Surface modification method of aramid fiber and application of product thereof

A technology for surface modification and aramid fibers, applied in fiber treatment, light/infrared/X-ray fiber treatment, textiles and papermaking, etc., can solve the problem of increasing the surface roughness and surface activity of aramid fibers, and weak mechanical chelation and other issues, to achieve the effect of suitability for industrialized production, increase of surface area and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

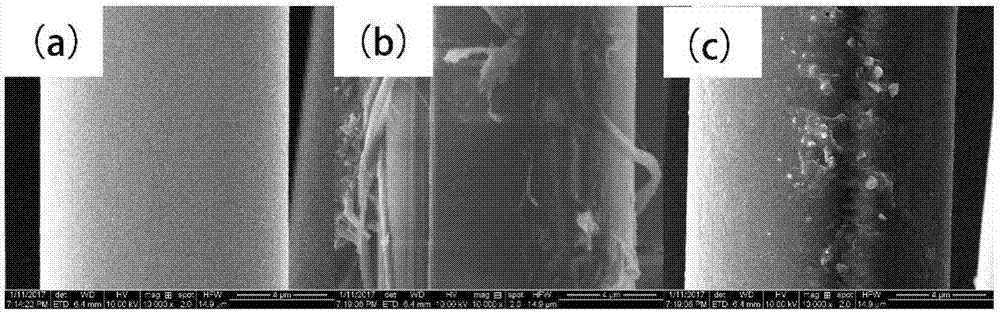

[0011] Embodiment 1 of the present invention: a method for surface modification of aramid fibers, placing aramid fiber bundles in a beaker, soaking them in acetone, cleaning them in an ultrasonic cleaner for 4 hours, removing impurities attached to the surface, and then heating them at 80°C After drying, the aramid fiber is cut into short fibers with a length of 6 mm, and sealed for later use.

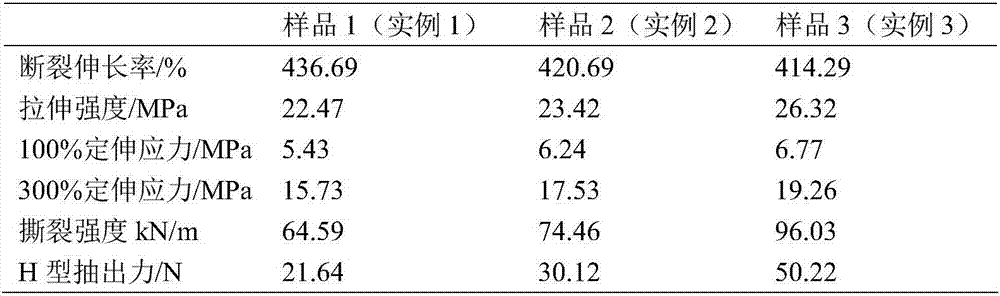

[0012] Add 3phr aramid fiber into 150phr carbon black / natural rubber compound to prepare aramid fiber / carbon black / natural rubber composite.

Embodiment 2

[0013] Embodiment 2 of the present invention: a method for surface modification of aramid fibers, placing aramid fiber bundles in a beaker, soaking them in acetone, cleaning them in an ultrasonic cleaner for 4 hours, removing impurities attached to the surface, and then heating them at 80°C drying.

[0014] Lay the dried aramid fiber into a layer, and use a UV lamp with a wavelength of 264nm and a power of 1000W to irradiate at a distance of 30cm from the aramid fiber. Under normal temperature and pressure conditions, the radiation time is 8 minutes. Then the aramid fiber is cut into short fibers with a length of 6 mm, and sealed for later use.

[0015] The aramid fiber / carbon black / natural rubber composite material was prepared by adding 3phr UV-etched aramid fiber into 150phr carbon black / natural rubber compound.

Embodiment 3

[0016] Embodiment 3 of the present invention: the surface modification method of aramid fiber, place the aramid fiber bundle in a beaker, soak it with acetone, put it in an ultrasonic cleaner for cleaning for 4 hours, remove the impurities attached to its surface, and then heat it at 80°C drying.

[0017] Lay the dried aramid fiber into a layer, and use a UV lamp with a wavelength of 264nm and a power of 1000W to irradiate at a distance of 30cm from the aramid fiber. Under normal temperature and pressure conditions, the radiation time is 8 minutes. Then the aramid fiber is cut into short fibers with a length of 6 mm, and sealed for later use.

[0018] Prepare 6wt% KH570 ethanol solution at room temperature, seal the mouth of the beaker tightly with plastic wrap, put it into an ultrasonic cleaner and vibrate for 5-20min to make it fully dispersed. Then put the aramid fibers modified by ultraviolet etching into the dispersed KH570 ethanol solution. The mouth of the beaker was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com