Patents

Literature

34results about How to "Increased mechanical occlusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

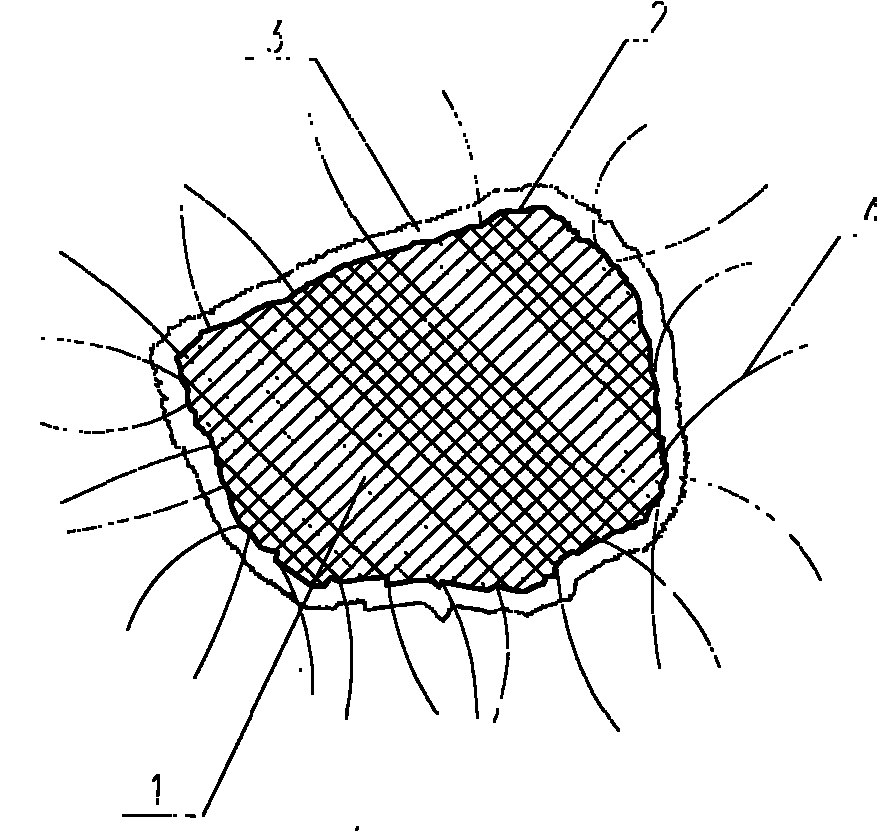

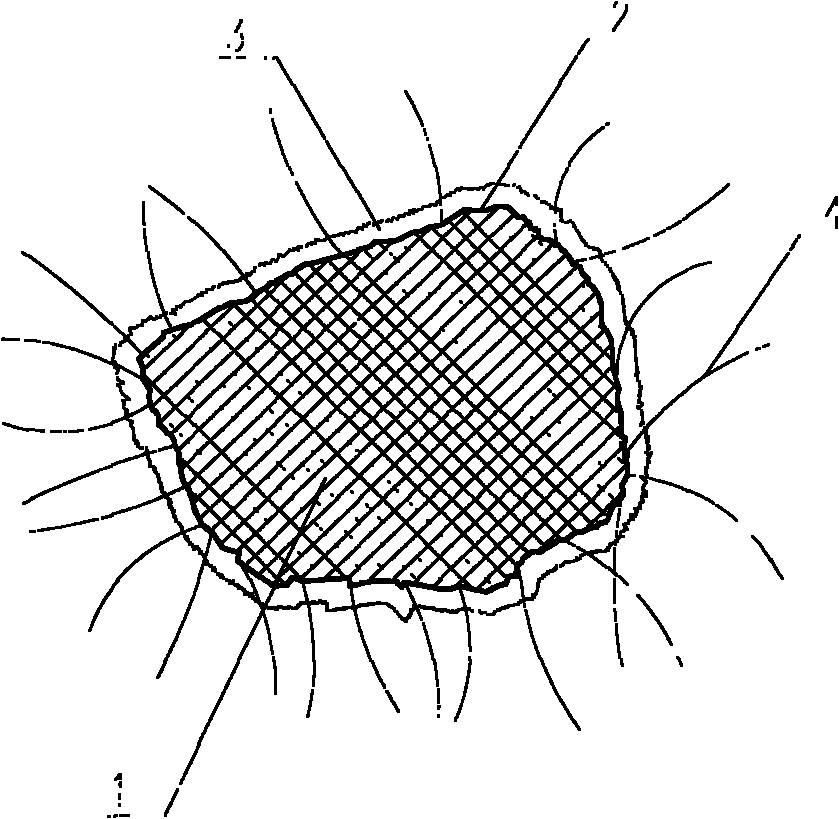

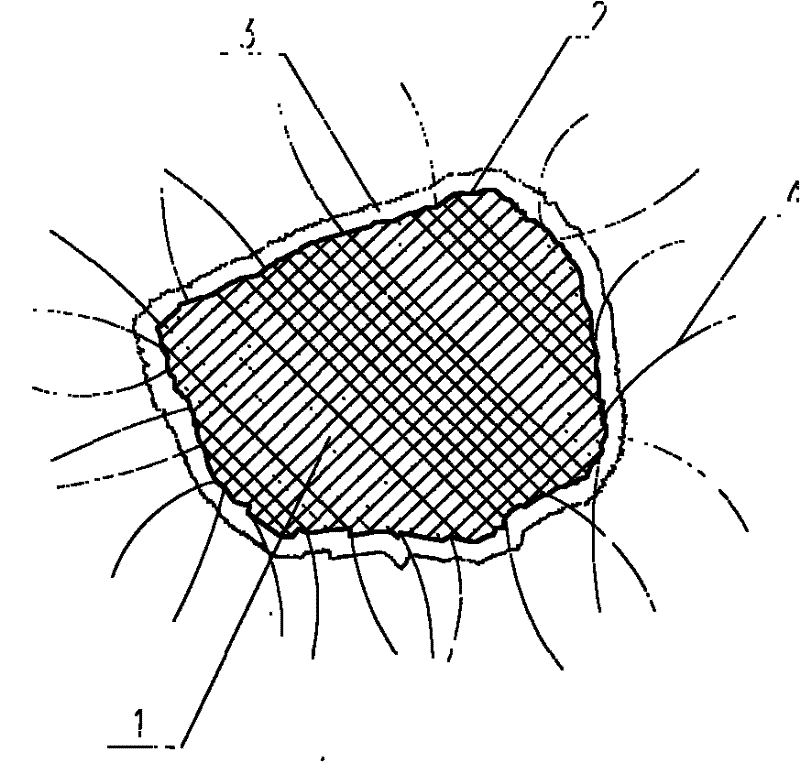

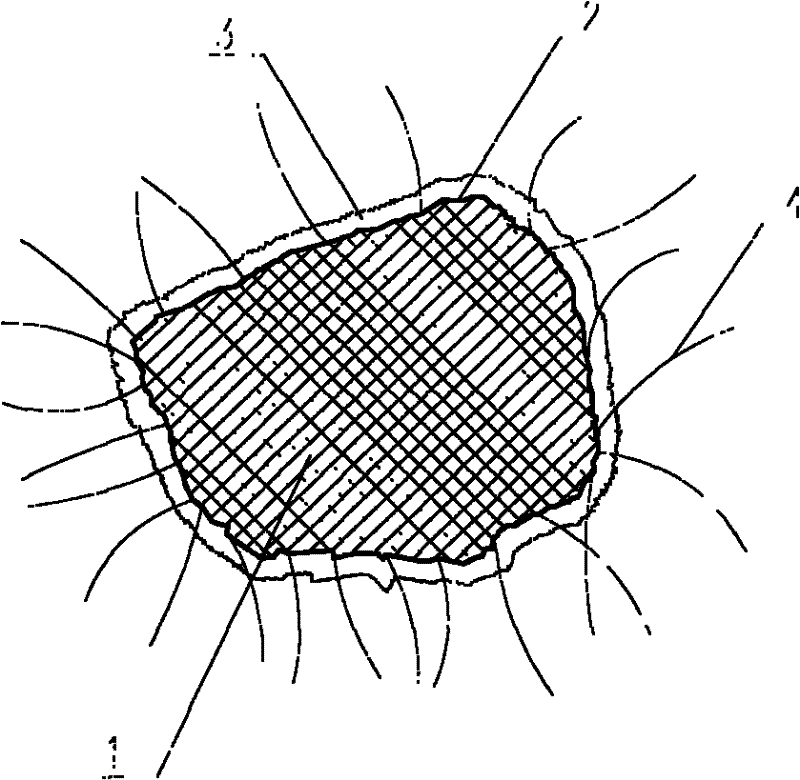

Stone aggregate wrapped by microfine fibre polymer mortar thin layer and preparation method thereof

InactiveCN101863631AHigh compressive strengthStrong resistance to deformationSilica fumeVolcanic ash

The invention discloses a stone aggregate wrapped by a microfine fibre polymer mortar thin layer and a preparation method thereof; the stone aggregate is formed by stone aggregate inner cores, an adhesive inner wrapping layer, a polymer cement mortar outer wrapping layer and an adhesive microfine fibre hair layer, wherein the adhesive inner wrapping layer and the stone aggregate are adhered firmly; microfine fibre filaments are anchored and rooted on the adhesive inner wrapping layer; and the polymer cement mortar outer wrapping layer and the adhesive inner wrapping layer are soluble mutually and can effectively form a whole body. Active powder in the polymer cement mortar outer wrapping layer contains silica fume, zeolite powder, finely-ground mineral slag, pulverized coal ash and the like, and can generate volcanic ash reaction with Ca(OH)2 crystal at the interface position of the set cement so as to generate gelled materials, and further carry out improved treatment on the weakest interfaces of set cement and the stone aggregate in concrete. The modified stone aggregate of the invention has good affinity with the set cement, and has higher binding power with the set cement.

Owner:NANTONG ZHONGRUN CONCRETE +1

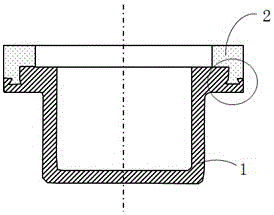

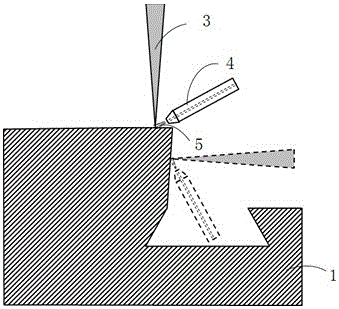

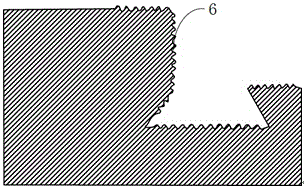

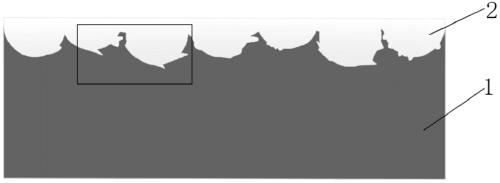

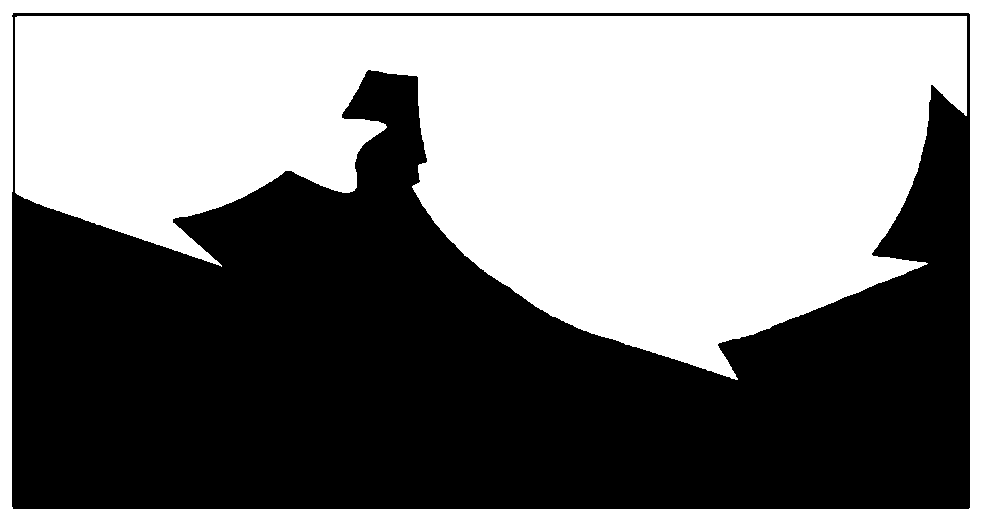

Method for connecting plastic and metal heterostructure

InactiveCN106393705AIncreased mechanical occlusionImprove the bonding strength of the interfaceLaser beam welding apparatusChemical LinkageTemperature control

The invention provides a method for connecting plastic and a metal heterostructure. The method comprises the following steps that S1, laser roughening treatment is conducted on the surface of a to-be-connected metal part, and local protrusions and dents are generated on the surface of the metal part, so that a metallic oxide layer is formed; S2, the metal part subjected to laser roughening treatment and a to-be-connected plastic part are hot-pressed, so that the metal part and the plastic part are bonded together; and S3, out-of-focus laser beams are adopted to penetrate through the plastic part so as to reach the interface between the plastic part and the metal part, and the portion, at the interface, of the plastic part is partially melted. According to the method for connecting the plastic and the metal heterostructure, operation is easy, the mechanical engaging and chemical bonding degree of the plastic and metal is increased through the required local protrusions and dents formed on the surface of the metal part and partial heating and temperature control of the interface, tight bonding of the plastic and the metal at the interface is facilitated, and the interface bonding strength and airtightness of the plastic and the metal heterostructure are improved accordingly.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Method for improving interfacial properties of aramid fiber/epoxy resin composite material

InactiveCN101205686AEnhanced interface bindingPromote infiltrationPhysical treatmentEpoxyLiquid medium

An aramid fibre / epoxy resin composite interface performance improving method relates to a macromolecule material modification processing method. The invention solves the problems that the interface between the prior Kevlar-49 fibre and the prior epoxy resin has weak combination and the fiber surface modification processing method is not suitable for industrialized production. The Kevlar-49 fibre surface modification processing method of the invention is as follows: firstly the Kevlar-49 fibre is dried, then the dried Kevlar-49 fibre and liquid medium are sealed in a glass reactor; under the condition of normal temperature, normal atmosphere and the protection of protective gas, a gamma ray with <60>Co as radiation source is adopted to radiate; the radiation dosage is between 0.1 and 1000 kGy and the radiation dosage rate is between 3 and 7 kGy / h. The invention has the advantages of simple operation, stable technique, reliable product quality, environmental protection and industrialized production. The method of the invention improves the fibre surface energy, thereby improving the combination intensity of the interface between the fibre and the epoxy resin matrix and exerting the comprehensive performance of Kevlar-49 fiber reinforced composite farthest.

Owner:HARBIN INST OF TECH

Lithium ion battery with high energy density and preparation method of lithium ion battery with high energy density

InactiveCN104241696AShorten the transmission distanceImpedance increases proportionallyCell electrodesFinal product manufacturePhysicsElectrical battery

The invention relates to the technical field of lithium ion batteries and in particular relates to a lithium ion battery with the high energy density and a preparation method of the lithium ion battery with the high energy density. The lithium ion battery comprises a positive electrode, a negative electrode, an isolation film and electrolyte, wherein the positive electrode comprises a positive current collector, an active material A layer and an active material B layer; the active material A layer is arranged between the positive current collector and the active material B layer; the particle diameter of an active material B is greater than that of an active material A; the weight ratio of the active material A layer to the active material B layer is 0.1-10; the negative electrode comprises a negative current collector, a conductive polymer C layer and a negative film; the conductive polymer C layer is arranged between the negative current collector and the negative film; the thickness of the conductive polymer C layer is less than or equal to 5 microns. The lithium ion battery prepared by adopting the method is relatively high in dynamics performance; the problem of risk of separating lithium out of a thickly-coated system lithium ion battery at the low temperature can be effectively solved. The prepared battery is safe, reliable, and long in cycle life.

Owner:MCNAIR TECH +1

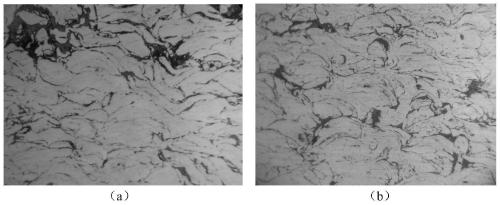

Method for preparing graphite-reinforced anti-attrition heat and electricity conduction coating layer by supersonic laser deposition

InactiveCN111378965AReduce the critical deposition rateImprove deposition efficiencyTransportation and packagingMetal-working apparatusElectrically conductivePowder

The invention provides a method for preparing a graphite-reinforced anti-attrition heat and electricity conduction coating layer by supersonic laser deposition. The method is to synchronously introduce a laser beam in the cold spraying process; and through a radiation effect of the laser, powder particles are softened without being molten, so that the critical deposition speed of powder is lowered, the deposition efficiency of the powder is improved, the bonding force of the coating layer is increased, multiple defects of the coating layer prepared by single cold spraying are solved, the comprehensive performance of a composite coating layer is greatly improved, both economy and environmental protection are achieved, and the idea of green development is quite met.

Owner:ZHEJIANG UNIV OF TECH

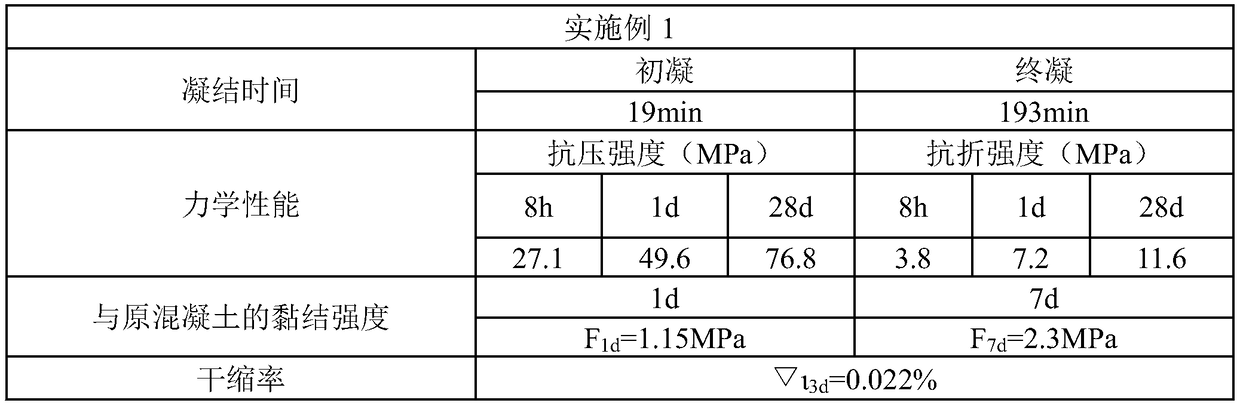

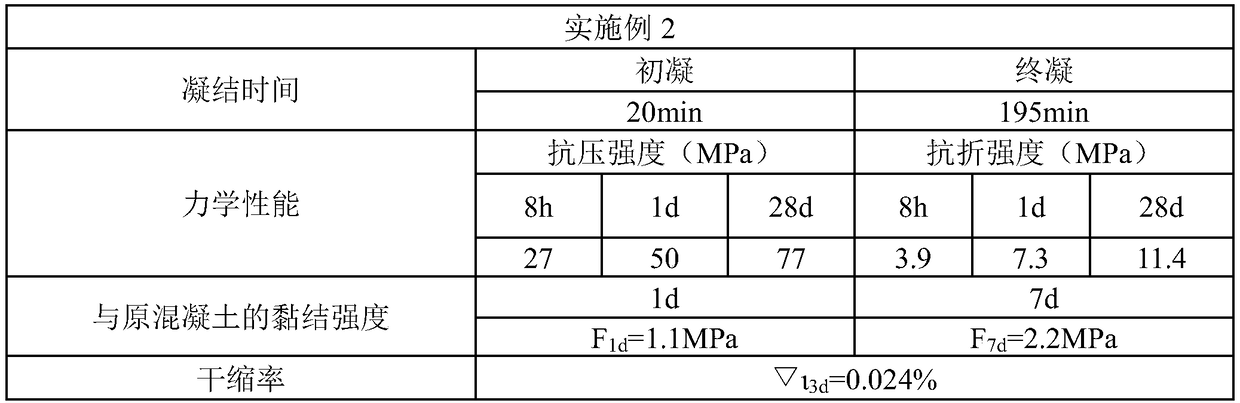

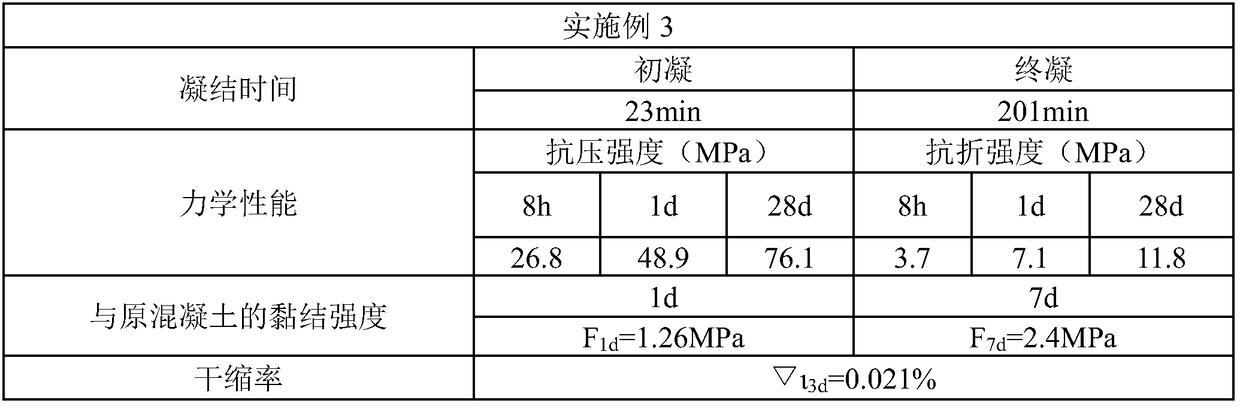

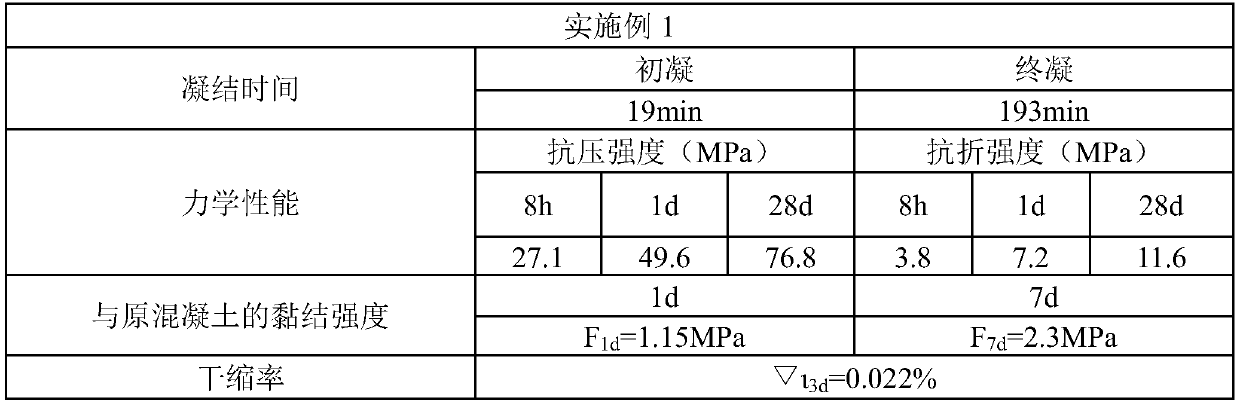

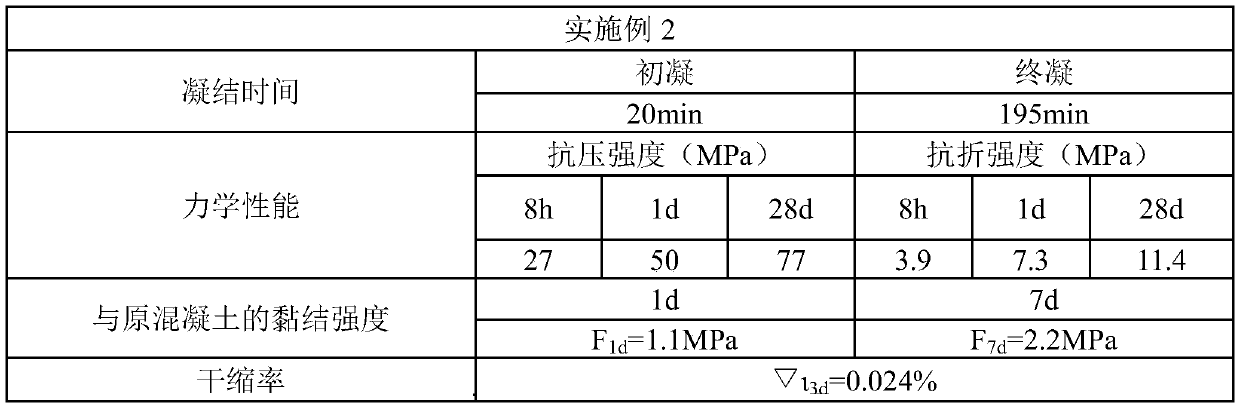

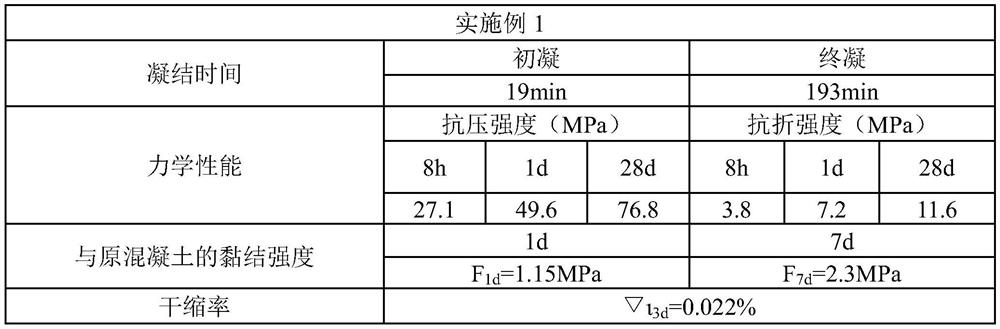

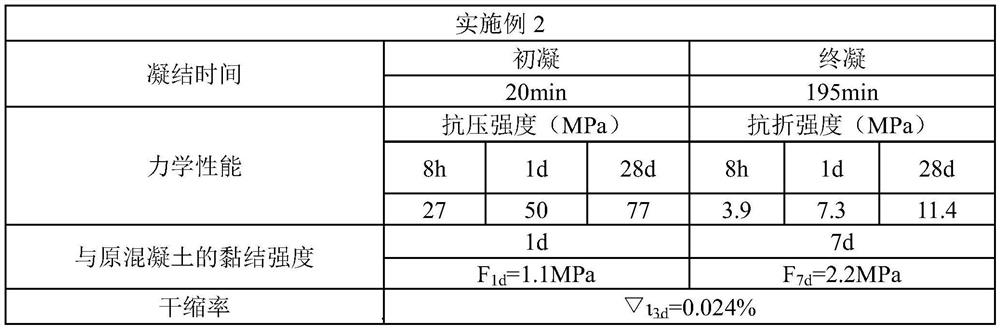

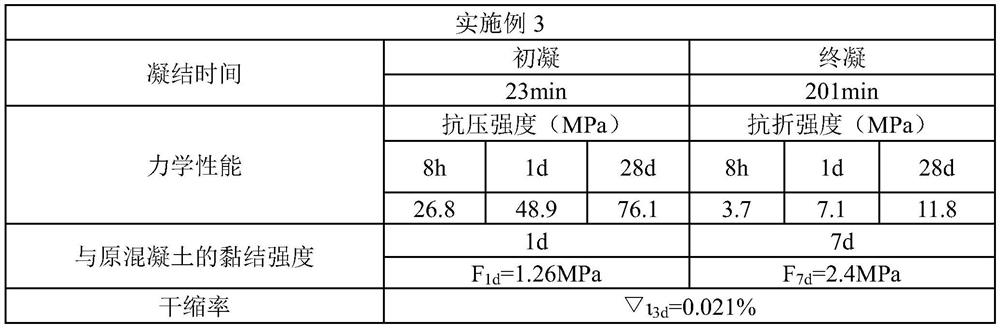

Fast hardening early strength type composite repair mortar

The invention belongs to the technical field of a building material, and provides fast hardening early strength type composite repair mortar. The mortar is prepared from the following ingredients in percentage by weight: 5 to 10 percent of water, 20 to 30 percent of cement, 1 to 5 percent of silicon ash, 1 to 5 percent of fly ash, 50 to 70 percent of quartz sand, 0.4 to 0.5 percent of compound early strength agents, 0.06 to 0.1 percent of water reducing agents, 1 to 5 percent of rubber powder and 0.06 to 0.8 percent of hybrid fiber, wherein the composite early strength agent is prepared from an ingredient A and an ingredient B; the ingredient A is lithium carbonate; the ingredient B is a mixture of triethanolamine and aluminum sulfate; the quartz sand consists of coarse sand, medium sand and fine sand; and the hybrid fiber consists of basalt fiber and polypropylene fiber. The fast hardening early strength type composite repair mortar solves the problems of reduced strength, high dry shrinkage rate and low bonding strength of the repair mortar in the prior art.

Owner:JILIN JIANZHU UNIVERSITY

Rapid hardening early strength type composite repair mortar

The invention belongs to the technical field of building materials, and provides rapid hardening early strength type composite repair mortar. The rapid hardening early strength type composite repair mortar comprises, by weight, 5%-10% of water, 20%-30% of cement, 1%-5% of silica fume, 1%-5% of fly ash, 50%-70% of quartz sand, 0.4%-0.5% of composite early strength agents, 0.06%-0.1% of water reducing agents, 1%-5% of gelatin powder and 0.06%-0.8% of hybrid fibers. The composite early strength agents comprise components A and components B, the components A are nanometer calcium carbonate whiskers, the components B are mixtures of triisopropanolamine and aluminum sulfate, the quartz sand comprises coarse sand, medium sand and fine sand, and the hybrid fibers include basalt fibers and polypropylene fibers. The rapid hardening early strength type composite repair mortar has the advantage that the problems of strength decreasing, high dry shrinkage and low bonding strength of repair mortar in the prior art can be solved by the aid of the rapid hardening early strength type composite repair mortar.

Owner:长春昌驰新材料科技有限公司

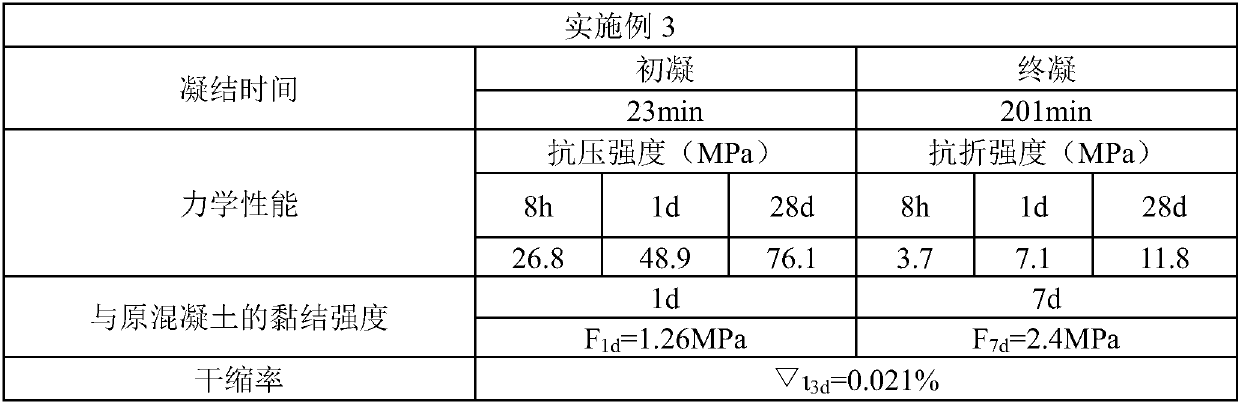

Steel tube concrete and sprayed concrete stiff combined structure tunnel support system and construction method

PendingCN111828053AHigh compressive strengthImprove corrosion resistanceUnderground chambersTunnel liningShotcreteSupporting system

The invention provides a steel tube concrete and sprayed concrete stiff combined structure tunnel support system and a construction method. Multiple steel tube concrete arch frames are arranged and are sequentially arranged in the longitudinal direction of a tunnel, and each steel tube concrete arch frame comprises multiple spliced square steel segments and fine aggregate concrete materials injected in steel tubes. After splicing of each steel tube concrete arch frame is completed, injection and filling are carried out in a segmented manner. Multiple cotter shearing force parts are fixed to the longitudinal inner and outer tube faces of each steel tube concrete arch frame. The left side and the right side of each transverse partition plate are connected with L-shaped embedded plates, and the L-shaped embedded plates are fixed to the longitudinal tube faces of the steel tube concrete arch frames. Multiple ring steel bars are welded to each transverse partition plate in a penetrating manner. The space between the steel tube concrete arch frames is filled with sprayed concrete, and the thickness of the sprayed concrete is flushed with the steel tube concrete arch frames. By means of the system, the bearing force and corrosion resistance of the square steel arch frames are enhanced, and the bonding capacity of the support system and the sprayed concrete is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

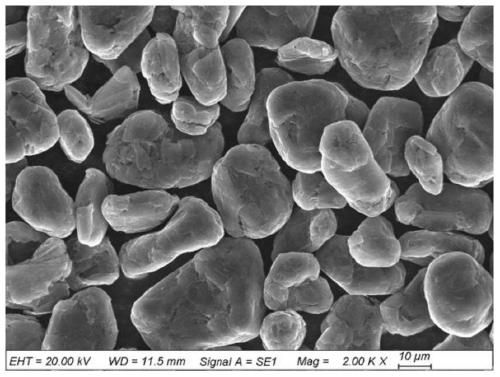

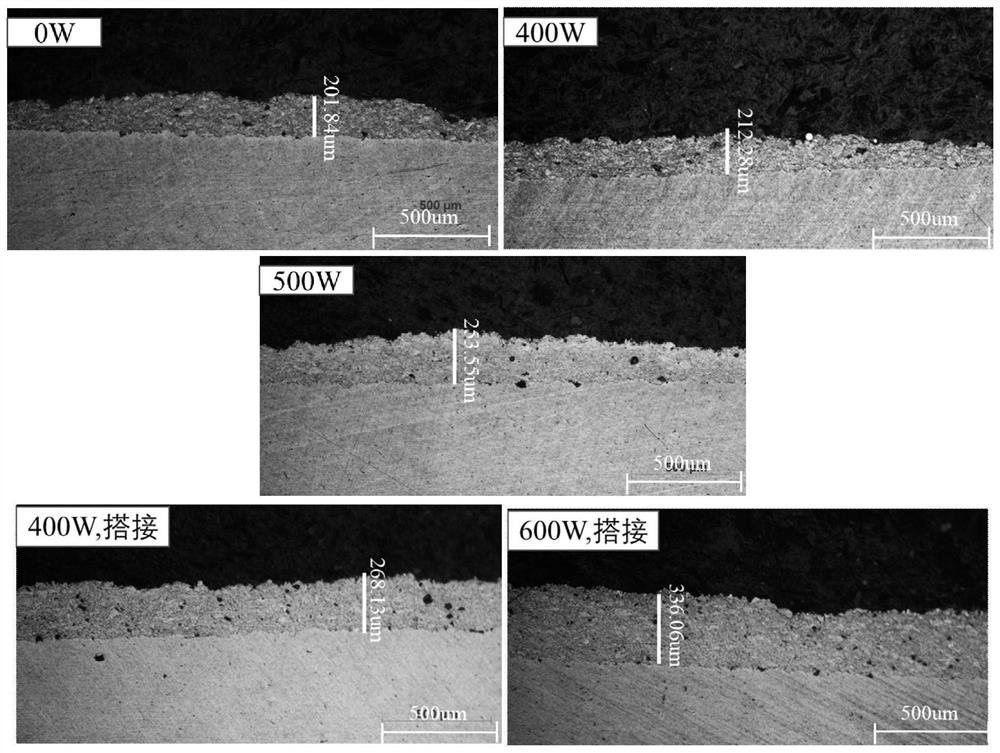

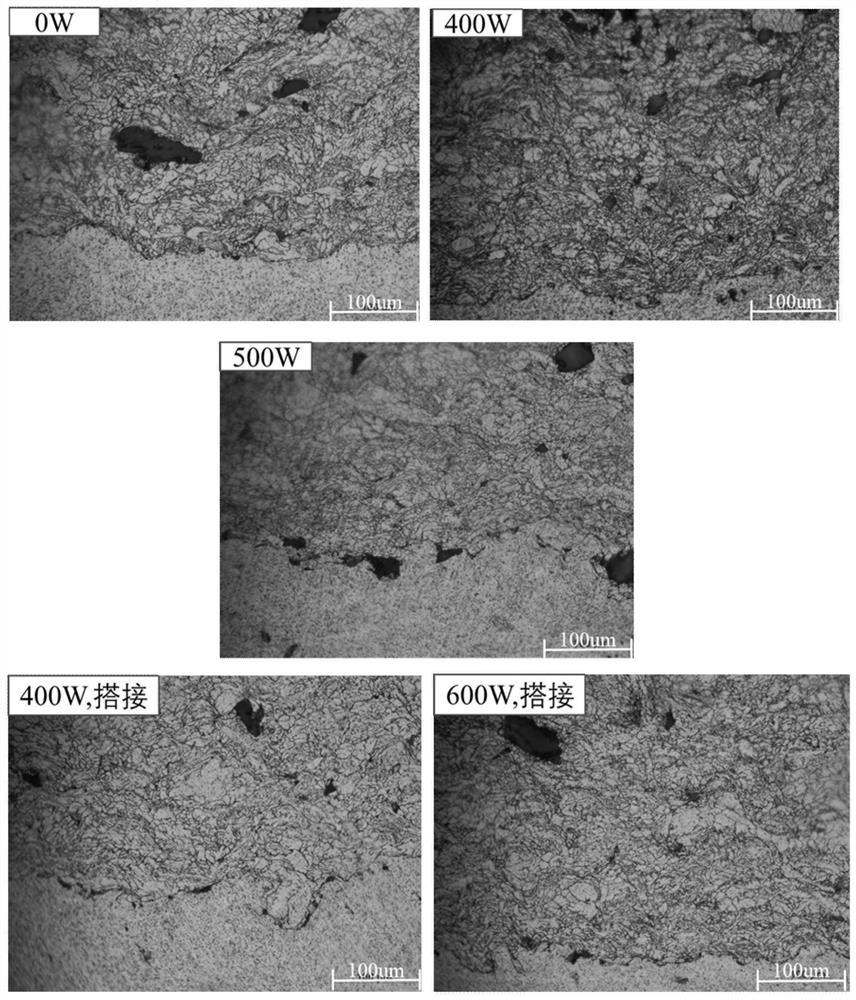

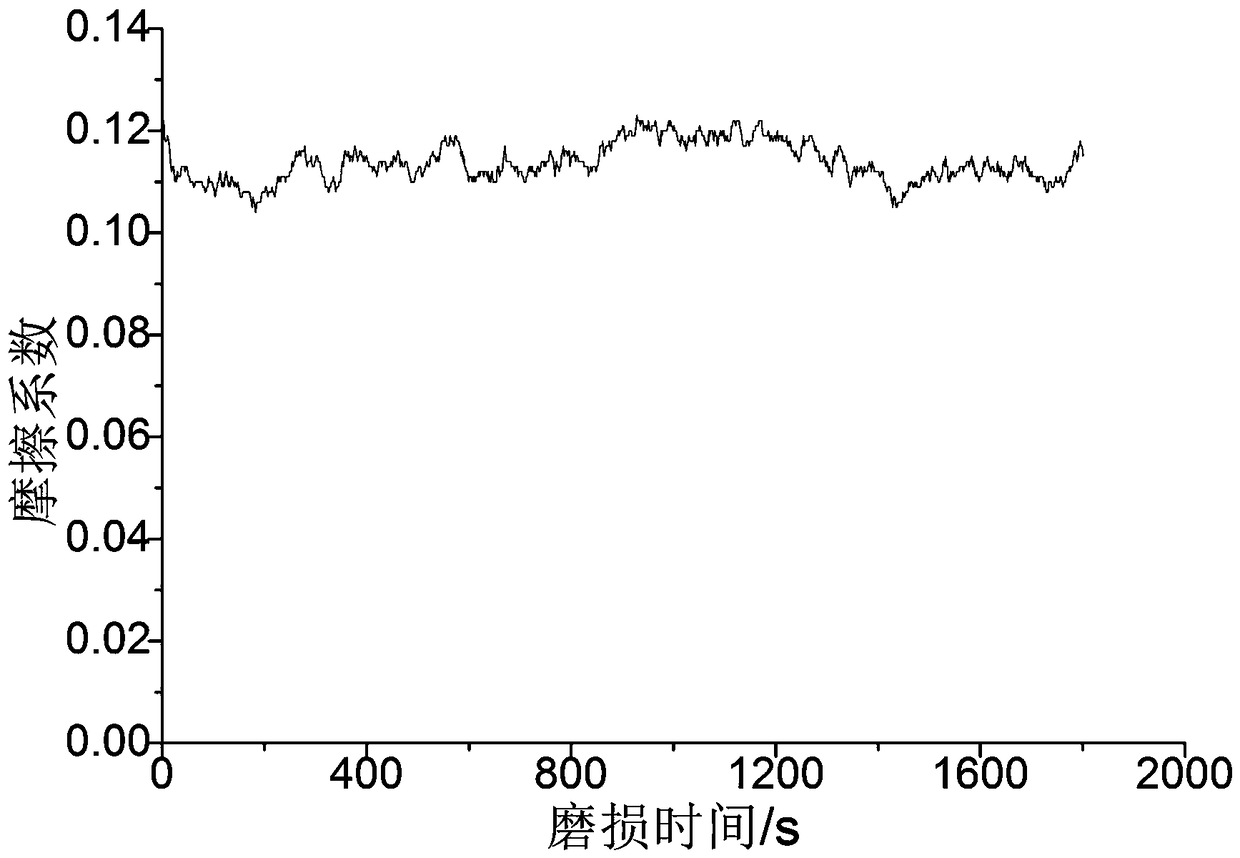

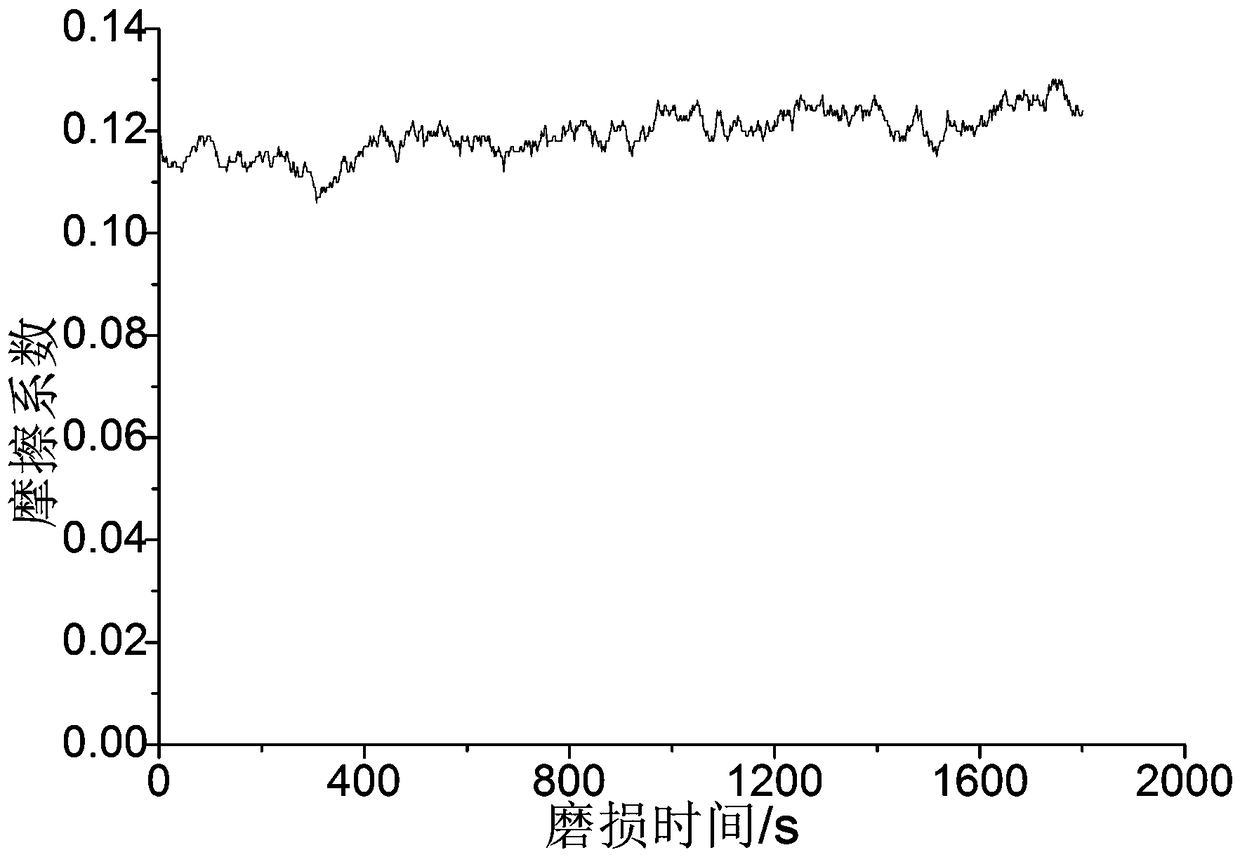

Preparation method for high-strength high-hardness synchronous gear ring coating with self-lubricating property

ActiveCN109338267AImprove organizational stabilityHigh hardnessMolten spray coatingCarbon monofluorideSurface engineering

The invention belongs to the technical field of surface engineering, and relates to a preparation method for a high-strength high-hardness synchronous gear ring coating with a self-lubricating property, in particular to a preparation method for a CFx-BN-Mo2S / Cr3C2-Mo2C-VC synchronous gear ring coating. According to the preparation method for the high-strength high-hardness synchronous gear ring coating with the self-lubricating property, on the basis of the high strength, the high hardness, the wear resistance, the corrosion resistance and the structure stability of a chromium carbide-molybdenum carbide-vanadium carbide material, carbon monofluoride, boron nitride, molybdenum disulfide and a trace amount of WC-10Co-4Cr are added to serve as reinforcing agents, and the reinforcing agents are sprayed to the surface of a synchronous gear ring through a supersonic-speed flame spraying technology; and compared with a traditional synchronous gear ring, the fatigue resistance, the oxidation resistance, the corrosion resistance and the wear resistance are significantly improved, the coating has the very good structure stability and self-lubricating property, and the service life of the synchronous gear ring is greatly prolonged.

Owner:SHANDONG JIANZHU UNIV

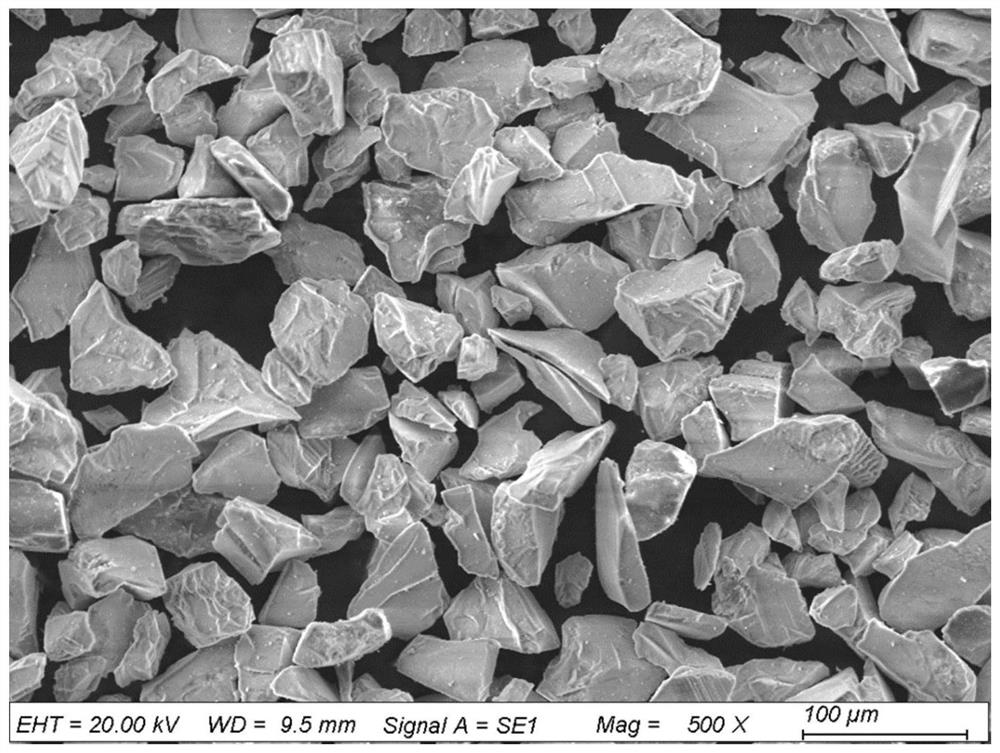

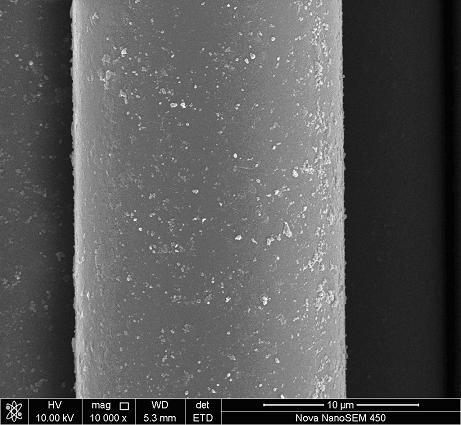

Method for preparing aluminum oxide reinforced copper-based wear-resistant, heat-conducting and electric-conducting coating through laser-assisted low-pressure cold spraying

PendingCN112981387AReduce the critical deposition rateImprove deposition efficiencyHeat inorganic powder coatingCopper coatingConductive coating

The invention provides a method for preparing an aluminum oxide reinforced copper-based wear-resistant, heat-conducting and electric-conducting coating through laser-assisted low-pressure cold spraying. The method comprises the following steps that a laser beam is synchronously introduced in a low-pressure cold spraying process, powder particles are softened but not melted under the irradiation action of laser, a matrix is heated at the same time, the critical deposition velocity of powder is reduced, the deposition efficiency of the powder is improved, the binding force of the coating is improved, and the porosity of the coating is reduced; and irregular aluminum oxide particles are added into the copper powder to enhance the wear resistance of the coating, so that the content of aluminum oxide in the coating is low, the mechanical performance is good, many problems of the copper coating prepared through single low-pressure cold spraying are solved, the wear resistance is greatly improved while the heat conduction and electric conduction performance is kept, the comprehensive performance of the composite coating is good, the resource utilization rate is high, and the green development concept is met.

Owner:ZHEJIANG UNIV OF TECH

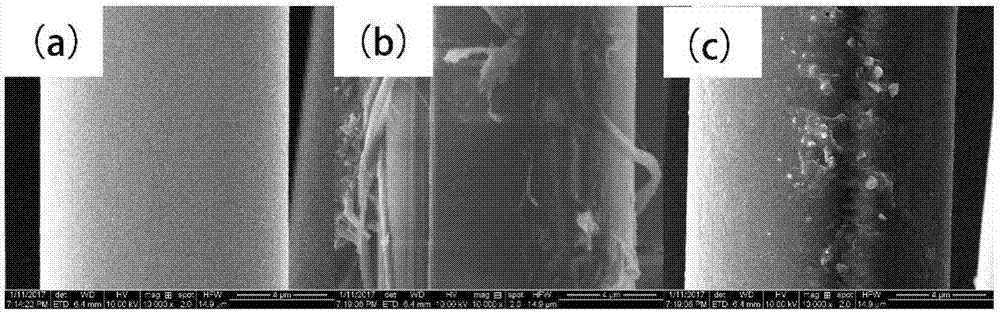

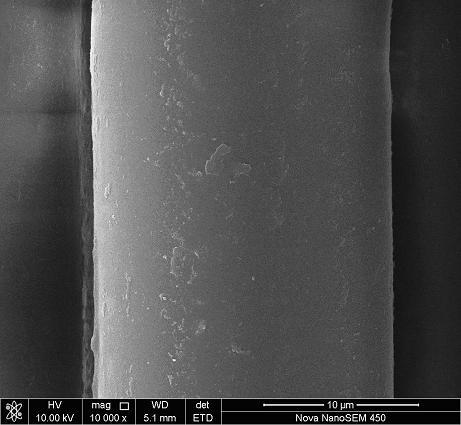

Surface modification method of aramid fiber and application of product thereof

InactiveCN107313242AIncrease surface areaIncreases the interfacial bond strengthFibre typesLight/infra-red/X-rays fibre treatmentInterfacial bondingDouble bond

The invention discloses a surface modification method of aramid fiber and a preparation method of a product thereof. According to the surface modification method, irradiation modification is performed on the aramid fiber in the air by taking ultraviolet light as an irradiation source, and a silane coupling agent KH570 is grafted twice. The surface roughness of the aramid fiber is increased since the surface of the aramid fiber is etched by ultraviolet modification, thereby increasing the surface area of the fiber, enhancing the mechanical bite between the aramid fiber and natural rubber, and increasing the interfacial bonding strength between the aramid fiber and the natural rubber. The irradiation modification can also excite the activity of surface functional groups of the aramid fiber, the active functional groups can be reacted with the silane coupling agent KH570, and the other end of the KH570 contains double bonds which can participate in the vulcanization reaction of the natural rubber, thereby increasing the interfacial adhesion. The surface modification method has the advantages of safety, high efficiency, low pollution, low energy consumption, simple equipment and suitability for industrialized production, and has a good development prospect in the modification of the aramid fiber.

Owner:GUIZHOU UNIV

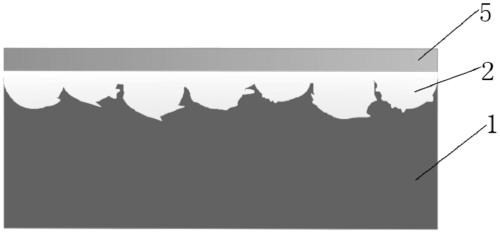

Carbon fiber and metal composite structure and preparation method thereof

InactiveCN111391421AImprove fatigue lifeImprove surface roughnessLamination ancillary operationsSynthetic resin layered productsPolymer scienceCarbon fibers

The invention discloses a preparation method of a carbon fiber and metal composite structure, which comprises the following steps: 1. carrying out shot blasting or shot penning treatment on the bonding surface of metal at least once to form roughened metal; 2, spraying an acetone resin solution on the surface of the rough metal, and carrying out pretreatment; 3, coating the surface of the pretreated rough metal with a binder; 4, carrying out infiltration treatment on an aramid short fiber film by using an acetone resin solution, and placing the aramid short fiber film on the rough metal surface; and 5, carrying out infiltration treatment on carbon fiber cloth by using an acetone resin solution, coating the surface of the carbon fiber cloth with a binder, covering the rough metal surface treated in the step 4 with the carbon fiber cloth, and carrying out static pressing until the carbon fiber and metal composite structure is cured and molded. Joint reinforcement of two interface layersbetween metal and a binder and between carbon fibers and the binder and a binder layer is realized.

Owner:CHANGAN UNIV

Preparation method of dopamine modified glass fiber/unsaturated polyester composite material

The invention relate to a preparation method of a dopamine modified glass fiber / unsaturated polyester composite material. Acetone is adopted to carry out desizing treatment on a glass fiber raw material, desized glass fiber is put into a dopamine hydrochloric acid solution for soaking, then the glass fiber is taken out and cleaned by deionized water, and dried to obtain modified glass fiber, and the modified glass fiber and unsaturated resin are mixed to prepare the dopamine modified glass fiber reinforced resin composite material. According to the preparation method, the glass fiber is modified by dopamine, the interface structure between the glass fiber and the resin on a microscopic scale is designed, adjusted and controlled, the wettability and the interface bonding strength between the glass fiber and the resin are increased, and the comprehensive performance of the modified glass fiber unsaturated polyester composite material is obviously improved. However, dopamine polymerization conditions are simple, and the environment is relatively mild. The thickness of the dopamine deposited on the surface of the glass fiber is controllable. Therefore, the preparation method is more conducive to the industrial production and wider application of the glass fiber composite material.

Owner:NANCHANG HANGKONG UNIVERSITY

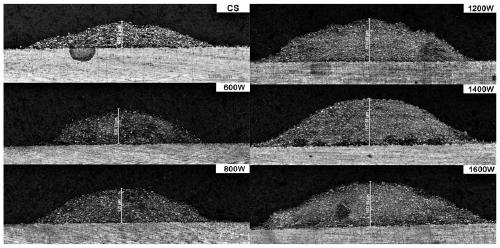

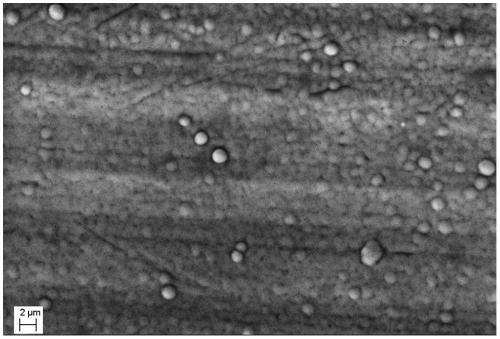

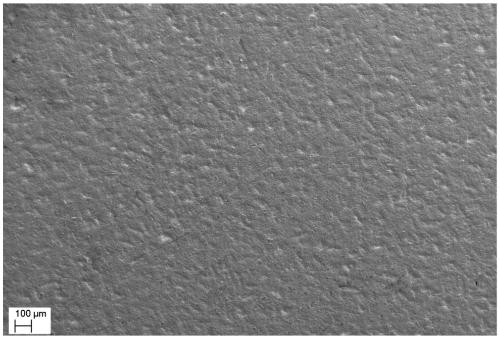

Method for improving crankshaft face plasma spraying Mo coating combination strength

ActiveCN108330430AHigh bonding strengthIncreased mechanical occlusionMolten spray coatingMicrometerTorque motor

The invention discloses a method for improving crankshaft face plasma spraying Mo coating combination strength. The requirement of a large-displacement large-torque motor crankshaft for combination force between a coating and a base body and combination force between the coating and the interior of the coating is higher and higher, WC-10Co-4Cr with the granularity being -30+5 micrometers and the weight ratio being 20 to 40% is added into Mo powder, in the spraying process, WC-10Co-4Cr particles impact a deposited coating by virtue of a certain speed obtained through plasma jet flow spraying, in the impacting process, kinetic energy of the particles is converted into deforming capacity and inner energy of the deposited particles, along with increasing of the impact number of the WC-10Co-4Crparticles, the deforming degree of the deposited coating is larger, the gap between the coating particles is extruded to be small and even the closing probability is larger, the hole shrinkage and crack arresting are achieved, mechanical occlusion between the coating and the base body is enhanced, cohesion between layers inside the coating is increased, the combination strength of the coating isimproved, and is improved to 58 MPa from 36 MPa, and the applying working condition need of a large-diameter crankshaft and large loads can be met.

Owner:GUANGDONG INST OF NEW MATERIALS

Brazing method of graphite material

ActiveCN112296472ARestrain harmful behaviorReduce surface tensionSoldering apparatusThermal dilatationAdhesive

The invention discloses a method for vacuum brazing connection of a graphite material by using brazing filler metal with added rare earth, belongs to the field of welding of materials, and particularly relates to a connecting method for a graphite material or between a metal material and the graphite material. Firstly, BNi75CrSiB nickel-based brazing filler metal and rare earth Y powder are evenlymixed through a ball-milling method, paste brazing filler metal is prepared through an organic adhesive, related base metal is coated with the paste brazing filler metal to form a base metal / brazingfiller metal / base metal sandwich structure, then the base metal / brazing filler metal / base metal sandwich structure is placed in a vacuum molybdenum sheet furnace, and brazing is conducted. By means ofthe method, the problems that the two-phase thermal expansion coefficient difference is too large, the wettability of brazing filler metal is poor, and the joint performance is poor due to large deformation at the local position of a joint are effectively solved, and related welding of the graphite material is economically and effectively achieved.

Owner:XIANGTAN UNIV

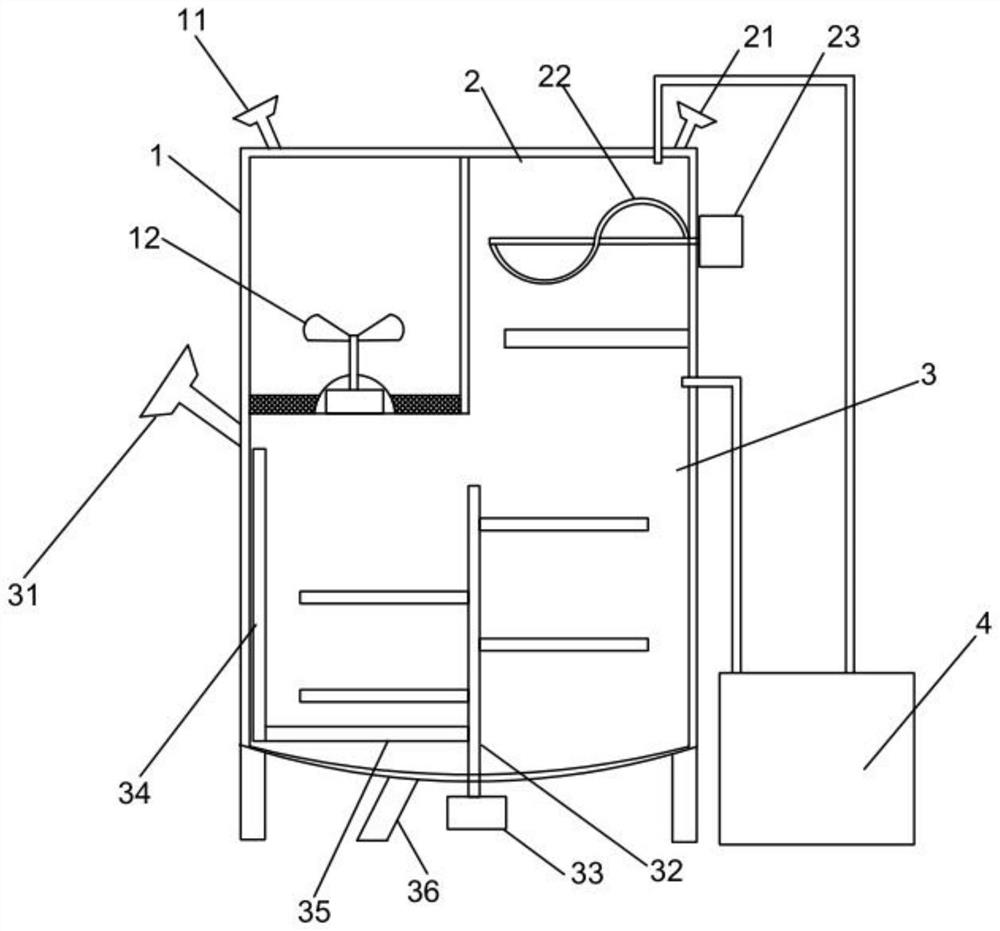

Road base material and preparation method thereof

PendingCN113698156AHigh activityImprove surface roughnessRoadwaysSolid waste managementRoad engineeringEnvironmental engineering

The invention belongs to the technical field of road engineering materials, and discloses a road base material and a preparation method thereof, the road base material comprises the following raw materials by weight: 24-58 parts of modified coal gangue, 10-36 parts of cement, 5-9 parts of silicon powder, 10-23 parts of gravel, and 2-3 parts of a water reducer. The invention also provides a preparation method of the road base material and a stirring device for preparing the road base material. The coal gangue can be effectively utilized, harm to the ecological environment is reduced, and the performance of the road base material is improved.

Owner:BEIJING UNIV OF TECH

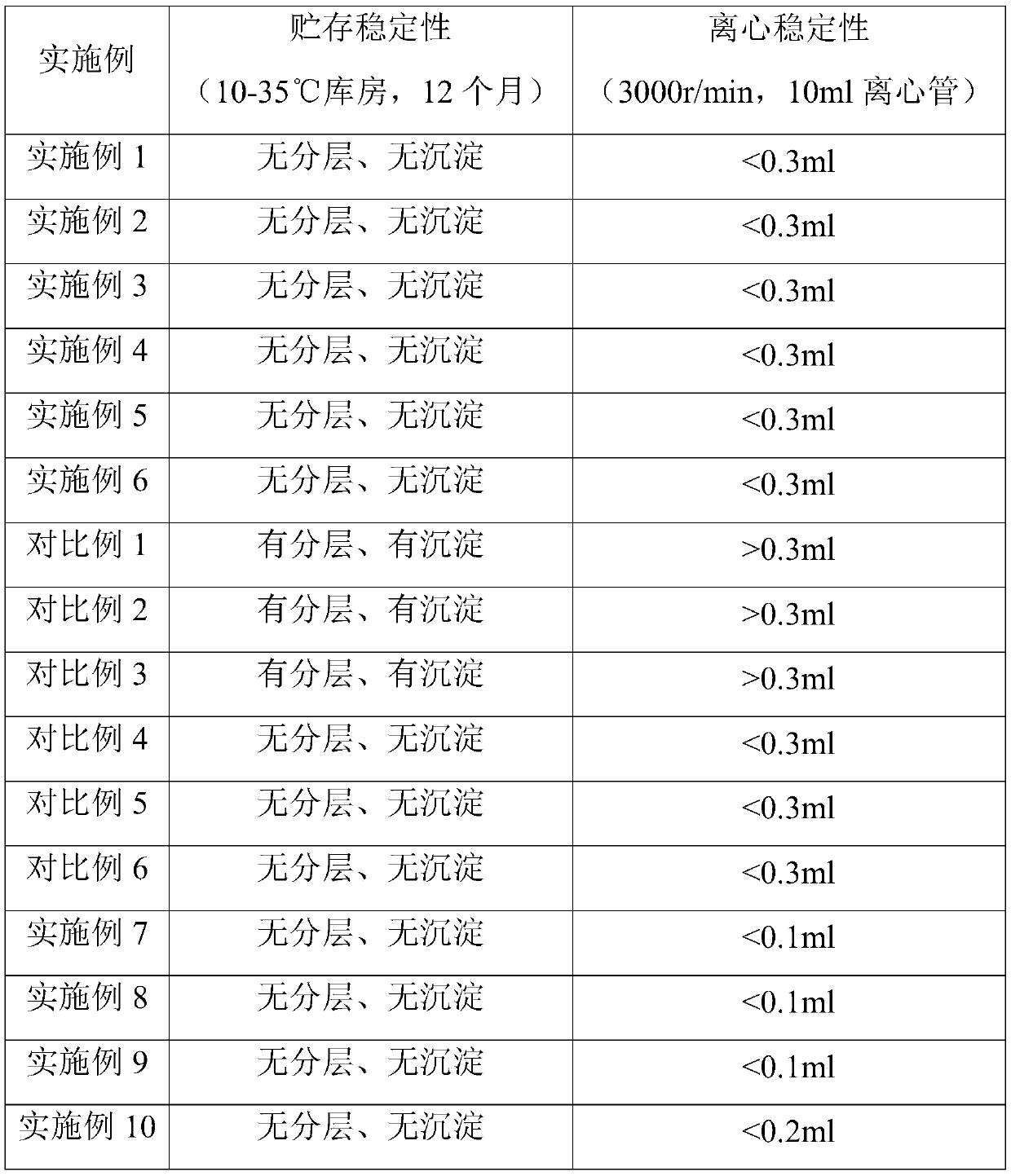

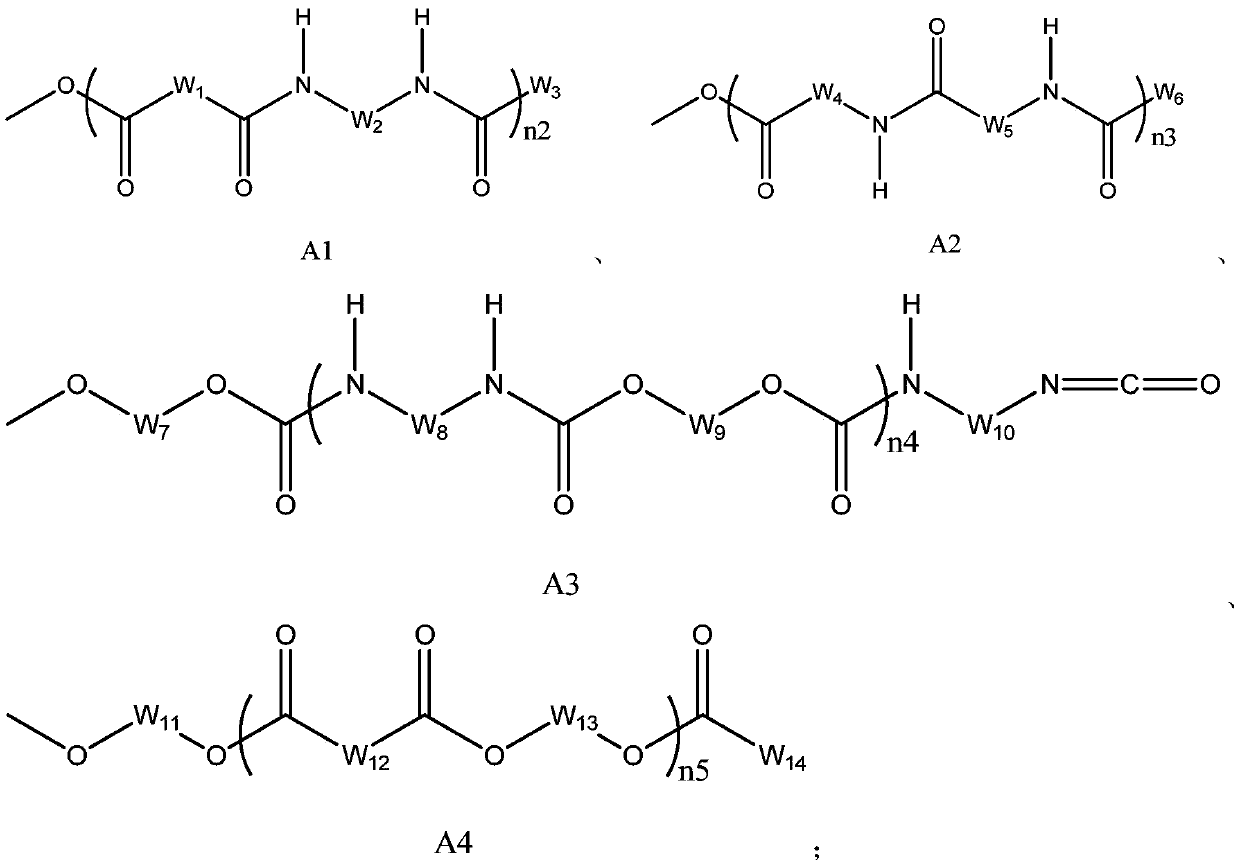

Sizing agent for graphene fibers and preparation method of sizing agent

The invention belongs to the technical field of sizing agents, and particularly relates to a sizing agent for graphene fibers and a preparation method of the sizing agent.The preparation method comprises the following steps: step 1, taking liquid bisphenol A epoxy resin, adding an emulsifier, heating to 105 DEG C and mixing uniformly, vacuumizing to remove residual moisture, then cooling to 80 DEGC, starting to add a chain extender, and then preserving heat for 6 h to obtain an epoxy resin emulsifier; step 2, mixing the liquid bisphenol A epoxy resin and the epoxy resin emulsifier according to a certain ratio and stirring uniformly, then starting to add deionized water, and continuing to stir when phase transformation begins to occur in a mixed system and adding deionized water at the same time to obtain an epoxy resin emulsion; step 3, adding a graphene aqueous solution to the epoxy resin emulsion, and adding deionized water and fully stirring at the same time to prepare the sizing agent for the graphene fibers.The sizing agent involved in the invention is used for protecting the graphene fibers, optimizing the physicochemical structure of the surface of the graphene fibers, andimproving the interfacial property of the graphene fibers and a polymer matrix material.

Owner:ZHEJIANG SCI-TECH UNIV

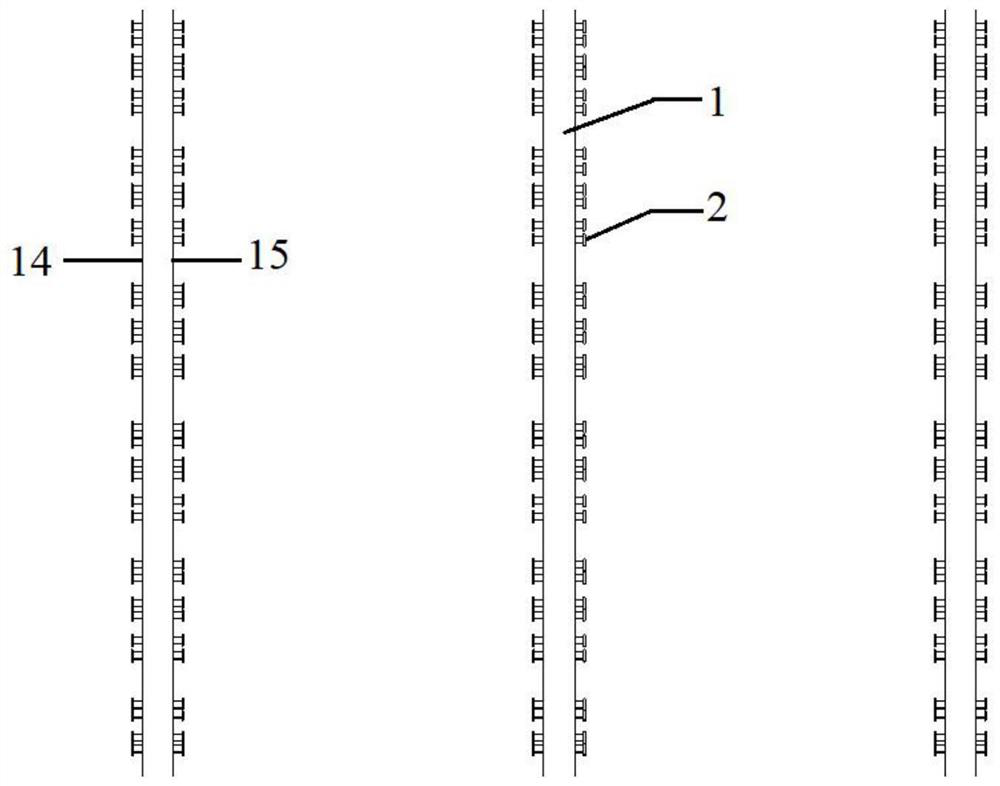

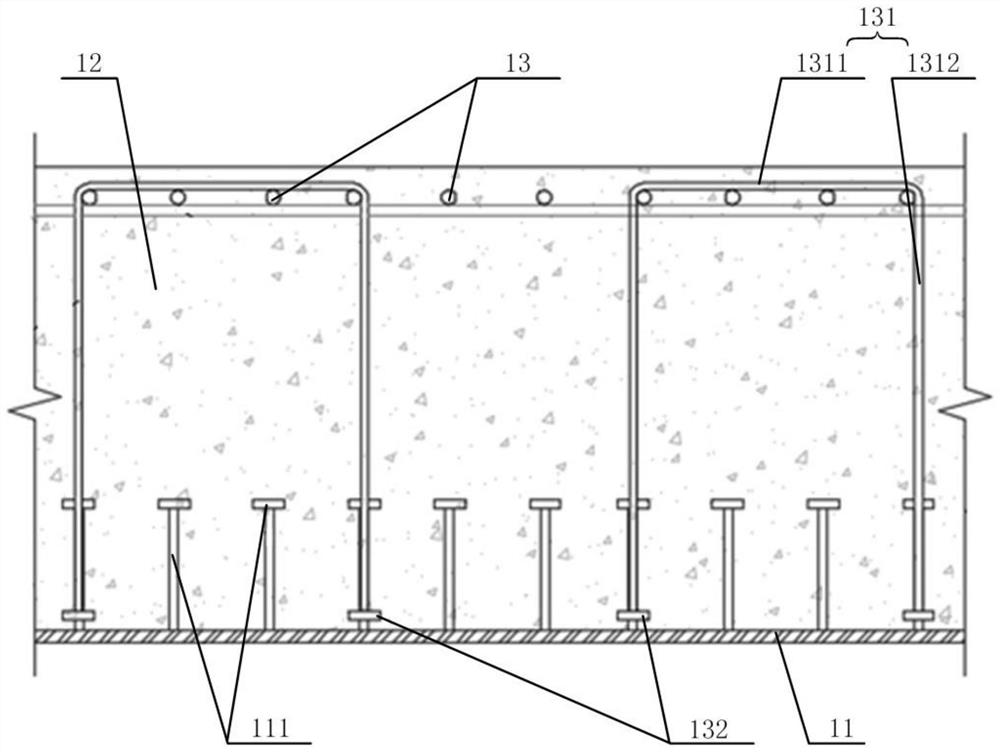

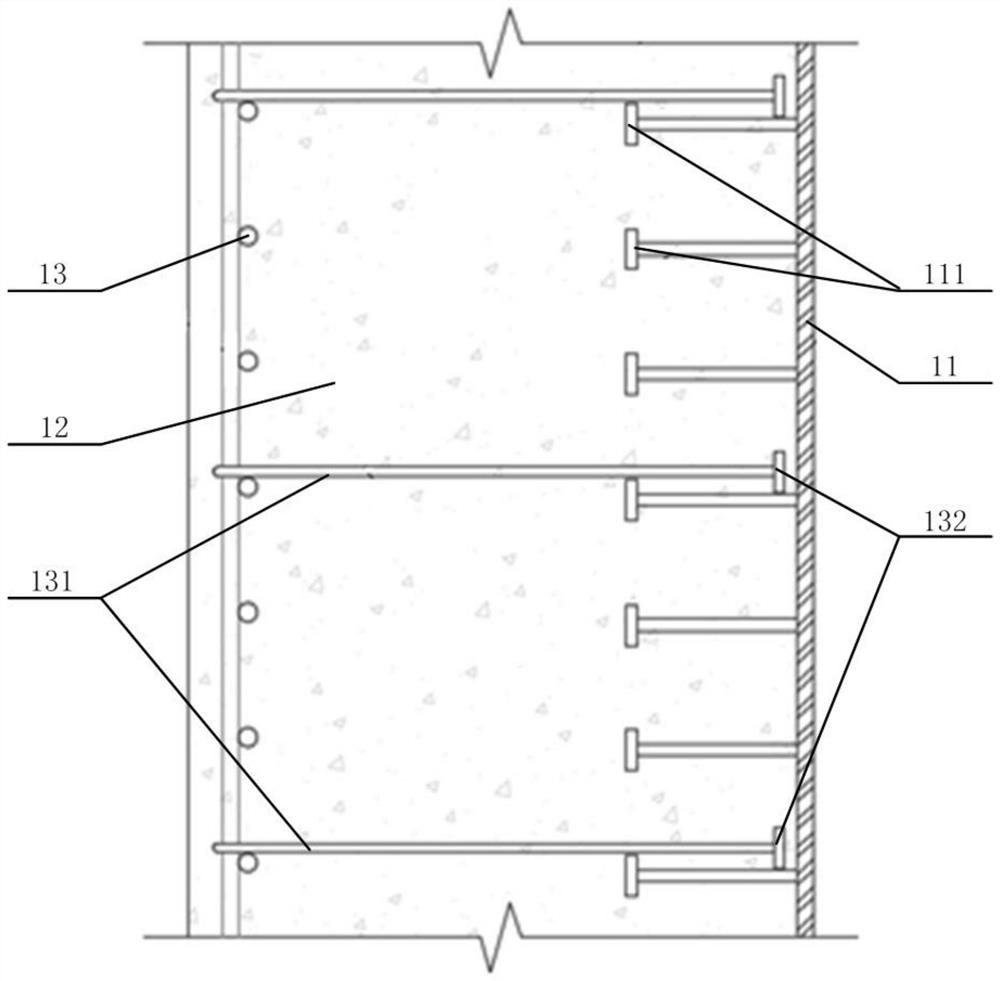

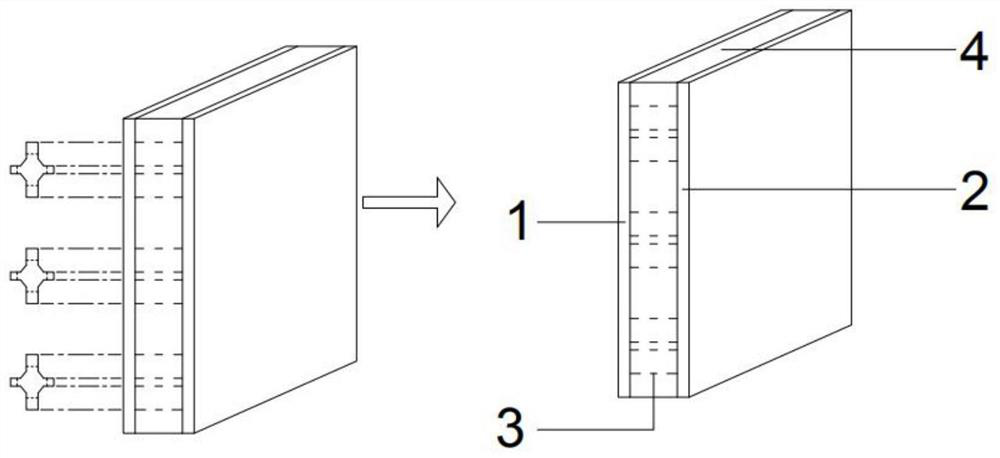

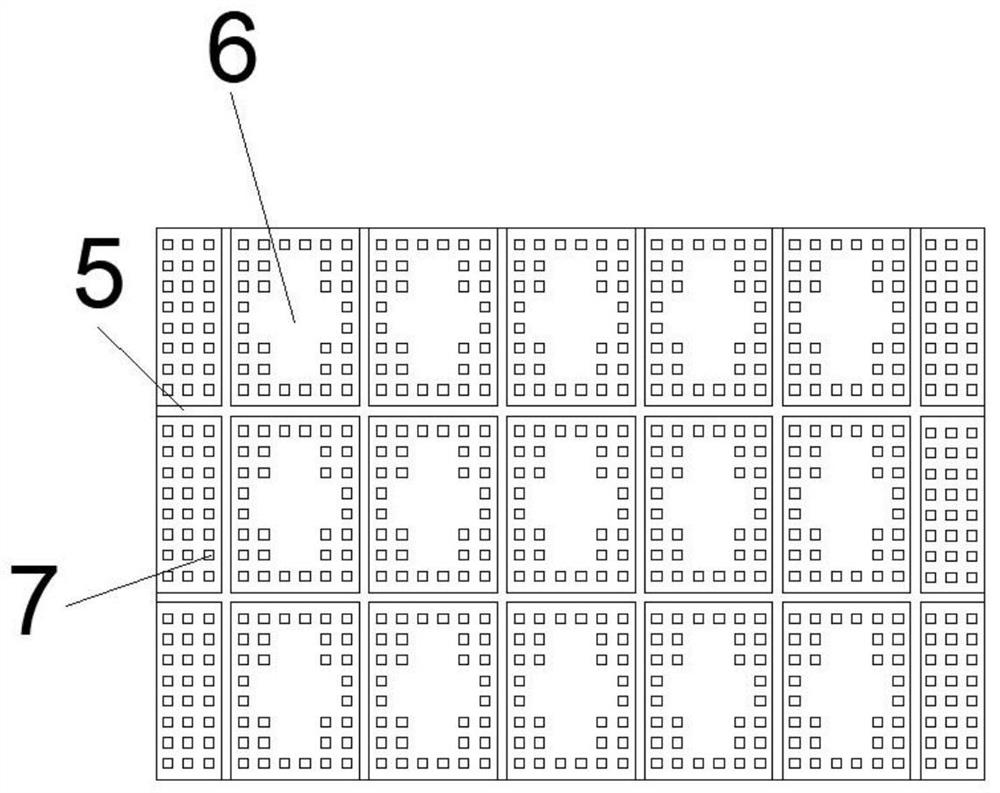

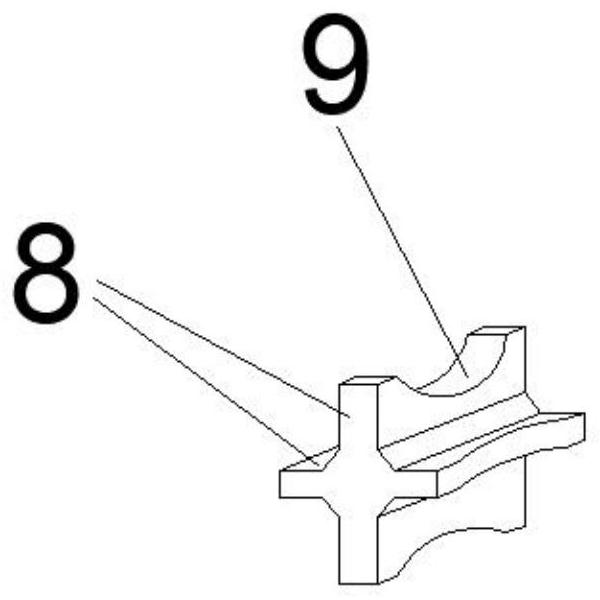

HSC structure with tie bar end anchor connection joints and construction method

PendingCN113585551AFirmly assembledIncreased mechanical occlusionWallsBuilding reinforcementsArchitectural engineeringMesh reinforcement

The invention discloses an HSC structure with tie bar end anchor connection joints and a construction method. The HSC structure comprises a steel plate and a wall body formed by pouring concrete, the steel plate is located on one side of the wall body, a reinforcing mesh which is in parallel alignment fit with the steel plate is embedded in the other side of the wall body, and the steel plate, the wall body and the main extension face of the reinforcing mesh are parallel to one another; a plurality of tie bars are arranged on the reinforcing mesh, the tie bars and the reinforcing mesh are in linkage in the direction perpendicular to the main extension face of the steel plate, a plurality of studs are evenly welded to the main extension face of the side, facing the wall body, of the steel plate in an array mode, and the free ends of the tie bars are provided with anchor heads which are in lap joint with the studs in an aligned mode and enhance the mutual anchoring effect. The HSC structure with the tie bar end anchor connection joints has a single-side steel plate structure, is simple, convenient and efficient to manufacture and form, is lower in construction difficulty and field workload, and is higher in overall construction efficiency. The invention further discloses a construction method for the HSC structure with a tie bar end anchor connecting joint.

Owner:CHINERGY CO LTD

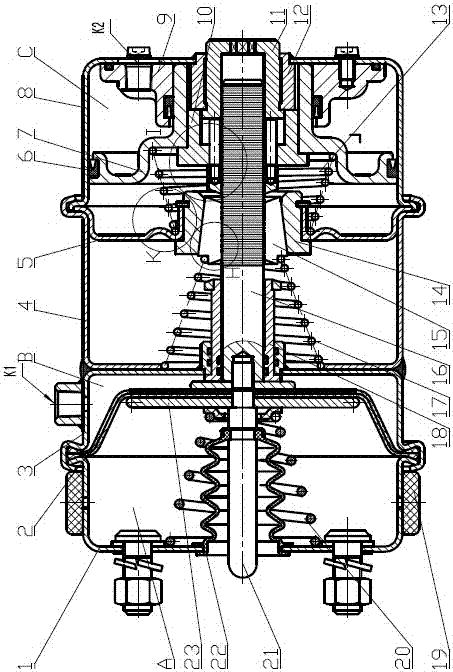

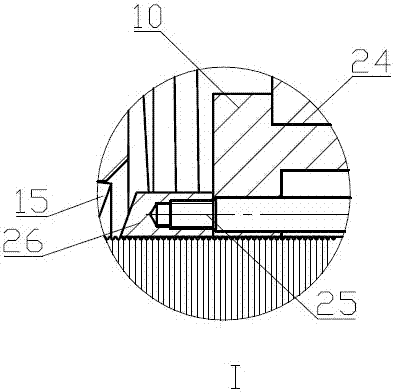

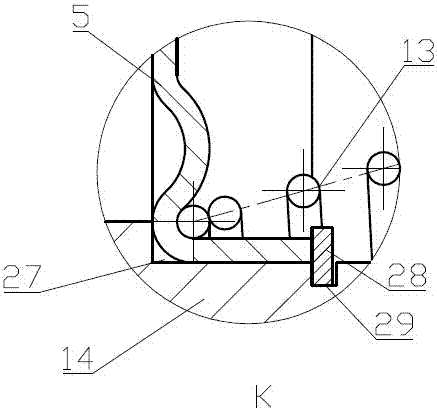

Brake air chamber with self-locking type parking mechanism

ActiveCN107882901AImprove securityEasy assembly and inspectionBrake actuating mechanismsWind energy generationStructural engineeringCylinder block

The invention discloses a brake air chamber with a self-locking type parking mechanism. The brake air chamber comprises a front cover assembly, a first middle body assembly, a second middle body assembly, a cylinder body assembly, a push rod disc assembly and a piston assembly; a leather membrane is arranged in first hollow formed by the front cover assembly and the first middle body assembly, thefirst space is divided into two cavities through the leather membrane, the two cavities are a push rod disc assembly cavity and a driving brake cavity, the push rod disc assembly is mounted in the push rod disc assembly cavity, the piston assembly is arranged in a second space formed by the second middle body assembly and the cylinder body assembly, a self-locking mechanism is arranged in the second space, and the piston assembly is arranged between the self-locking mechanism and the cylinder body assembly. Original energy storage strong springs are replaced, parking tasks are finished, safety of the brake air chamber is higher, and the service life is longer.

Owner:JIAXING SHENGDING MACHINERY

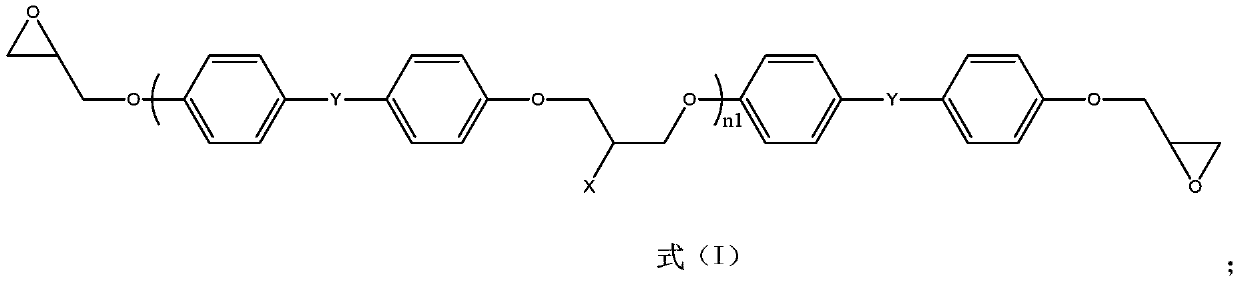

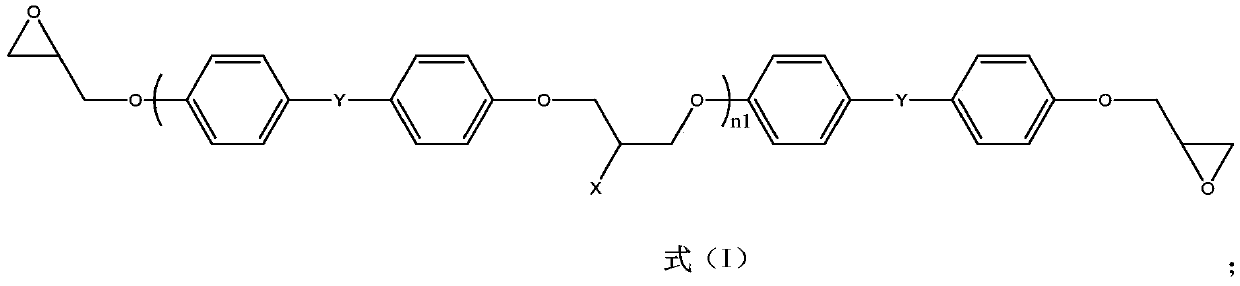

Thermoplastic epoxy resin and application thereof, and surface modifier for carbon fibers

PendingCN111574719AIncrease roughnessIncreased wetted contact areaCarbon fibresPolymer chemistryThermoplastic matrix

The invention discloses thermoplastic epoxy resin and application thereof, and a surface modifier for carbon fibers. The thermoplastic epoxy resin comprises a structure as shown in a formula (I) whichis described in the specification, and can be applied as a surface modifier to surface treatment of carbon fibers. The carbon fibers treated by the thermoplastic epoxy resin have better interfacial compatibility with thermoplastic matrix resin, desizing treatment is not needed, influence on the strength loss of the carbon fibers is small, and good application prospects are obtained.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

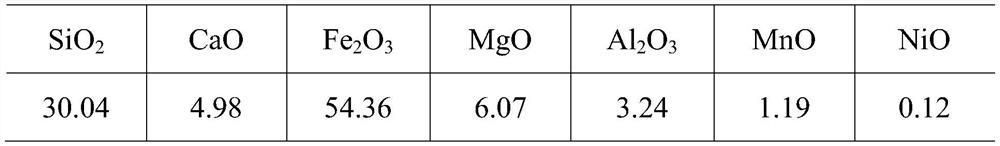

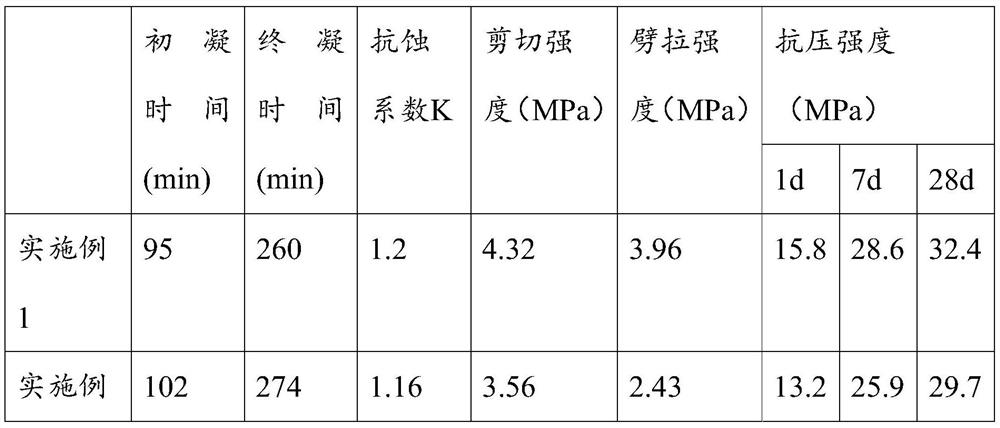

Solid-waste-based maritime work repair material and preparation method thereof

ActiveCN113511870ARealize the reuse of solid waste resourcesReduce economic spendingSolid waste managementSilica fumeSlag

The invention relates to a solid-waste-based maritime work repair material and a preparation method thereof, in particular to a method for preparing the solid-waste-based maritime work repair material by utilizing industrial solid waste, and relates to the fields of physical chemistry, solid waste reutilization, environmental protection and the like. The maritime work repair material is composed of red mud, nickel slag, sulphoaluminate cement, rubber powder, limestone powder, fiber, silica fume, a curing agent and an exciting agent with a mass ratio of (30-60):(10-25):(10-25):(0.5-1.5):(10-20):(0.7-1.3):(4-7):(1-5):(5-10), and the total amount of the components is 100 percent. The maritime work repair material has the characteristics of good seawater erosion resistance, strong bonding capacity and the like, and is suitable for maritime work repair engineering such as cross-sea bridge pile foundation repair and the like.

Owner:SHANDONG UNIV +2

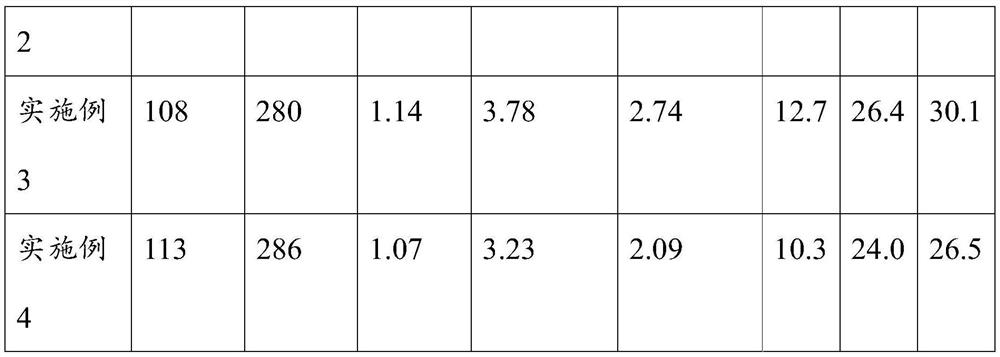

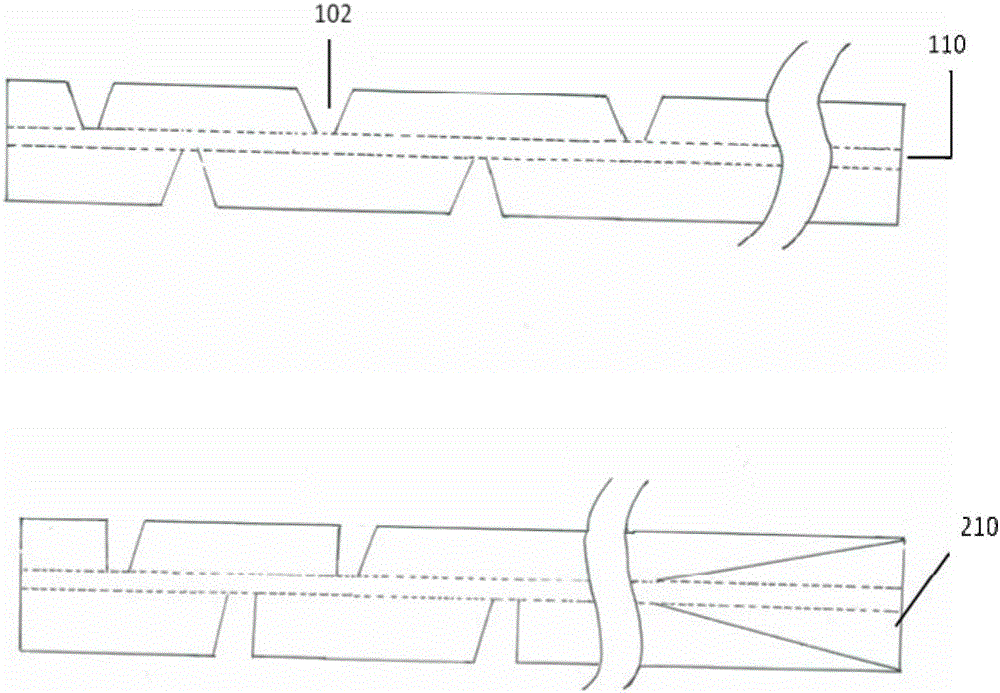

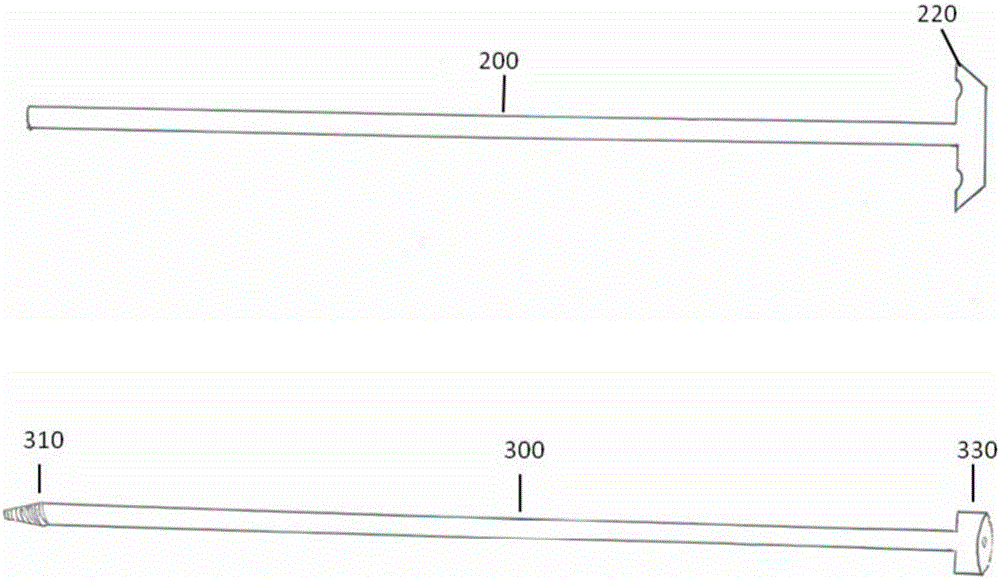

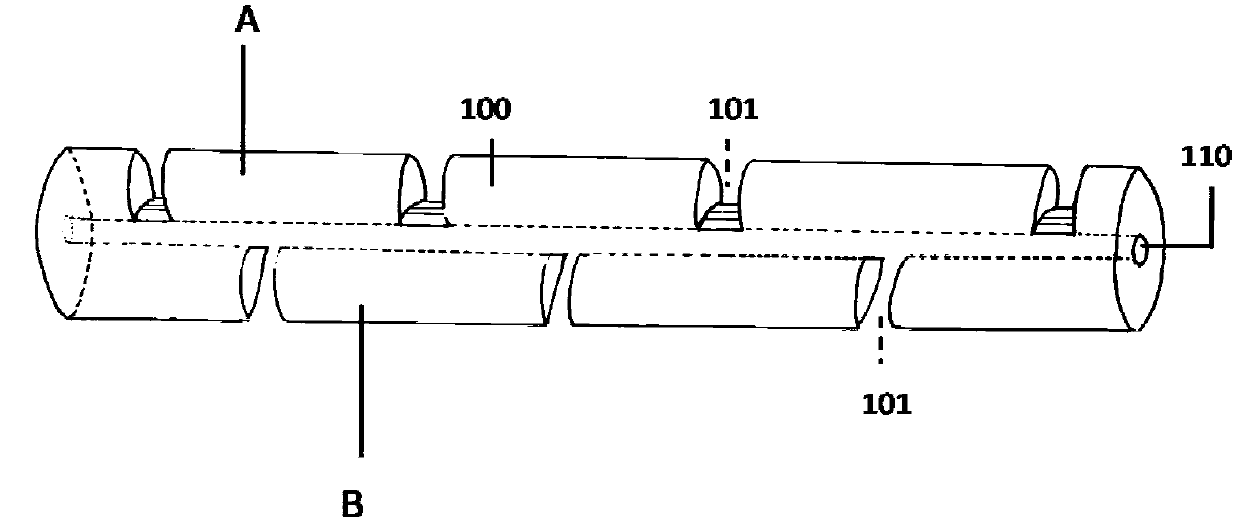

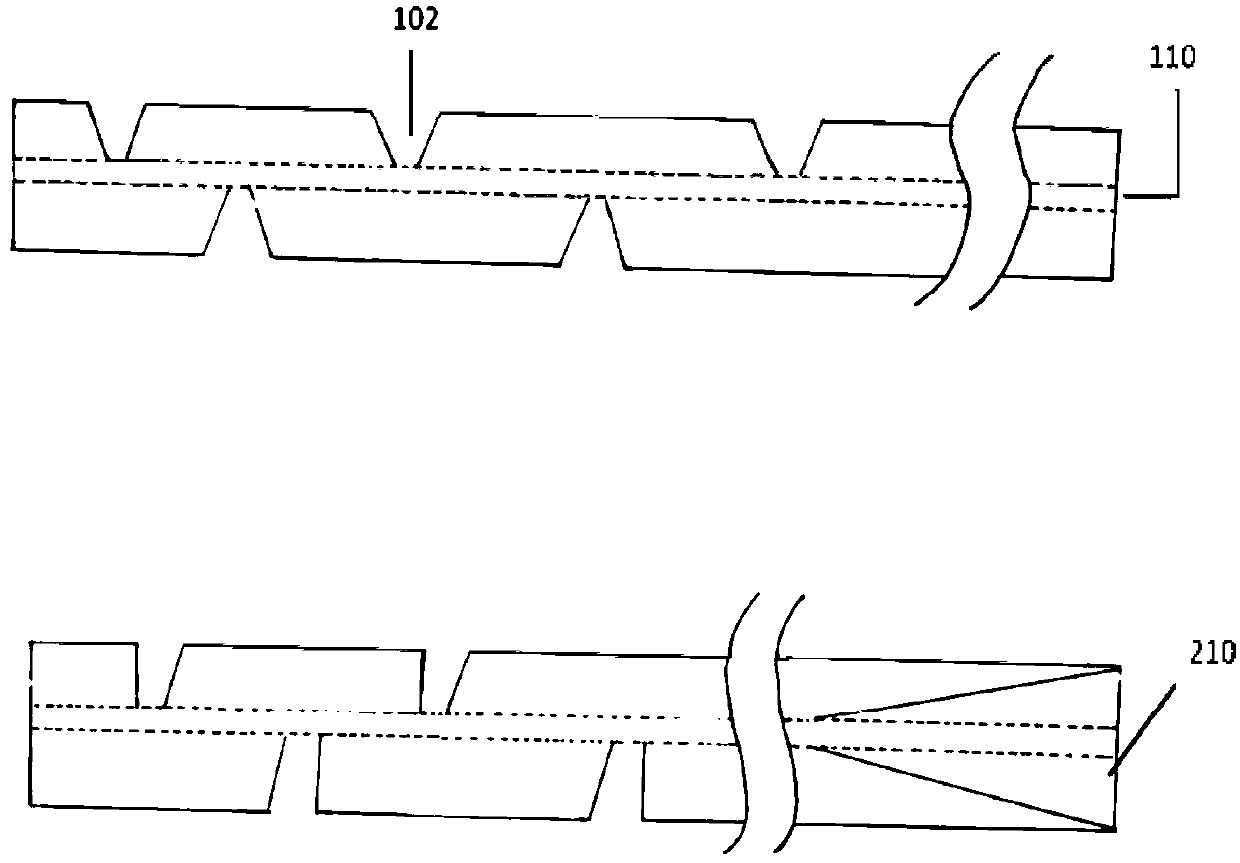

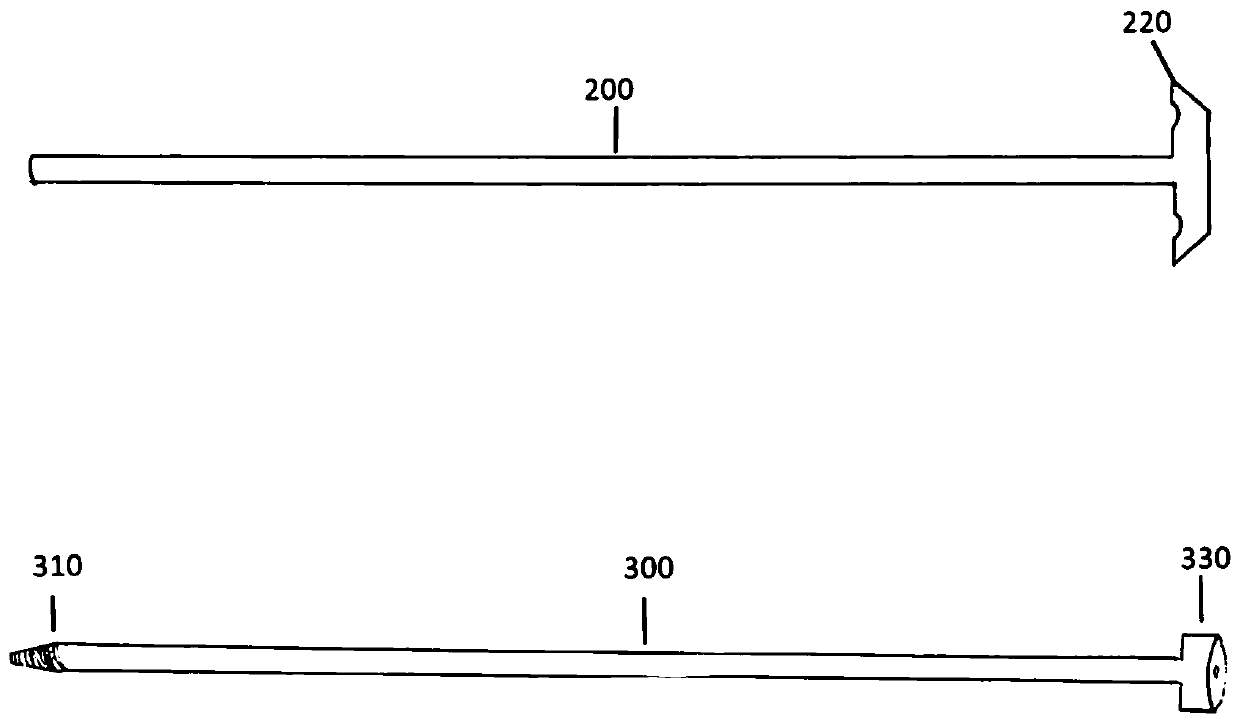

Injectable vertebra repairing device

ActiveCN105769324AMaintain normal biomechanical propertiesEvenly distributedOsteosynthesis devicesSpinal columnLesion site

The invention relates to an injectable vertebra repairing device for treating a spinal vertebral fracture.The injectable vertebra repairing device comprises an injectable chain and a filling tool; the injectable chain is in the shape of a cylinder with the rough surface, a central through hole is formed in the injectable chain, multiple grooves are formed in the upper portion and the lower portion of the chain, and the grooves are communicated with the central through hole; the filling tool comprises a filling casing pipe and a push rod casing pipe, and the tail end of the filling casing pipe and the tail end of the push rod casing pipe are provided with grab handles respectively; the front end of the push rod casing pipe and the near end of the injectable chain are designed to be of a tapper thread structure.When the device is operated, the top end of the filling casing pipe stretches into the lesion part, and the chain is filled into the damaged vertebra through the push rod casing pipe; bone cement is injected into the central through hole of the chain through the push rod casing pipe; the central through hole and the grooves are sequentially fully filled with the bone cement, solidification is performed to complete repairing, pressure exerting on the lesion part can be uniform and be reduced, and therefore the effect of effectively repairing the vertebra is achieved.The injectable vertebra repairing device is applied to the field of medical instruments and mainly used for achieving the purposes of stabilizing the fracture, recovering the vertebral mechanical strength and relieving pain.

Owner:山东明德生物医学工程有限公司

Plating of high-volume-fraction silicon carbide particle reinforced aluminum-based composite and preparation method thereof

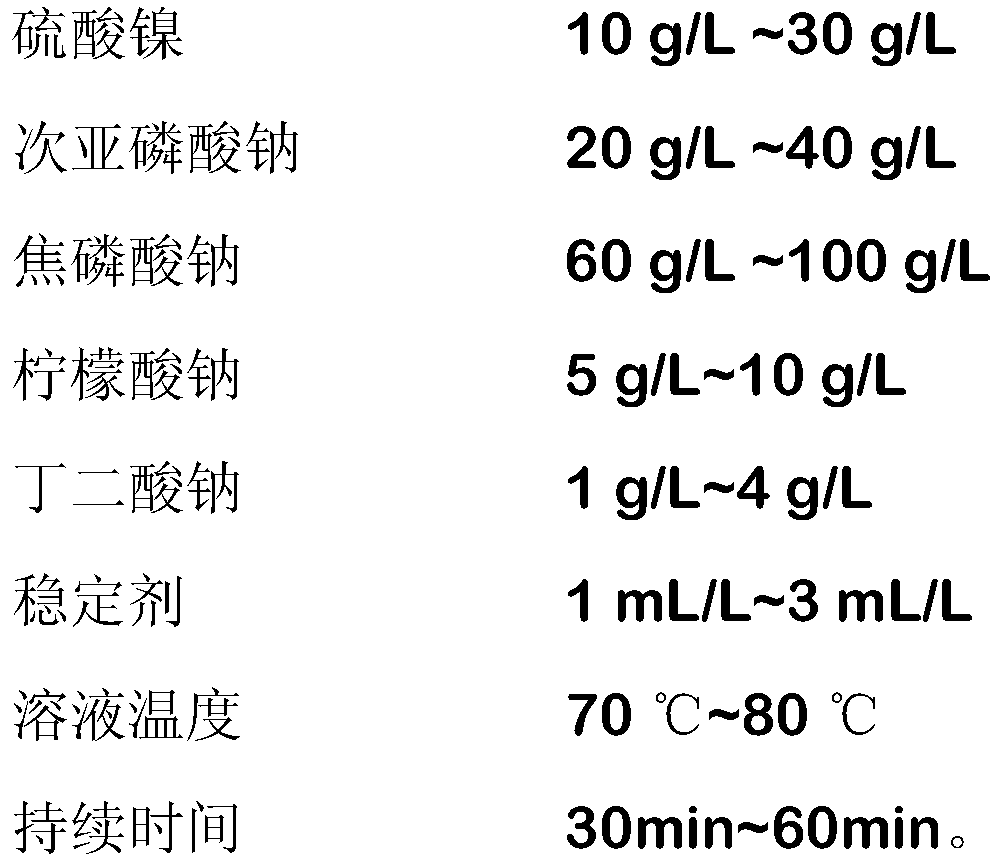

InactiveCN110284127AGuaranteed normal growthAchieve full coverageLiquid/solution decomposition chemical coatingSuperimposed coating processSurface engineeringMicrowave transmission

The invention belongs to the technical field of surface engineering and relates to a plating of a high-volume-fraction silicon carbide particle reinforced aluminum-based composite and preparation method thereof. The high-volume-fraction silicon carbide particle reinforced aluminum-based composite is hereinafter called high-volume-fraction SiCp / Al composite. By means of plating on the surface of the high-volume-fraction SiCp / Al composite, the electric conduction function, the microwave transmission function, the welding function and the like of the high-volume-fraction SiCp / Al composite can be guaranteed. The plating is mainly applied to high-volume-fraction SiCp / Al composite load structure products such as spacecraft high-power microwave products, phased-array antennas and aerospace power sources.

Owner:BEIJING SATELLITE MFG FACTORY

Multi-layer modified cast nylon material

InactiveCN110744876AImprove performanceLow costLamination ancillary operationsCarbon fibresNylon materialPolymer science

The invention relates to the field of nylon materials, in particular to a multi-layer modified cast nylon material. The invention discloses a multi-layer modified cast nylon material, which is characterized in that it comprises a plurality of functional layers; the functional layer is one of a wear-resistant layer, a reinforcing layer, an aging-resistant layer and a heat-resistant layer. The invention solves the problem that adding a single component to the existing cast nylon can only slightly increase part of the performance of the cast nylon, and if more complex components are added, the performance of the cast nylon will decrease. Compared with the cast nylon modified by adding various fillers at the same time, the multi-layer nylon material of the invention not only has a plurality ofimproved properties, but also has different properties at different levels, and can meet the requirements of different use positions of parts for different properties.

Owner:徐州兰贵机械科技有限公司

A kind of prefabricated sandwich wall panel using loose thermal insulation material and its manufacturing process

The invention relates to a prefabricated sandwich wall panel utilizing loose heat insulating materials and a manufacturing process thereof, belonging to the technical field of building energy-saving materials. The invention aims at the problems of poor thermal insulation effect and poor fire resistance of the sandwich wallboard, changes the internal structure and manufacturing process, optimizes the stress mode of the sandwich wallboard, and has the advantages of light weight, good integrity, high thermal insulation efficiency, It has the advantages of strong fire resistance, durability and good economic benefits. Splice one side of the foam plate and the foam web into one, fill the loose insulation material in the cavity formed by the foam web, splice the other side of the foam plate, and wrap the FRP material on the outer surface of the foam plate and the foam web After the FRP shell is solidified, the fiber braided mesh is laid on both sides of the insulation layer and in the channel reserved to accommodate the cross-shaped web, and the foam web and the fiber braided mesh in the two foam flat plates are connected as one by sewing technology , impregnated with epoxy resin, then poured high-performance concrete, and removed the formwork after 14 days of curing.

Owner:HARBIN INST OF TECH

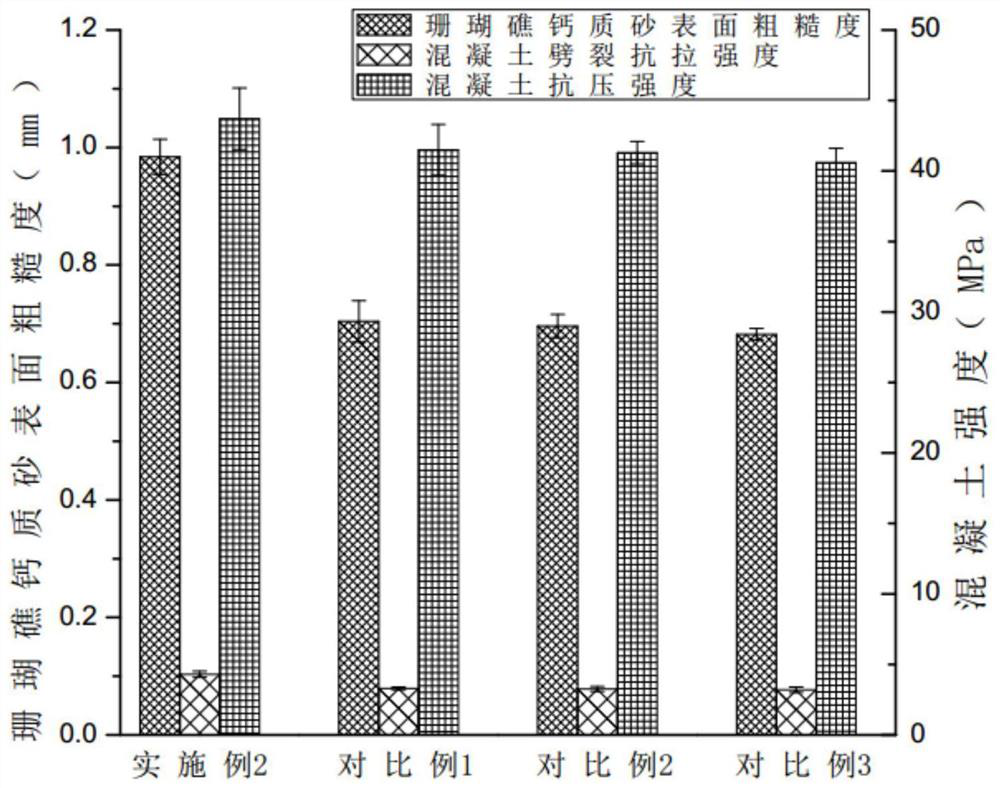

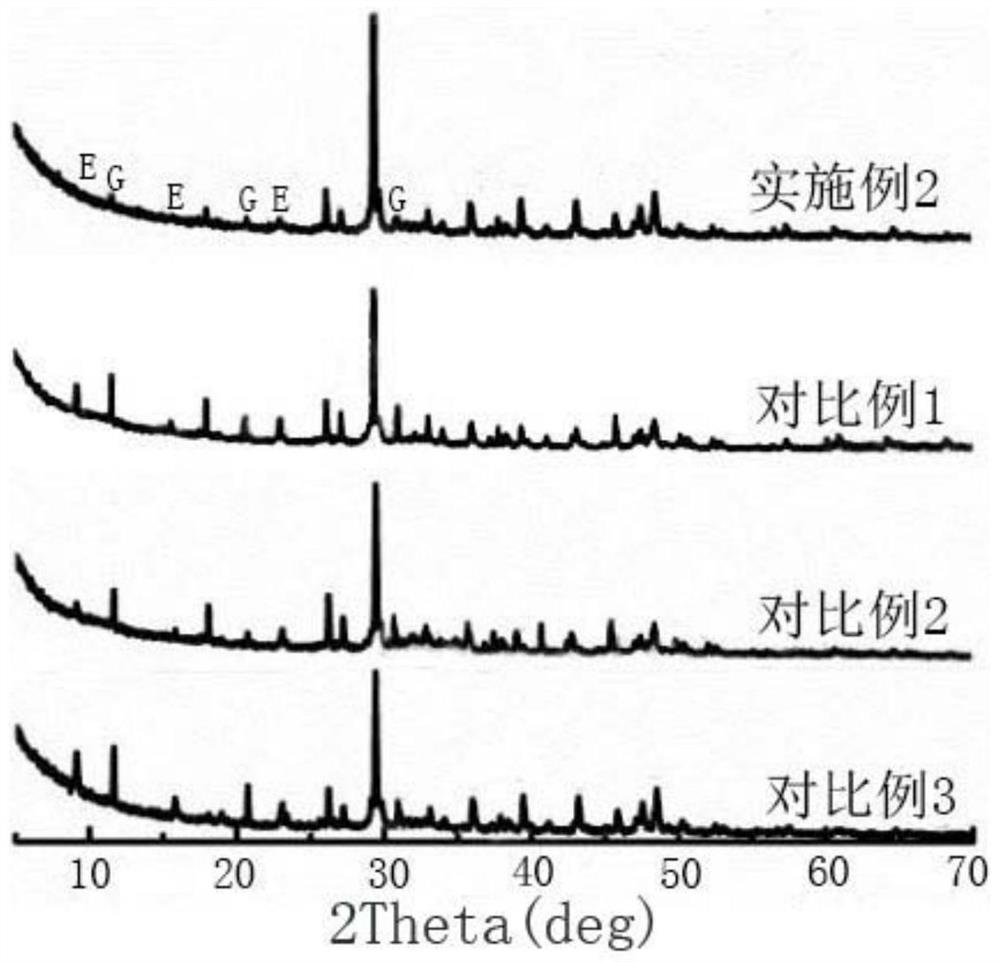

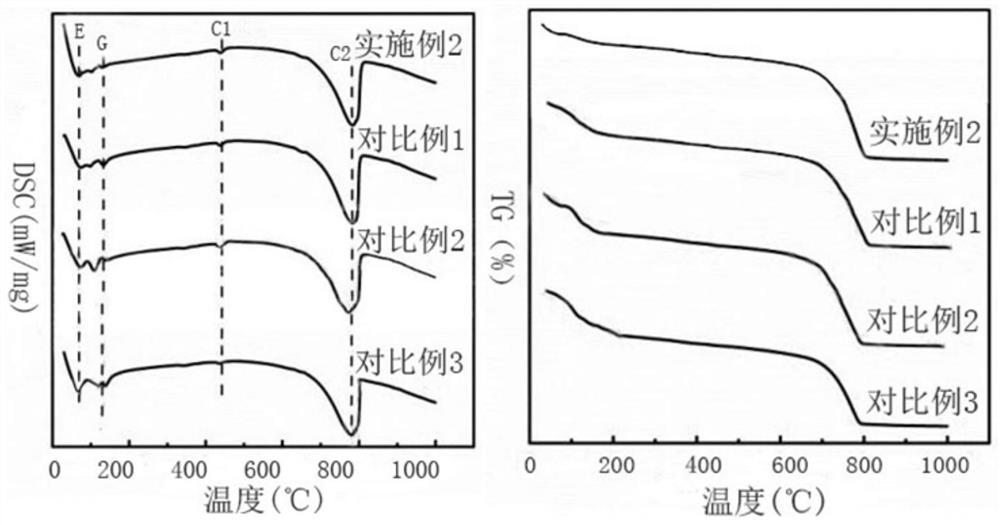

A microbial repair agent for self-healing of marine concrete cracks

The invention provides a microbial repairing agent for self-repairing of marine concrete cracks, which belongs to the technical field of concrete self-repairing, and comprises Bacillus kirsi, regulator, calcium lactate, and coral reef calcareous sand, and uses polyoxyethylene, vinyl methyl ether After the coral reef calcareous sand is treated, the Bacillus colii, regulator and calcium lactate are immobilized on the coral reef calcareous sand. The invention can increase the surface roughness of coral reef calcareous sand, improve the bonding strength of the interface transition zone, reduce gaps, and suppress SO 4 2‑ Enter the interior of the concrete to reduce the increase of expansive erosion products; the calcium carbonate particles that can regulate the formation of Bacillus kirsi are mainly stable calcite type, and can form a dense and structurally stable sealing layer in the cracks.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

A fast-hardening and early-strength composite repair mortar

The invention belongs to the technical field of building materials, and proposes a fast-hardening and early-strength composite repair mortar, which is composed of the following components in weight percent: 5% to 10% of water, 20% to 30% of cement, and 1% to 5% of silica fume. %, fly ash 1% to 5%, quartz sand 50% to 70%, composite early strength agent 0.4% to 0.5%, water reducing agent 0.06% to 0.1%, rubber powder 1% to 5%, mixed fiber 0.06% ~0.8%, the composite early strength agent is composed of A component and B component, the A component is nano-calcium carbonate whiskers, and the B component is a mixture of triisopropanolamine and aluminum sulfate, so The quartz sand is composed of coarse sand, medium sand and fine sand, and the hybrid fiber is composed of basalt fiber and polypropylene fiber. The invention solves the problems in the prior art that the strength of the repair mortar shrinks back, the dry shrinkage rate is large, and the bonding strength is low.

Owner:长春昌驰新材料科技有限公司

Stone aggregate wrapped by microfine fibre polymer mortar thin layer and preparation method thereof

The invention discloses a stone aggregate wrapped by a microfine fibre polymer mortar thin layer and a preparation method thereof; the stone aggregate is formed by stone aggregate inner cores, an adhesive inner wrapping layer, a polymer cement mortar outer wrapping layer and an adhesive microfine fibre hair layer, wherein the adhesive inner wrapping layer and the stone aggregate are adhered firmly; microfine fibre filaments are anchored and rooted on the adhesive inner wrapping layer; and the polymer cement mortar outer wrapping layer and the adhesive inner wrapping layer are soluble mutuallyand can effectively form a whole body. Active powder in the polymer cement mortar outer wrapping layer contains silica fume, zeolite powder, finely-ground mineral slag, pulverized coal ash and the like, and can generate volcanic ash reaction with Ca(OH)2 crystal at the interface position of the set cement so as to generate gelled materials, and further carry out improved treatment on the weakest interfaces of set cement and the stone aggregate in concrete. The modified stone aggregate of the invention has good affinity with the set cement, and has higher binding power with the set cement.

Owner:NANTONG ZHONGRUN CONCRETE +1

An injectable vertebral body repair device

ActiveCN105769324BMaintain normal biomechanical propertiesEvenly distributedOsteosynthesis devicesSpinal columnLesion site

The invention relates to an injectable vertebra repairing device for treating a spinal vertebral fracture.The injectable vertebra repairing device comprises an injectable chain and a filling tool; the injectable chain is in the shape of a cylinder with the rough surface, a central through hole is formed in the injectable chain, multiple grooves are formed in the upper portion and the lower portion of the chain, and the grooves are communicated with the central through hole; the filling tool comprises a filling casing pipe and a push rod casing pipe, and the tail end of the filling casing pipe and the tail end of the push rod casing pipe are provided with grab handles respectively; the front end of the push rod casing pipe and the near end of the injectable chain are designed to be of a tapper thread structure.When the device is operated, the top end of the filling casing pipe stretches into the lesion part, and the chain is filled into the damaged vertebra through the push rod casing pipe; bone cement is injected into the central through hole of the chain through the push rod casing pipe; the central through hole and the grooves are sequentially fully filled with the bone cement, solidification is performed to complete repairing, pressure exerting on the lesion part can be uniform and be reduced, and therefore the effect of effectively repairing the vertebra is achieved.The injectable vertebra repairing device is applied to the field of medical instruments and mainly used for achieving the purposes of stabilizing the fracture, recovering the vertebral mechanical strength and relieving pain.

Owner:山东明德生物医学工程有限公司

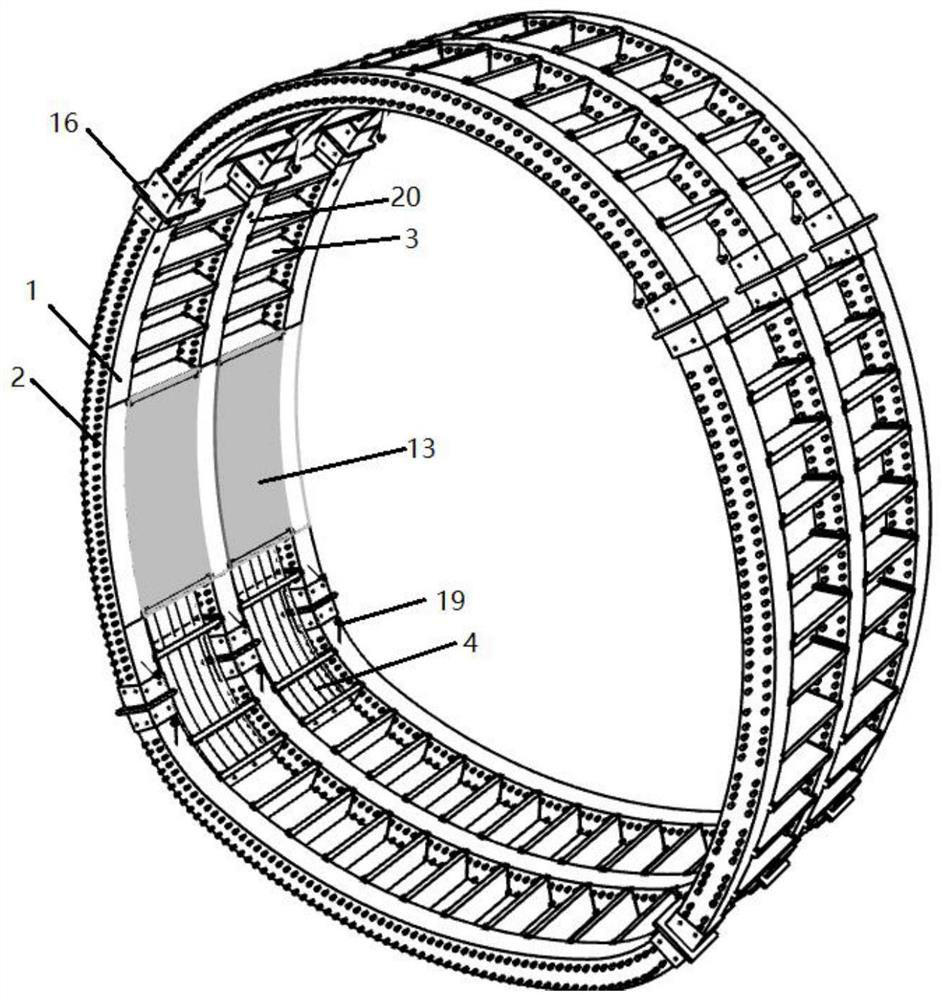

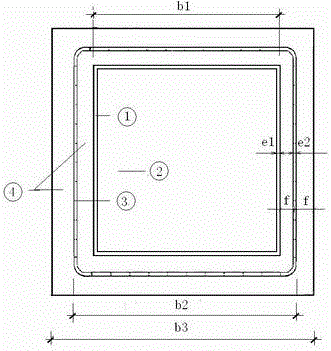

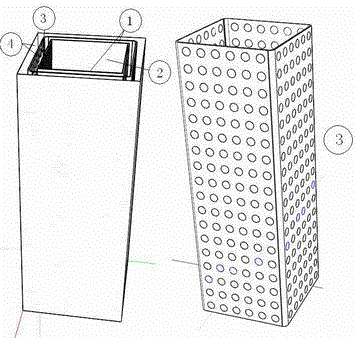

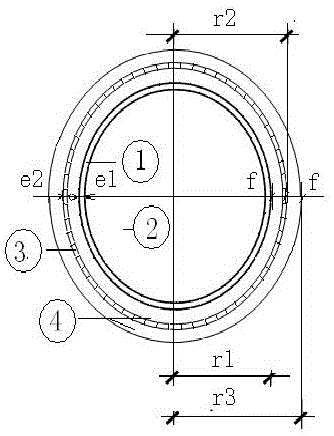

A Construction Method of Built-in Hollow Steel Fiber Concrete Protective Layer

ActiveCN103541547BStrong fatigue resistanceResistance to wind and wavesFoundation engineeringBuilding material handlingPipeFiber-reinforced concrete

The invention relates to a construction method of a built-in hollow steel fiber reinforced concrete protective layer, in which steel fiber hollowed steel fiber reinforced concrete is arranged on the outer side of a steel filled concrete structural column for protection; and the durability of the structural components is improved. The thickness 2f of the protective layer is not less than 70 mm. The wall thickness e2 of the thin-walled hollow steel pipe is not less than 5mm. The hollow steel pipe is in the middle of the protective layer. The protective layer is poured with steel fiber concrete. The amount of steel fiber added is 1-1.5% of the concrete volume. The 50mm round hole forms a hollow structure. The net spacing of the circular holes is the same as the diameter d, both are 50mm. Due to the anti-corrosion effect of steel fibers and the restraint effect of hollow steel pipes on the protective layer, the internal steel pipe concrete structural columns are protected in corrosive environments, and the hollow steel pipes also have auxiliary load-bearing capacity. It can be used in harsh environments with corrosive environments such as artificial islands, river courses, port projects, and offshore platforms.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com