Asynchronous rolling-local liquid phase compounding method for preparing aluminum/magnesium composite plate

A technology of asynchronous rolling and clad plate, used in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of interface brittle products, unsatisfactory interface performance, affecting interface bonding, etc., and achieve good plate shape. , Small rolling force, the effect of alleviating the degree of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

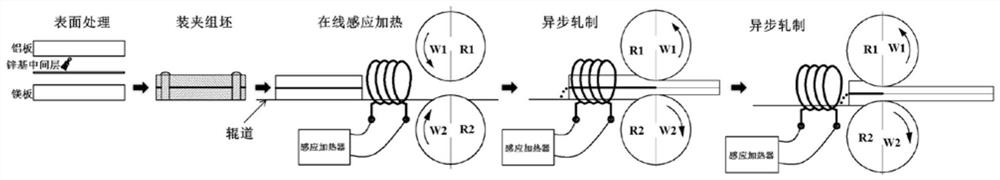

[0041] Asynchronous rolling-partial liquid phase compounding method for preparing aluminum / magnesium clad plate, the process flow chart is as follows figure 1 As shown, this embodiment adopts an asynchronous rolling mill, when R1=R2, w1≠w2; when w1=w2, R1≠R2. R1 and R2 are the radii of the upper and lower rolls respectively, w1 and w2 are the angular velocities of the upper and lower rolls respectively; the material of the aluminum alloy plate is 1060 industrial pure aluminum, the size of the aluminum plate is 300×300×20mm, and the material of the magnesium alloy plate is AZ31 magnesium alloy, magnesium plate size: 300×300×20mm; middle layer composition is Zn58Sn40Cu, size is 300×300×0.1mm. First, polish the surface of the aluminum plate, magnesium plate and the intermediate layer to remove the oxide layer and oil stain; stack them in the order of aluminum / intermediate layer / magnesium, drill holes in the four corners of the blank and fix them with aluminum rivets to ensure the...

Embodiment 2

[0043] The material of the aluminum alloy plate is 6061 aluminum alloy, the size of the aluminum plate is 300×300×15mm, the material of the magnesium alloy plate is AZ31 magnesium alloy, the size of the magnesium plate is 300×300×30mm; the composition of the middle layer is Zn95Al, and the size is 300×300 ×0.1mm. First, polish the surface of the aluminum plate, magnesium plate and the intermediate layer to remove the oxide layer and oil stain; stack them in the order of aluminum / intermediate layer / magnesium, drill holes in the four corners of the blank and fix them with aluminum rivets to ensure the tight fit between the plates; The billet is placed on the roller table, the induction heating temperature is set to 460°C, the composite billet passes through the induction heating device at a speed of 1m / s, and enters the rolling mill; the asynchronous ratio of rolling on both sides of magnesium and aluminum is set to 1.2, and the reduction rate of the first pass is 5%, the second...

Embodiment 3

[0045] The material of the aluminum alloy plate is 7050 aluminum alloy, the size of the aluminum plate: 300×300×12mm, the material of the magnesium alloy plate is ZK60 magnesium alloy, the size of the magnesium plate: 300×300×36mm; the composition of the middle layer is Zn65Al20Cu, the size is 300×300 ×0.2mm. First, polish the surface of the aluminum plate, magnesium plate and the intermediate layer to remove the oxide layer and oil stain; stack them in the order of aluminum / intermediate layer / magnesium, drill holes in the four corners of the blank and fix them with aluminum rivets to ensure the tight fit between the plates; The billet is placed on the roller table, the induction heating temperature is set to 500°C, the composite billet passes through the induction heating device at a speed of 1m / s, and enters the rolling mill; the asynchronous ratio of both sides of magnesium and aluminum is set to 1.3, and the reduction rate of the first pass is 5% The second, third, fourth,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com