is enabled to be communicated with a copper piece corresponding to water level by utilizing buoyancy of water to jack up a floating block to realize working of a part corresponding to the electric heating wire, heating power is increased, targeted local heating is realized, water heating efficiency is improved, and electric energy loss is lowered.

Owner:杭州傲贯网络科技有限公司

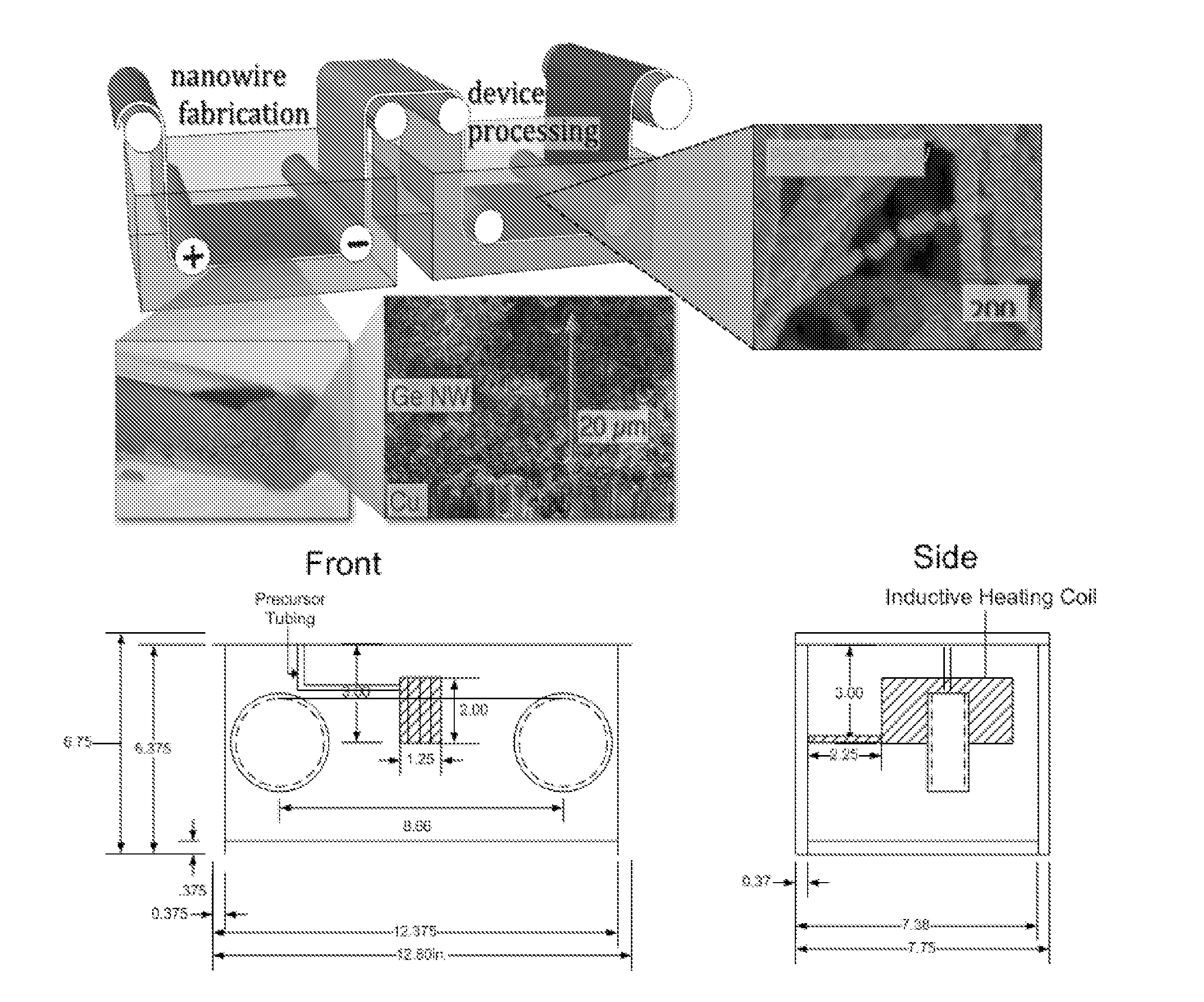

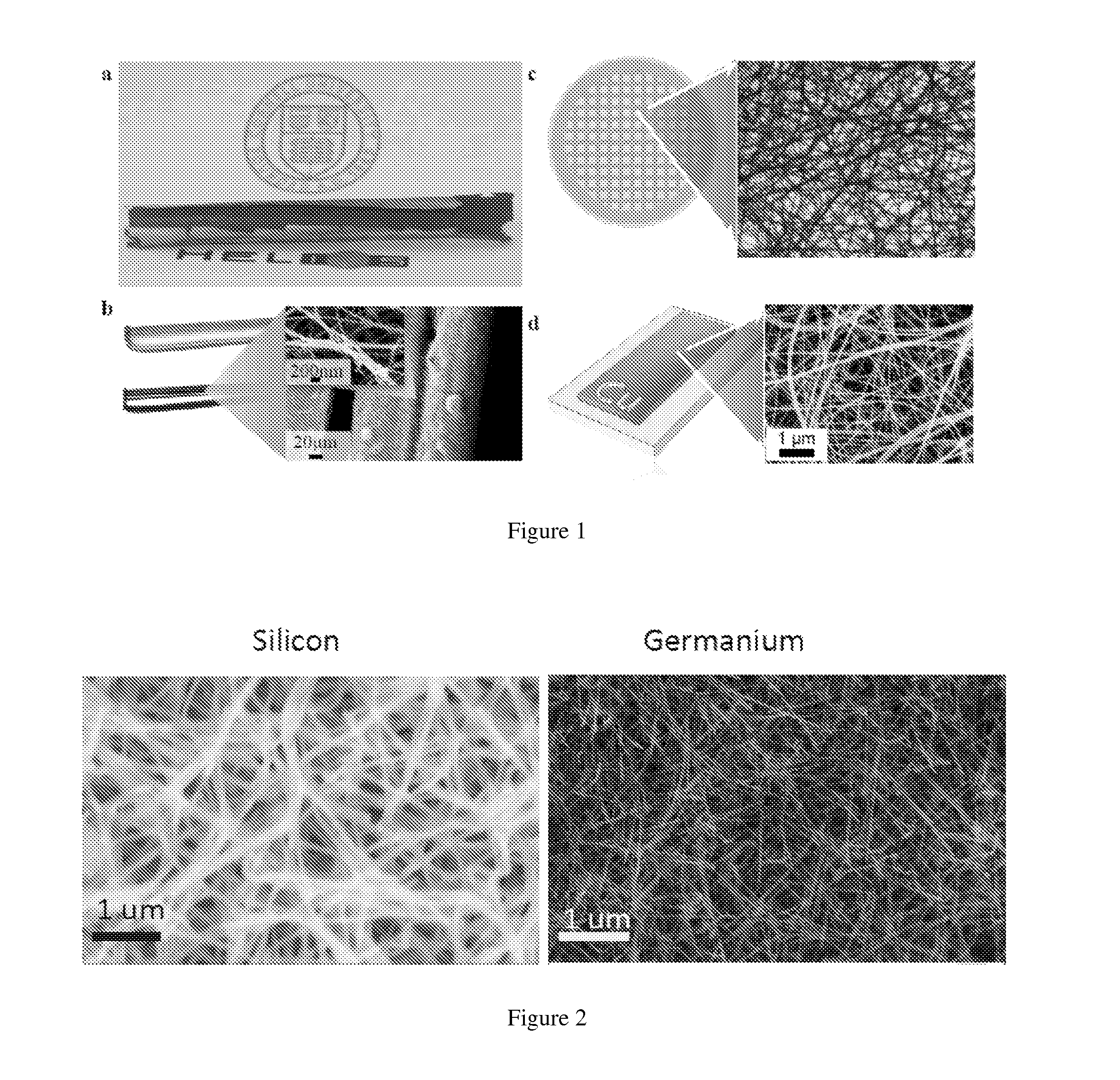

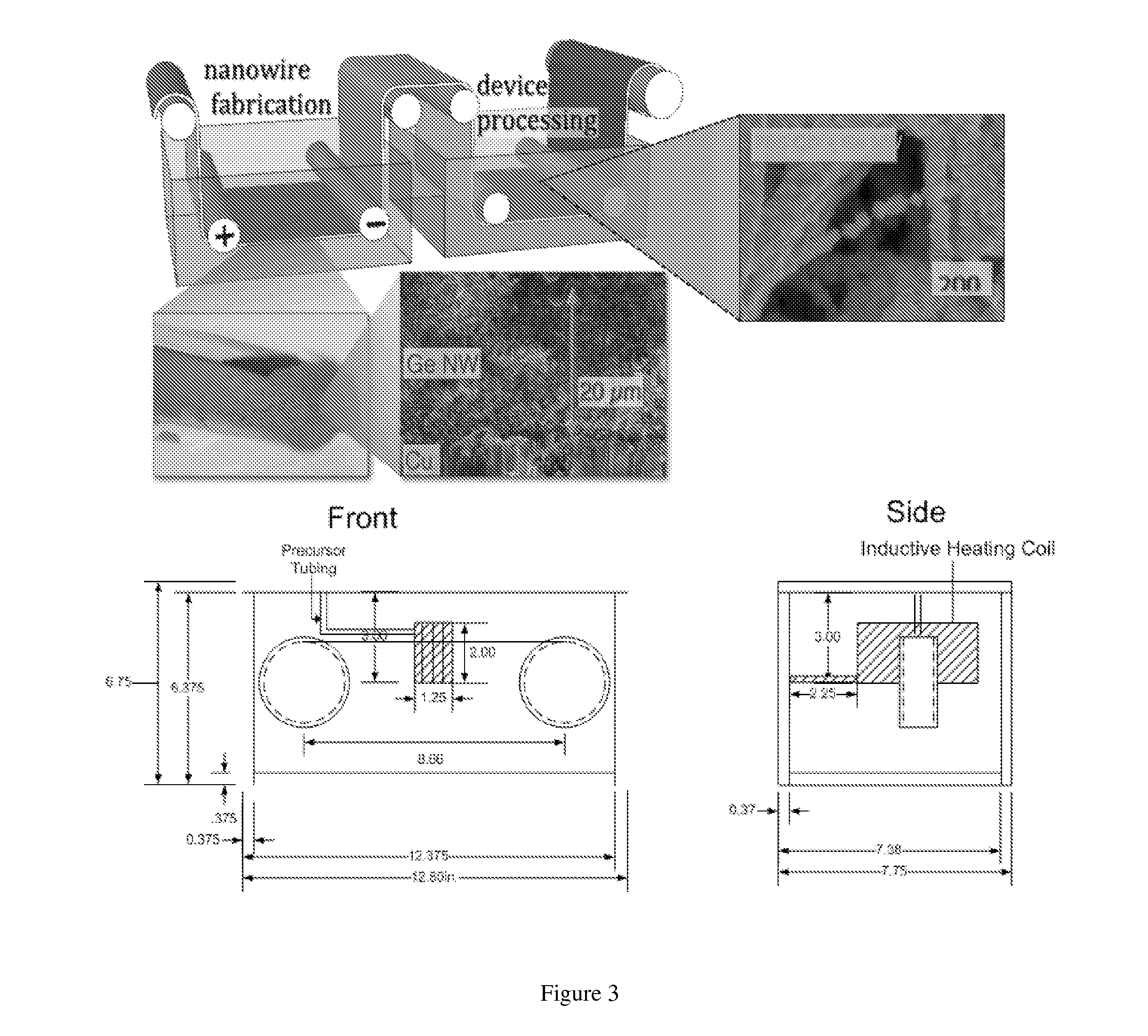

Group iv nanowires grown from inductively or resistively heated substrates

InactiveUS20160237591A1Improve nanowire growthRapid productionPolycrystalline material growthFrom normal temperature solutionsNanowireSurface loading

Growth of Group IV nanowires with a substrate and a Group IV metalloid is performed using resistive or inductive heating of the substrate. A roll-to-roll process enables a metal surface to move through a reaction environment while reacting with a stream or bath of precursor to form the nanowire-metal complex. The Group IV nanowires on a surface of the substrate can have a surface loading greater than 10 mg / cm2.

Owner:CORNELL UNIVERSITY

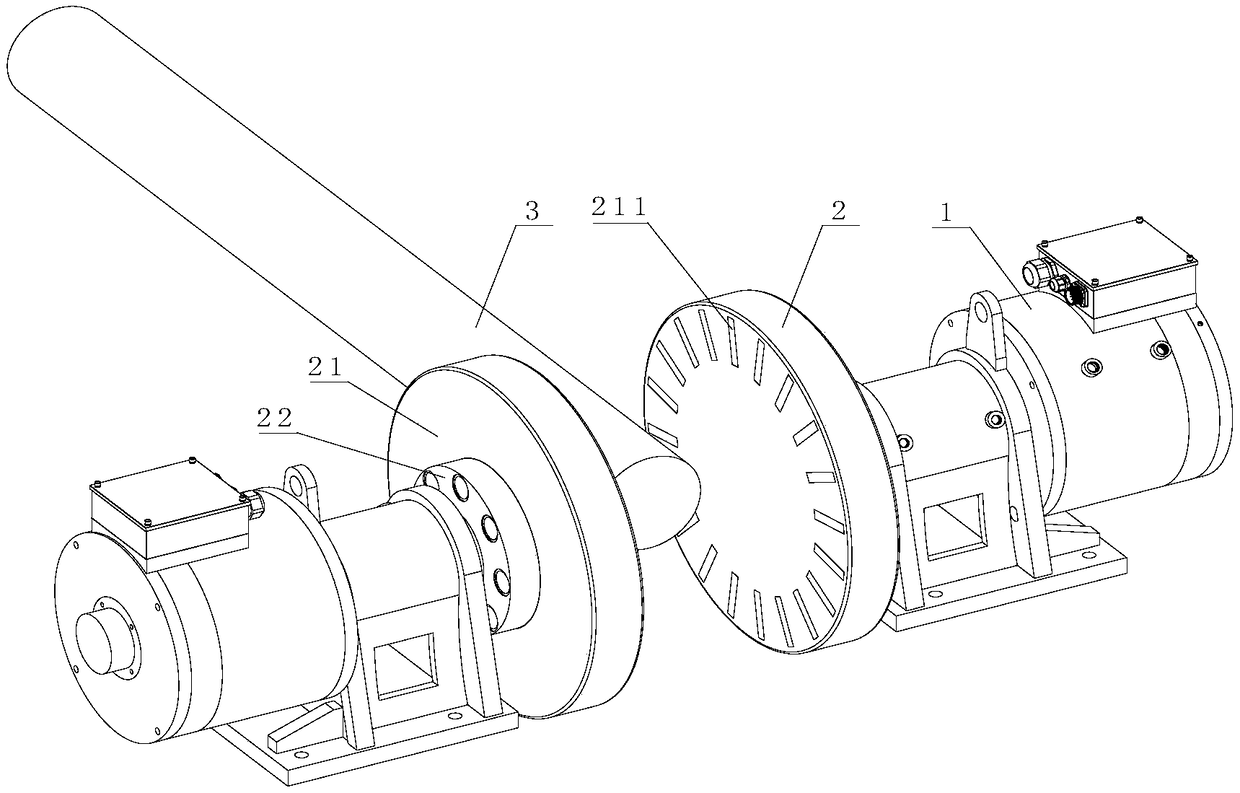

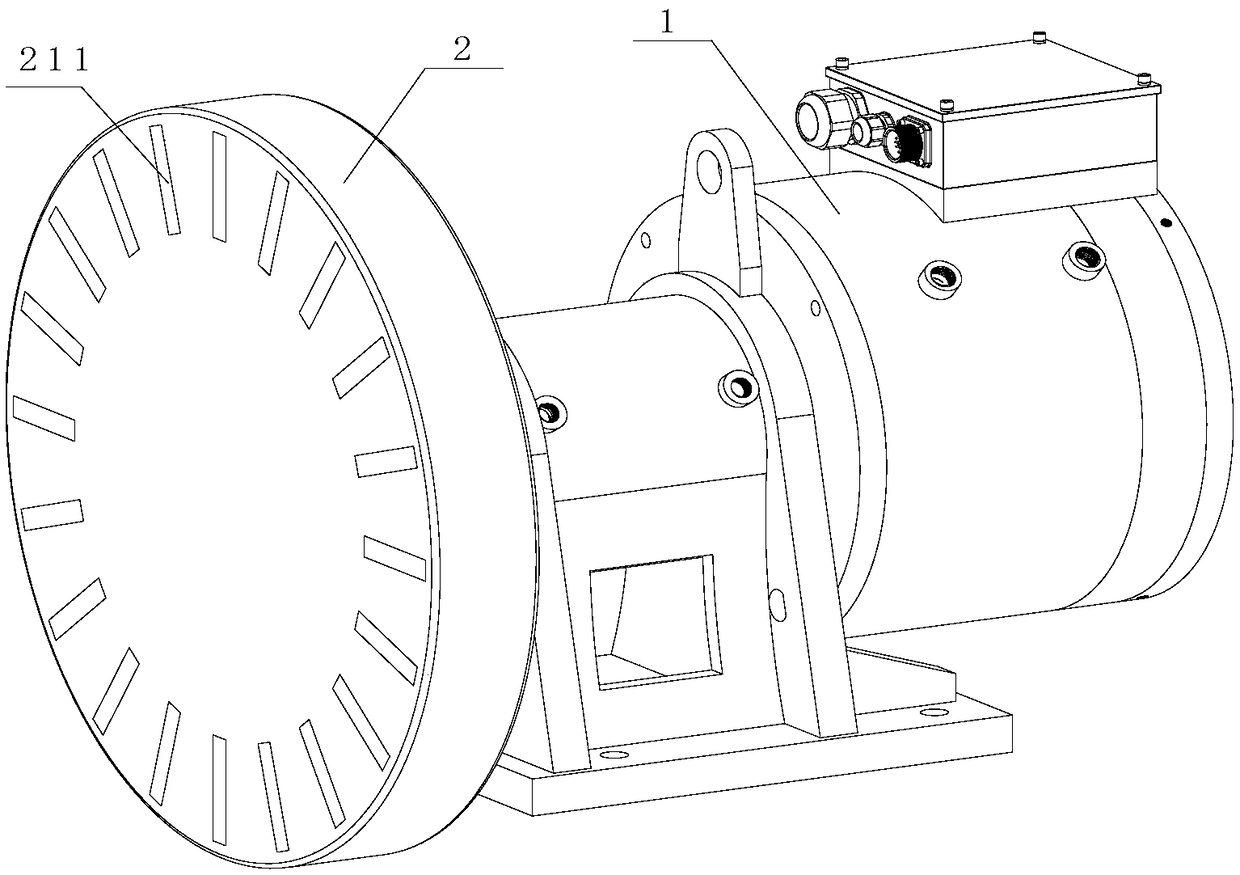

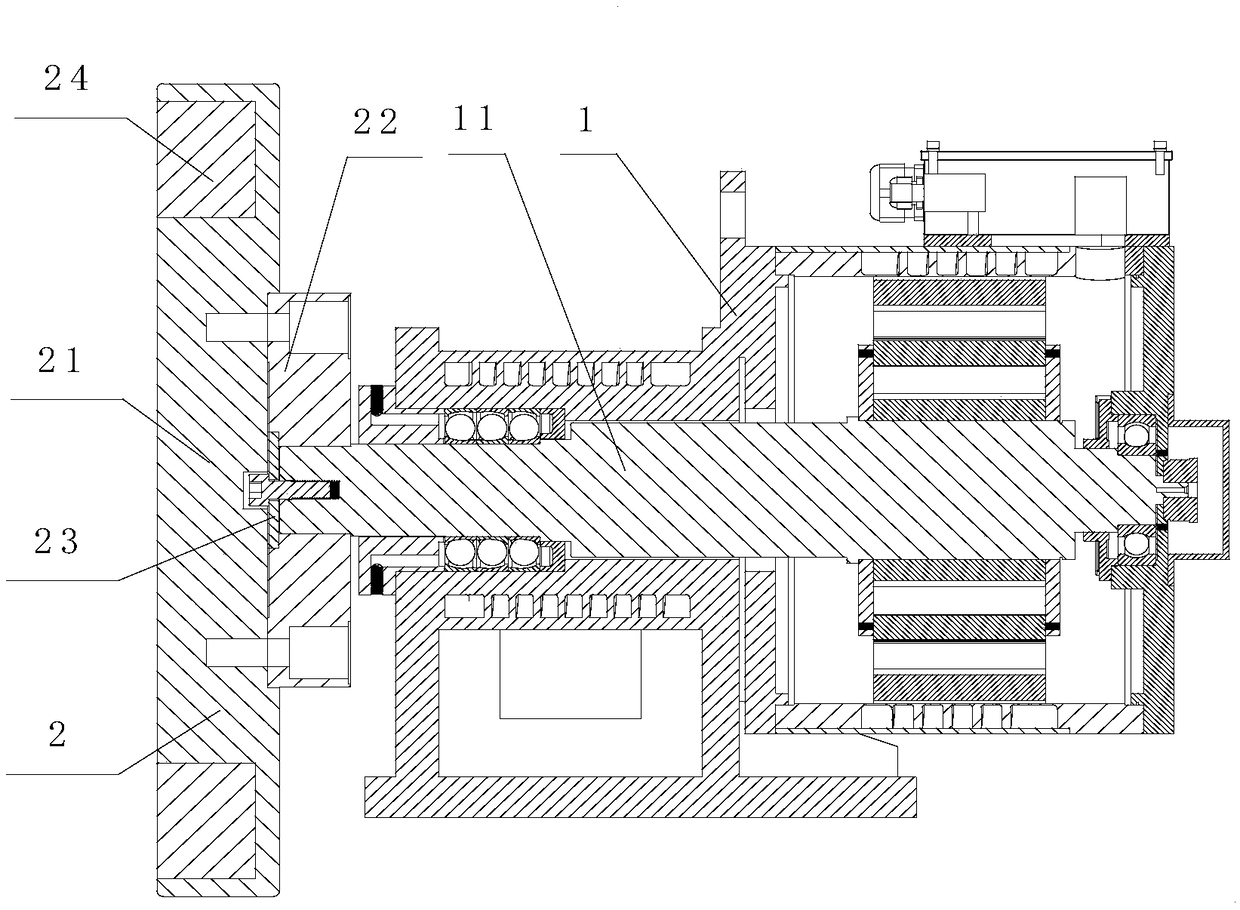

Electromagnetic induction heating motor, heading system, and heating method

PendingCN109302760ASimple structural designReduced precision requirementsInduction heating apparatusElectric machineElectromagnetic shielding

The invention relates to an electromagnetic induction heating motor comprising a motor body and an electromagnetic induction heating device. The electromagnetic induction heating device comprises a driving turntable sleeving a motor shaft of a motor body, a driving turntable compressing plate being arranged at the outer end surface and being fixedly connected to the motor shaft, and an electromagnetic induction disc being fixedly connected to the outer end surface of the driving turntable. A plurality of rectangular grooves are distributed on the electromagnetic induction disc uniformly alongthe circumferential direction and center lines of the rectangular grooves point to the circular center of the electromagnetic induction disk to form adial arrangement; and N-Pole or S-pole magnetic steel plates orienting to the bottoms of the grooves together are arranged in the grooves. According to the novel provided unique mode of heating a metal blank material, the metal blank material is heated by using electromagnetic induction and the electromagnetic induction disc being a core element for heating has no temperature rising during the heating process, so that no thermal losses are causedand energy-saving and environment-friendly effects are good. The electromagnetic induction heating motor has advantages of reasonable structure, wide application range, low manufacturing cost and good local heating capability and the like.

Owner:HI HLDG

Preparation method of paving brick with guiding gutter

InactiveCN108640589AAvoid damageSolve the situation that is not easy to demouldSingle unit pavingsPaving gutters/kerbsSurface layerMaterials science

The invention discloses a preparation method of a paving brick with a guiding gutter. The method comprises the following steps that paraffin is poured into a core mold structure of a drainage channel,and the inner portion of a core mold is provided with a metal thermal conductive wire; the core mold made from the paraffin is clamped in a mold frame,the distance between the very bottom end of the core mold and the very bottom end of the mold frame is 50-80 millimeters; a moderate bottom material and surface material are weighed in proportion,the bottom material and surface material in the moldframe are pressed,shaped and de-molded to obtain a green brick; the green brick is maintained; shot blasting is carried out on the surface of a surface layer of a maintained product; the core mold isheated to be de-molded,the metal thermal conductive wire in the core mold is heated,thereby cleaning away the paraffin core mold after the paraffin core mold is melted. The preparation method of the paving brick with the guiding gutter has the advantages that the paraffin mold replace a traditional mold,subsequent de-molding only needs heating for melt,so that the de-molding can be carried out quickly,the problem of difficult de-molding of the traditional mold is solved,the drainage channel penetrating through the inner portion of the paving brick can be arranged through the paraffin mold,andthe de-molding can be convenient.

Owner:陈卫

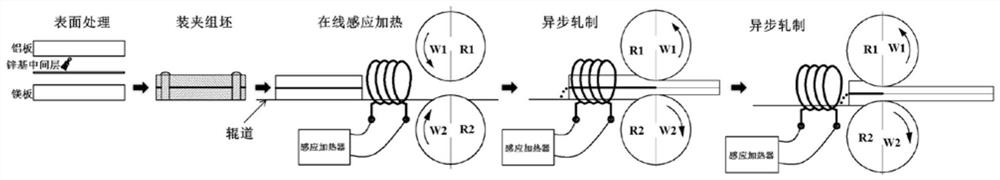

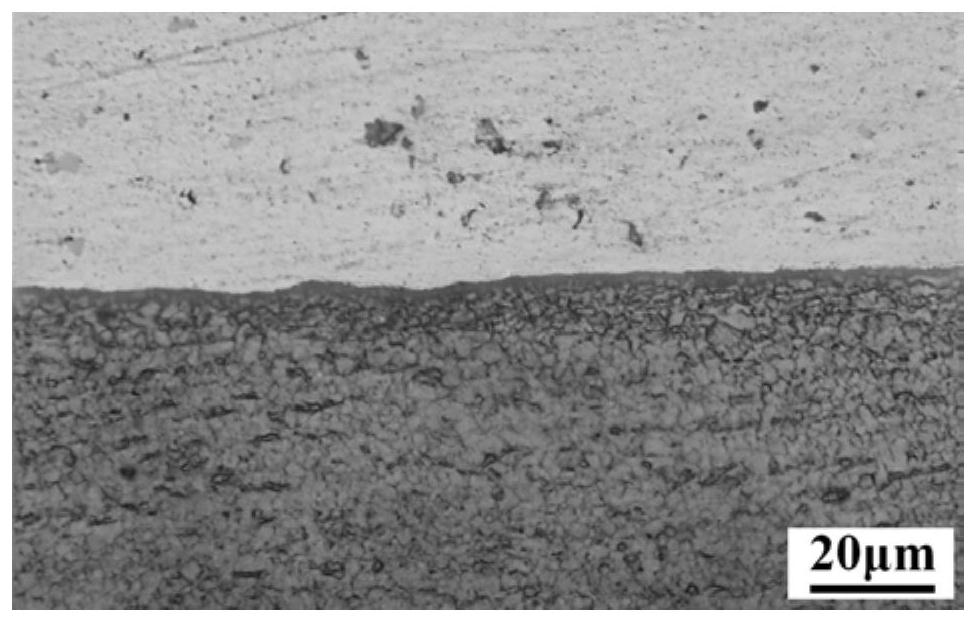

Asynchronous rolling-local liquid phase compounding method for preparing aluminum/magnesium composite plate

ActiveCN113290051AAchieve localized heatingRelief of oxidationAuxillary arrangementsMetal rolling arrangementsMetallic materialsComposite plate

The invention discloses an asynchronous rolling-local liquid phase compounding method for preparing an aluminum / magnesium composite plate, and belongs to the technical field of metal material machining. The method comprises the following steps that an aluminum alloy plate, a magnesium alloy plate and a zinc-based middle layer with preset sizes are machined; oil stains are removed, and an oxide layer is cleaned and blow-dried; tightly fitting, assembling and fixing are performed according to an aluminum / zinc / magnesium sequence; a blank is subjected to induction heating to 350-550 DEG C, and the middle layer is molten; different asynchronous ratios are adjusted for asynchronous rolling, and the total reduction rate is 50%-70%; and heat treatment is performed on a hot-rolled composite plate to obtain a composite plate product. According to the method, the aluminum-magnesium composite plate is prepared through online induction heating, local liquid-phase compounding and asymmetrical rolling, generation of interface products of a composite interface is greatly reduced, and interface oxidation is prevented; rolling force is small, rolling mill load is low, and the requirement for rolling mill capacity is low; and the composite plate has small residual stress and good rolled plate shape quality. The prepared aluminum / magnesium composite plate is high in interface bonding strength and good in plate shape, has few interface brittle products, and is free of assembling and separant, short in process, low in energy consumption, energy-saving and environment-friendly.

Owner:NORTHEASTERN UNIV

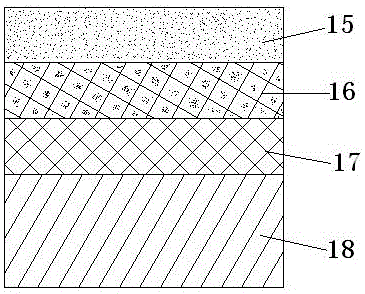

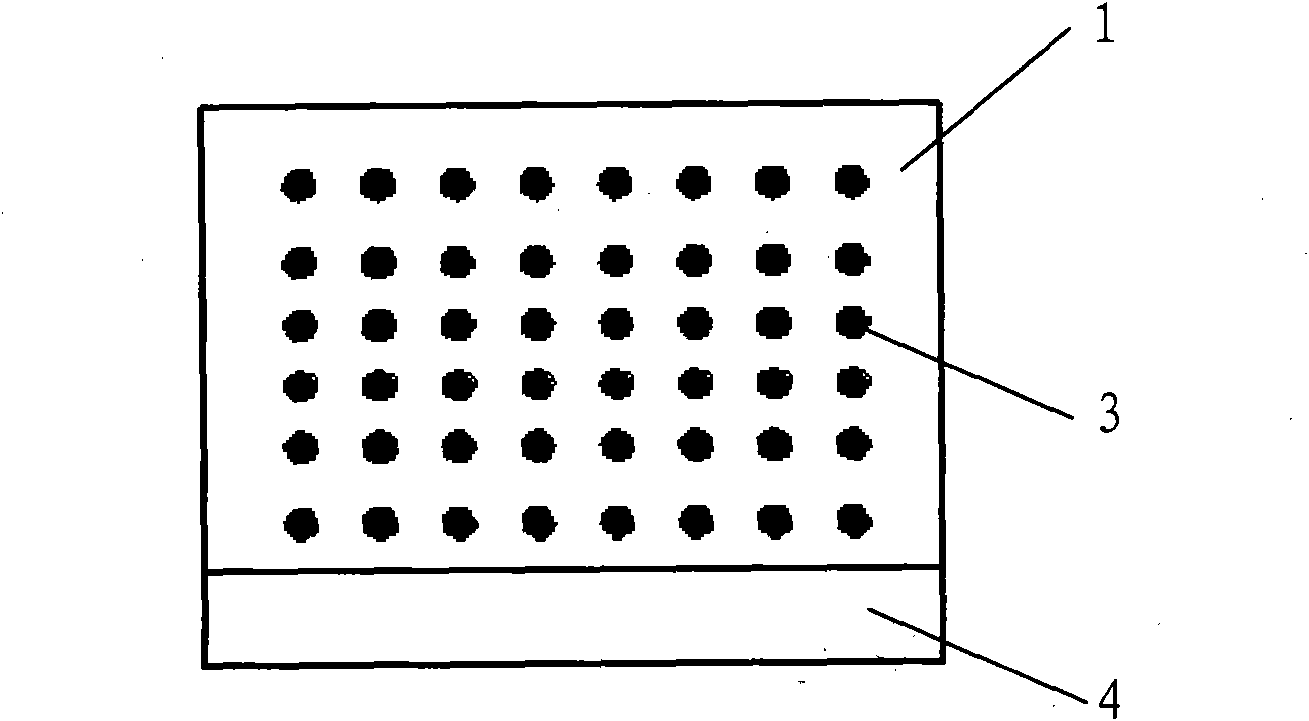

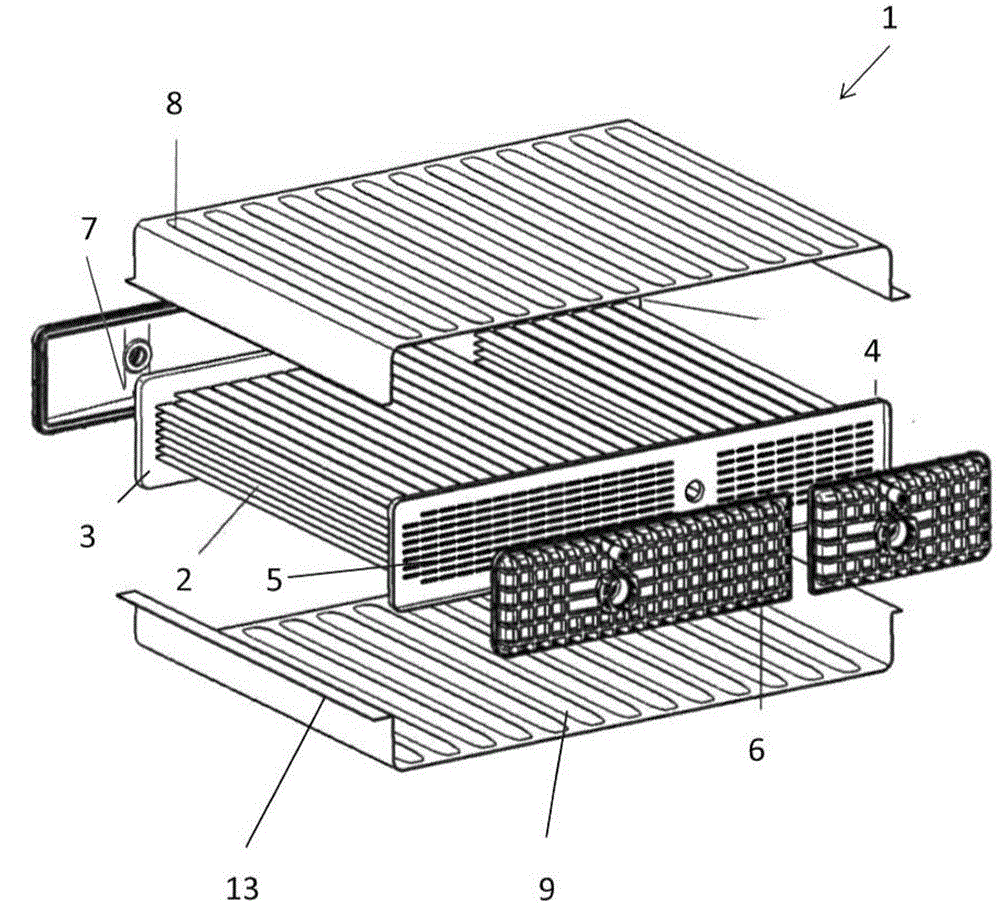

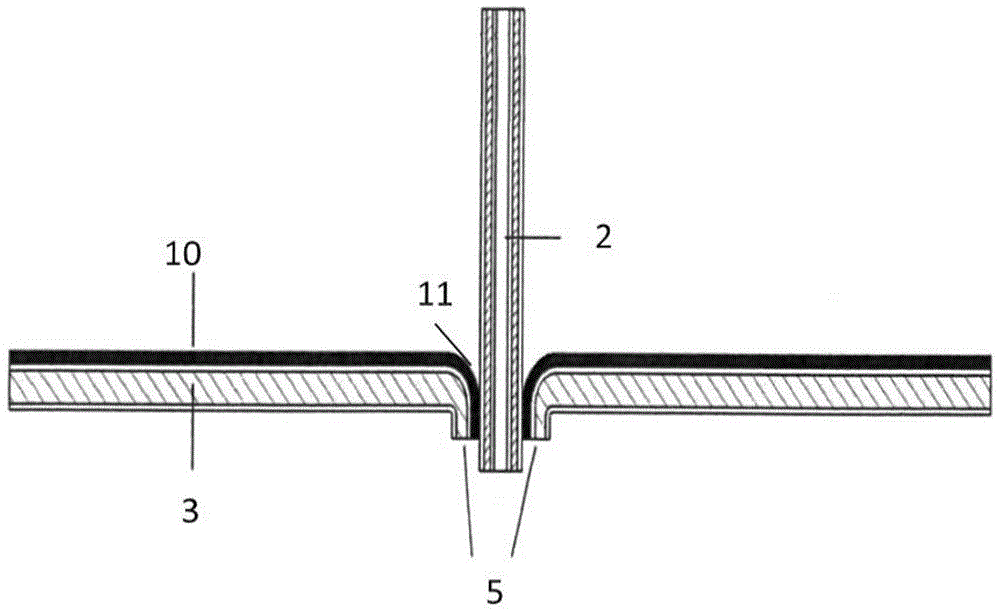

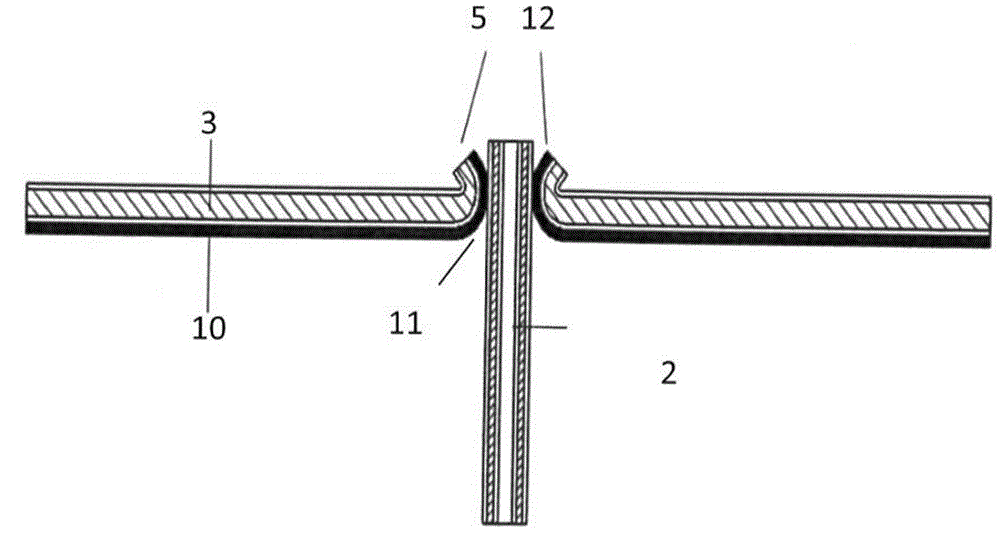

Minitype electric heating plate and manufacturing method thereof

InactiveCN101111104AEasy to assembleEasy to disassembleLaminationLamination apparatusCompression moldingPhysical well being

The present invention relates to a small size electric heating board and the manufacturing method. The small size electric heating board of the present invention is composed of a box shaped board being equipped with at least two air vents, a connecting box and a channel and coated with a far infrared ray emission coating; a natural carbon bed, which is formed in the box shaped board through compressing and is imbedded with at least two ceramic heating elements; an outer layer material stuck on the lower part laminated with the natural carbon bed without fabric fiber layer. The present invention makes the ceramic heating elements cast in an functional natural carbon bed, and provides an environment protective warming environment, a comfortable indoor living space and a sleeping environment through the environment protective positive function (the production of the far infrared ray and the anion, the antibiotic action, humidity adjusting, air purified, and the generating controlling of electromagnetic wave) of the natural charcoal, thus enhancing health. In particular, the present invention utilizes the natural carbon hot coal with a semi-permanent environmental protection positive function, and lengthens the service life of the electric heating board for twice.

Owner:金玉淑 +1

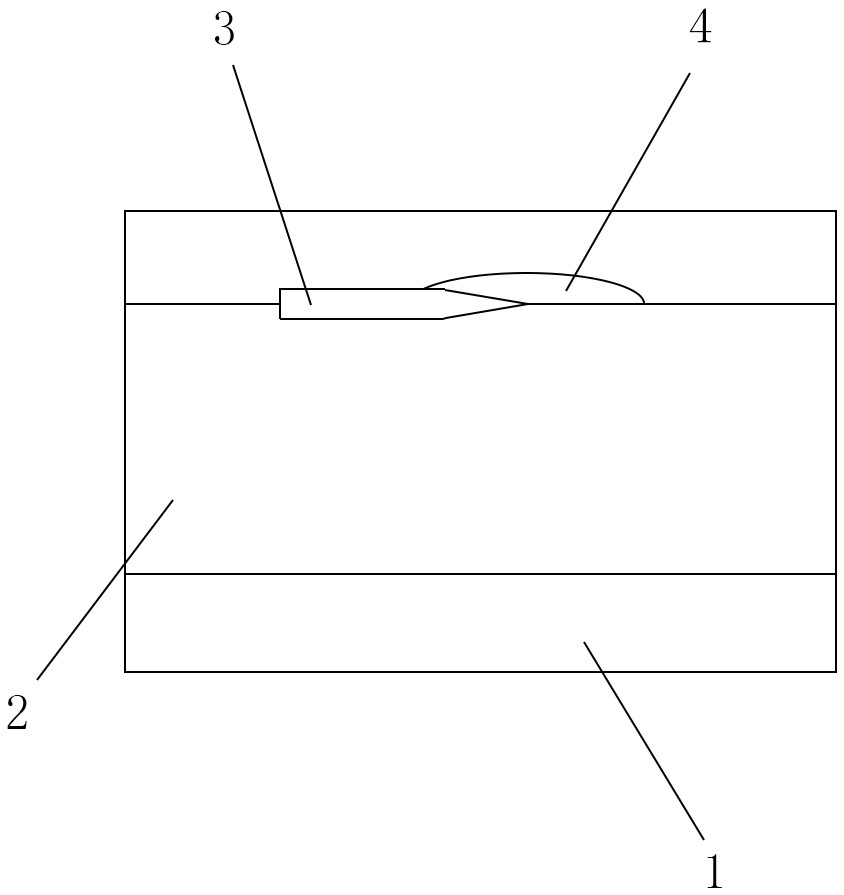

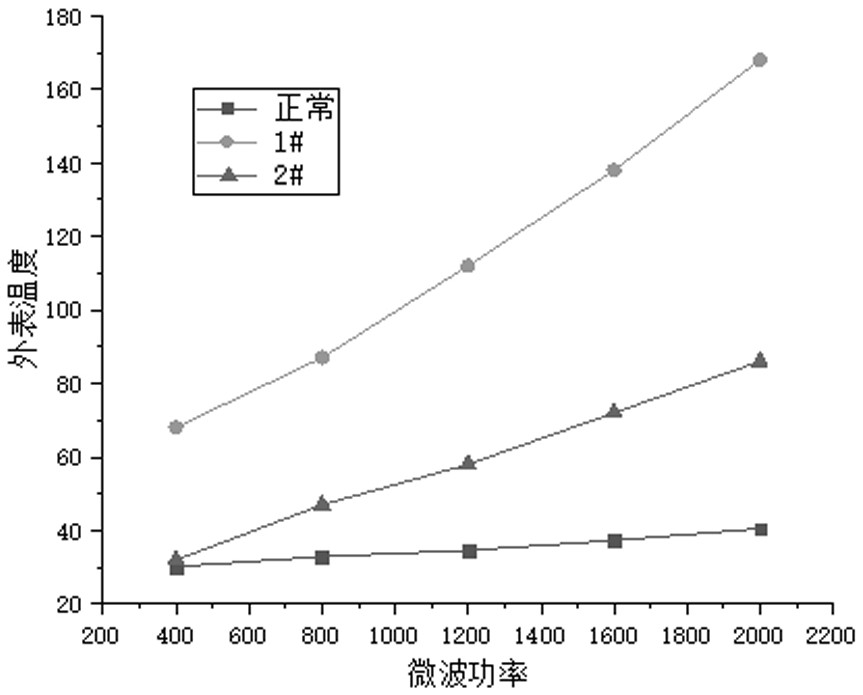

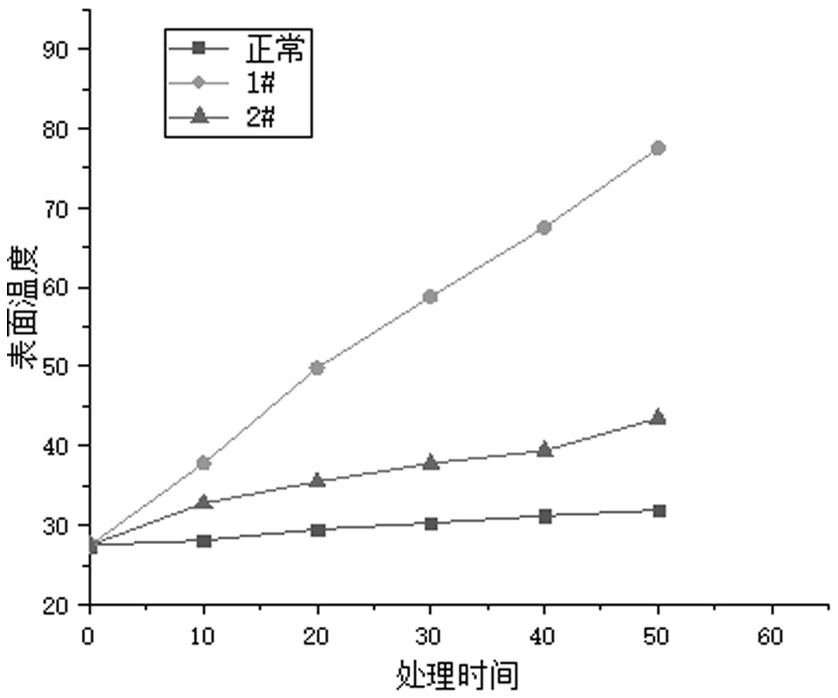

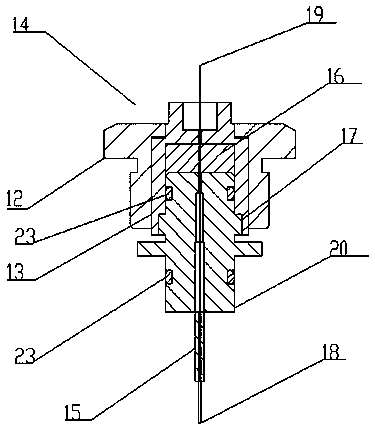

Tool and method for simulating internal heating of composite insulator

PendingCN112432874AAchieve localized heatingPrecise positioningWeather/light/corrosion resistanceTemperatue controlDielectric lossConductive materials

In order to simulate the heating phenomenon of a composite insulator on site as much as possible and further research the influence of high temperature on the rotten fracture of the composite insulator, the invention provides a mechanism of causing the rotten fracture of the composite insulator by high temperature so as to find effective measures for preventing the rotten fracture of the compositeinsulator. The invention provides a tool and method for simulating the internal heating of a composite insulator, and the tool comprises a silicone rubber sheath at the outer layer and a glass fiberreinforced plastic cylindrical core rod wrapped by the sheath, a tiny simulated defect is placed at the critical part of the sheath and the core rod, and the tiny simulated defect, the sheath and thecore rod form the composite insulator with the defect. A semi-ellipsoidal air gap is formed between the simulated defect and the sheath, and the length of the simulated defect is far less than that ofthe core rod; wherein the simulated defect is a high dielectric loss or conductive material, and the sheath and the core rod are made of an insulating material; and microwave heating is carried out on the simulated composite insulator sample to obtain a simulated sample of composite insulator rotting fracture caused by high temperature.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

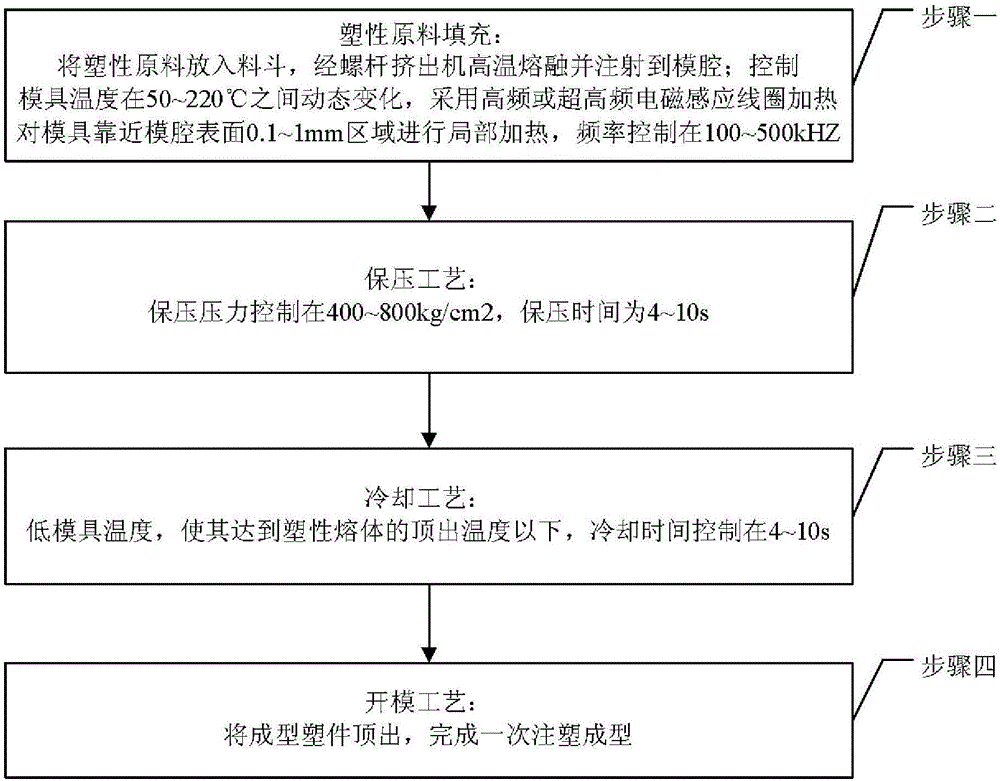

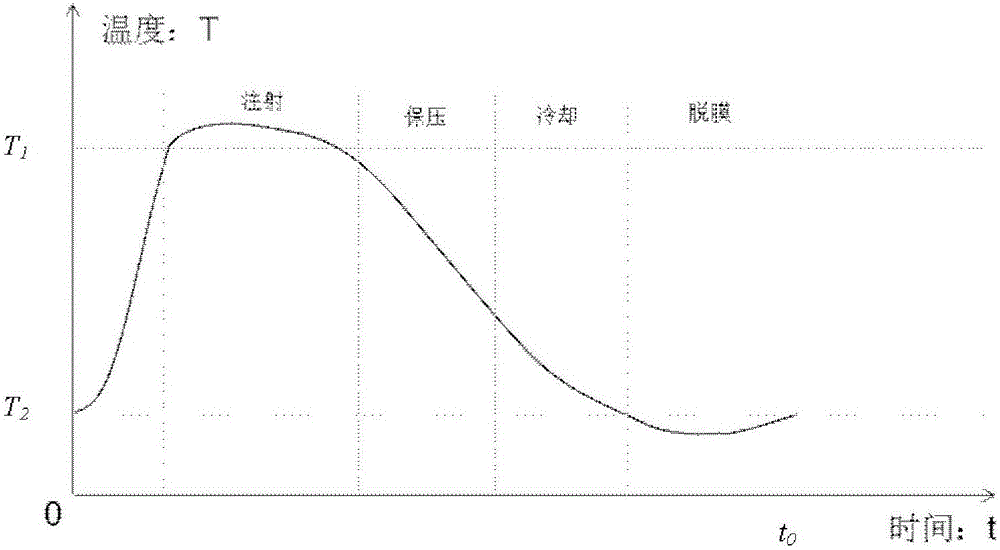

Injection molding method for thin-wall plastic part

The invention provides an injection molding method for a thin-wall plastic part. The injection molding method comprises the following steps of putting plastic raw materials into a hopper, conducting high-temperature melting on the raw materials through a screw extruder, and injecting the raw materials into a mold cavity, wherein the injection pressure ranges from 1500 kg / cm<2> to 3000 kg / cm<2>, injection time is 0.5-2 seconds, and the injection speed is controlled to be 500-1000 mm / s; controlling the temperature of a mold to change dynamically between 50 DEG C and 220 DEG C, and conducting local heating on areas, 0.1-1 mm away from the surface of the mold cavity, of the mold through a high-frequency or ultrahigh-frequency electro-magnetic induction coil, wherein the frequency is controlled to be 100-500 kHz; implementing a pressure maintaining process, wherein the maintained pressure is controlled to be 400-800 kg / cm<2>, and pressure maintaining time is 4-10 seconds; lowering the temperature of the mold, so that the temperature of the mold reaches the ejection temperature of plastic melt or below, wherein the cooling time is controlled to be 4-10 seconds; and implementing a mold opening process, so that the molded plastic part is ejected. By means of the injection molding method for the thin-wall plastic part, cooling time of the mold can be effectively shortened, and energy waste can be reduced.

Owner:TAIZHOU KUANYUAN FURNITURE CO LTD

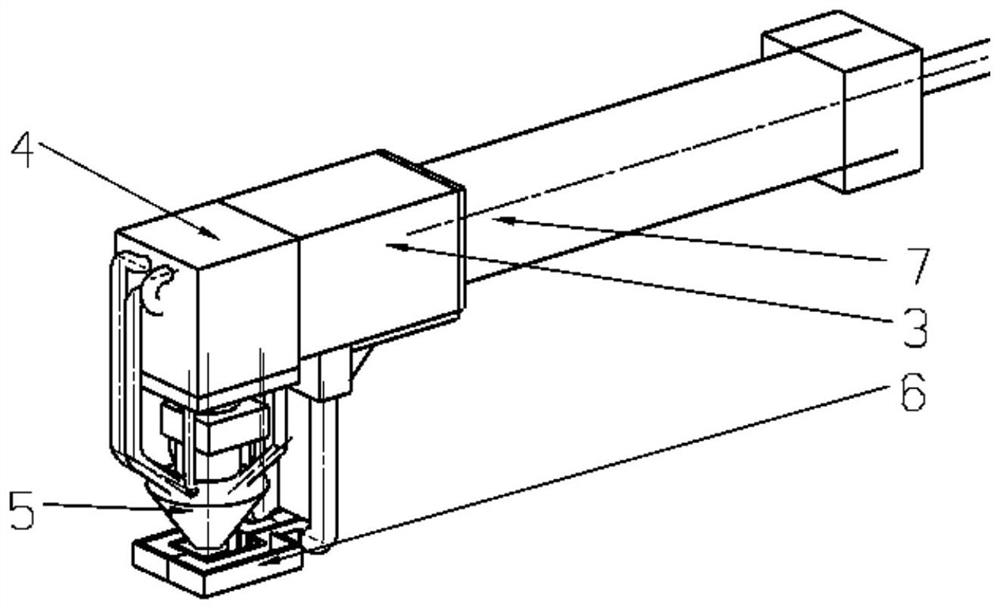

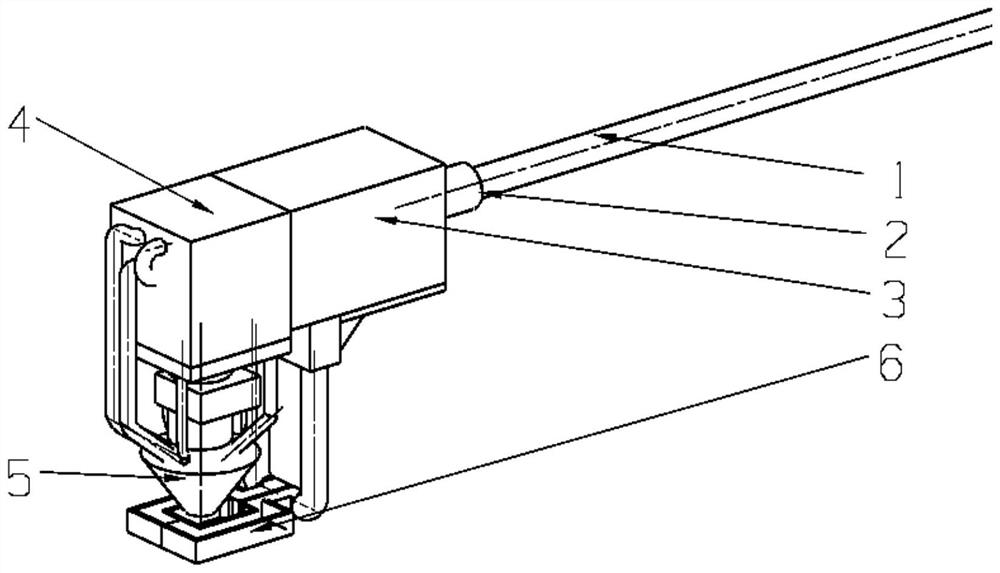

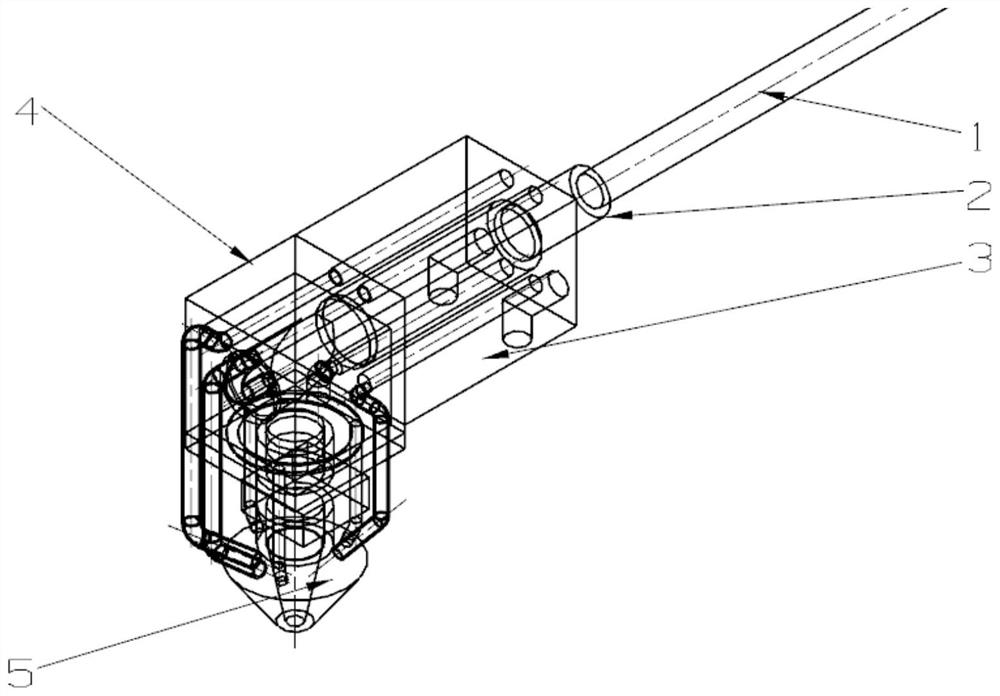

Laser cladding repairing method for inner hole of rolling mill roller end shaft sleeve and composite device for laser cladding

InactiveCN113802117AImprove bindingMinor repairabilityMetallic material coating processesAssembly disassemblySurface cleaning

The invention discloses a laser cladding repairing method for an inner hole of a rolling mill roller end shaft sleeve. The laser cladding repairing method comprises the steps of shaft sleeve assembly disassembly, shaft sleeve surface cleaning, component detection, pre-sequence heat treatment, layered cladding, post-sequence heat treatment, machining, inspection and flaw detection and qualified product delivery. In the step (4) of pre-sequence heat treatment, specifically, preheating is carried out before cladding can be in-furnace heating and heating belt heating; or in-furnace heating and induction device heating are adopted; or the induction device is independently used for heating; and in the step of (6) post-sequence heat treatment, specifically, an induction heating mode can be induction heating or other heating modes. According to the laser cladding repairing method, a cladding layer with high wear resistance, high strength and high binding force is cladded on the surface of the inner hole of a roller end shaft, and the service life of the roller end shaft sleeve is prolonged.

Owner:泰尔(安徽)工业科技服务有限公司

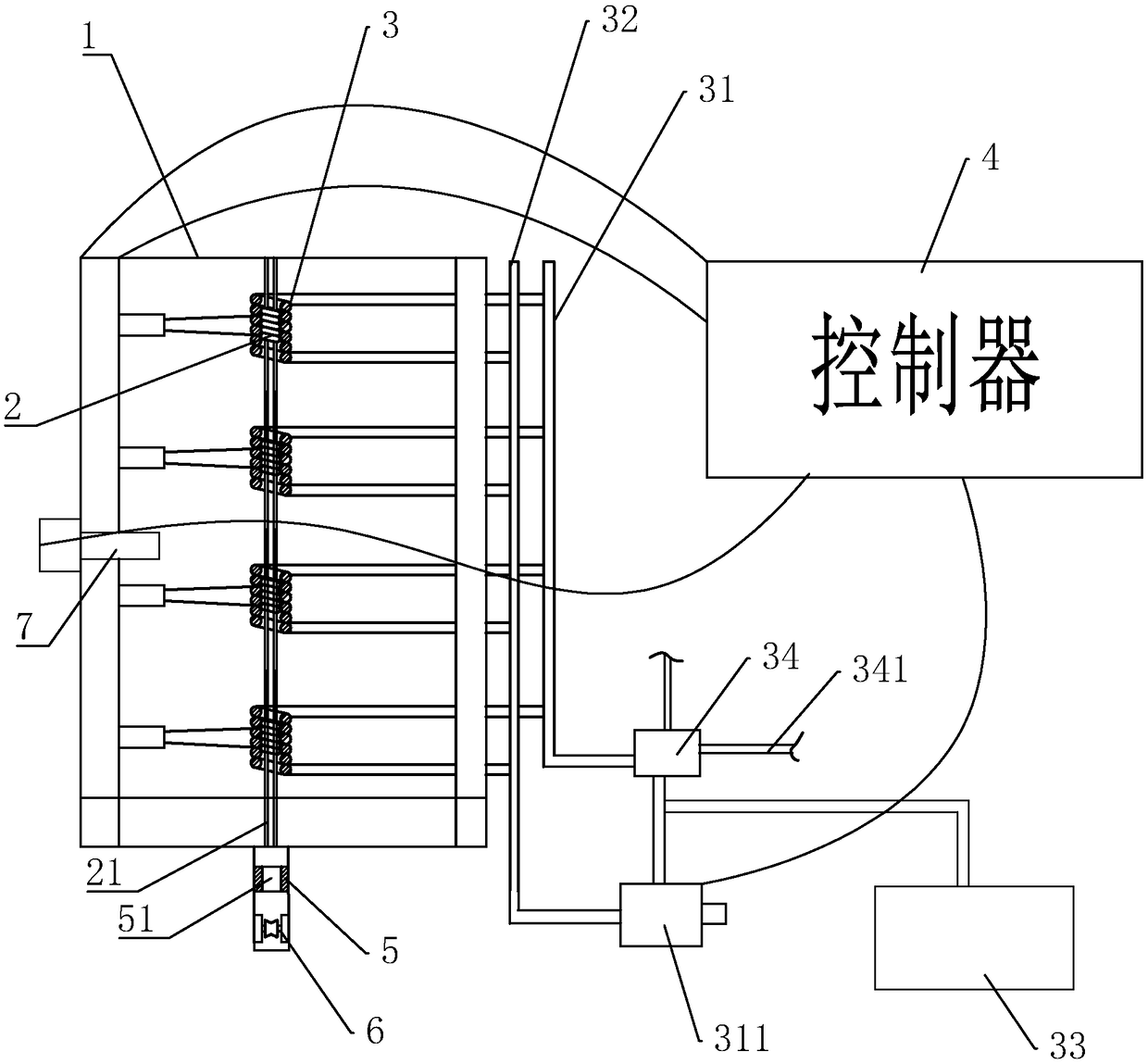

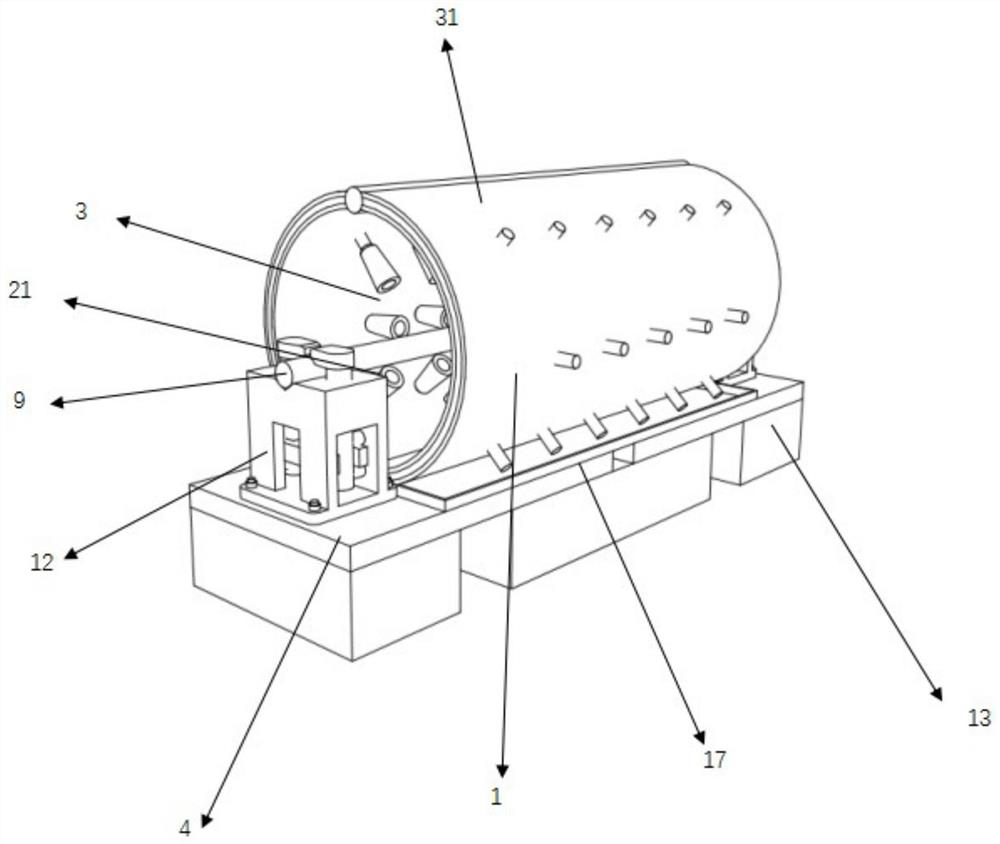

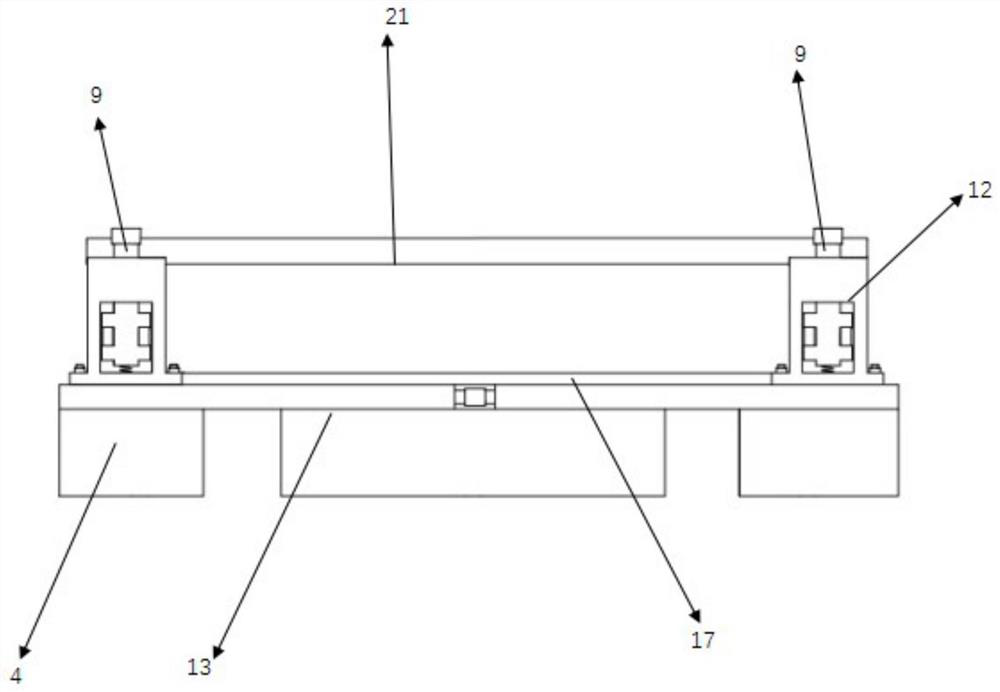

Medium-frequency induction heating furnace for heating lashing bar, and method

PendingCN108777892AHeating fastMonitor temperature in real timeCoil arrangementsInduction heating controlMedium frequencyEngineering

The invention discloses a medium-frequency induction heating furnace for heating a lashing bar, and a method. The induction heating furnace comprises a pedestal, and the pedestal is coaxially providedwith a plurality of induction coils which are connected with a controller and are connected to a power supply. The exterior of the induction coils is provided with cooling water circulating pipes, and the input ends of the cooling water circulating pipes are jointly connected with one water incoming pipe. The water incoming pipe is connected with a water pump, and the output ends of the cooling water circulating pipes are jointly connected with one water outgoing pipe. The water outgoing pipe is connected with a water pump, and the water pump is connected with a water supplementing box. The water incoming pipe is connected with a heat exchanger, and the heat exchanger is connected with a tap water pipe. The induction heating furnace provided by the invention can control the temperature ofthe induction heating furnace in a better way, and reduces the size of a floating range of temperature.

Owner:NANJING AIMANDA SHIP EQUIP MFG

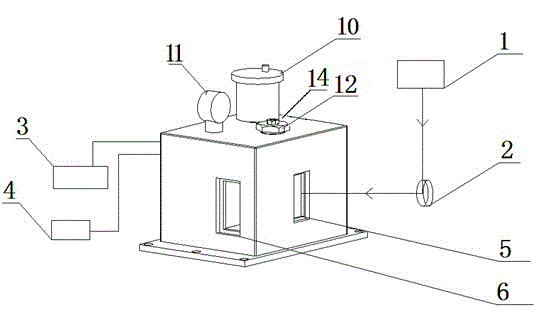

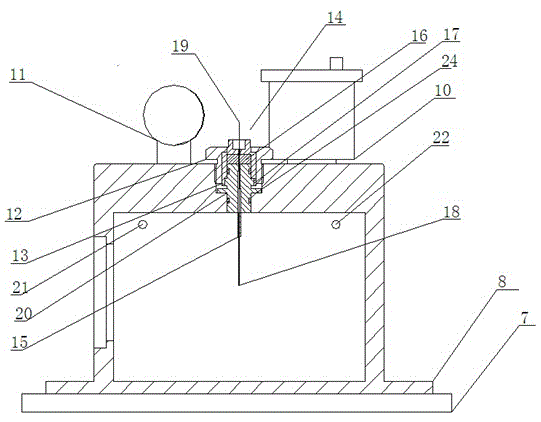

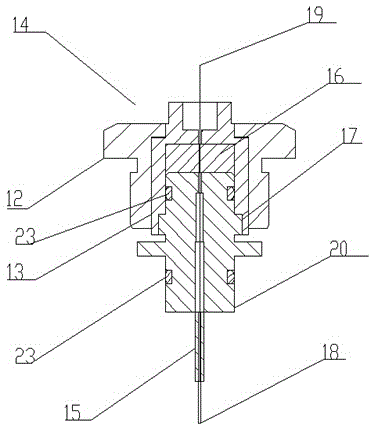

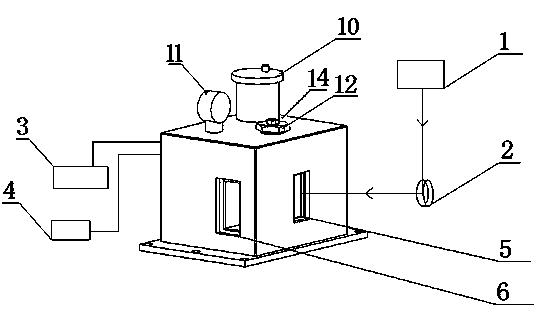

Device and technology for plating surface of glass capillary tube with carbon film

ActiveCN104195527AReduce energy lossAchieve localized heatingChemical vapor deposition coatingCarbon filmPrism

The invention provides a device and a technology for plating the surface of a glass capillary tube with a carbon film. The device comprises a carbon dioxide laser printer fixed on a base and a prism matched with the carbon dioxide laser printer and further comprises a hollow casing, wherein a light transmitting window corresponding to the prism is formed in one side surface of the casing, a first gas hole and a second gas hole are formed in the other side surface of the casing, the first gas hole is communicated with a vacuum pump, and the second gas hole is communicated with an acetylene and nitrogen gas tank; an optical fiber clamp is arranged on the casing, and the inner part of the casing is hermetically sealed with the outer part of the casing. The carbon film plating device is suitable for carrying out carbon film deposition on the surface of the glass capillary tube in a chemical vapor deposition method. The glass capillary tube needing to plated with the film is inserted in a collimated glass tube, a tail fiber on the tail is tightened and sealed through a rubber pad, the optical fiber clamp, an optical fiber fixing clamp and a nut, and two turriform joint devices are respectively connected with the vacuum pump and the gas tank. The glass capillary tube coated with the carbon film can effectively prevent the corrosion of hydrogen ions in an external environment. The service life of the glass capillary tube is prolonged.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

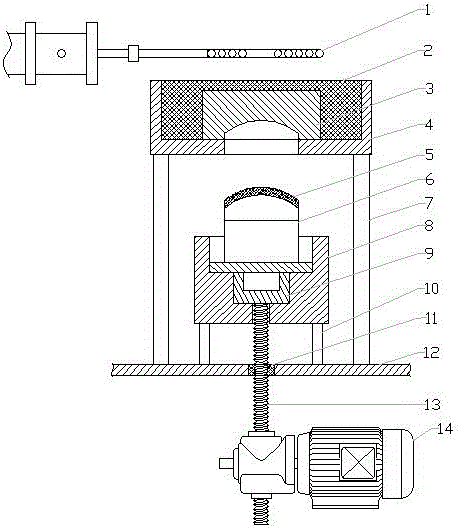

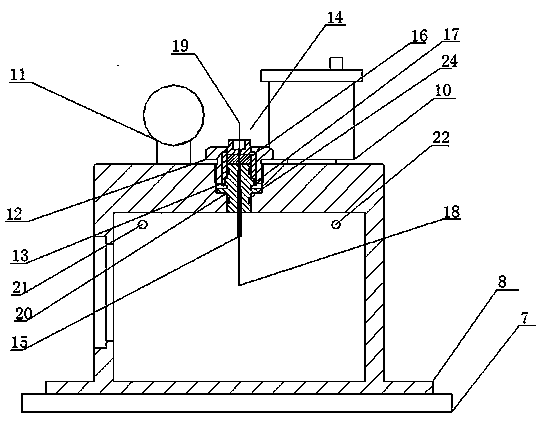

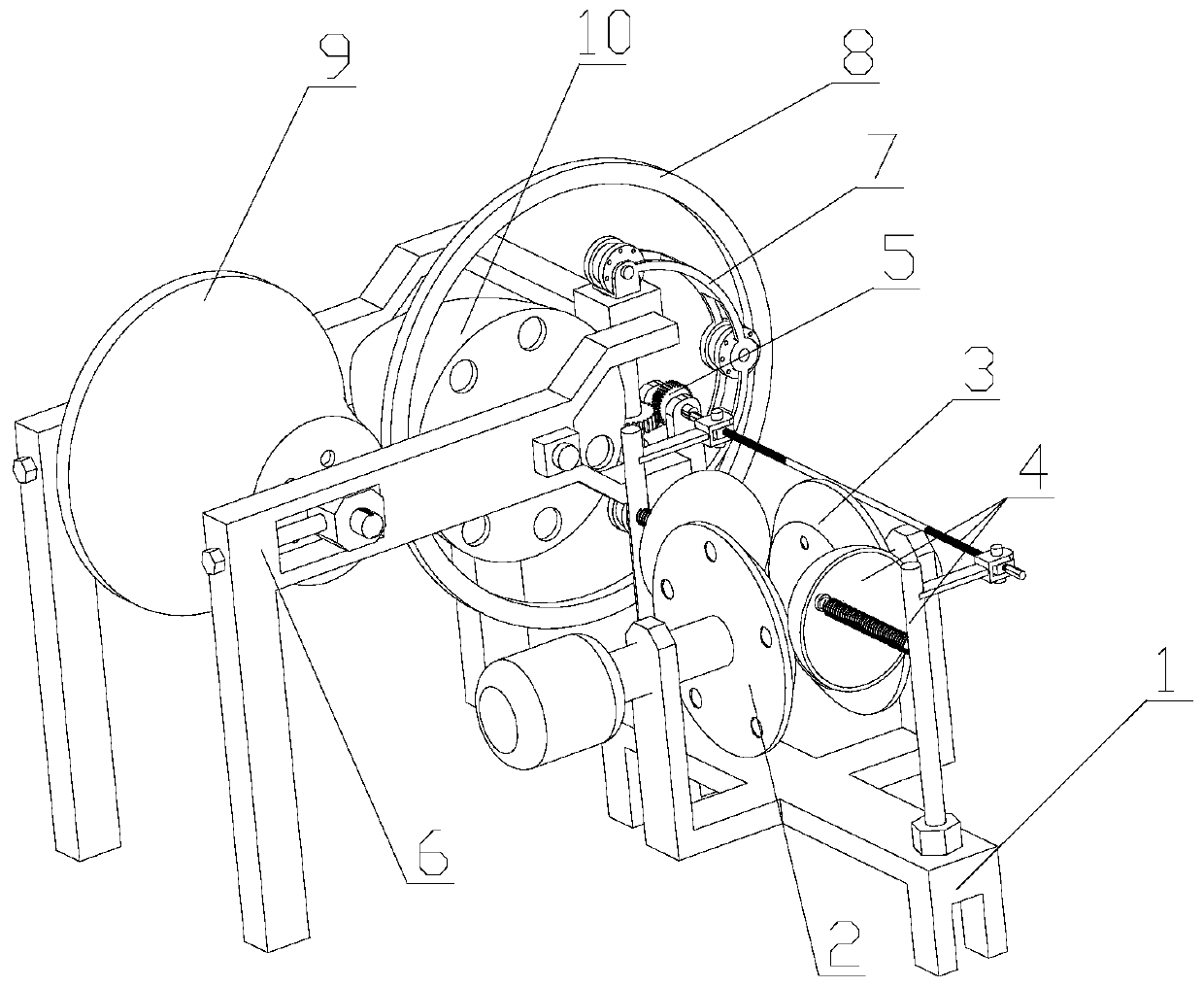

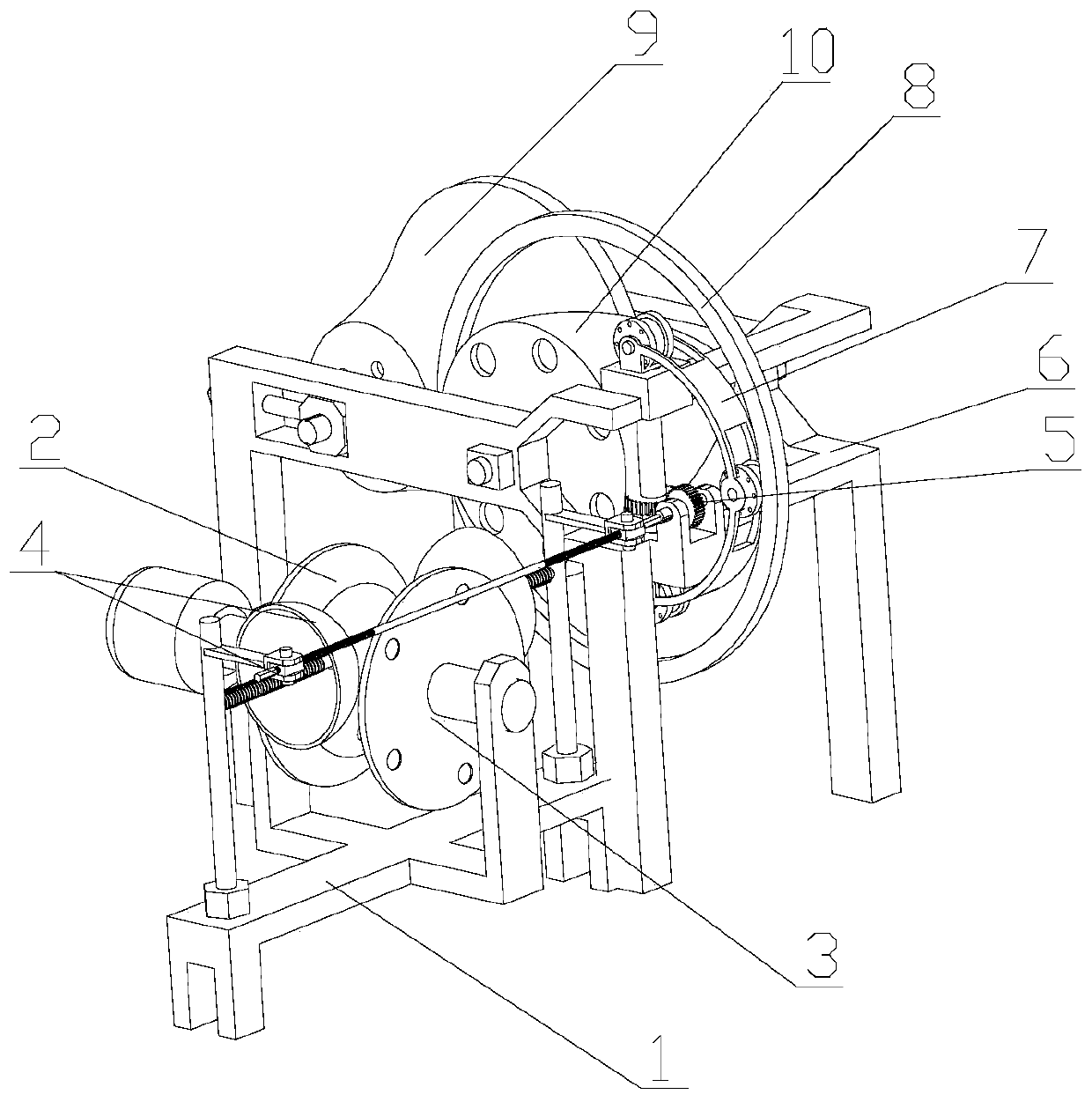

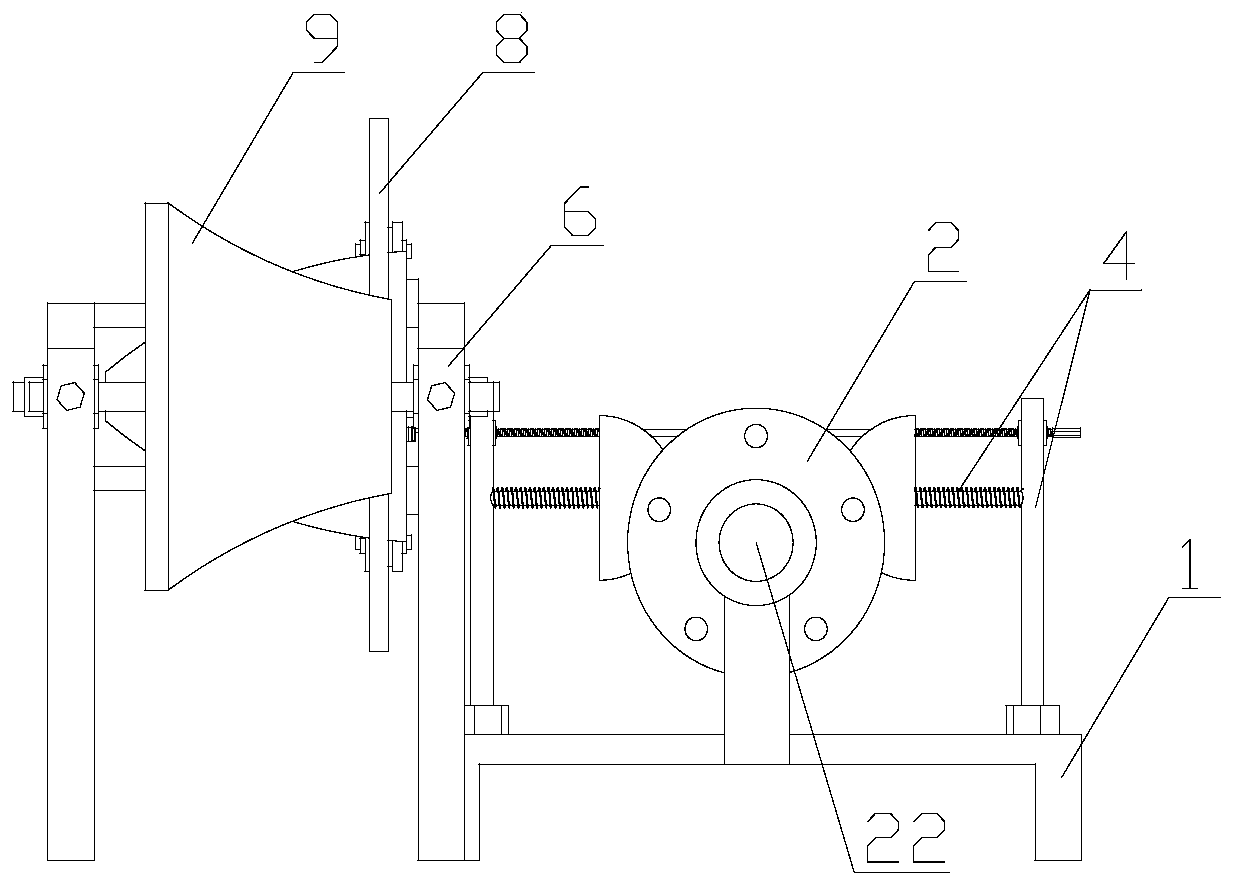

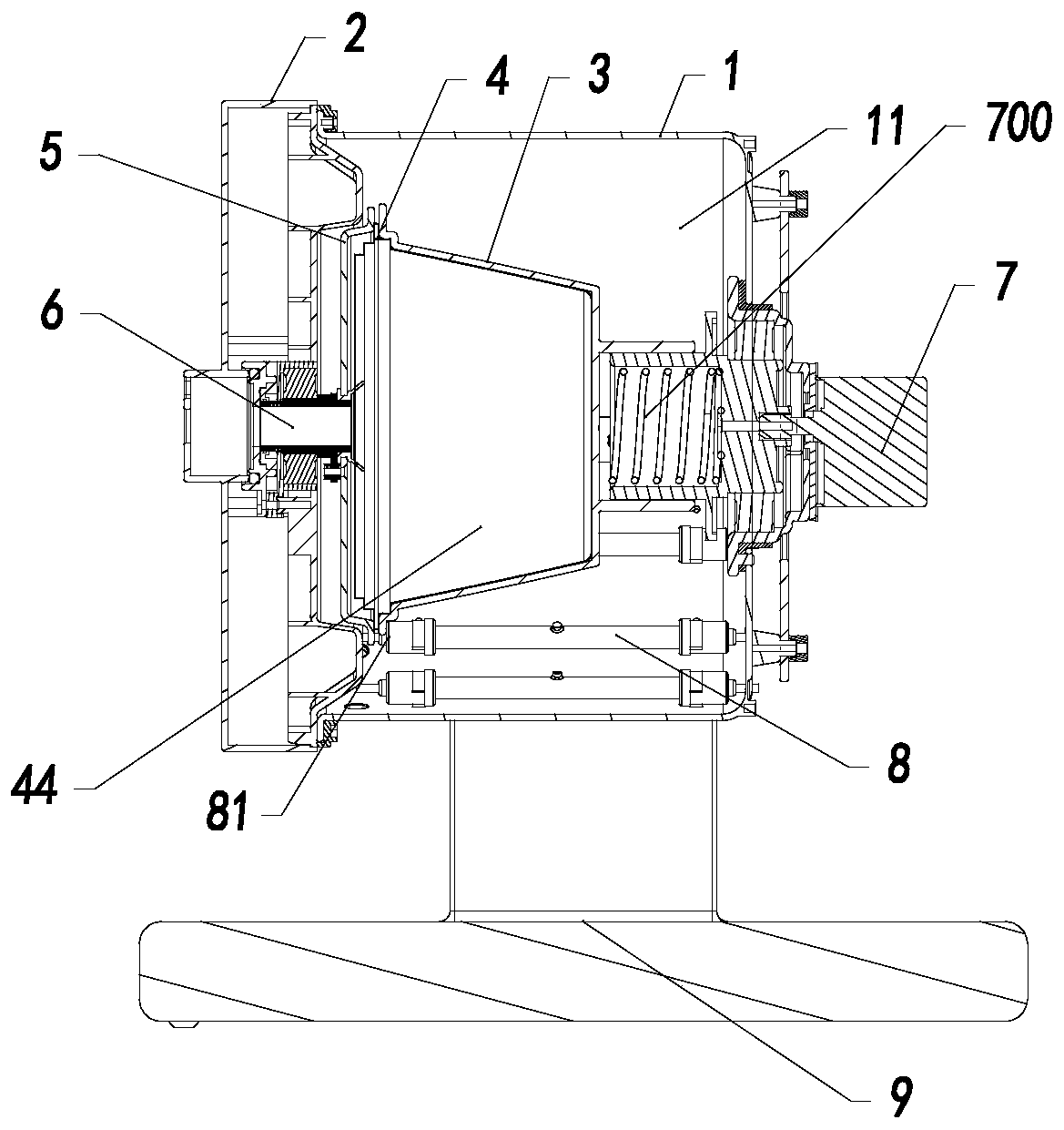

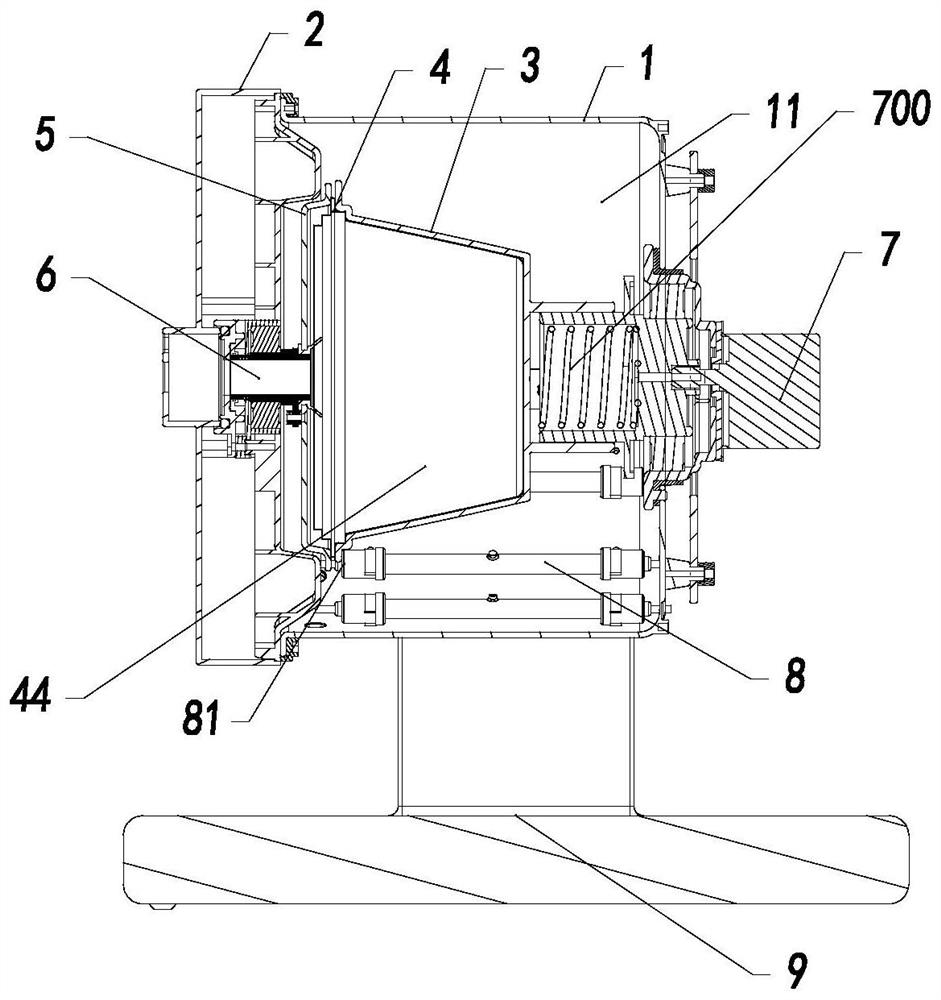

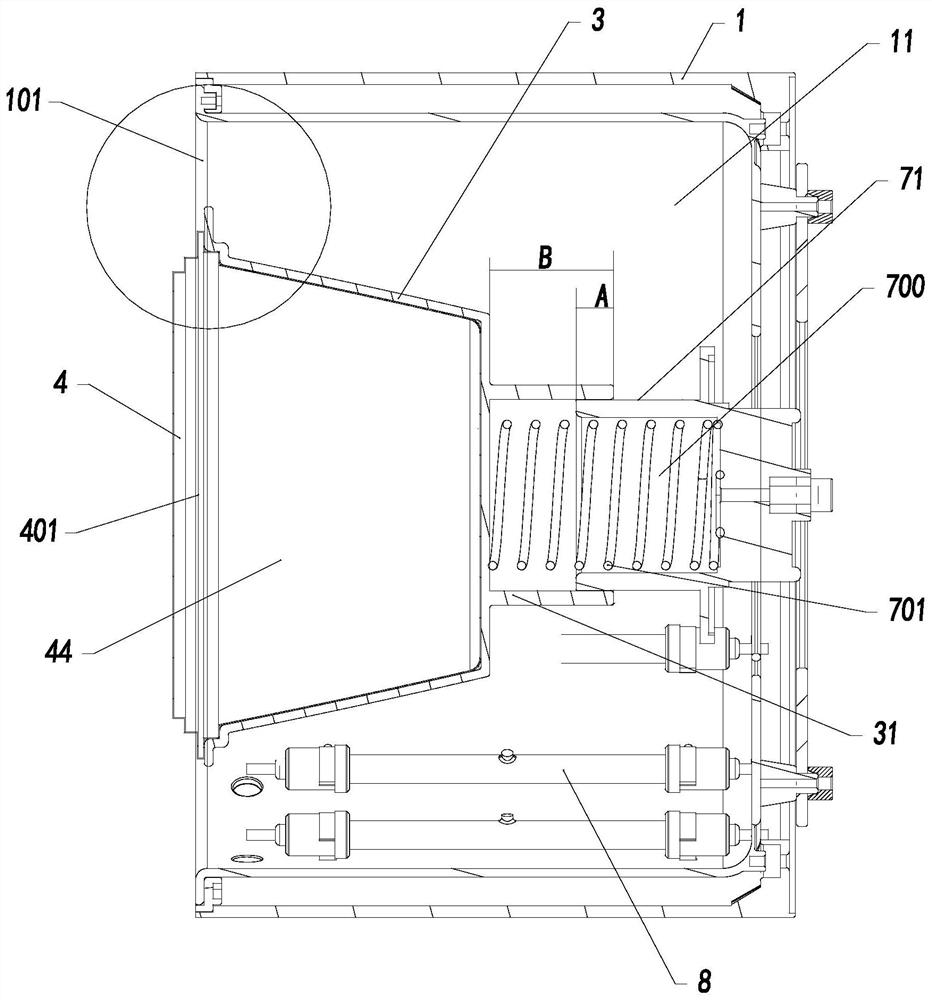

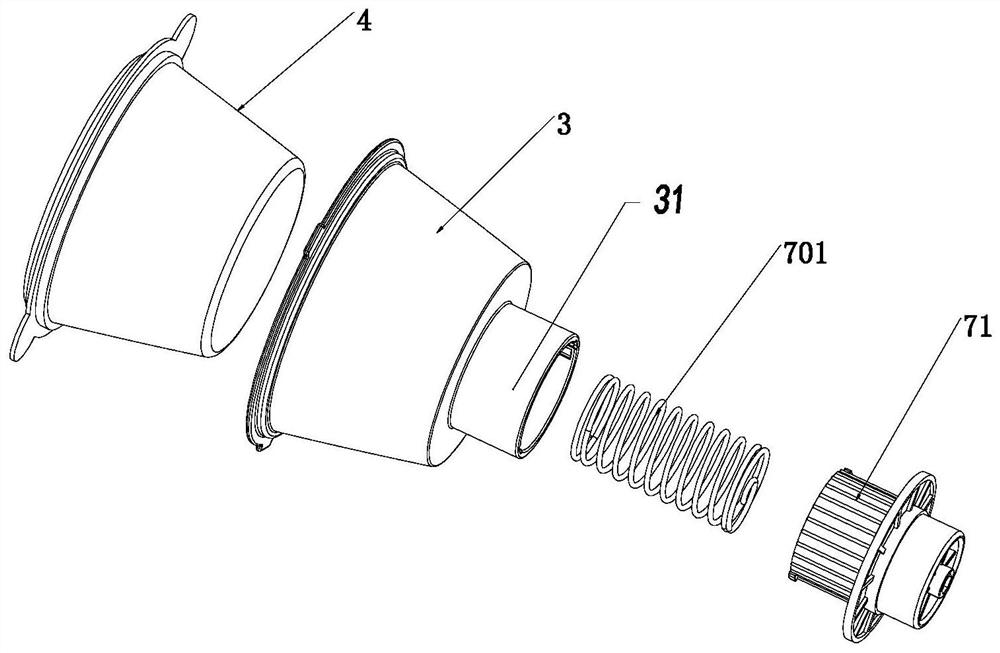

Spinning forming machining device and spinning forming method thereof

The invention provides a spinning forming machining device and a spinning forming method thereof. The spinning forming machining device comprises a base; a main driving mechanism and a driven drivingmechanism are oppositely arranged on the base, an output speed adjusting structure is arranged between the main driving mechanism and the driven driving mechanism, a spinning forming support is provided with a swing component, a spinning forming mechanism driven by the swing component, the machined tool connected with the outer side face of the spinning forming mechanism in a spinning and abuttingmode and a spinning forming guide roller making contact with the inner side face of the spinning forming mechanism. The spinning forming machining device and the spinning forming method thereof havethe beneficial effects that the machined tool is locally heated through induction heating, the machined tool can be deformed in the air in accordance with the final shape even if a mandrel is not used, the deformed object part of the machined tool is consistent with the outline of the outer side surface of the spinning forming guide roller in the spinning forming process, and the deformed object part is rotationally cut and pressed by the spinning forming mechanism while being heated by a heater element.

Owner:IND INTERNET INNOVATION CENT (SHANGHAI) CO LTD

Application of cesium-tungsten bronze as welding flux for welding sapphire

ActiveCN112958942AAchieve localized heatingHigh transparencyWelding/cutting media/materialsSoldering mediaIr laserWeld seam

The invention provides an application of cesium-tungsten bronze as a welding flux for welding sapphire, and belongs to the technical field of sapphire welding. According to the invention, the cesium-tungsten bronze is filled in a sapphire welding seam, so that the absorption efficiency of the welding seam on laser energy can be increased, then local heating for the sapphire welding seam is realized, and then welding for the sapphire is completed; and meanwhile, the sapphire is also an oxide and can be mutually dissolved with the cesium-tungsten bronze to a certain extent, in an infrared laser transillumination welding process, the sapphire at a welding seam joint is melted, the cesium-tungsten bronze is dissolved into the sapphire, so that the spatial distribution density of the sapphire is reduced, the light energy absorption energy density of the welding seam is reduced until the absorbed light energy is not enough to keep the sapphire in the volume of the welding seam in a molten state, the sapphire welding seam is solidified, and the welding process is completed.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Multifunctional water-based ink spraying device

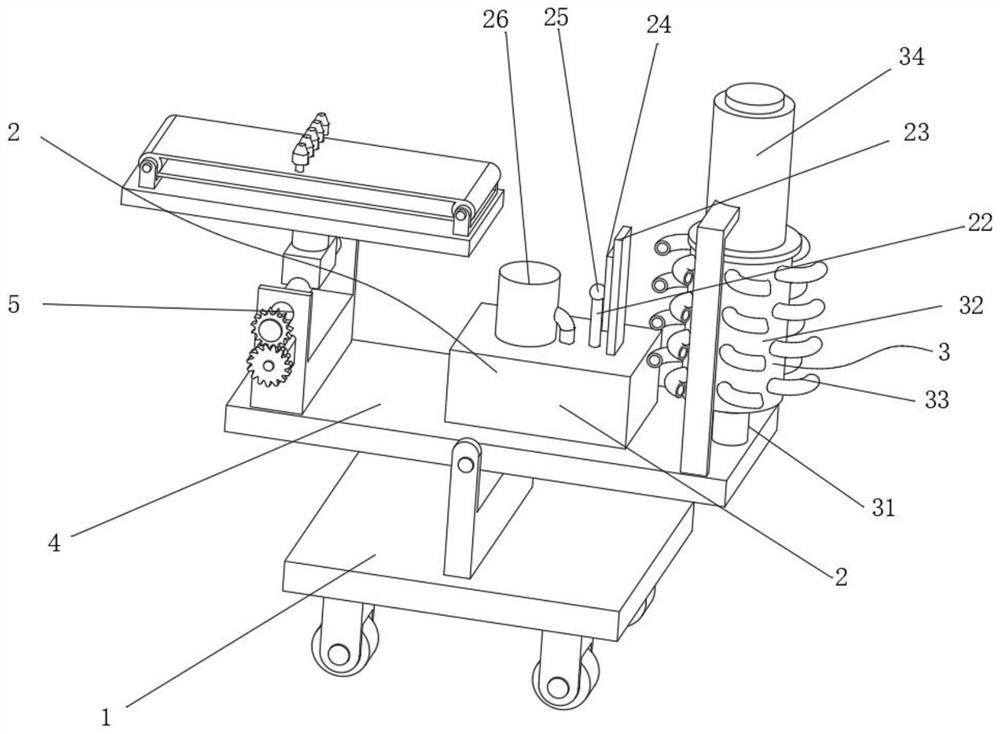

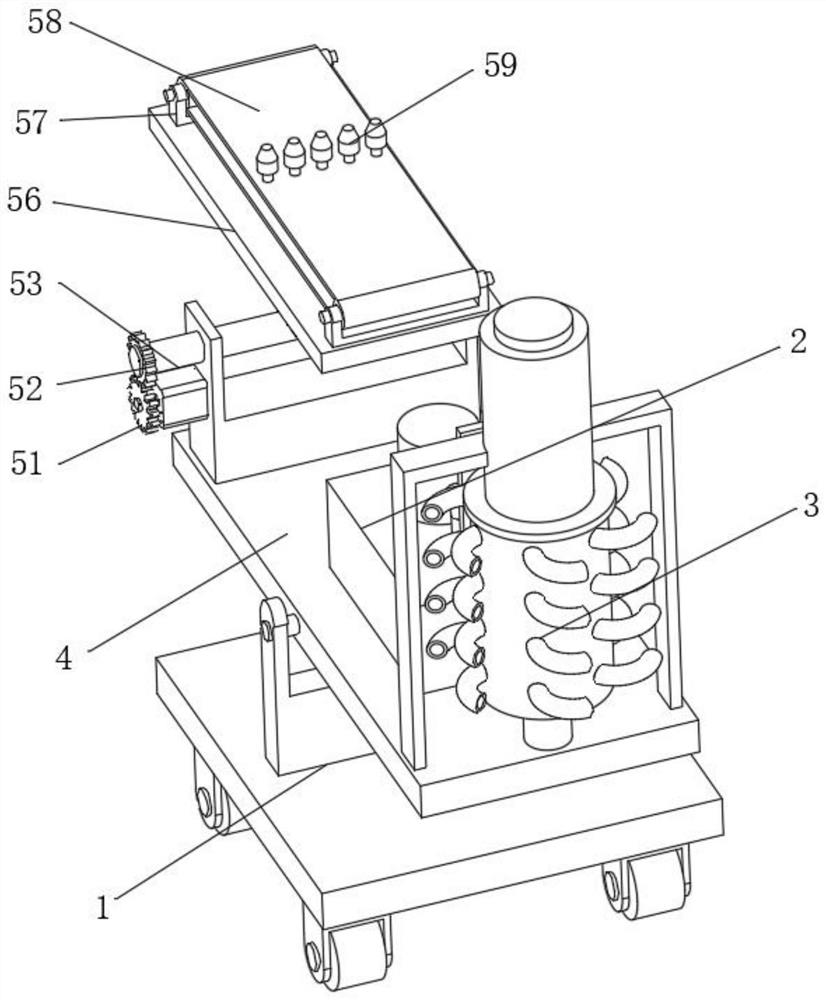

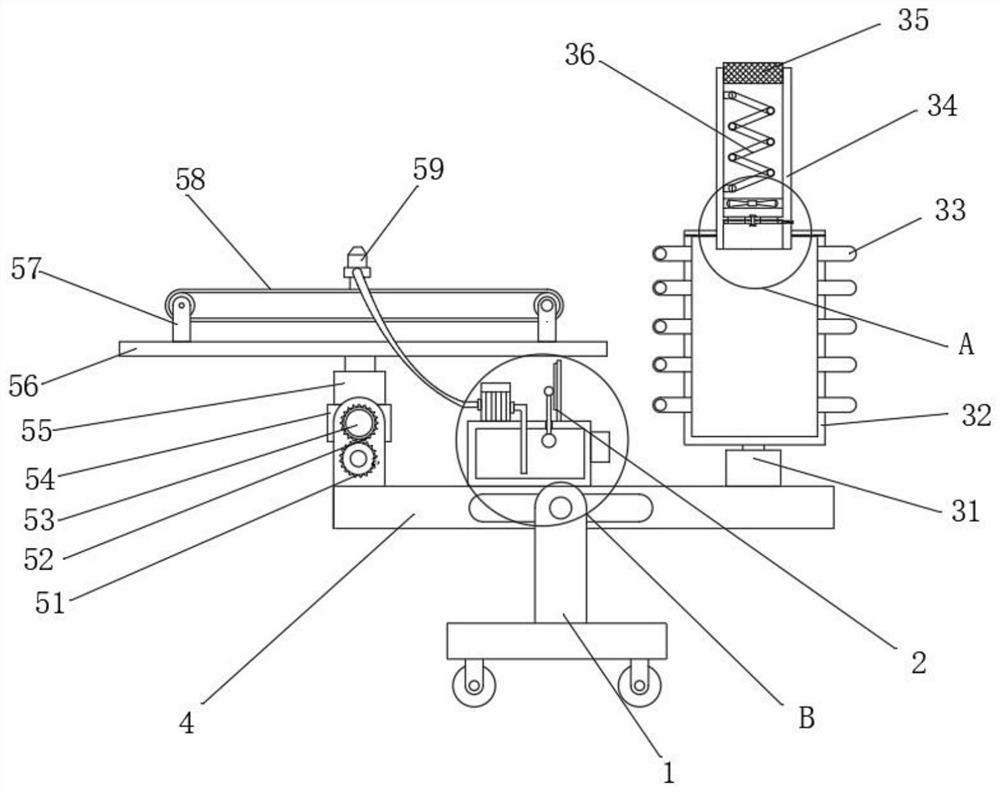

PendingCN112549781ARealize multi-angle rotation and swingEasy to applyTypewritersOther printing apparatusDrive shaftGear wheel

The invention discloses a multifunctional water-based ink spraying device which comprises a vehicle body, a start-stop structure, a heating structure, a swing frame and a displacement spraying structure. The swing frame is installed on the top layer of the vehicle body through bolts in a matched mode, the displacement spraying structure is installed at one end of the top side of the swing frame ina matched mode, the start-stop structure is installed in the middle of the top side of the swing frame in a matched mode, and the heating structure is installed at the other end of the top side of the swing frame. The displacement spraying structure is arranged, a power motor acts, a driving gear is driven to rotate, swing rotation of a driven shaft is achieved through cooperation of a matching gear, multi-angle rotary swing of the displacement frame can be achieved through swing rotation of the driven shaft and matching rotation of a servo motor, spraying of spray heads can be achieved through various sweeping angles under the cooperation of a transmission belt, the spray heads can be better suitable for use scenes, and a better spraying effect is achieved.

Owner:哈尔滨绿科科技有限公司

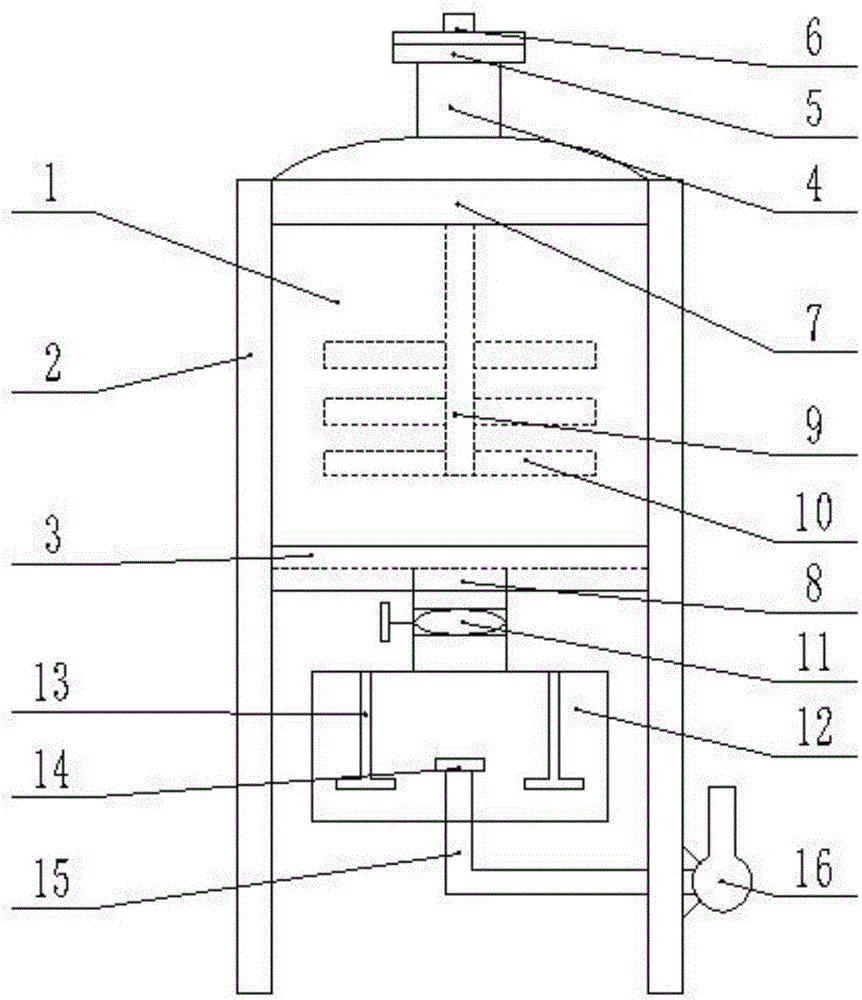

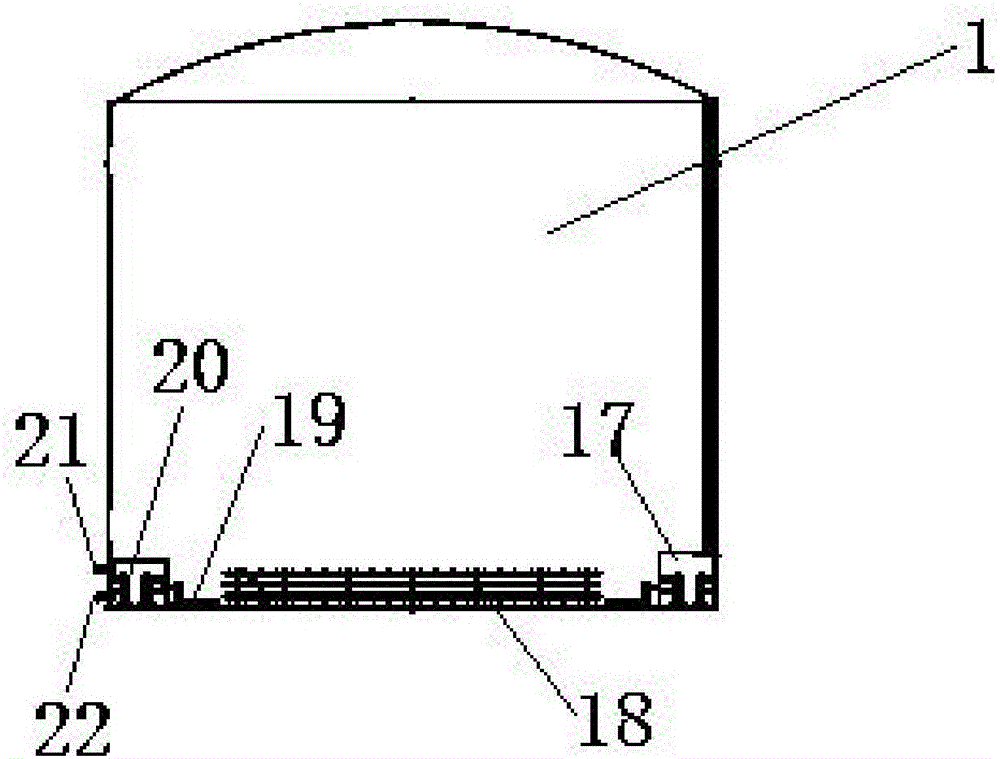

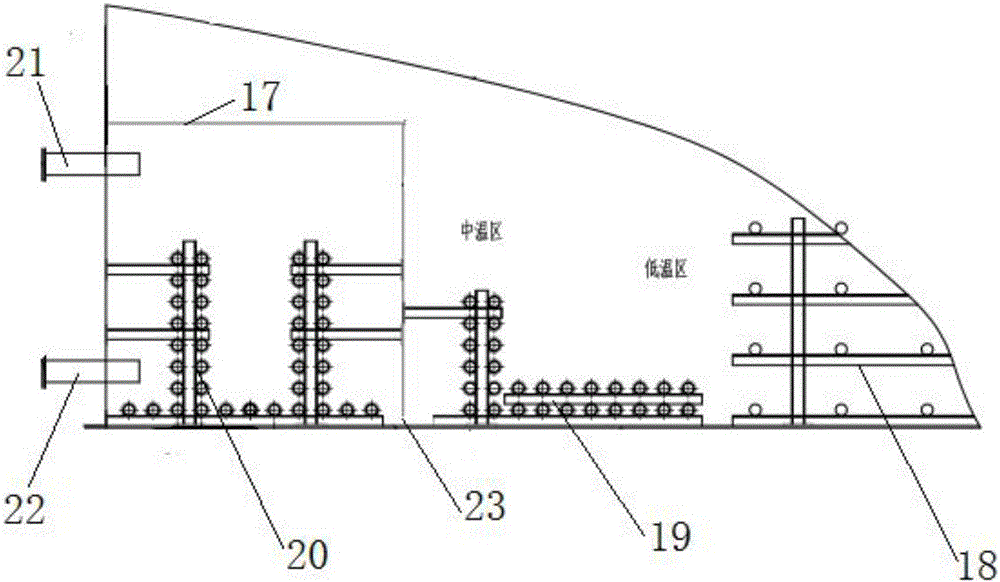

Intelligent ring belt type pitch local high temperature fast oil extracting device

InactiveCN106395726AAchieve heatingAchieve localized heatingLiquid transferring devicesHeating oilEngineering

The invention relates to an intelligent ring belt type pitch local high temperature fast oil extracting device which comprises a pitch tank. The left end and the right end of the pitch tank are fixedly connected with a high frame. The lower end of the pitch tank is fixedly connected with a lower fixing frame. The upper end of the pitch tank is fixedly connected with an upper fixing frame. The upper end of the pitch tank is fixedly connected with a feeding port. The interior of the pitch tank is fixedly connected with a rotating shaft. The periphery of the rotating shaft is fixedly connected with a stirring blade. The lower end of the pitch tank is fixedly connected with a discharging port. The upper end of the discharging port is provided with a control valve. The lower end of the discharging port is fixedly connected with a heating tank. The upper end of the interior of the heating tank is fixedly connected with heating blocks. An oil suction pipe is arranged in the heating tank. The lower end of the oil suction pipe is fixedly connected with an oil discharging pipe, the tail end of the oil discharging pipe is fixedly connected with an oil suction pump, and the oil suction pump is fixedly connected with the high frame. A low-temperature heating area, an intermediate-temperature heating area and a high-temperature heating oil extracting device are arranged at the bottom end of the pitch tank. According to the intelligent ring belt type pitch local high-temperature fast oil extracting device, due to the heating tank, the function of fast oil extraction through local heating of pitch is achieved, and energy losses in the oil extraction process are reduced.

Owner:广州西二环高速公路有限公司

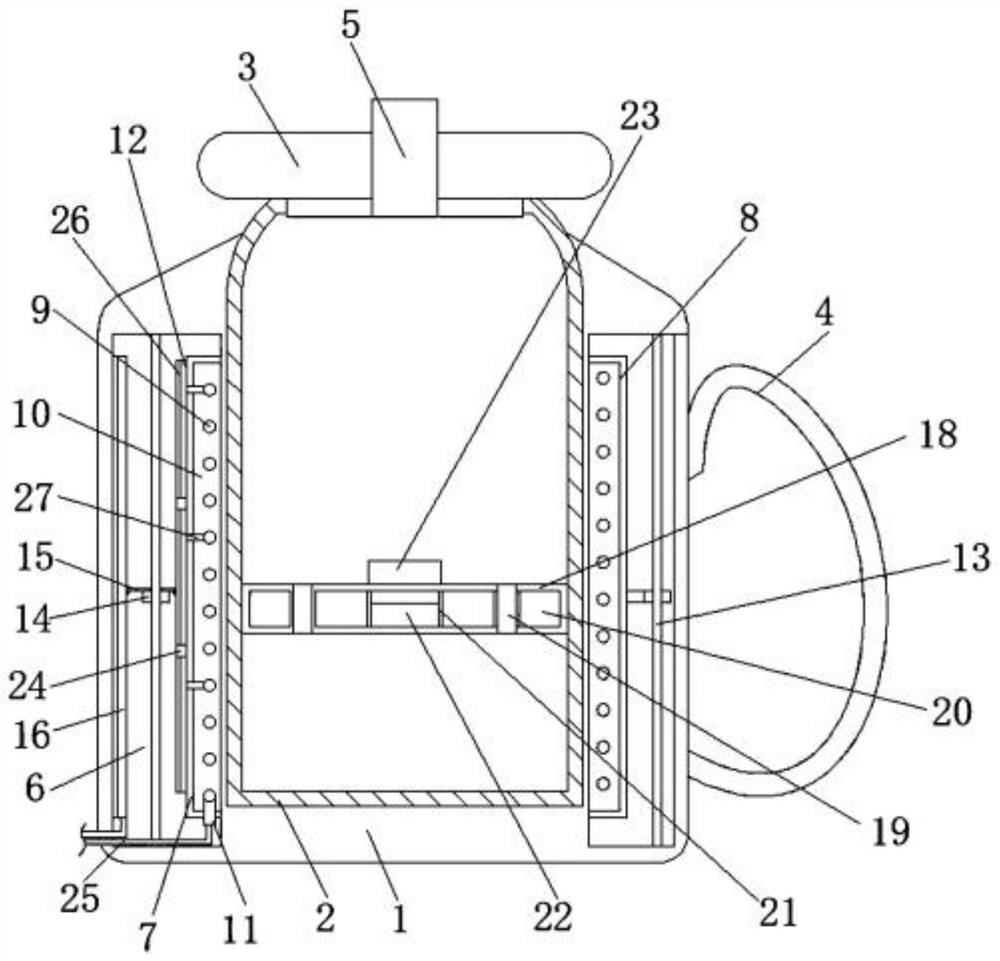

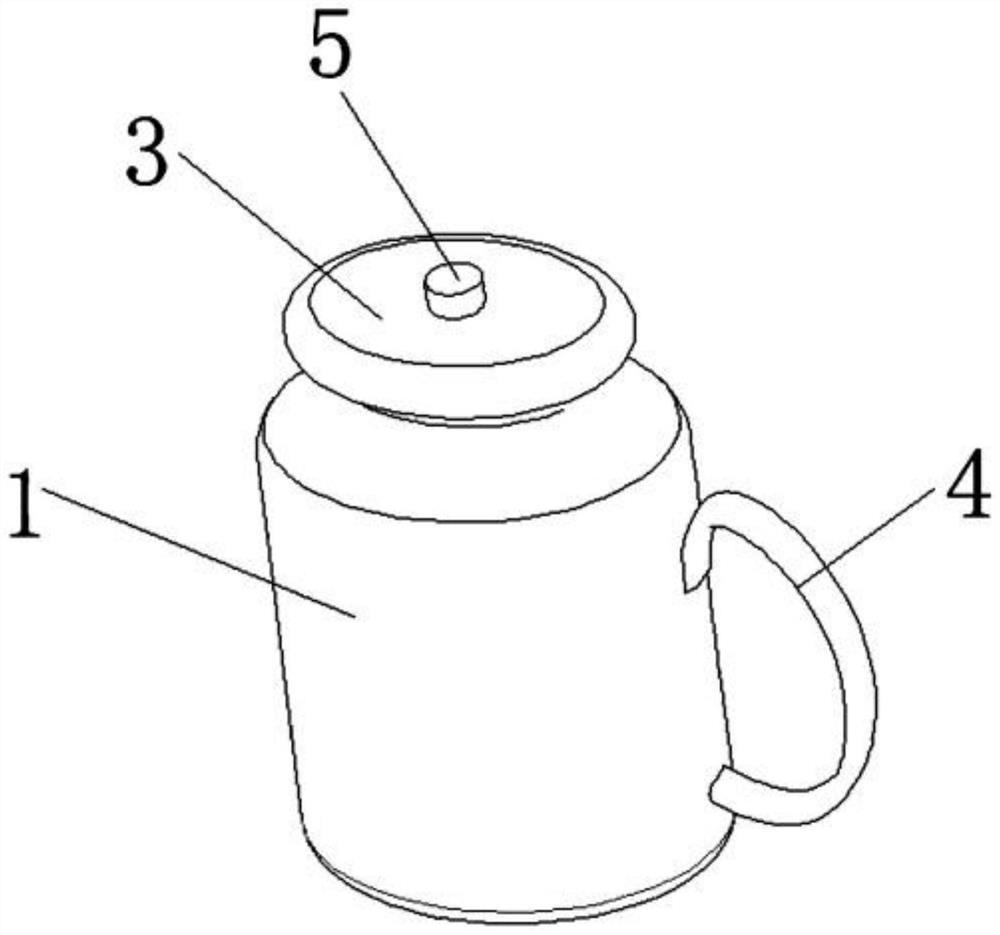

Cooking machine with pop-up mechanism

ActiveCN111449486AImprove experienceQuality improvementCooking vessel constructionsEngineeringMechanical engineering

The invention discloses a cooking machine with a pop-up mechanism, and belongs to the field of kitchen appliances. The cooking machine can pop up a rotating device so as to conveniently take food materials by a user, and comprises a pot body and a rotating device, wherein the rotating device is arranged in the inner containing cavity of the pot body, a driving device is arranged on the pot body, the rotating device is detachably connected with the driving device, the driving device drives the rotating device to rotate, an elastic mechanism is arranged between the rotating device and the driving device, a heating device is arranged on the inner wall of the containing cavity, and the elastic mechanism drives the rotating device to be close to or away from the heating device.

Owner:JOYOUNG CO LTD

Lifting type self-adaptive local heating electric kettle and using method

InactiveCN111759169AReduce lossAchieve localized heatingWater-boiling vesselsEngineeringHome appliance

The invention belongs to the technical field of household appliances, and discloses a lifting type self-adaptive local heating electric kettle and a using method. The lifting type self-adaptive localheating electric kettle comprises a shell, an inner container, a kettle cover, a handle and an air escape valve. The inner container is fixedly connected into the shell in a sleeved mode. The kettle cover is inserted into an opening of the inner container, the air escape valve is installed in a hole in the middle of the kettle cover, a handle is welded to the right side face of the shell, an annular cavity is formed in the shell, a heating shell is welded to the side wall, close to the inner container, of the annular cavity, and an electric heating wire is arranged in an annular notch formed in the side wall, close to the inner container, of the heating shell. According to the lifting type self-adaptive local heating electric kettle, through the sectional design of the electric heating wire, a floating block is supported by utilizing the buoyancy of water, so that a contact piece can be communicated with a copper piece corresponding to the water level, the corresponding part of the electric heating wire works, the heating power is improved, targeted local heating is realized, the water boiling efficiency is improved, and the electric energy loss is reduced.

Owner:南京溧水高新产业股权投资有限公司

Re-melting interconnection approach for high-frequency electromagnetic radiation solder micro-boss

InactiveCN1258810CAchieve localized heatingSelf-heating and melting fastSemiconductor/solid-state device manufacturingSemiconductor devicesInterconnectionHigh frequency electromagnetic radiation

The invention discloses a method for packaging, assembling and interconnecting electronic devices - a method for remelting and interconnecting micro-protrusion platforms of high-frequency electromagnetic radiation solder. It is achieved through the following steps, (1) pre-preparing solder and flux on the surface of the interconnection pad of the electronic device; (2) using high-frequency electromagnetic radiation on the solder at the interconnection pad of the electronic device, The brazing material at the interconnection pad is self-heated and melted under the action of high-frequency electromagnetic radiation and wetted on the surface of the interconnection pad; (3) stop the high-frequency electromagnetic radiation, and the solder is on the surface of the interconnection pad of the electronic device Cool and form the solder boss; (4) align the interconnection pads of the electronic devices forming the solder bumps with the pads on the printed circuit board and mount them; (5) use high-frequency electromagnetic radiation at the solder pads The solder boss, the solder boss melts by self-heating, and wets between the interconnection pad of the electronic device and the pad surface of the printed circuit board; (6) stop high-frequency electromagnetic radiation, and naturally form an interconnection solder after cooling point. The invention has the advantages of reliable operation, novel method and great popularization value.

Owner:HARBIN INST OF TECH

Test device for fire damage of steel cable structure and use method

PendingCN112229708AAchieve localized heatingHeating evenlyMaterial thermal analysisStrength propertiesMicrocomputerTemperature control

The invention discloses a test device for fire damage and cooling treatment of a steel cable structure. The test device comprises a high-temperature calcinator, a cooling device and a loading device,the high-temperature calcinator comprises a high-temperature calcinator inner wall and a high-temperature calcinator outer wall, the high-temperature calcinator is of two semicircular structures, andthe lower ends of the two semicircular structures of the high-temperature calcinator can be closed or separated. The loading device is a microcomputer-controlled electronic pressure testing machine, the two ends of the loading device are each fixedly provided with a clamping device used for clamping and fixing the two ends of a test piece, the high-temperature calcining furnace and the cooling device can move left and right along the loading device, the cooling device is provided with a plurality of water spraying openings, and the water spraying openings are connected with a temperature control type cooling water tank. Open fire heating and water spraying cooling are used, and the situation that the steel cable structure suddenly encounters big fire in the using process is simulated moretruly.

Owner:ANYANG INST OF TECH

A cooking machine with pop-up mechanism

ActiveCN111449486BImprove experienceQuality improvementCooking vessel constructionsEngineeringMechanical engineering

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com