A kind of prefabricated sandwich wall panel using loose thermal insulation material and its manufacturing process

A technology of thermal insulation materials and sandwich walls, applied in the direction of thermal insulation, manufacturing tools, walls, etc., can solve the problems of poor thermal insulation effect, poor fire resistance, poor integrity, etc., to improve thermal insulation efficiency, enhance integrity, reduce quality and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

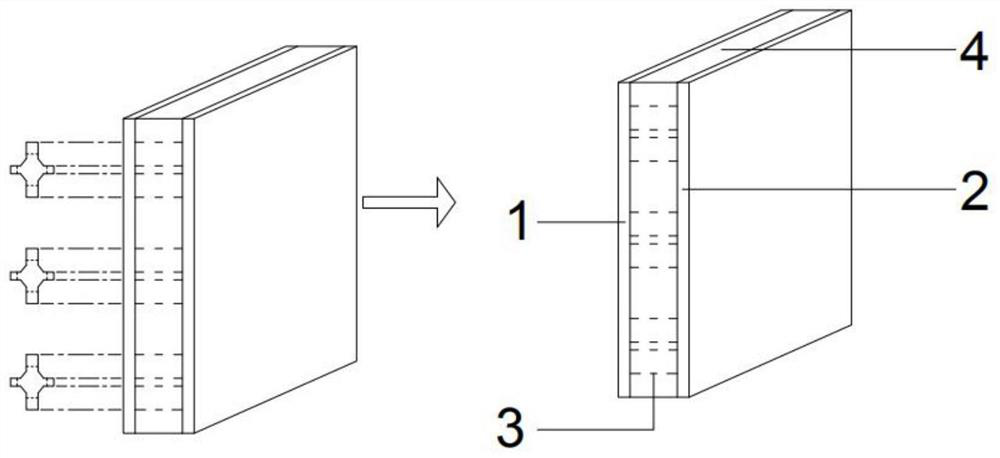

[0031] Specific implementation mode 1: This implementation mode records a prefabricated sandwich wall panel using loose thermal insulation materials, such as figure 1 As shown, the sandwich wall panel includes an inner leaf concrete slab 1, an outer leaf concrete slab 2, a cross-shaped web 3 and an insulation layer 4;

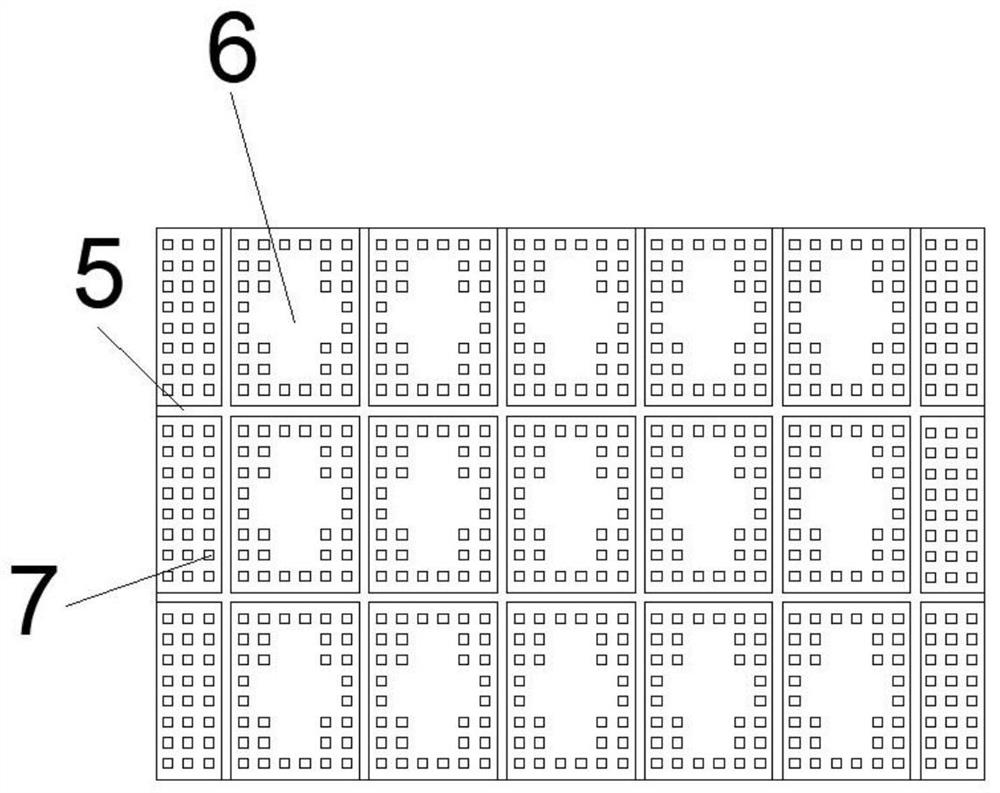

[0032] The opposite surfaces of one side of the inner leaf concrete slab 1 and the outer leaf concrete slab 2 are provided with vertically and horizontally intersecting grooves one 5, and the area surrounded by the groove one 5 includes a plurality of array units, and each array unit Contains a cross-shaped plane 6, and the area other than the cross-shaped plane in each array unit is provided with a plurality of blind holes 7 in an array, such as figure 2 shown;

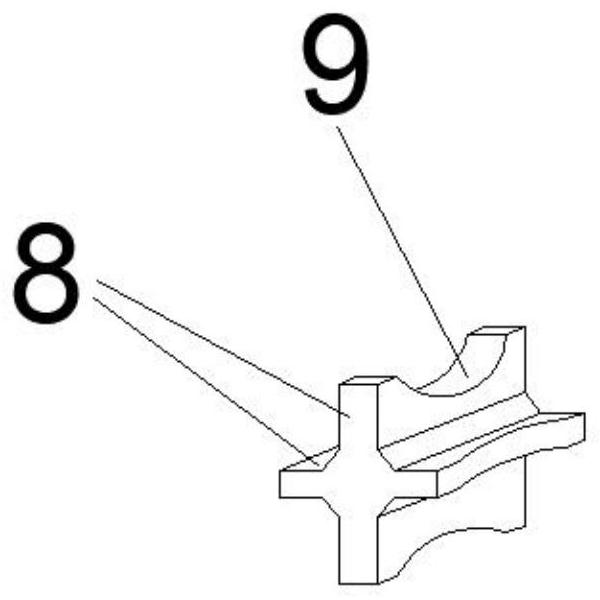

[0033] The cross-shaped web 3 is composed of four rectangular plates 8 intersecting in a cross shape, each intersection of two adjacent rectangular plates 8 has a chamfer, and the middle part of the...

specific Embodiment approach 2

[0036] Specific embodiment two: a prefabricated sandwich wall panel using loose thermal insulation materials described in specific embodiment one, the inner leaf concrete slab 1, the outer leaf concrete slab 2 and the cross-shaped web 3 are all reinforced by fiber braided mesh High-performance concrete is made by integral pouring and one-time molding, and has excellent integrity.

specific Embodiment approach 3

[0037] Specific embodiment three: a manufacturing process of prefabricated sandwich wall panels using loose thermal insulation materials described in specific embodiment one or two, the process steps are as follows:

[0038] Step 1: Fabrication of the insulation layer: use the mold to prepare the foam flat plate 11 and the foam web 10, splice the foam flat plate 11 and the foam web 10 on one side into one, and fill the loose insulation material into the void formed by the foam web 10 In the cavity 15, the other side of the foam plate 11 is spliced, and the FRP material is coated on the outer surface of the foam plate 11 and the foam web 10 by using a vacuum forming process. After the FRP shell is cured for 24 hours, the insulation layer 4 is completed; the FRP material Composed of resin and fiber, after the resin is cured, FRP is formed;

[0039] Step 2: Lay the fiber braided net on both sides of the insulation layer 4 and in the channel reserved to accommodate the cross-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com